Low-temperature heating oriented electrical steel with good surface coating and production method thereof

A kind of oriented electrical steel, good technology, applied in the direction of temperature control, etc., can solve the problems of billet burning, high heating temperature, high energy consumption, etc., achieve the effects of eliminating magnetic aging, simplifying the process flow, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

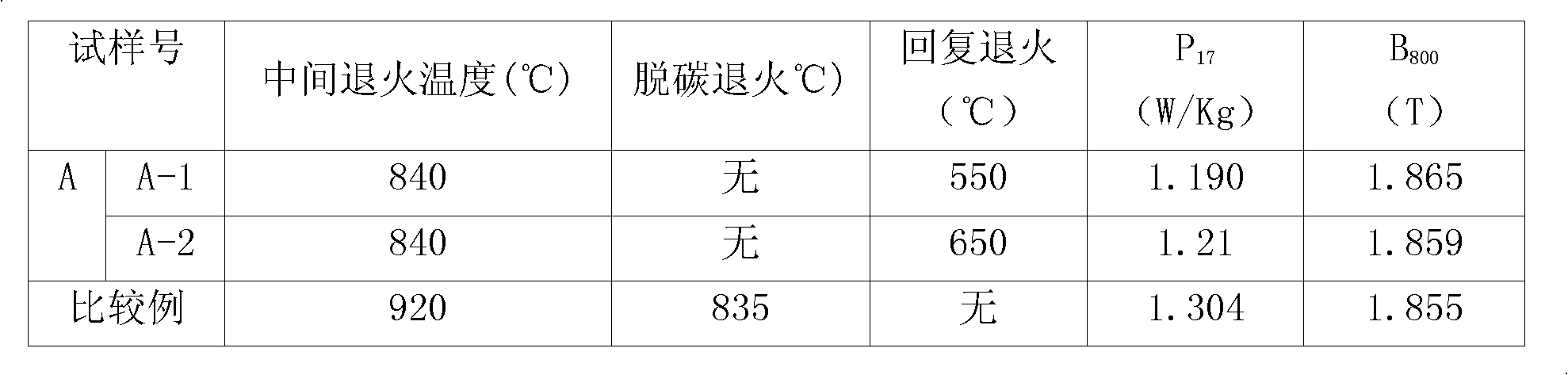

[0028] Embodiment 1: use 25kg vacuum furnace to make steel, the chemical composition is as shown in Table 1, and the rest is iron and unavoidable impurities. The slab was heated at 1250°C for 2.5h and then hot rolled to 2.3mm. After the first cold rolling, the strip steel is subjected to intermediate annealing, and the process system is wet H 2 and N 2 Incubate at 840°C for 5 minutes under the mixed gas, where H 2The content volume percentage is 15%. The second cold rolling to the thickness of the finished product is 0.285mm, and then recovery annealing is carried out to improve the surface quality of the strip. The annealing system is wet H 2 and N 2 Under the mixed gas of 550 and 650°C for 1.5min, the MgO spacer is coated and then high-temperature annealing is carried out, in which the temperature is raised at a rate of 50°C / h in the stage of 400-700°C.

[0029] Comparative example for intermediate annealing in H 2 and N 2 Incubate at 920°C for 5 minutes under the mix...

Embodiment 2

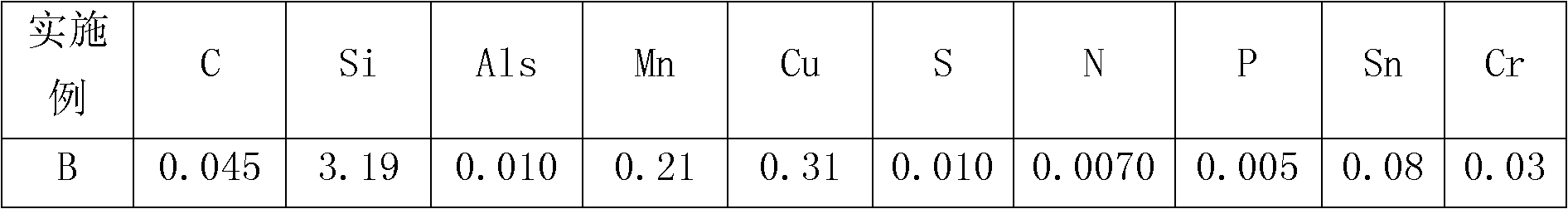

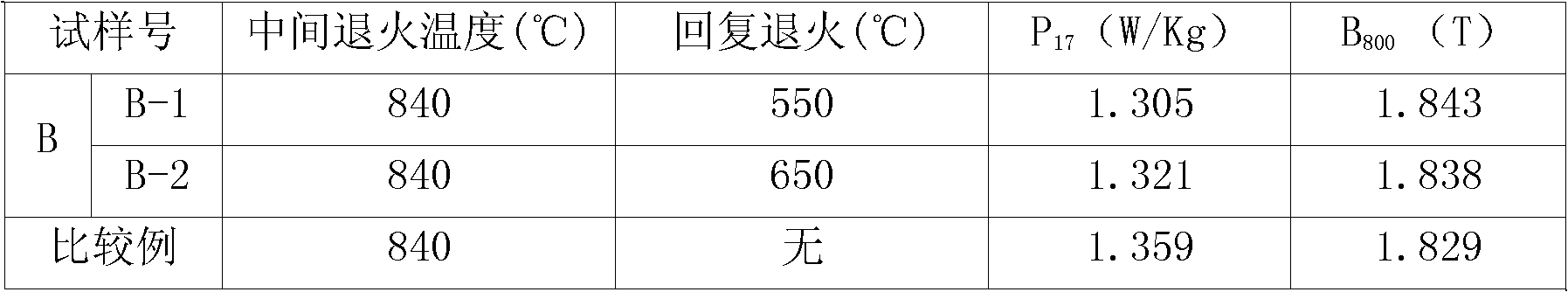

[0035] Embodiment 2: use 25kg vacuum furnace to make steel, the chemical composition is as shown in Table 3, and the rest is iron and unavoidable impurities. The slab was heated at 1150°C for 2.5h and then hot rolled to 2.2mm. After the first cold rolling, the strip steel is subjected to intermediate annealing, and the process system is wet H 2 and N 2 Incubate at 840°C for 5 minutes under the mixed gas, where H 2 The content volume percentage is 15%. The second cold rolling to the thickness of the finished product is 0.285mm, and then recovery annealing is carried out to improve the surface quality of the strip. The annealing system is wet H 2 and N 2 Under the mixed gas of 550 and 650°C for 1.5min, the MgO spacer is coated and then high-temperature annealing is carried out, in which the temperature is raised at a rate of 50°C / h in the stage of 400-700°C.

[0036] Comparative example for intermediate annealing in wet H 2 and N 2 Incubate at 840°C for 7 minutes under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com