Microorganism fermentation jar

A technology of microbial fermentation and oxygen tank, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, enzymology/microbiology device, etc., can solve the problem of shortening the contact between bubbles and the liquid at the bottom of the fermentation tank. Time and reaction effect, the speed of bubble rising, and the inability to supply oxygen to the bottom liquid, etc., to achieve the effect of speeding up the reaction rate and reaction effect, increasing the contact area and contact effect, and speeding up the fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

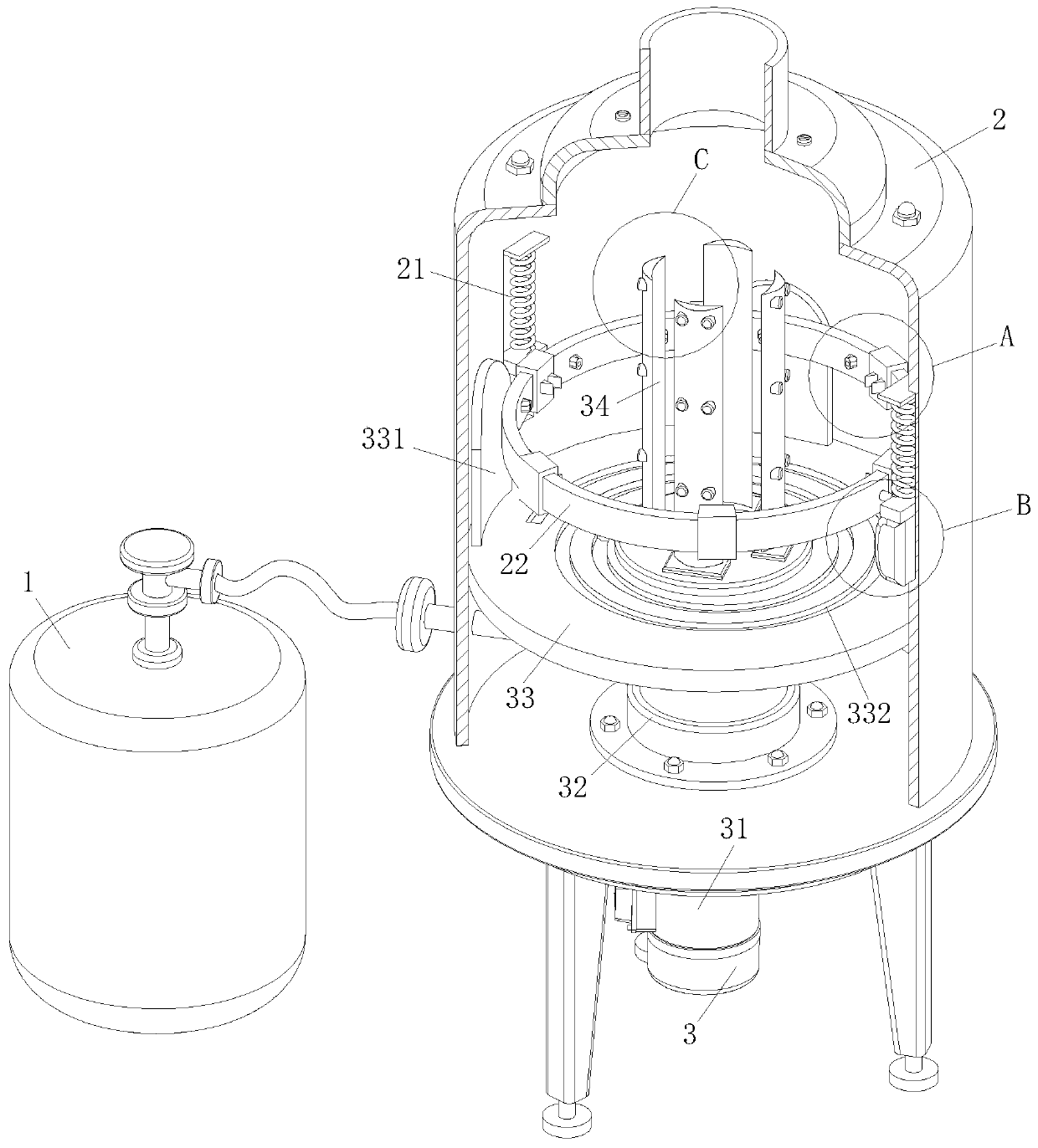

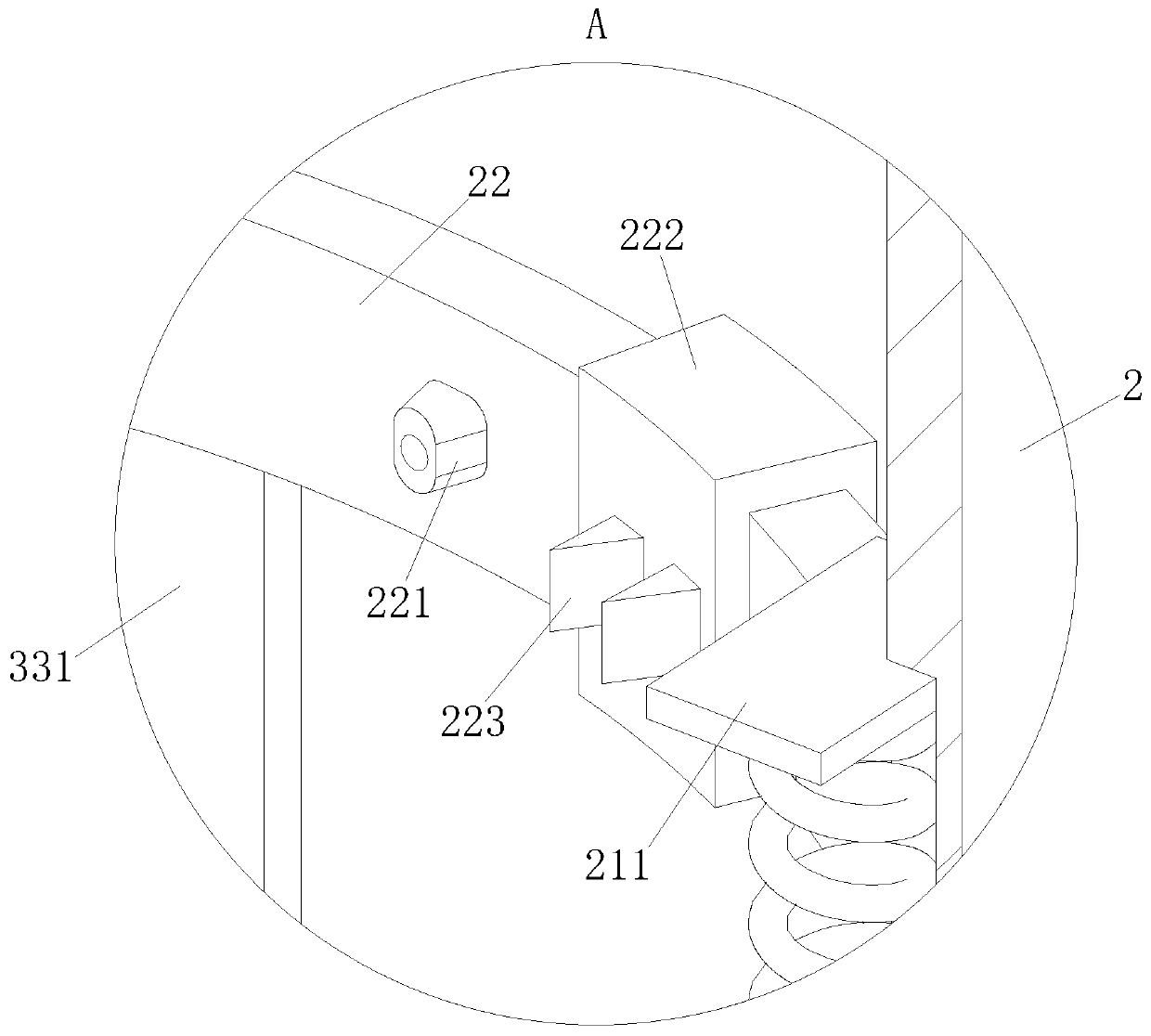

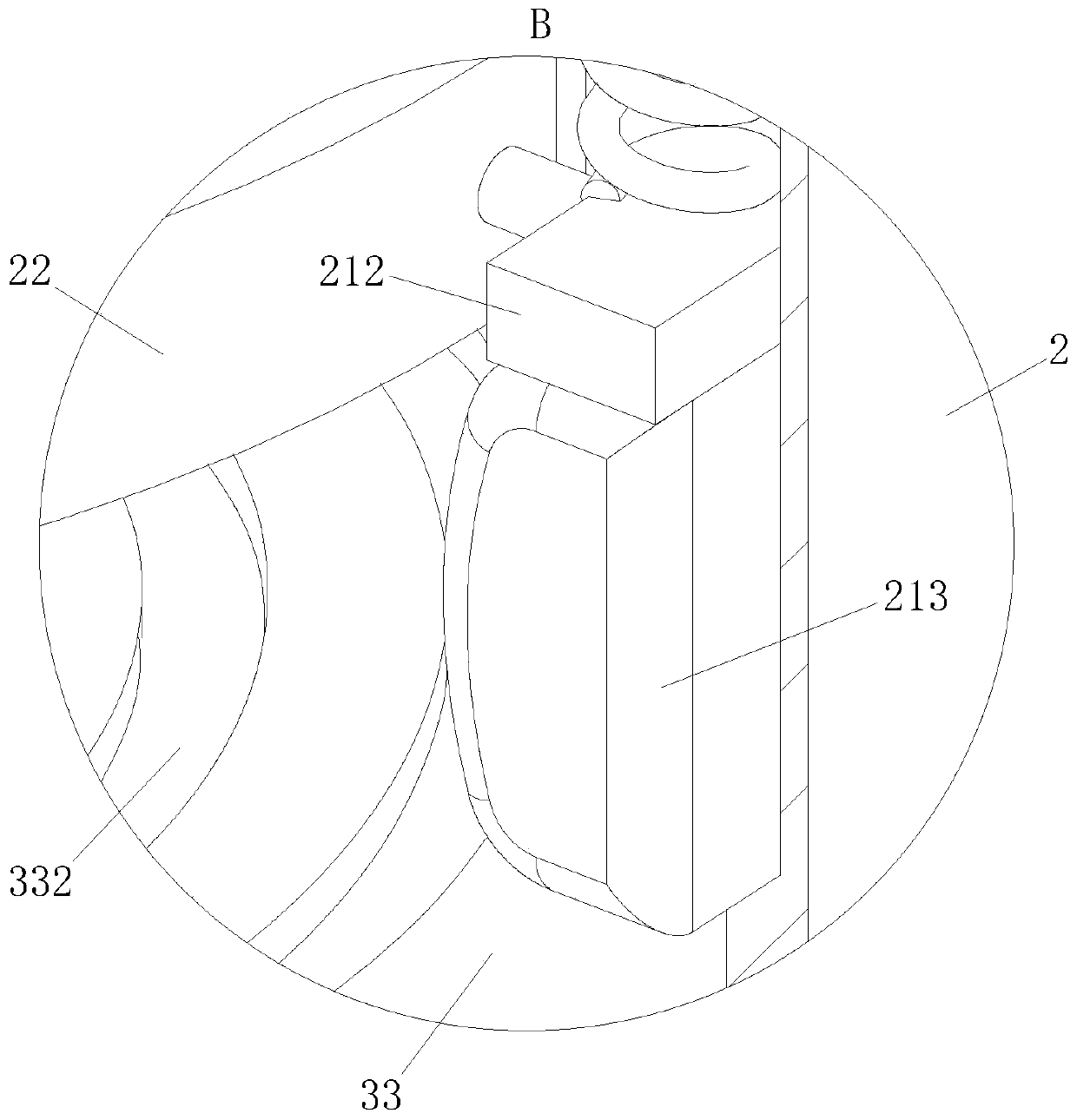

[0022] As an embodiment of the present invention, the inner side wall of the housing 2 is symmetrically opened with a chute 21; the top of the chute 21 is provided with a baffle 211, and a slider 212 is slidably connected to the chute 21 through a spring; A collar 22 is installed between the sliders 212, so that the collar 22 slides on the outside of the ventilation plate 34; the arc support plate 331 is symmetrically installed on the bottom plate 33, so that in the process of the bottom plate 33 rotating, the arc support plate The plate 331 can be in reciprocating contact with the slider 212; through the cooperation of the arc-shaped support plate 331, the slider 212, the baffle plate 211 and the collar 22, the oxygen bubbles can be broken up, and the solution in the fermenter can be transposed up and down. Effect: when working, when it is necessary to infuse oxygen into the fermenter, open the oxygen tank 1, so that the oxygen in the oxygen tank 1 is transmitted to the ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com