Processing method for small-size and high-strength niobium-hafnium alloy bar

A technology of alloy rods and processing methods, which is applied in the field of processing small-sized high-strength niobium-hafnium alloy rods, can solve problems such as insufficient radial deformation, poor mechanical properties, and differences in grain size, and achieve the elimination of work hardening, Improvement of mechanical properties and reduction of oxidation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

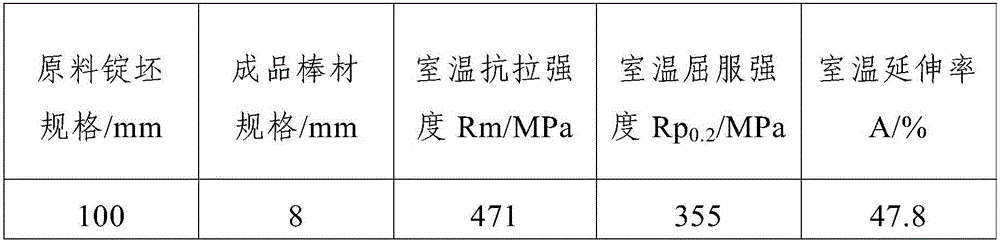

Embodiment 1

[0031] In this embodiment, a niobium-hafnium alloy ingot with a specification of Φ100 mm is used as a raw material to prepare a small-sized high-strength niobium-hafnium alloy rod with a specification of Φ8 mm. The processing method of the small-sized high-strength niobium-hafnium alloy rod in this embodiment includes the following steps:

[0032] Step 1. Sawing and blanking the niobium-hafnium alloy ingot with a circular cross-section and a cross-sectional diameter of 100mm. The sawing length is not more than 250mm, and then put it into a box-type resistance furnace and heat it to 150°C. After heating, The surface of the niobium-hafnium alloy extruded billet is evenly coated with an anti-oxidation protective lubricant. In this embodiment, the specific coating is Ti-1200 anti-oxidation protective lubricant, and the coating thickness is 0.2 mm;

[0033] Step 2: Heat the niobium-hafnium alloy extruded ingot coated with anti-oxidation protective lubricant in step 1 to 1260°C in a me...

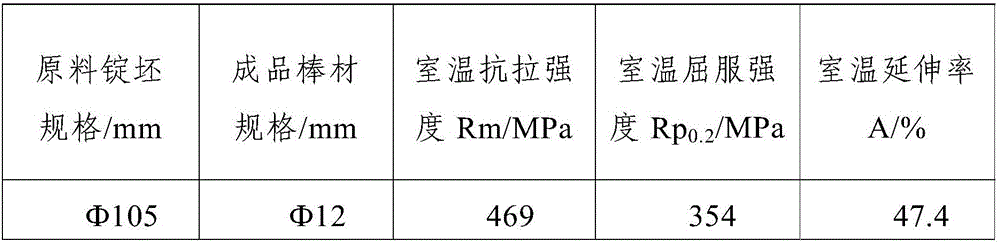

Embodiment 2

[0044] In this embodiment, a niobium-hafnium alloy ingot with a specification of Φ105 mm is used as a raw material to prepare a small-sized high-strength niobium-hafnium alloy rod with a specification of Φ12 mm. The processing method of the small-sized high-strength niobium-hafnium alloy rod in this embodiment includes the following steps:

[0045] Step 1. Sawing and blanking the niobium-hafnium alloy ingot with a circular cross-section and a cross-sectional diameter of 105mm. The sawing length is not more than 250mm, and then put it into a box-type resistance furnace and heat it to 150°C. After heating, The surface of the niobium-hafnium alloy extruded billet is evenly coated with an anti-oxidation protective lubricant. In this embodiment, the specific coating is Ti-1200 anti-oxidation protective lubricant, and the coating thickness is 0.2mm;

[0046] Step 2: Heat the niobium-hafnium alloy extruded ingot coated with anti-oxidation protective lubricant in step 1 to 1280°C in a ...

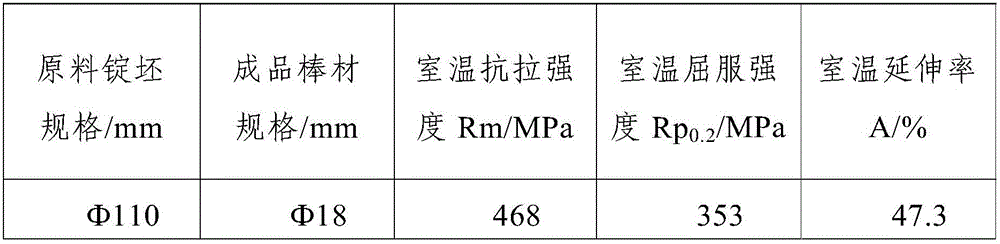

Embodiment 3

[0057] In this embodiment, a niobium-hafnium alloy ingot with a specification of Φ110 mm is used as a raw material to prepare a small-sized high-strength niobium-hafnium alloy rod with a specification of Φ18 mm. The processing method of the small-sized high-strength niobium-hafnium alloy rod in this embodiment includes the following steps:

[0058] Step 1. Sawing and blanking the niobium-hafnium alloy ingot with a circular cross-section and a cross-sectional diameter of 110mm. The sawing length is not more than 250mm, and then put it into a box-type resistance furnace and heat it to 150°C. After heating, The surface of the niobium-hafnium alloy extruded billet is evenly coated with an anti-oxidation protective lubricant. In this embodiment, the specific coating is Ti-1200 anti-oxidation protective lubricant, and the coating thickness is 0.2mm;

[0059] Step 2: Heat the niobium-hafnium alloy extruded ingot coated with anti-oxidation protective lubricant in step 1 to 1290°C in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com