Patents

Literature

119results about How to "Eliminate work hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

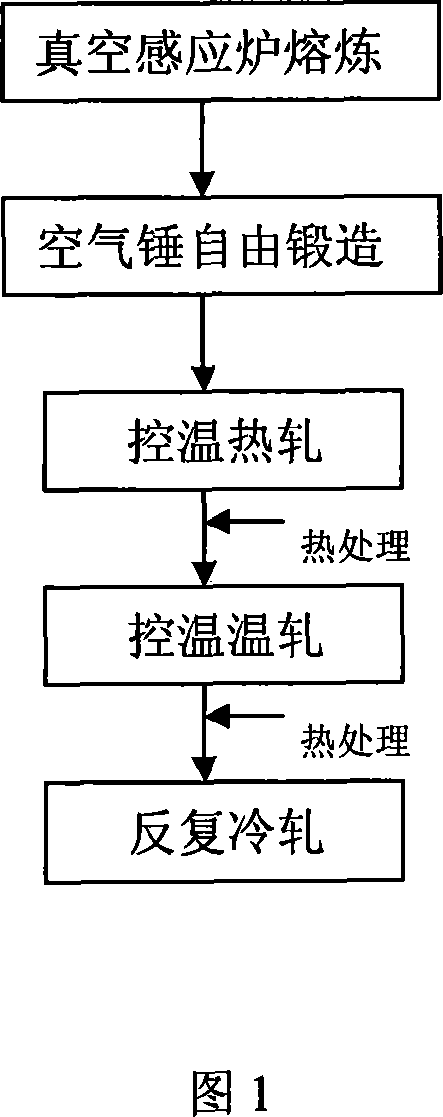

Preparation method for cold rolling sheet of duriron

InactiveCN101049669AWide applicabilityLow purityRoll force/gap control deviceTemperature control deviceAlloyThin sheet

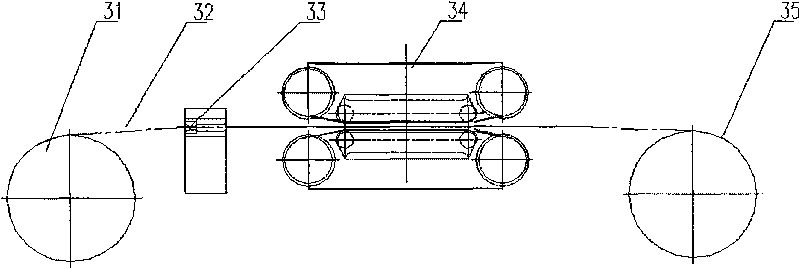

A cold rolling method for preparing high-Si steel sheet containing Fe (85-96 Wt%) and Si (4-15) includes such steps as providing raw material containing Si, B and Fe, smelting, casting, forging, hot rolling, warm rolling, heat treating and cold rolling.

Owner:UNIV OF SCI & TECH BEIJING

High precision spinning forming method for thin wall closing head with radius-thickness ratio less than three per mille

The invention relates to a thin-walled closure head high accuracy spinning forming method. The invention is to resolve the problem of big size closure head, thin wall thickness, high accuracy size and high difficulty of forming. Spinning machine is started to make rolling wheel do axial and circumferential movement along track loaded into program in head while spinning, meanwhile main axle of spinning machine drives core and bar plate to spin. When rolling wheel rolls to the distance of 20mm from edge it quits. The invention has the advantages of simple process and high accurate product.

Owner:HARBIN INST OF TECH

Method for preparing aluminum foil for lithium battery

ActiveCN105063429AImprove performanceUniform compositionMetal rolling arrangementsFiltrationAluminum foil

The invention relates to a method for preparing an aluminum foil for a lithium battery and belongs to the technical field of machining of aluminum alloy materials. The method for preparing the aluminum foil for the lithium battery includes the steps of performing smelting and cast rolling processes: heating and smelting raw materials of the aluminum foil for the lithium battery to form an aluminum alloy melt, sequentially carrying out refining slagging-off, grain refining, degassing deslagging and filtration treatment and subjecting the filtered aluminum alloy melt to continuous cast rolling to form a blank; performing a cold rolling process: subjecting the blank to cold rolling firstly and then to primary annealing treatment, rough rolling and secondary annealing treatment; performing foil pressing treatment: carrying out finish rolling on the annealed aluminum foil, and finally slitting the foil to obtain the aluminum foil finished product for a lithium battery finished product. According to the method for preparing the aluminum foil for the lithium battery, composition segregation in the process of alloy cast rolling is improved through added uniform annealing treatment; an original cast rolling structure is improved so that the product with uniform constituents and structure and stable performances can be obtained; moreover, the performances of the aluminum foil for the lithium battery can be improved.

Owner:浙江中金铝业有限公司

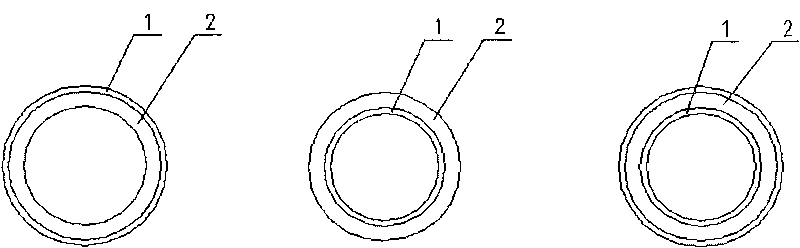

Method for manufacturing copper-aluminum composite tube

InactiveCN101737565AEffective combinationCombined with effective maintenanceRigid pipesSurface cleaningAluminum composites

The invention relates to a method for manufacturing a copper-aluminum composite tube, and belongs to the technical field of manufacturing a metal composite tube. The method is characterized by comprising the following steps: A, preparing an inner tube and a covering belt, B. performing surface cleaning on the inner tube and the covering belt, C. covering the covering belt after surface cleaning on the surface of the inner tube after surface cleaning, performing vertical covering welding to manufacture a copper-aluminum composite tube blank, D. performing linear drawing on the copper-aluminum composite tube blank without strain furling, E. final annealing, and F. winding and furling to manufacture a finished product and other processing steps. The method can be used for manufacturing a copper-clad aluminum tube, an aluminum-clad copper tube and the copper-aluminum composite tube of which an inner layer and an outer layer are copper and the middle part is aluminum; and firm metallurgical bonding can be achieved between the copper and the aluminum.

Owner:JIANGSU XINGRONG HI TECH

Method for producing wide-amplitude double-zero aluminum foil blank by adopting cast-rolled compact

InactiveCN102492900ASolve the problem of soft tensile propertiesImprove rolling effectMetallurgyCu element

The invention belongs to the technical field of aluminum alloy sheet strip foil material processing, and in particular relates to a method for producing a wide-amplitude double-zero aluminum foil blank by adopting a cast-rolled compact. By adjusting 8079, 1235 and other alloying components and adopting twice intermediate annealing processes, the non-uniform compound scale and distribution, caused by roll cooling intensity difference, of the wide-amplitude cast-rolled compact along the same board plane are eliminated, thus the pinhole degree and performances of the blank foil after rolling are superior to those of 1235; at the same time, through addition of Cu element, the problem of soft tensile property when the wide-amplitude blank is rolled to the double-zero foil after twice annealing is solved; and the rolling performance and foil rolling efficiency of the wide-amplitude blank are improved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD +1

Medical high-nitrogen nickel-free austenitic stainless steel material and production method thereof

ActiveCN102888566AImprove long-term use safetyImprove wear and corrosion resistanceProsthesisNickel freeWear resistance

The invention relates to a medical high-nitrogen nickel-free austenitic stainless steel material and a production method thereof. The material is a single-phase austenite structure and comprises the following components by weight percent: 15-18% of Cr, 10-16% of Mn, 1.5-2.5% of Mo, 0.4-0.7% of N, 0.02-0.08% of RE, less than or equal to 0.06% of unavoidable impurities and the balance of Fe. The material is free of toxic nickel, has good cytotoxicity and pyrogenic testing performances, excellent mechanical performance, higher abrasion resistance and good corrosion resistance, especially spot corrosion resistance and intergranular corrosion resistance.

Owner:CHONGQING MATERIALS RES INST

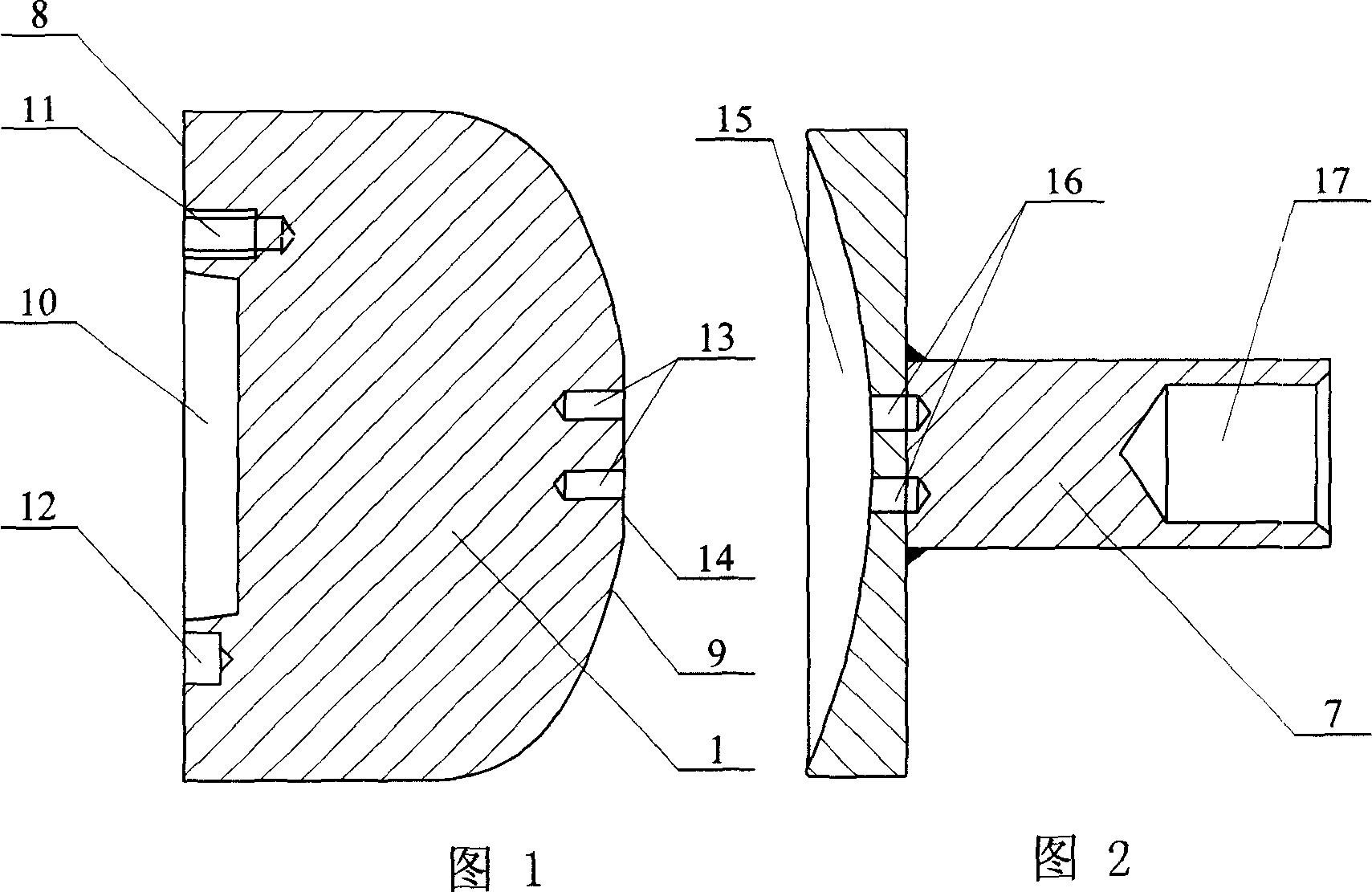

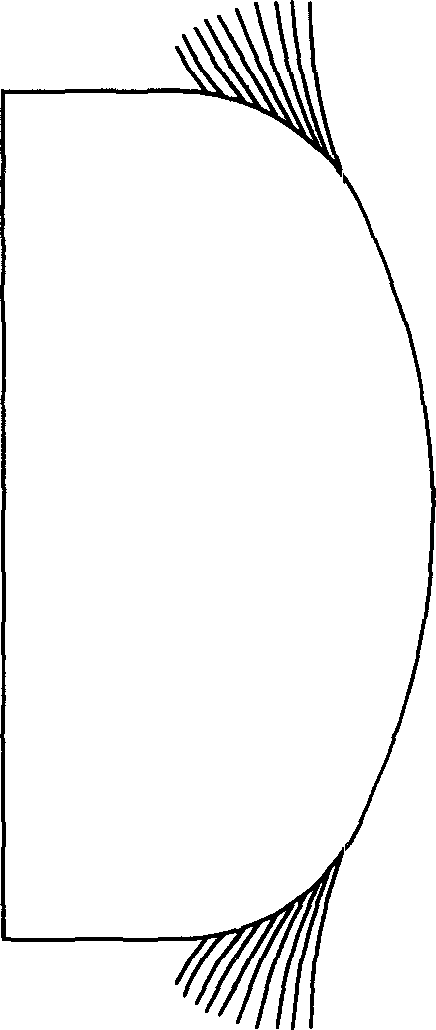

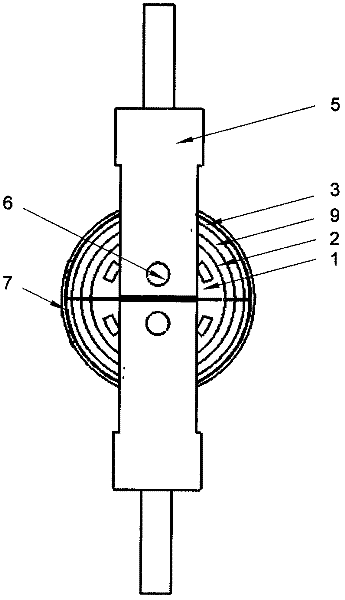

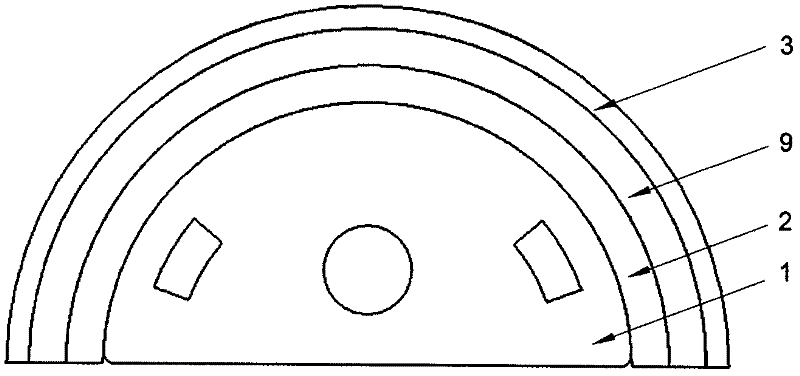

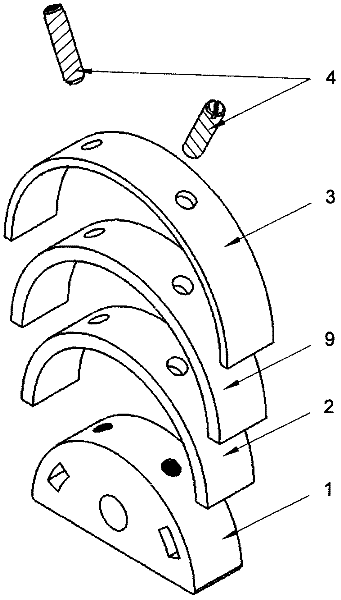

Clamp for testing annular tensile property of tubular product

ActiveCN102445384AShape unchangedEliminate the effects of elastic deformationStrength propertiesEngineering

The invention discloses a clamp for testing the annular tensile property of a tubular product. An inner liner ring, a middle layer liner ring and an outer liner ring are formed by folding two semicircular rings of the same diameter respectively; the inner liner ring, the middle layer liner ring and the outer liner ring are embedded in sequence, so that a liner ring body is formed; a first inner insert and a second inner insert are semicircles of the same diameter, and are folded to form a circular block; the liner ring body is sleeved on the first inner insert and the second inner insert; a tubular product sample is sleeved on the outer surface of the liner ring body; and the liner ring body on which the tubular product sample is sleeved is embedded into a first fixture block and a secondfixture block. The clamp has a compact structure and is convenient to replaced; components are connected tightly; and measurement of the annular tensile properties of tubular products of various specifications can be realized on an ordinary material tester. Testing of the annular tensile properties of tubular products of which the inner diameters are 60-150 millimeters can be met by only changingthe combination way of the inner inserts and the liner rings, high generality is realized, the testing cost is reduced, and accurate measurement of the annular tensile properties of tubular products is realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

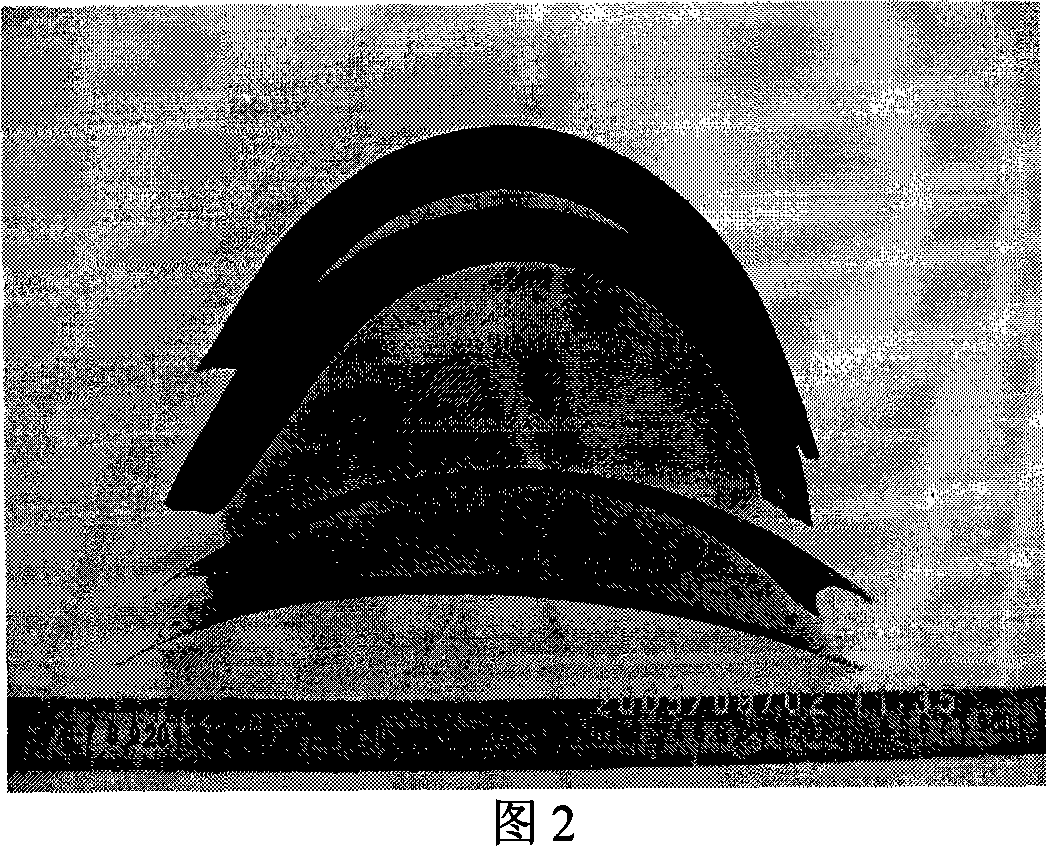

Deep overcooling treatment method for fine grain copper alloy shaped charge liner

The invention provides a preparation method of a fine grain copper alloy shaped charge liner. The preparation method of the fine grain copper alloy shaped charge liner comprises the following steps: carrying out compound cold extrusion plastic deformation, carrying out deep overcooling treatment, and carrying out recrystalization annealing, wherein the compound cold extrusion plastic deformation comprises the steps of putting a blank into a mould cavity of a preformed blank forming mould, carrying out forward extrusion forming to obtain a designed copper alloy preformed blank under the actions of three-dimensional compressive stress and deformation rate and then putting the preformed blank into a mould cavity of a shaped charge liner forming mould and gradually forming the shaped charge liner preformed blank by carrying out gradual-pass diameter-expanded extrusion plastic deformation, thus obtaining the shaped charge liner blank of a required shape structure; the deep overcooling treatment comprises the step of carrying out heat preservation on the shaped charged liner blank for 2-4 hours at the temperature ranging from -196 DEG C to 130 DEG C; and the recrystallization annealing comprises the step of carrying out heat preservation on the shaped charge liner (subjected to deep overcooling treatment) for 5-15 minutes at the temperature of 450-550 DEG C in a protective atmosphere, thus obtaining a shaped charge liner component. The preparation method of the fine grain copper alloy shaped charge liner has the advantages that strict requirements of the shaped charge liner on grain structure homogeneity, consistency of performance and stress state and distribution can be met, and quality of the shaped charge liner can be improved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

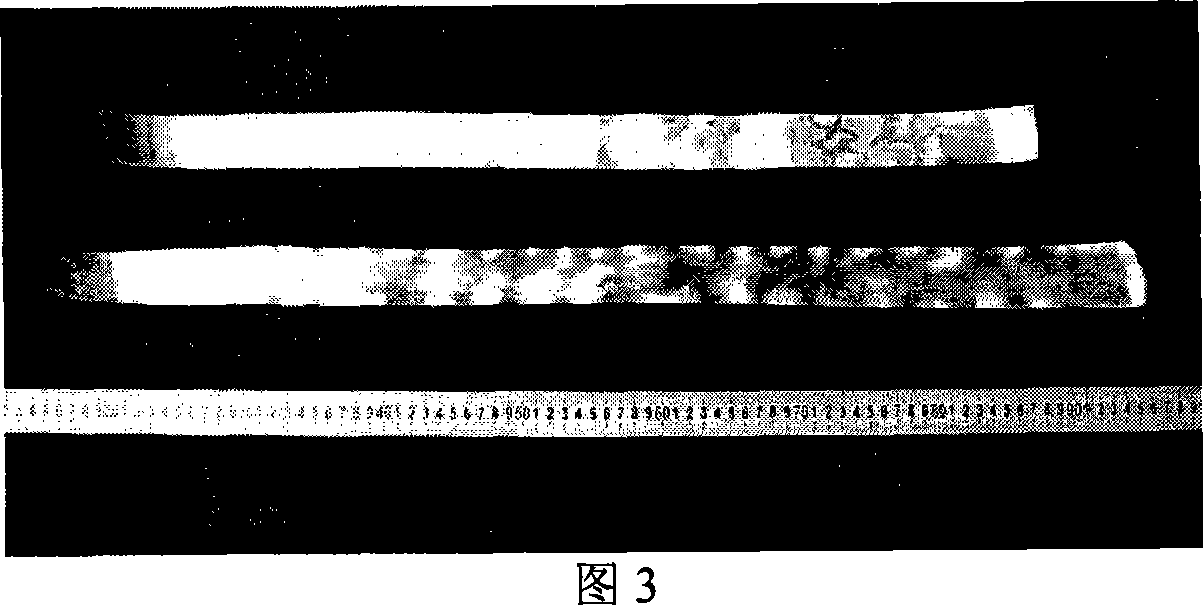

Method for preparing molybdenum-rhenium alloy foil

The invention discloses a method for preparing a molybdenum-rhenium alloy foil, and particularly relates to a technology for preparing the foil with thickness less than 0.1mm. The method comprises the following steps of preparing molybdenum-rhenium alloy powder; mould-pressing the molybdenum-rhenium alloy powder so as to obtain a pressed shape; sintering the pressed shape so as to obtain a sintered base; sequentially carrying out hot rolling, warm rolling and cold rolling on the sintered base so as to obtain the molybdenum-rhenium alloy foil with required thickness. The method is applicable to industrial mass production, has high production efficiency, and can also be used for preparing different thicknesses of molybdenum-rhenium sheets according to market requirement.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Preparation method for high-strength, high-plasticity and high-precision beta titanium alloy pipe

The invention discloses a preparation method for a high-strength, high-plasticity and high-precision beta titanium alloy pipe. The preparation method comprises the steps that firstly, raw materials are mixed and pressed into electrode blocks, the electrode blocks are welded into an electrode, and the electrode is smelted into a beta titanium alloy ingot; secondly, the beta titanium alloy ingot issubjected to beta phase region cogging forging and thus a square billet is formed, after upsetting and drawing are conducted for three or more times, rounding is conducted and thus a bar billet is formed, and the bar billet is machined into an extruded pipe billet; thirdly, the extruded pipe billet is extruded and then subjected to solution treatment, cogging rolling and finish rolling are conducted, and thus a semi-finished beta titanium alloy pipe is obtained; and fourthly, the semi-finished beta titanium alloy pipe in the third step is subjected to solution treatment and aging treatment, then precision machining is conducted, and thus the beta titanium alloy pipe is obtained. The beta titanium alloy pipe prepared through the preparation method is uniform in alloy structure, fine in grain size, uniform in wall thickness and good in straightness, and the results of the mechanical properties of the beta titanium alloy pipe show that the beta titanium alloy pipe has high strength and high plasticity and meanwhile also has better size precision.

Owner:西安秦钛智造科技有限公司

Continuous stainless steel strip production method

ActiveCN106244783AQuality improvementThe process steps are simpleFurnace typesHeat treatment furnacesStrip steelPlastic property

The invention discloses a continuous stainless steel strip production method. According to the continuous stainless steel strip production method, continuous uncoiling, straightening and welding are conducted on a hot rolled steel roll which is not subjected to annealing and acid pickling; then, cold rolling, annealing and rust removal are conducted; and finally, flattening and coiling are conducted. Compared with an existing method, the continuous stainless steel strip production method is simple in process step, the production cost is effectively reduced, a crystalline phase tissue, produced during rolling and damaged by plastic deformation, of a steel strip can be effectively repaired, the crystal lattice tissue is refined, the grain size of materials is controlled, the rolling deformation stress is eliminated, plasticity of the steel strip is increased, and the surface of the steel strip is brighter and straighter.

Owner:WUHAN QIAN YE ENG TECH CO LTD

Processing, formation and manufacturing method of piston rod using 38CrMoAlA steel as materials

InactiveCN102534392AReduce contentHigh purityProcess efficiency improvementPiston rodsHardnessHigh pressure

The invention discloses a processing, formation and manufacturing method of a piston rod using 38CrMoAlA steel as a material, which belongs to the technical field of powder metallurgy. A gear is realized through the following work procedures of baiting, powder metallurgical blank manufacture, annealing, tongs center emptying, rough turning, tempering, fine turning, center hole accurate grinding, hexagon milling and nitriding treatment. The piston rod manufactured by the manufacture method does not deform at high temperature and high pressure, the surface hardness is high, the abrasion performance is good, the bending resistance capability is high, the fatigue strength is high, in addition, the center roughness is good, the service life is long, the work reliability is high, and because blanks are manufactured by the powder metallurgy, the high-temperature resistance is good.

Owner:无锡市万邦机械制造厂

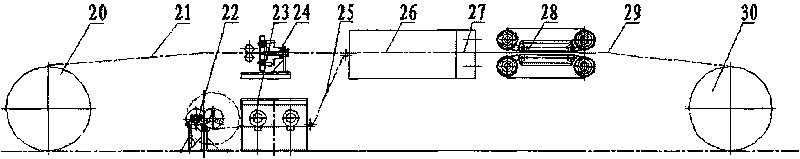

Production technology of copper-clad steel wire in soft state

ActiveCN102254629AAvoid crackingGuaranteed elongationCommunication cablesManufacturing extensible conductors/cablesElectricityElectrolysis

The invention relates to a production technology of a copper-clad steel wire in a soft state. The production technology successively comprises the following steps: drawing; tempering under high temperature; carrying out electro-deposition pretreatment; carrying out acid electrolysis; washing; carrying out pretreatment of electro-deposition; washing; carrying out electrodeposition thick treatment; washing; carrying out anti-oxidation processing; drying; drawing; washing; carrying out anti-oxidation processing; tempering under high temperature; polishing; carrying out anti-oxidation processing; and spooling to obtain a finished product. An advantage of the production technology of the copper-clad steel wire in the soft state is that an elongation rate of the produced copper-clad steel wire is greater than or equal to 8%, wherein the elongation rate, which is compared with an elongation rate of a copper-clad steel wire produced by a traditional tempering technology, can be enhanced by at least more than one time..

Owner:ZHEJIANG PUJIANG BAICHUAN IND

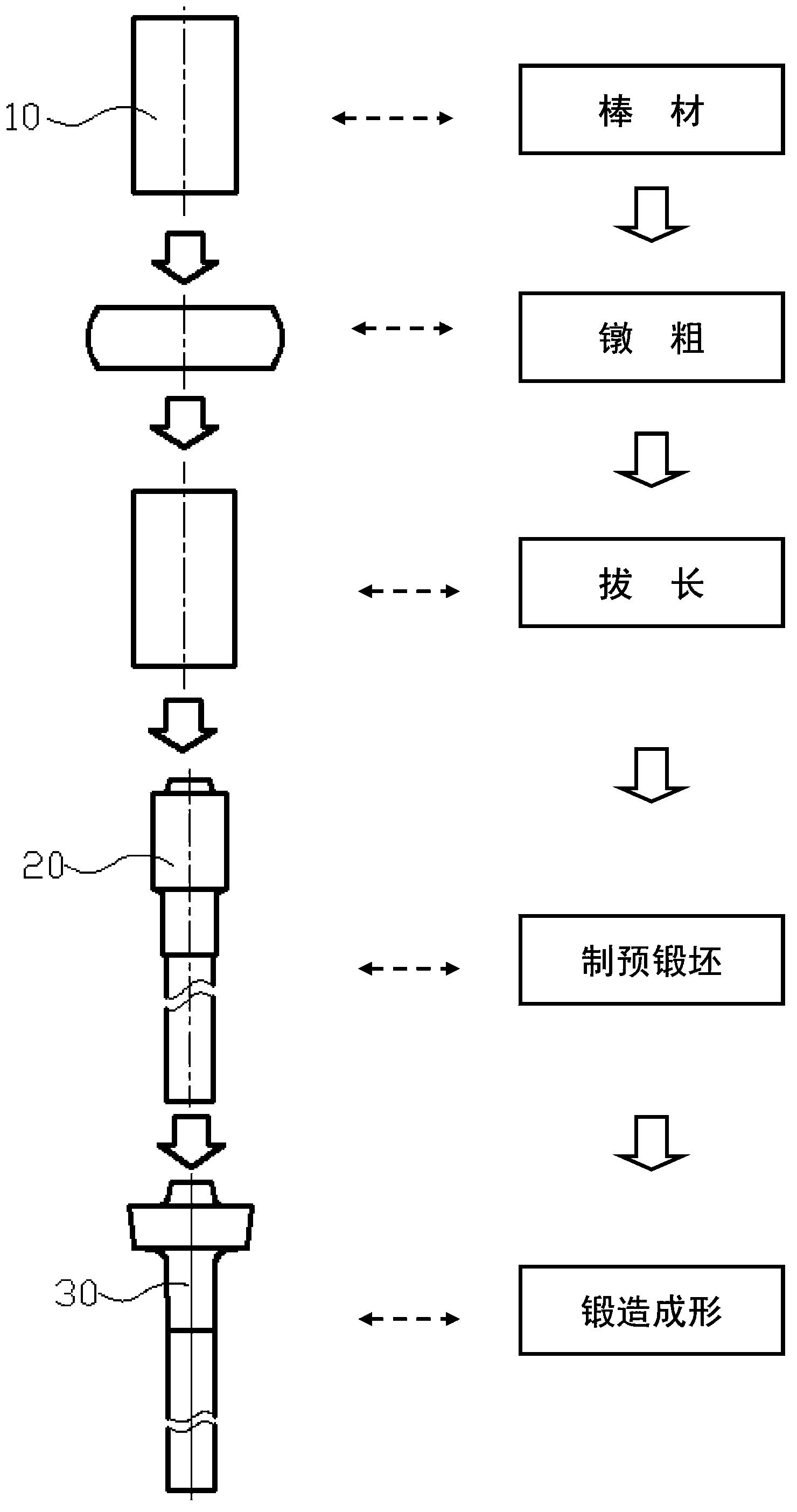

Forging forming method of low-pressure turbine shaft made of C250 maraging steel

The method discloses a forging forming method of a low-pressure turbine shaft made of C250 maraging steel, which is provided for obtaining a forging with a better structure and a better property. The method comprises processing steps as follows: a C250 maraging steel bar material which is subjected to blanking according to specification is heated to a forging temperature ranging from 990 DEG C to 1,040 DEG C, heated to the forming temperature again after upset and stretched, and prepared into a pre-forged blank in a forging die; the pre-forged blank is forged into a low-pressure turbine shaft forging at a strain rate of 0.015s<-1>-0.0015s<-1> in the forging die after heated to a forging temperature ranging from 1,020 DEG C to 1,060 DEG C; and the low-pressure turbine shaft forging is subjected to solid solution and aging heat treatment after forged, the solid solution is that the low-pressure turbine shaft forging is heated to 825 DEG C and is subjected to air cooling after heat insulation, and the aging is that the low-pressure turbine shaft forging is heated to 485 DEG C and is subjected to air cooling after heat insulation. The forging is mainly used for being prepared into a low-pressure turbine shaft part of an aero-engine.

Owner:GUIZHOU ANDA AVIATION FORGING

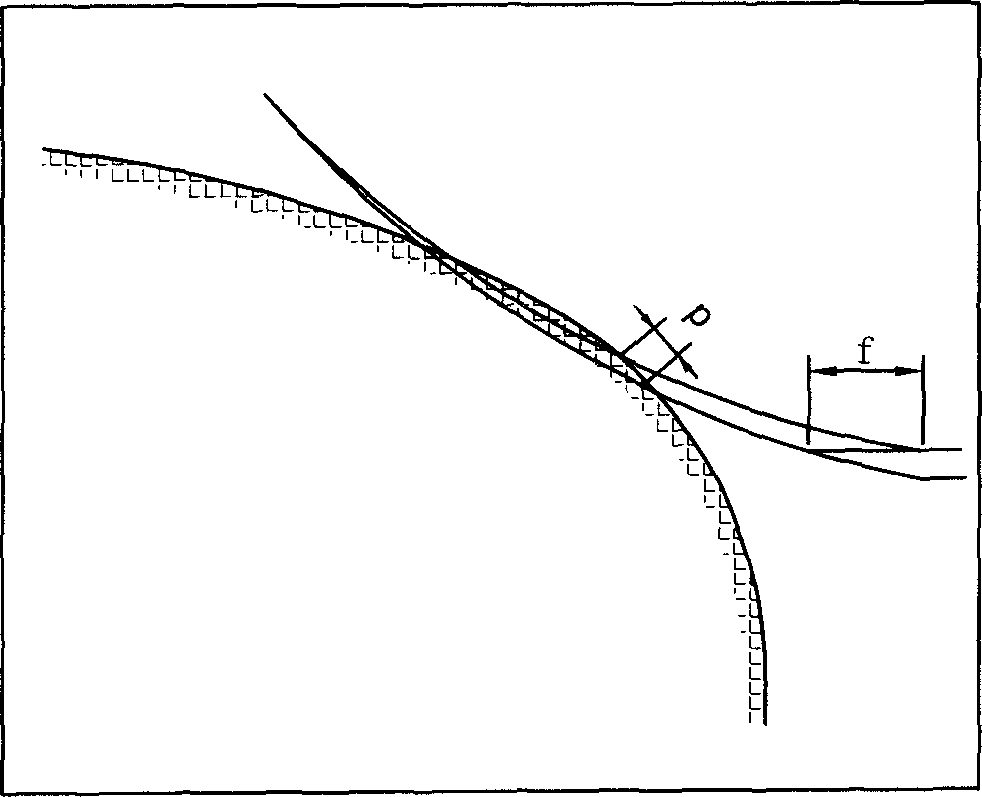

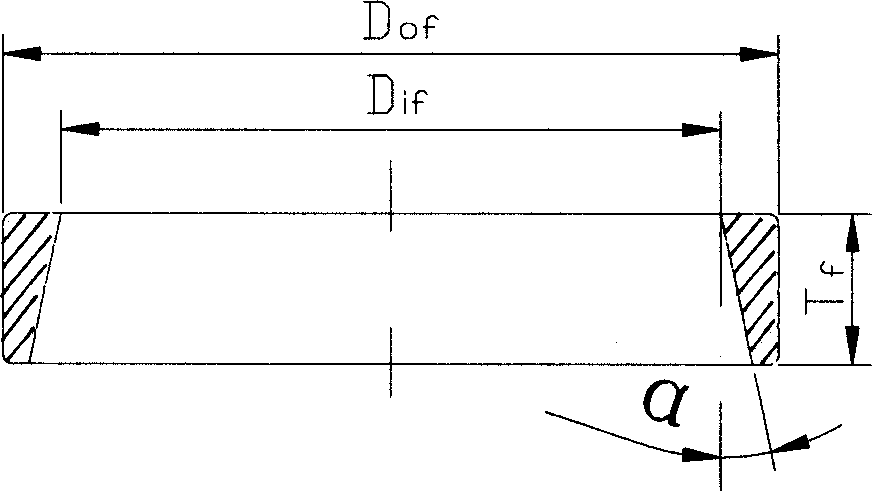

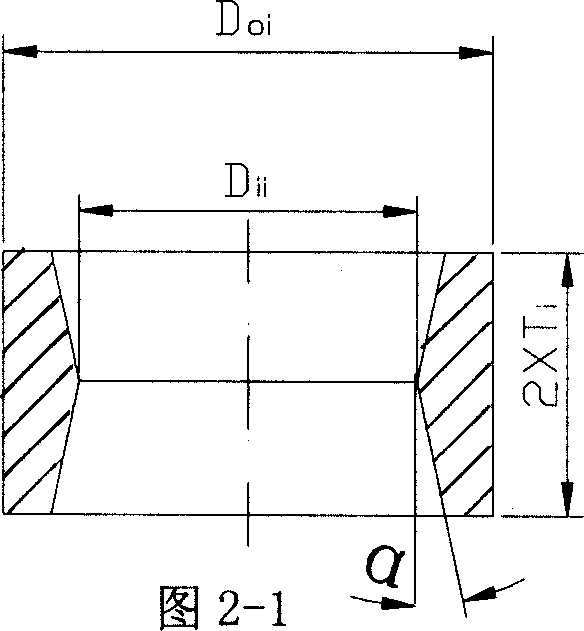

Method for forming two conical sestion ring pieces by once cold rolling spreading

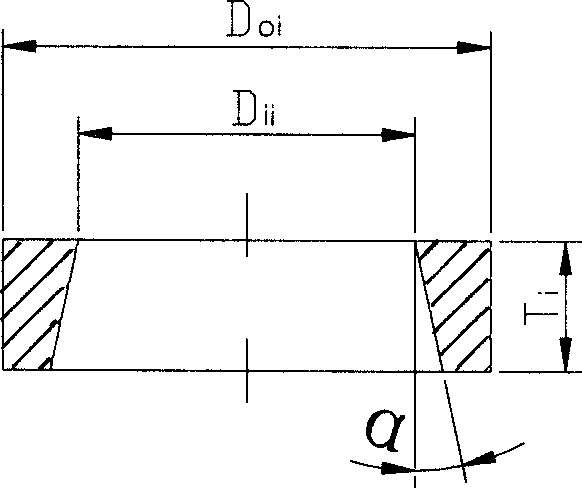

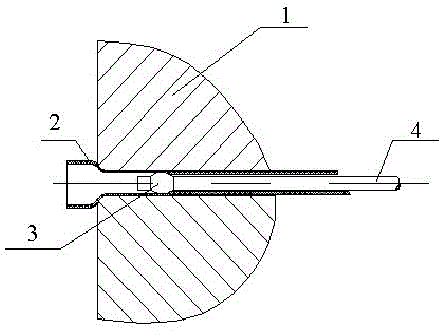

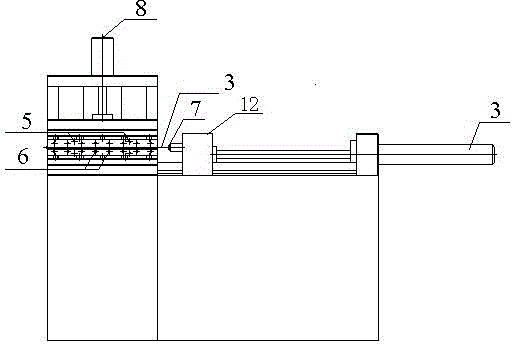

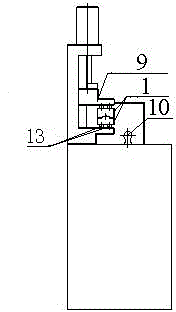

InactiveCN1748898AGood physical and mechanical propertiesIncrease productivityMetal-working feeding devicesOther manufacturing equipments/toolsHeat deflection temperatureMechanical engineering

The present invention relates to method of forming conic cross section ring and has two technological schemes adopted, including integral rolling and spreading and split rolling and spreading. The present invention features that the cold rolling and spreading process includes the following steps: cutting rod into material sections; heating the material section to heat deformation temperature, upsetting, punching hole and punching connecting sheet to form integral blank; annealing; coarse turning to form integral blank for rolling and spreading; cold rolling and spreading in a rolling and spreading machine with V-slot core roller to form two conic rings; and turning to obtain two conic cross section rings. The present invention has the features of low cost, high production efficiency and high product quality.

Owner:WUHAN UNIV OF TECH

Method for preparing metal thin-wall microtubes

InactiveCN103331582AAvoid the possibility of breakingReduced tensile stress zoneShaping toolsUltra fineMetal

The invention discloses a method for preparing metal thin-wall microtubes. The method includes the steps of material pretreatment, blank manufacture and female die stretching. Tube blanks are fixed in a female die, the tube walls are extruded by a die core which moves on the inner sides of the tube blanks, so that the purpose of reducing the thickness of the tube walls is reduced. The wall thickness of the tube blanks can be continuously thinned by replacing the die core, and then the metal tubes with the thin walls are prepared. The method of severe plastic deformation is adopted to treat materials, so that ultra-fine grained microscopic structures are acquired, and then the deformability of the materials is improved. On the basis, a novel female die stretching technology is adopted, namely the tube blanks are placed in the female die, the overall dimension of the tube blanks is limited, and the die core moves inside the tube blanks, so that the wall thickness of the tube blanks is reduced and generally reaches the needed dimension, then tube stocks are straightened, polished, and eventually finished products are acquired. The method for preparing the metal thin-wall microtubes has the advantages of being high in machining accuracy and yield.

Owner:YANGZHOU UNIV

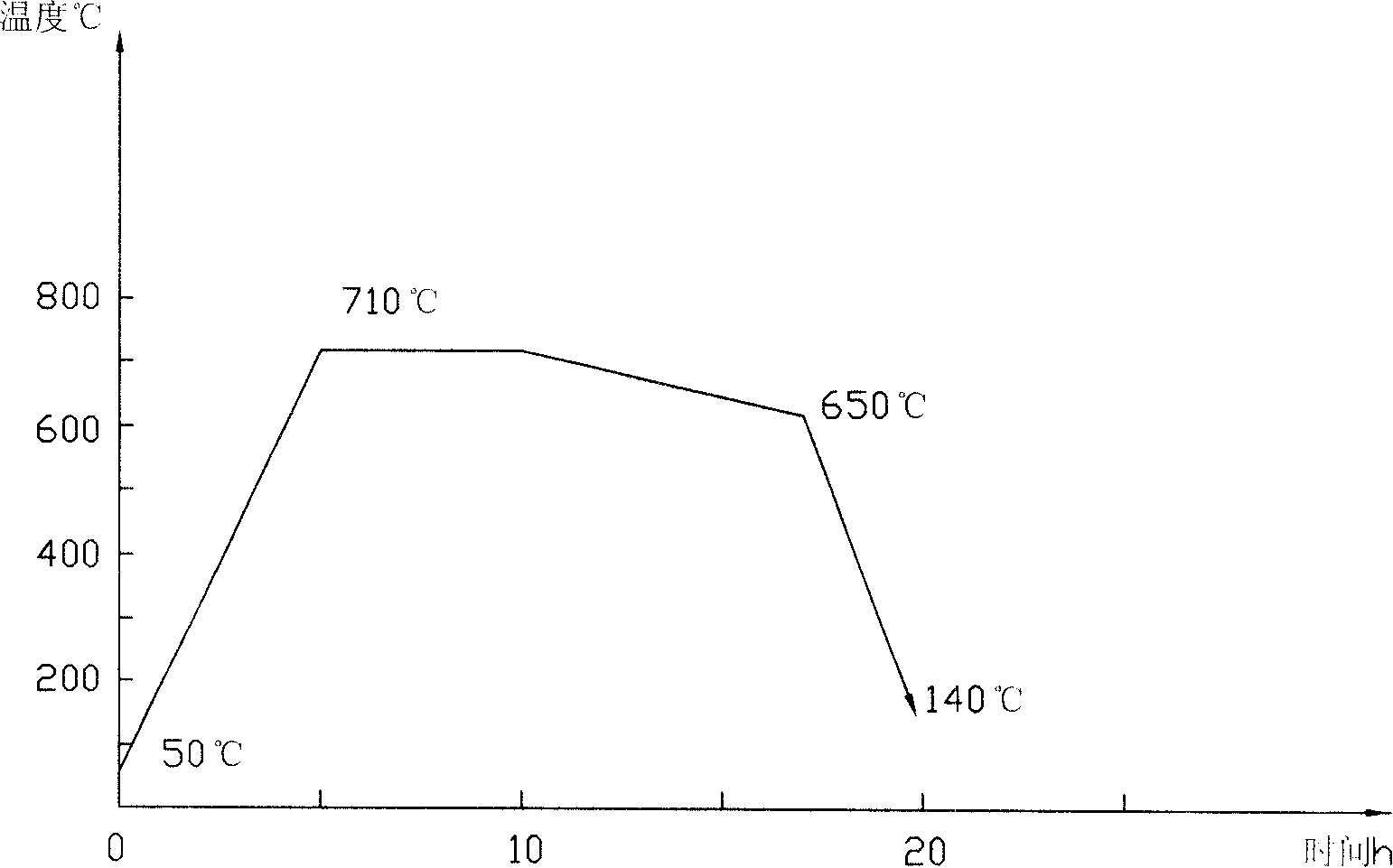

Annealing method for high-speed steel cold-drawing wire products

InactiveCN101205590AEliminate work hardeningImprove uniformityFurnace typesHeat treatment process controlWire rodNitrogen

The invention discloses annealing method for high speed tool steel cold drawn steel wire finished products, solving the problems of low annealing efficiency, large energy consumption, etc. The mass percentage compositions of a high speed tool steel cold drawn steel wire rod are: 0.80 to 0.90 percent by mass of C, less than or equal to 0.40 percent by mass of Mn, less than or equal to 0.40 percent by mass of Si, 3.80 to 4.40 percent by mass of Cr, 1.75 to 2.20 percent by mass of V, 5.50 to 6.75 percent by mass of W, 4.50 to 5.50 percent by mass of Mo, less than or equal to 0.030 percent by mass of P, less than or equal to 0.030 percent by mass of S, and the balance Fe. The method comprises the following steps of: 1) annealing of finished product, in which the rod is placed into a strong-convection annealing furnace, a heating mantle is cover on the furnace, and then nitrogen purging is carried out to replace the air in the furnace with nitrogen which is used for atmosphere protection during the annealing process; 2) heating the product with the furnace to a temperature of between 710 and 750 DEG C and keeping the temperature for 4 to 8 hours, covering the heating mantle, and then cooling down the furnace to a temperature below 650 DEG C, at a cooling speed less than or equal to 30 DEG C per hour, and removing the heating mantle; 4) covering a cooling mantle to cool down the product to a temperature below 140 DEGC at a cooling speed more than 100 DEG C per hour. The invention is high in annealing efficiency, thereby greatly reducing the energy consumption.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Copper belt production technology for new energy automobile connector

ActiveCN105420647AAvoid the phenomenon of rolling partsEasy to set upWork cooling devicesMetal rolling arrangementsNew energyEngineering

The invention discloses a copper belt production technology for a new energy automobile connector, and belongs to the technical field of the copper plate belt production technology. The technology comprises the first step of cast ingot smelting, the second step of face milling, the third step of hot rolling, the fourth step of rough rolling, the fifth step of one-time annealing, the sixth step of one-time cleaning, the seventh step of intermediate rolling, the eighth step of two-time annealing, the ninth step of two-time cleaning, the tenth step of intermediate rolling, the eleventh step of three-time annealing, the twelfth step of three-time cleaning, the thirteenth step of finish rolling, the fourteenth step of four-time cleaning and the fifteenth step of leveling, wherein in the fourth step of rough rolling, after rough rolling, the regulated thickness of a belt roll is 2.5 mm. By means of the technical scheme, the copper belt annealing technology quality and the copper belt surface quality can be improved, and therefore the workshop cost can be reduced, and the productive profit can be increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

Manufacturing method of aluminum alloy plate for high-strength thinning and drawing

ActiveCN108220692AIncrease profitControllable surface roughnessJackets/cases materialsSlagRaw material

The invention belongs to the technical field of aluminum alloy plate strip foil machining, and particularly relates to a manufacturing method for producing an aluminum alloy plate for high-strength thinning and drawing by adopting a cast-rolled blank. The manufacturing method of the aluminum alloy plate for high-strength thinning and drawing comprises the following specific steps of preparing an aluminum alloy with an industrial aluminum ingot, a Fe agent, a Si agent, a copper agent, a magnesium ingot and the like as raw materials, the aluminum alloy is subjected to smelting, refining and standing, and titanium wires are added, and then the aluminum alloy is subjected to cast rolling after online slag removal and degassing and is machined into a cast-rolled plate blank roll; and homogenizing annealing is carried out during cold rolling machining of the plate blank roll, annealing is carried out in a nitrogen annealing furnace, then intermediate annealing is carried out on the rolled material, and finally a finished product with the thickness of 0.5 mm is obtained through cold rolling. According to the manufacturing method of the aluminum alloy plate for high-strength thinning and drawing, the manufactured aluminum alloy plate is high in tensile strength, low in lug-making rate and controllable in surface roughness, good deep punching and thinning performance is met, and meanwhile, the utilization rate of the material is improved; and compared with existing common hot-rolled plates, the plate produced though the cast-rolled blank is capable of reducing the cost by about 20%and has a wide application prospect.

Owner:JIANGSU UNIV

Small-size LED copper strip production process

The invention discloses a small-size LED copper strip production process, and belongs to the technical field of the copper strip production process. The production process includes the following stepsof (1) smelting and ingot casting, (2) hot rolling, (3) milling, (4) rough rolling, (5) first annealing, (6) one-step cleaning, (7) intermediate rolling, (8) secondary annealing, (9) secondary cleaning, (10) intermediate finish rolling, (11) third annealing, (12) third cleaning, (13) finish rolling, (14) unwinding, (15) fourth annealing, (16) fourth cleaning, (17) refine rolling, (18) fifth cleaning, (19) flattening and (20) cutting and delivery. According to the technical scheme, the quality of small-size LED copper strips can be improved, the workshop cost is reduced, and the production profits are increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

Forging process for preparing isotropic ultrahigh-strength heat-resistant magnesium alloy structural member

The invention discloses a forging process for preparing an isotropic ultrahigh-strength heat-resistant magnesium alloy structural member. Firstly, a cast ingot prepared through semi-continuous electromagnetic casting is subjected to homogenizing annealing, an ingot blank is formed through machining, the height direction of the cylindrical ingot blank and any two mutually perpendicular radial directions are used as the Z direction, the Y direction and the X direction correspondingly, 3-6 passes of heading are performed in the Z direction, the Y direction and the X direction, and the pass deformation amount is 20-40%; then the X direction or the Y direction is used as the axis, 2-6 passes of corner angle rolling compressing are performed, the pass deformation amount is 10-20%, intermediate annealing is performed, and the forging process is performed repeatedly once or twice; a forge piece is subjected to T6 treatment after forging is finished, and a final forge piece with the diameter being 450-650 mm and the height being 300-700 mm is obtained; as for both the height direction and the radial directions of the T6 state at the room temperature, the tensile strength is larger than or equal to 460 MPa, the yield strength is larger than or equal to 400 MPa, the ductility is larger than or equal to 4%, and the strength difference between the height direction and the radial directions is smaller than or equal to 10 MPa, and the ductility difference between the height direction and the radial direction is smaller than or equal to 0.5%; and as for both the height direction and the radial directions at the temperature of 200 DEG C, the tensile strength is larger than or equal to 350 MPa, and the ductility is larger than or equal to 6%.

Owner:CENT SOUTH UNIV

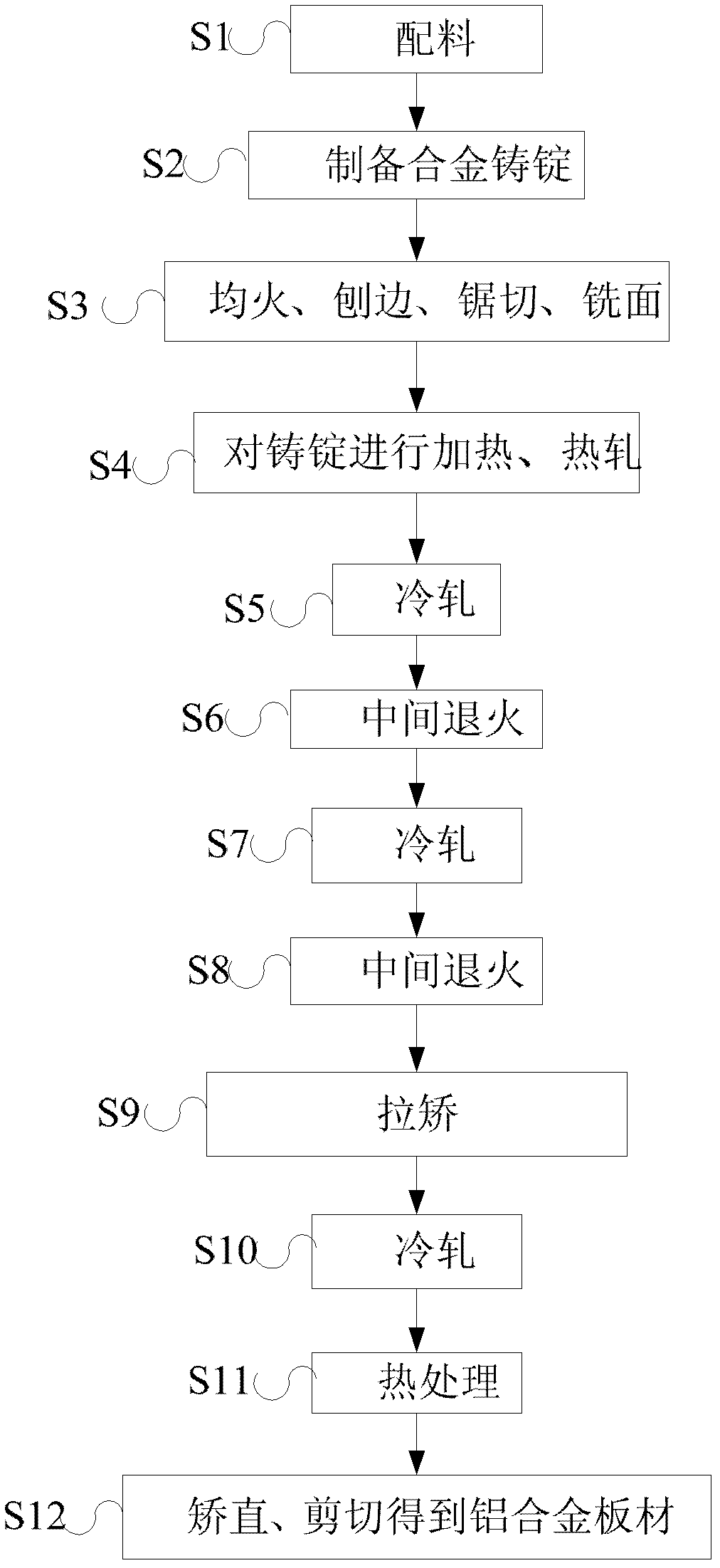

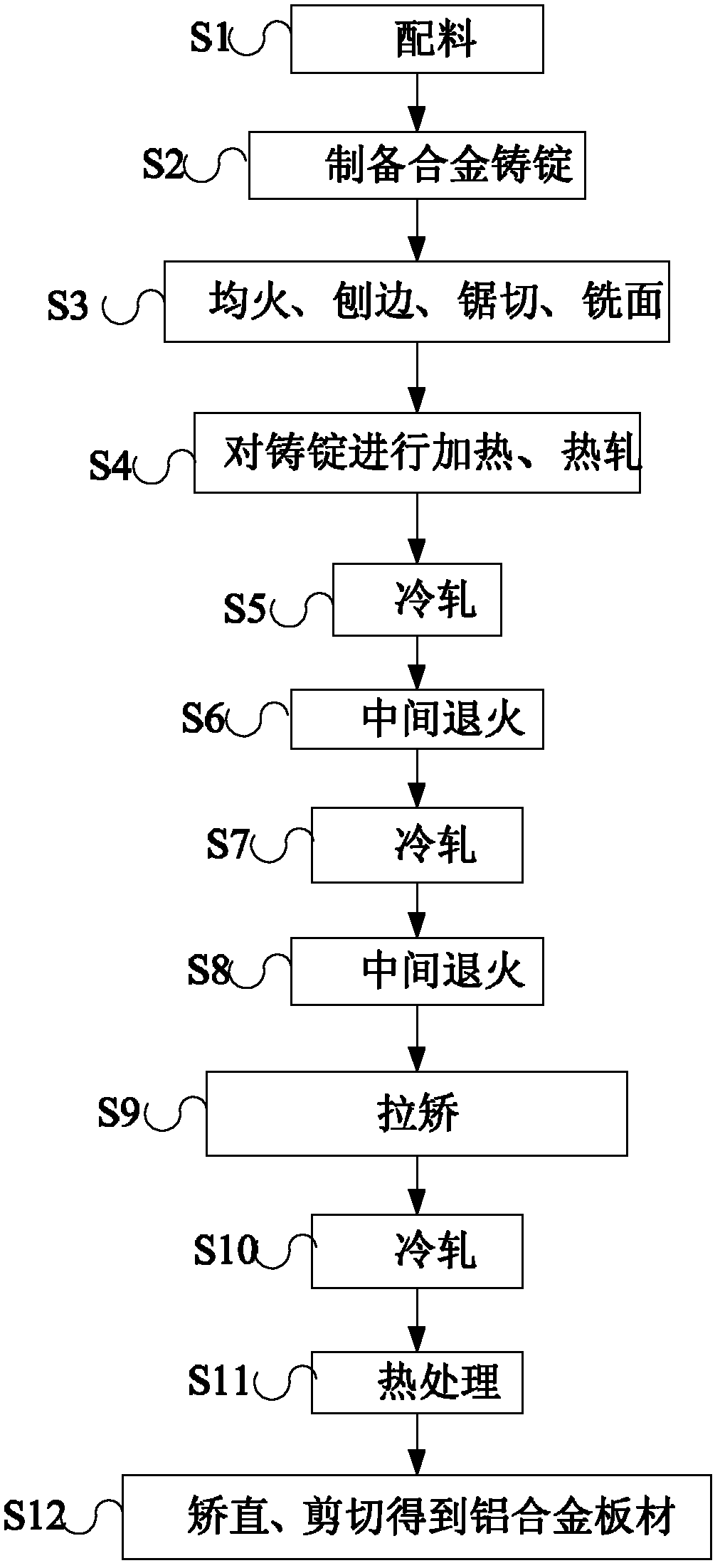

Method for producing aluminum alloy plate

The invention discloses a method for producing an aluminum alloy plate. The method comprises the following steps of: preparing materials: uniformly mixing 0.4% of Si, 0.6% of Fe, 4% of Cu, 0.1% of Mn, 0.22% of Cr, 0.06% of Ti, 2% of Mg, 0.2% of Zn and the balance of Al; processing the prepared materials into a cast alloy ingot; heating and hot-rolling the cast alloy ingot to obtain a blank; cold-rolling the blank; carrying out intermediate annealing; cold-rolling; carrying out intermediate annealing; drawing and straightening; cold-rolling; thermally treating; and straightening and sharing to obtain the aluminum alloy plate with the preset thickness. According to the invention, a cold-rolling process is carried out in two steps, the intermediate annealing is carried out after the cold-rolling so as to eliminate work hardening and recover metal plasticity, and finally, the thermal treatment is carried out to increase the performance of the aluminum alloy plate to meet a requirement so as to obtain the qualified aluminum alloy plate, so that the finished product rate of the aluminum alloy plate is increased.

Owner:SOUTHWEST ALUMINUM GRP

Method for manufacturing high-silicon steel sheet containing novel composite inhibitors

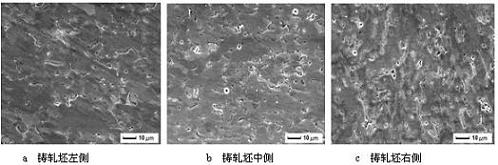

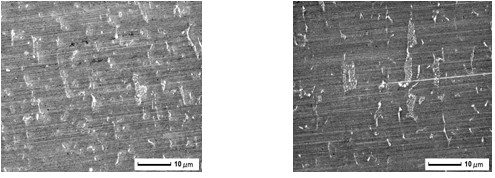

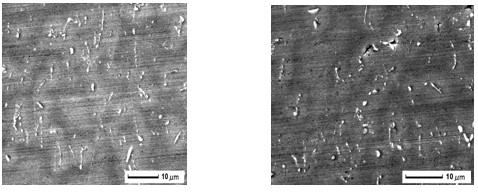

The invention discloses a method for manufacturing a high-silicon steel sheet containing novel composite inhibitors, and belongs to the field of metal materials. High-silicon steel comprises (by wt%) from 4.5 to 7.0 of Si, from 0.05 to 0.9 of Nb, from 0.05 to 0.3 of B, from 0.01 to 0.05 of Mn, from 0.010 to 0.020 of S, from 0.010 to 0.020 of P, from 0.020 to 0.040 of C, from 0.003 to 0.020 of Al and the balance Fe and inevitable impurities. The method mainly includes adding proper quantities of Nb and B elements to be used as the composite inhibitors for thinning as-cast grains in a vacuum melting stage; then forging to form a sheet blank; carrying out hot rolling for the sheet blank until the thickness of the sheet blank ranges from 1.0mm to 4.0mm; carrying out diffusion annealing for the sheet blank; then carrying out warm-rolling for the sheet blank for 5 to 30 minutes to obtain a sheet with the thickness ranging from 0.2mm to 0.8mm; carrying out heat treatment for the sheet at the temperature ranging from 500 DEG C to 800 DEG C; and carrying out cold rolling to obtain the high-silicon steel sheet with the thickness ranging from 0.05mm to 0.6mm. The Nb and B elements are added to form the inhibitors capable of obviously suppressing the grains from growing in various stages, so that room-temperature brittleness of the high-silicon steel sheet is improved, and cold rolling yield of the high-silicon steel sheet is increased. In addition, productivity is increased on the basis of improving plasticity of materials by the quick heat treatment after the warm-rolling, and the high-silicon steel sheet is finally manufactured by the cold rolling. Besides, the manufactured cold-rolled sheet is excellent in surface quality and good in shape.

Owner:UNIV OF SCI & TECH BEIJING

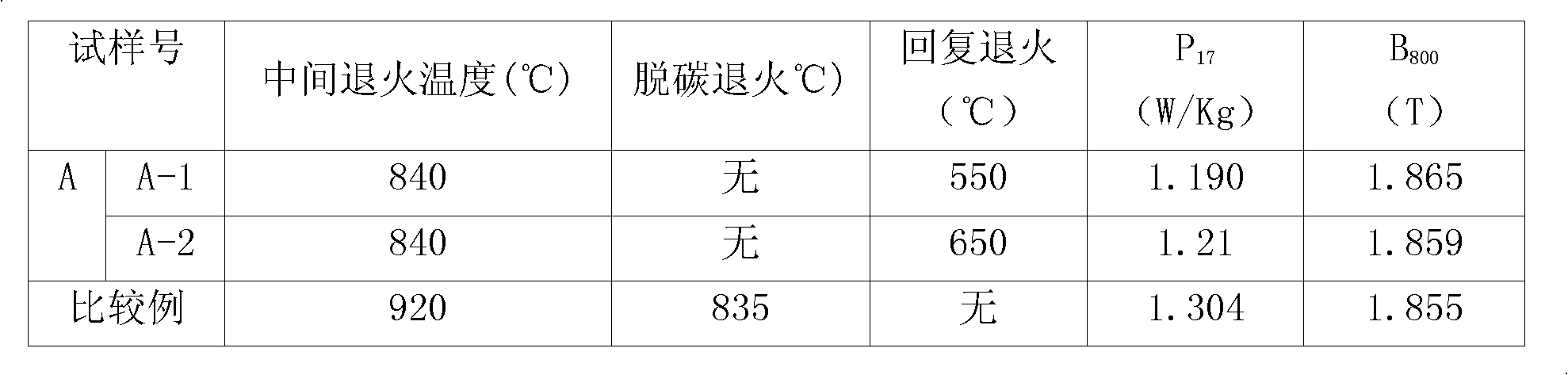

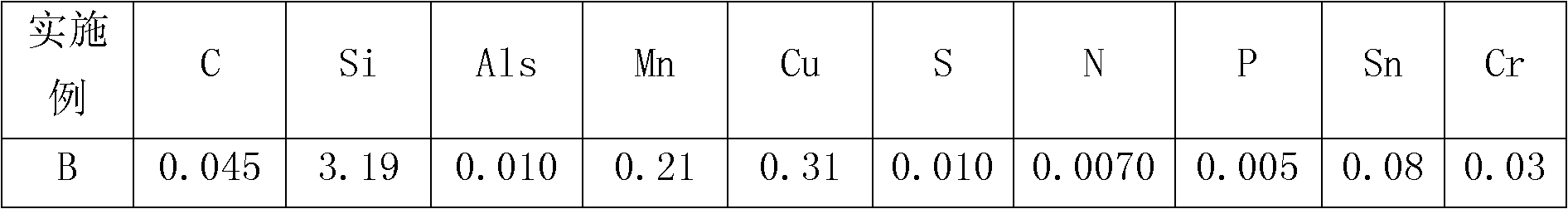

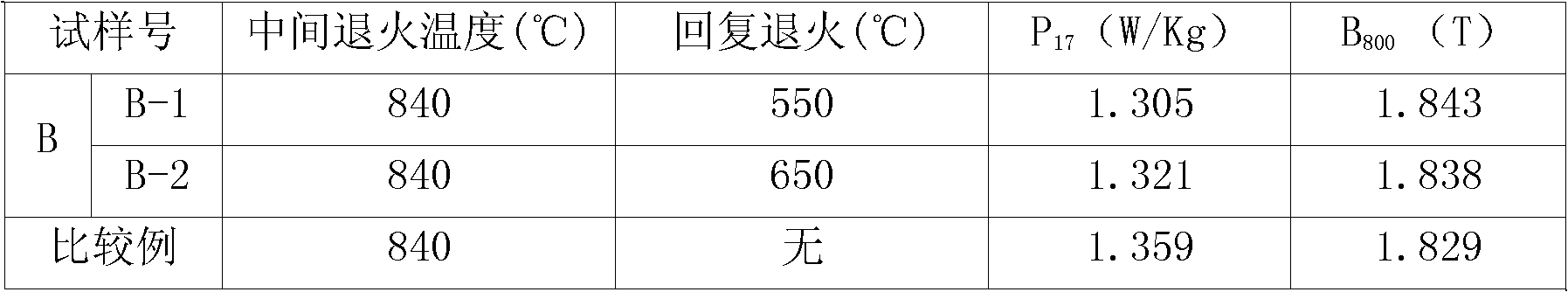

Low-temperature heating oriented electrical steel with good surface coating and production method thereof

InactiveCN102127716AEliminate work hardeningEliminate magnetic agingTemperature control deviceElectrical steelProduct gas

The invention relates to a low-temperature heating oriented electrical steel with good surface coating and a production method thereof, belonging to the technical field of oriented electrical steels. A casting blank comprises the following components: 0.005-0.08wt% of C, 2.5-6.5wt% of Si, 0.005-0.03wt% of Als, 0.001-0.4wt% of Mn, 0.01-0.3wt% of Cu, 0.003-0.010wt% of N, 0.001-0.03wt% of S, 0.01-0.3wt% of Sn, 0.001-0.1wt% of Cr, less than or equal to 0.02wt% of P and the balance of Fe and inevitable impurities. The casting blank is heated to 1150-1300 DEG C and then is subjected to hot rolling, a hot rolled plate is subjected to acid pickling, two-step cold rolling containing intermediate annealing is carried out until the thickness of a finished product is achieved, the intermediate annealing is carried out at the temperature of 750-850 DEG C, the heat preservation is carried out 3-6 minutes, and the furnace atmosphere is mixed gas of wet H2 and N2. The invention has the advantages that an auxiliary inhibitor is added, the intermediate annealing process is improved, and the short-time low temperature recovery annealing is carried out after cold rolling, thus the intermediate full-decarbonizing annealing time is reduced, the production efficiency is improved, and the quality of the surface coating is improved.

Owner:SHOUGANG CORPORATION

Production technology of copper strip for automobile contact

The invention discloses a production technology of a copper strip for an automobile contact and belongs to the technical field of copper plate and strip production technologies. The production technology comprises 1, ingot melting casting, 2, surface milling, 3, hot rolling, 4, rough rolling, 5, primary annealing, 6, primary washing, 7, medium rolling, 8, secondary annealing, 9, secondary cleaning, 10, medium finish rolling, 11, tertiary annealing, 12, tertiary washing, 13, finish rolling, 14, quaternary washing and 15, leveling. The production technology improves annealing process quality and copper strip surface quality, reduces a workshop cost and improves productive profits.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

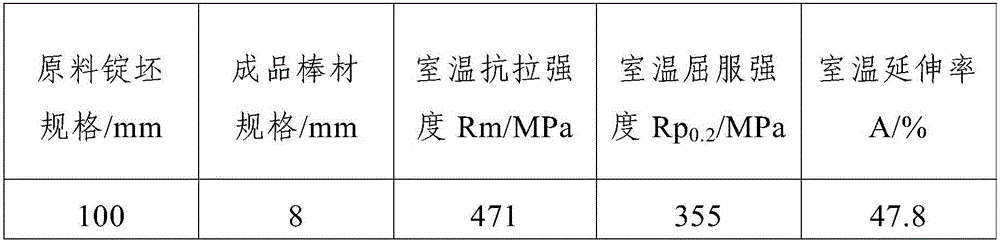

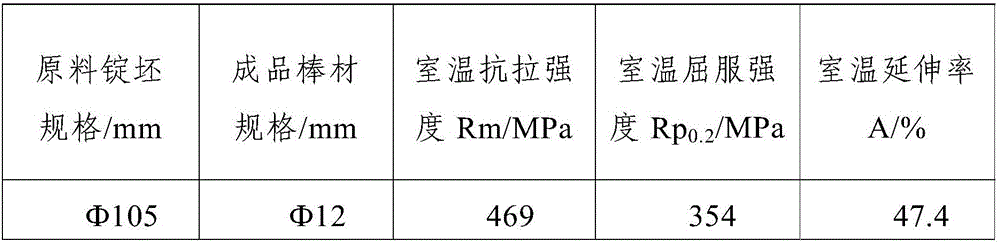

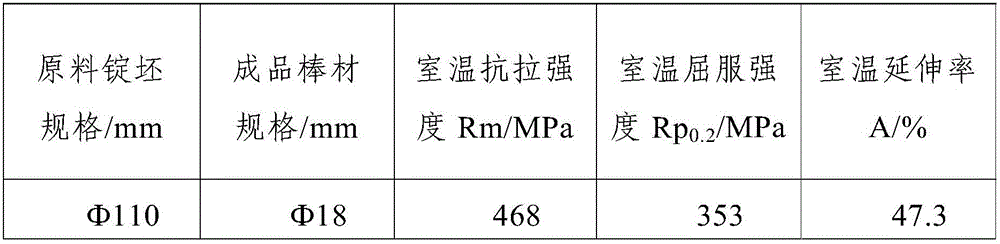

Processing method for small-size and high-strength niobium-hafnium alloy bar

The invention provides a processing method for a small-size and high-strength niobium-hafnium alloy bar. The processing method comprises the following steps that 1, a niobium-hafnium alloy ingot blank is sawn, and after being heated, the sawn niobium-hafnium alloy ingot blank is coated with an anti-oxidative protective lubricant; 2, the niobium-hafnium alloy ingot blank coated with the anti-oxidative protective lubricant is forged through upsetting and stretching to obtain a bar billet; 3, the bar billet is sequentially turned, ground and vacuum-annealed for the first time; 4, the vacuum-annealed bar billet is heated, the heated bar billet is coated with an anti-oxidative protective lubricant, and the bar billet coated with the anti-oxidative protective lubricant is formed through die forging to obtain a forging stock; 5, the forging stock is sequentially turned, ground and vacuum-annealed for the second time; 6, the vacuum-annealed forged stock is rolled with grooved rolls to obtain a small-size bar billet; and 7, the small-size bar billet is sequentially straightened, scalped, polished, pickled and annealed to obtain the small-size and high-strength niobium-hafnium alloy bar. The diameter of the section of the bar obtained according to the processing method is 8-20 mm, the room temperature tensile strength of the bar is up to above 465 MPa, the yield strength of the bar is up to above 350 MPa, the elongation of the bar is above 47%, and the grain structure of the bar is fine and uniform.

Owner:西安诺博尔稀贵金属材料股份有限公司

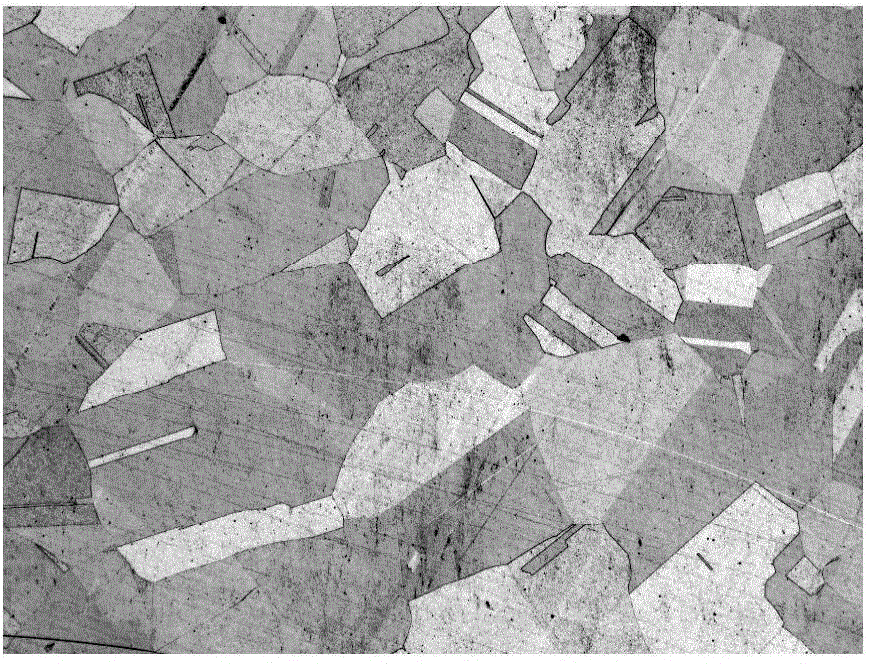

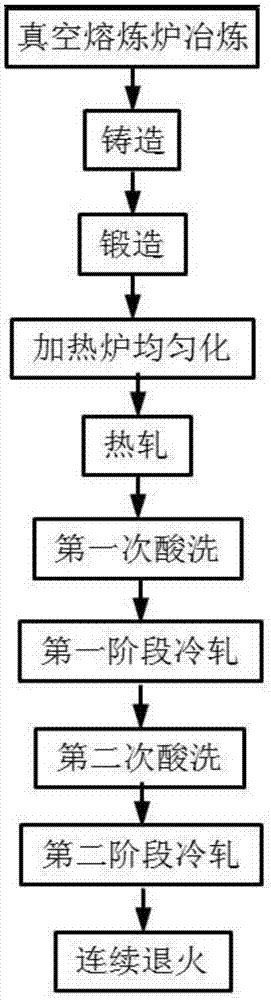

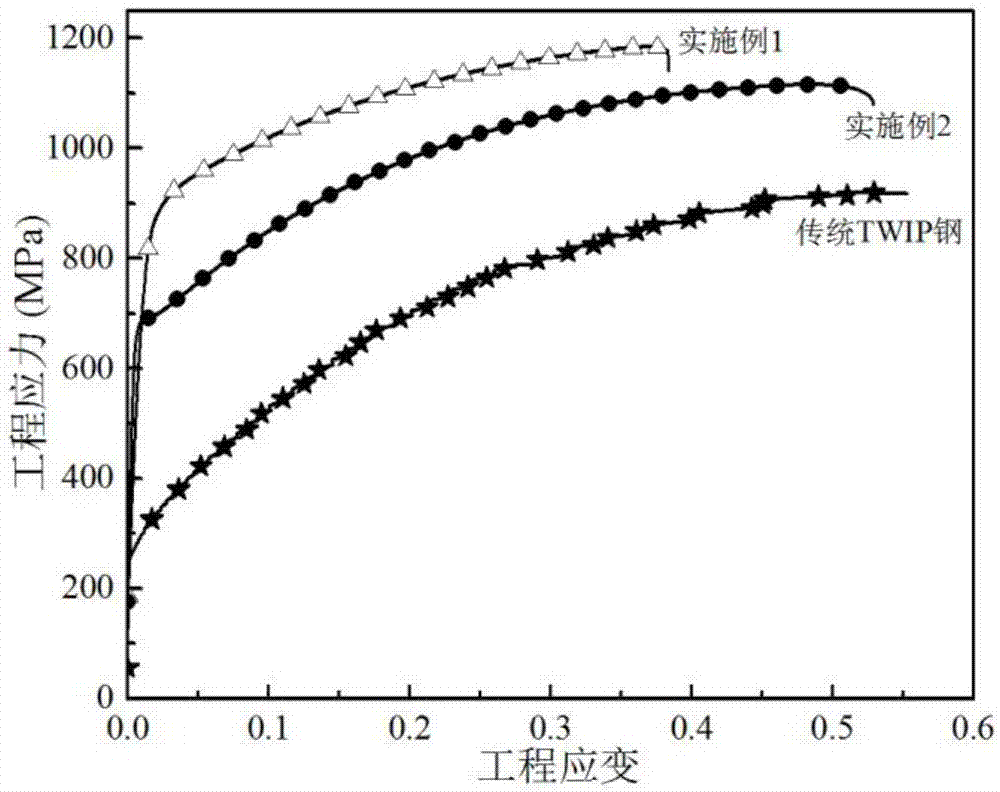

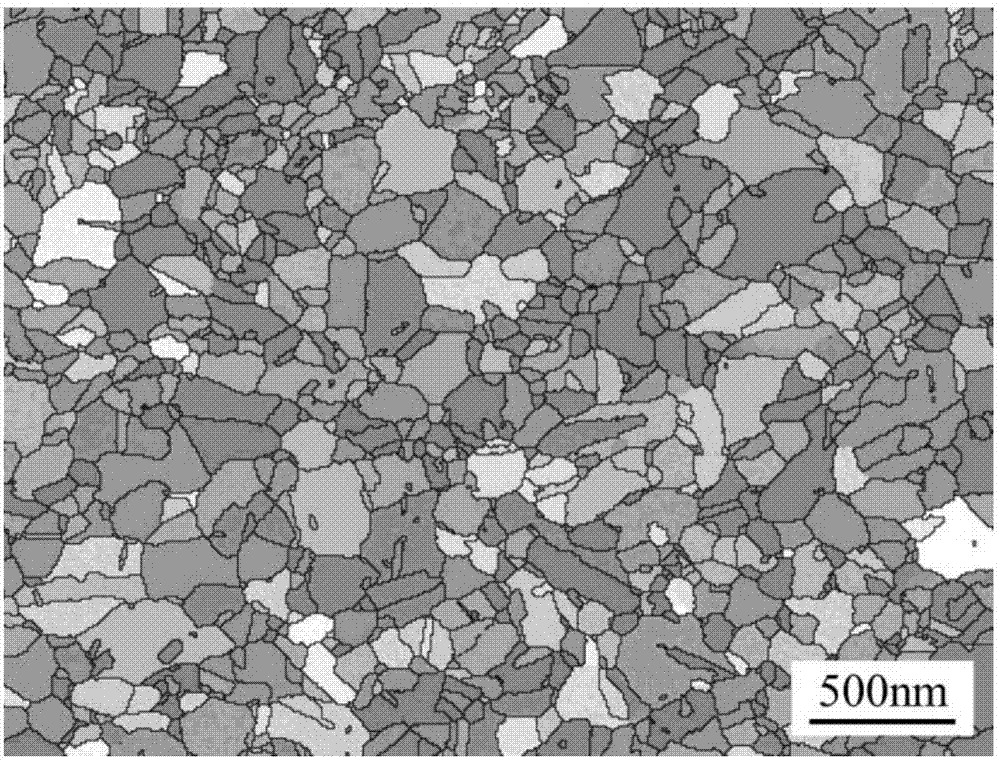

Nanostructure-based high-energy-absorption and high-manganese type TWIP steel and preparation method thereof

The invention relates to nanostructure based high-energy-absorption and high-manganese type TWIP steel and a preparation method of the nanostructure based high-energy-absorption and high-manganese type TWIP steel, and belongs to the field of metal materials. The nanostructure comprises nano-scale tissues and nano-sized precipitates, wherein the nano tissues can improve the strength of the materials and can also improve the plasticity of the materials, and the reinforcement of the materials is dominated by the nano precipitates. According to the nanostructure-based high-energy-absorption and high-manganese type TWIP steel and the preparation method of the nanostructure based high-energy-absorption and high-manganese type TWIP steel, on the basis of the addition of V element, Ni and Ti microalloy elements are further added, the TWIP steel which is of the nanostructure and the high energy absorption capability is obtained after the working procedures of smelting, casting, forging, homogenizing in a heating furnace, hot rolling, acid pickling, two-stage cold rolling and annealing. After the high-manganese TWIP steel is subjected to a one-way tensile test with the speed rate being 1 mm / min at the room temperature, the yield strength of the high-manganese TWIP steel is 650-820 MPa, the anti-extension strength of the high-manganese TWIP steel is 1080-1180 MPa, the cracked extension rate is 30% or above, the energy absorbed in the process of extension and deformation is 35 GPa% or above; and the nanostructure based high-energy-absorption and high-manganese type TWIP steel is excellent in chemical property, and the preparation method of the nanostructure based high-energy-absorption and high-manganese type TWIP steel is simple and feasible.

Owner:UNIV OF SCI & TECH BEIJING

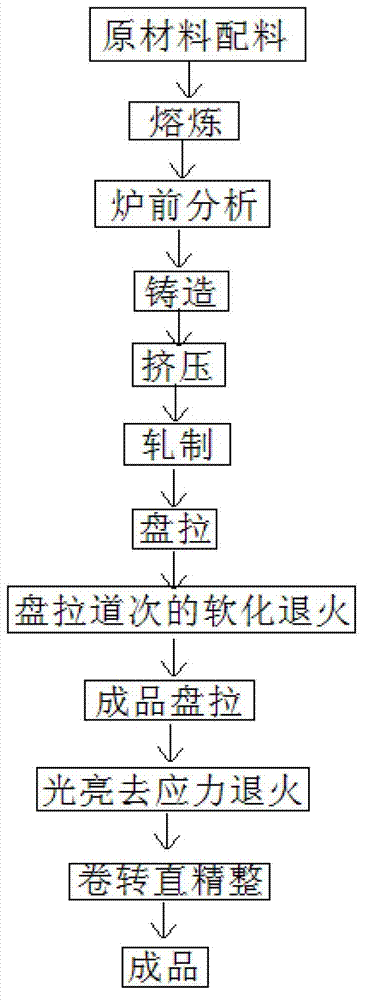

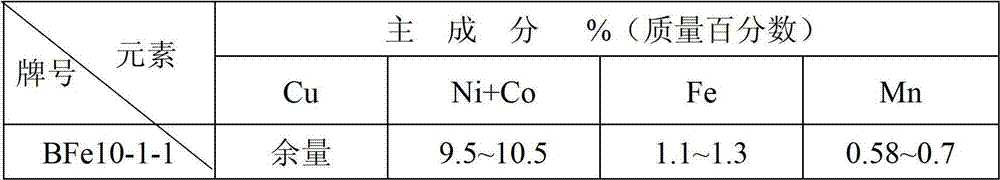

Copper-nickel alloy tube preparation method

InactiveCN102899595AMeet the requirements of mechanical propertiesMeet the requirements of the processCupronickelStraight tube

The invention relates to a copper-nickel alloy tube preparation method, which comprises the following steps: placing a BFe10-1-1 cupronickel material in a casting apparatus to carry out smelting and casting to obtain an ingot; placing the ingot in an extruder to carry out extrusion to obtain a tube billet; placing the tube billet into a tube rolling machine to carry out rolling to obtain a roll-type tube billet; placing the roll-type tube billet into a disk drawing machine to carry out disk drawing to obtain a roll-type finished product; placing the roll-type finished product in a bright annealing furnace to carry out annealing to obtain a bright finished product; and placing the bright finished product into a coil straightening machine unit to carry out straightening, straight placing and sawing cutting to obtain the ultra-long qualified finished product. The semi-hard state BFe10-1-1 copper-nickel alloy straight tube produced by the method of the present invention has characteristics of excellent plasticity and high tube end expansion processing property, high size deviation precision, thin wall thickness, long length, saved intermediate softening degradation time, and high yield, wherein production efficiency of the method of the present invention is 3 times production efficiency of the traditional straight drawing production method.

Owner:SUZHOU FURUI COPPER ALLOY TECH CO LTD

Double strong copper strip production technology for automobile connector

The invention discloses a double strong copper strip production technology for an automobile connector, and belongs to the technical field of a copper strip production technology. The double strong copper strip production technology comprises the following steps of (1), smelting and ingot casting; (2), hot rolling; (3), milling; (4), rough rolling; (5), once annealing; (6), once cleaning; (7), medium rolling; (8),twice annealing and cleaning; (9), finish rolling; (10), three times annealing and cleaning; (11), finish rolling; (12), four times cleaning; (13), leveling; and (14), examining and delivering; and specified thickness of strip coil after rough rolling is 2.5 mm. According to the technical scheme, brass products can meet the double requirements of tensile strength and elongation index of automobile connector industry.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

Formed part preparation method based on reduced graphene oxide and copper composite material

InactiveCN110819842AGood formabilityEasy dischargeTransportation and packagingMetal-working apparatusHydrogen atmosphereHigh conductivity

The invention relates to a formed part preparation method based on a reduced graphene oxide and copper composite material. According to the method, graphene oxide / copper mixed powder is prepared through wet ball milling; then, the mixed powder is reduced under hydrogen atmosphere; and finally, the reduced graphene oxide and copper composite material is obtained through a repressing and resinteringpowder metallurgy method. By means of the method, reduced graphene oxide is well and evenly scattered in a copper matrix, the prepared reduced graphene oxide / copper composite material has the advantages of being high in strength, high in plasticity and high in conductivity, the repressing and resintering sintering forming method is simple and controllable in process, low in production cost and high in production efficiency, and large-scale industrialized production is easy to achieve. Formed pieces prepared through the formed part preparation method are little in oxide, less in pore and highin compactness and has excellent comprehensive performance such as high strength, high conductivity and high plasticity.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com