Method for manufacturing copper-aluminum composite tube

A technology of copper-aluminum composite and aluminum alloy pipes, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., which can solve the problems of reducing copper-aluminum bonding strength, high technical difficulty, and reducing product yield, and eliminate processing Hardening, simplification of process procedures, effect of ensuring effective implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

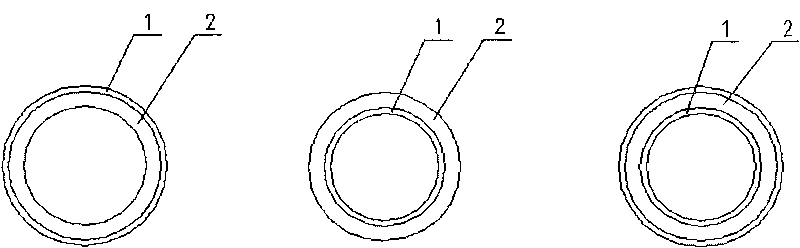

[0060] Embodiment 1: Manufacture copper-clad aluminum tube

[0061] The inner tube is made of Φ30×2mm 3003 extruded aluminum coil tube, and the weight of a single coil is 800 kg. The covering tape is made of red copper tape with a thickness of 0.6 mm. Continuously draw to 13.8×0.92mm in a straight line, and then draw to Φ9.2×0.6mm by a drawing machine on the upper plate, and go through online induction annealing (pit furnace annealing) until the finished product is wound and rolled. The copper-clad aluminum tube has a good metallurgical bond at the copper-aluminum interface, and can be used as the inner conductor of the radio frequency cable instead of the copper tube. The weight of the copper-clad aluminum tube is only about 50% of the copper tube, and the single tube is super long. High production efficiency.

Embodiment 2

[0062] Embodiment 2: Manufacture copper-clad aluminum tube

[0063] The Φ12.7X1mm pure aluminum tube extruded by Kangfeng continuous extrusion machine is covered with 0.34mm copper strip, and after the surface is cleaned, it is continuously drawn linearly and coiled to Φ5.08×0.5mm or Φ3.75×0.4mm, After on-line annealing, it is wound and rolled to produce finished pipes. The copper-aluminum interface metallurgical bonding of this copper-clad aluminum pipe is good, and it can replace the copper-clad aluminum wire of the same outer diameter as the inner conductor of the radio frequency cable. At this time, the weight of the copper-clad aluminum pipe It is also about half the weight of copper-clad aluminum wire with the same outer diameter.

Embodiment 3

[0064] Embodiment 3: manufacture aluminum-clad copper pipe

[0065] The 0.5mm copper strip is longitudinally welded into a copper tube with a diameter of Φ42 as the inner tube, and then the aluminum strip with a thickness of 3mm is coated and welded on the outer surface of the inner tube after surface cleaning, and then drawn continuously to Φ20 through 8 passes ×1.25mm, after on-line annealing, it is continuously drawn to Φ12×0.55mm, and then formed into a Φ9.52mm copper-aluminum composite tube with internal thread after on-line annealing, which can be used to manufacture the two parts of the air conditioner. Condenser and evaporator, compared with the traditional internal threaded copper tube, the weight of the aluminum-clad copper internal threaded corrugated tube is 1 / 2 of the copper tube, and the heat transfer efficiency can be increased by 2-5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com