Blade number optimization method of hydraulic torque converter on the basis of neural network and complete machine

A technology of hydraulic torque converter and neural network is applied in the field of optimization of the number of blades of hydraulic torque converter, which can solve the problems of separation of main components and achieve the effect of realizing digital and customized design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

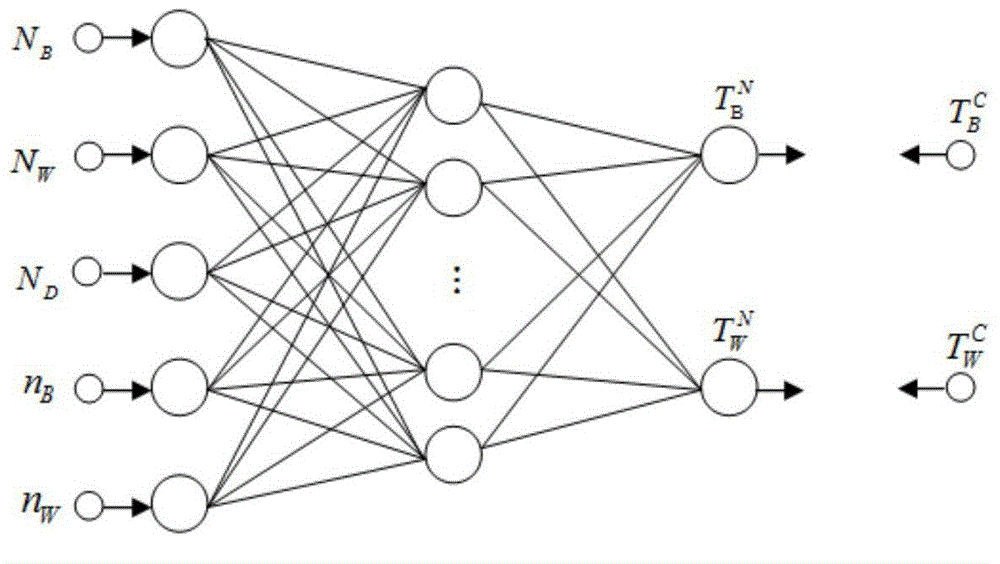

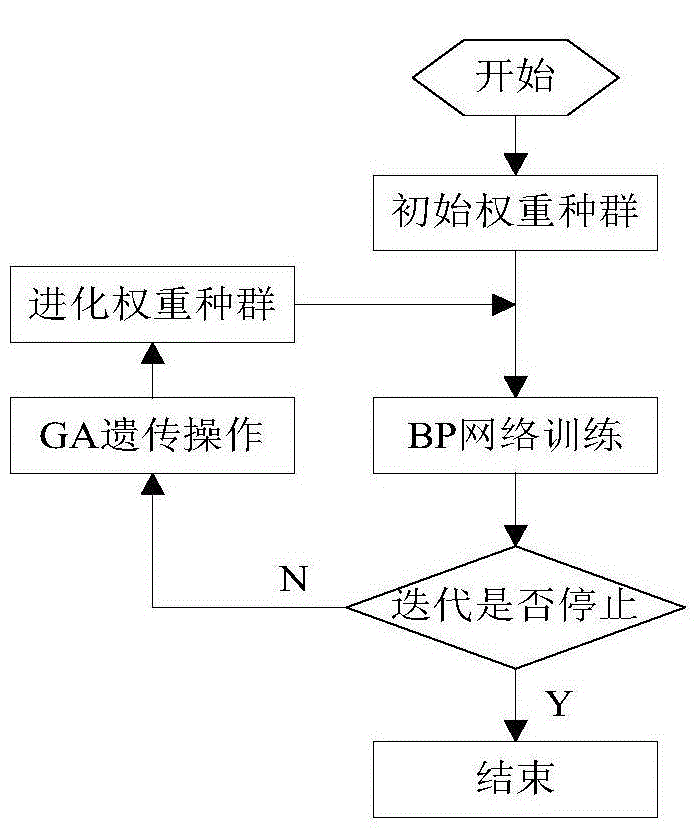

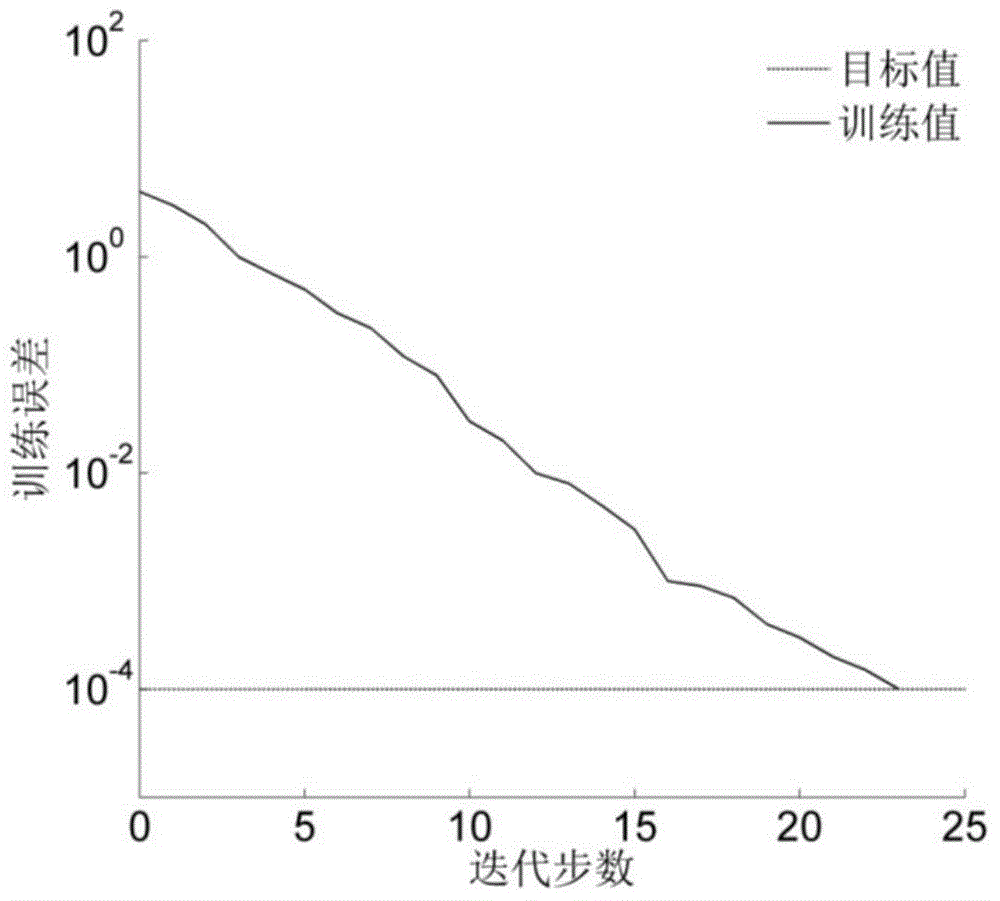

[0029] The invention is a method for optimizing the number of vanes of a hydraulic torque converter based on a neural network and a complete machine. The hydraulic torque converter is placed in the digital model of the whole machine system, and the number of blades is optimized with the improvement of the overall machine efficiency as the optimization goal. In order to combine with the digital model of the whole machine system, the three-layer BP neural network is used to establish the neural network model of the number of blades, which is equivalent to establishing the functional relationship between the performance of the hydraulic torque converter and the number of blades and the speed of the pump and turbine, as follows:

[0030] ( T B N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com