Integrated digital control system for high temperature superconducting magnetic suspension energy accumulation flywheel magnetic bearing

A technology of digital control system and energy storage flywheel, which is applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of inability to control with high precision, achieve the improvement of DSP data processing ability and communication speed, improve data processing ability, meet The effect of real-time requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

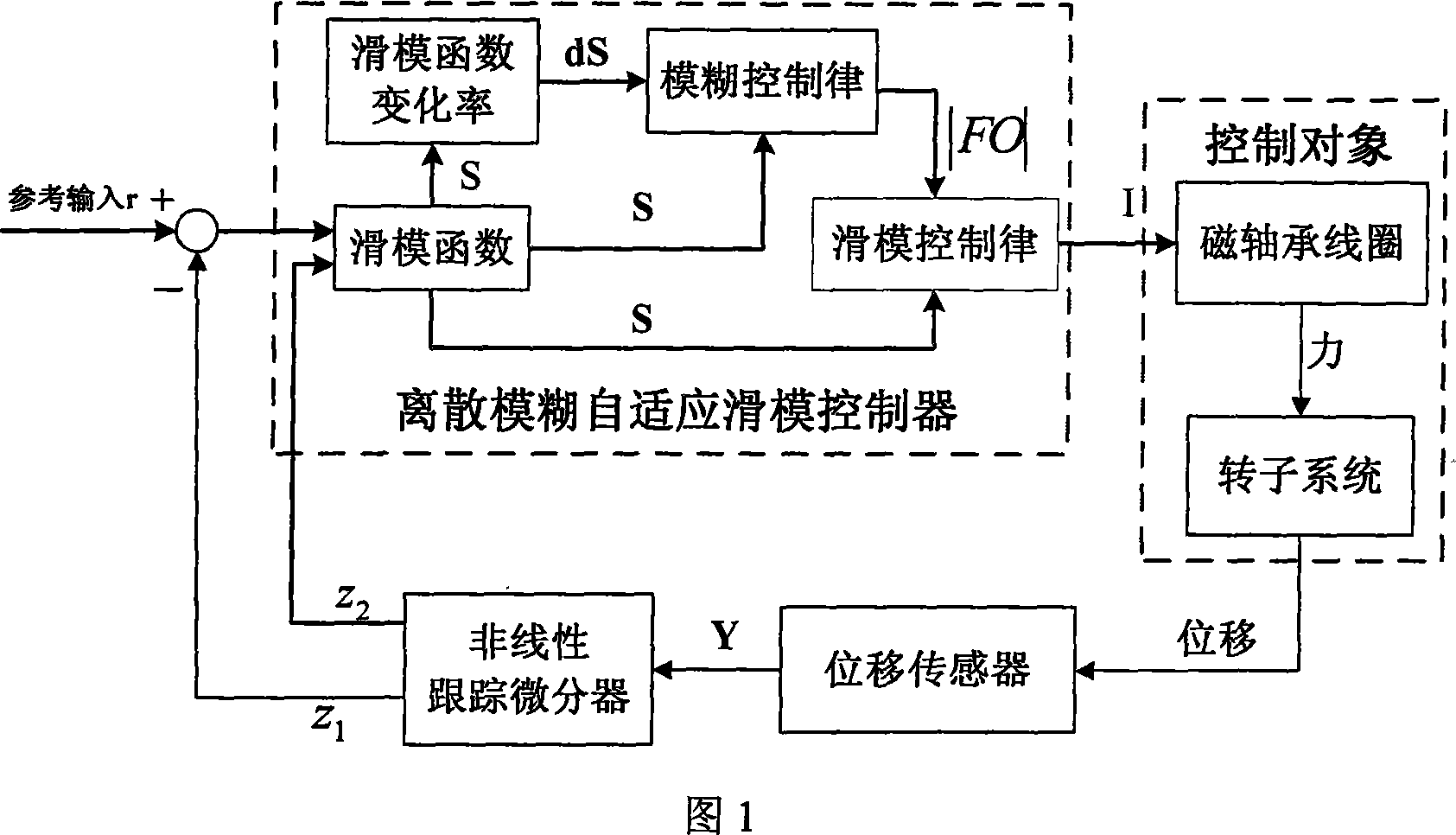

Method used

Image

Examples

Embodiment Construction

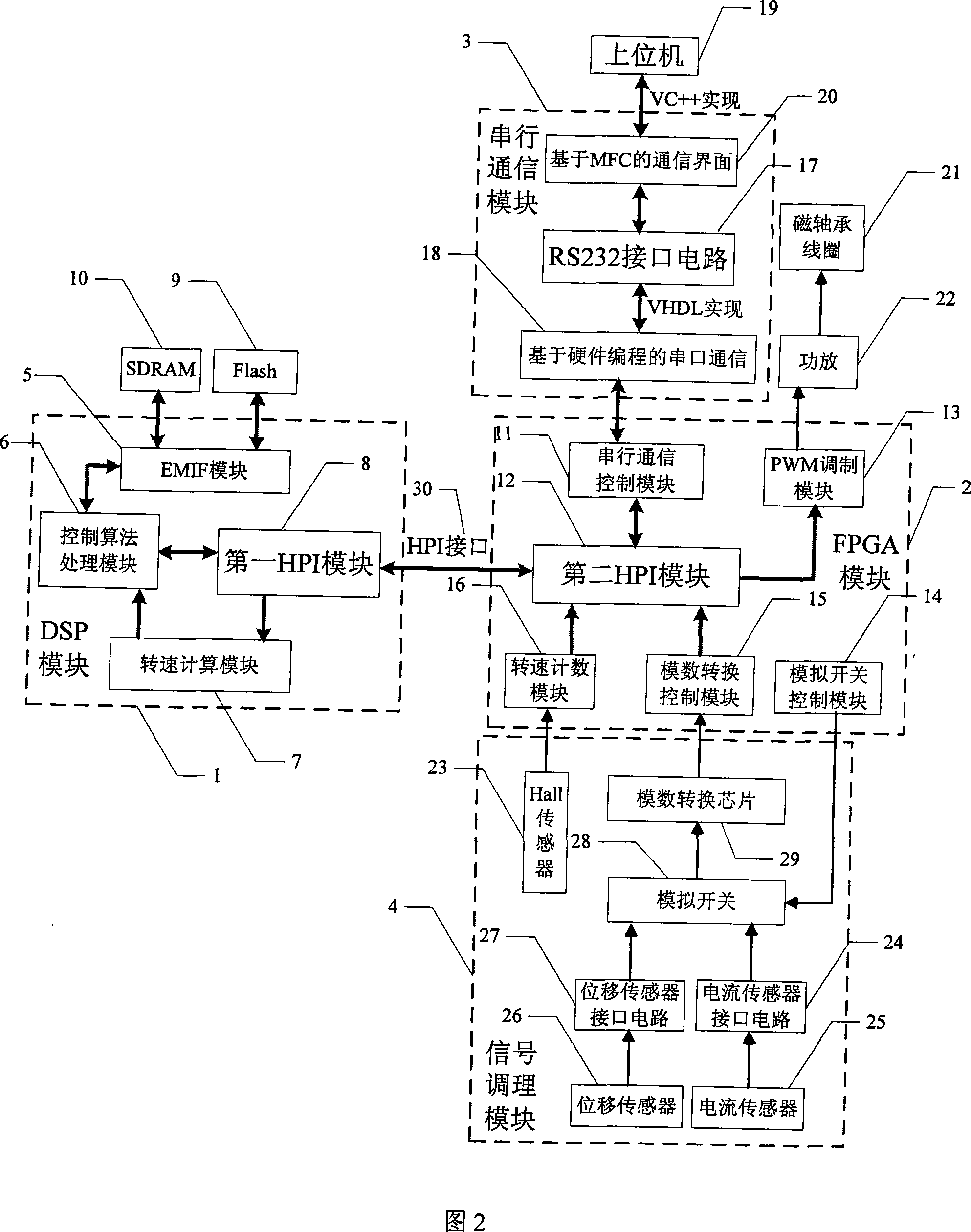

[0028]As shown in Figure 2, it is a block diagram of the composition of the control system of the present invention, the control system includes several parts such as DSP module 1, FPGA module 2, serial communication module 3, signal conditioning module 4, wherein DSP module 1 includes control algorithm processing module 6 , the first HPI module 8, the rotational speed calculation module 7 and the EMIF module 5, the FPGA module 2 includes a serial communication control module 11, a second HPI module 12, an analog-to-digital conversion control module 15, an analog switch control module 14, and a rotational speed counting module 16 And PWM modulation module 13, serial communication module 3 comprises the communication interface 20 based on MFC, the serial port communication 18, RS232 interface circuit 17 based on hardware programming, signal conditioning module 4 comprises analog-to-digital conversion chip 29, Hall sensor 23, current sensor interface Circuit 24, current sensor 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com