Smoke duct device and reducing elbow thereof

A technology of variable diameter elbow and flue air duct, which is applied in exhaust gas device, combustion product treatment, combustion method, etc., can solve the problems of large resistance and uneven flow field, so as to reduce energy consumption and achieve uniform flow field. , the effect of avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

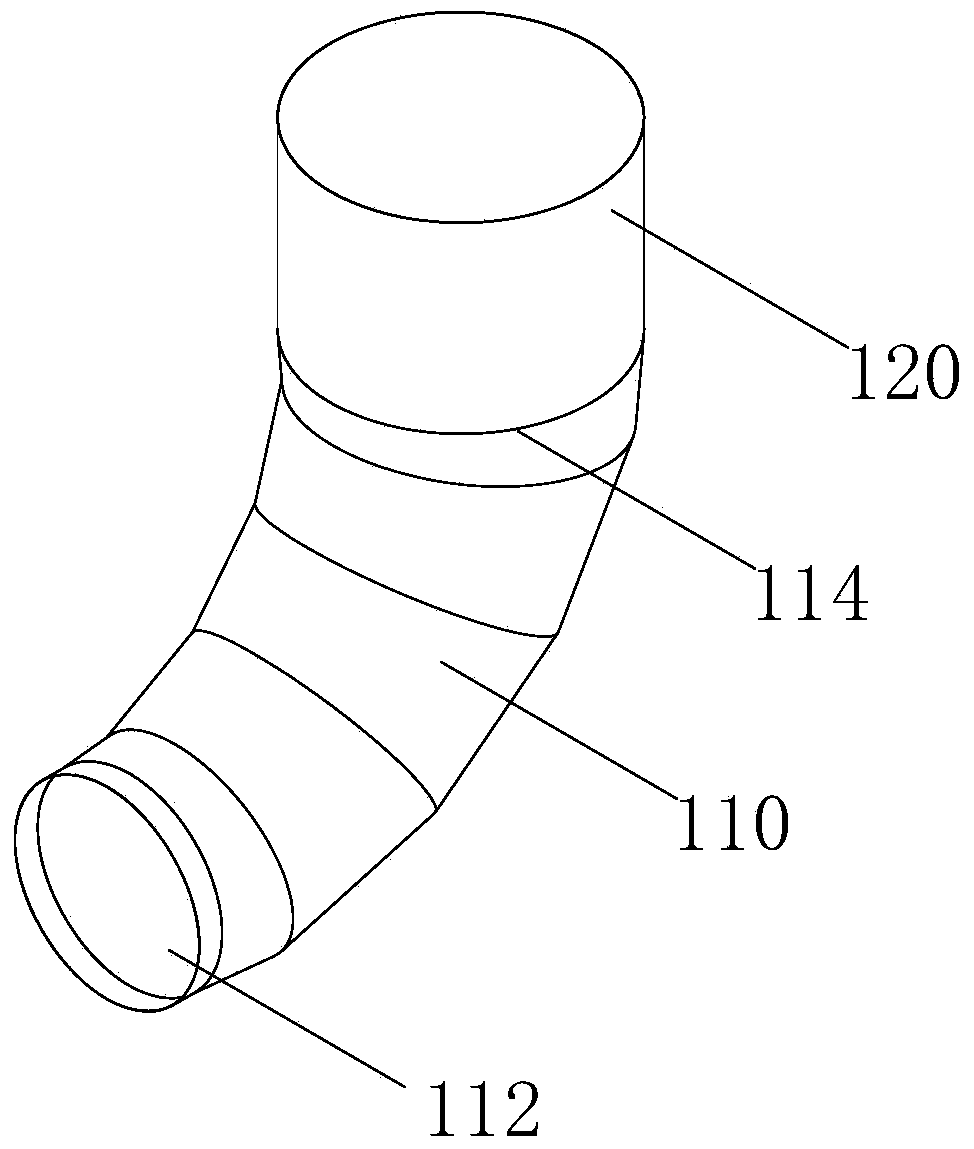

[0022] Such as figure 1 As shown, a reducing elbow 100 includes a reducing section 110 and a main body section 120, the cross sections of the reducing section 110 and the main section 120 are circular, and the reducing section 110 includes a small end 112 and a large end 114, the diameter reducing section 110 is a curved shape whose diameter gradually increases from the small end 112 to the large end 114. The ratio of 1.0 to 3.0. The diameters of each cross-section of the main body section 120 in this embodiment are equal.

[0023] The diameter reducing elbow 100 in this embodiment is provided with a diameter reducing section 110 and a main body section 120 with a circular cross section, and the diameter reducing section 110 is a curved shape whose diameter gradually increases from the small end 112 to the large end 114, Its large end 114 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com