Patents

Literature

82 results about "Space-filling curve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

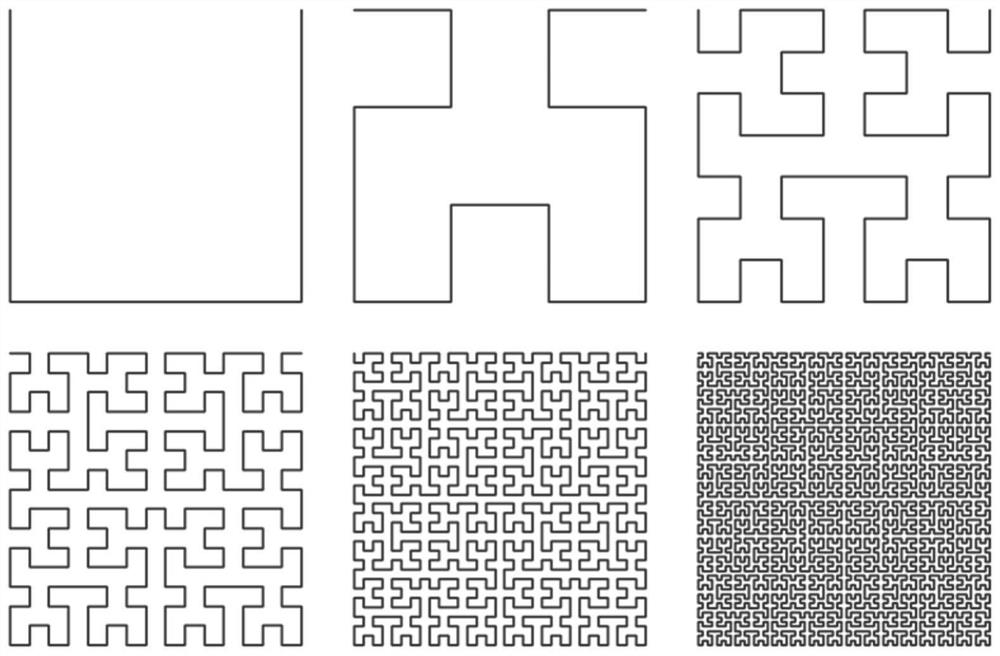

In mathematical analysis, a space-filling curve is a curve whose range contains the entire 2-dimensional unit square (or more generally an n-dimensional unit hypercube). Because Giuseppe Peano (1858–1932) was the first to discover one, space-filling curves in the 2-dimensional plane are sometimes called Peano curves, but that phrase also refers to the Peano curve, the specific example of a space-filling curve found by Peano.

Two-dimensional indexes for quick multiple attribute search in a catalog system

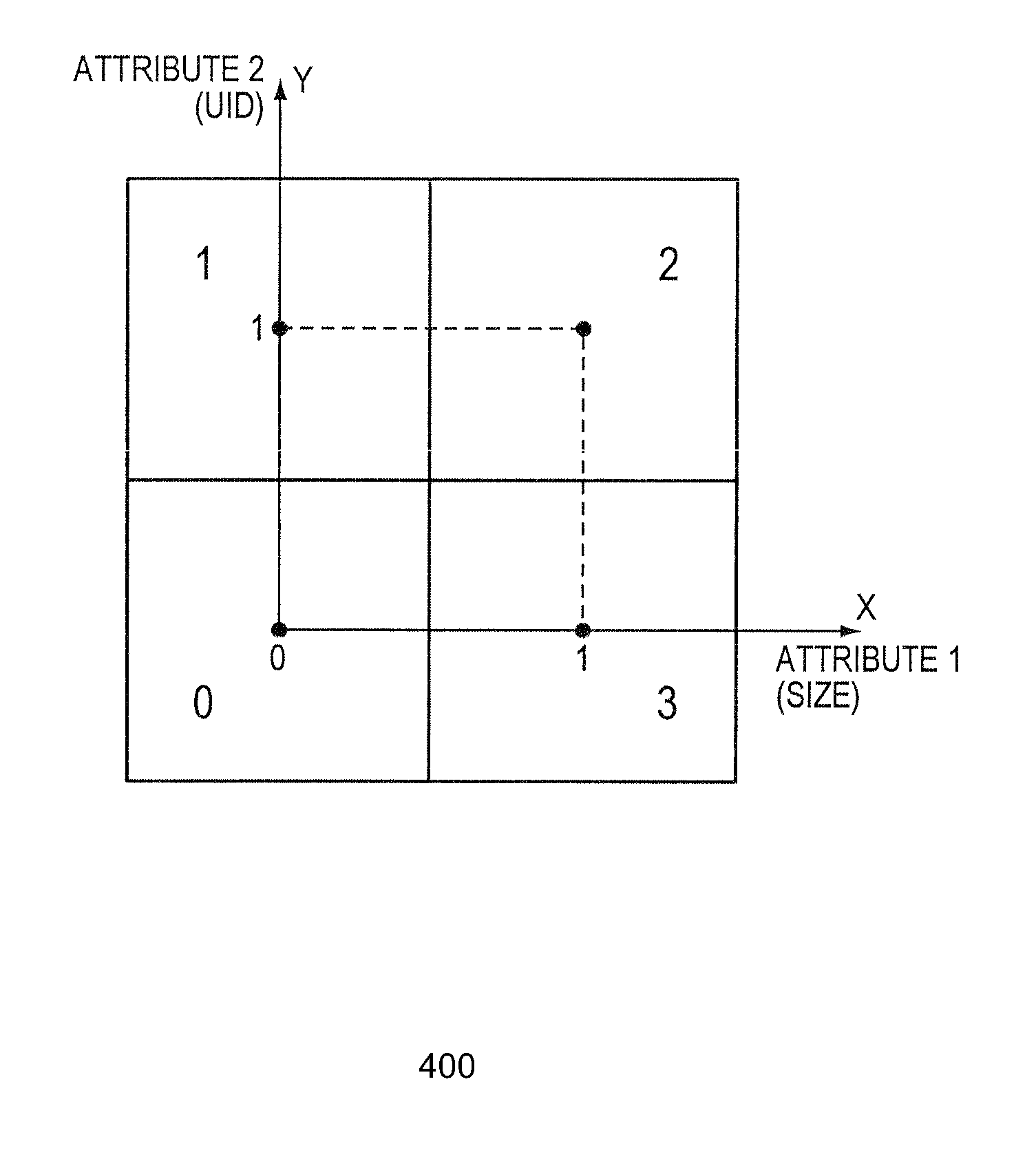

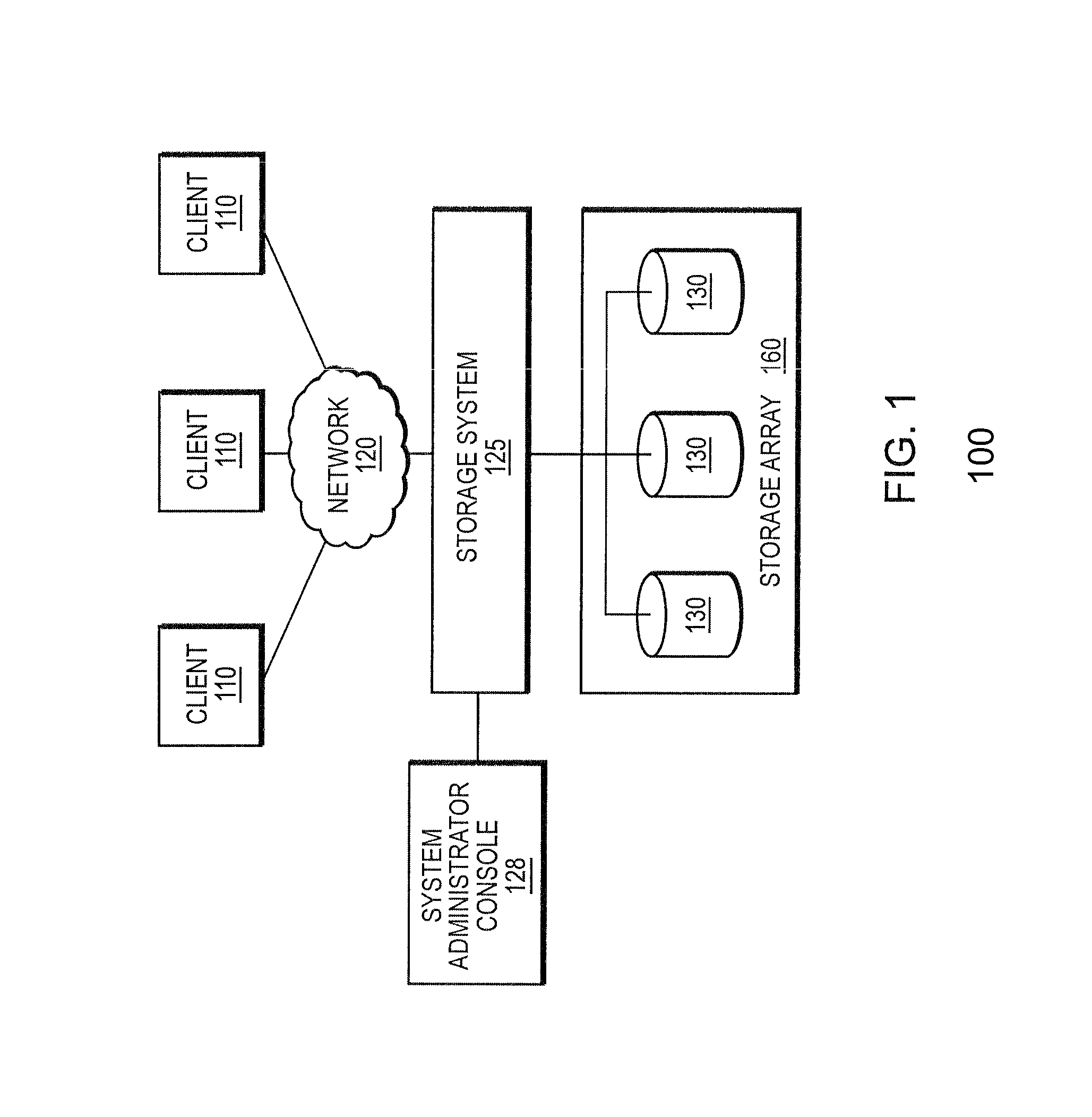

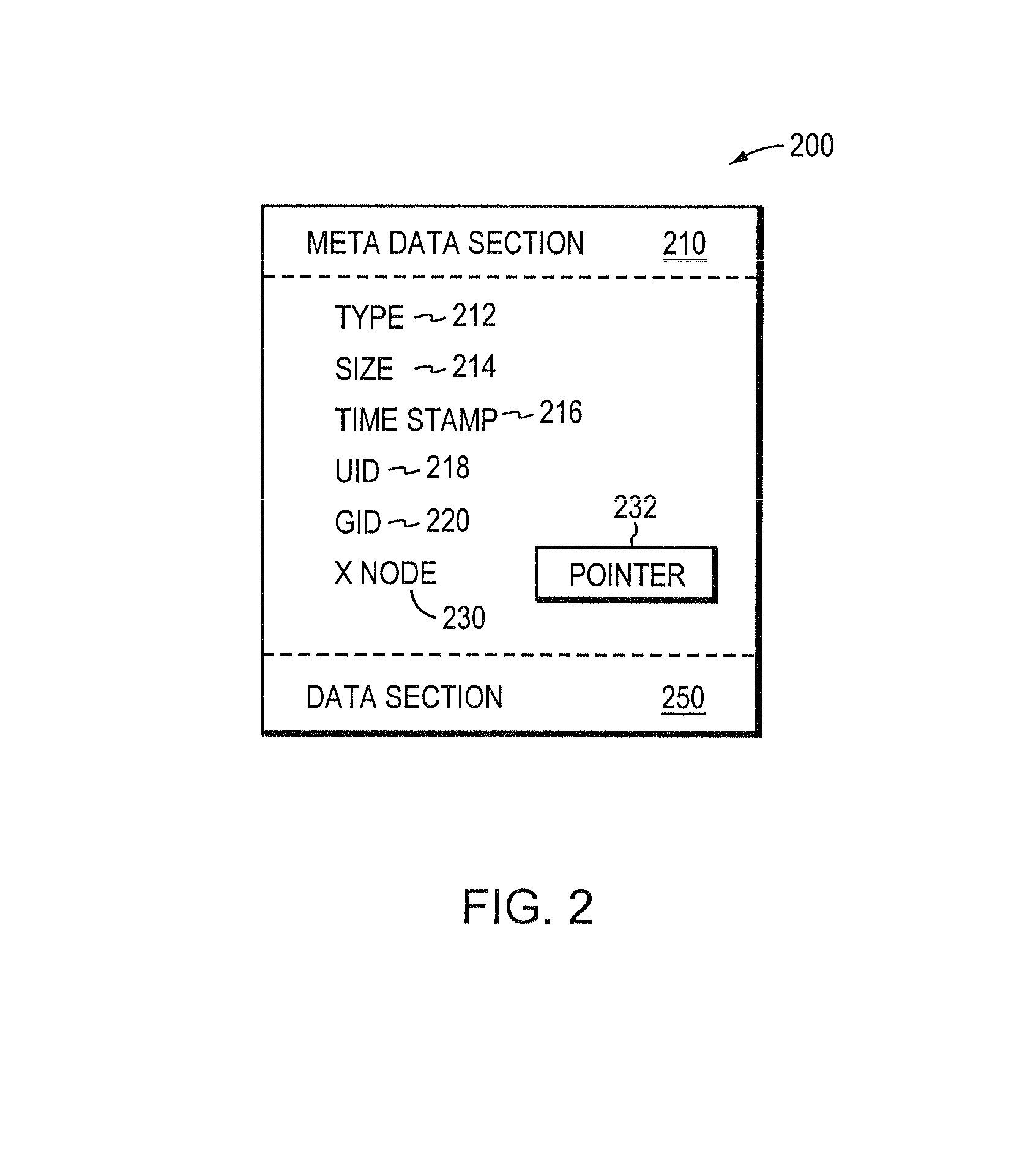

ActiveUS8219564B1Reduce in quantityShorten the timeDigital data processing detailsOther databases indexingMultiple attributeSpace-filling curve

Embodiments of the present invention provide mechanisms that overcome limitations of existing indexes by creating two-dimensional (2D) spatial indexes to quickly locate data containers that match two or more predicates. This is accomplished by representing metadata attributes describing a data container as dimensions in a 2D space so that a data container can be expressed as a point or a cell in a 2D space with coordinates being a pair of values of the selected attributes. A space filling curve is used to traverse the 2D space and convert each pair of the 2D coordinates to a single space filling curve value. A 2D spatial index is then created based on the computed space filling curve values so that one value can be associated with one or more points (data containers) in the index. Advantageously, the created spatial index provides for searching and processing fewer metadata entries, thereby decreasing the time typically used to search for data.

Owner:NETWORK APPLIANCE INC

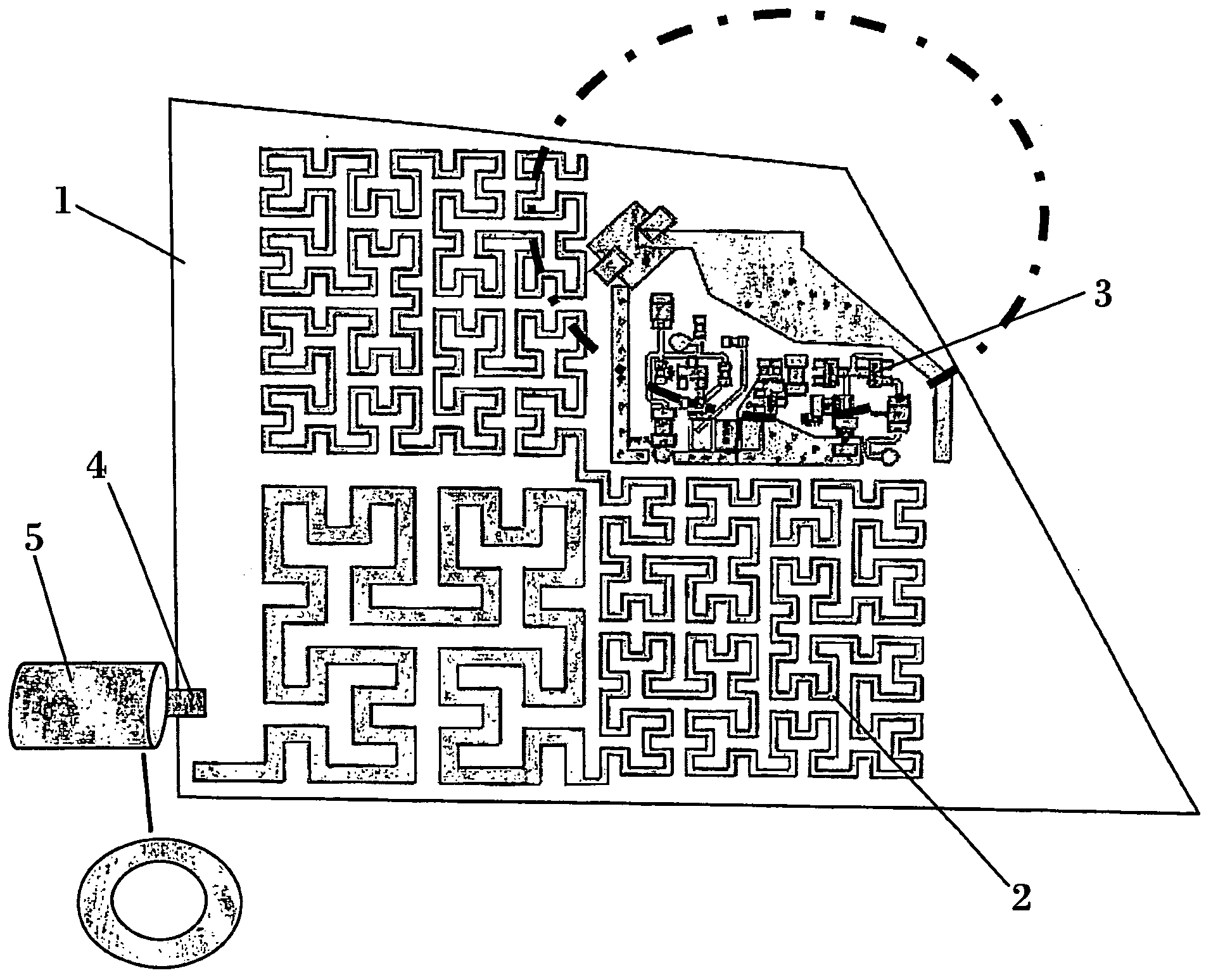

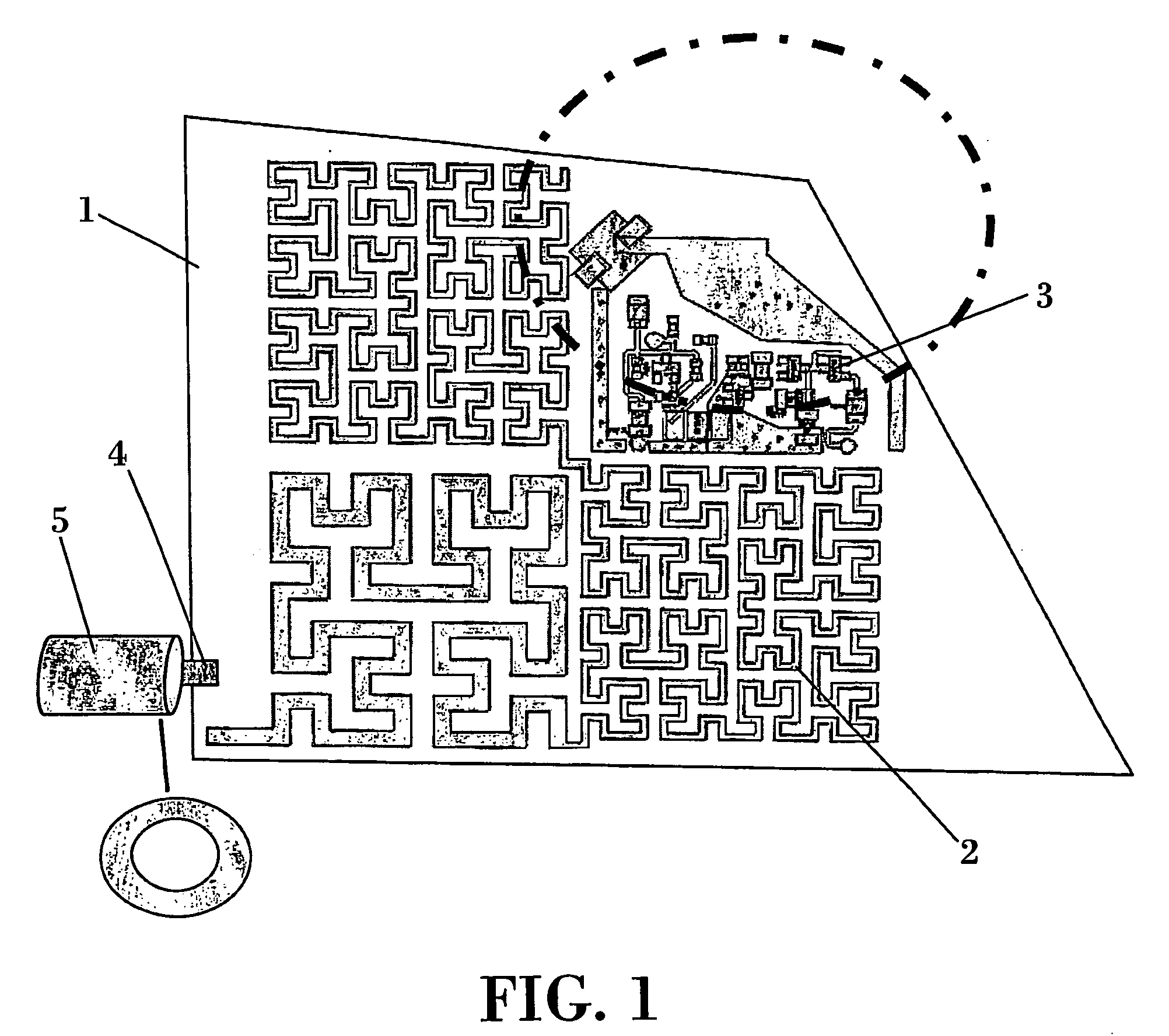

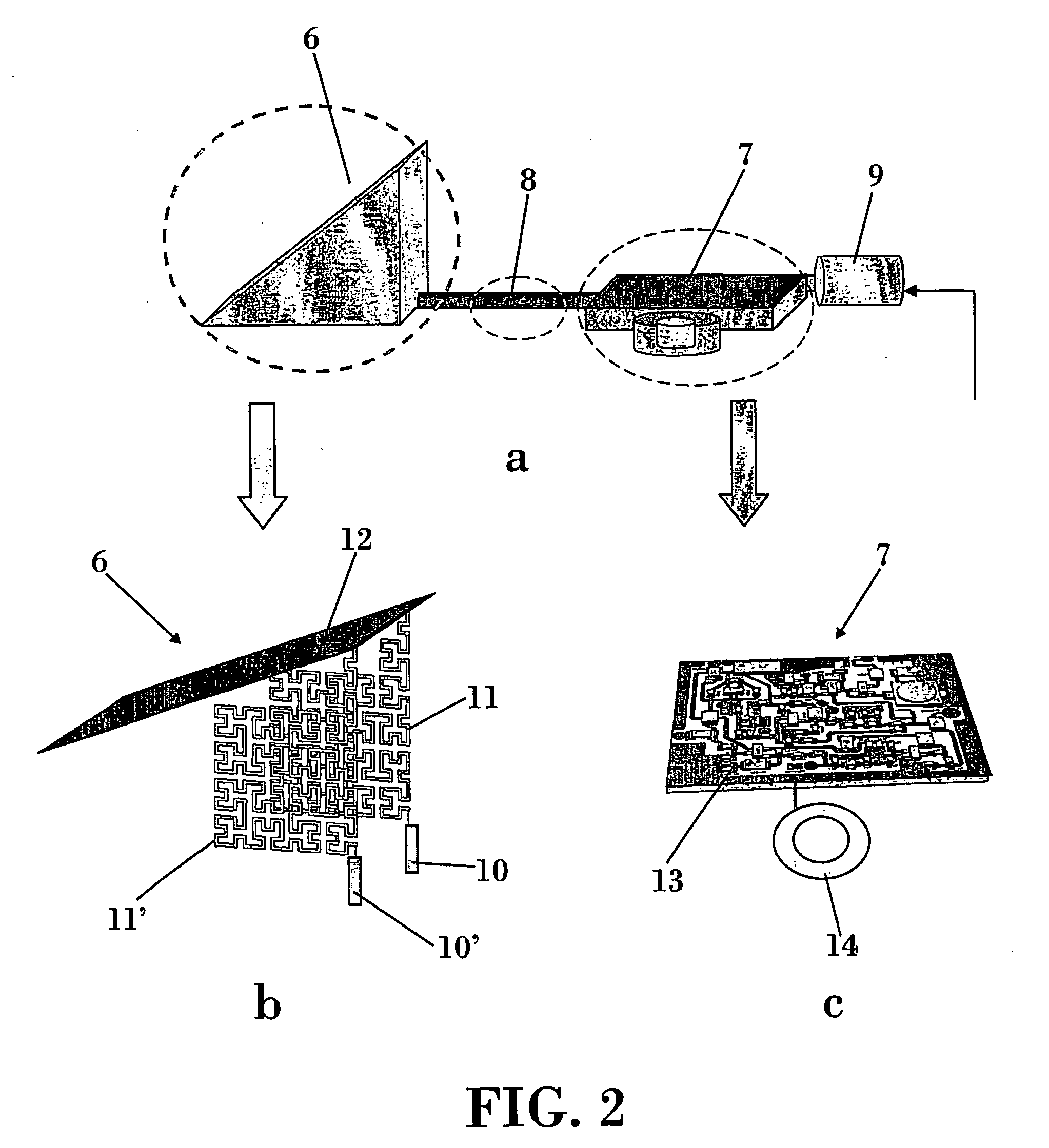

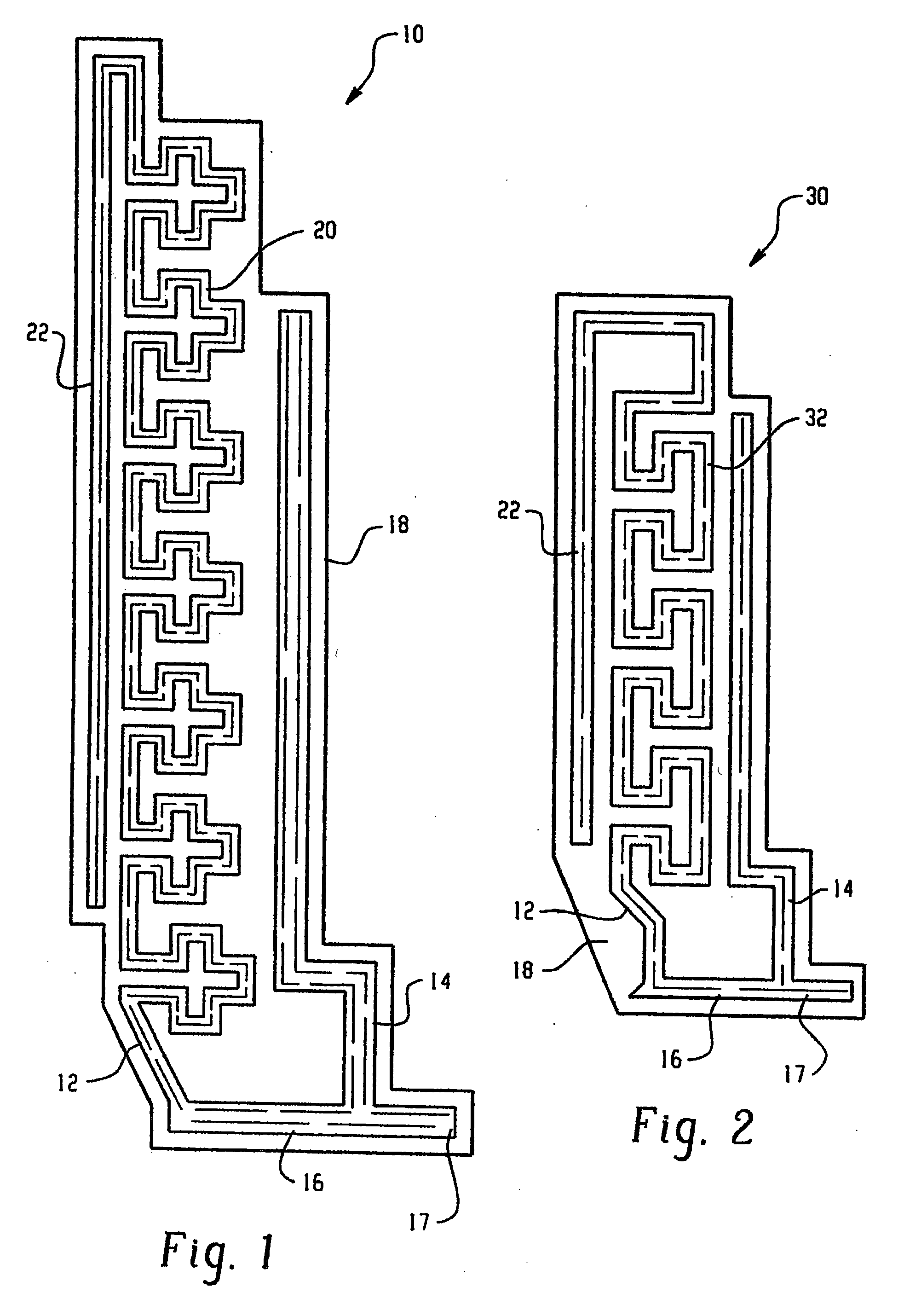

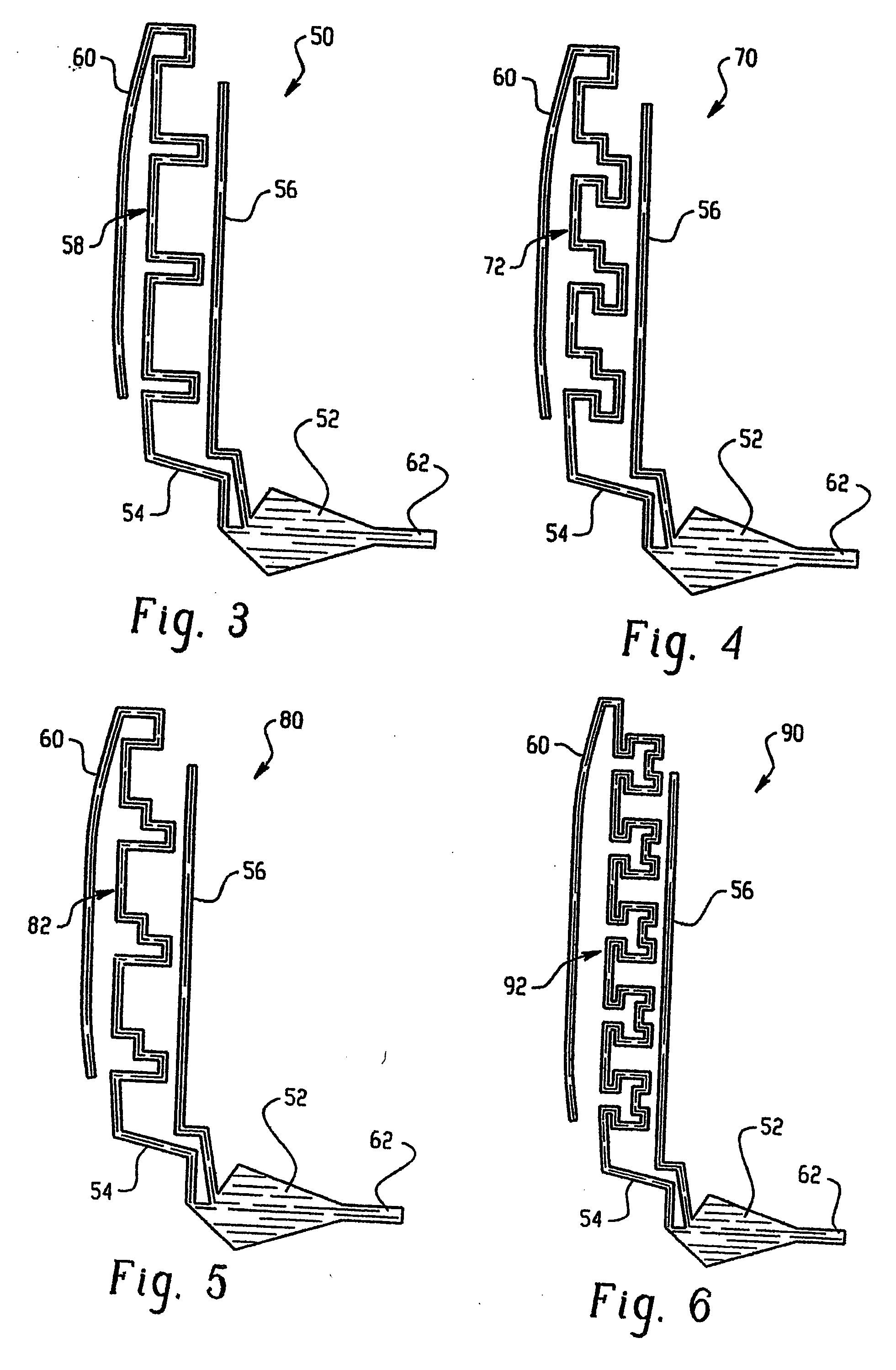

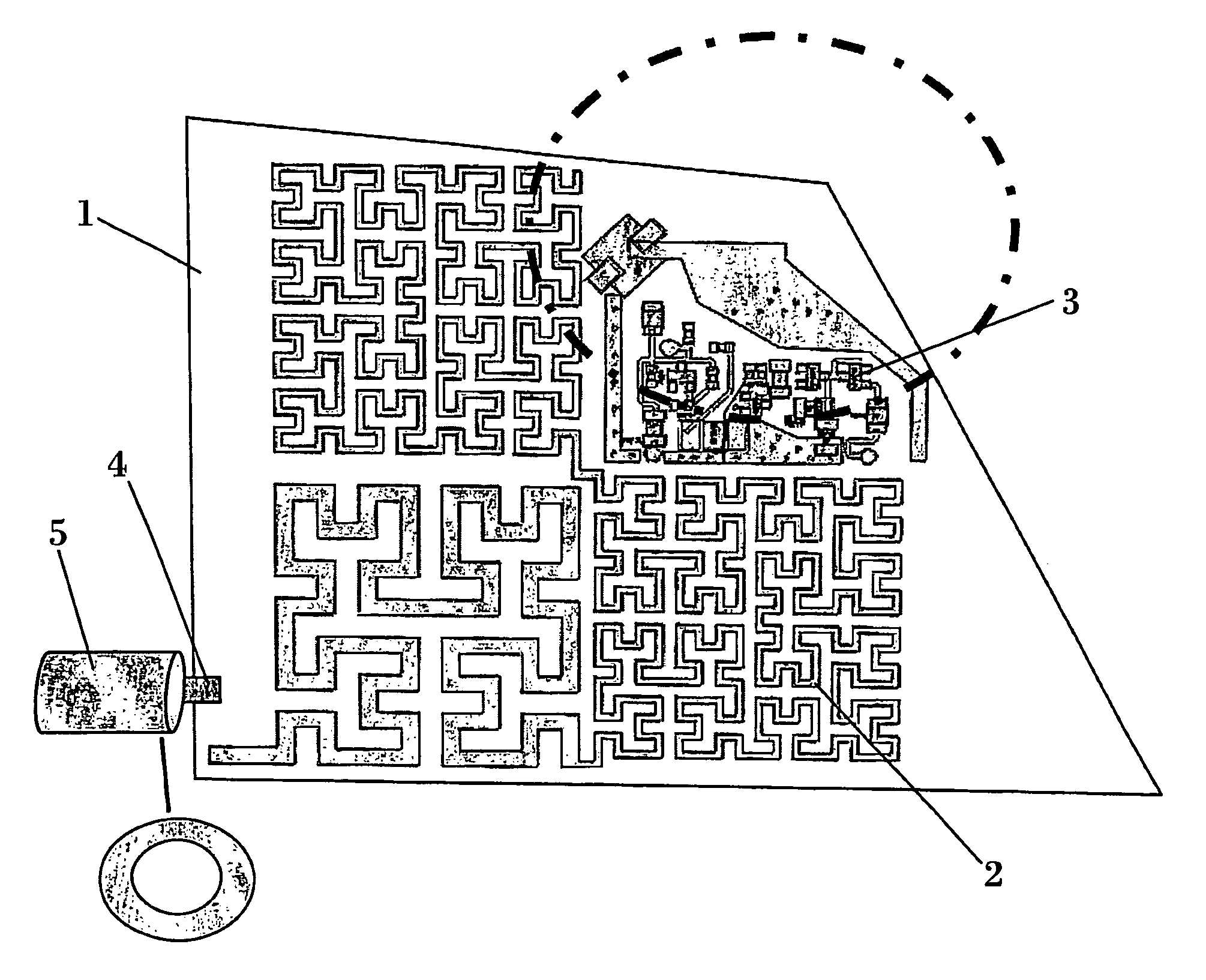

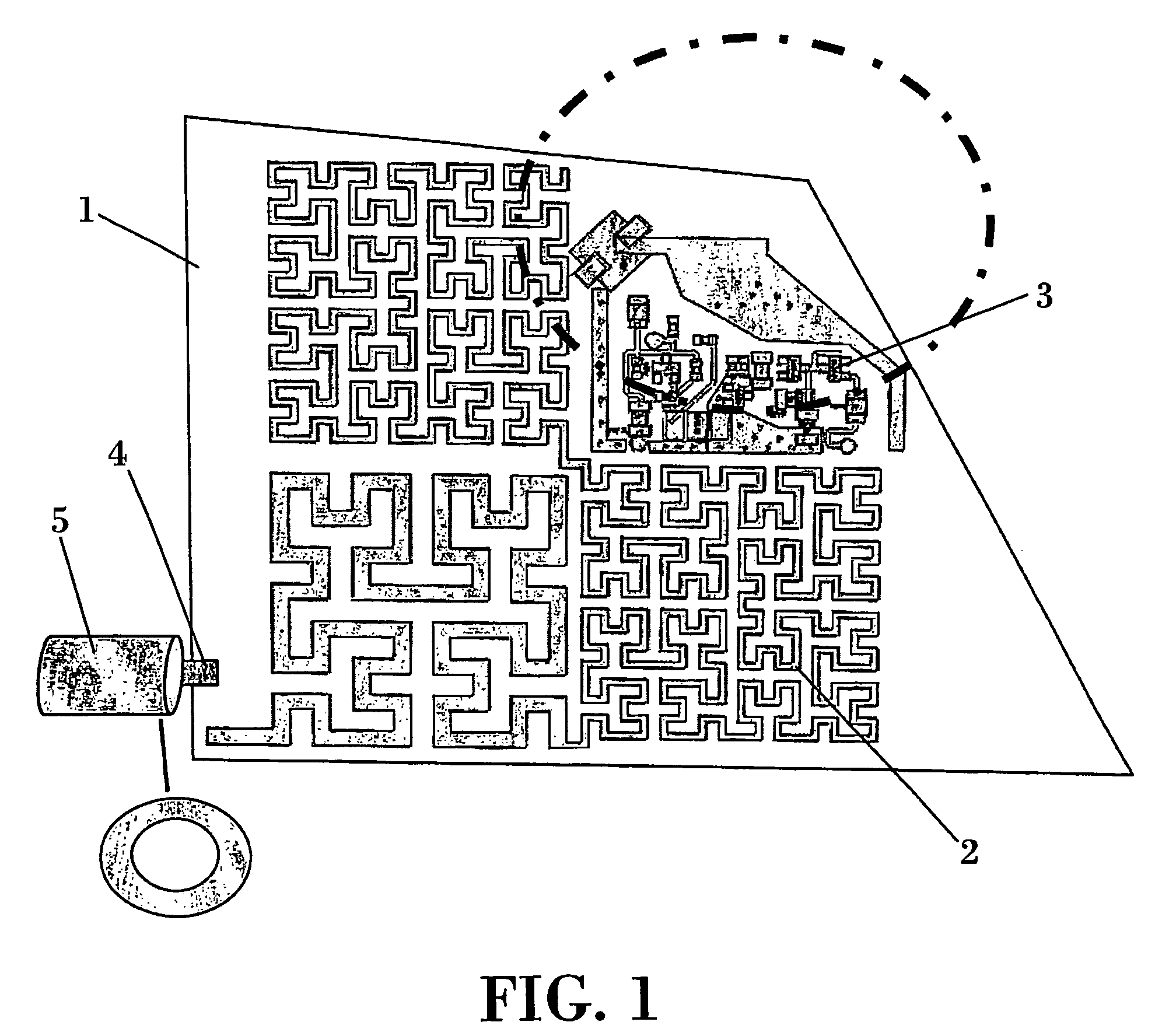

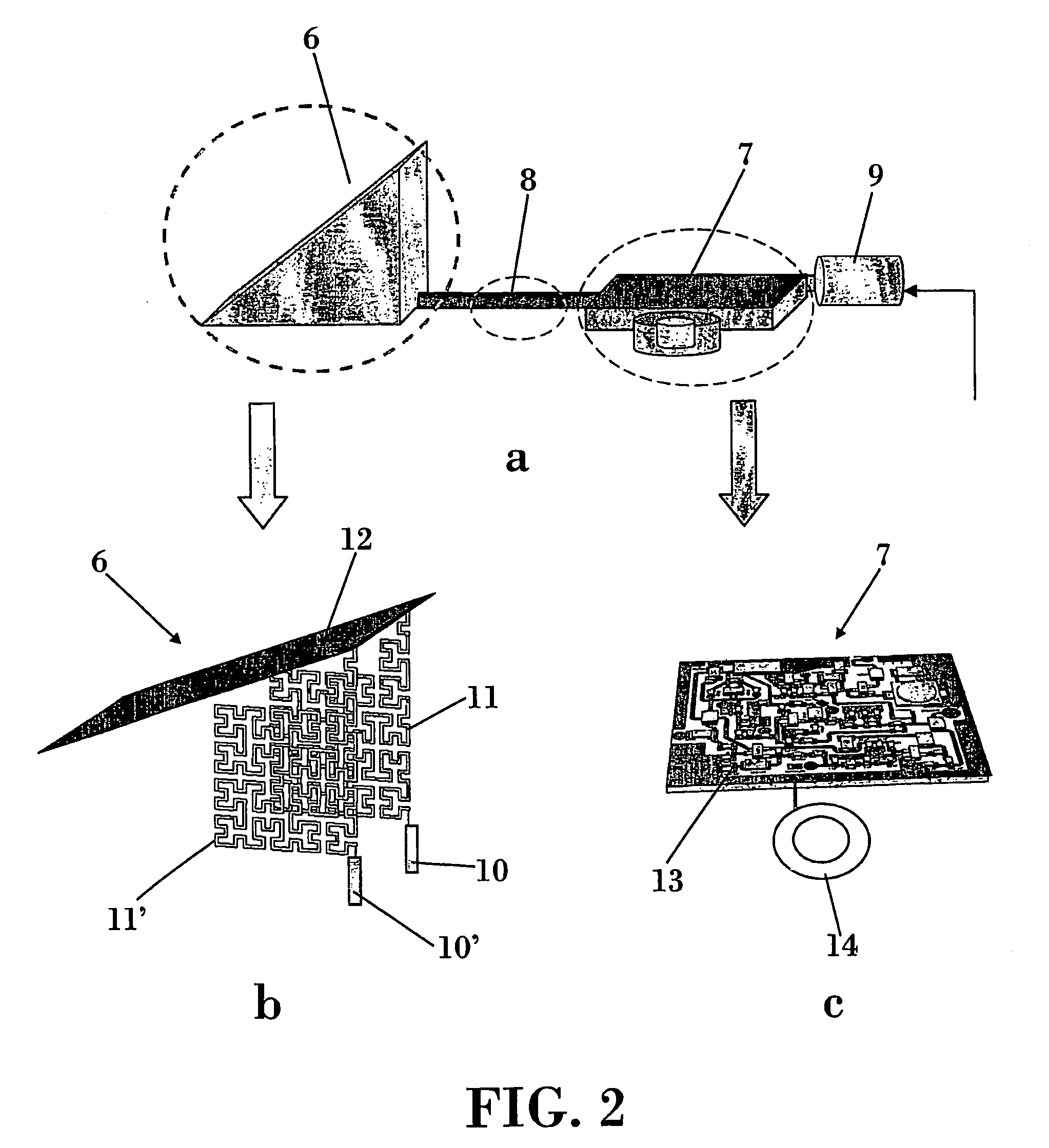

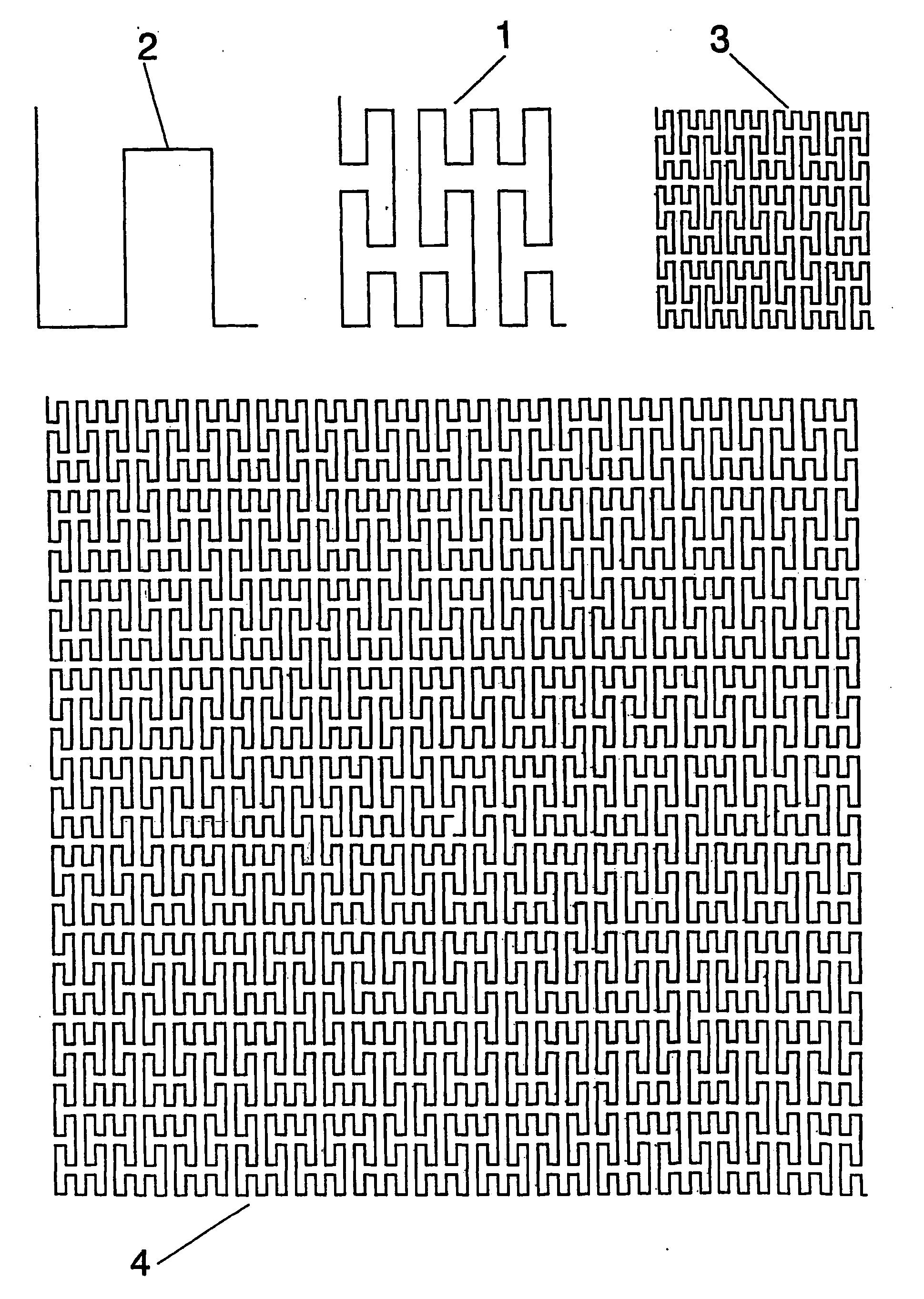

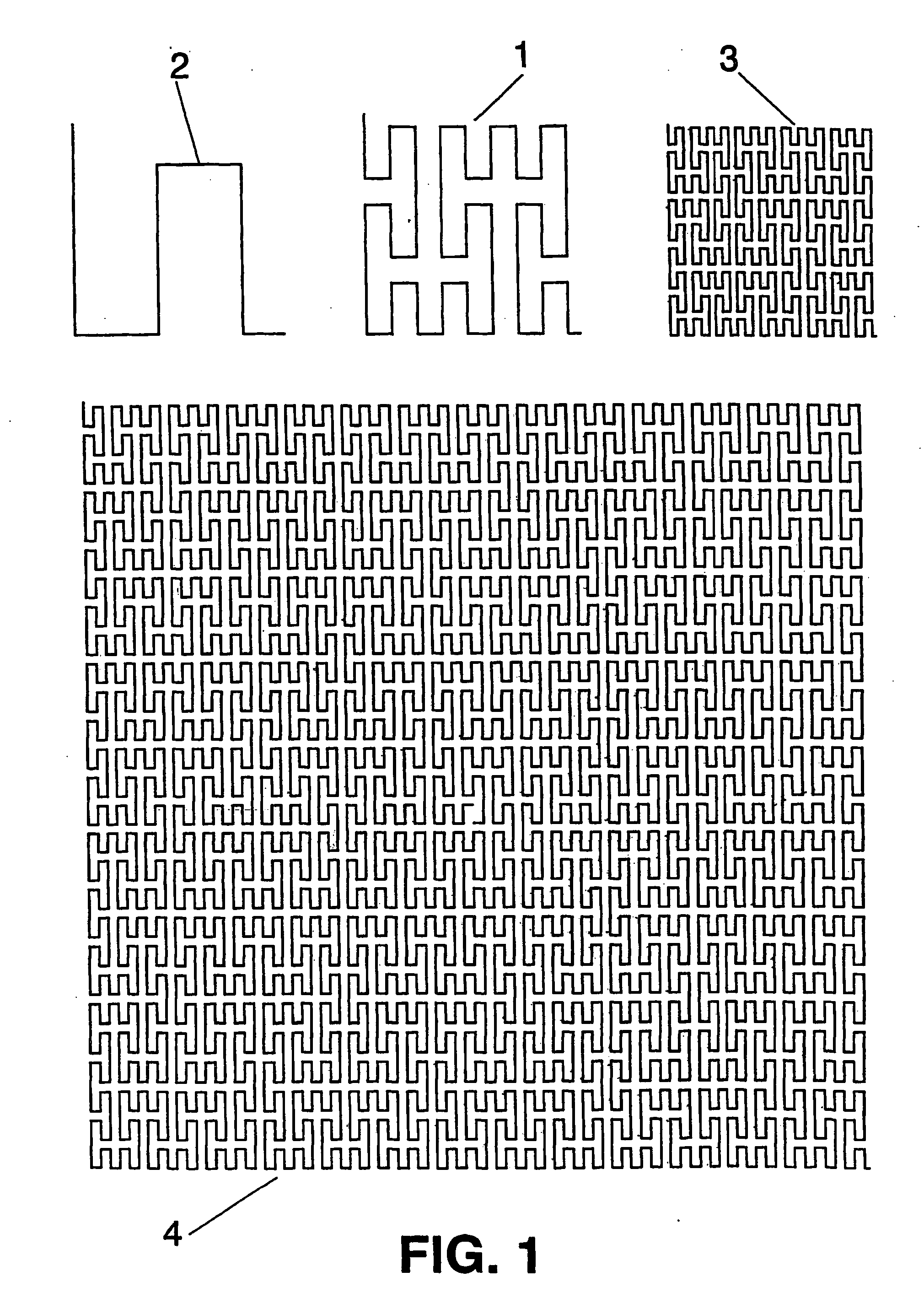

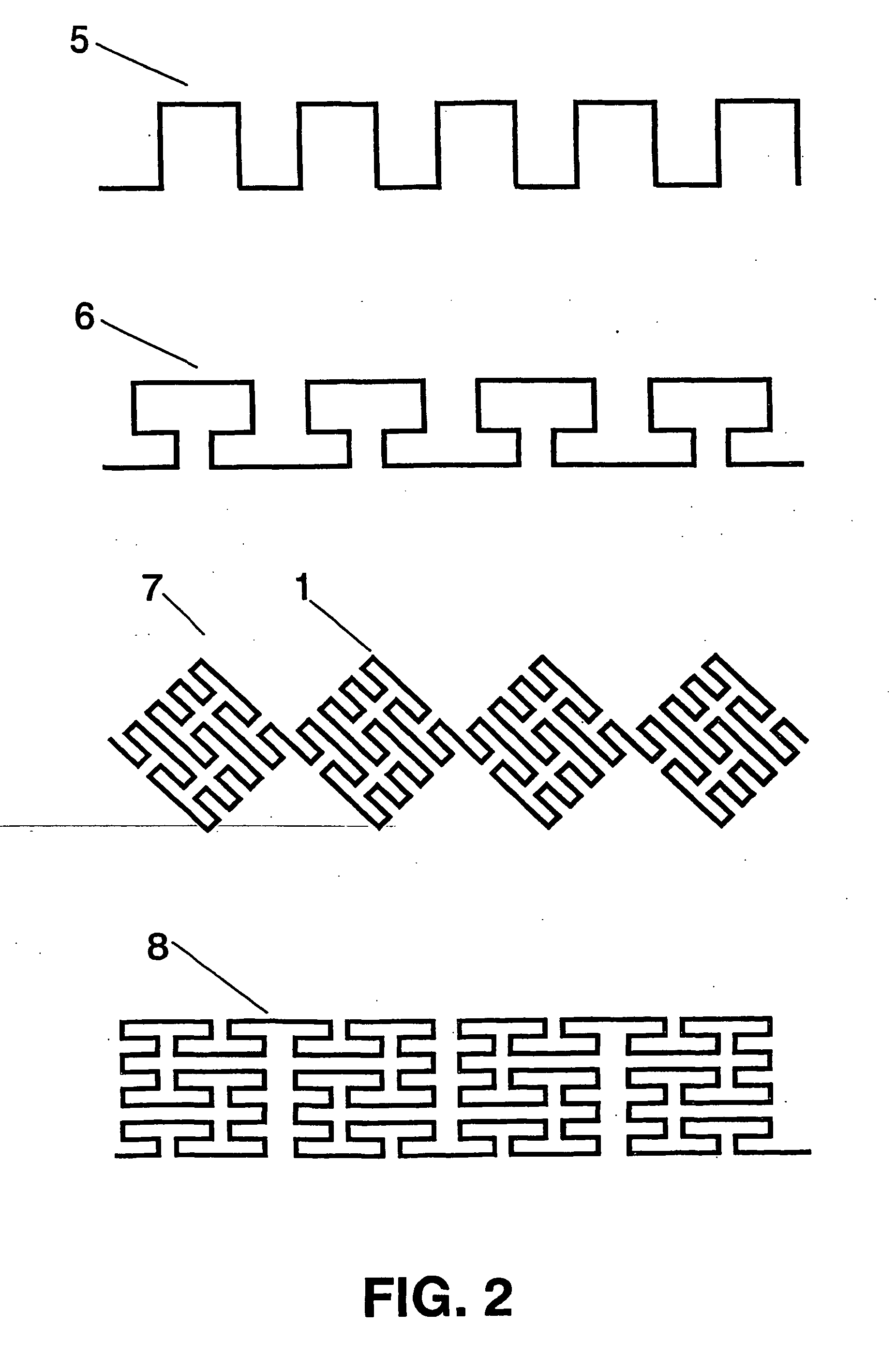

Tamper-proof structures for protectig electronic modules

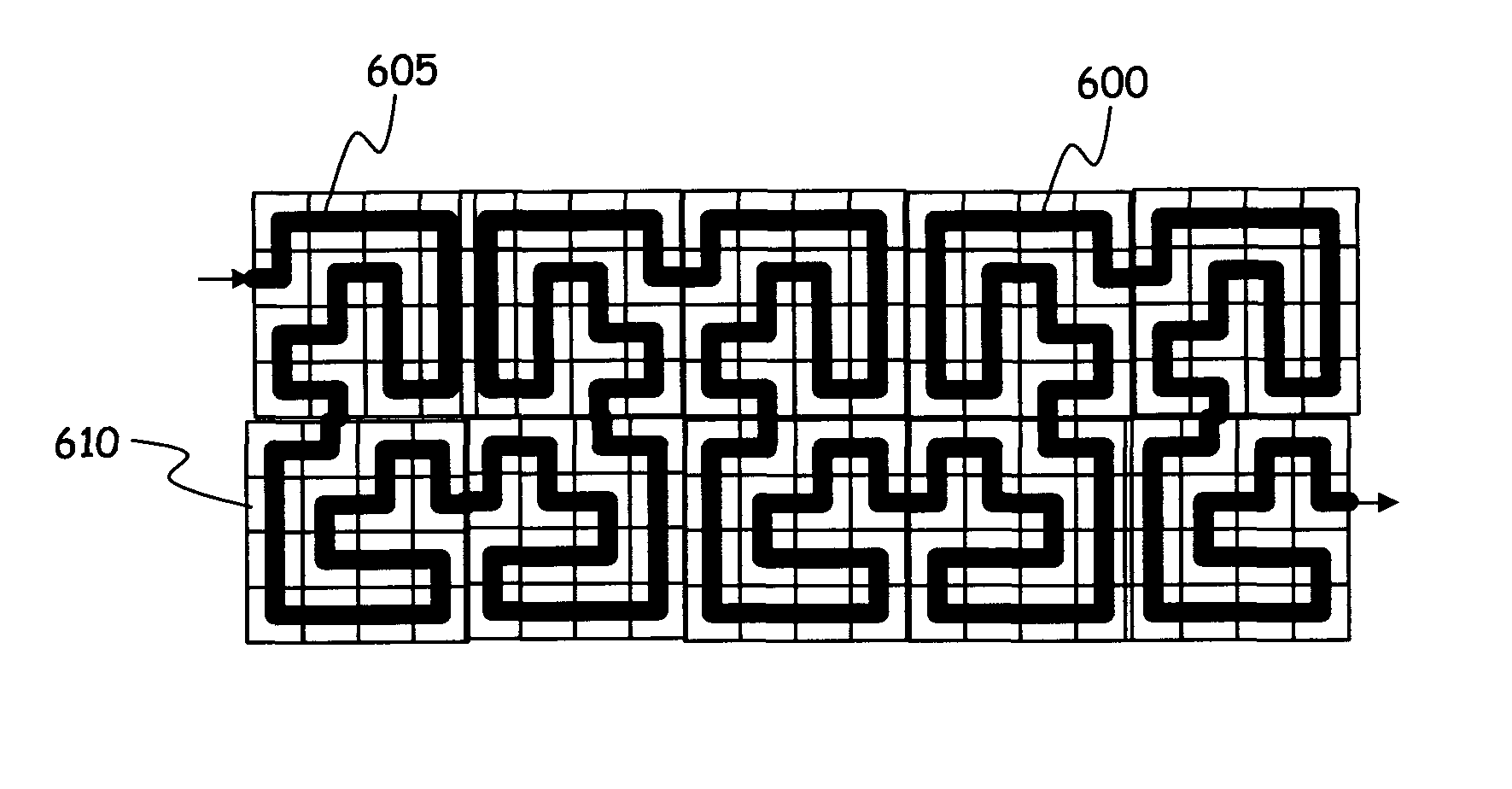

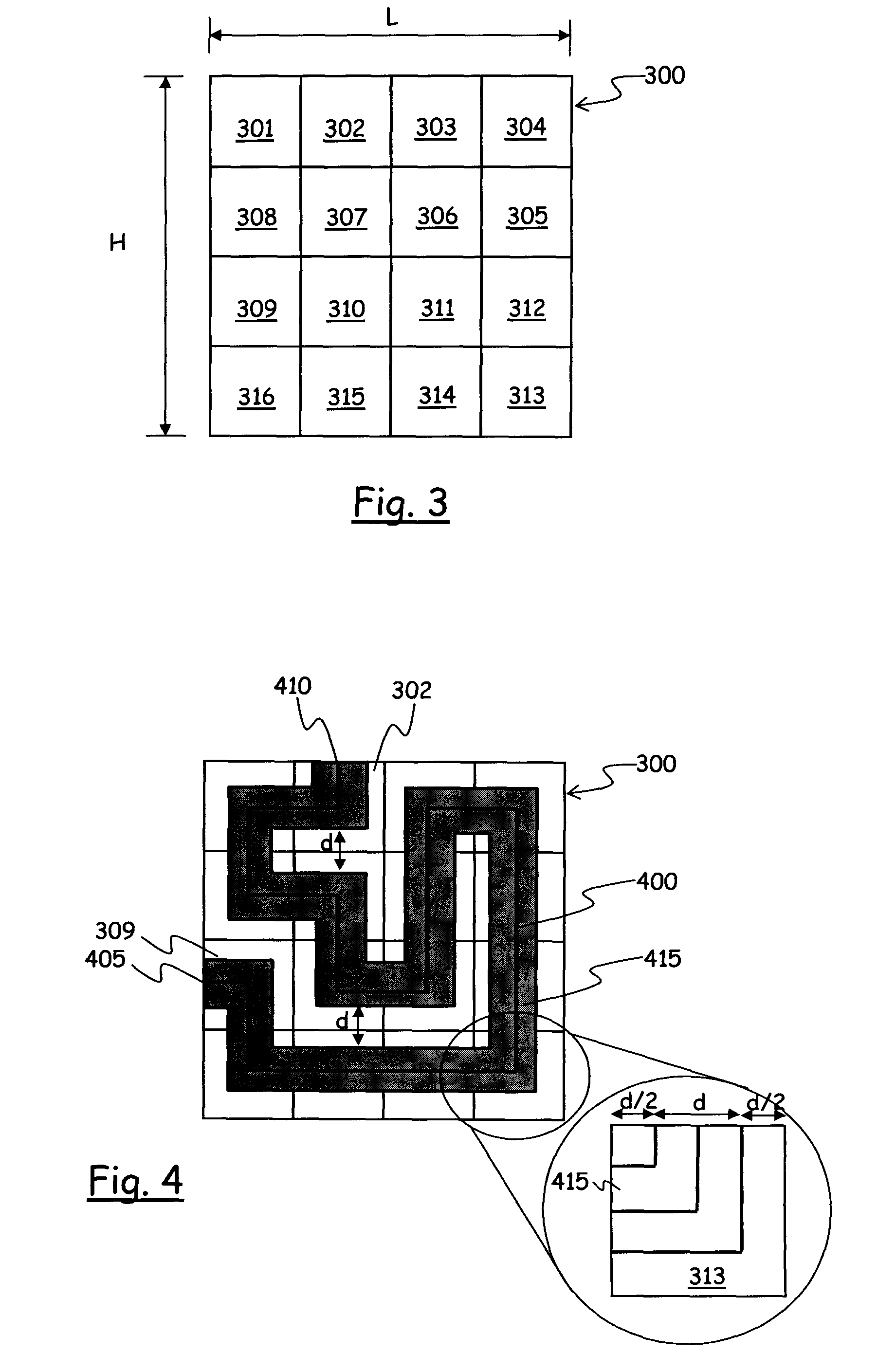

InactiveUS20080036598A1Improve robustnessJeopardize effectivenessCircuit security detailsPrinted circuit aspectsComputer scienceSpace-filling curve

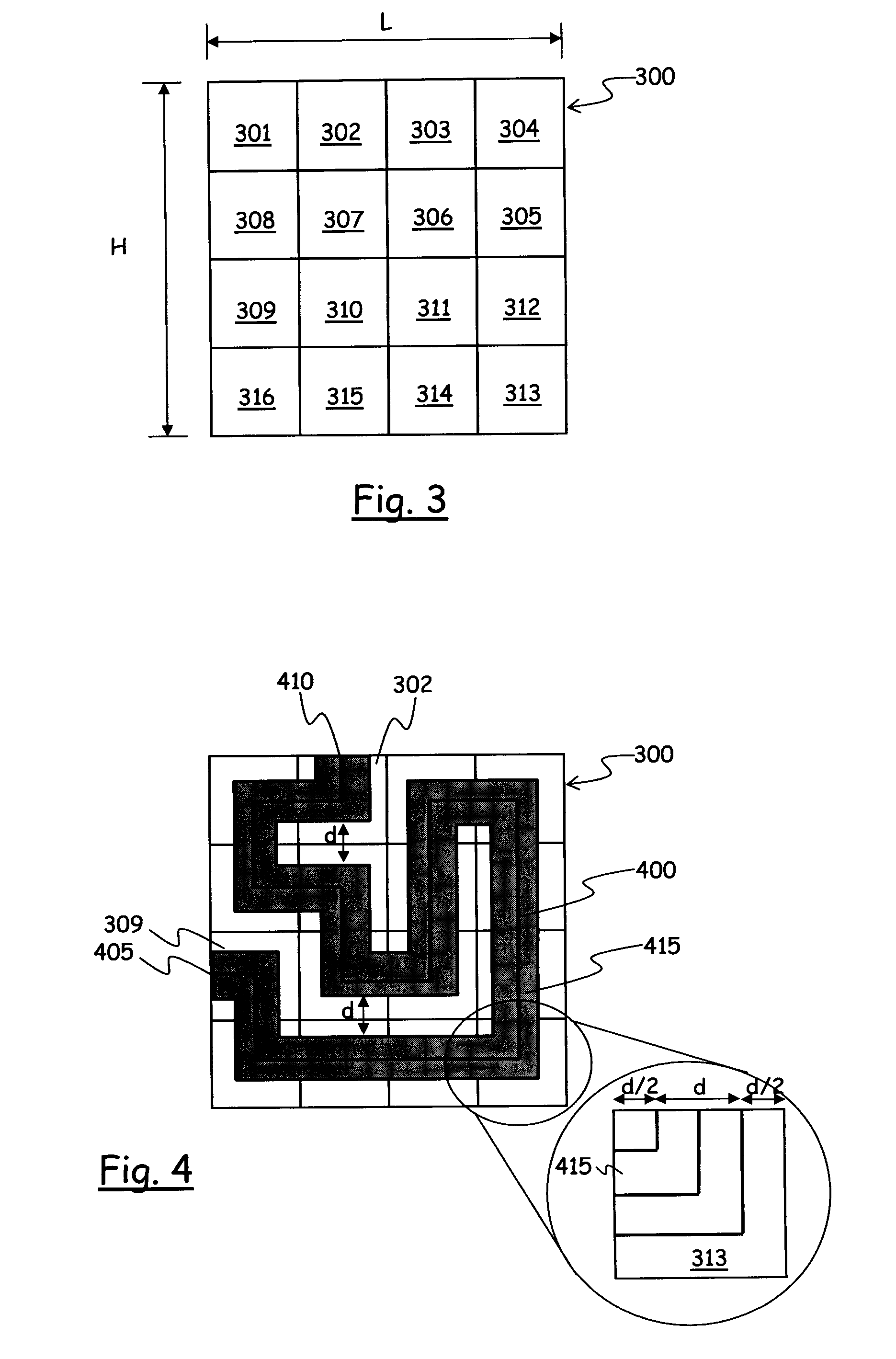

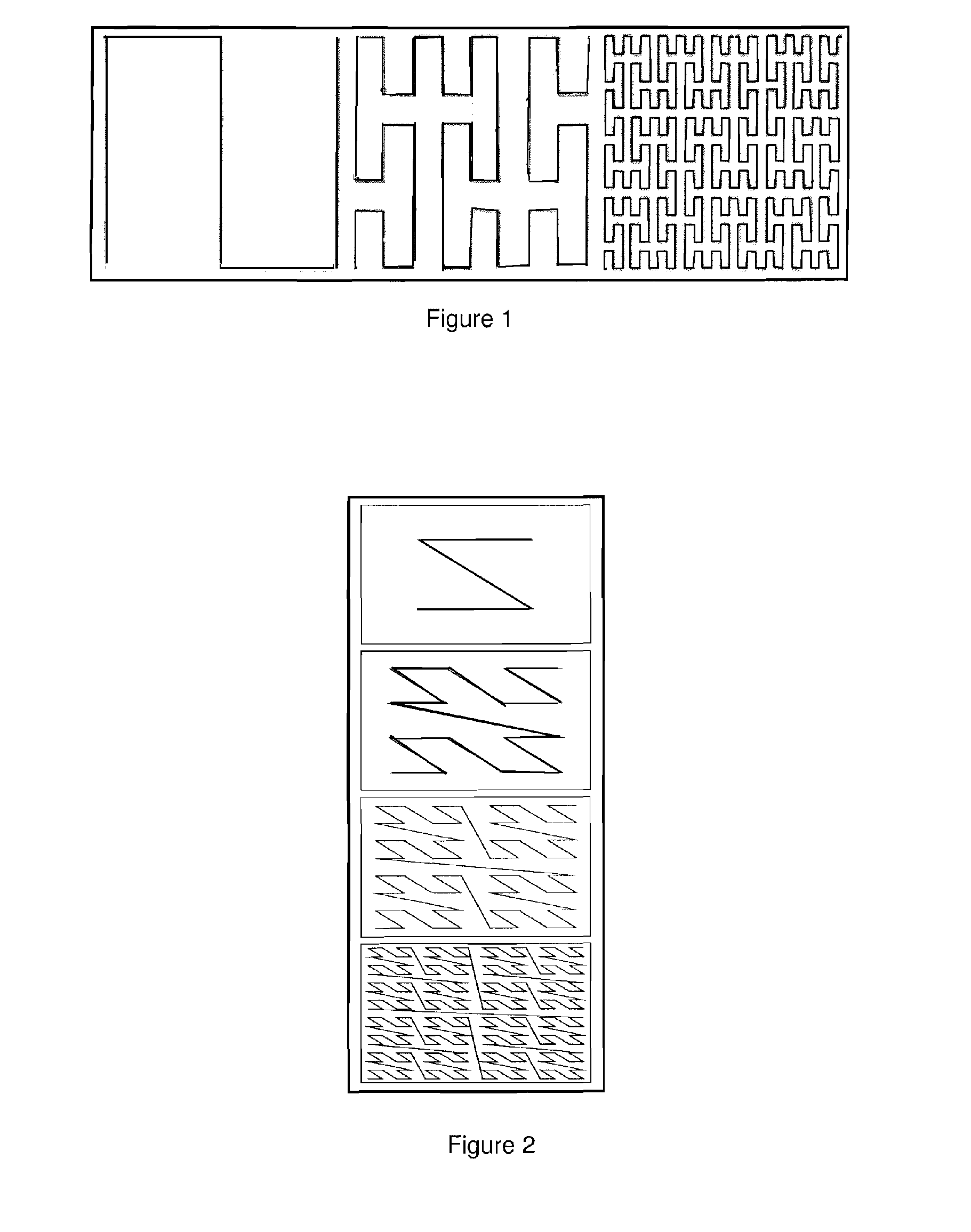

A tamper-proof structure for protecting an electronic module, comprising a pattern of signal lines having a highly unpredictable layout, which is an approximation of a space-filling curve obtained by the replication of at least one elementary space element having an inscribed base curve inscribed therein. The base curve is adapted, by replication of the elementary space element, to generate an approximation of an at least two-dimensional space-filling curve, the replication being such that an end of the base curve in one elementary space element is connected to the end of the base curve in another, adjacent elementary space element of the replication.

Owner:IBM CORP

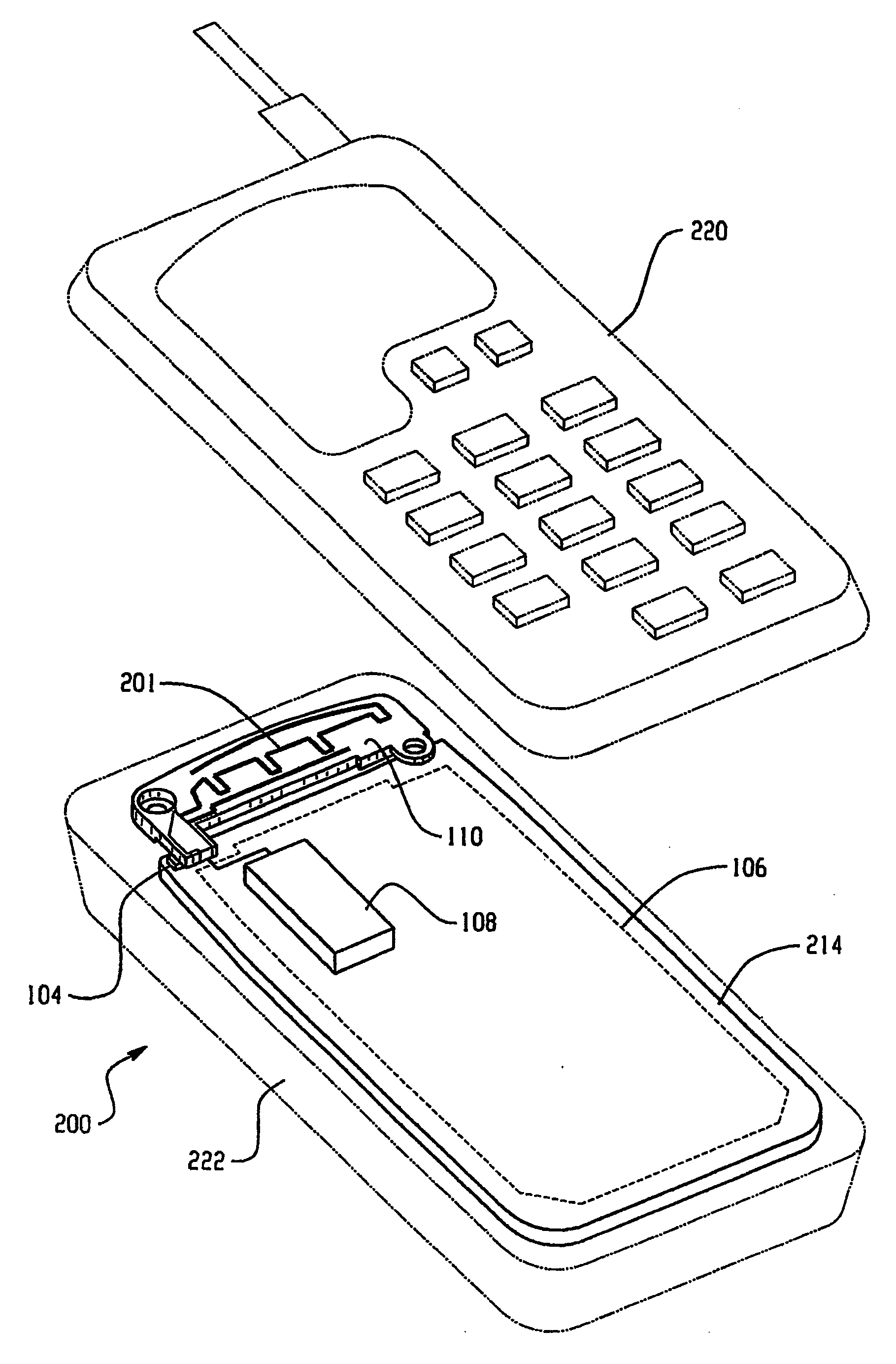

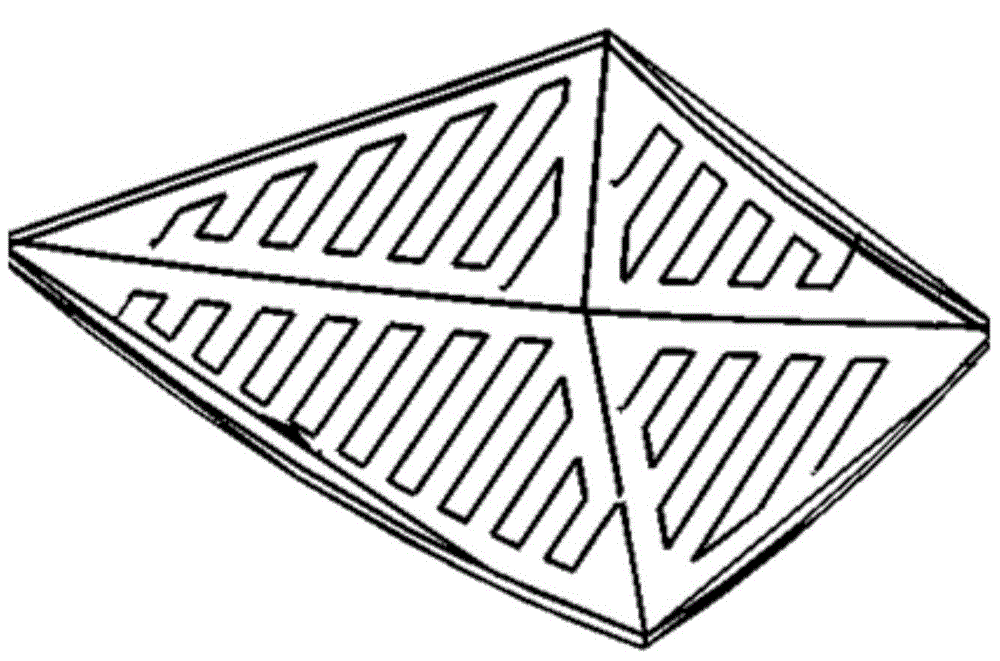

Multi-band monopole antenna for a mobile communications device

InactiveUS20050259031A1Simultaneous aerial operationsAntenna supports/mountingsMulti bandElectrical conductor

Owner:FRACTUS

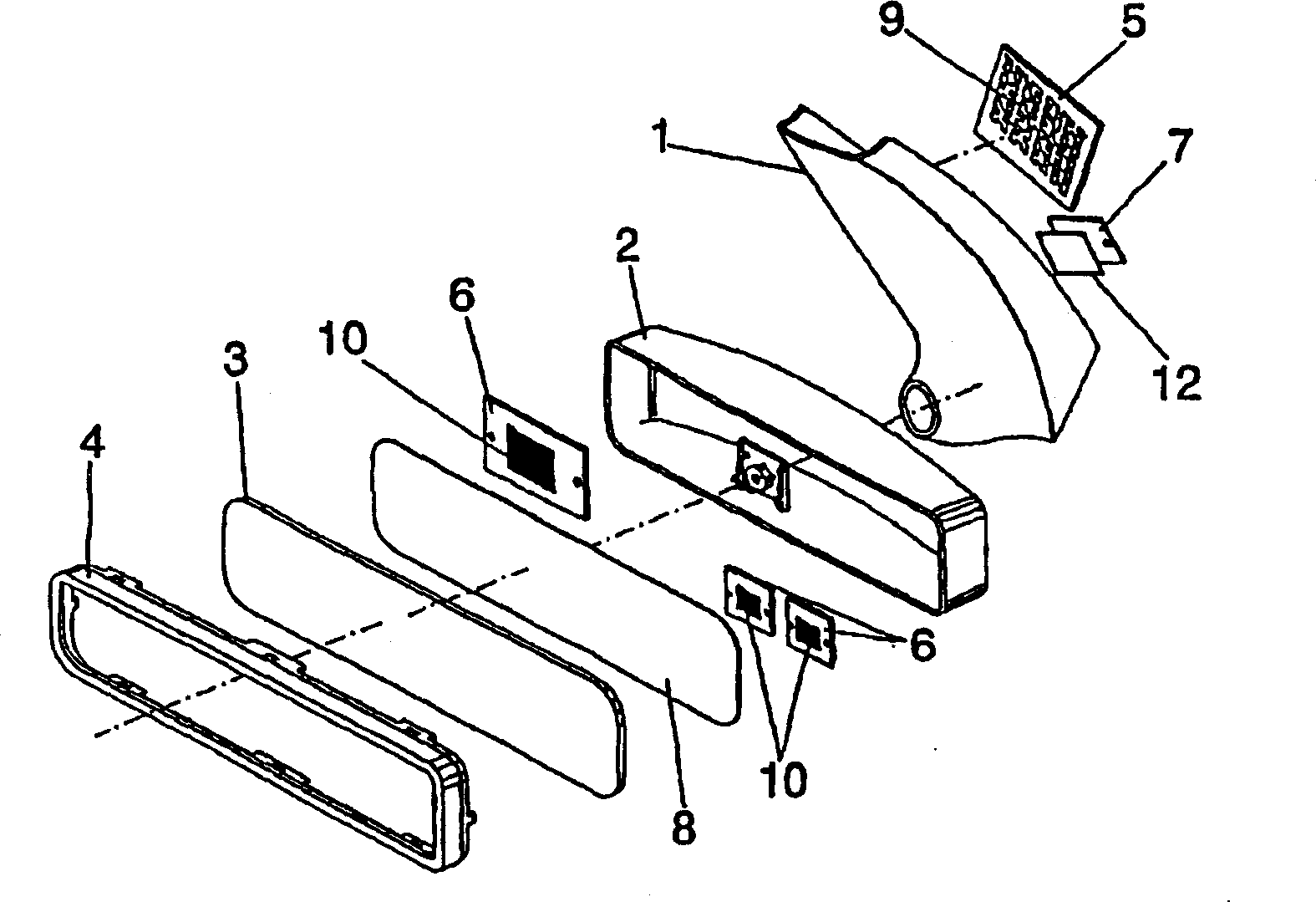

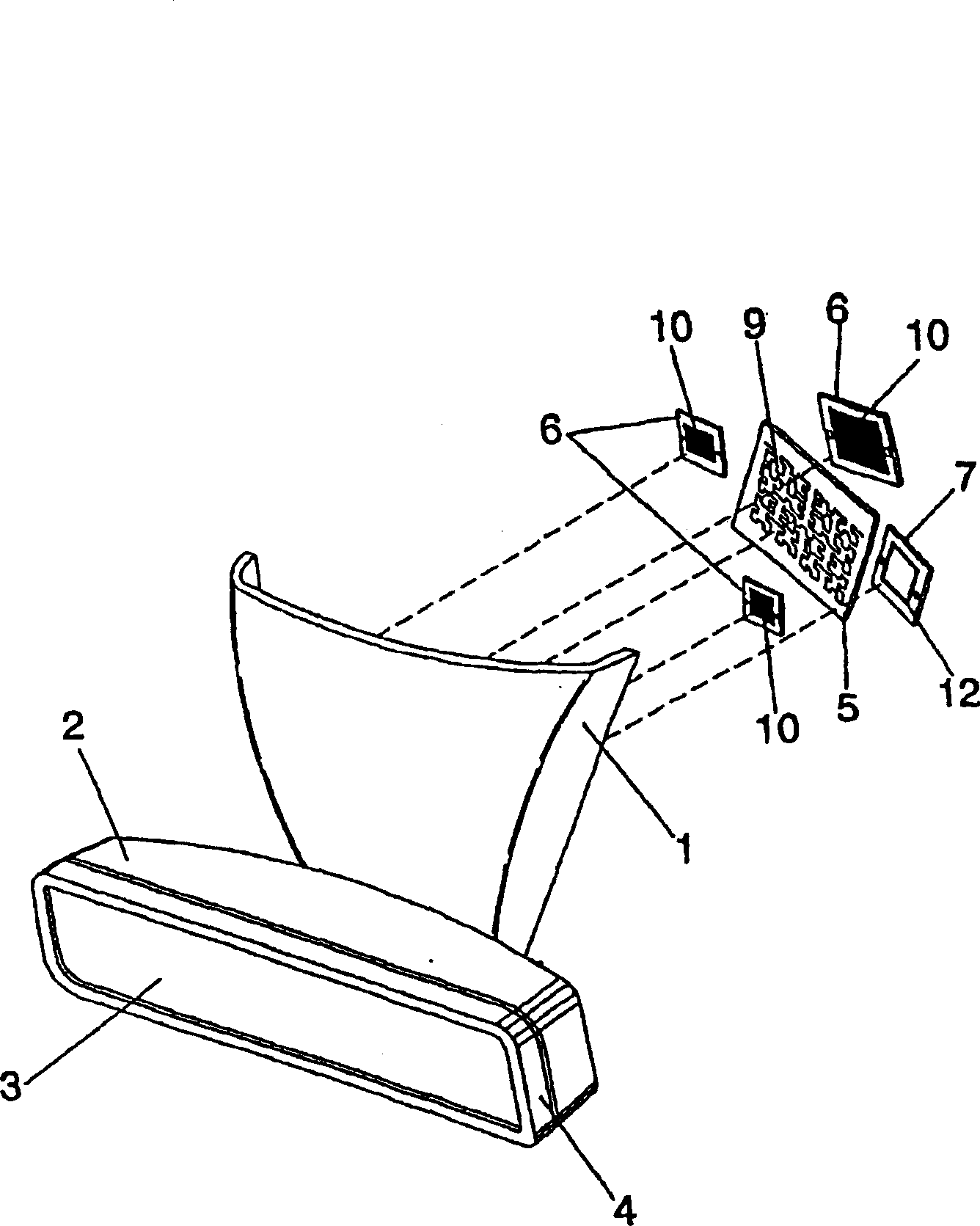

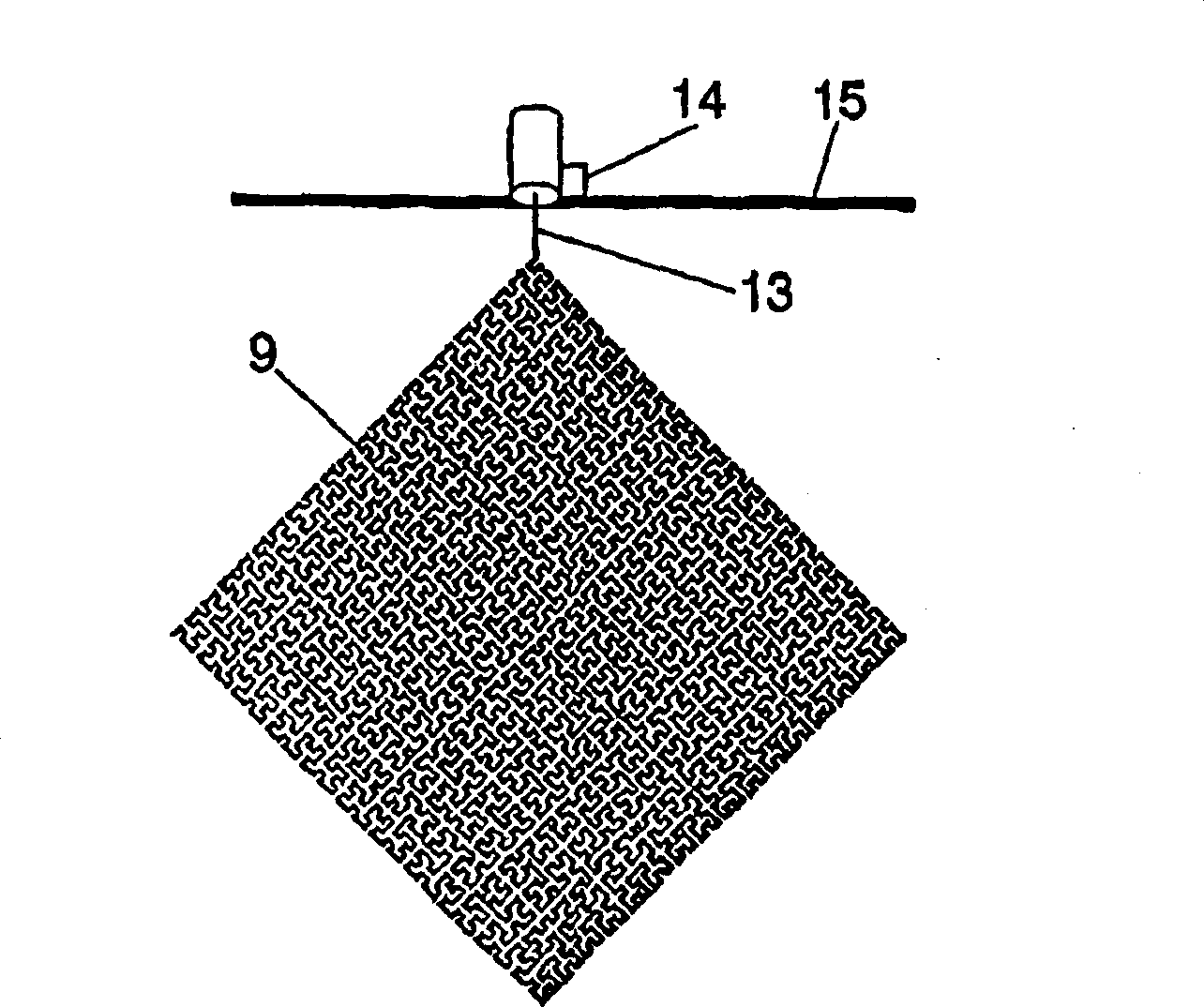

Miniature antenna for a motor vehicle

ActiveUS20090237313A1Improve aestheticsLess opportunity to stealSimultaneous aerial operationsAntenna adaptation in movable bodiesEngineeringMotorized vehicle

The present invention relates to a miniature antenna for a motor vehicle. The antenna may, for example, be a printed board miniature radio antenna for AM / FM signal reception. The antenna may, for example, be placed in an internal mirror of a motor vehicle or on an exterior surface of the motor vehicle, such as the vehicle's roof. The antenna is shaped as a curve of conductive material in which the geometry of at least a part of said curve comprises a space-filling curve or a grid dimension curve.

Owner:ADVANCED AUTOMOTIVE ANTENNAS

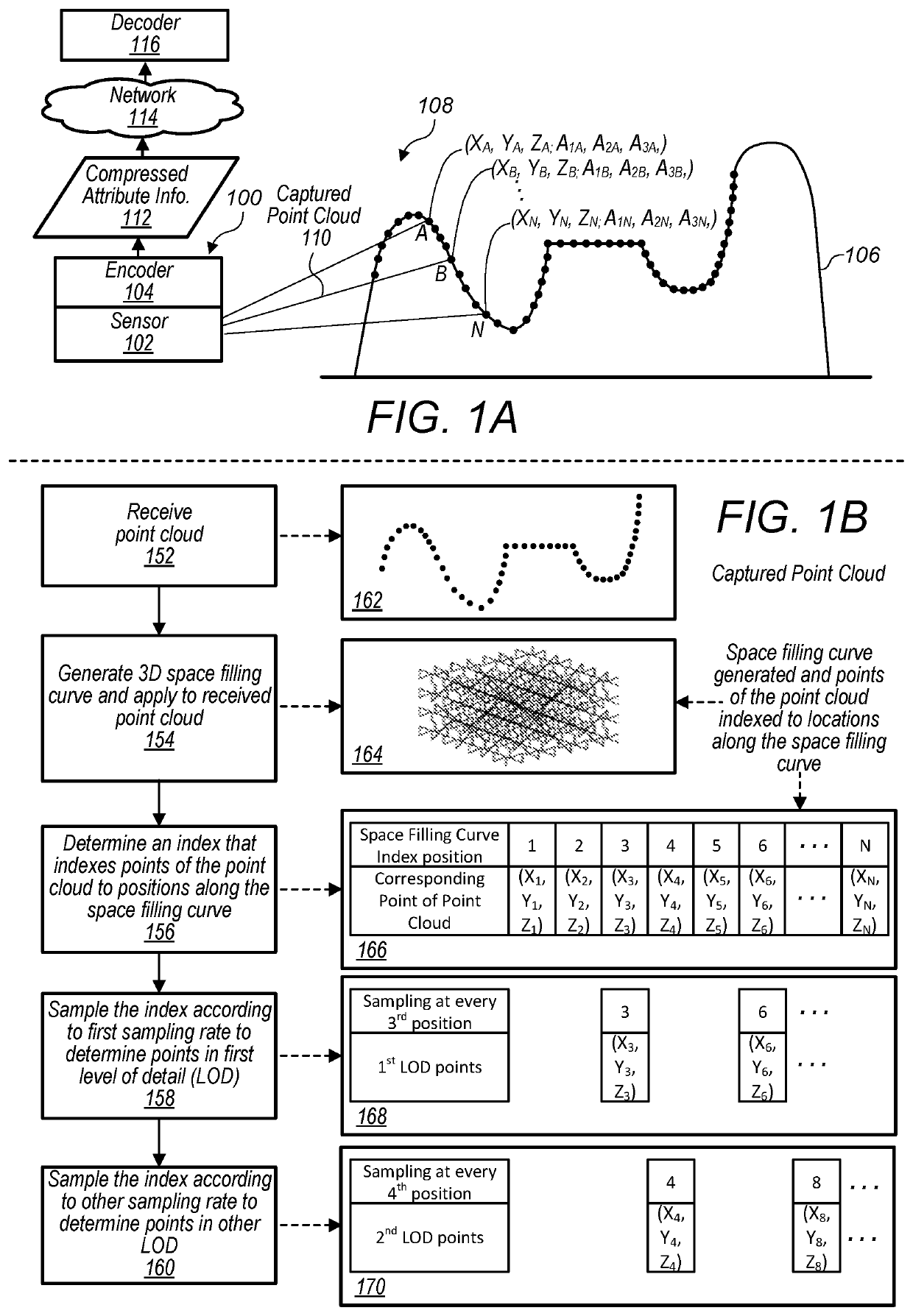

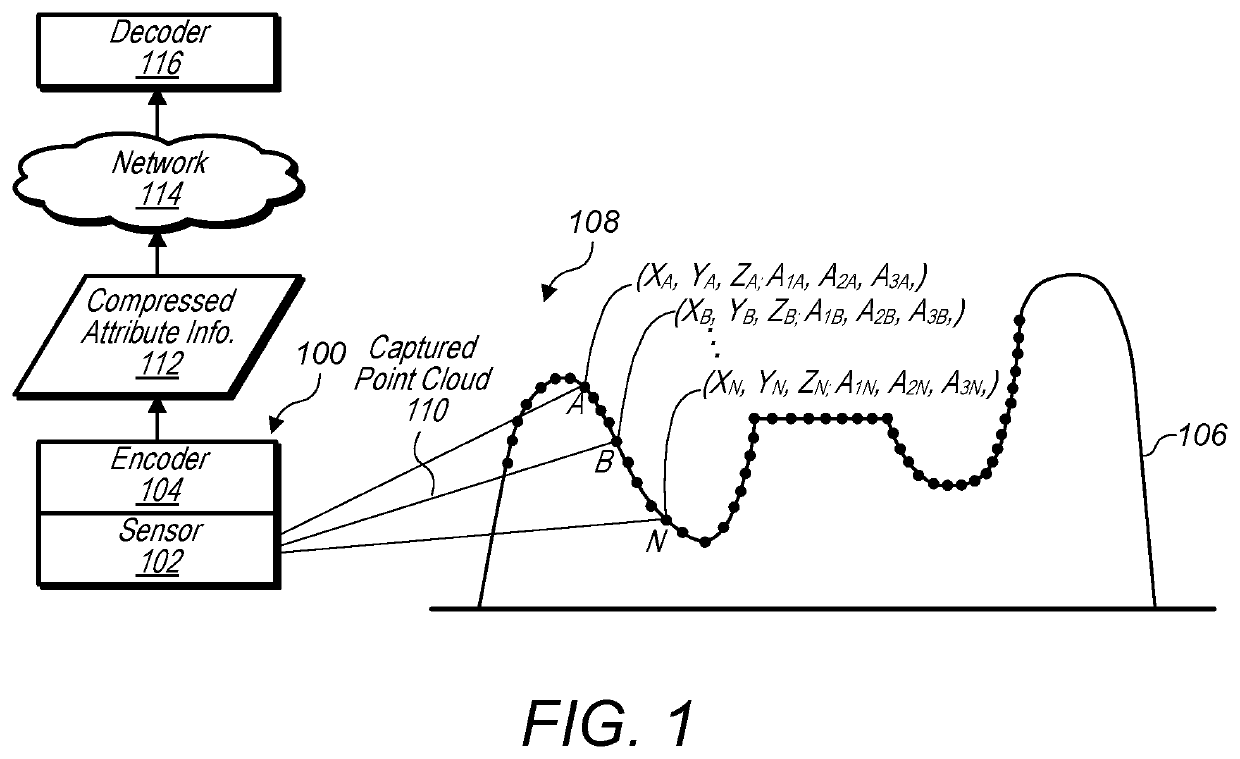

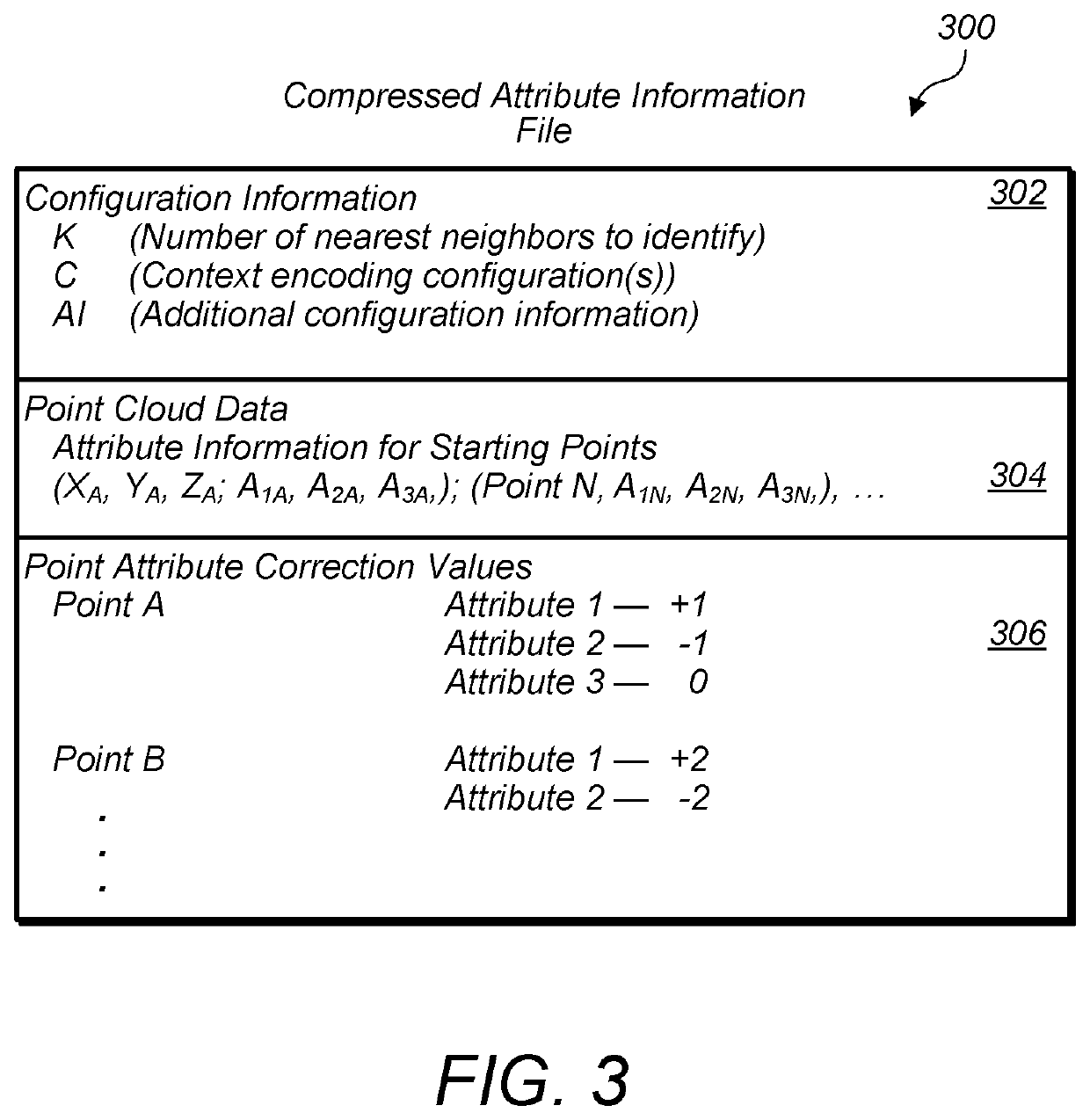

Point cloud compression using a space filling curve for level of detail generation

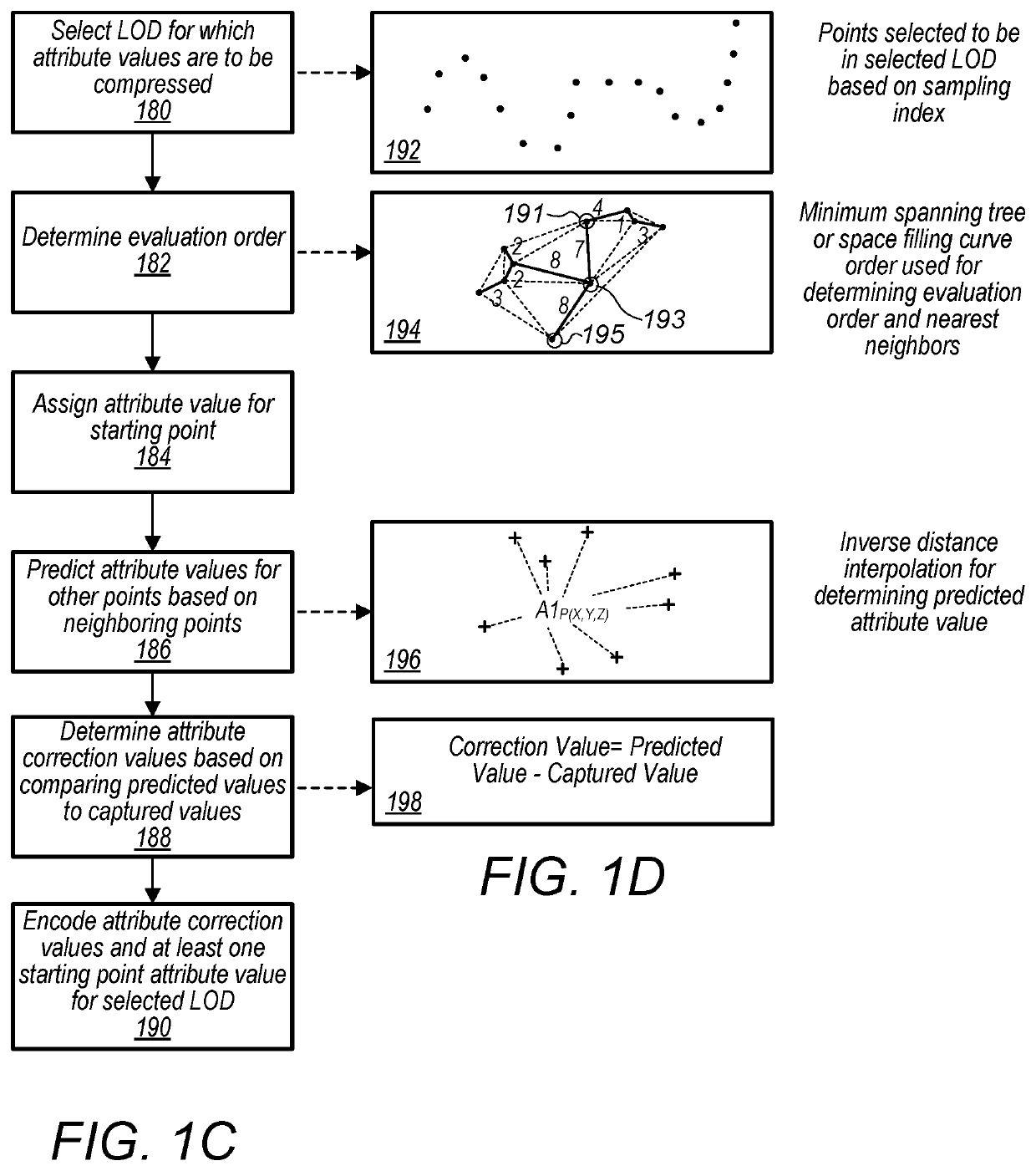

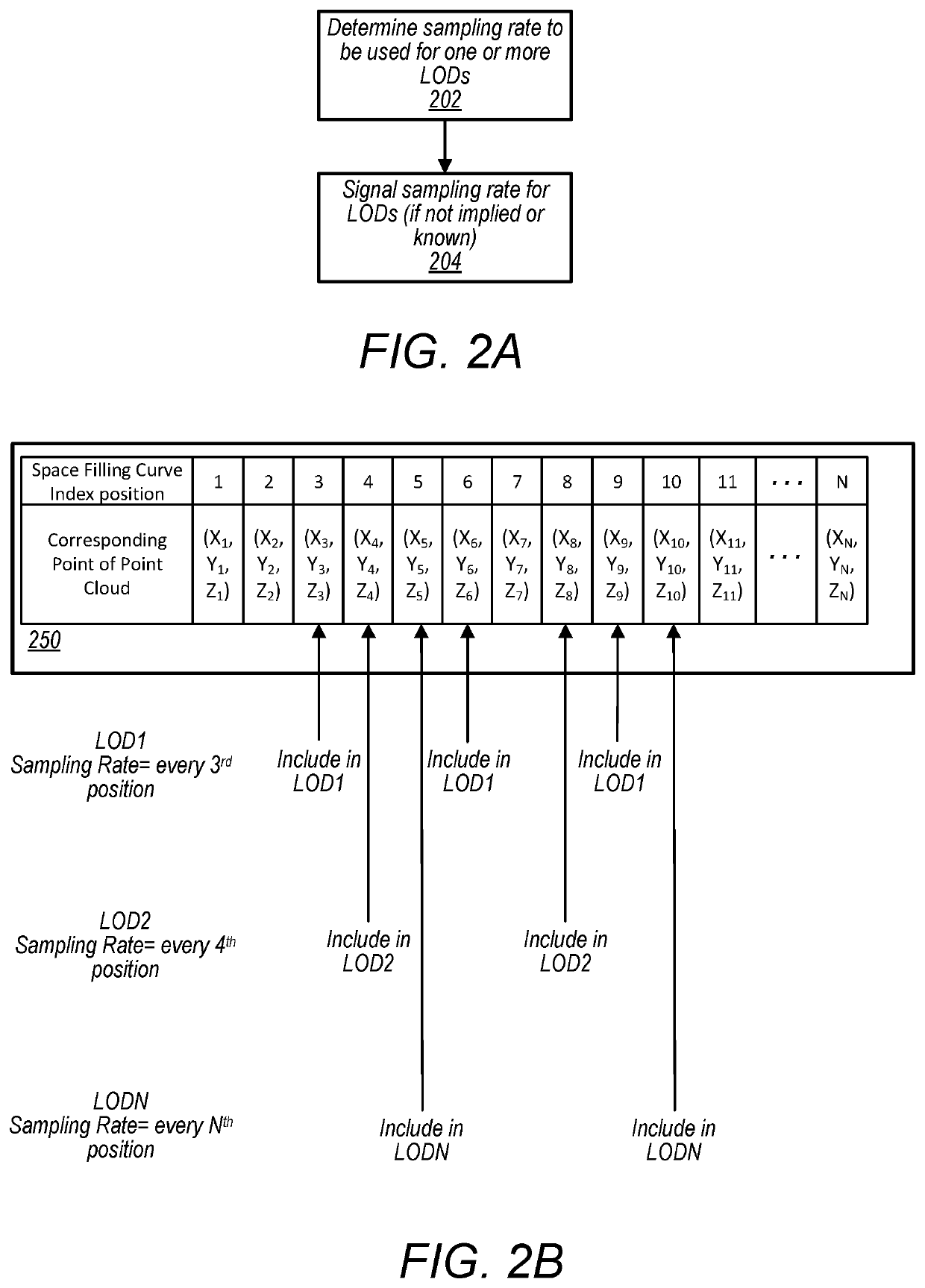

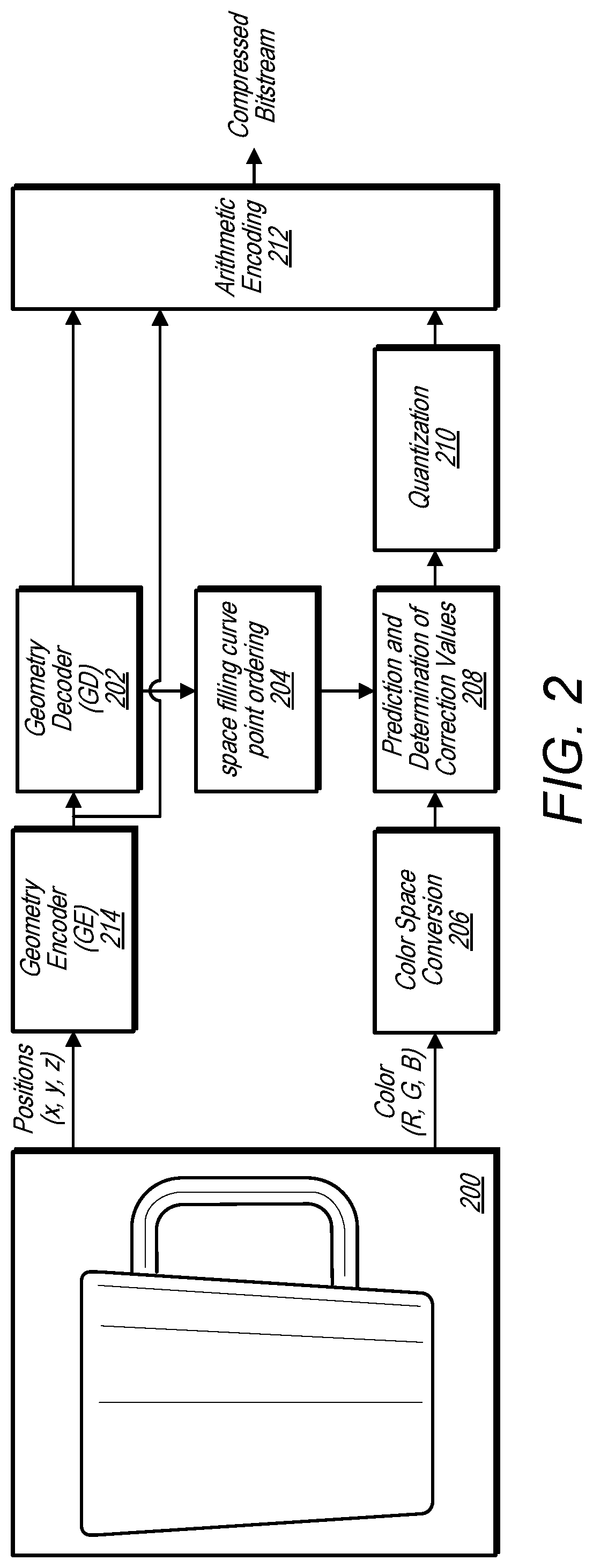

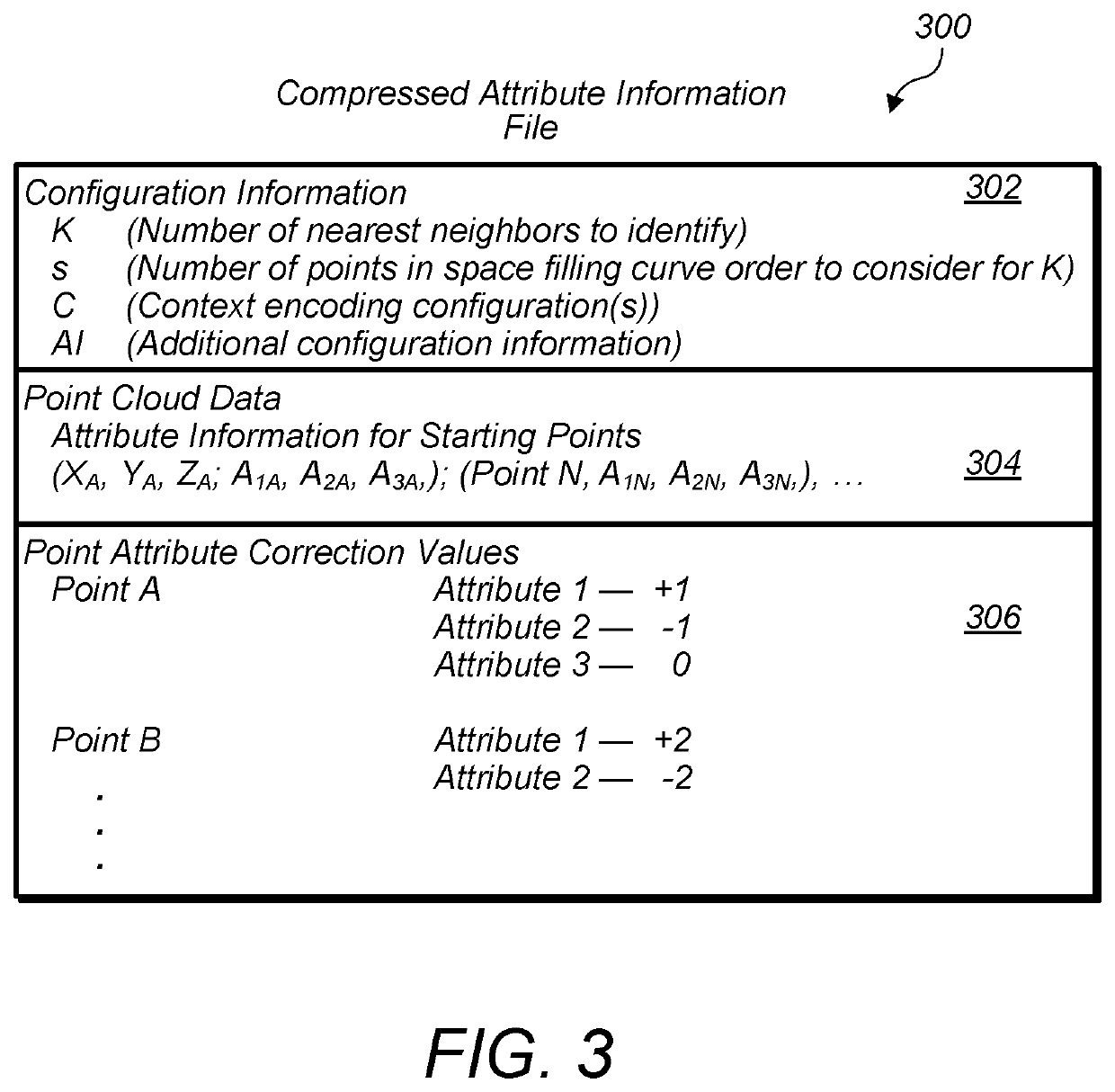

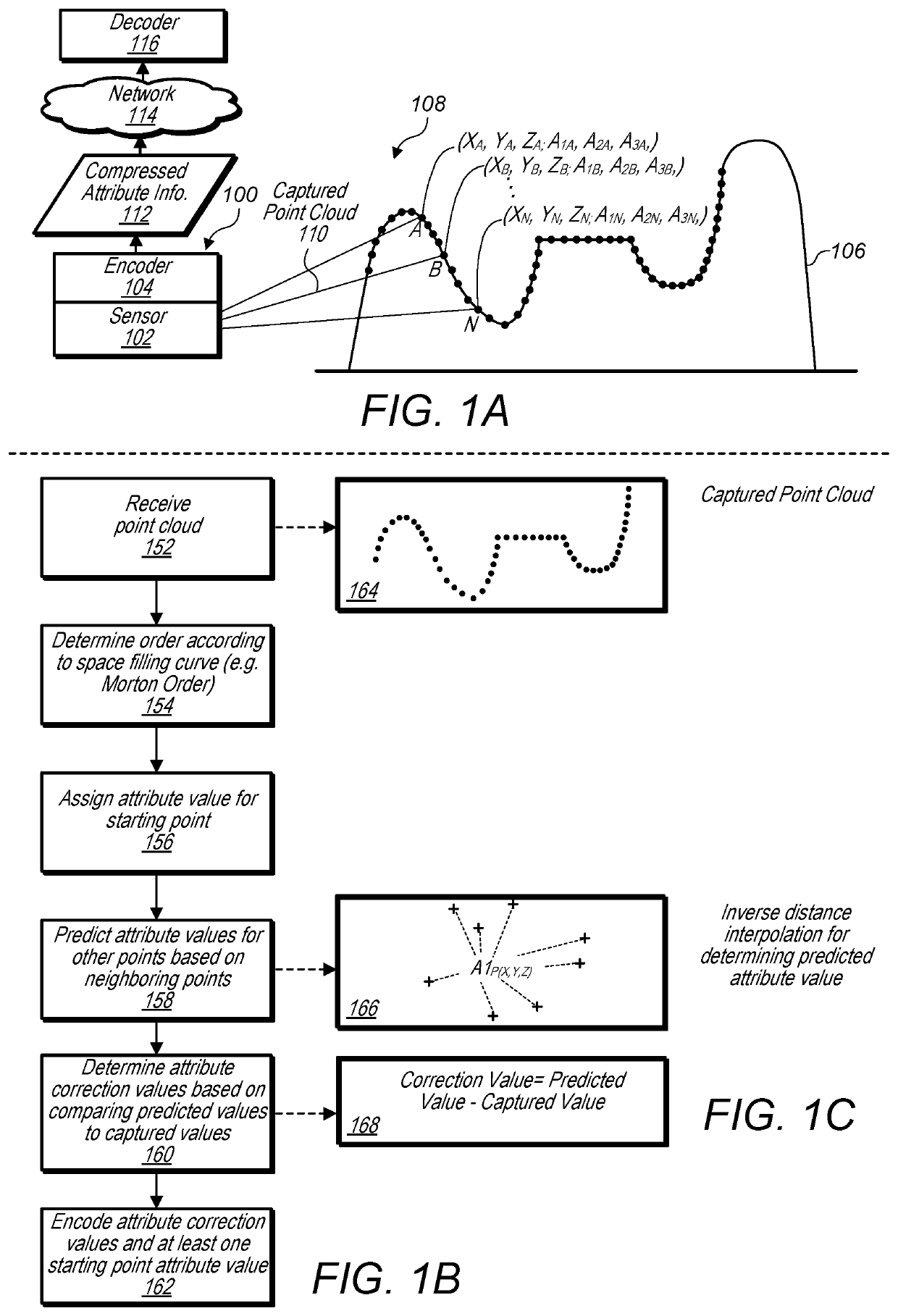

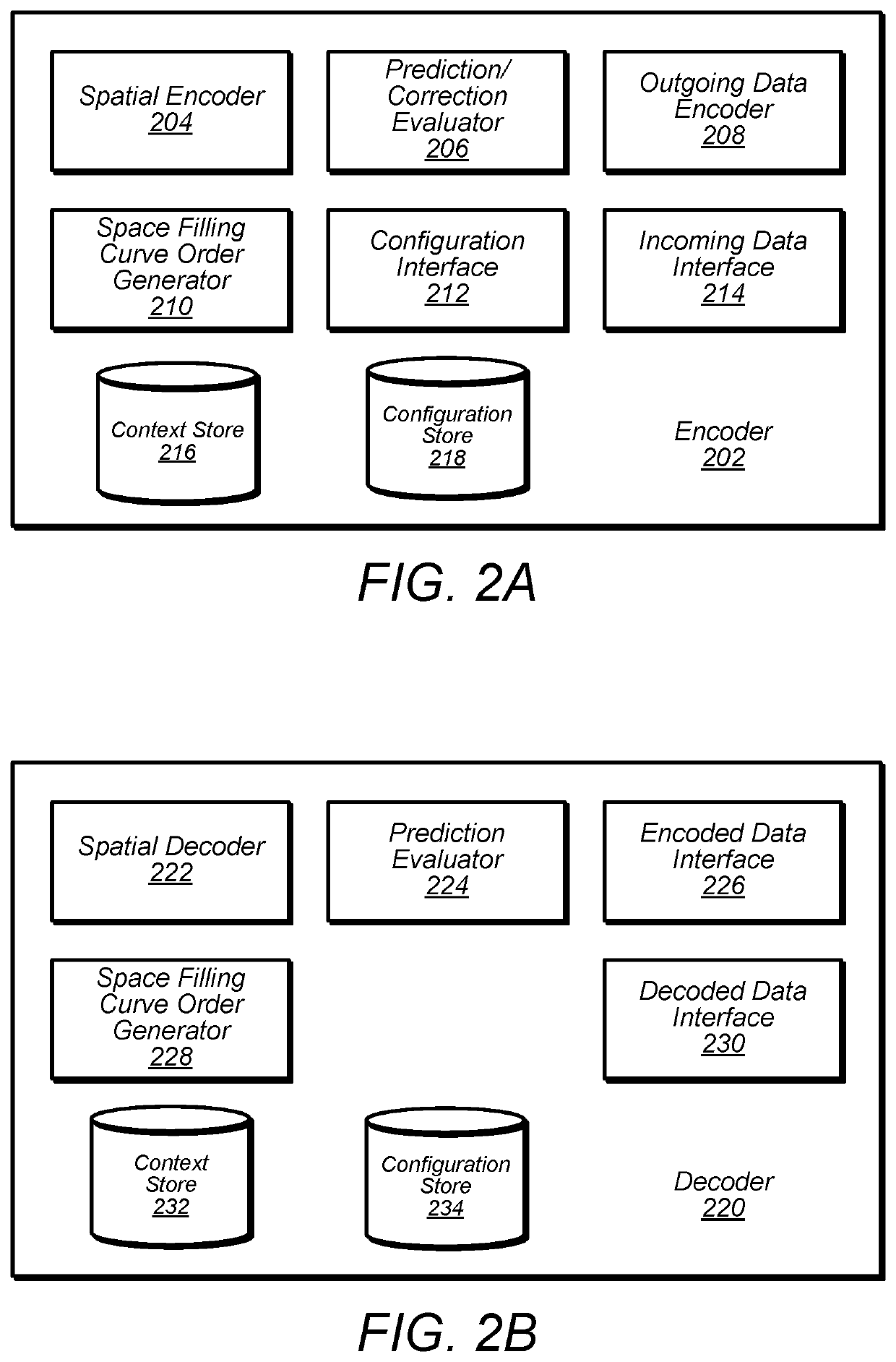

A system comprises an encoder configured to compress attribute information for a point cloud and / or a decoder configured to decompress compressed attribute information. Attribute values for at least one starting point are included in a compressed attribute information file and attribute correction values are included in the compressed attribute information file. An order for the points is determined based on a space filling curve, wherein an encoder and a decoder determine a same order for the points based on the space filling curve. Levels of detail are determined by sampling the ordered points according to different sampling parameters, and attribute values are predicted for the points in the levels of detail using the determined order. The encoder determines attribute correction values based on a comparison of the predicted values to an original value prior to compression. The decoder corrects the predicted attribute values based on received attribute correction values.

Owner:APPLE INC

Multi-band monopole antenna for a mobile communications device

InactiveUS20070152894A1Simultaneous aerial operationsAntenna supports/mountingsMulti bandElectrical conductor

Owner:FRACTUS

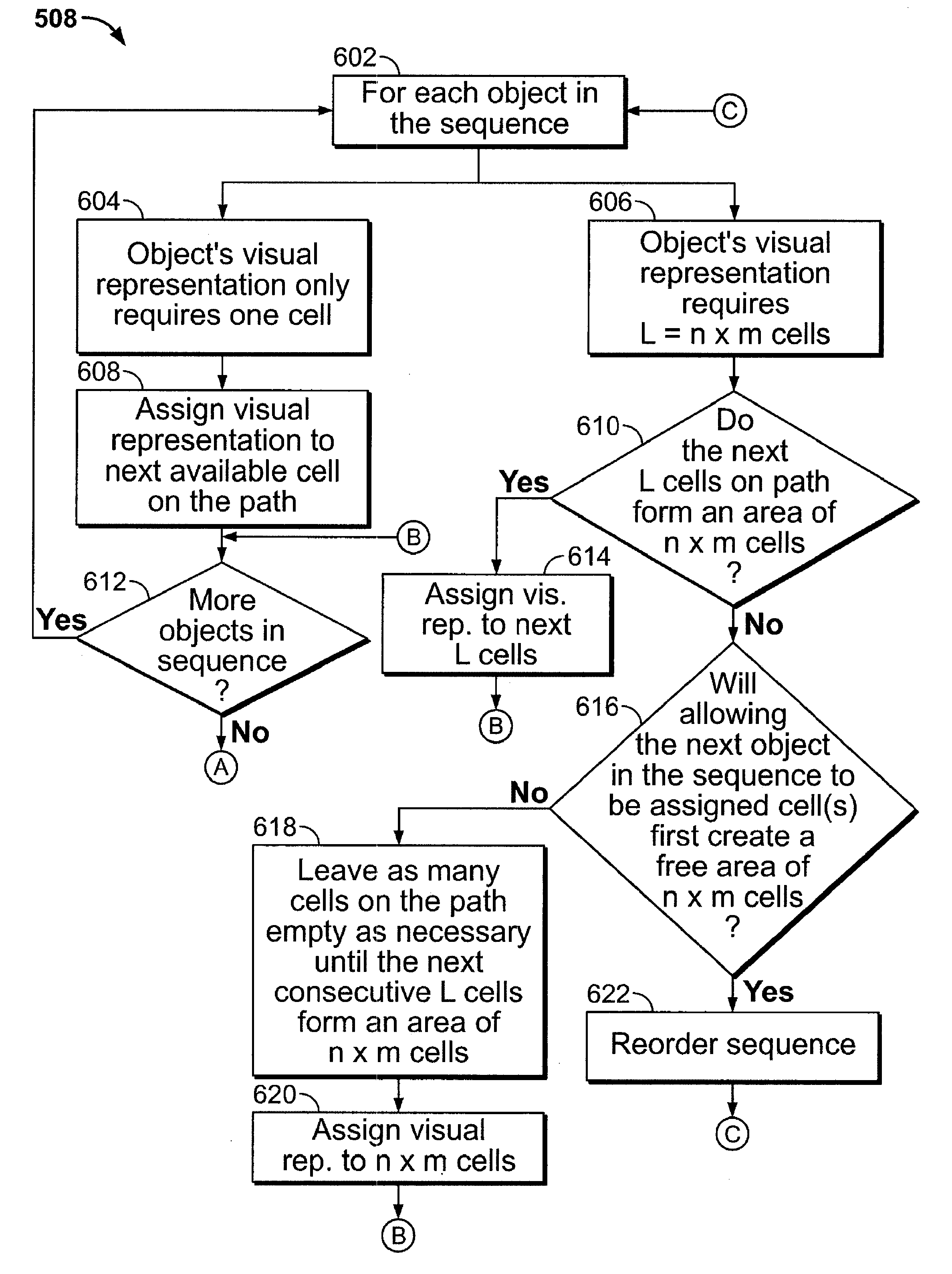

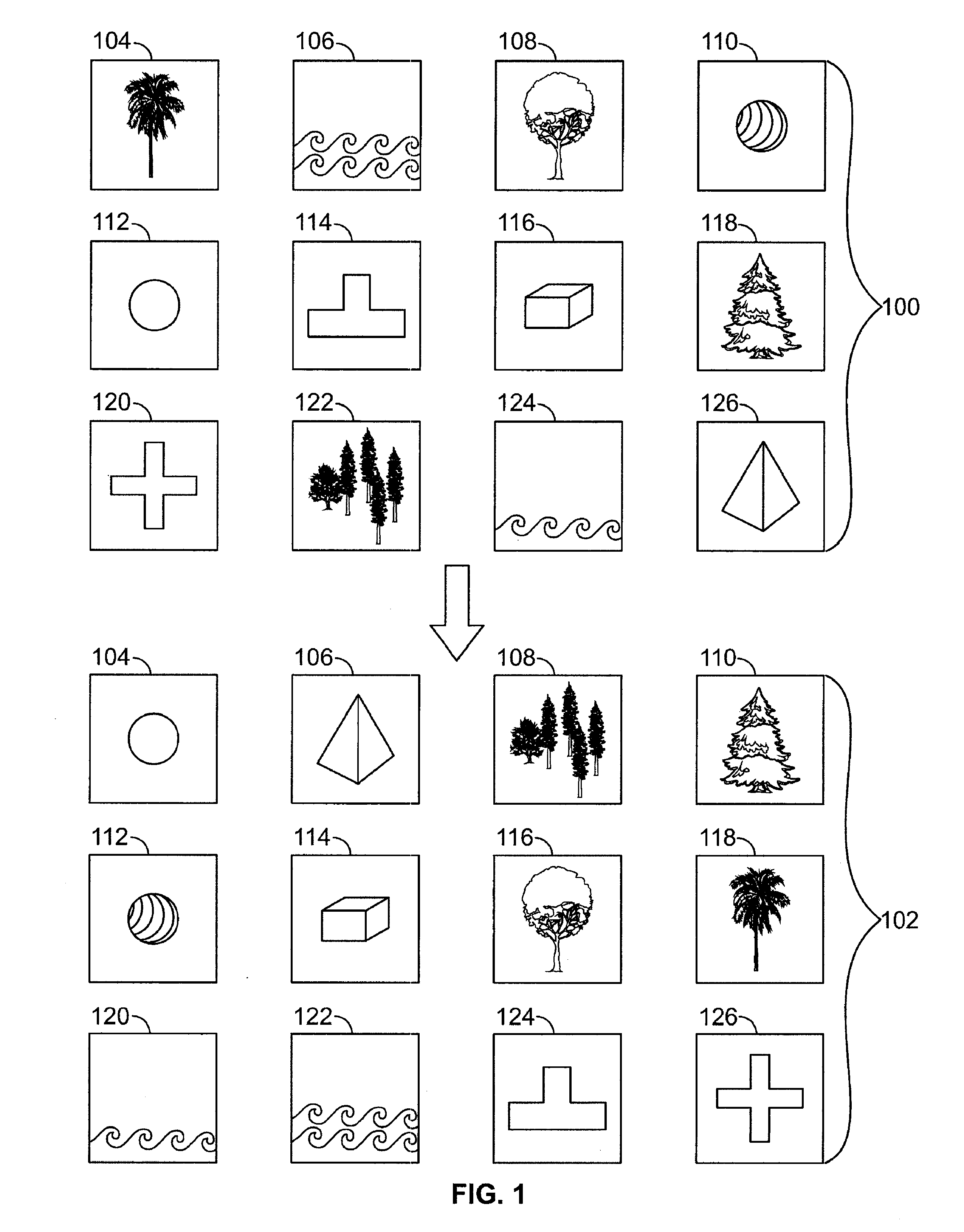

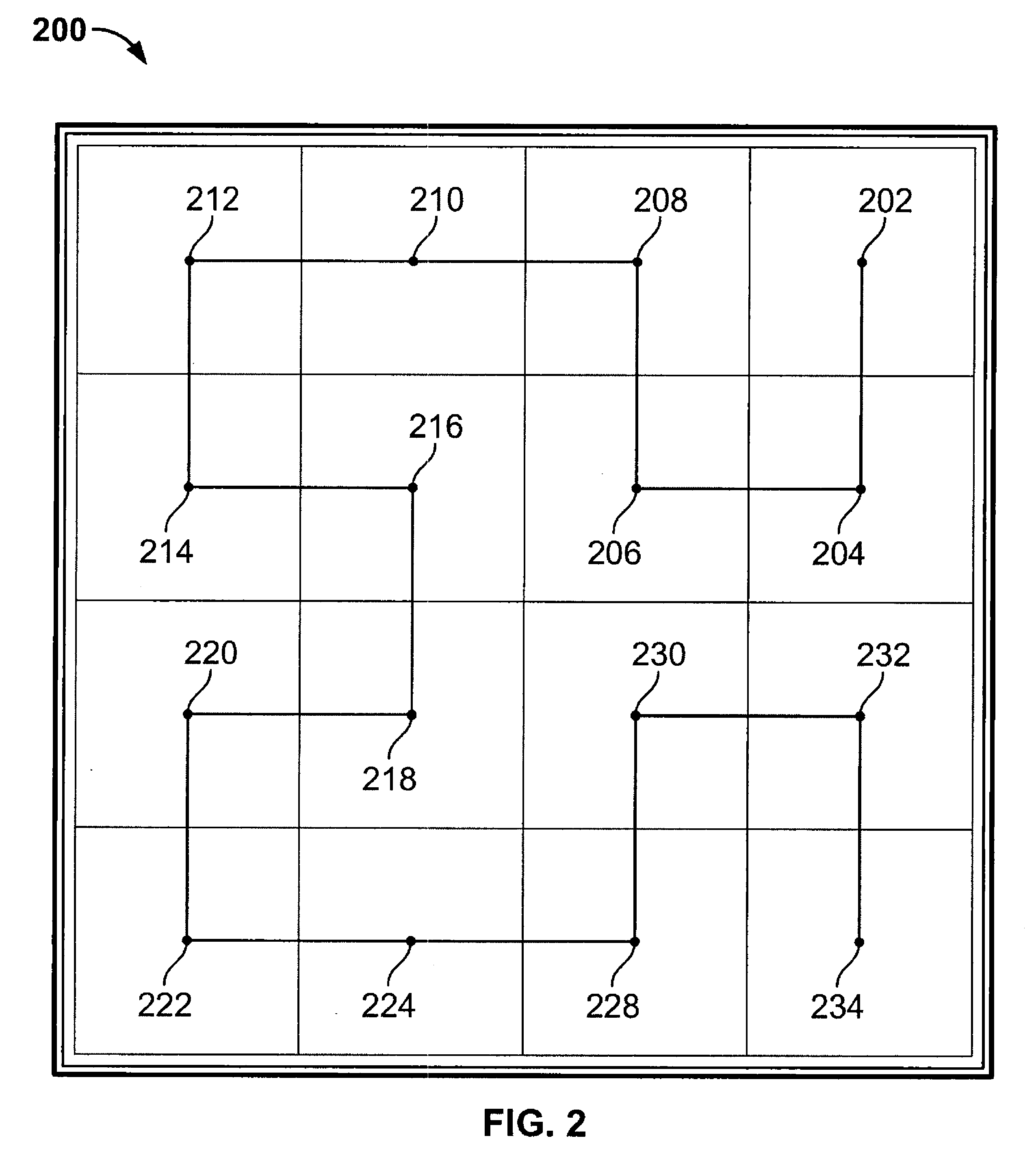

Compact clustered 2-D layout

Methods and apparatus, including computer program products, for receiving user selection of an ordering for a plurality of objects. Each object in the plurality having one or more associated attributes and an associated visual representation. The selected ordering specifies a sequential arrangement of the plurality of objects based on one or more values associated with each of the one or more associated attributes. The sequential arrangement is presented in a visual presentation by presenting for each object in the sequential arrangement the associated visual representation at a position on a path defined by a space filling curve and according to the sequential arrangement.

Owner:ADOBE INC

Miniature antenna for a motor vehicle

ActiveUS7868834B2Improve aestheticsLess opportunity to stealAntenna adaptation in movable bodiesRadiating elements structural formsEngineeringConductive materials

The present invention relates to a miniature antenna for a motor vehicle. The antenna may, for example, be a printed board miniature radio antenna for AM / FM signal reception. The antenna may, for example, be placed in an internal mirror of a motor vehicle or on an exterior surface of the motor vehicle, such as the vehicle's roof. The antenna is shaped as a curve of conductive material in which the geometry of at least a part of said curve comprises a space-filling curve or a grid dimension curve.

Owner:ADVANCED AUTOMOTIVE ANTENNAS

Predicting attributes for point cloud compression according to a space filling curve

Attributes for point cloud compression may be predicted according to a space filling curve. An order for selecting points of a point cloud to be compressed in order to predict attributes of the points may be determined according to values of a space filling curve applied to spatial information for the points. A point of the point cloud may be selected according to the determined ordering. A prediction technique may be performed with respect to the selected point based on a set of neighboring points in the point cloud also selected according to the ordering. Predicted attribute values and correction values may be determined for the predicted values. The correction values may be encoded as part of a compressed version of the point cloud.

Owner:APPLE INC

Hierarchical point cloud compression

A system comprises an encoder configured to compress attribute information for a point cloud and / or a decoder configured to decompress compressed attribute information for the point cloud. To compress the attribute information, multiple levels of detail are generated based on an ordering of the points according to a space filling curve and attribute values are predicted. The attribute values may be predicted simultaneously while points are being assigned to different levels of detail. A decoder follows a similar prediction process based on level of details. Also, attribute correction values may be determined to correct predicted attribute values and may be used by a decoder to decompress a point cloud compressed using level of detail attribute compression. In some embodiments, attribute correction values may take into account an influence factor of respective points in a given level of detail on attributes in other levels of detail.

Owner:APPLE INC

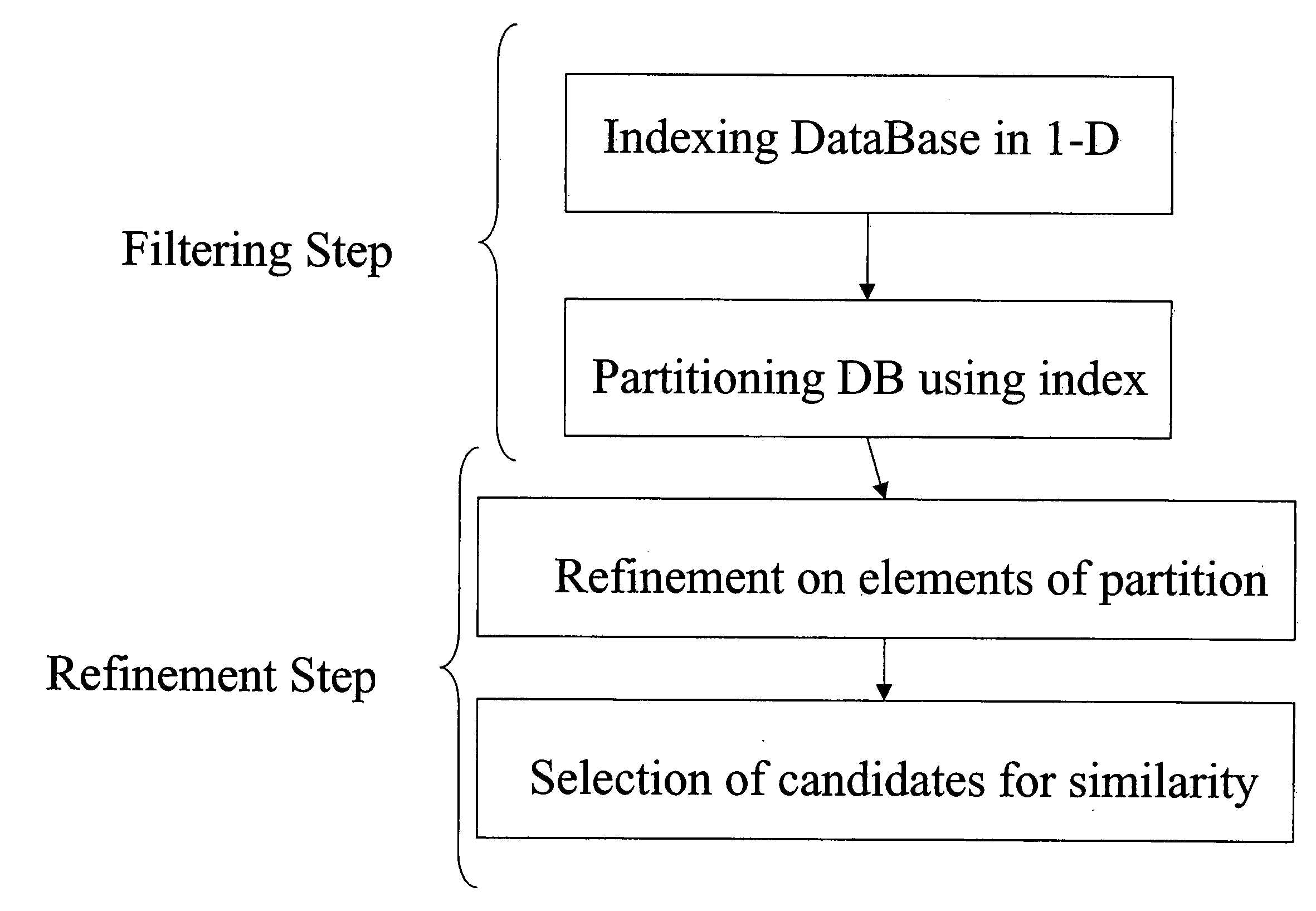

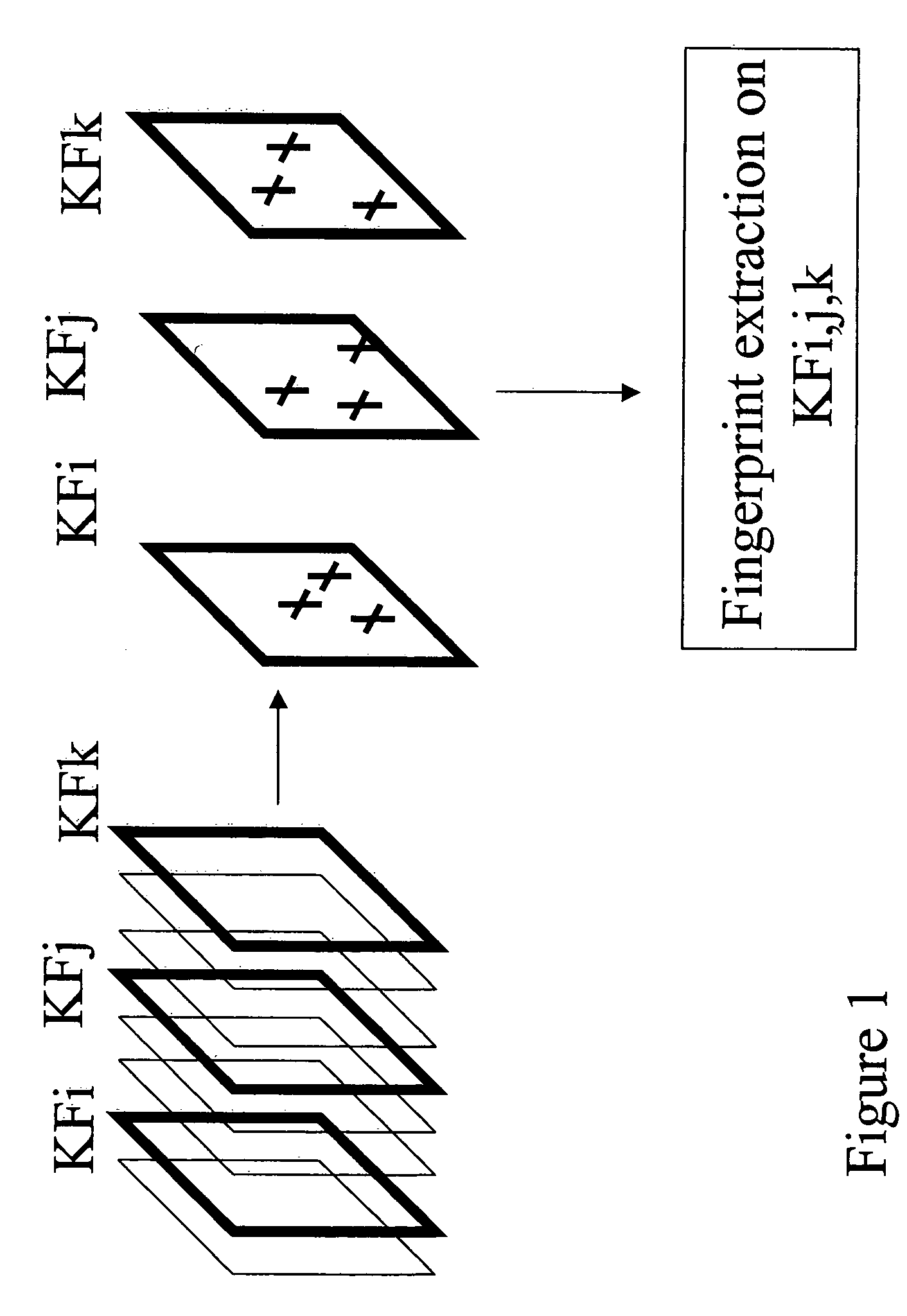

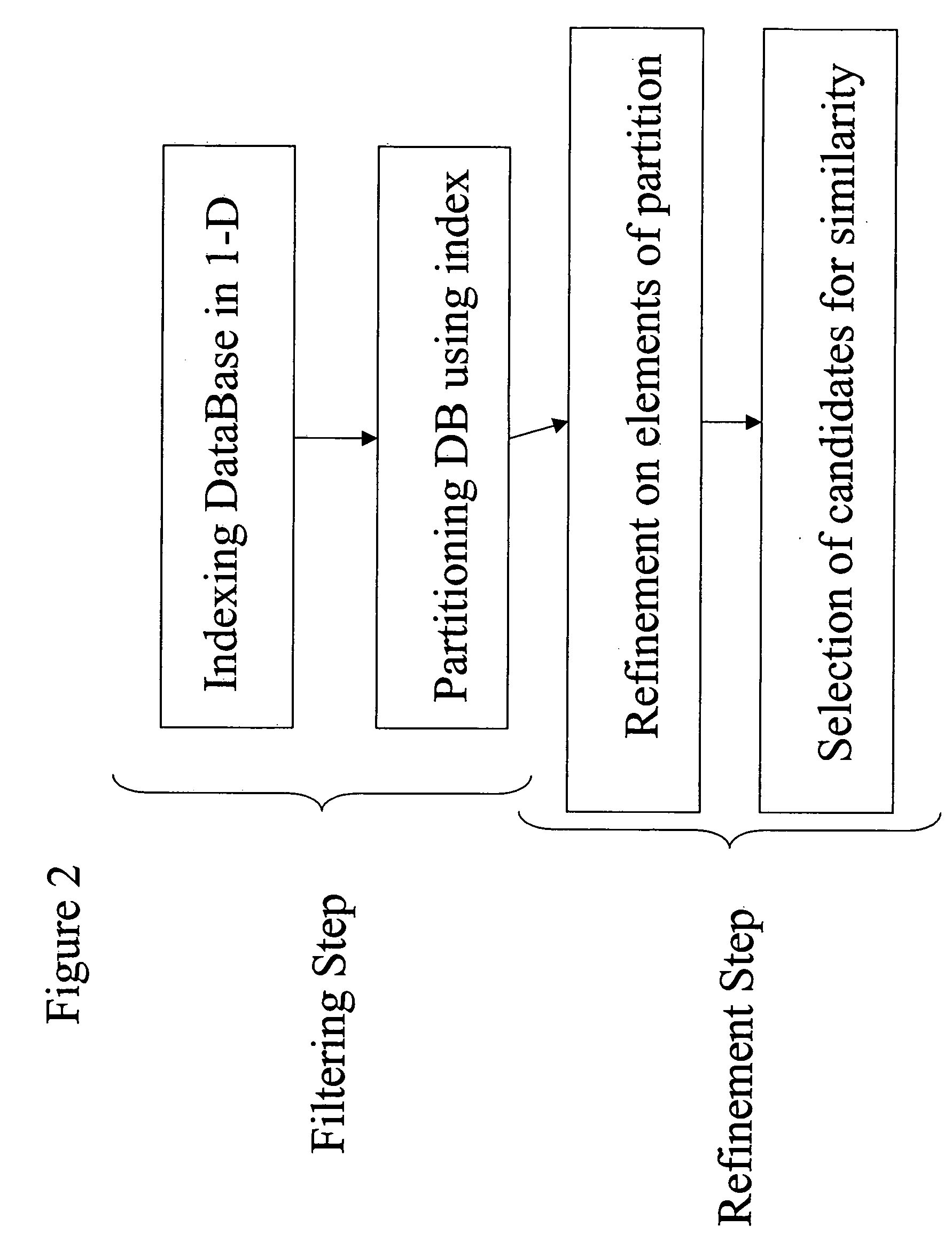

Search of similar features representing objects in a large reference database

ActiveUS20060083429A1Data processing applicationsStill image data indexingReference databaseHilbert space

This invention is a method dedicated to pseudo-invariant features retrieval and, more particularly, applied to content-based copy identification. The range of a query is computed during the search according to deviation statistics between original and observed features. This approximate search range is directly mapped onto a Hilbert's space-filling curve allowing an efficient access to the database. Such a method is sublinear in database size and does not suffer from dimensionality problems.

Owner:INSTITUT NAT DE LAUDIOVISUEL INA

Remote sensing image data storage method and system

ActiveCN110599490AImprove retrieval speedReduce occupancyImage enhancementImage analysisImage resolutionComputer science

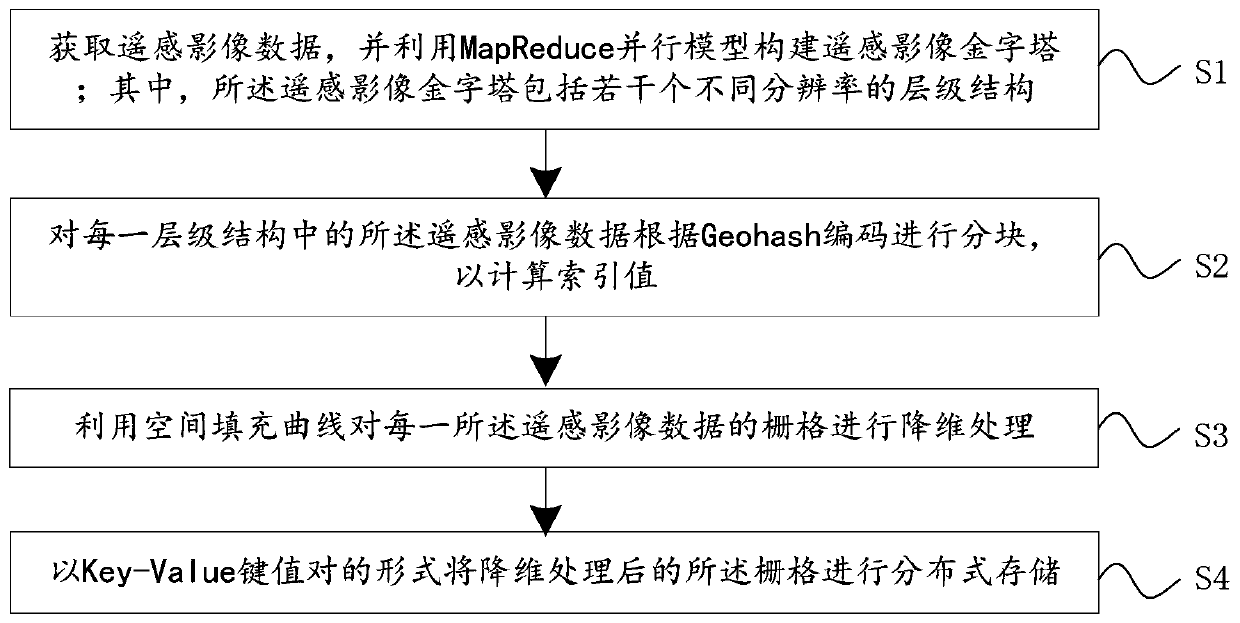

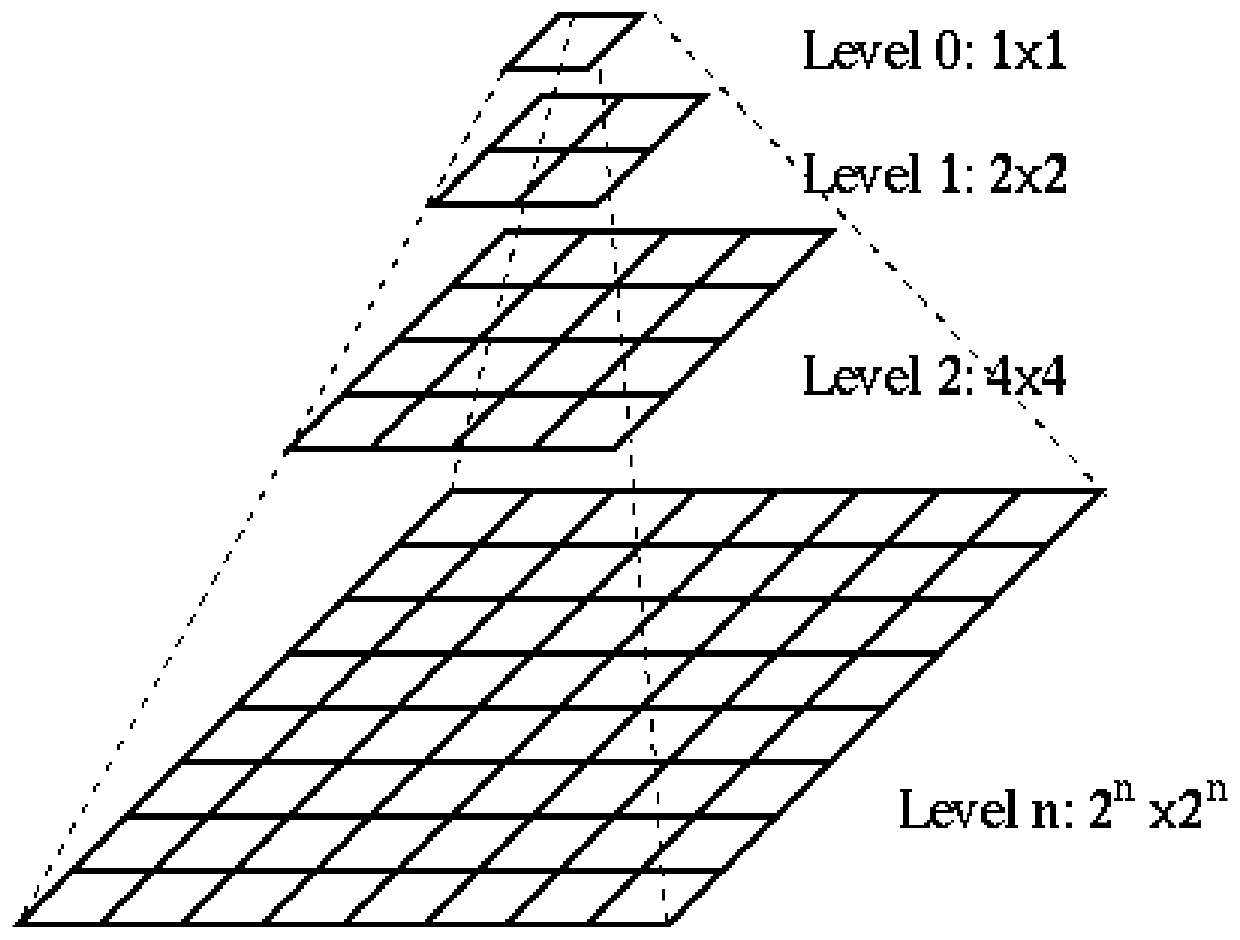

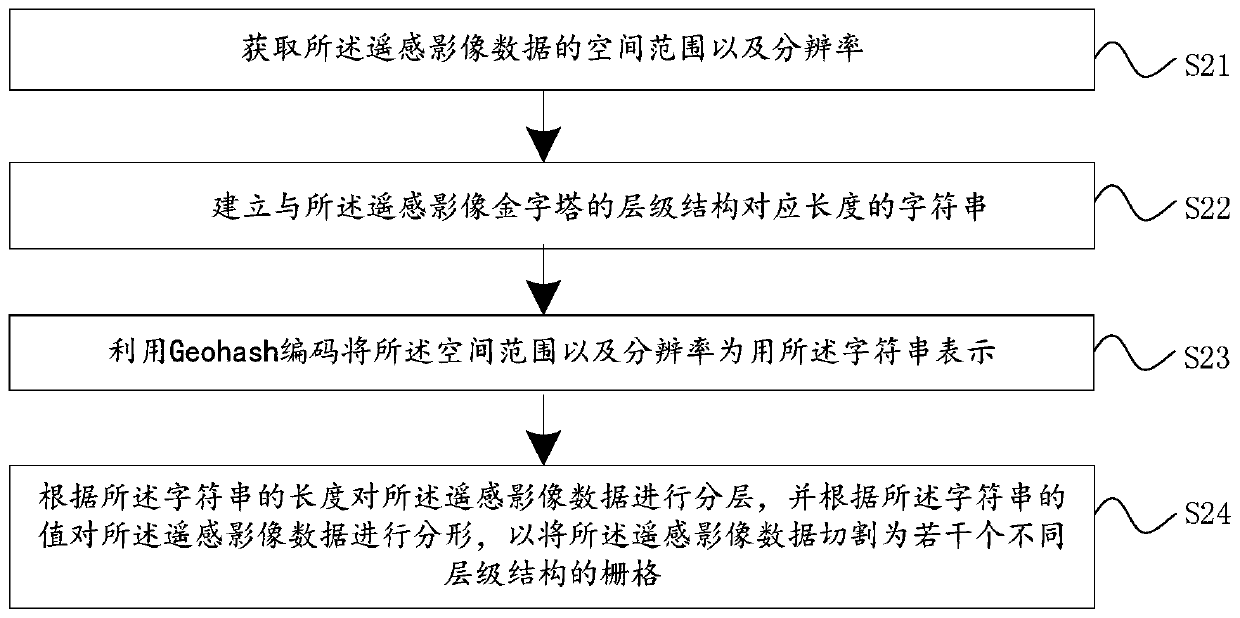

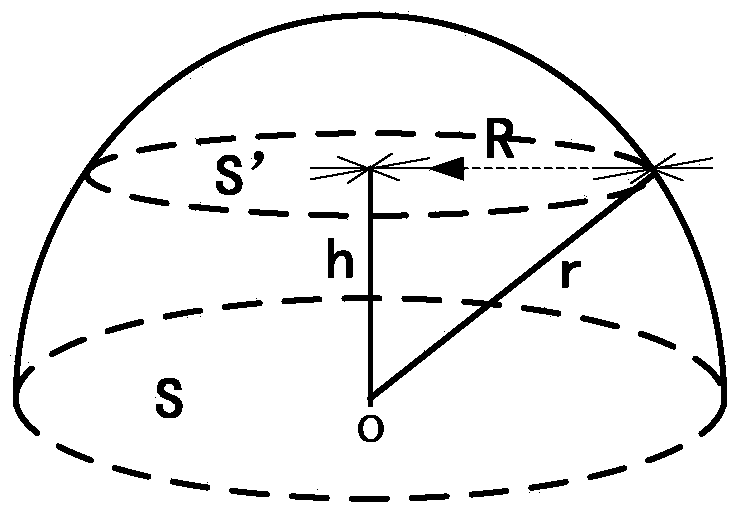

The invention discloses a remote sensing image data storage method which comprises the following steps: acquiring remote sensing image data, and constructing a remote sensing image pyramid by utilizing a MapReduce parallel model; wherein a remote sensing image pyramid comprises a plurality of hierarchical structures with different resolutions; partitioning the remote sensing image data in each hierarchical structure according to Geohash coding so as to calculate an index value; performing dimension reduction processing on the grid of each piece of remote sensing image data by utilizing a spacefilling curve; and carrying out distributed storage on the grids subjected to the dimension reduction processing in a Key-Value key value pair form. The invention further discloses a remote sensing image data storage system. By adopting the embodiment of the invention, massive remote sensing image data can be effectively stored in the distributed data storage database, the storage efficiency is improved, tile data of different levels can be called according to requests of different resolutions, and efficient indexes are provided for reading and querying the tile data.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

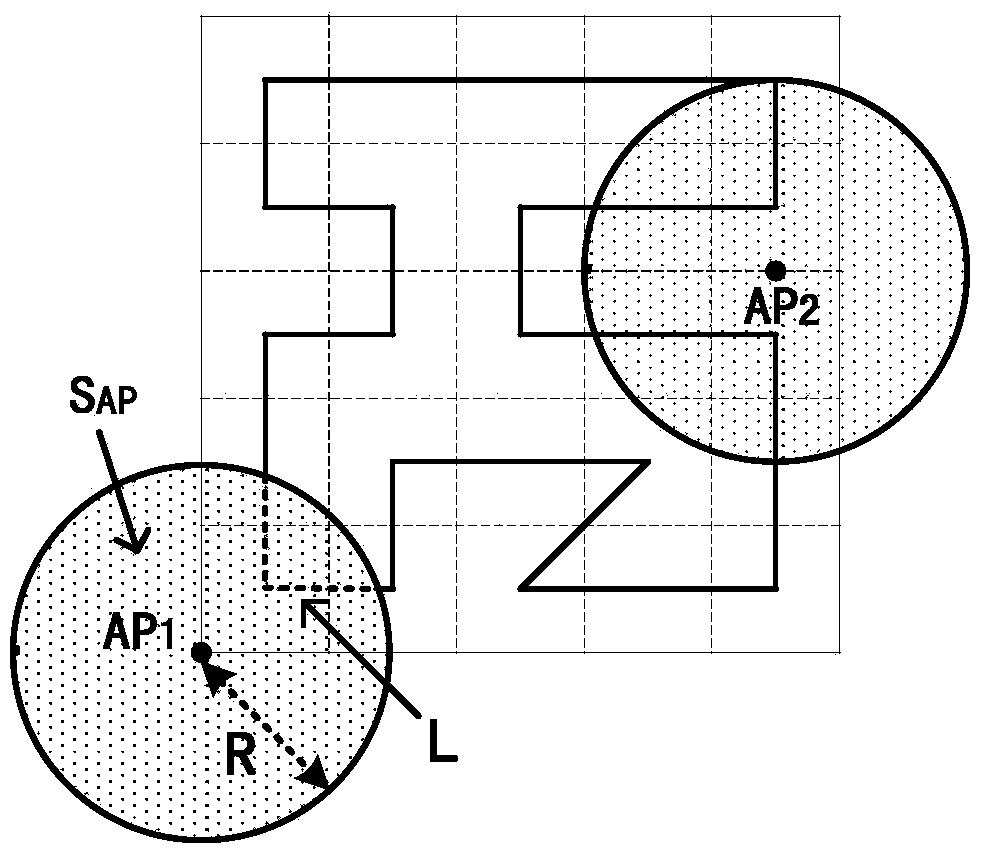

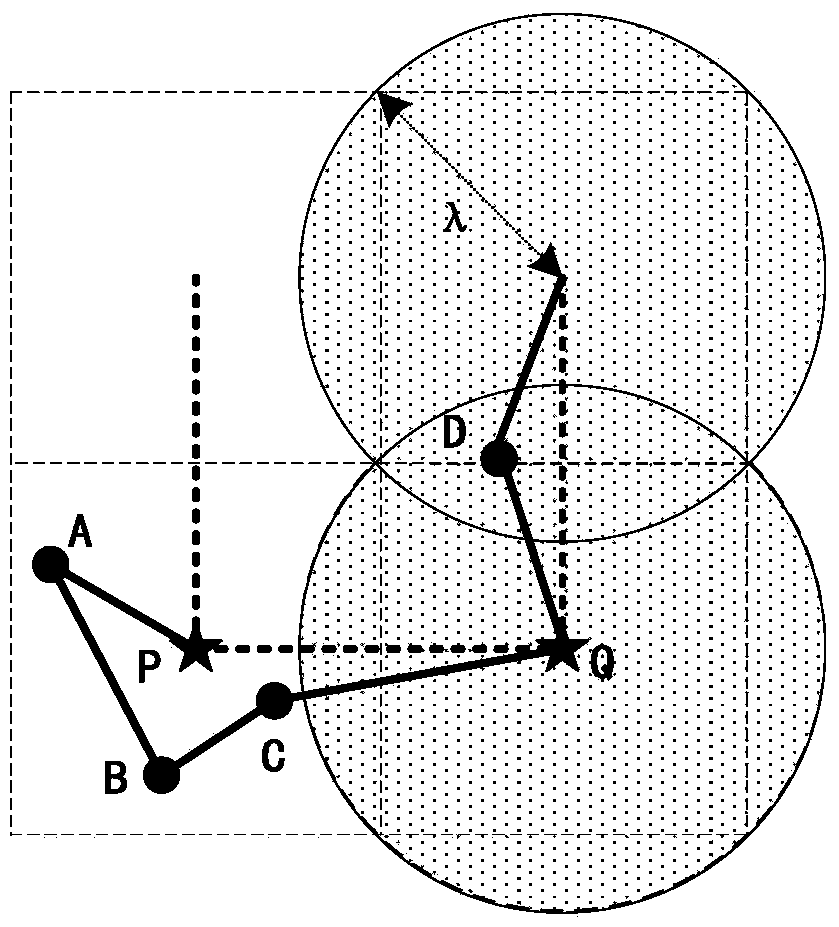

Target wireless device positioning method based on regional division

ActiveCN104039009AAchieve positioningHigh positioning accuracyWireless communicationSpace-filling curveFlight distance

Owner:NORTHWEST UNIV

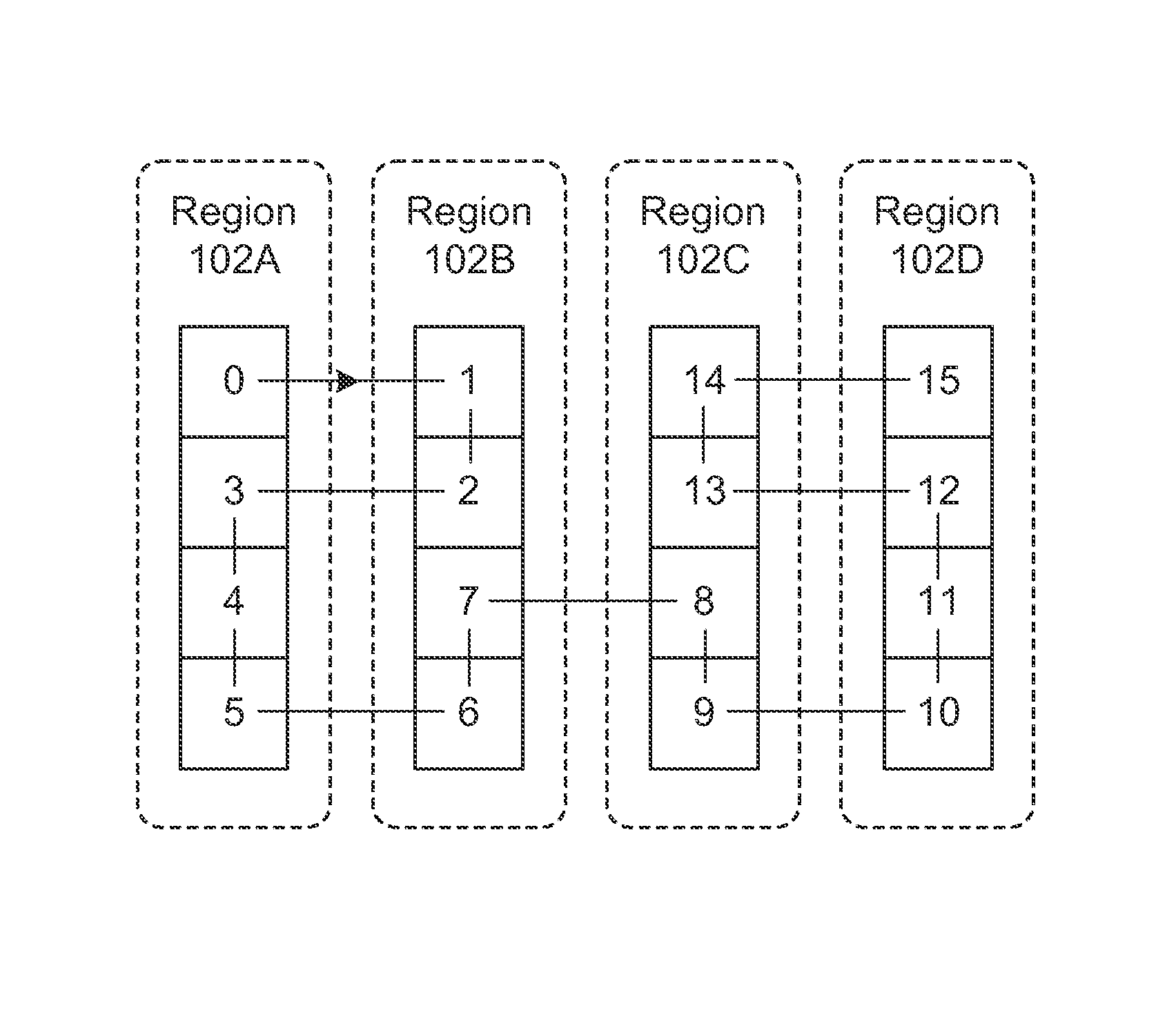

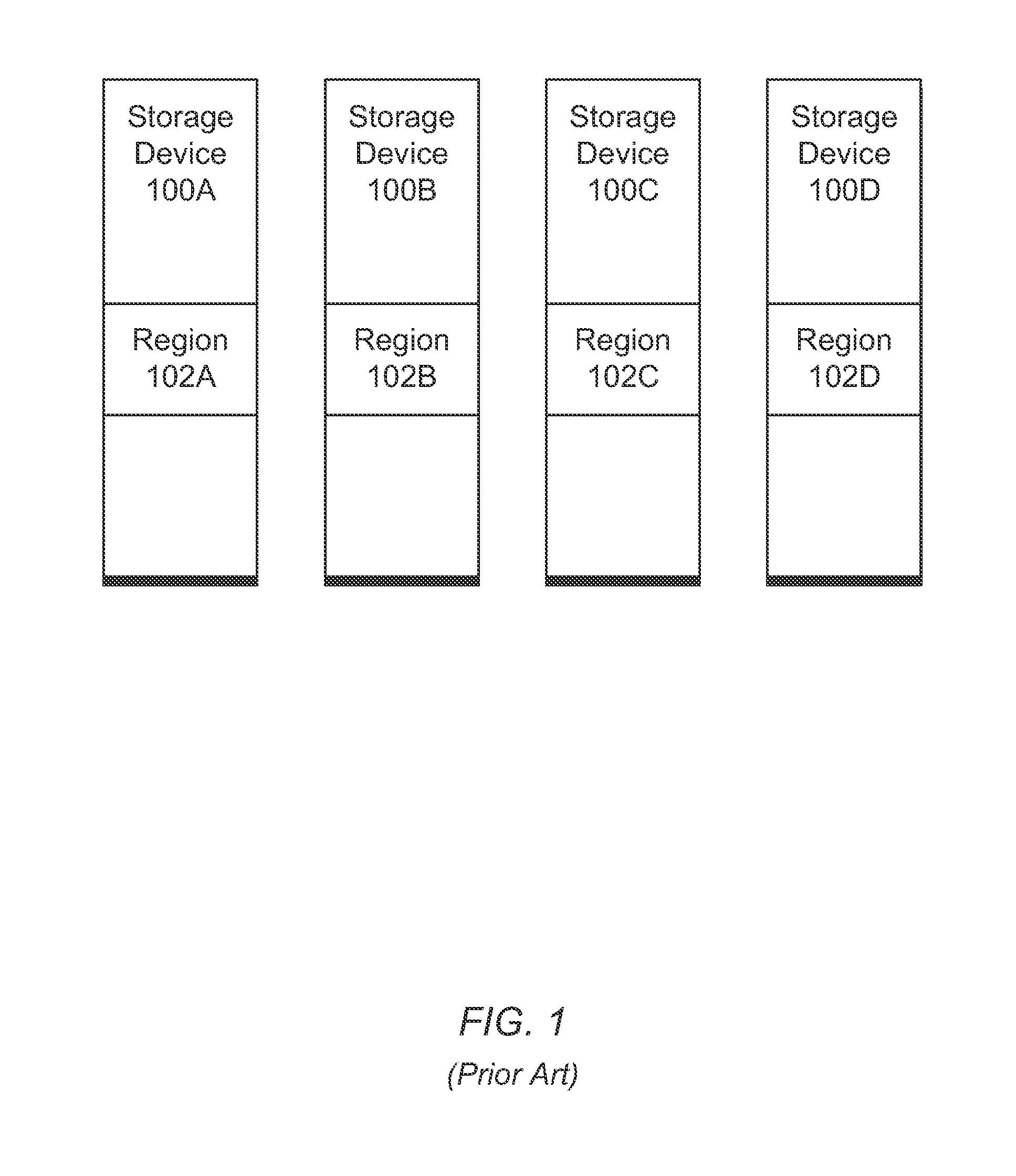

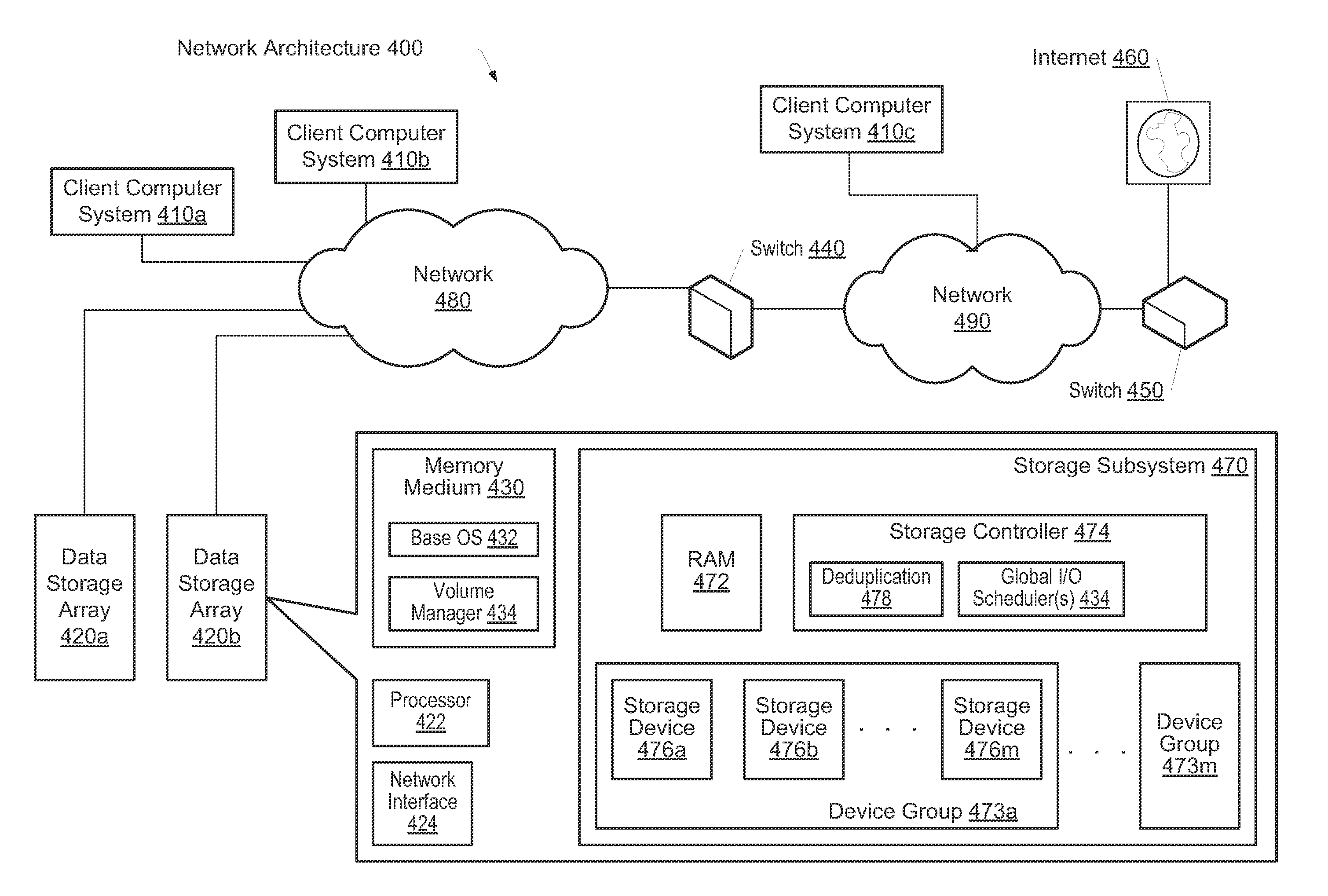

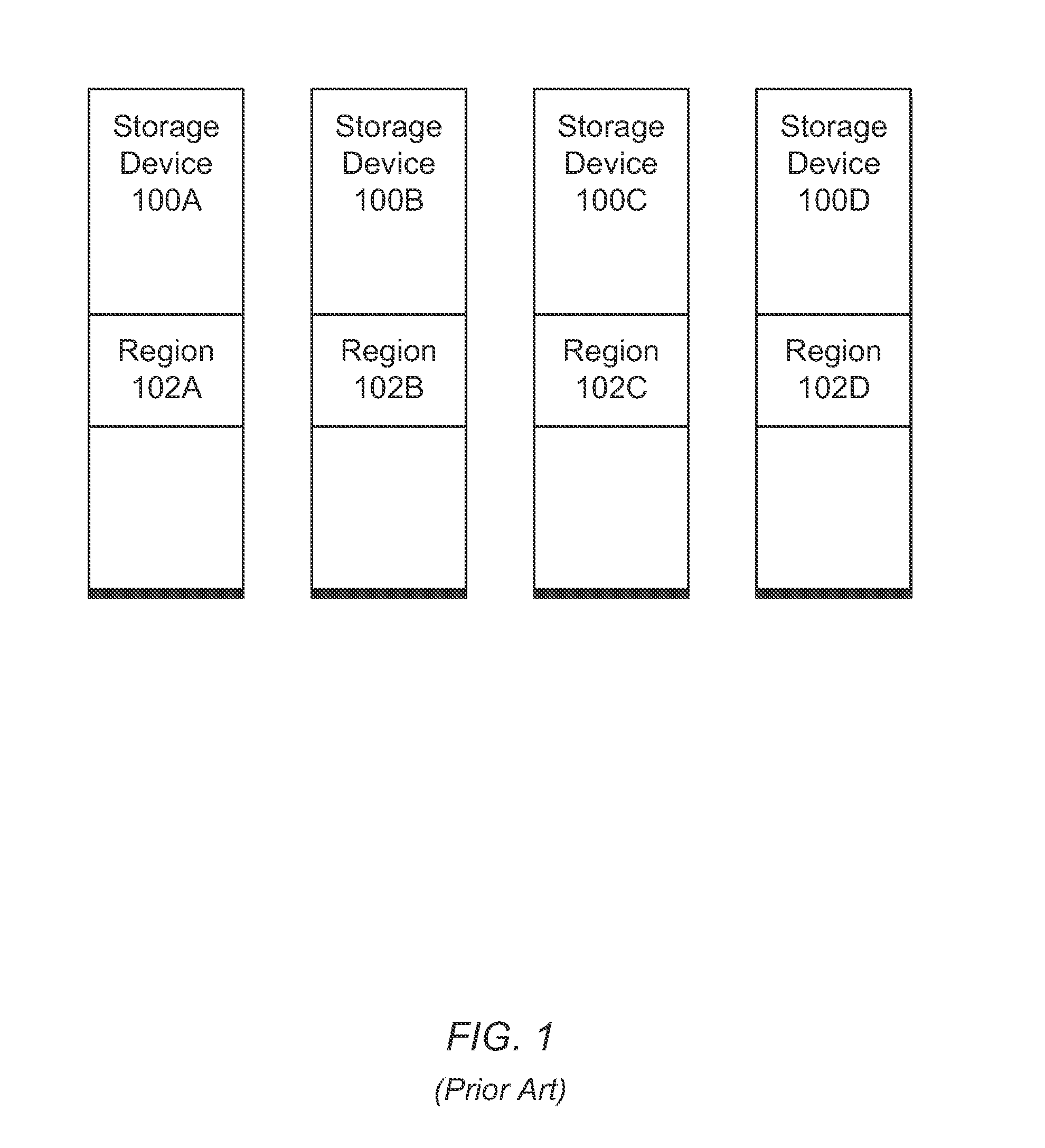

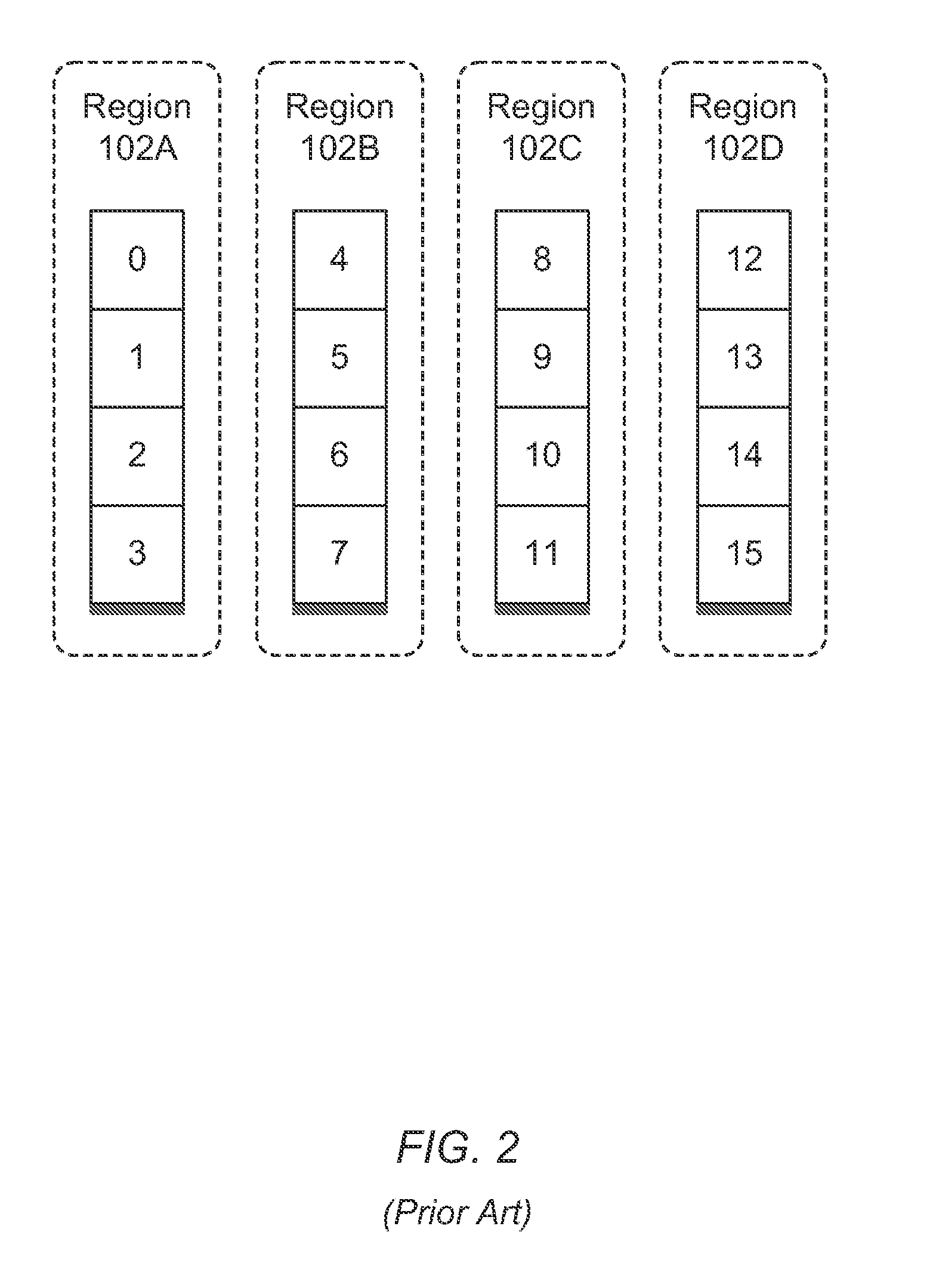

Fractal layout of data blocks across multiple devices

ActiveUS8719540B1Memory architecture accessing/allocationInput/output to record carriersData layoutSpace-filling curve

A system, method, and computer-readable storage medium for mapping block numbers within a region to physical locations within a storage system. Block numbers are mapped within a region according to a fractal-based space-filling curve. If the region is not a 2k by 2k square, then the region is broken up into one or more 2k by 2k squares. Any remaining sub-region is centered within a 2k by 2k square, the 2k by 2k square is numbered using a fractal-based space-filling curve, and then the sub-region is renumbered by assigning numbers based on the order of the original block numbers of the sub-region.

Owner:PURE STORAGE

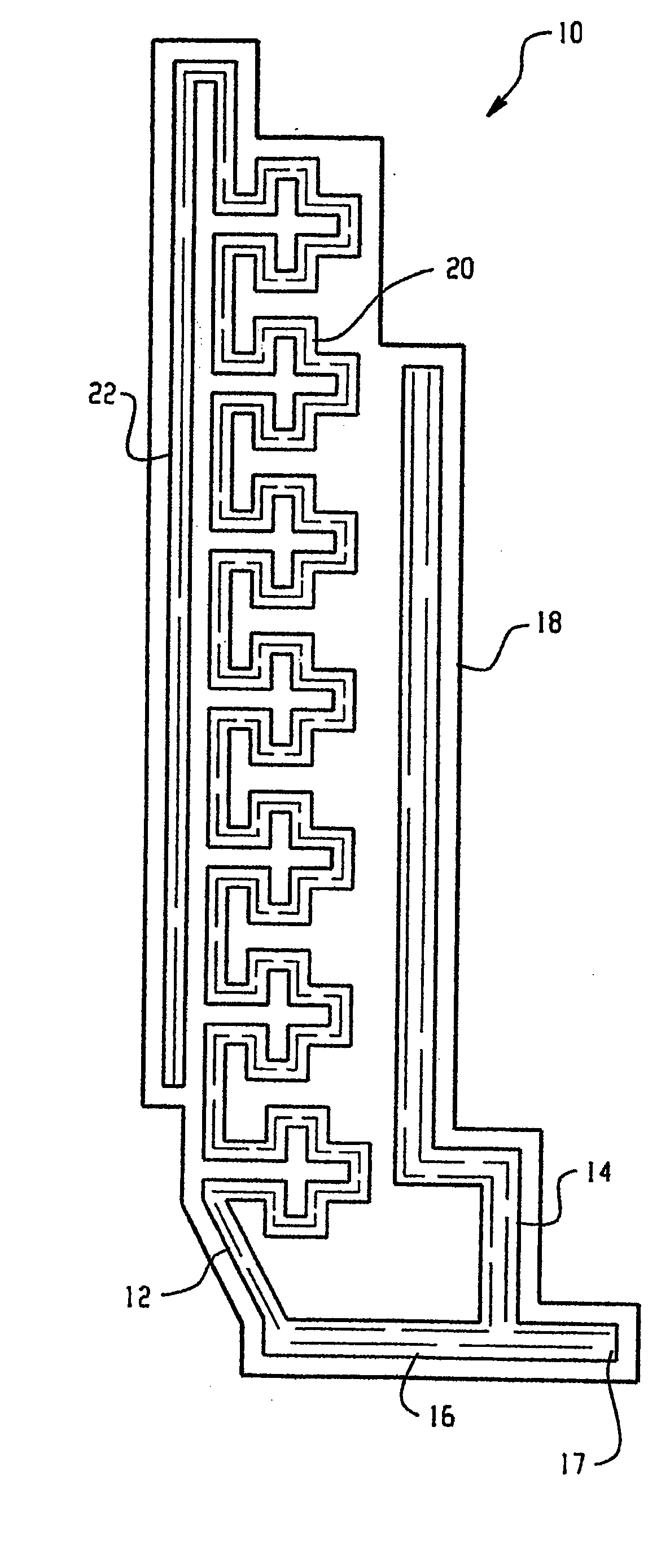

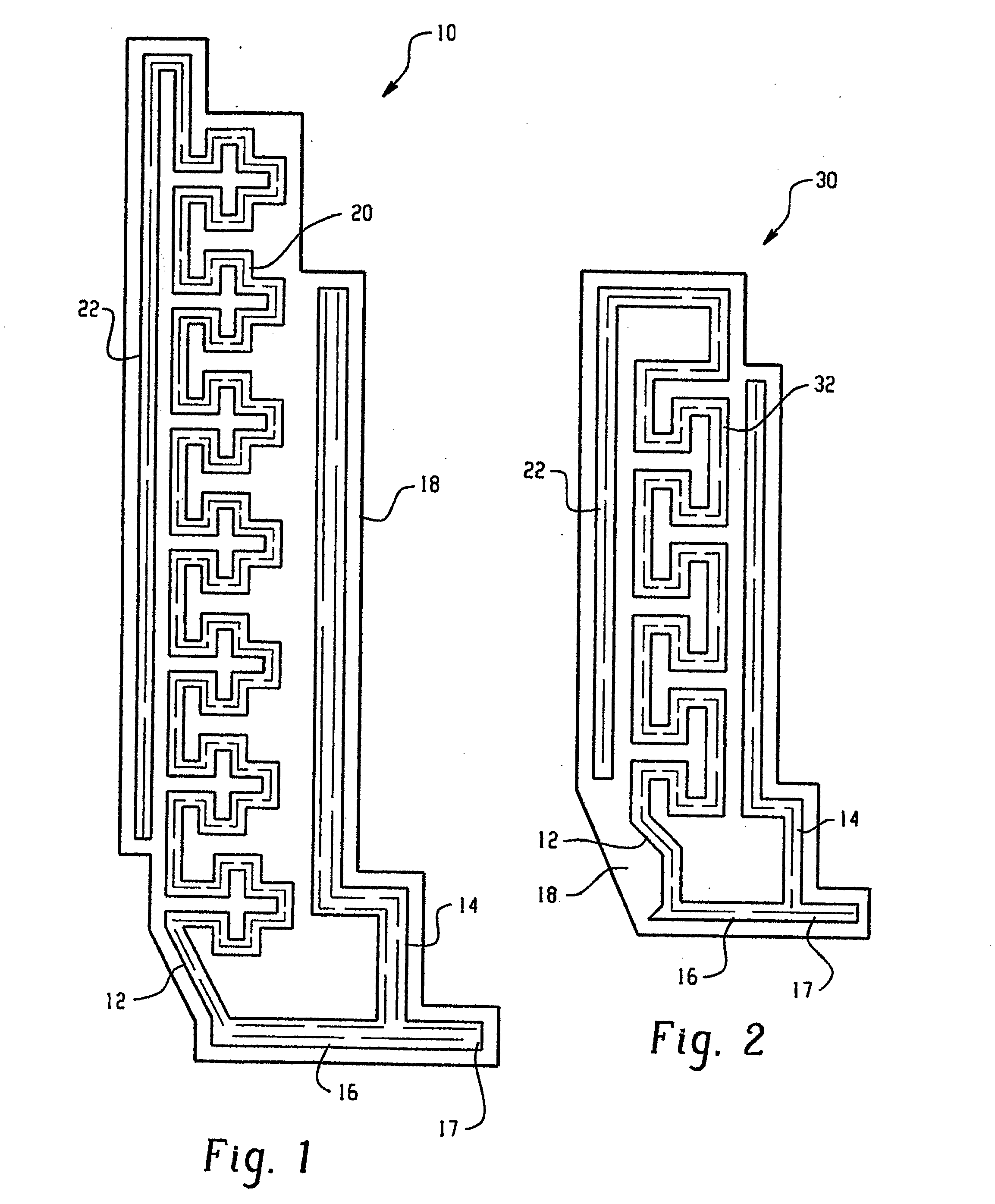

Space-filling miniature antennas

InactiveUS20050231427A1Simultaneous aerial operationsAntenna supports/mountingsState of artSpace-filling curve

A novel geometry, the geometry of Space-Filling Curves (SFC) is defined in the present invention and it is used to shape a part of an antenna. By means of this novel technique, the size of the antenna can be reduced with respect to prior art, or alternatively, given a fixed size the antenna can operate at a lower frequency with respect to a conventional antenna of the same size.

Owner:FRACTUS

Fractal layout of data blocks across multiple devices

ActiveUS20140215155A1Memory architecture accessing/allocationInput/output to record carriersData layoutSpace-filling curve

A system, method, and computer-readable storage medium for mapping block numbers within a region to physical locations within a storage system. Block numbers are mapped within a region according to a fractal-based space-filling curve. If the region is not a 2k by 2k square, then the region is broken up into one or more 2k by 2k squares. Any remaining sub-region is centered within a 2k by 2k square, the 2k by 2k square is numbered using a fractal-based space-filling curve, and then the sub-region is renumbered by assigning numbers based on the order of the original block numbers of the sub-region.

Owner:PURE STORAGE

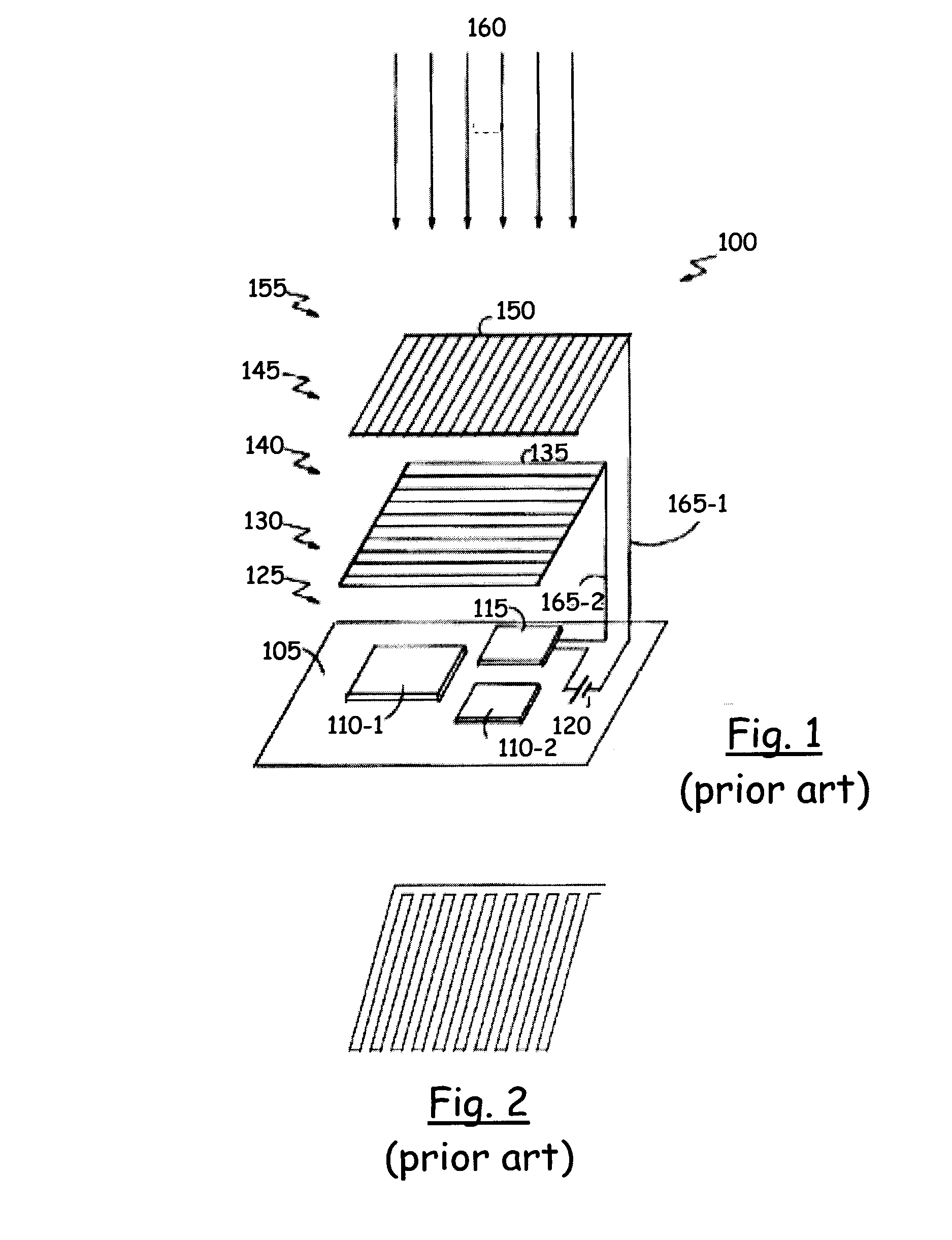

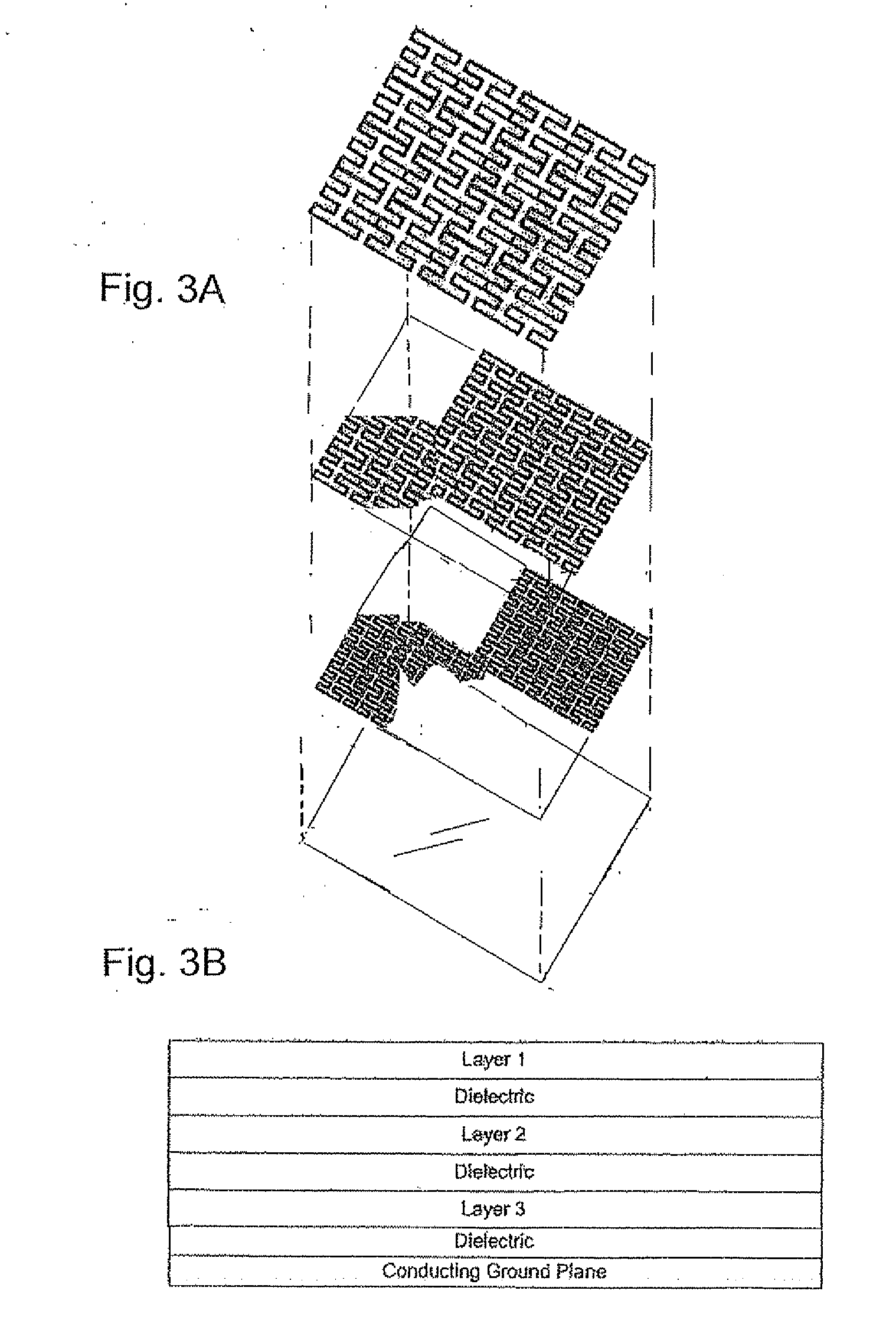

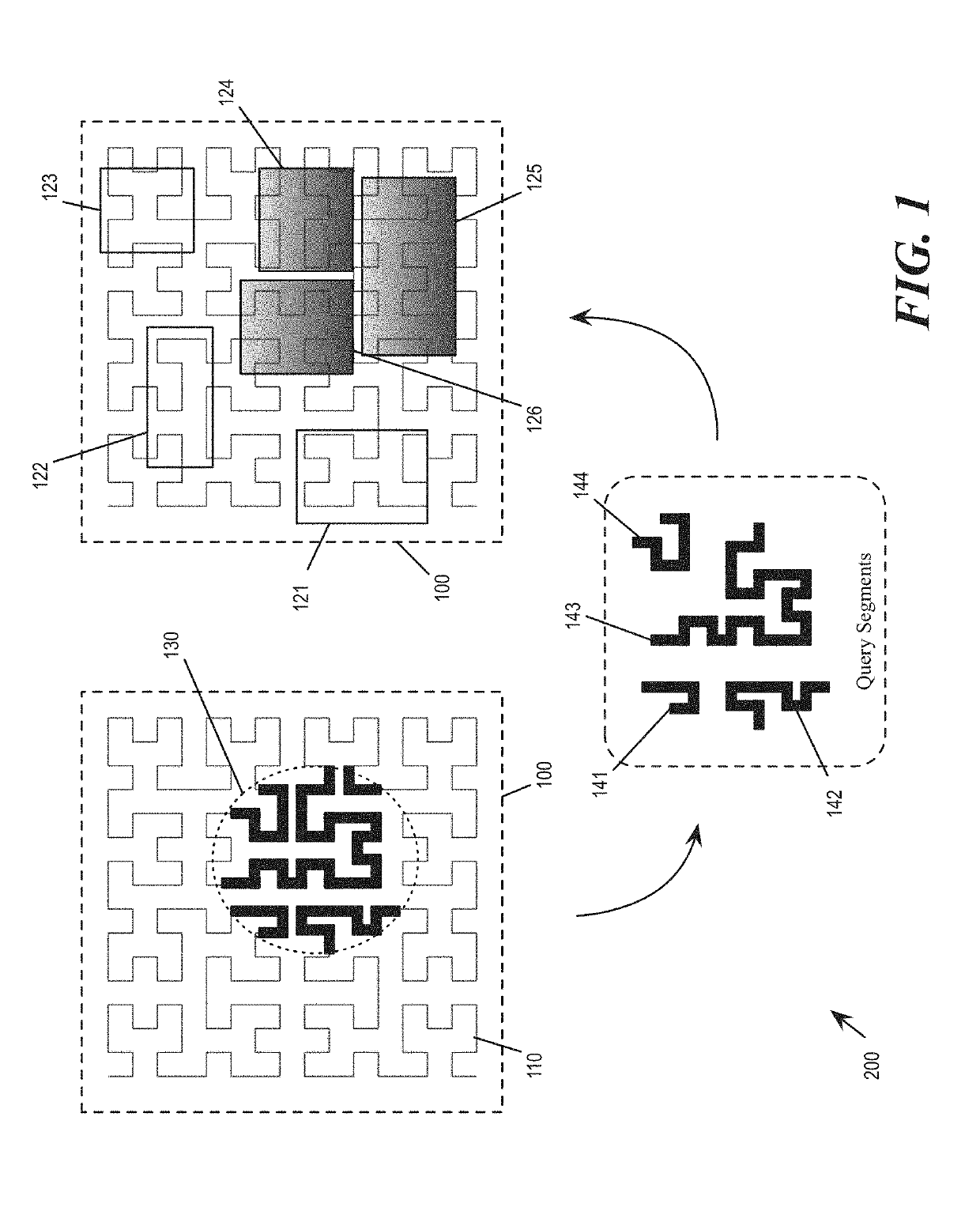

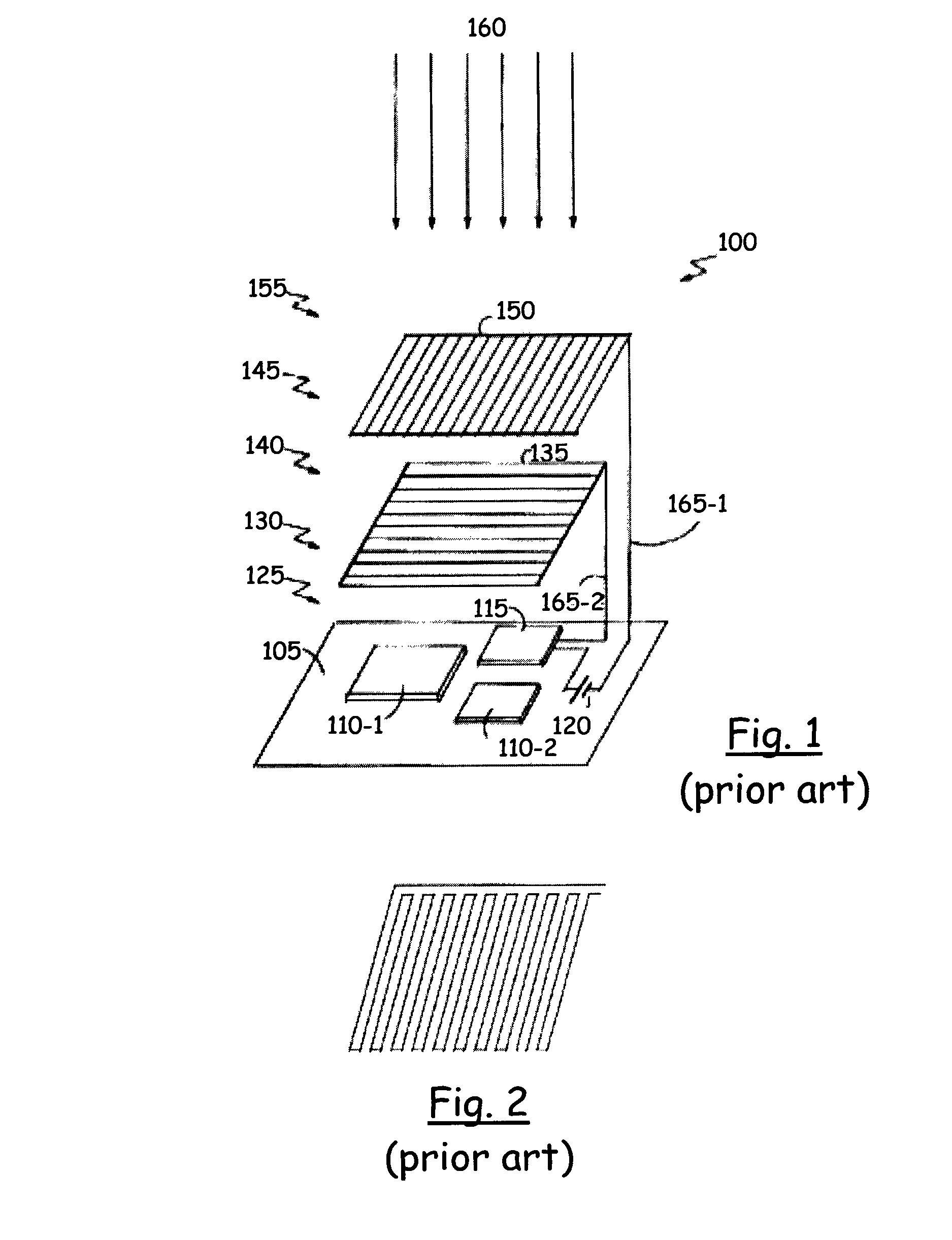

Meta materials integration, detection and spectral analysis

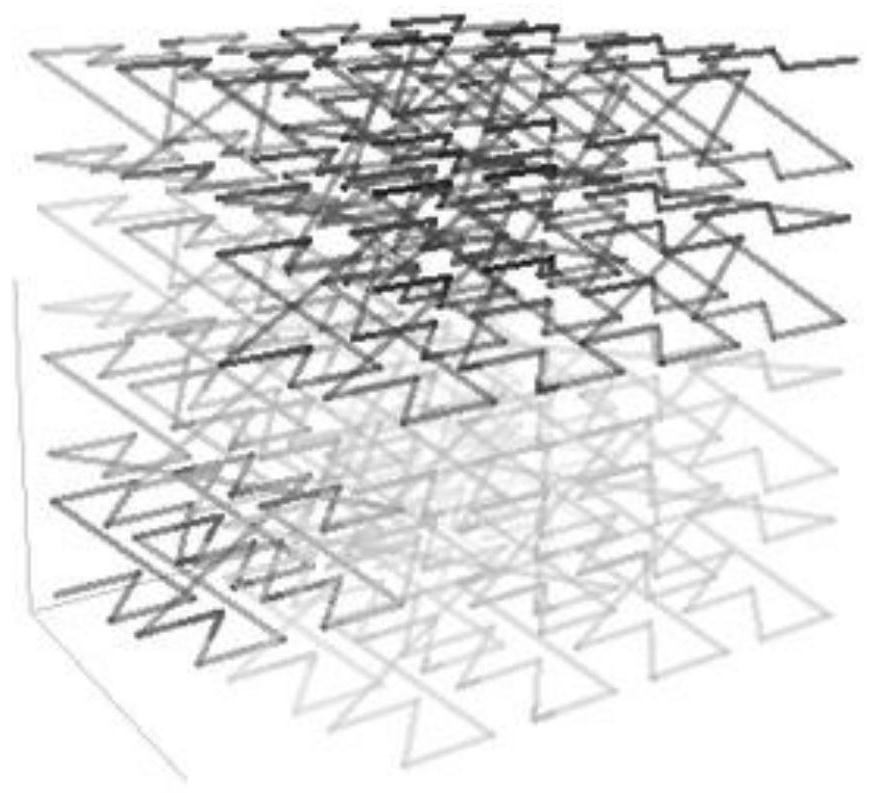

A detector and modulator of electromagnetic radiation is 3-dimensional structure made of substantially 2 dimensional high impedance metamaterial surfaces stacked one above the other with a dielectric layer in between and located above a conducting ground plane. Each 2 dimension surface may be formed by an open continuous conductive trace, such as metallic wire or a printed circuit line, which is cast or plated on or into a 2-D periodic arrangement of an element that belongs to the Hilbert space filling curves.

Owner:PHYSICAL LOGIC

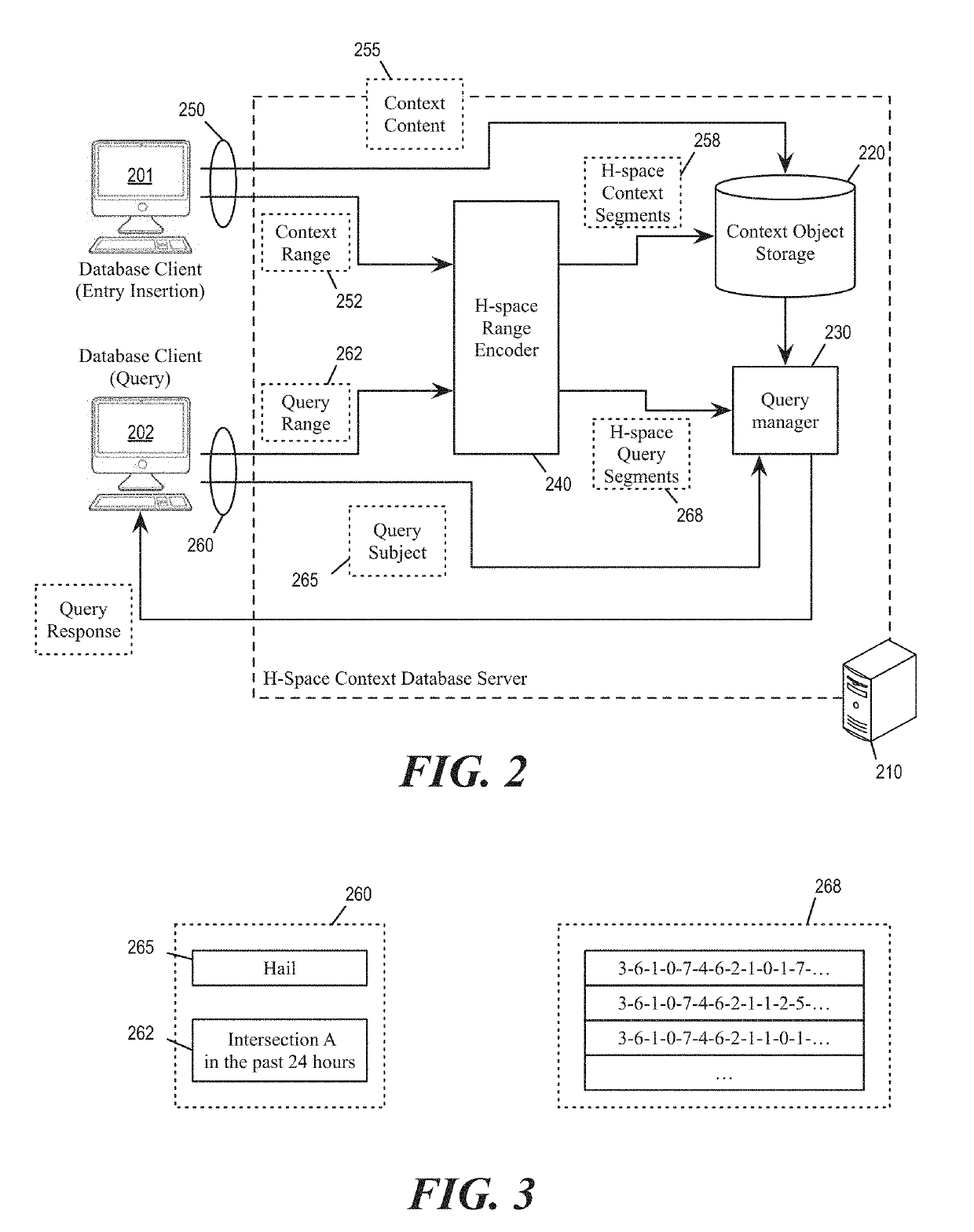

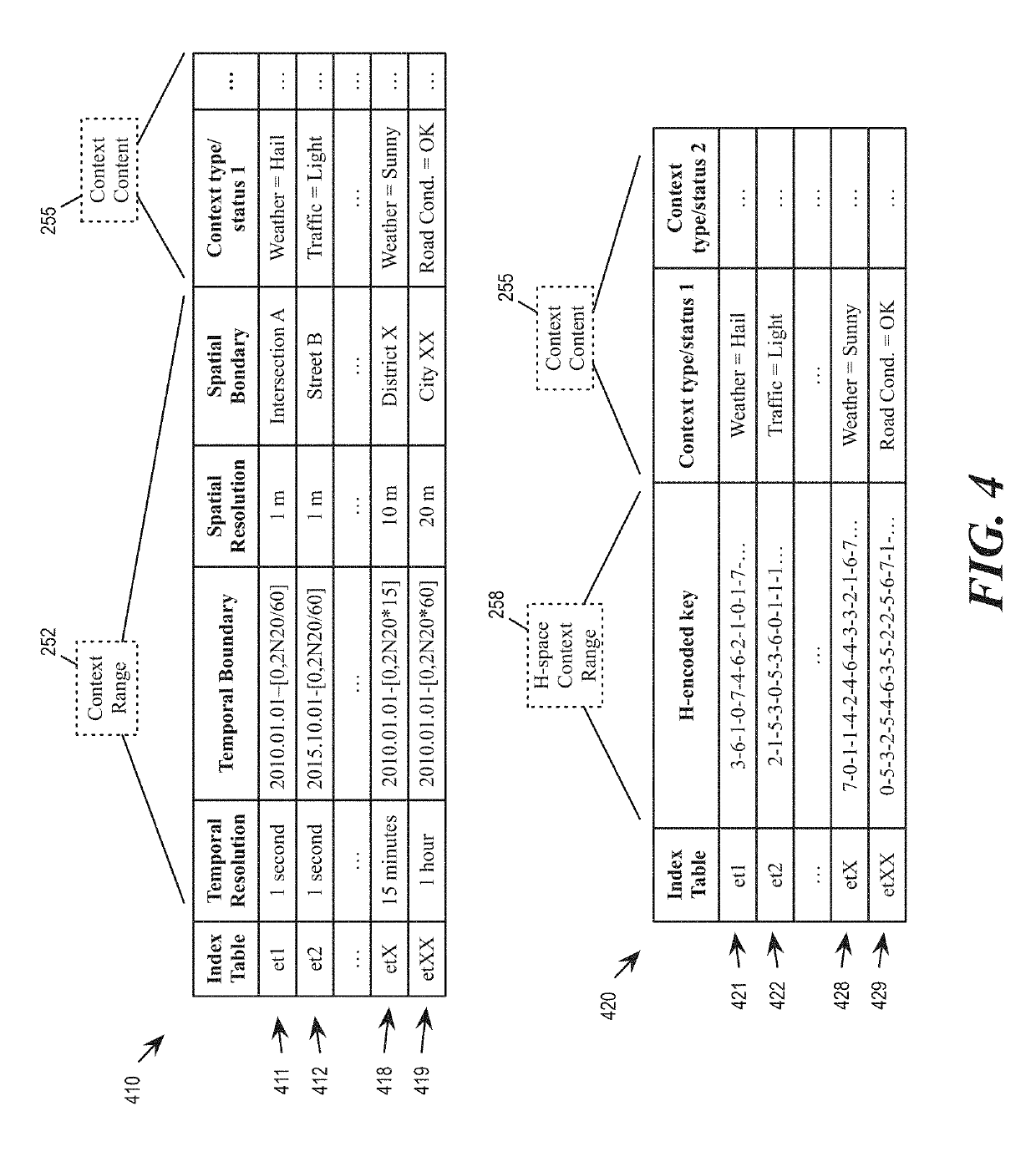

Spatial-Temporal Query for Cognitive IoT Contexts

ActiveUS20190171737A1Easy to set upMulti-dimensional databasesSpecial data processing applicationsMultiple contextMulti dimensional

A method and / or system for managing a database that stores space-time context objects is provided. The system receives a query range in a multi-dimensional space. The system maps the query range into a set of fragments of a space-filling curve that fills the multi-dimensional space in all dimensions of the multi-dimensional space. The system uses each mapped fragment in the set of mapped fragments as a key to query the database for space-time context objects that are mapped to the space-filling curve. The system queries the database by identifying one or more context objects that intersect the mapped fragment at the space-filling curve.

Owner:IBM CORP

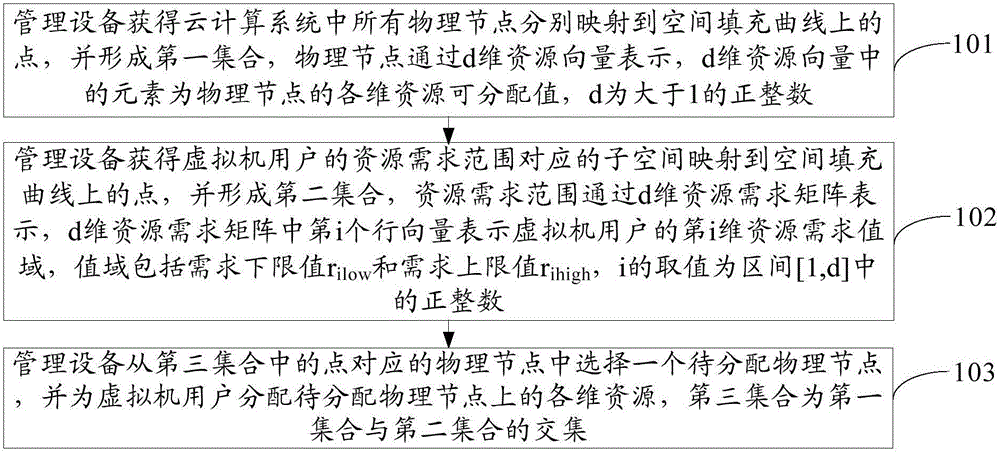

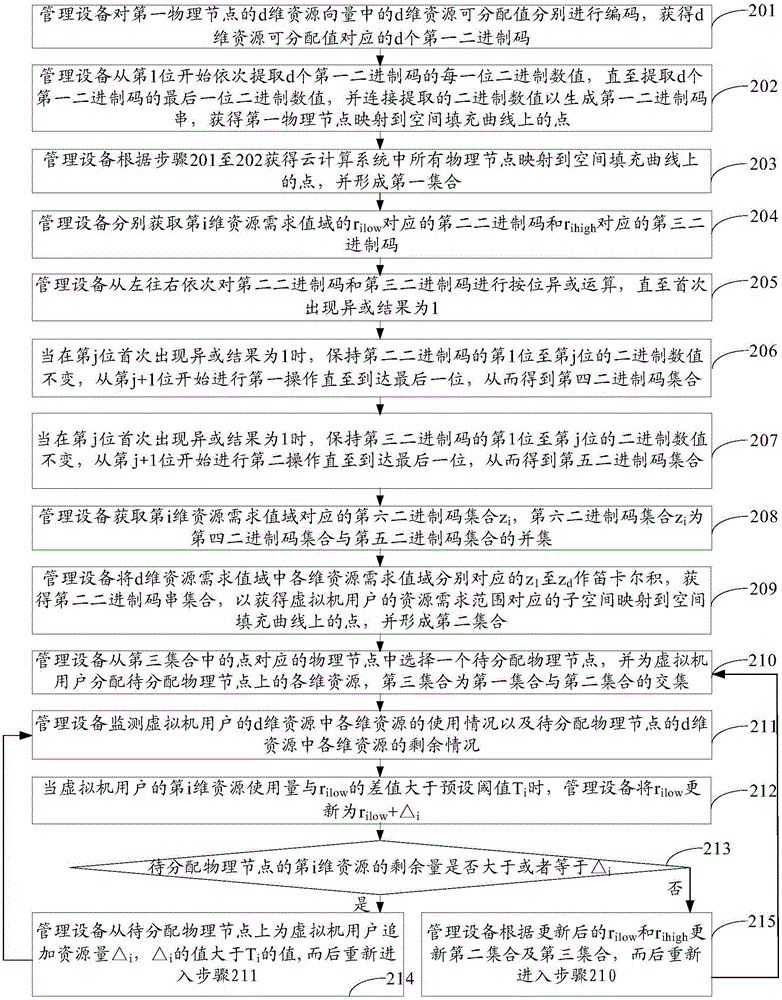

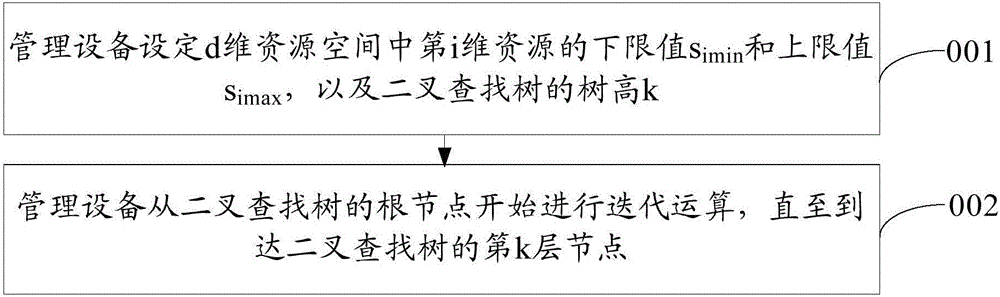

Resource scheduling method and management equipment

ActiveCN105099951ASolve the problem of high resource consumptionData switching networksRound complexityResource consumption

The embodiment of the invention provides a resource scheduling method and management equipment, relates to the technical field of communication, and can solve a problem in the prior art that the resource consumption of the management equipment is large caused by high matching complexity because resource demand values of a virtual machine user in all dimensions are needed to be compared with resource distributable values of all physical nodes in all dimensions in a cloud computing system one by one during resource scheduling. The specific scheme is that the management equipment obtains the mapping points of all physical nodes to a spatial filling curve in the cloud computing system, and forms a first set; the management equipment obtains mapping points of subspaces corresponding to the resource demand ranges of virtual machine users to the spatial filling curve, and forms a second set; the management equipment selects one to-be-distribute physical node from the physical nodes corresponding to the points in a third set, and distributes resources in all dimensions on the to-be-distribute physical node for the virtual machine users; and the third set is the intersection of the first and second sets. The method and equipment are used for resource scheduling.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

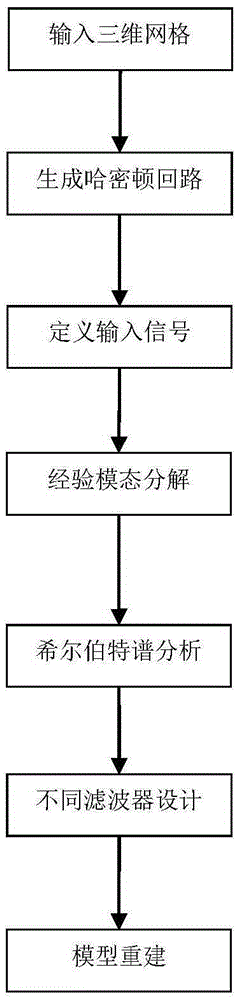

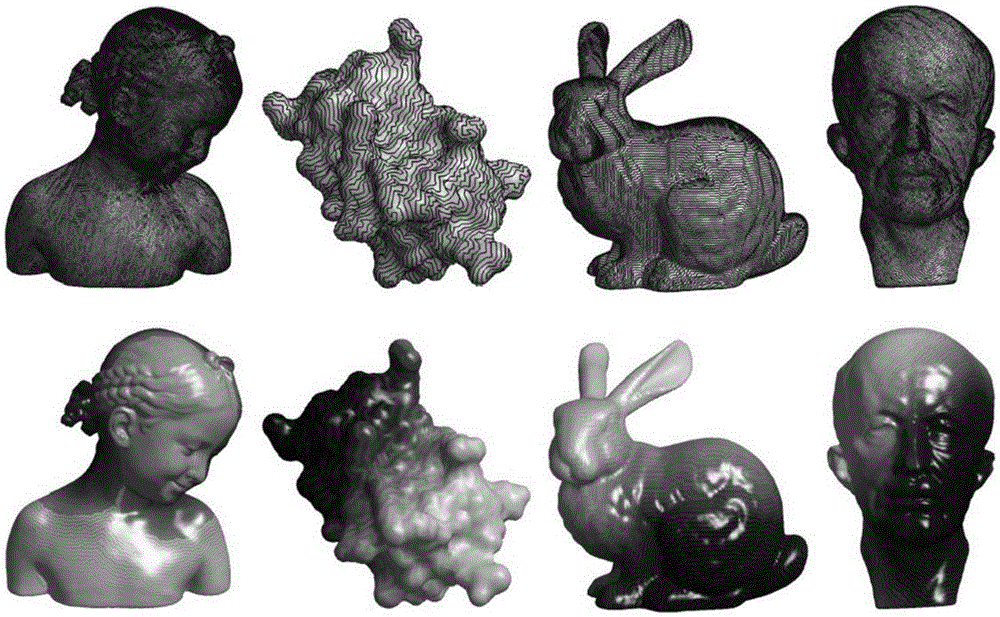

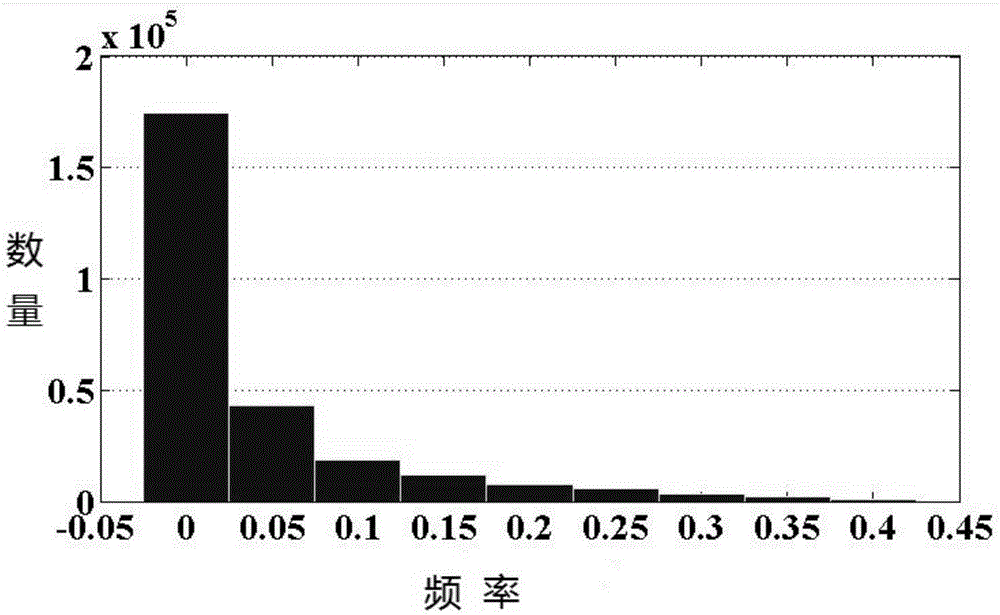

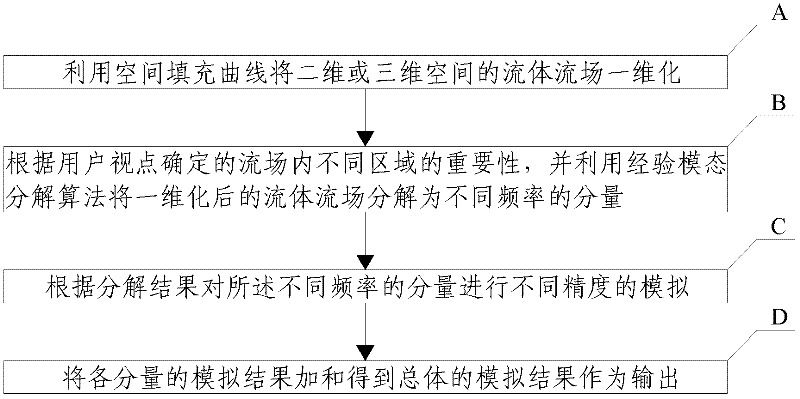

Three-dimensional grid processing method based on empirical mode decomposition and Hilbert spectrum calculation of space filling curve

InactiveCN105354877AEfficient Empirical Mode DecompositionEasy to handle3D modellingModel reconstructionDecomposition

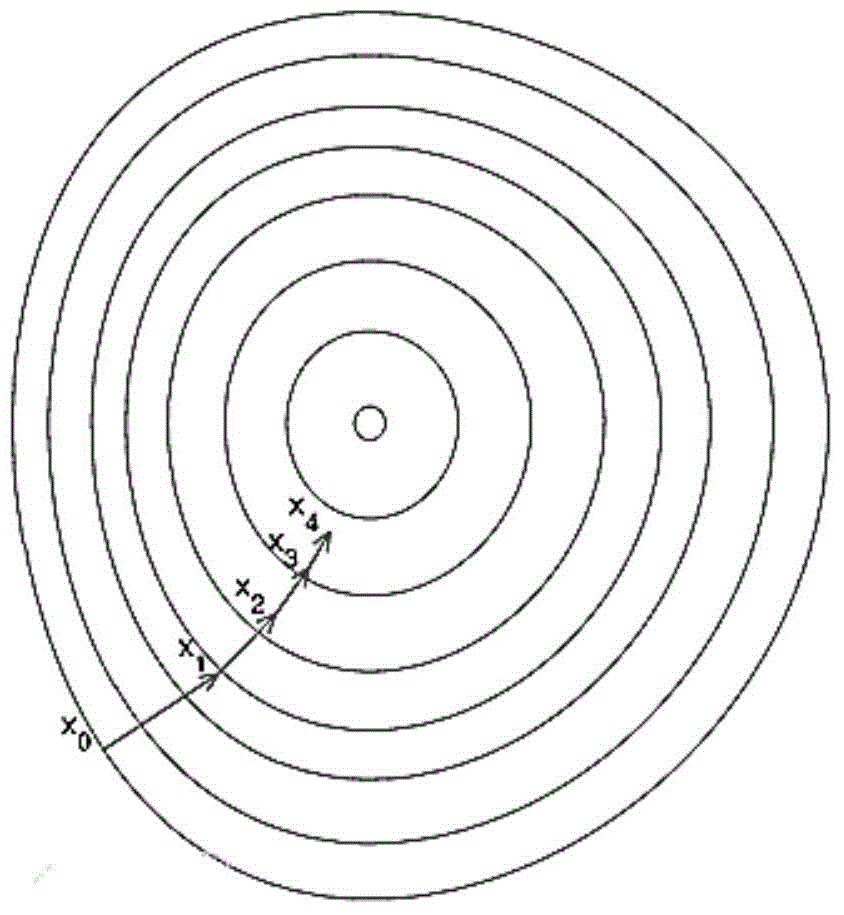

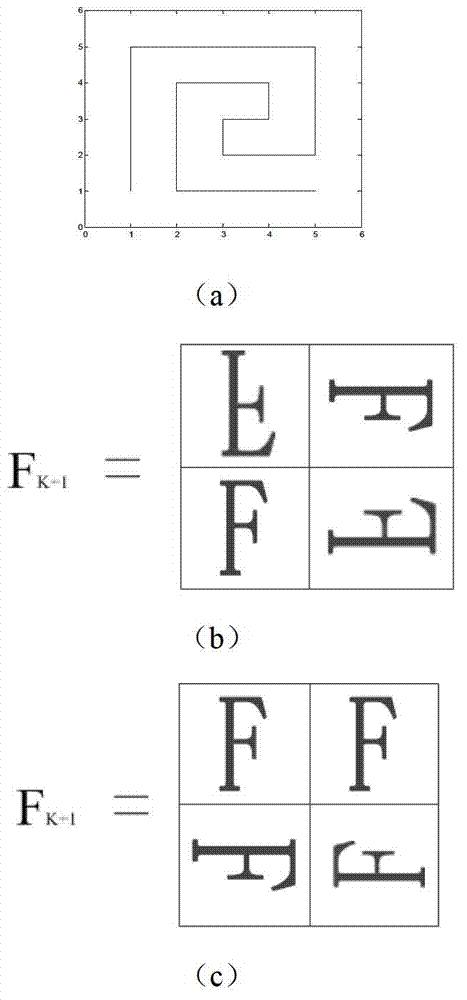

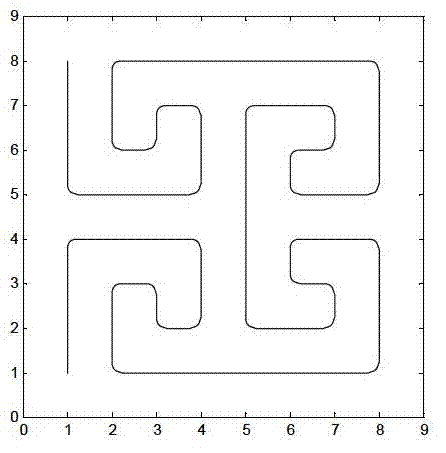

The invention relates to a three-dimensional grid processing method based on empirical mode decomposition and Hilbert spectrum calculation of a space filling curve. The method comprises six steps of an initial stage, namely, a space filling curve generation stage, of generating the space filling curve by an input three-dimensional grid model, wherein a Hamiltonian circuit is used as the space filling curve; an input signal defining stage of adopting average curvature of each point as a signal value of each point of a three-dimensional grid, wherein a signal can be converted into a one-dimensional signal according to a global sequence number of data points in the Hamiltonian circuit; an empirical mode decomposition stage of decomposing the one-dimensional signal into a plurality of intrinsic mode functions and one residual; a Hilbert spectrum calculation stage of performing Hilbert spectrum calculation on the intrinsic mode functions in the previous stage to generate an instantaneous frequency and instantaneous amplitude; a filter design stage; and a model reconstruction stage of processing the signal to obtain a new signal and reconstructing the three-dimensional grid. Therefore, the processing and analysis of the three-dimensional grid are realized.

Owner:BEIHANG UNIV

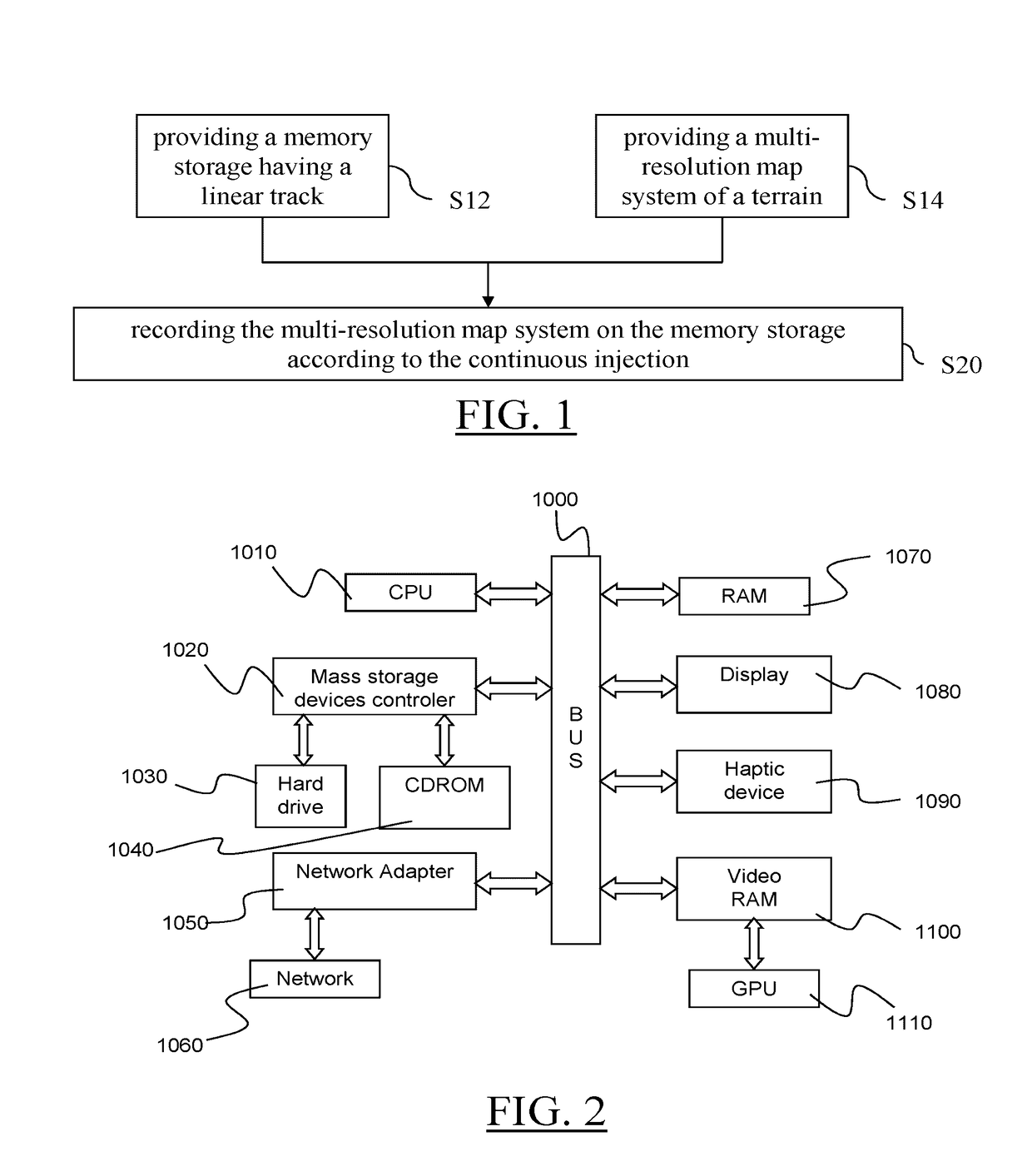

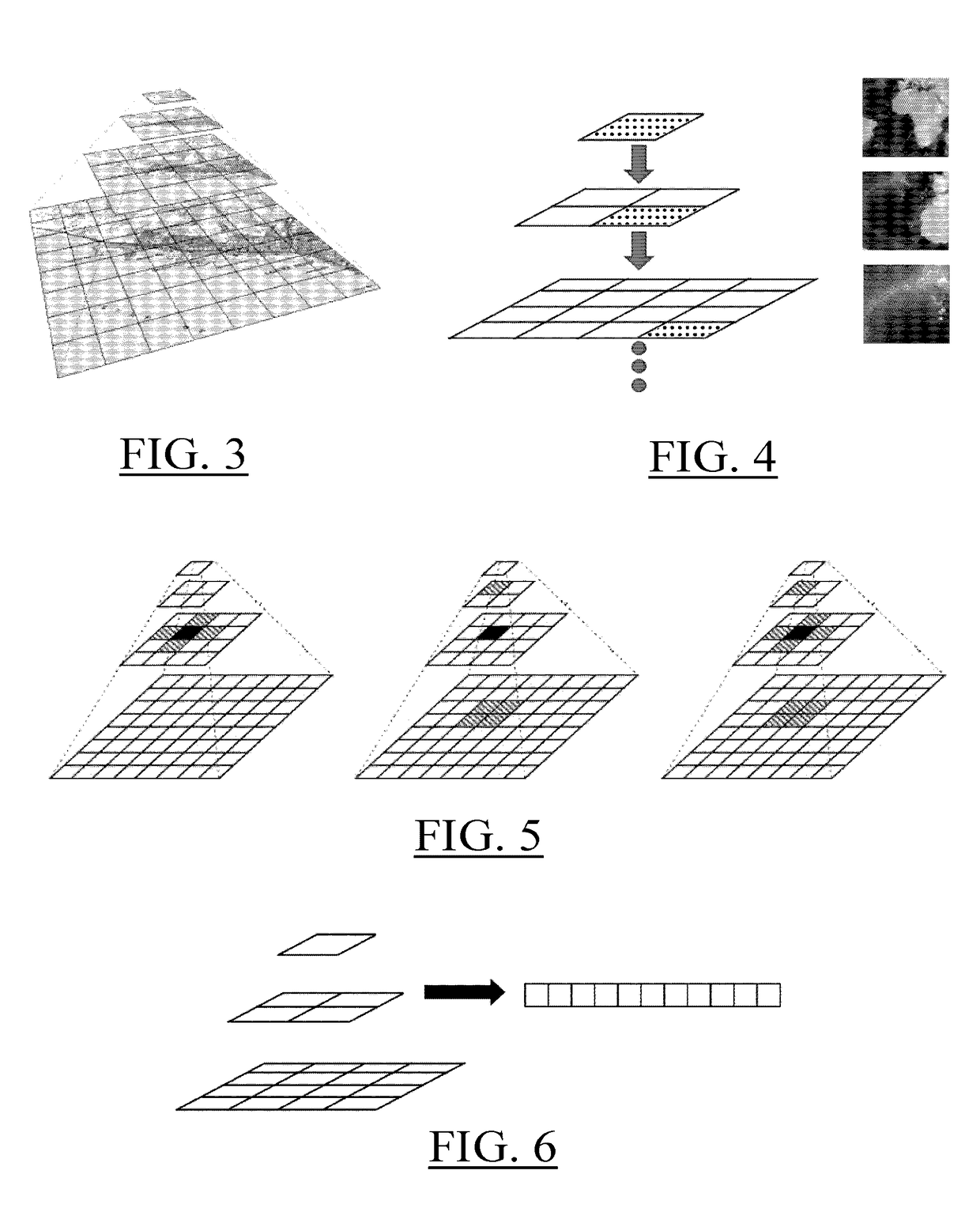

Multi-resolution image system

ActiveUS20170169544A1Geometric image transformationImage memory managementImage resolutionMulti resolution

The invention notably relates to a memory storage having a linear track and having recorded thereon a multi-resolution image system of an object, the multi-resolution image system including a set of images, each image representing the object and having a respective resolution, wherein the recording is according to a continuous injection from a space-filling curve of the set of images to the linear track, the space-filling curve interlaces the different images, and the intersection between the space-filling curve and each image is on a Hilbert curve.The invention improves the way to record a multi-resolution image system of an object on a memory storage.

Owner:DASSAULT SYSTEMES

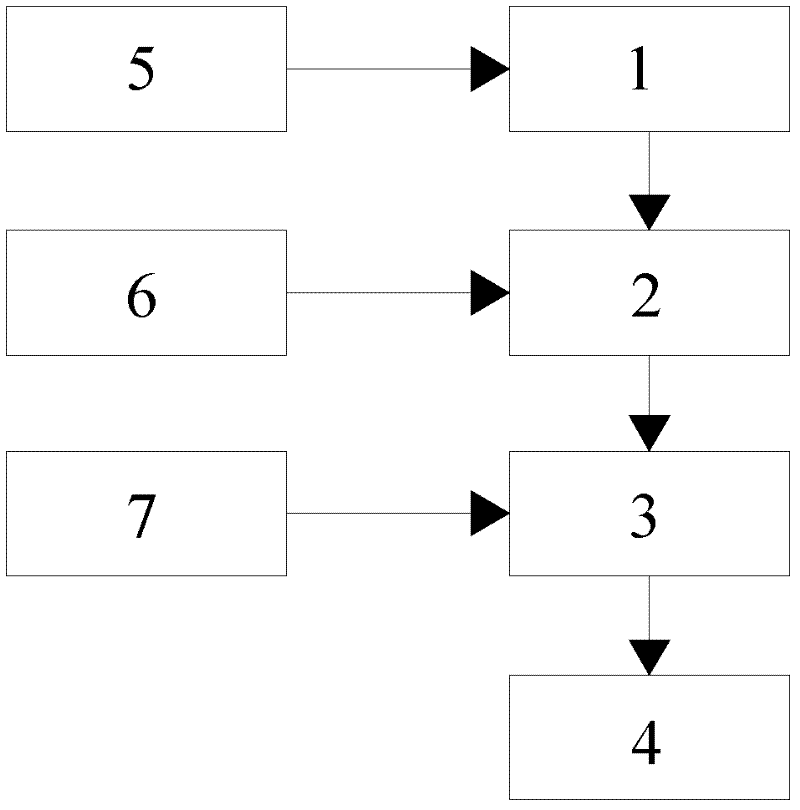

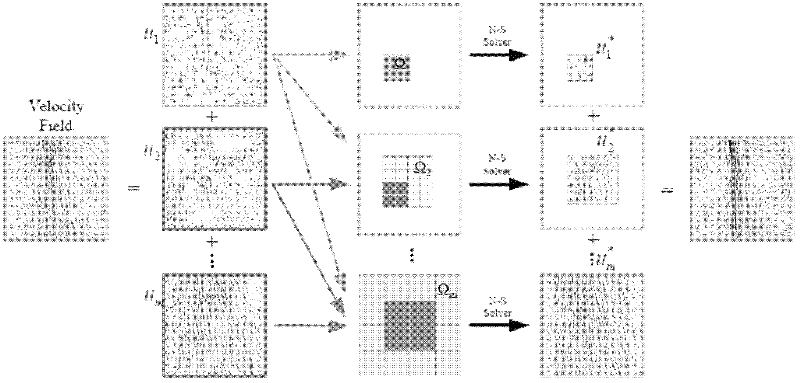

Fluid simulation rendering method and device

The invention discloses a fluid simulation rendering method, relating to the technical field of computer image rendering. The fluid simulation rendering method comprises the steps of: A, converting a fluid flow field in a two-dimension or three-dimension space into a one-dimension fluid flow field by using a space filling curve; B, decomposing the one-dimension fluid flow field into components with different frequencies by using an empirical mode decomposition algorithm according to the importance of different areas in the flow field determined on the basis of user view points; C, performing simulation with different precisions on the components with different frequencies according to analysis results; and D, summing the simulation results of the components to obtain a total simulation result serving as output. According to the fluid simulation rendering method and device, the speed and the fineness of the fluid simulation rendering can be improved; meanwhile, the system resources can be effectively saved.

Owner:TSINGHUA UNIV

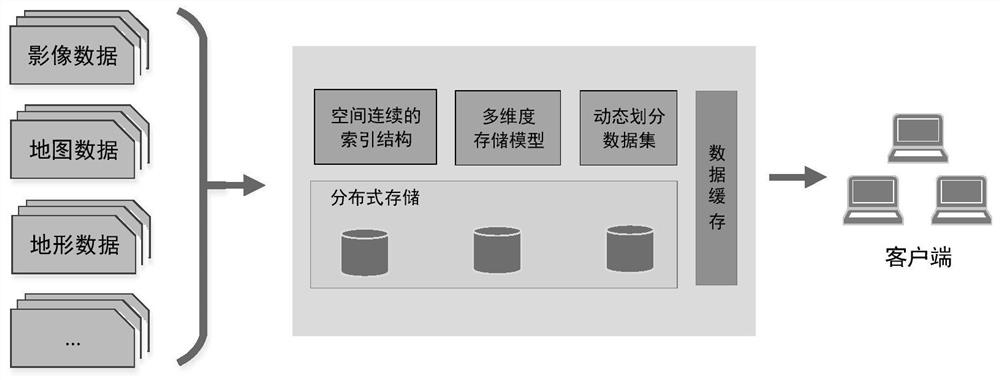

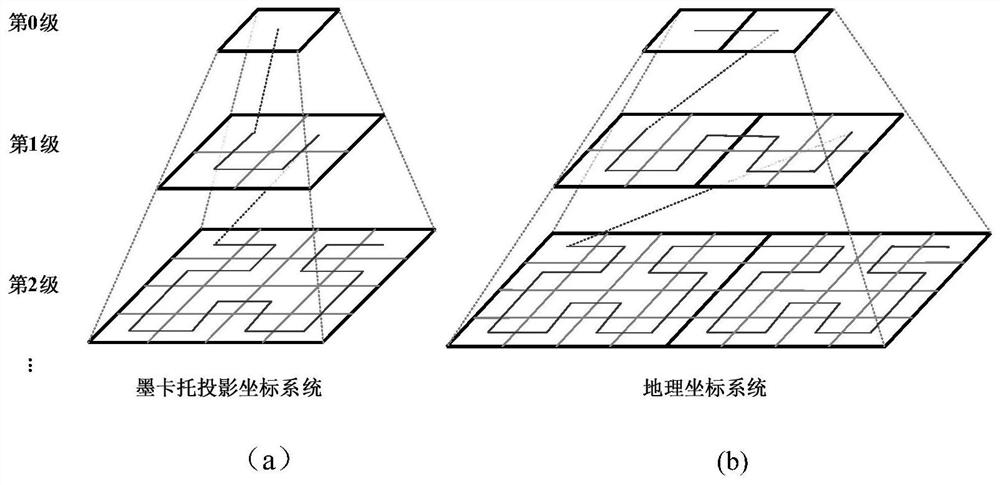

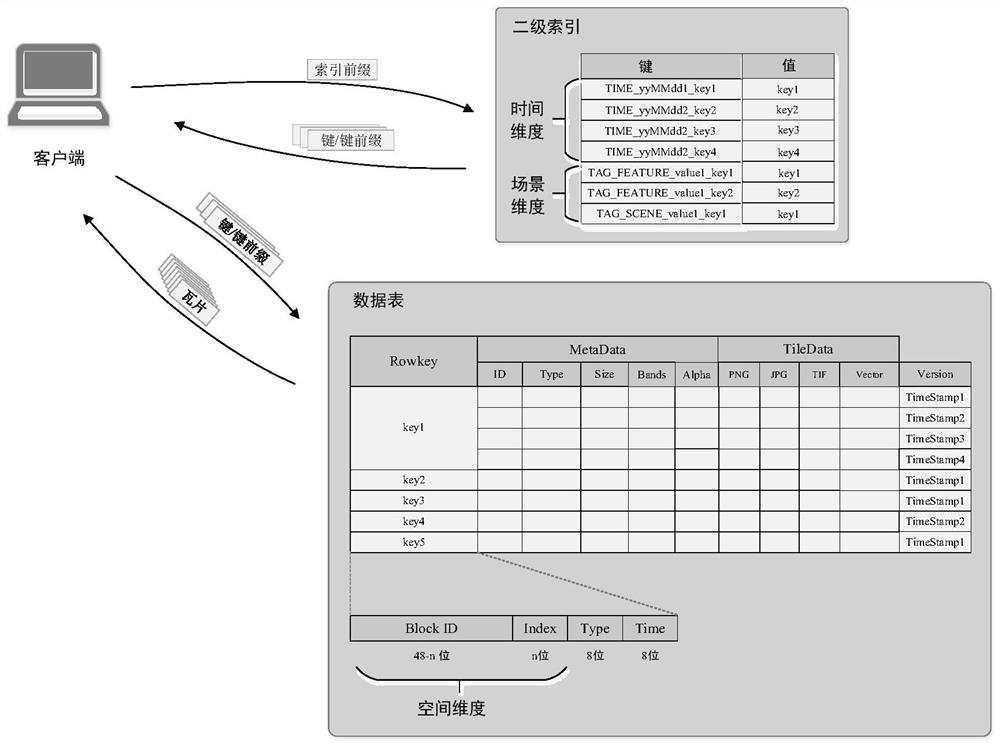

Storage and retrieval method and system for large-scale geographic space data

ActiveCN111782742AQuick searchImprove access speedGeographical information databasesSpecial data processing applicationsDatasheetData set

The invention provides a storage and retrieval method and system for large-scale geographic space data. The method comprises the following steps: mapping geographic space data to a tile pyramid model,filling a tile pyramid by using a space filling curve, and carrying out coded expression on tile nodes on the space filling curve to construct a space continuous index coding structure; constructinga multi-dimensional structured storage model which comprises a tile data table and a secondary index table, storing geographic space tile data, basic information of the geographic space tile data andtile data keys into the tile data table, and storing tile index keys and tile index values into the secondary index table; and generating a data query filter for data set retrieval according to the retrieval conditions of the data and the correlation between each dimension and the data storage structure. The multi-dimensional retrieval method and the quick query process of the geographic space data are realized, the access frequency of the database is reduced, and the access speed of the data is increased.

Owner:中国科学院电子学研究所苏州研究院

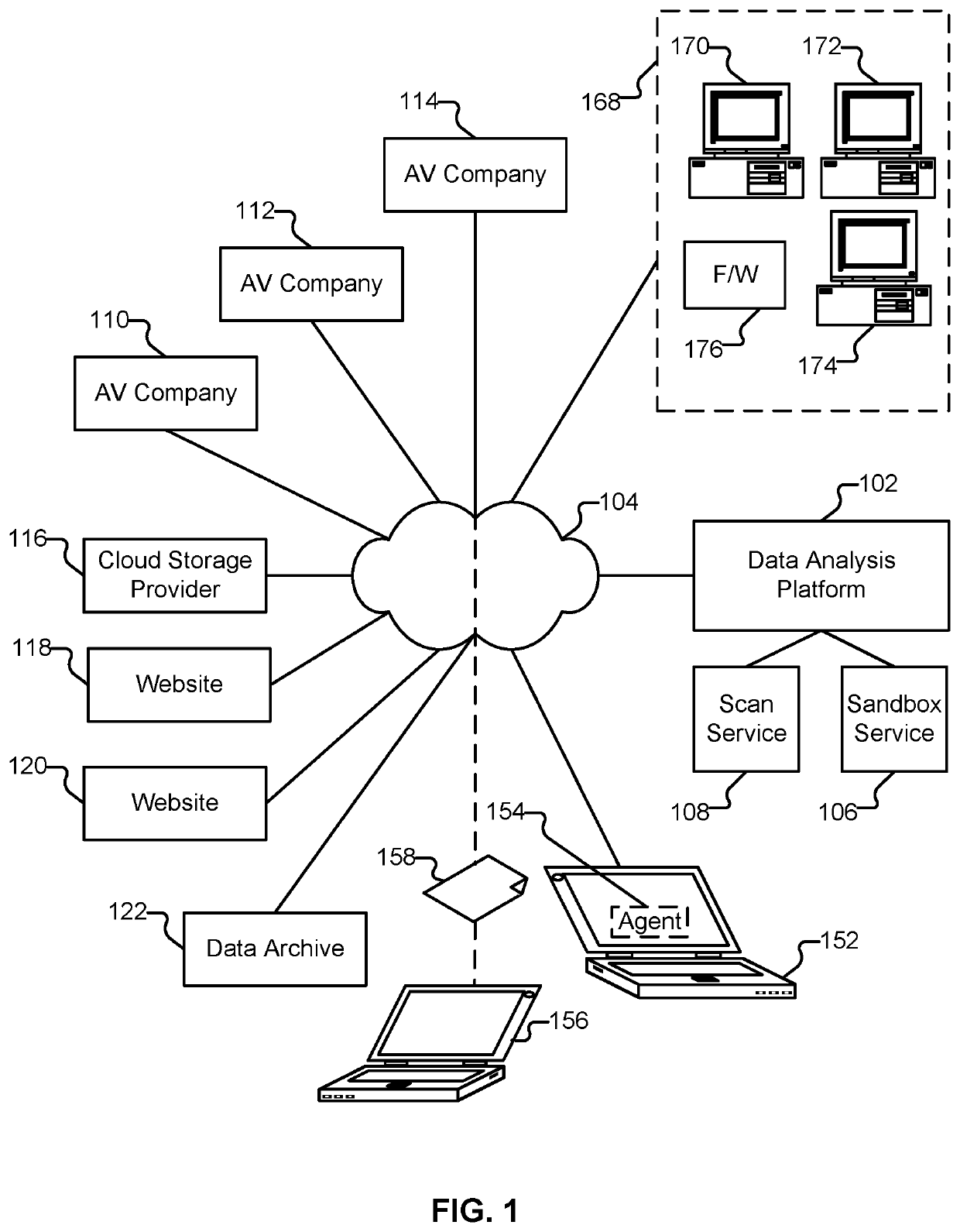

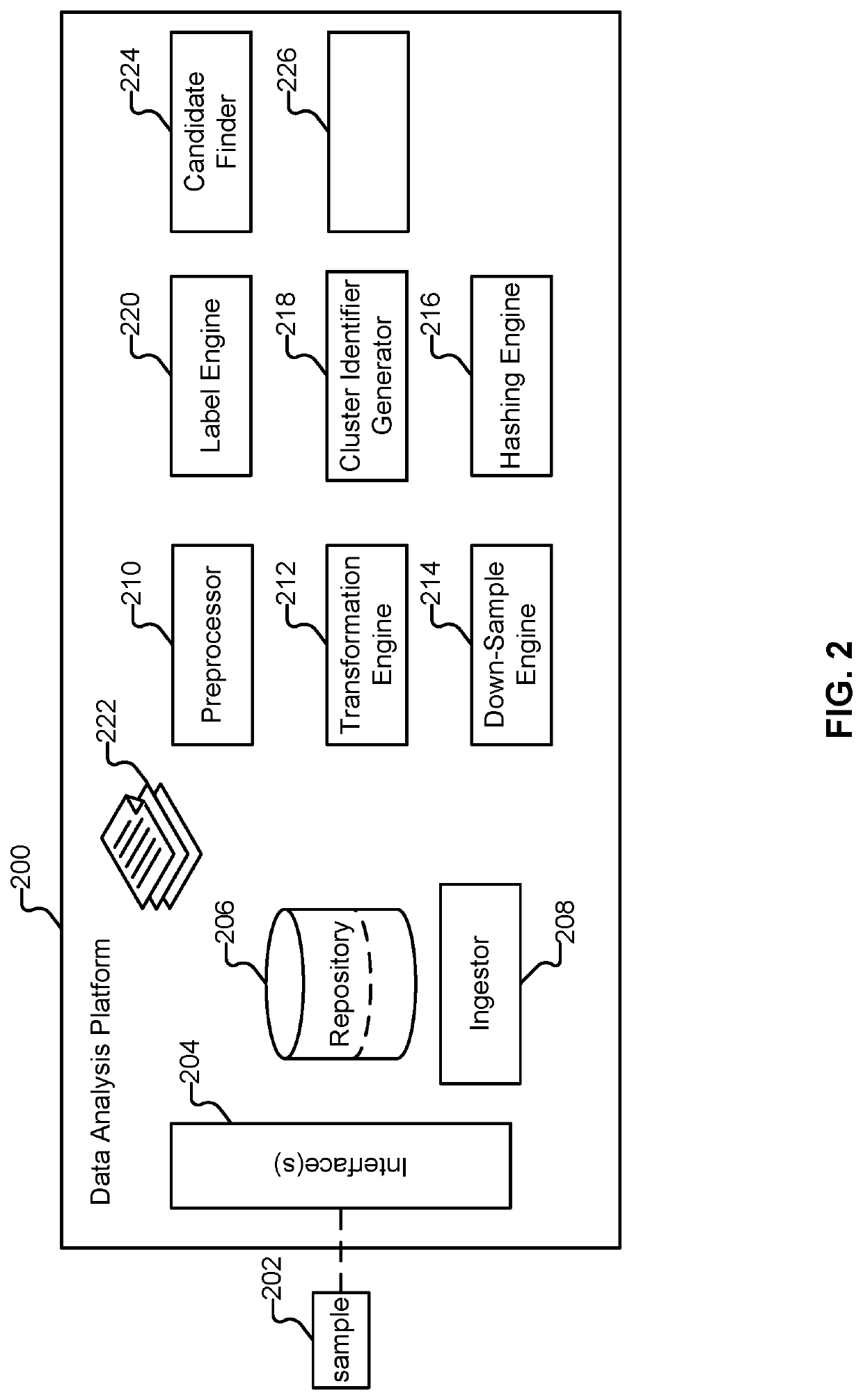

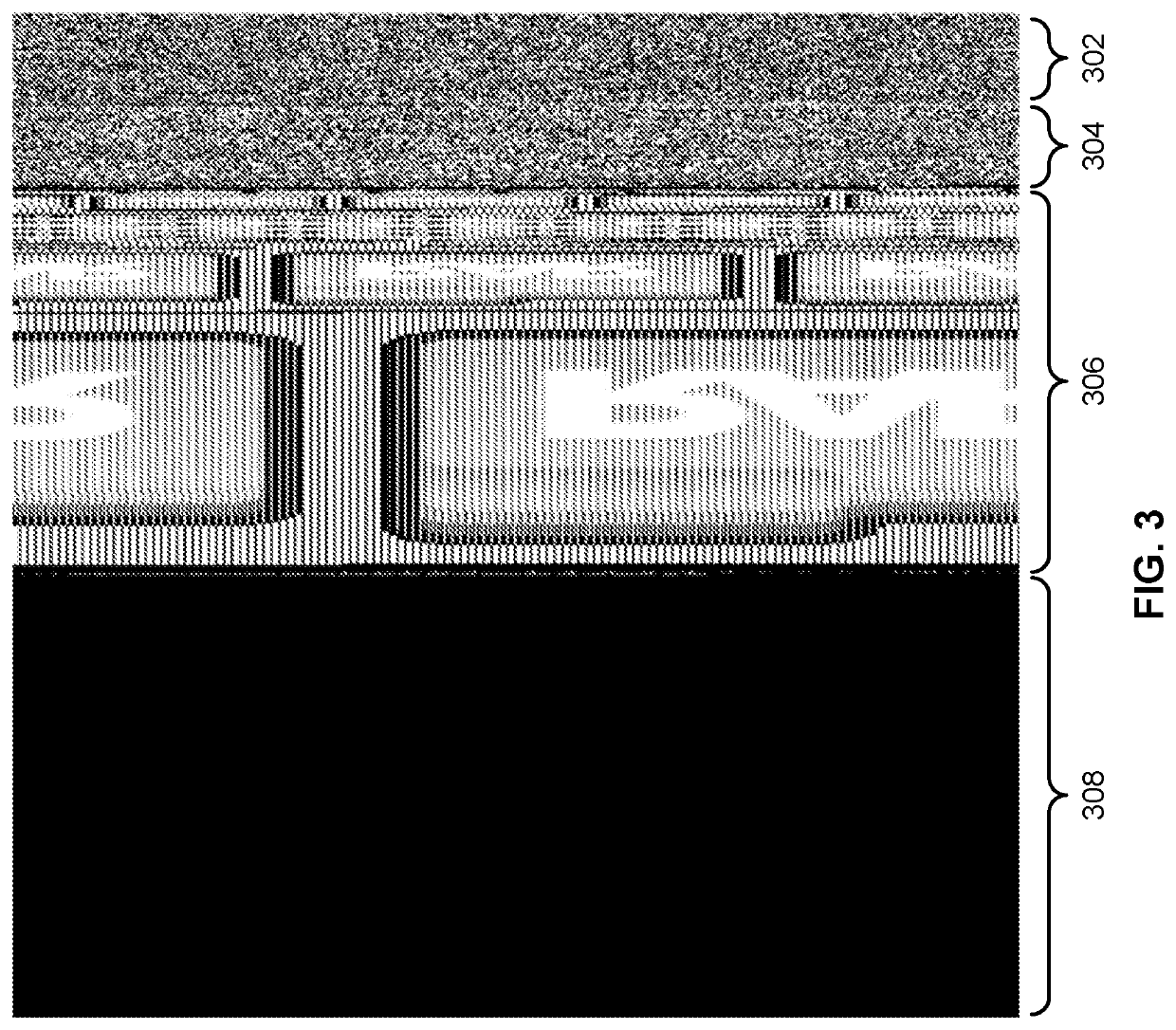

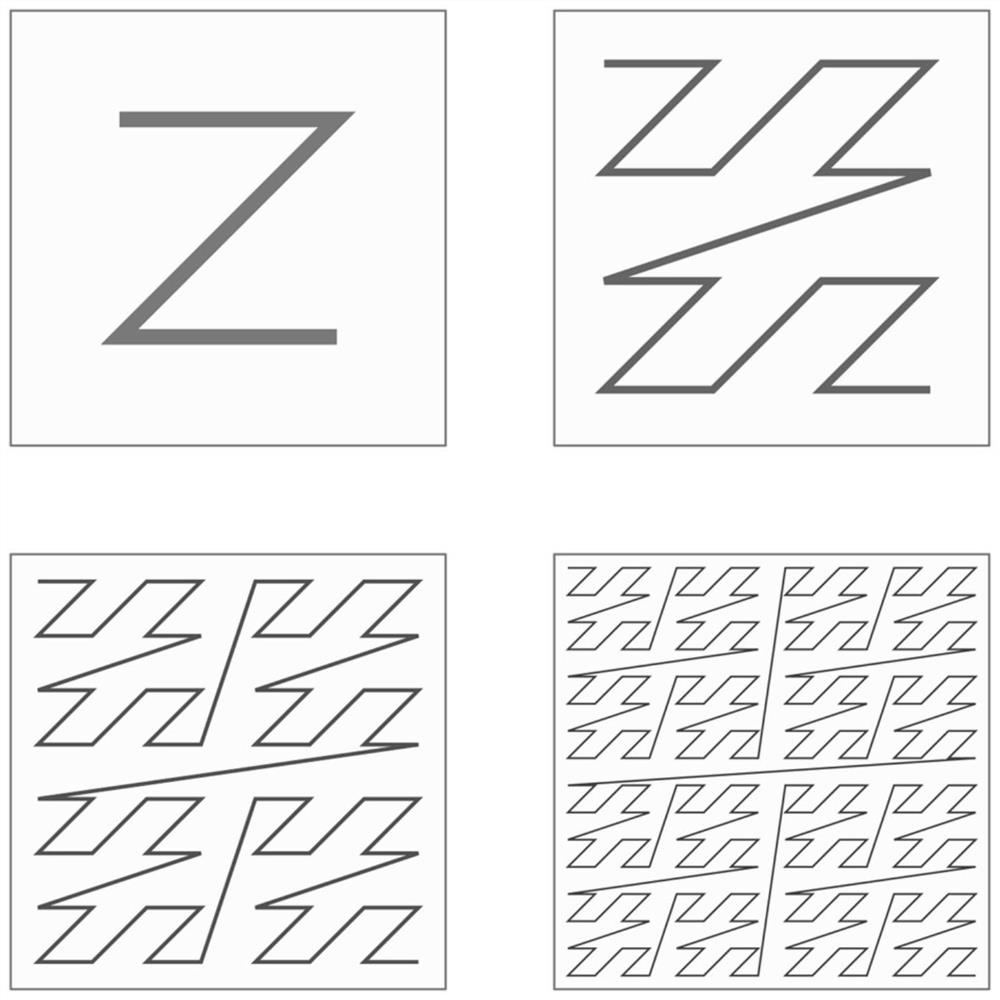

System and method for clustering files and assigning a maliciousness property based on clustering

ActiveUS10546143B1Digital data protectionFile access structuresTheoretical computer scienceNear neighbor

A file is received. File contents are transformed using a space-filling curve. The results are down-sampled to generate a sample locus. A cluster identifier is assigned to the file. In response to a determination that the cluster identifier is not present in a data store, a set of candidate nearest neighbors is determined for the cluster identifier. For each candidate nearest neighbor, a set of existing cluster identifiers present in the data store is determined. For each existing cluster identifier, a set of member loci is determined. An edit distance between the sample locus and each of the member loci is determined. Finally, in response to a determination that a first locus in the set of member loci is within a threshold edit distance of the sample locus, one or more properties associated with the first locus is assigned to the file.

Owner:SUPPORT INTELLIGENCE

Spatio-temporal data encoding method and device, storage medium and computing equipment

PendingCN111914043AOvercoming consecutive codingNatural language data processingGeographical information databasesEngineeringData encoding

The invention discloses a spatio-temporal data encoding method and device, a storage medium and computing equipment. The method comprises the steps that a space filling curve is decomposed into a plurality of sub-curves, and each sub-curve corresponds to one space geometry; segmenting the space geometry according to a preset order to obtain a plurality of sub-space geometries; converting vertex coordinates of each secondary vertex in the subspace geometry into one-dimensional coded information to obtain a plurality of pieces of one-dimensional coded information corresponding to each secondaryvertex; and splicing the plurality of pieces of one-dimensional coded information corresponding to secondary vertexes to obtain coded data corresponding to the space filling curve. The technical problem that the Z filling curve is used as the space filling curve, although the coding of the Z filling curve can continuously code the space-time space, the inflection points of the space filling curveare spatially non-adjacent and have obvious mutability, so that the workload of secondary filtering needs to be increased during adjacent query is solved.

Owner:TAOBAO CHINA SOFTWARE

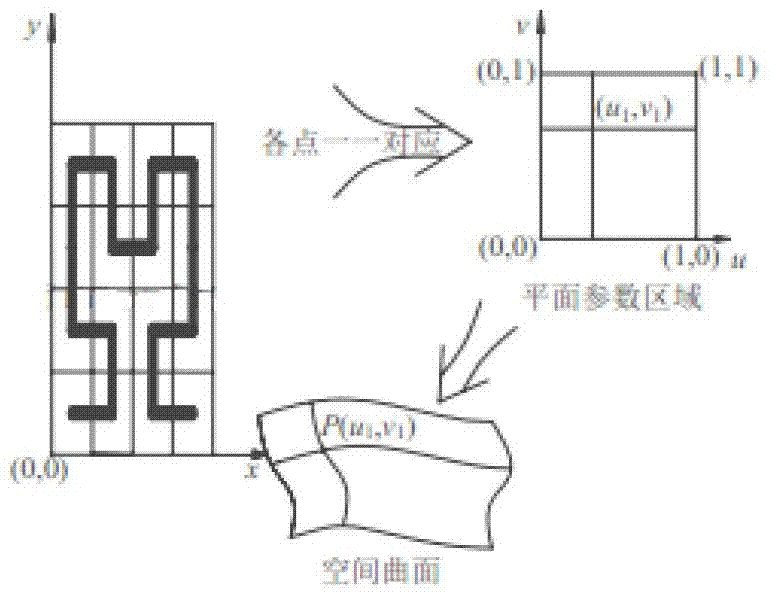

Space filling curve-based numerical control machining tool path generation method

ActiveCN105022343AShorten the lengthReduce the number of turnsNumerical controlNumerical controlPath generation

The invention provides a space filling curve-based numerical control machining tool path generation method, and the steps of: 1. performing regional division on a curved surface according to the shape of the curved surface and a path with the steepest gradient and determining the order of a two-dimensional region filling curve of each region according to residual height, and then generating the two-dimensional region filling curves of corresponding orders, and connecting the two-dimensional region filling curves of adjacent regions in an end-to-end manner to obtain a two-dimensional filling curve; and 2. mapping the two-dimensional filling curve to a space curved surface according to a mapping principle, thereby obtaining a numerical control machining tool path. The space filling curve-based numerical control machining tool path generation method provided by the invention uses the path with the steepest gradient to perform regional division on the curved surface, and then generates the two-dimensional filling curve, not only is the length of the whole tool path shortened, but the number of times of steering is reduced to about eighty percent of a previous number, and machining quality is better than most methods.

Owner:SHANGHAI JIAO TONG UNIV

Antenna system for a motor vehicle

InactiveCN1816943ASmall sizeImprove aestheticsAntenna supports/mountingsAntenna adaptation in movable bodiesRadio receptionRadio receiver

An integrated multi-service antenna system for a motor vehicle includes a plurality of antenna structures integrated within a physical component of the motor vehicle. The plurality of antenna structures includes a radio antenna and at least one of a cellular telephony antenna and a satellite-signal antenna. The radio antenna has a radiating arm, with at least a portion of the radiating arm defining a space-filling curve, the radio antenna further has a feeding point for coupling the radio antenna to a radio receiver in the motor vehicle.

Owner:ADVANCED AUTOMOTIVE ANTENNAS

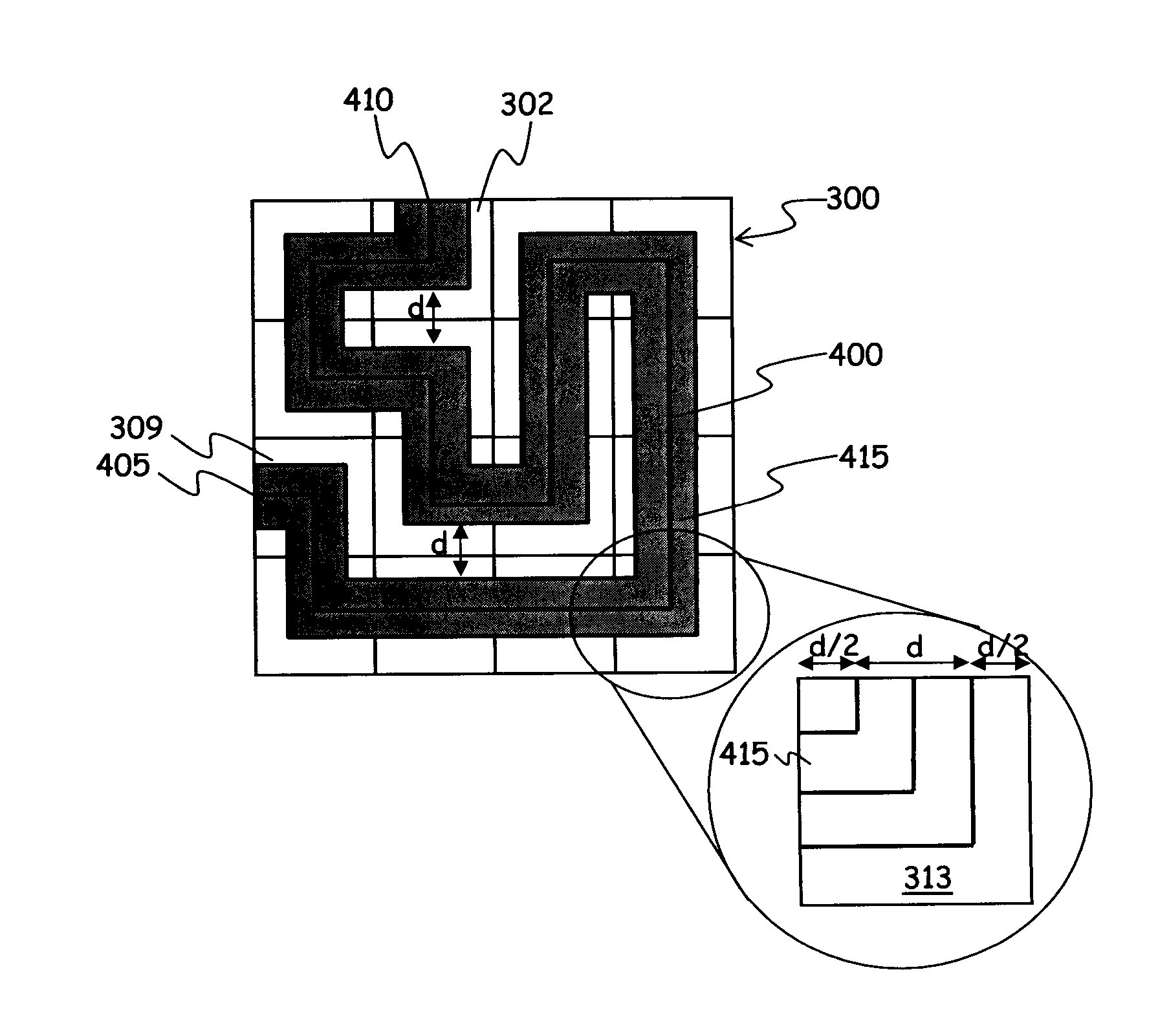

Tamper-proof structures for protecting electronic modules

InactiveUS7915540B2Easy to carryMinimal spaceCircuit security detailsPrinted circuit aspectsTamper resistanceComputer science

A tamper-proof structure for protecting an electronic module, comprising a pattern of signal lines having a highly unpredictable layout, which is an approximation of a space-filling curve obtained by the replication of at least one elementary space element having an inscribed base curve inscribed therein. The base curve is adapted, by replication of the elementary space element, to generate an approximation of an at least two-dimensional space-filling curve, the replication being such that an end of the base curve in one elementary space element is connected to the end of the base curve in another, adjacent elementary space element of the replication.

Owner:INT BUSINESS MASCH CORP

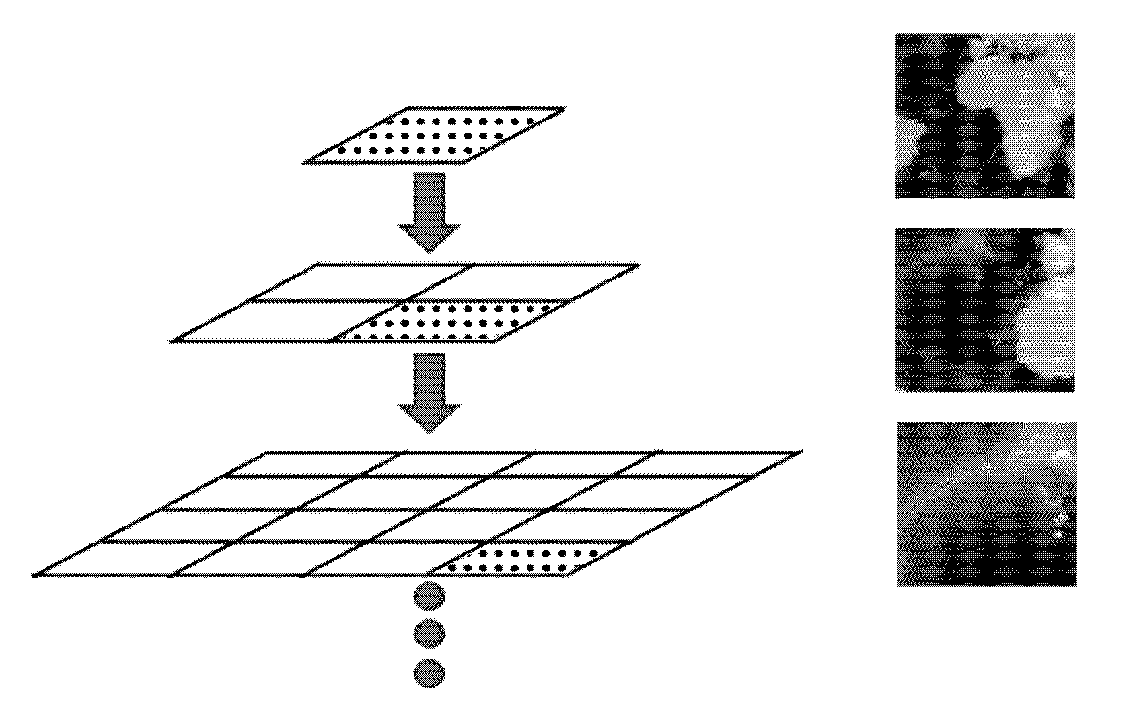

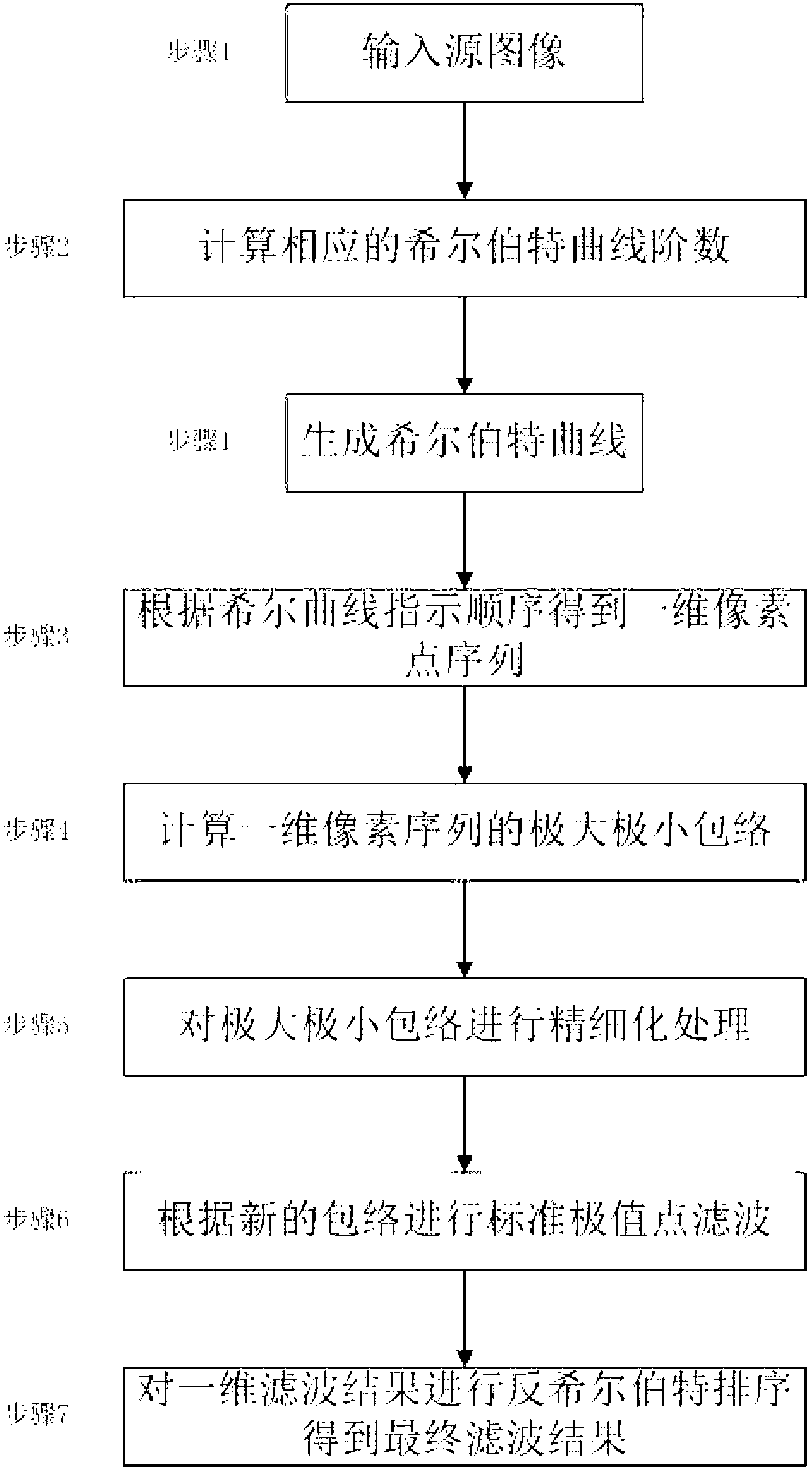

Fast image filtering method based on space filling curves and extreme points

InactiveCN103218784AImprove filtering effectReduce interpolation errorImage enhancementPoint sequenceSource image

The invention relates to a fast image filtering method based on space filling curves and extreme points. The fast image filtering method based on the space filling curves and the extreme points comprises the following steps: a first step is that a source image to be filtered is input; a second step is that a Hilbert curve is generated; a third step is that pixel points in a two-dimensional image domain are subjected to sequencing according to an order indicated by the Hilbert curve, and a one-dimensional pixel point sequence is generated; a fourth step is that a maximum envelope and a minimum envelope of the one-dimensional pixel point sequence are calculated, and the obtained envelopes are subjected to fine processing; a fifth step is that the maximum envelope and the minimum envelope after the fine processing are used as input values, and an image base and image details after a smoothing filtering process are obtained through calculation of a mean value; and a sixth step is that one-dimensional filtering results of the image base and the image details are subjected to counter-Hilbert sequencing, an original two-dimensional image is divided into a smooth part and a detail part, and therefore filtering is finished. The fast image filtering method based on the space filling curves and the extreme points can extremely reduce interpolation errors and lower the complexity of the filtering, and can achieve a quasi-real-time effect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Numerical control machining cutter path generation method based on double helix space filling curves

The invention discloses a numerical control machining cutter path generation method based on double helix space filling curves. The numerical control machining cutter path generation method comprises step 1 of determining orders of the filling curves according to residual height and curve shapes and generating the double helix space filling curves which meets requirements for the orders on a two-dimensional plane; step 2 of improving corner portions of cutter paths and optimizing the cutter paths; and step 3 of mapping two-dimensional filling curves on a space curve surface according to a mapping principle to obtain the satisfied cutter paths in numerical control machining. The numerical control machining cutter path generation method conducts element improvement on the basis of the existing space filling curves, shortens length of the whole cutter path and reduces turning of the whole cutter path. Arc transition is carried out at the corner to enable the whole cutter path to be smooth, frequent starting and stopping of speed and frequent changing of feeding directions in a manufacture process caused by 90-degree right-angle connection are avoided, impacts on a machine tool, a cutter and a manufactured surface are reduced, and quality of the manufactured surface is improved accordingly.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com