Patents

Literature

96results about How to "Improve quality characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

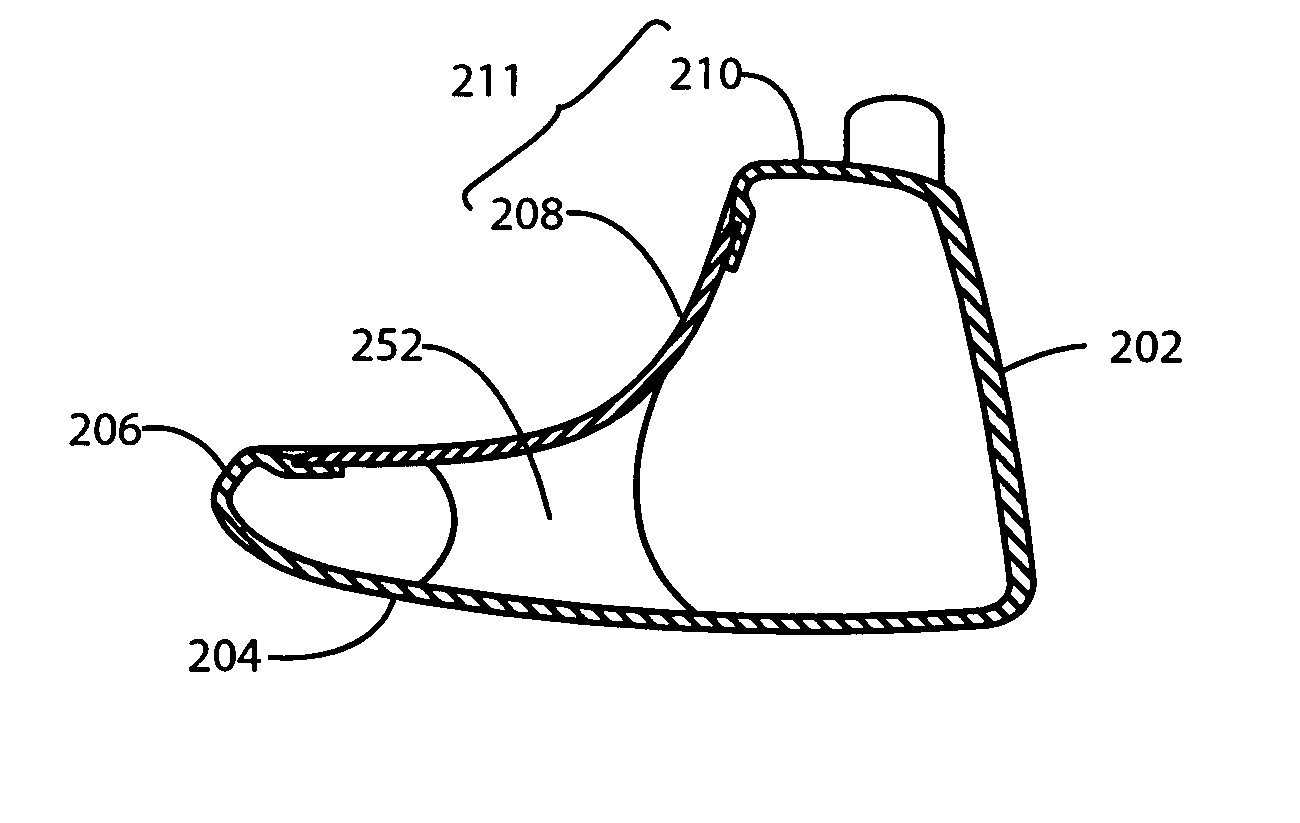

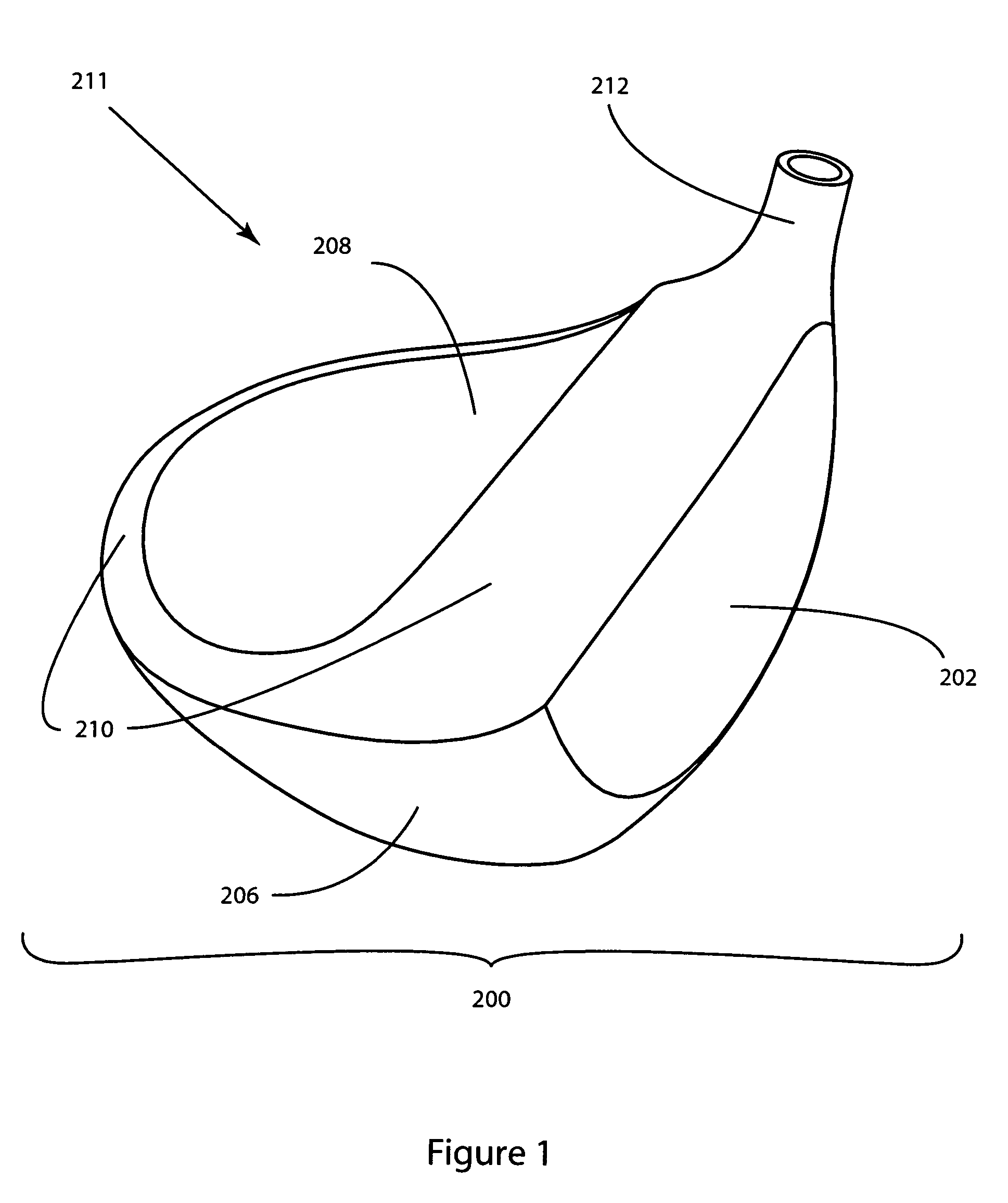

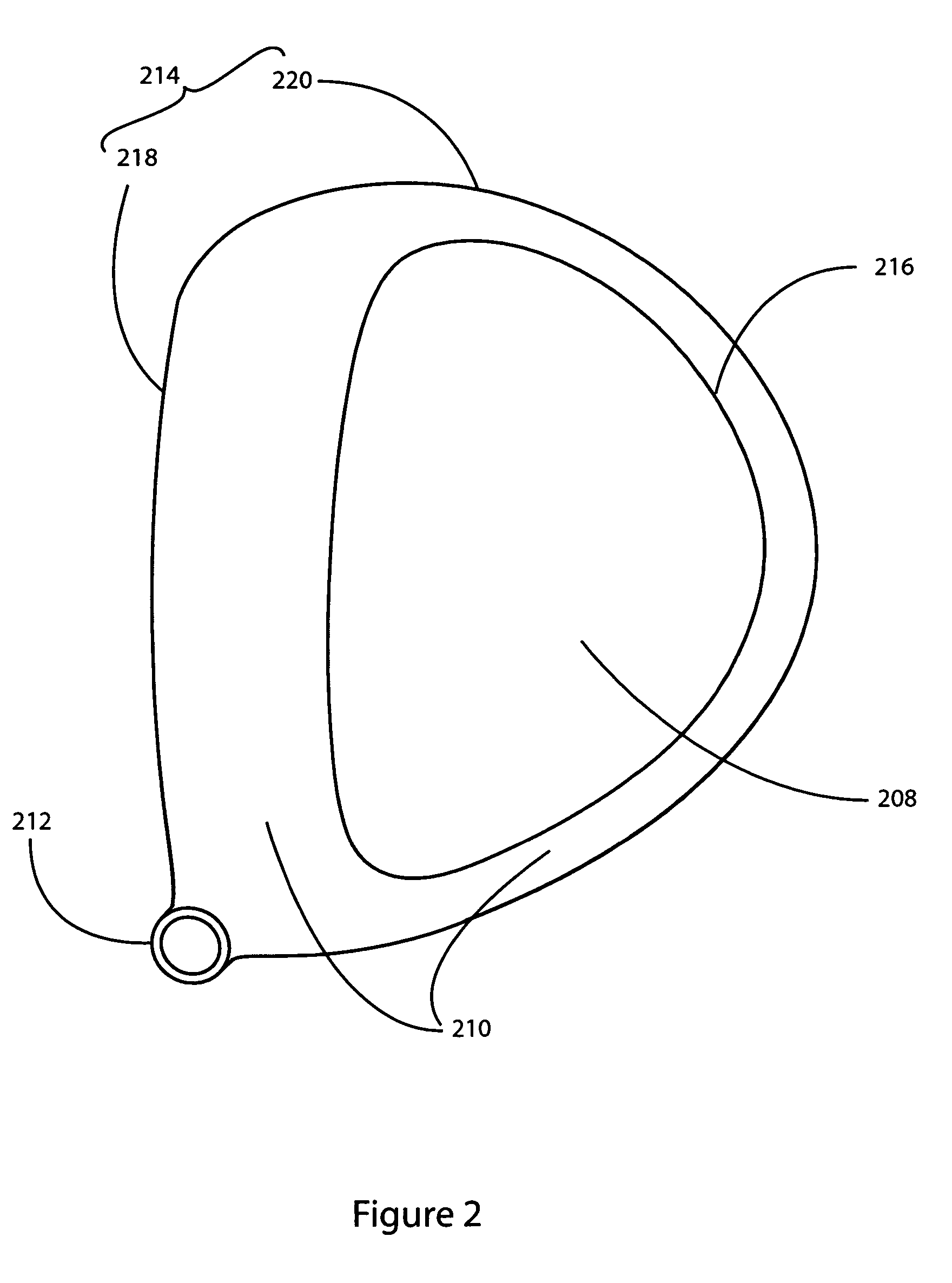

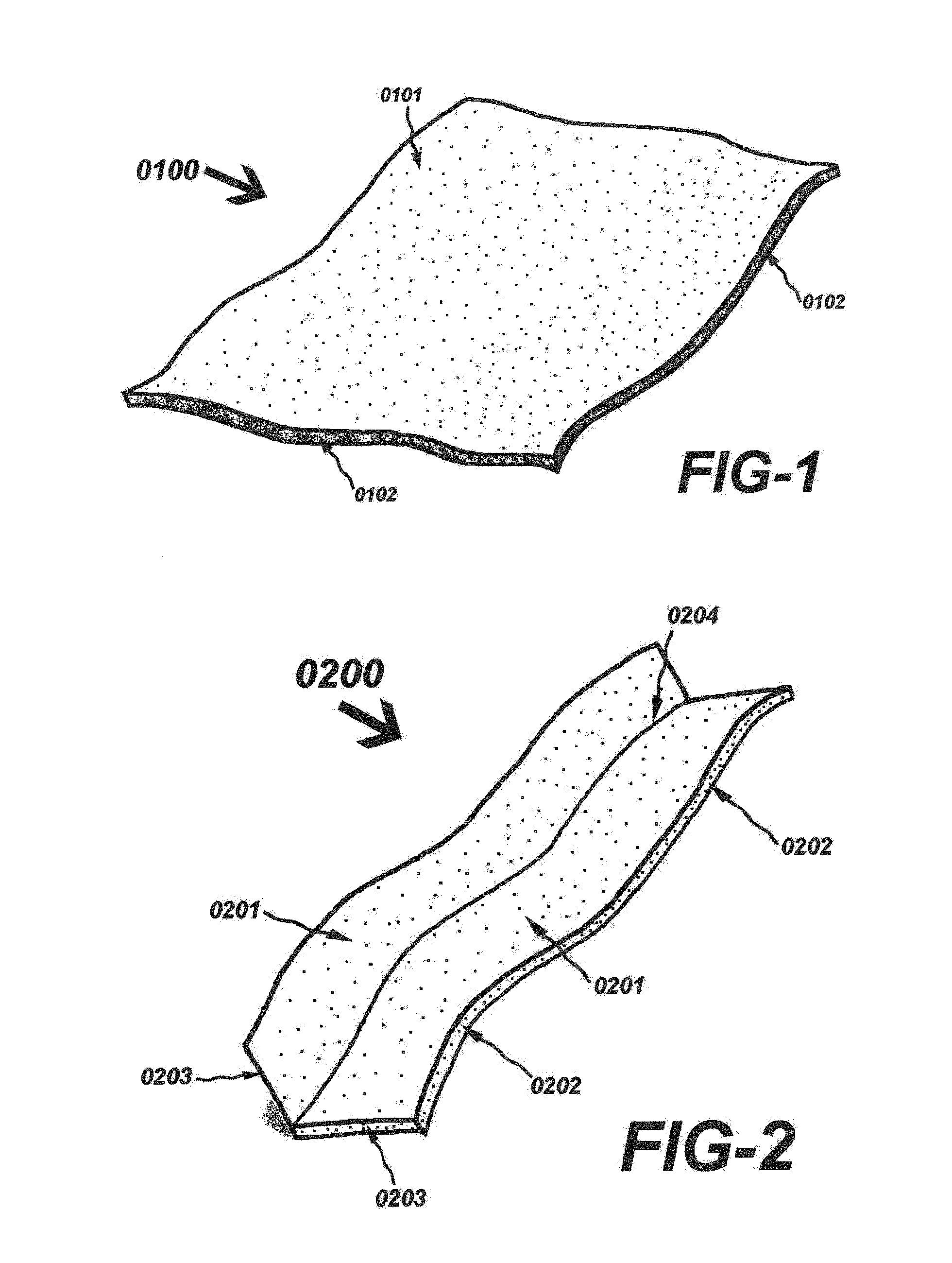

Golf club head having a displaced crown portion

InactiveUS7651414B2Increased weight budgetImprove quality characteristicsGolf clubsGolf BallIncreasing weight

A hollow wood-type golf club head having an increased weight budget and improved mass characteristics at minimum structural mass is disclosed. The club head has a striking face portion, a sole portion, a skirt portion, and a crown portion having a total surface area. A hosel portion joins the club head for connecting a shaft to the club head. The crown portion has a major crown portion and a minor crown portion, the major portion having greater surface area than the minor portion, and the major portion being displaced vertically lower relative to the minor crown portion. The major crown portion may have a generally concave curvature and the minor crown portion may have a generally convex curvature such that the major crown portion is in effect inverted with respect to the minor crown portion. The major crown portion may be upwardly inclined from the heel to the toe of the head. The head may exhibit a parabolic top view silhouette.

Owner:DUNLOP SPORTS CO LTD

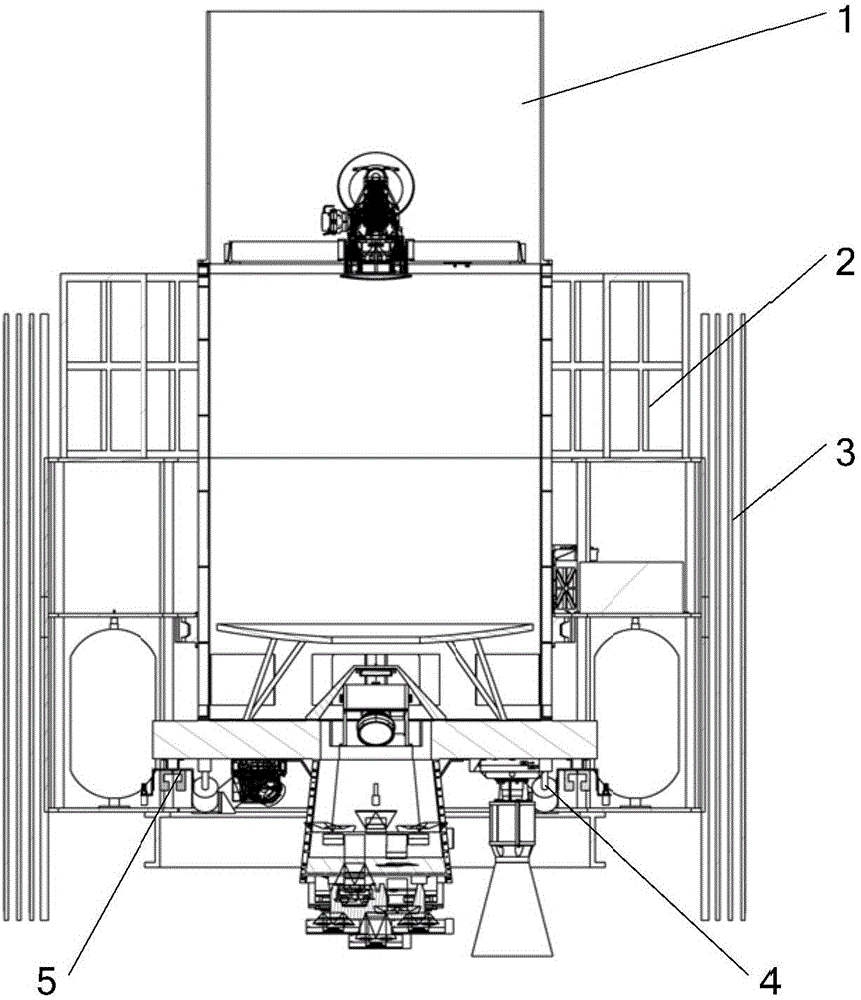

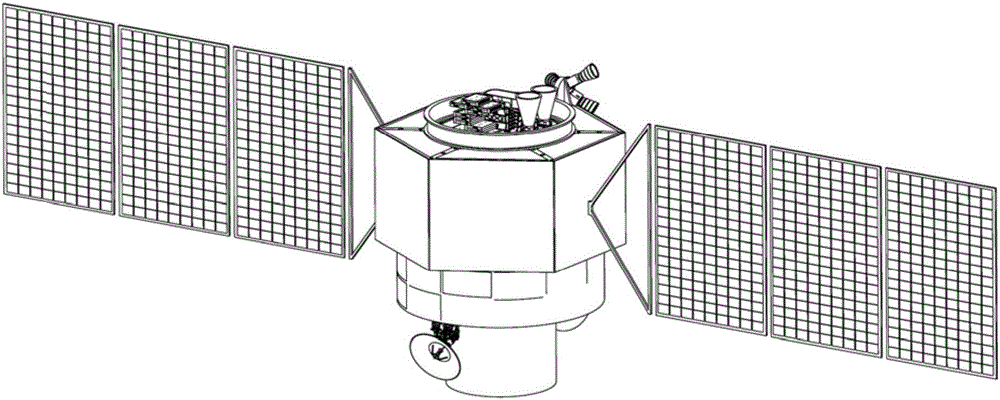

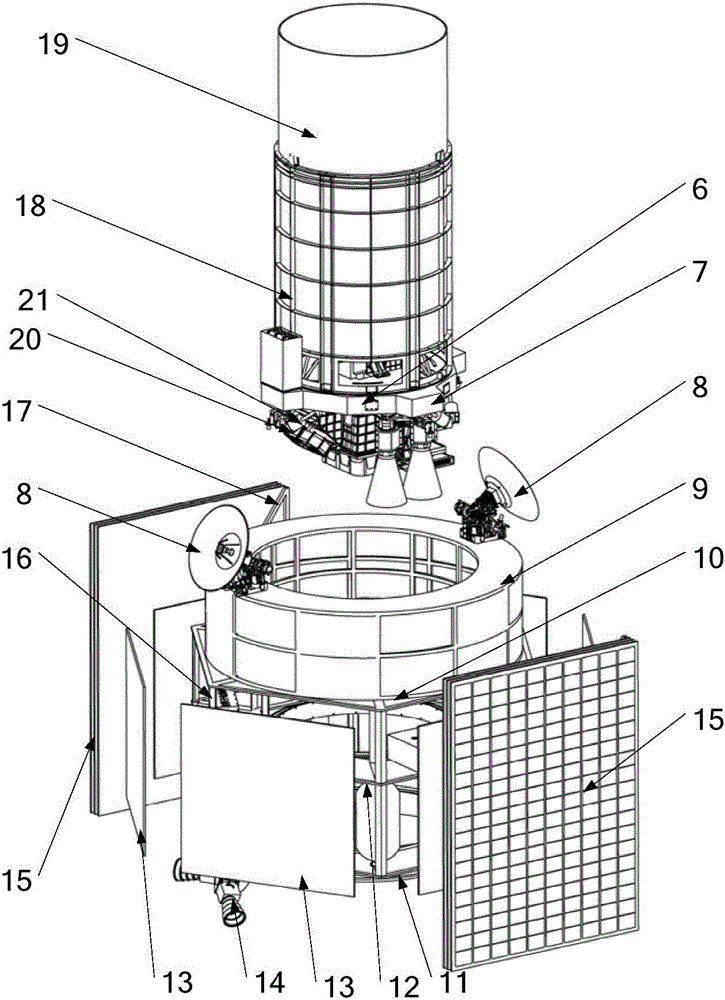

Embedded satellite configuration

InactiveCN106742063AReduce feature sizeReduce the inertia of the whole starCosmonautic power supply systemsArtificial satellitesSpace environmentSolar cell

The invention provides an embedded satellite configuration. The embedded satellite configuration comprises a platform cabin, a loading cabin, a docking locking-unlocking mechanism, a non-contact magnetic suspension direct force control mechanism and a solar cell array. The platform cabin is in a hollow annular structure; the loading cabin is arranged in the platform cabin; the docking locking-unlocking mechanism and the non-contact magnetic suspension direct force control mechanism are arranged between the platform cabin and the loading cabin respectively; the solar cell array is arranged on the side of the platform cabin. Ultrahigh-precision ultrahigh-stability control requirements of satellites are met, quality characteristics and agile mobility performances of the satellites are improved, a loading space environment is improved, and influences of platform disturbance and thermal cycling on satellite loading are reduced. According to a design conception of non-contact split design and centralized control, the embedded satellite configuration has advantages of structural configuration compactness, high control precision, high environmental adaptability, low development risk, short cycle and simplicity and feasibility in integration and final assembly.

Owner:SHANGHAI SATELLITE ENG INST

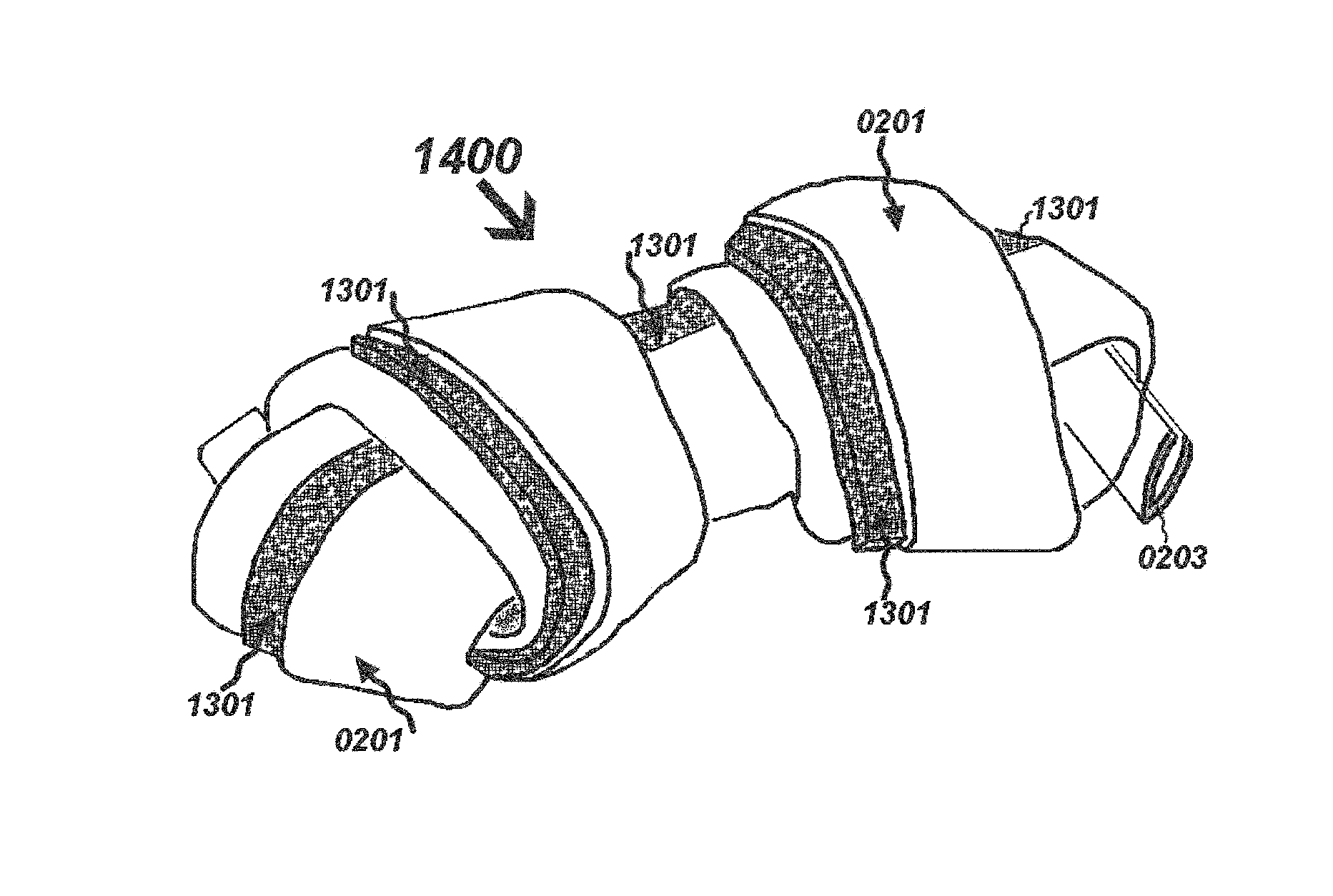

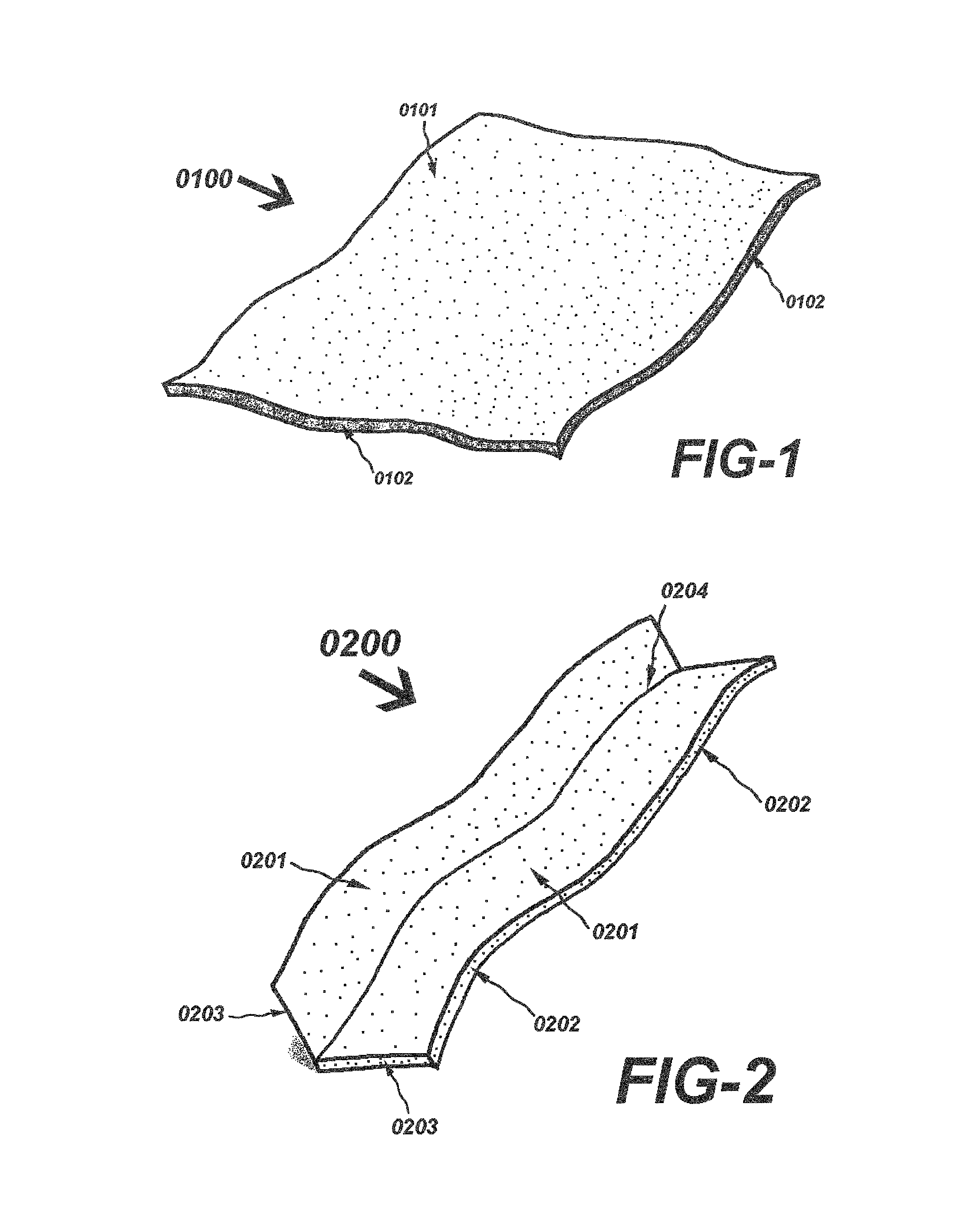

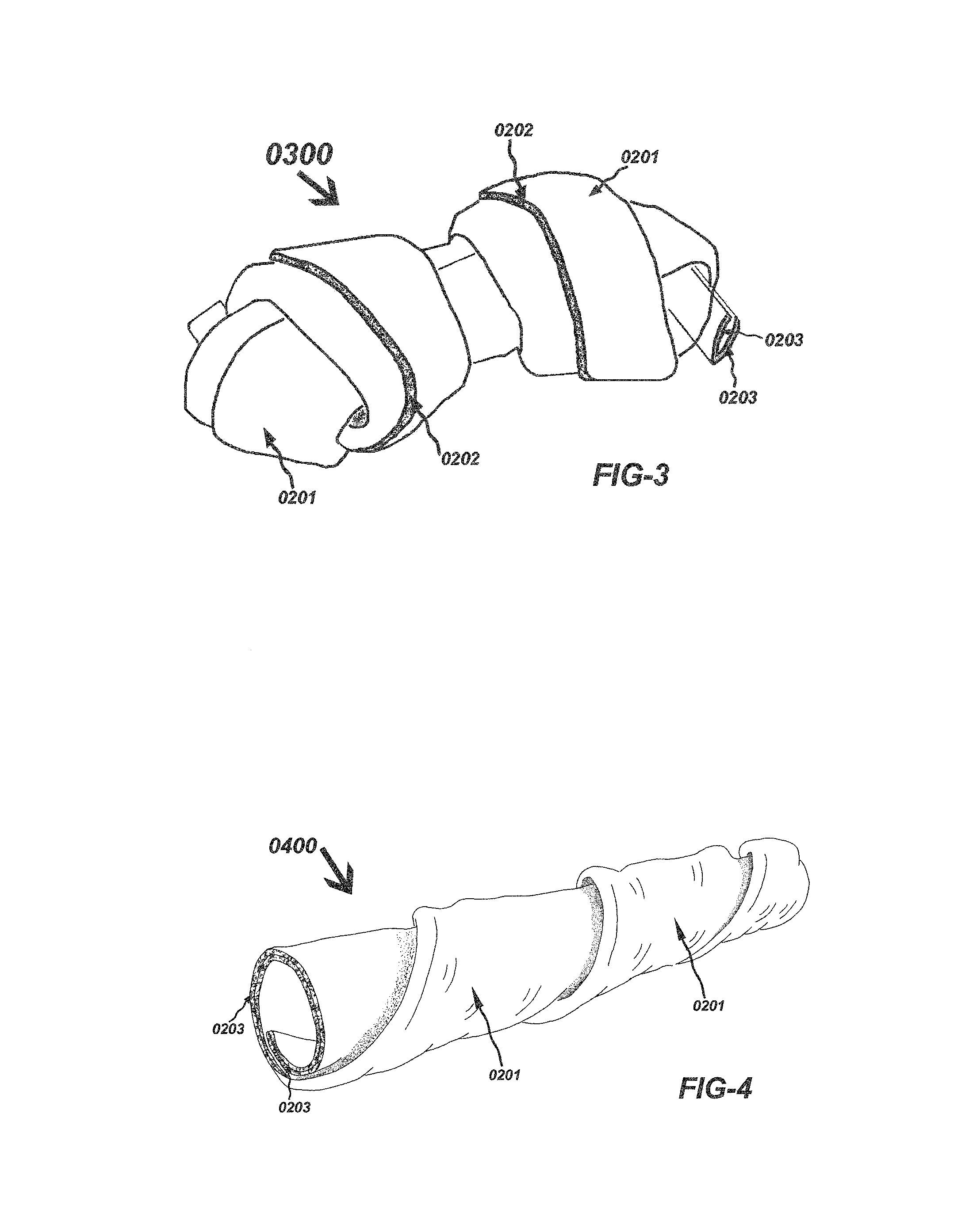

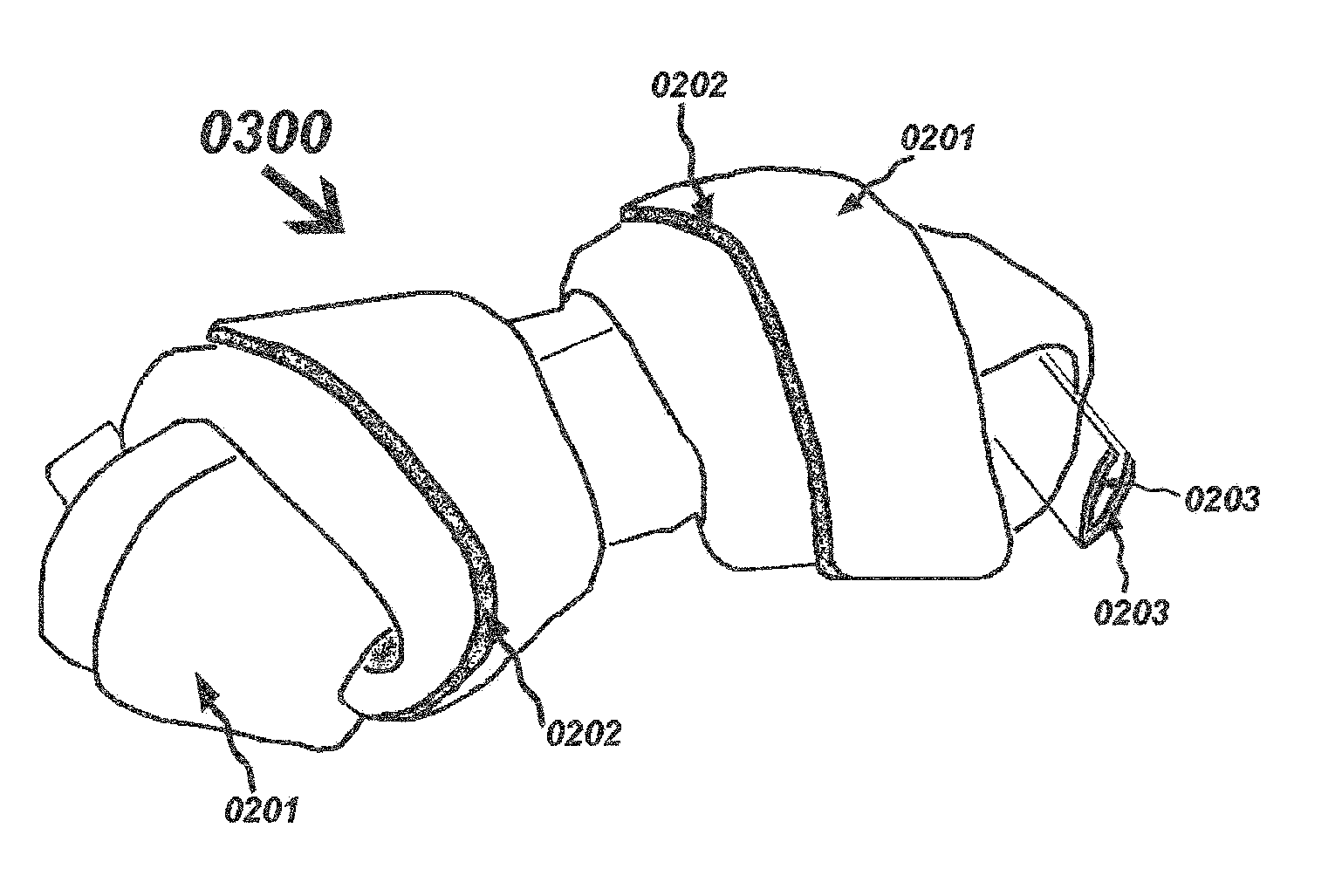

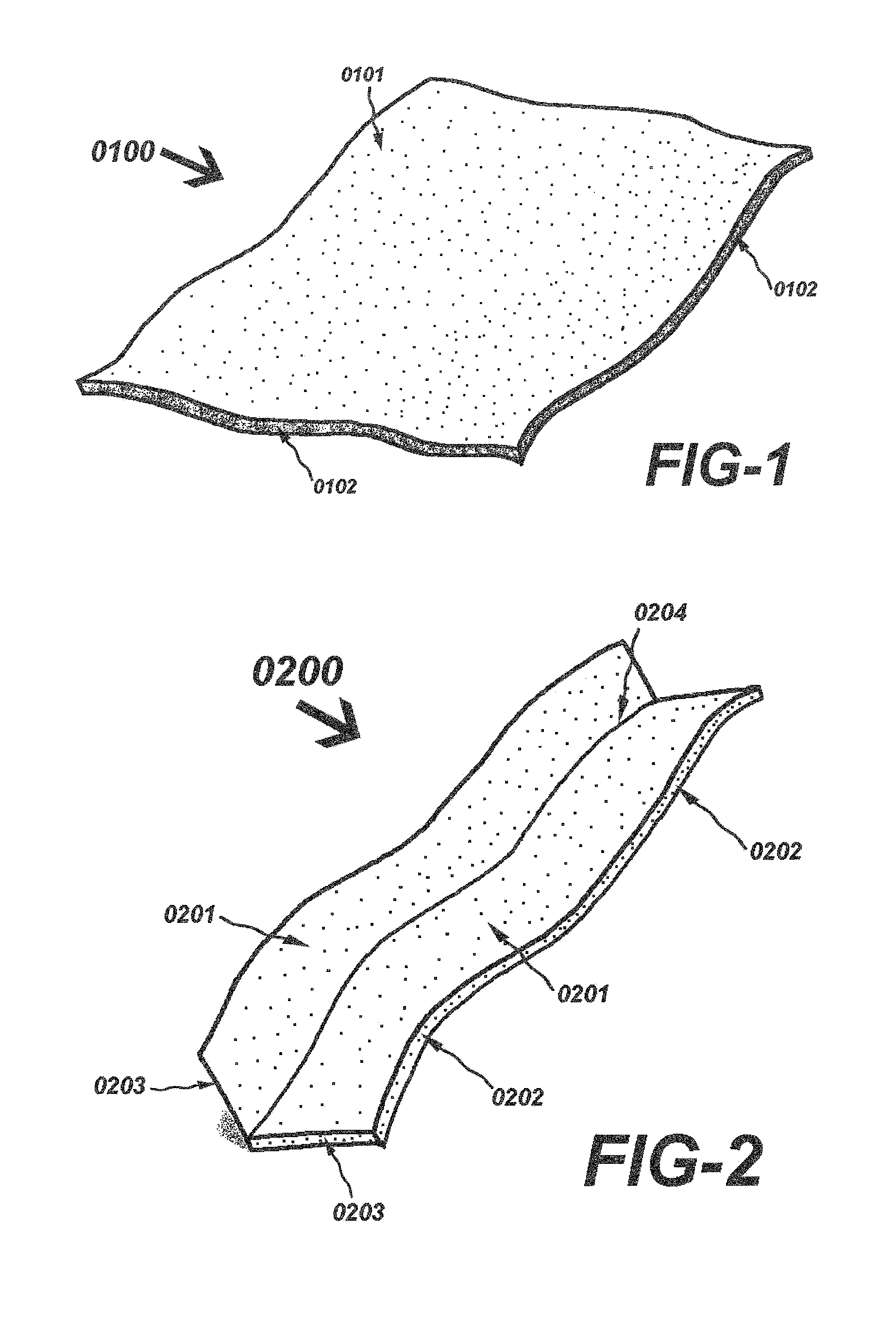

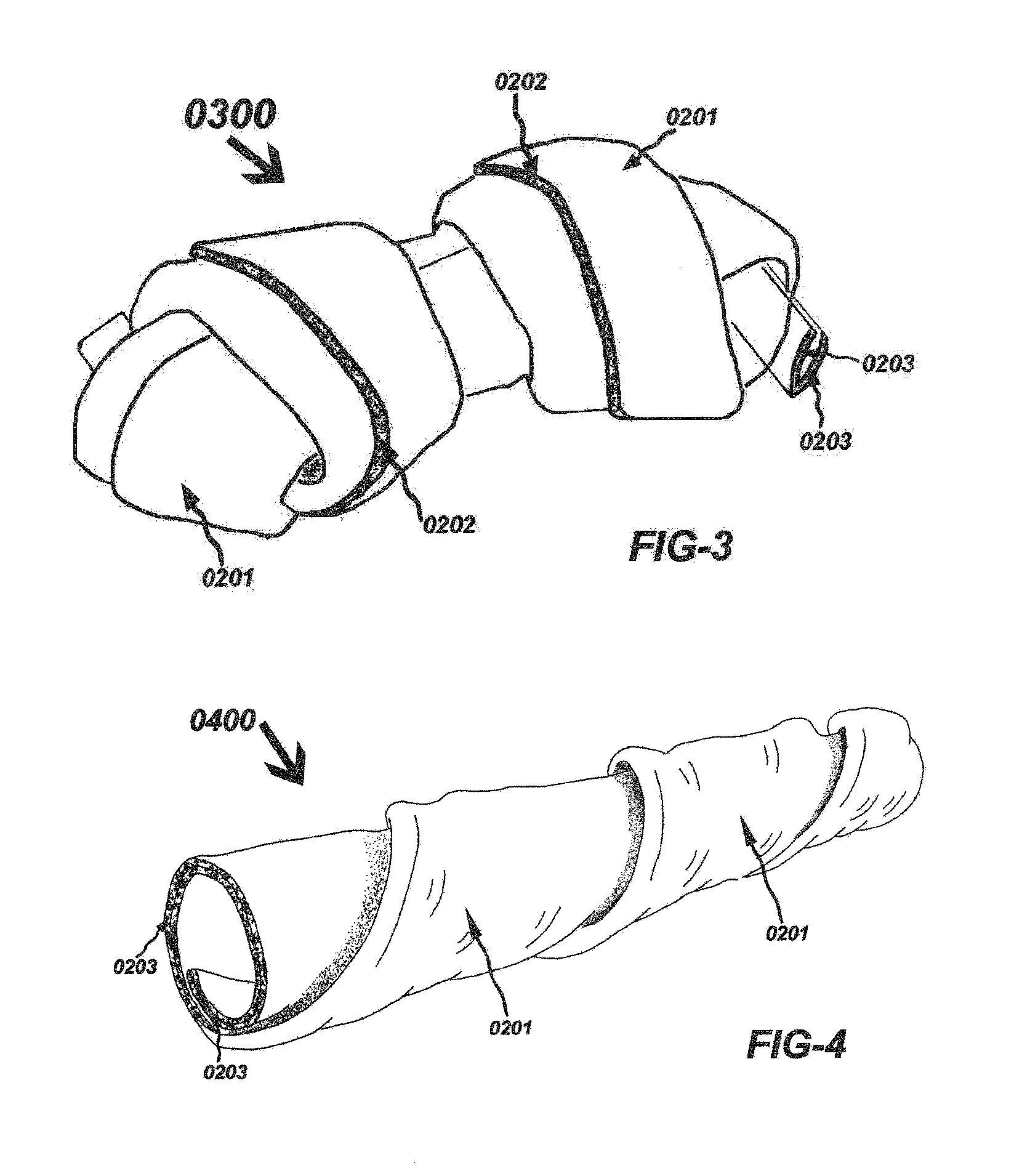

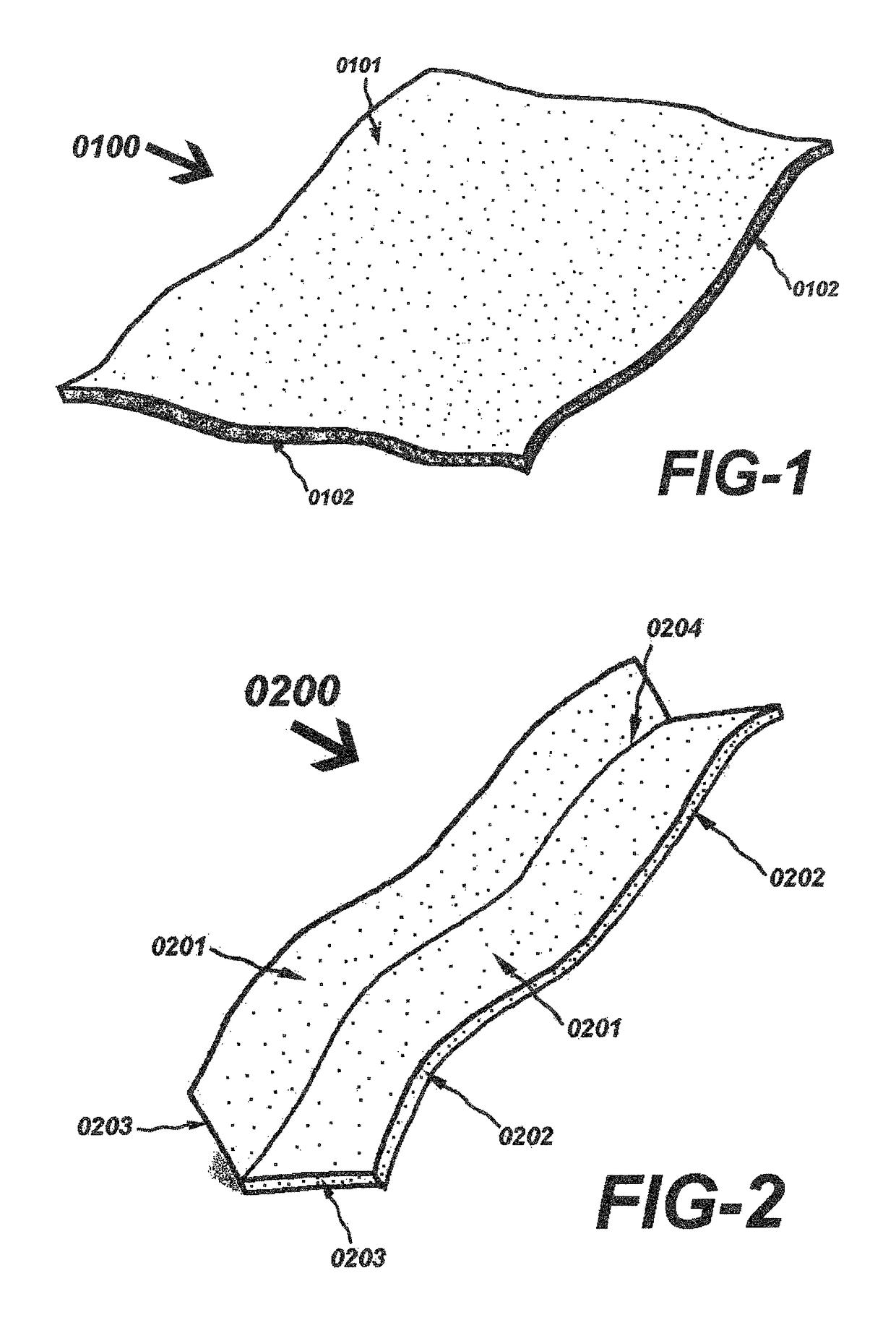

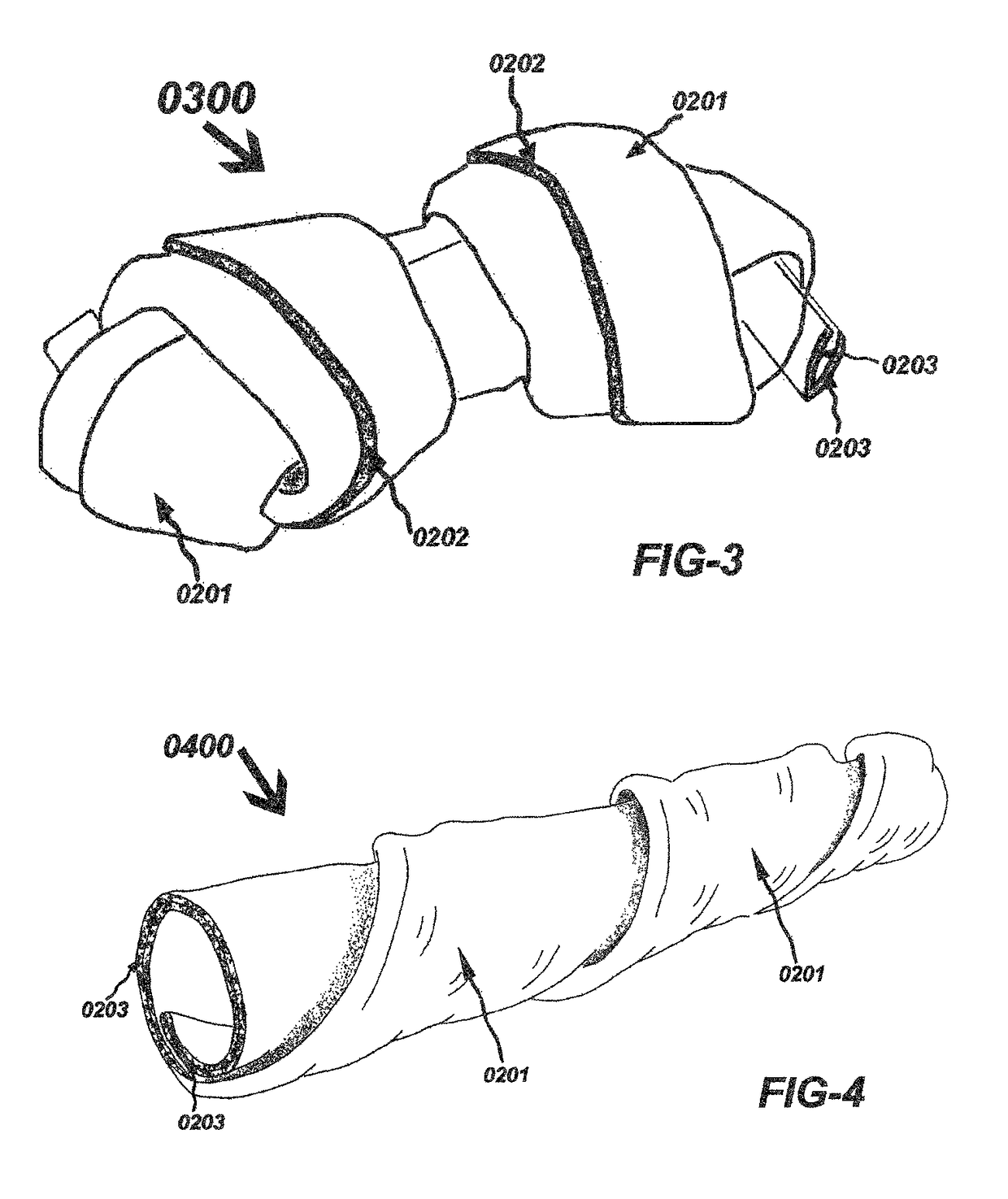

Edible pet chew and method for making the same

ActiveUS9044039B2Improve quality characteristicsSimple structureFood processingAnimal feeding stuffThree dimensional shapeCompanion animal

Owner:SHANGHAI SUNLIGHT INNOV TRADING CO LTD

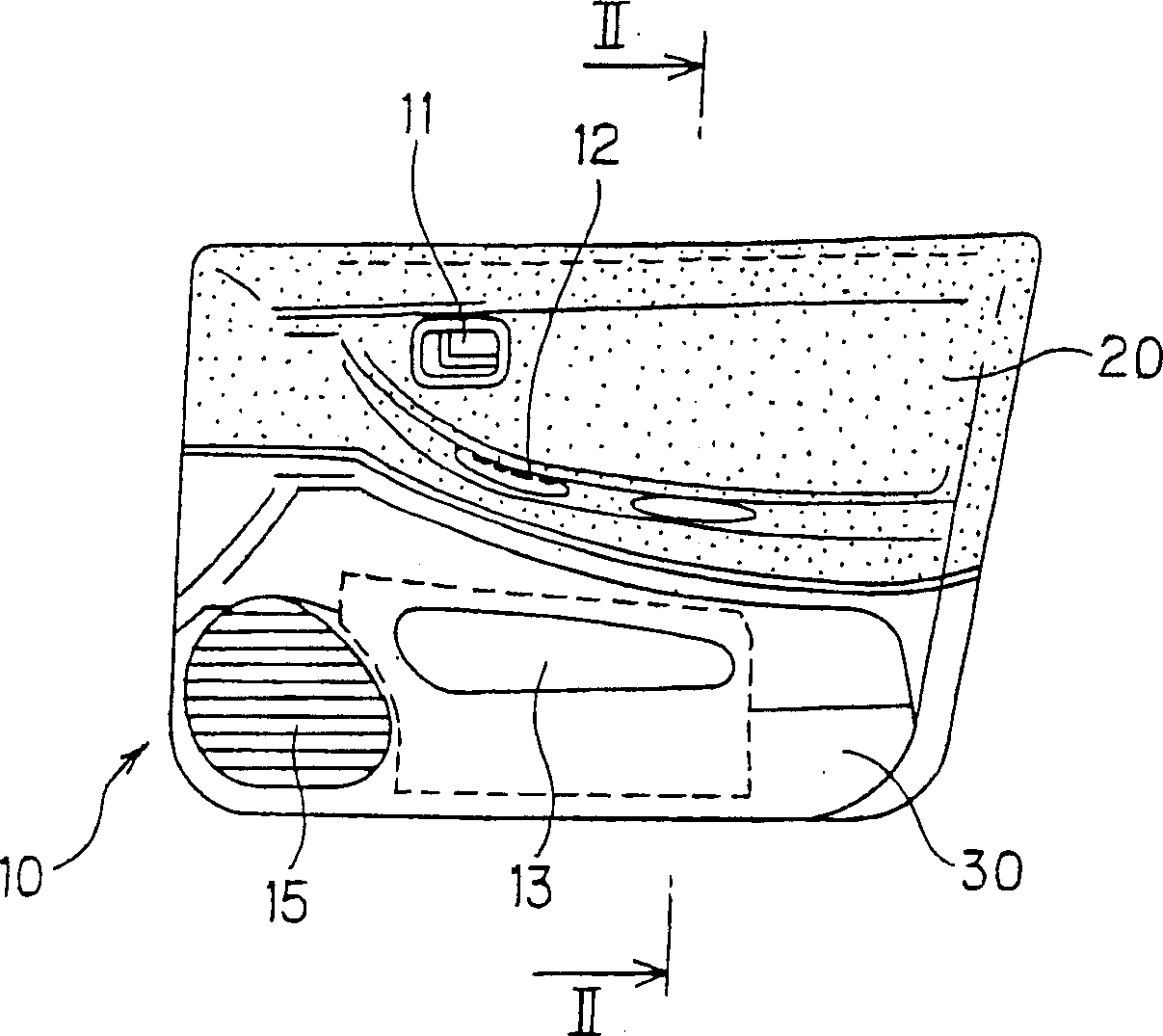

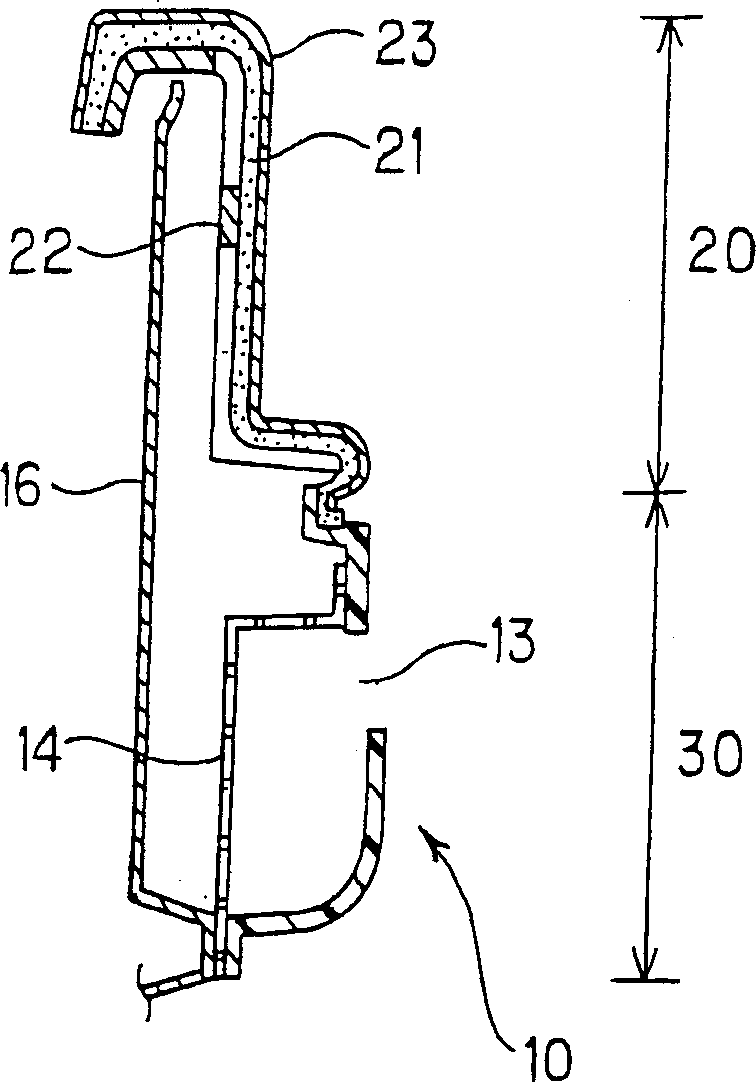

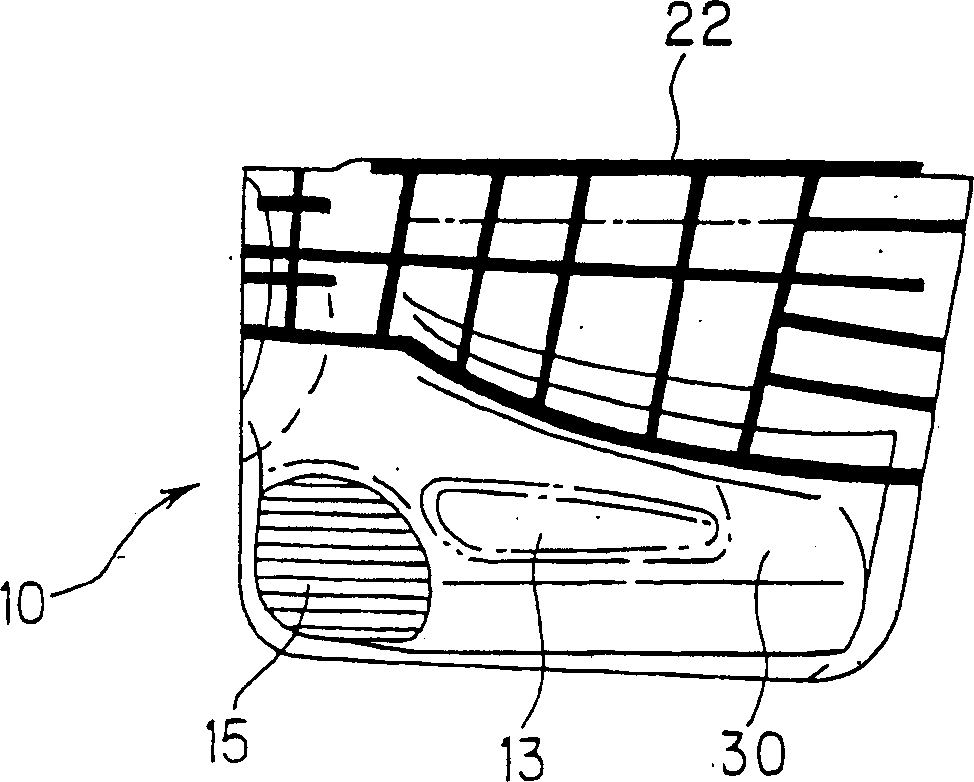

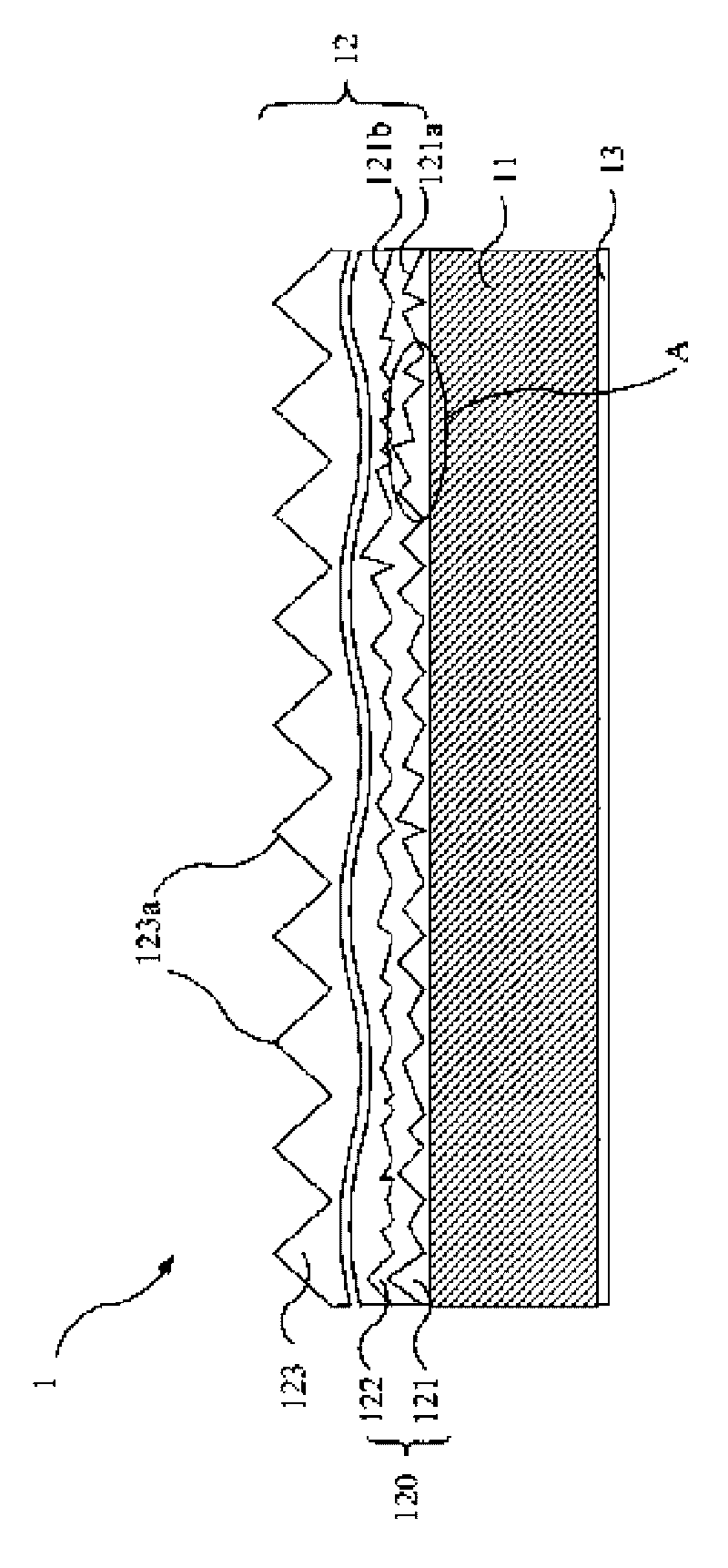

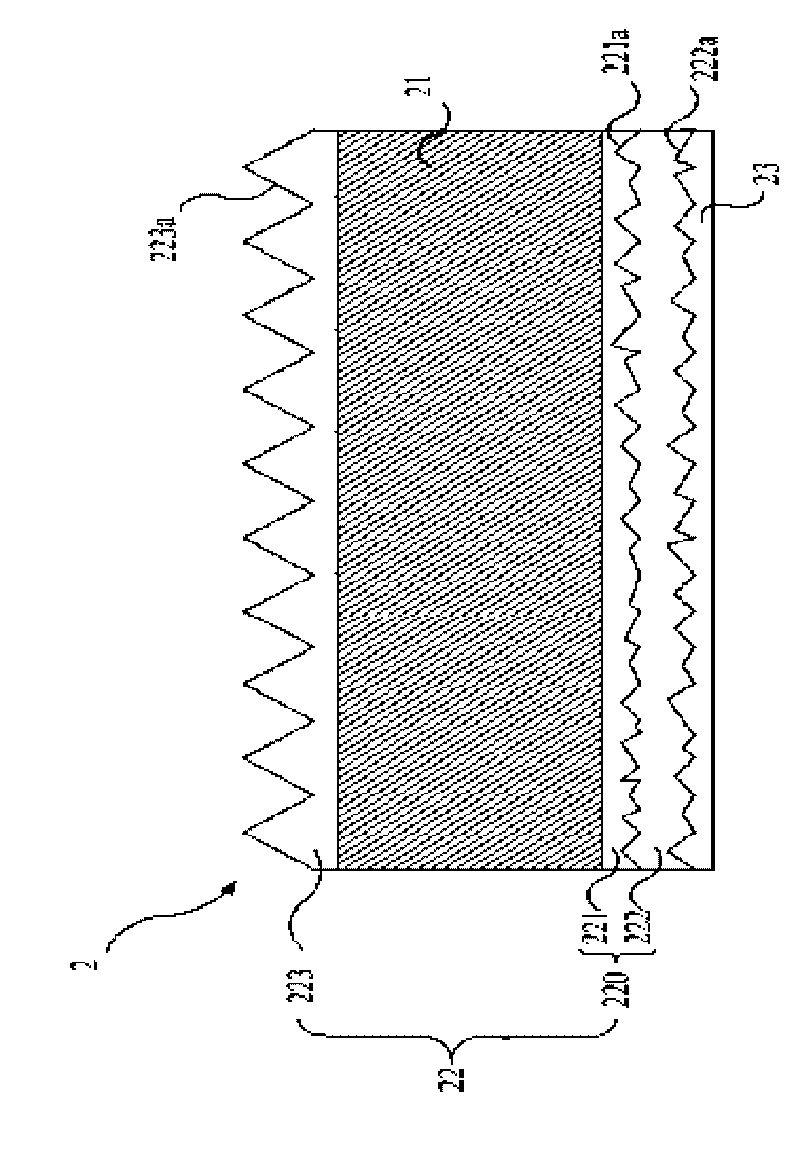

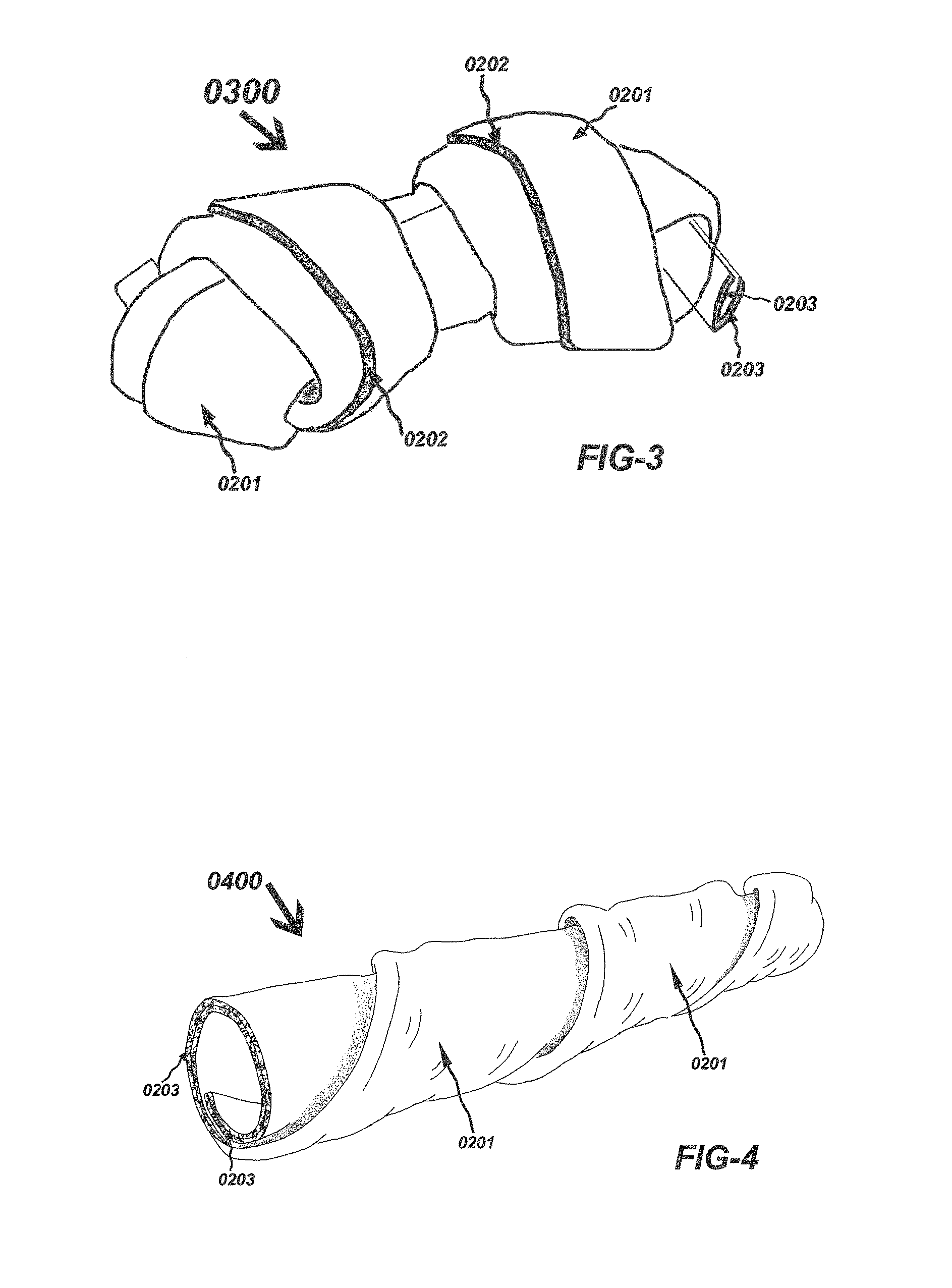

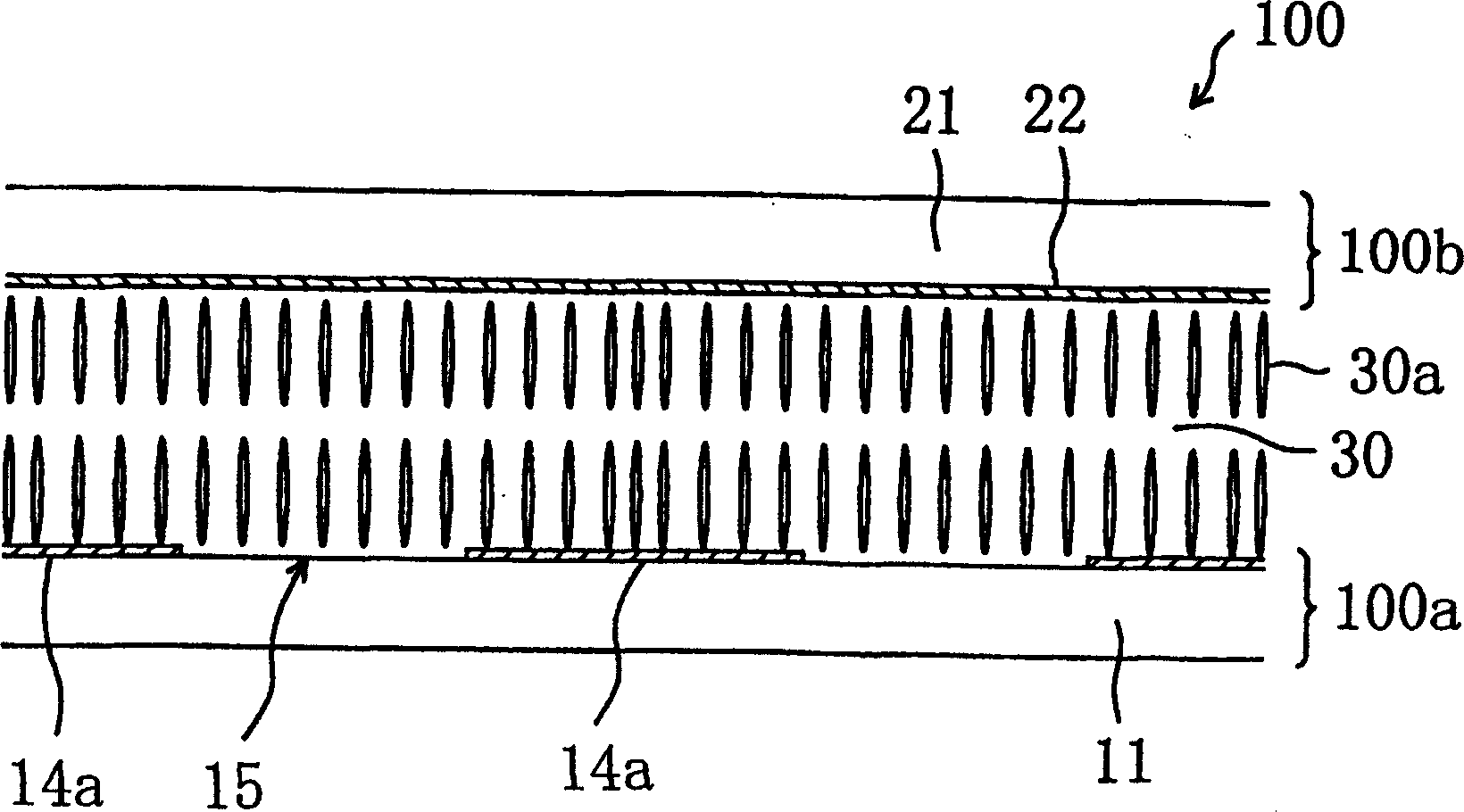

Interior decoration parts for automobiles and its manufacturing method

InactiveCN1799870ADownshifting does not occurUniform thicknessOrnamental structuresPunchingEngineering

The invention relates to a method for providing inner decoration part of which comprises layered structure and relative producing method, which can avoid inclined fluff when punching and improve the appearance. The method comprises that the inner decoration is formed by foam resin basic material (21) which is light with form-keeping ability and has a resin rib (22), a layered structure (the upper part of said decoration) whose surface is adhered with additional decoration (23) and a resin monomer element (the lower part of decoration) (30). Wherein, the layered structure (20) can combine the additional decorations (23) which is only processed by low-temperature soft treatment without heating process with the foam resin sheet (S) which is processed by heating soft treatment, to be put into molding metal mould (40), and via low-pressure punching shaping to be integrated. Therefore, the invention can avoid inclined fluff and heat deformation of decoration (23) to confirm better form-keeping ability and reduce the shaping load.

Owner:KASAI KOGYO CO LTD

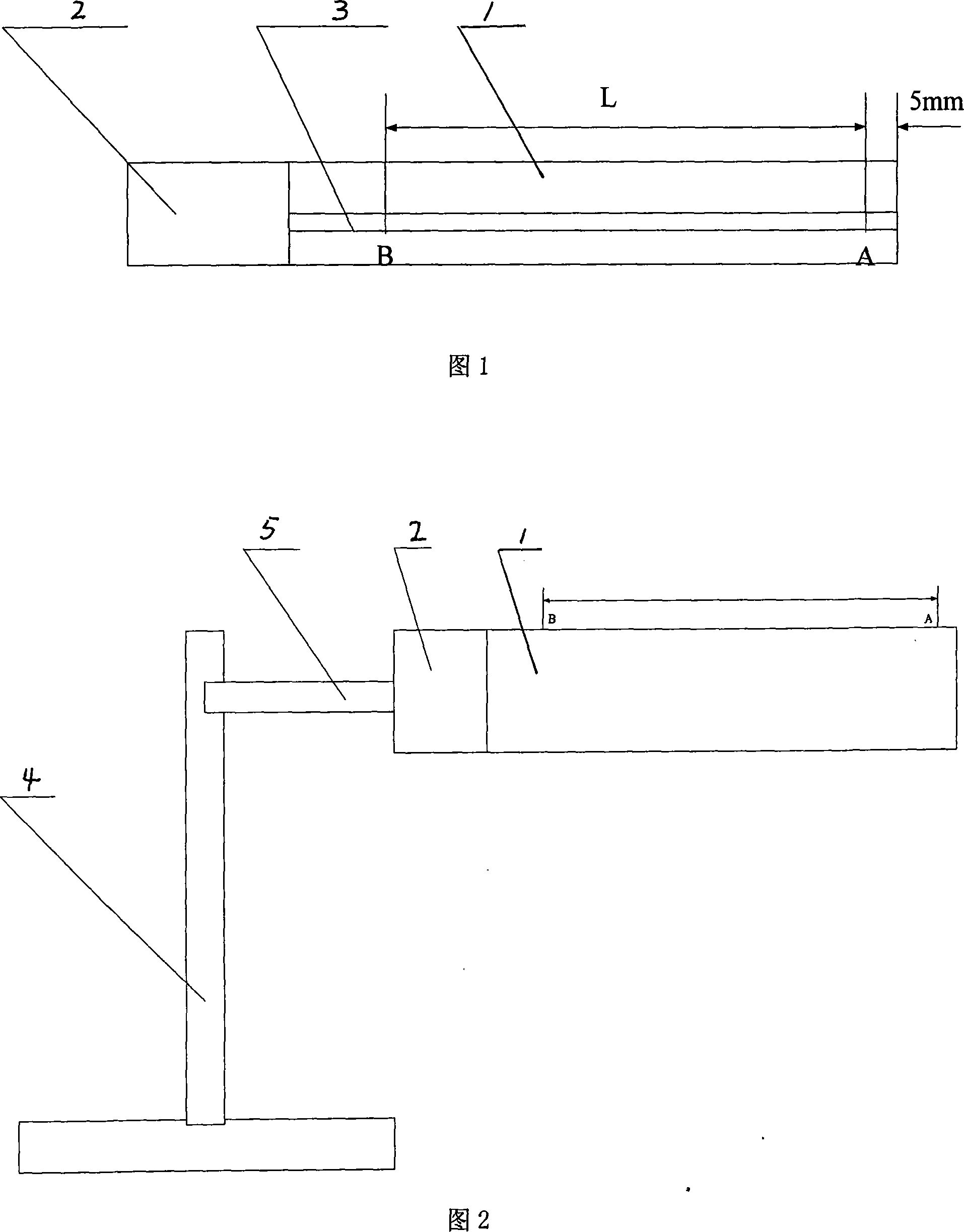

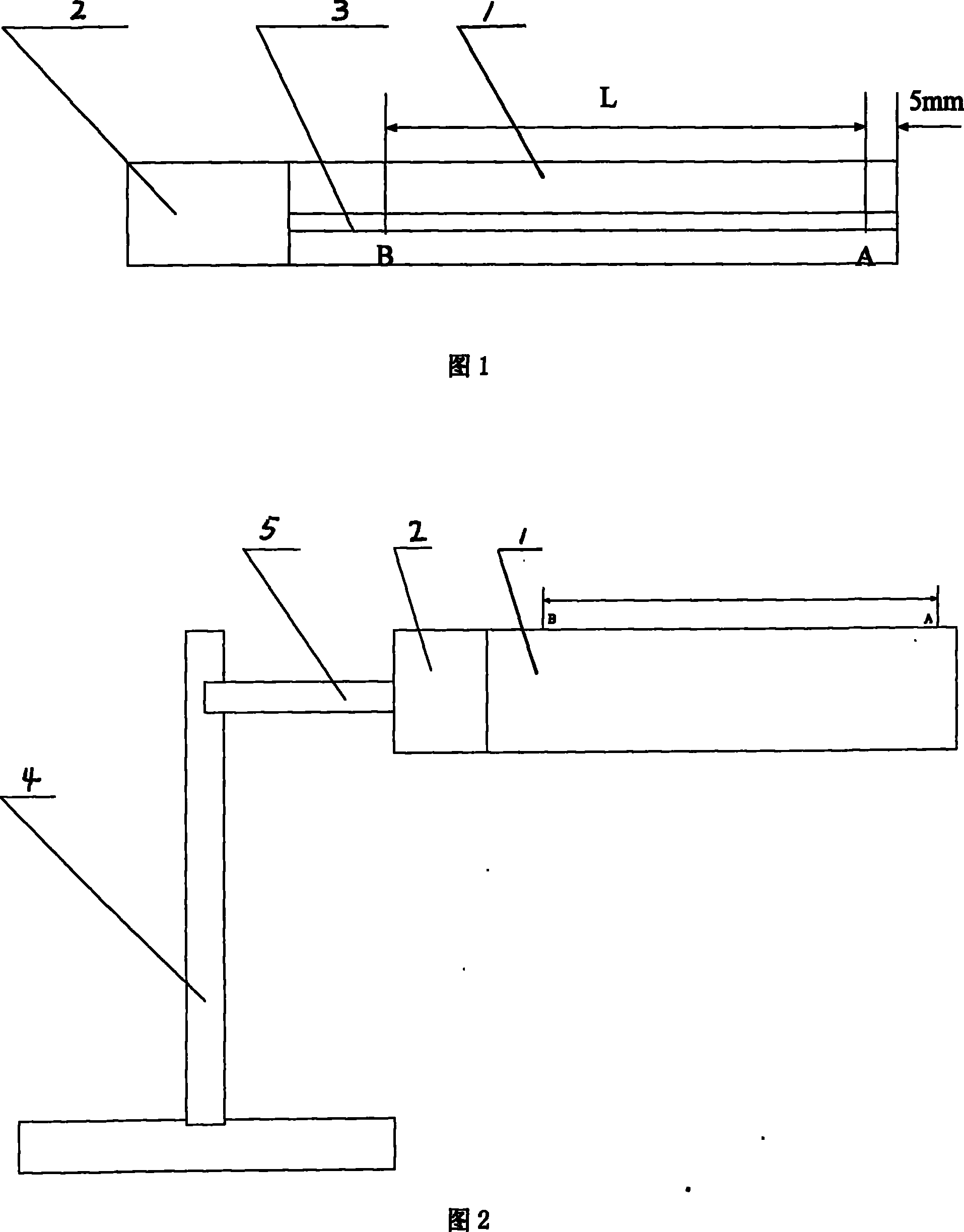

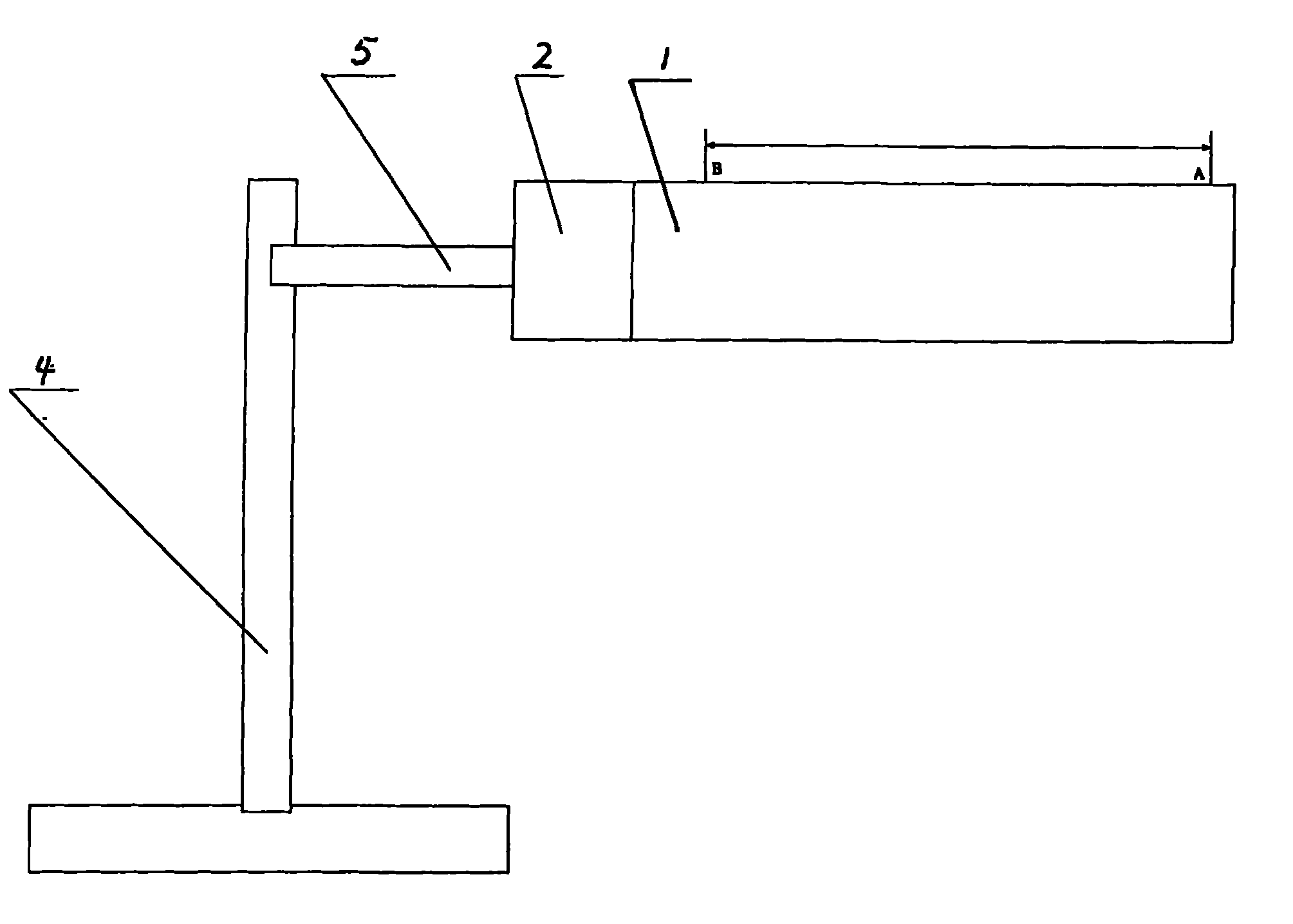

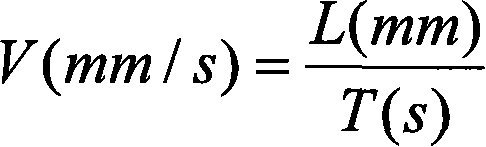

Method for determining cigarette paper smolder speed

InactiveCN101226186AGood repeatabilitySmall discreteChemical analysis using combustionPaper testingPulp and paper industrySingle level

The invention relates to a measuring method of smoldering speed of cigarette paper, which comprises a, preparing a cigarette hollow paper drum sample, b, setting relative marks, c, setting fixing method, d, setting test conditions, e, calculating out the cigarette paper smoldering speed via formula. Compared with prior three test methods, the invention has the advantages that 1, the test result has good repeatability, 2, the test result has good stability, 3, the test result can actually represent product quality, 4, the test result can represent the application character of product, 5, and the method has good operability. The test result indicates that since the cigarette paper has single-layer drum structure, is suspended and horizontally arranged and smoldered, the sample is in one small space, to make smoldering line regular, obtain the test result with good repeatability and reduce dispersion as small variation factor, thereby truly representing the quality and application character of product.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

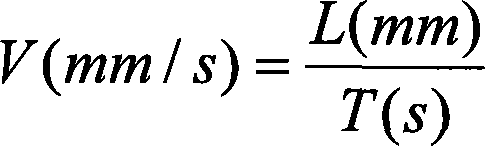

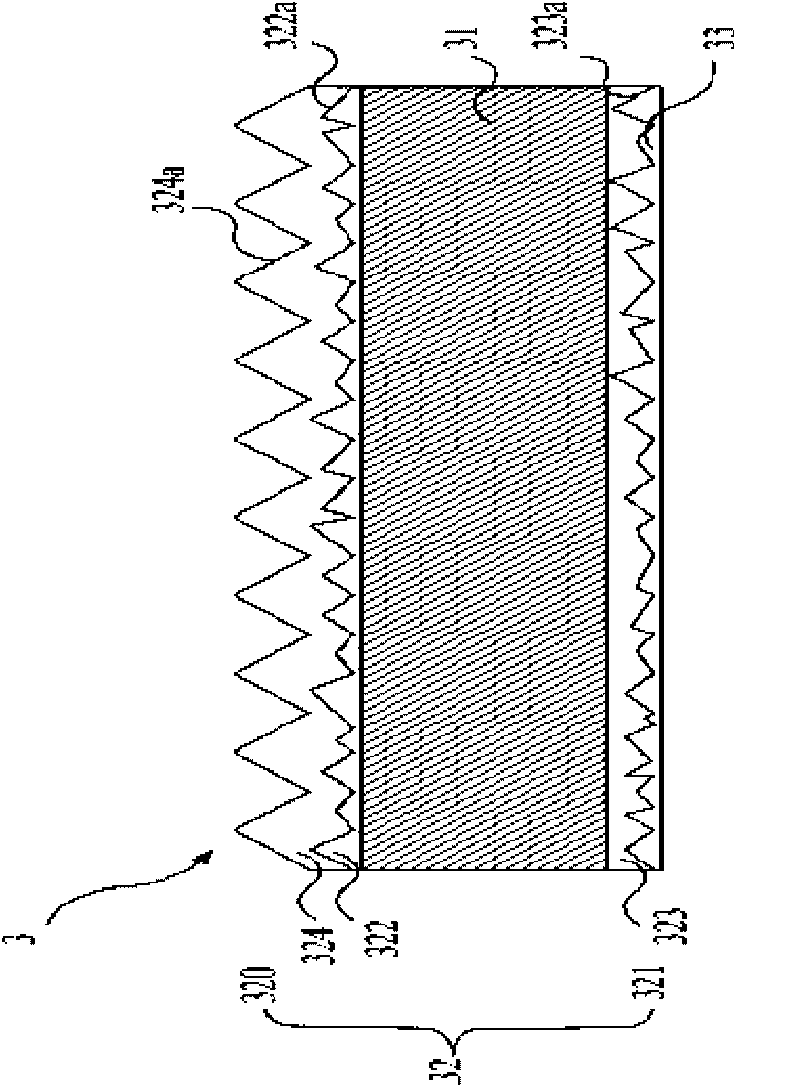

Composite optical film structure with multiple coatings

InactiveCN101738649AReduces the problem of scratching blemishesEasy to assembleDiffusing elementsSynthetic resin layered productsIonFilm material

The invention relates to a composite optical film structure with multiple coatings. With a diffusion layer with an interface microstructure as a photo diffusion mechanism, the invention comprises a transparent base material, a multiple coating and a protection coating; wherein a diffusion layer combination of the inner layer of the multiple coating is provided with at least more than one diffusion layer with a port microstructure, a condensation layer at the first surface layer of the multiple coating is provided with an optical rotation microstructure. On the basis, composite design is carried out by light source diffusion as a result of the multiple coating technology and condensation effect; with the optical film structure integrated into an optical film, material cost can be effectively reduced; and when the diffusion layer with the port microstructure serves as the photo diffusion mechanism, not only brightness performance can be effectively improved, meanwhile quality variables created by dispersion of doping ions and film material warpage and the like can also be reduced; as a result, while assembly of a backlight module is simplified to improve assembly efficiency thereof, film material quality and optical property of the composite optical film can also be improved.

Owner:GIGASTORAGE CORP

Edible Pet Chew and Method for Making the Same

ActiveUS20140255553A1Visually attractiveReduce pollutionMeat/fish preservationFood processingThree dimensional shapeCompanion animal

Owner:SHANGHAI SUNLIGHT INNOV TRADING CO LTD

Glass substrate manufacturing method, glass substrate polishing method, glass substrate polishing apparatus and glass substrate

InactiveCN102019579AImprove grinding precisionImprove quality characteristicsLapping machinesRecord information storageEngineeringElectric power

Owner:AGC INC

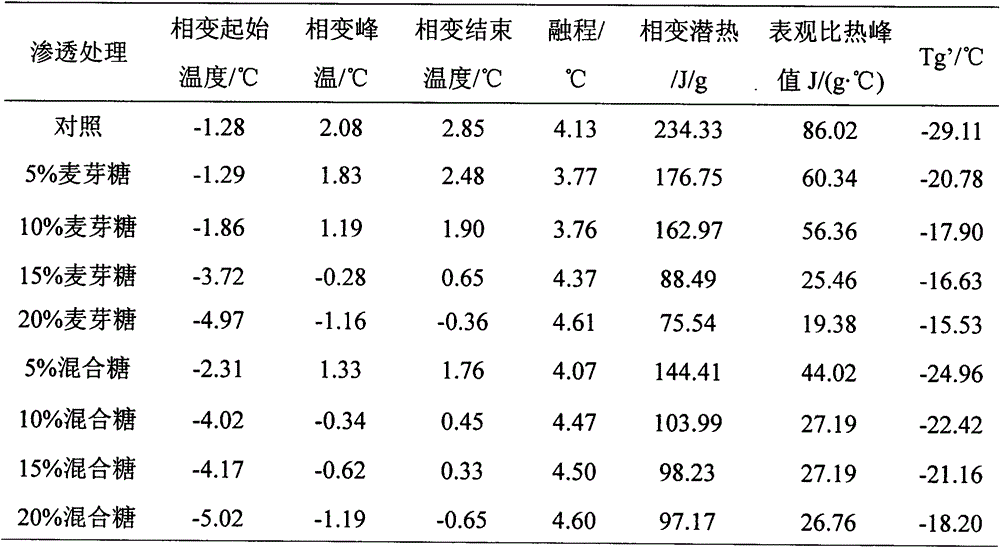

Processing method of high-quality frozen lotus root slices

ActiveCN103947744AIncrease moisture contentAvoid damageFruits/vegetable preservation by irradiation/electric treatmentClimate change adaptationChemistryLotus root

The invention relates to the vegetable and fruit freezing processing field and specifically relates to a processing method of high-quality frozen lotus root slices. The processing method comprises the following steps: performing color-protecting and microwave blanching treatment on lotus roots which are cleaned, peeled and sliced previously, putting the lotus root slices under a vacuum condition and performing permeation treatment on the lotus root slices in a conditioning solution at a temperature ranging from 15 to 25 DEG C for 20-50 minutes, wherein the weight ratio of the lotus root slices to the conditioning solution is 1:1.5 to 1:2.5; draining, and then quickly freezing at a temperature ranging from -40 DEG C to -30 DEG C until the core temperature of the lotus root slices is below -18 DEG C; and putting the frozen lotus root slices in cold storage at a temperature ranging from -22 DEG C to -25 DEG C. The method has the advantages that the storage quality of the frozen lotus root slices is improved, and the obtained high-quality frozen lotus root slices are kept to be good in nutrition, color and luster, and brittleness.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES +1

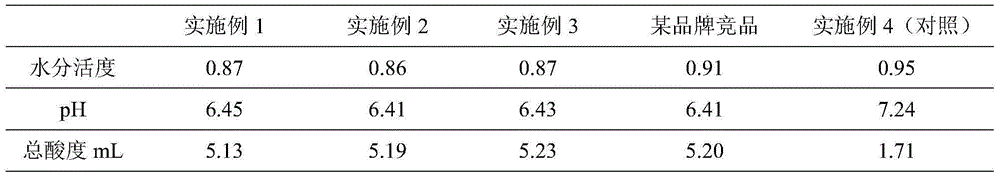

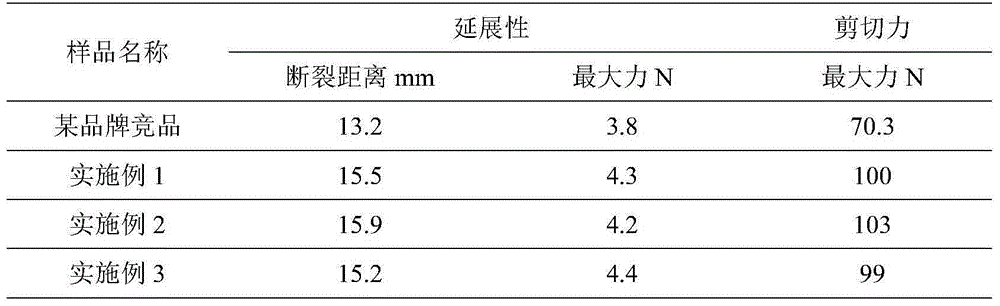

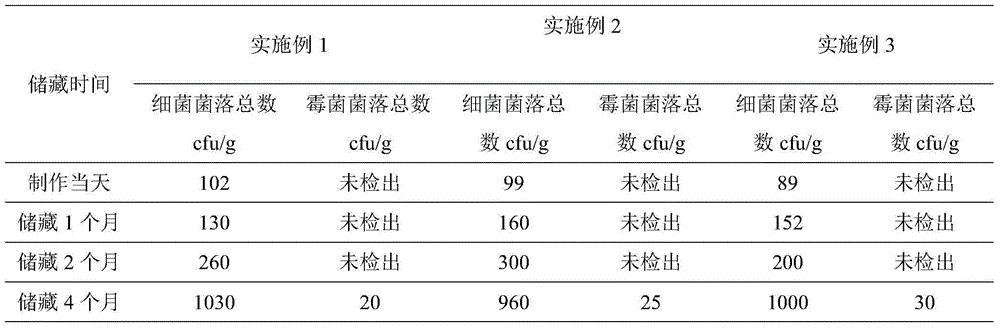

Method for preparing microwave instant taco through sour dough

ActiveCN105010463AEasy to prepareReduce energy consumptionBaking processesBakery productsNutrientExpiration date

The invention discloses a method for preparing a microwave instant taco through sour dough and belongs to the technical field of food production. According to the method, firstly, liquid sour dough paste fermented through lactobacillus plantarum is prepared; secondly, the sour dough is taken to prepare taco dough, and the taco is prepared through the steps of fermenting, cooking and the like. According to the taco prepared through the method, the product technology can be effectively simplified, the product cost can be reduced, the amount of chemical addition agents can be decreased, the taco can be stored at least for four months at the normal temperature, the shelf expiration date of the product is effectively prolonged, the aging speed of the product is reduced, and the taco has the advantages of being nutrient, health, easy to process and the like.

Owner:JIANGNAN UNIV

Edible Pet Chew and Method for Making the Same

ActiveUS20140044838A1Improve quality characteristicsSimple structureMeat/fish preservationConfectioneryAnimal scienceCompanion animal

Owner:SHANGHAI SUNLIGHT INNOV TRADING CO LTD

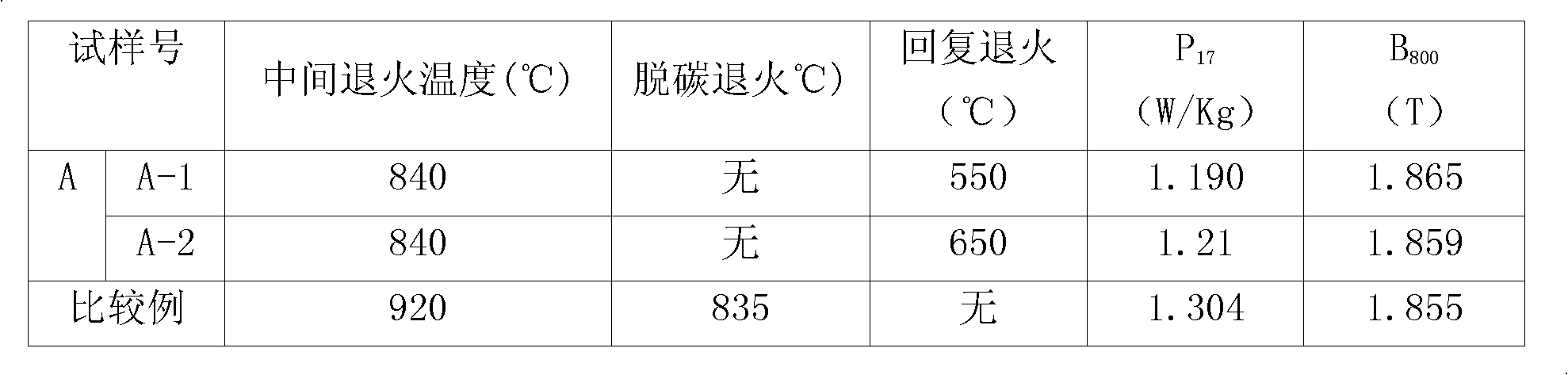

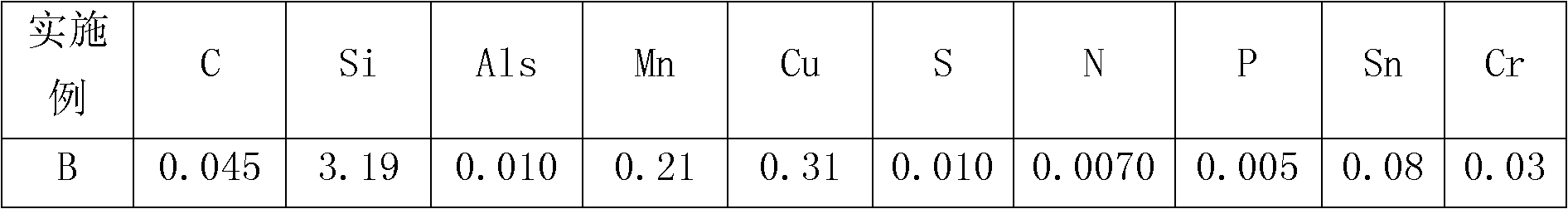

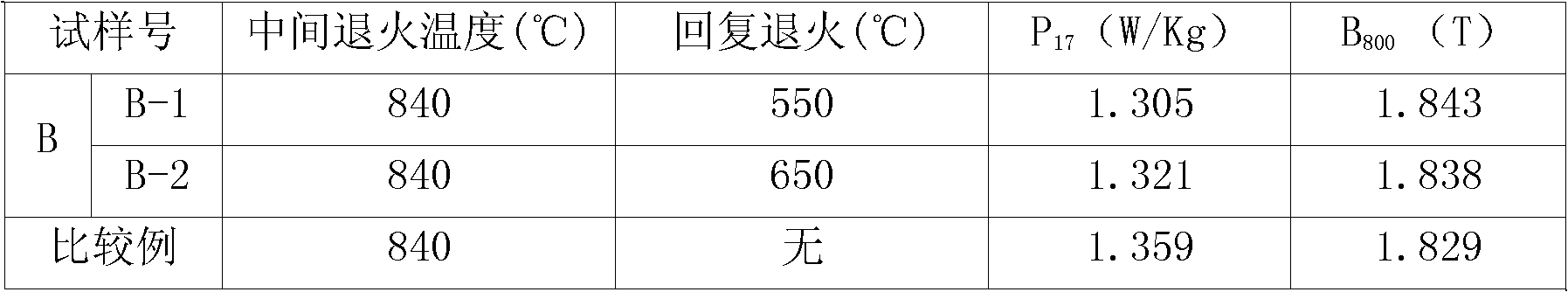

Low-temperature heating oriented electrical steel with good surface coating and production method thereof

InactiveCN102127716AEliminate work hardeningEliminate magnetic agingTemperature control deviceElectrical steelProduct gas

The invention relates to a low-temperature heating oriented electrical steel with good surface coating and a production method thereof, belonging to the technical field of oriented electrical steels. A casting blank comprises the following components: 0.005-0.08wt% of C, 2.5-6.5wt% of Si, 0.005-0.03wt% of Als, 0.001-0.4wt% of Mn, 0.01-0.3wt% of Cu, 0.003-0.010wt% of N, 0.001-0.03wt% of S, 0.01-0.3wt% of Sn, 0.001-0.1wt% of Cr, less than or equal to 0.02wt% of P and the balance of Fe and inevitable impurities. The casting blank is heated to 1150-1300 DEG C and then is subjected to hot rolling, a hot rolled plate is subjected to acid pickling, two-step cold rolling containing intermediate annealing is carried out until the thickness of a finished product is achieved, the intermediate annealing is carried out at the temperature of 750-850 DEG C, the heat preservation is carried out 3-6 minutes, and the furnace atmosphere is mixed gas of wet H2 and N2. The invention has the advantages that an auxiliary inhibitor is added, the intermediate annealing process is improved, and the short-time low temperature recovery annealing is carried out after cold rolling, thus the intermediate full-decarbonizing annealing time is reduced, the production efficiency is improved, and the quality of the surface coating is improved.

Owner:SHOUGANG CORPORATION

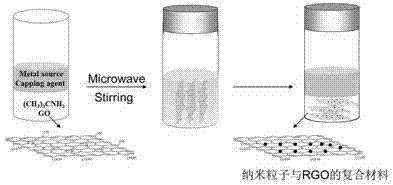

Preparation method of titanium dioxide and grapheme composite nanomaterial

InactiveCN103936065AImprove quality characteristicsHigh crystallinityMaterial nanotechnologyGrapheneCrystallinityParticle-size distribution

The invention provides a preparation method of a titanium dioxide and grapheme composite nanomaterial. The method comprises the following steps: taking and mixing a graphene oxide aqueous solution and tert-butylamine so as to obtain mixed liquid, mixing the obtained mixed liquid with a titanium precursor solution, carrying out magnetic stirring on the obtained mixture under the condition that the obtained mixture is heated to 120-200 DEG C by way of microwave-assisted heating, carrying out a reaction on the obtained product so as to obtain an organic phase solution, and separating the titanium dioxide and grapheme composite nanomaterial from the organic phase solution, wherein the titanium precursor solution is composed of titanium propoxide, an organic coating agent and toluene. The method is used for preparing high-quality titanium dioxide and grapheme composite nanomaterial. The high quality means that nanoparticles are good in crystallinity, narrow in particle size distribution, and controllable in size; nanoparticles can be uniformly dispersed on the surface of grapheme in the composite material, do not fall off, are not agglomerated, and are good in stability.

Owner:NANJING UNIV OF POSTS & TELECOMM

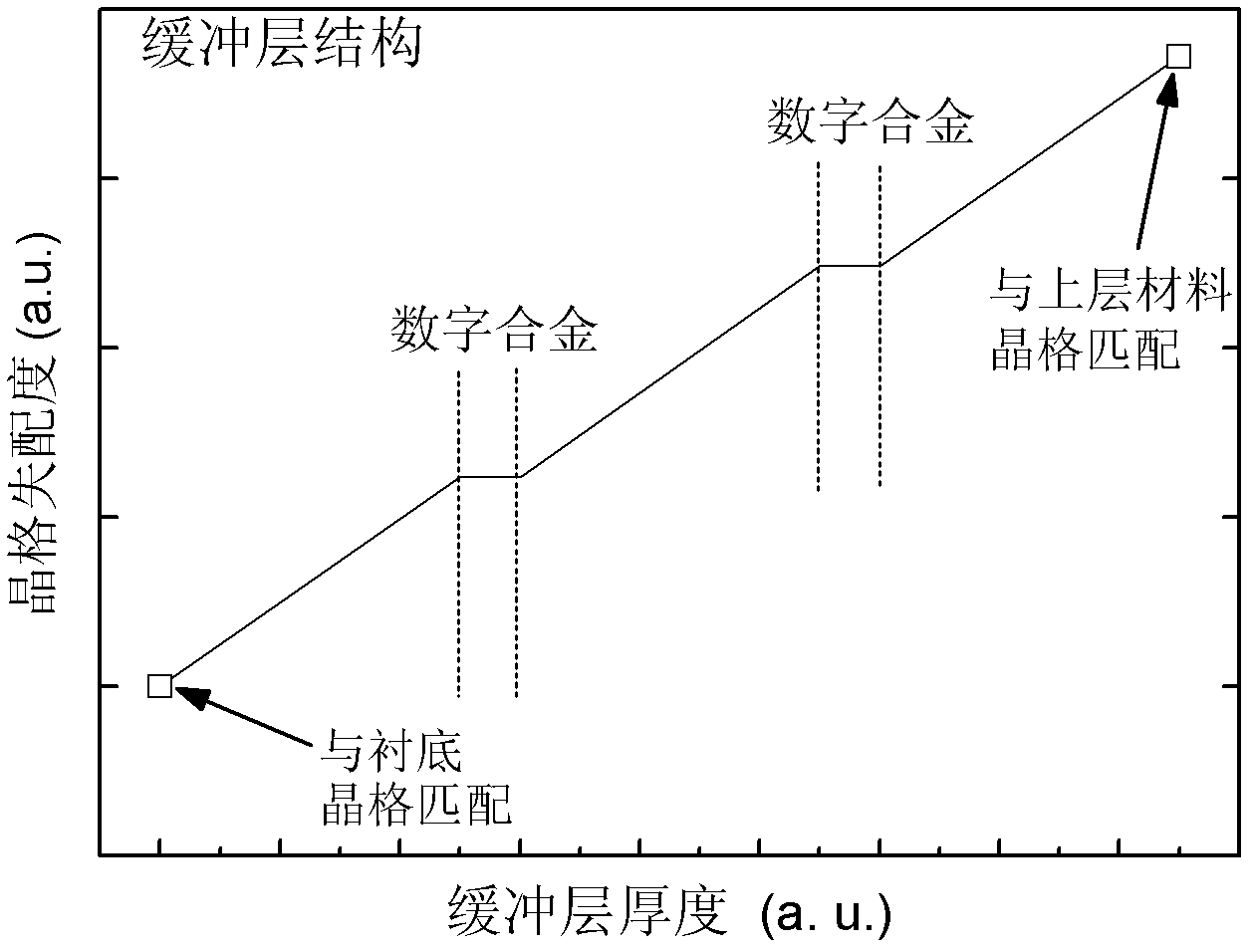

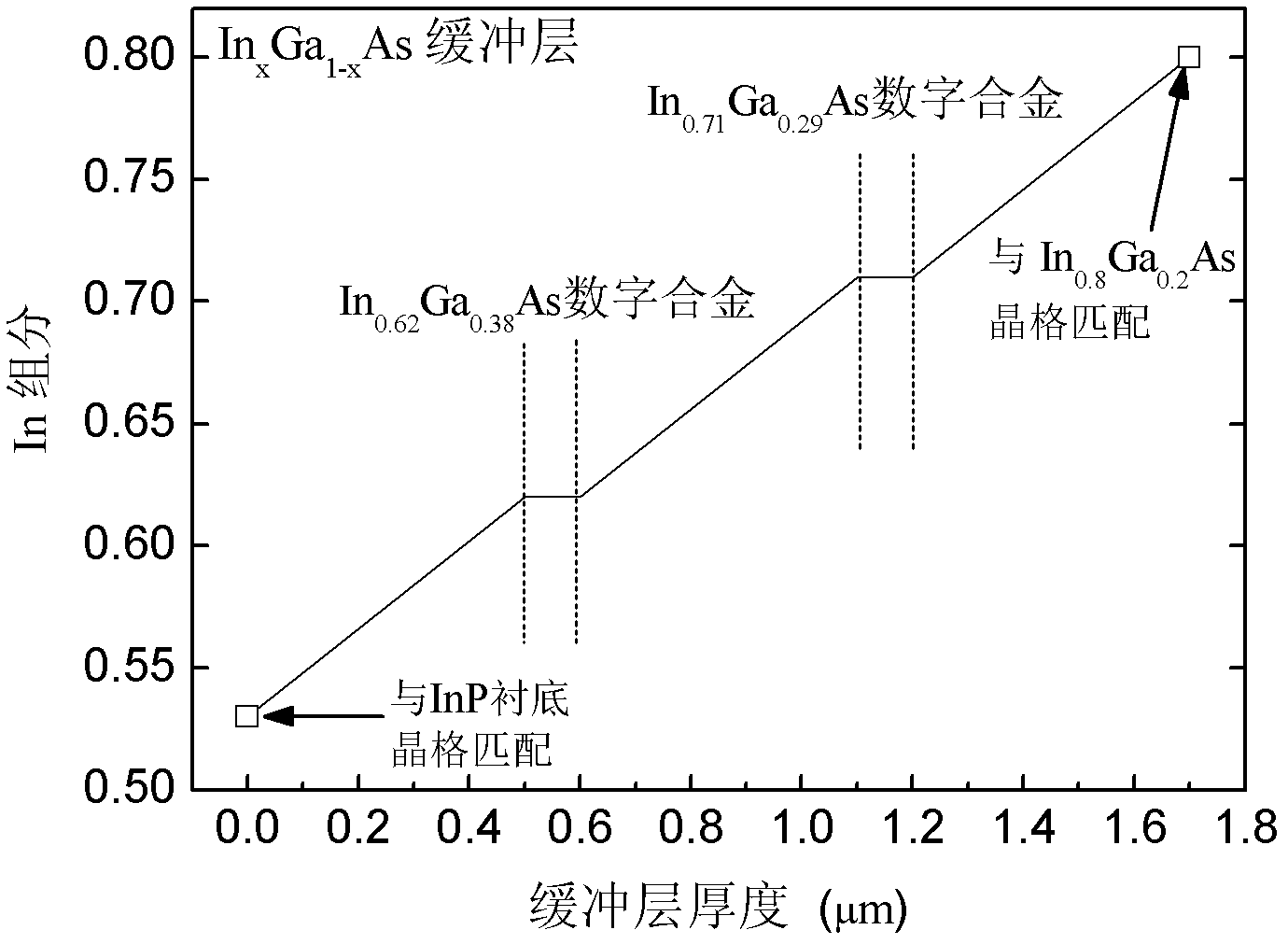

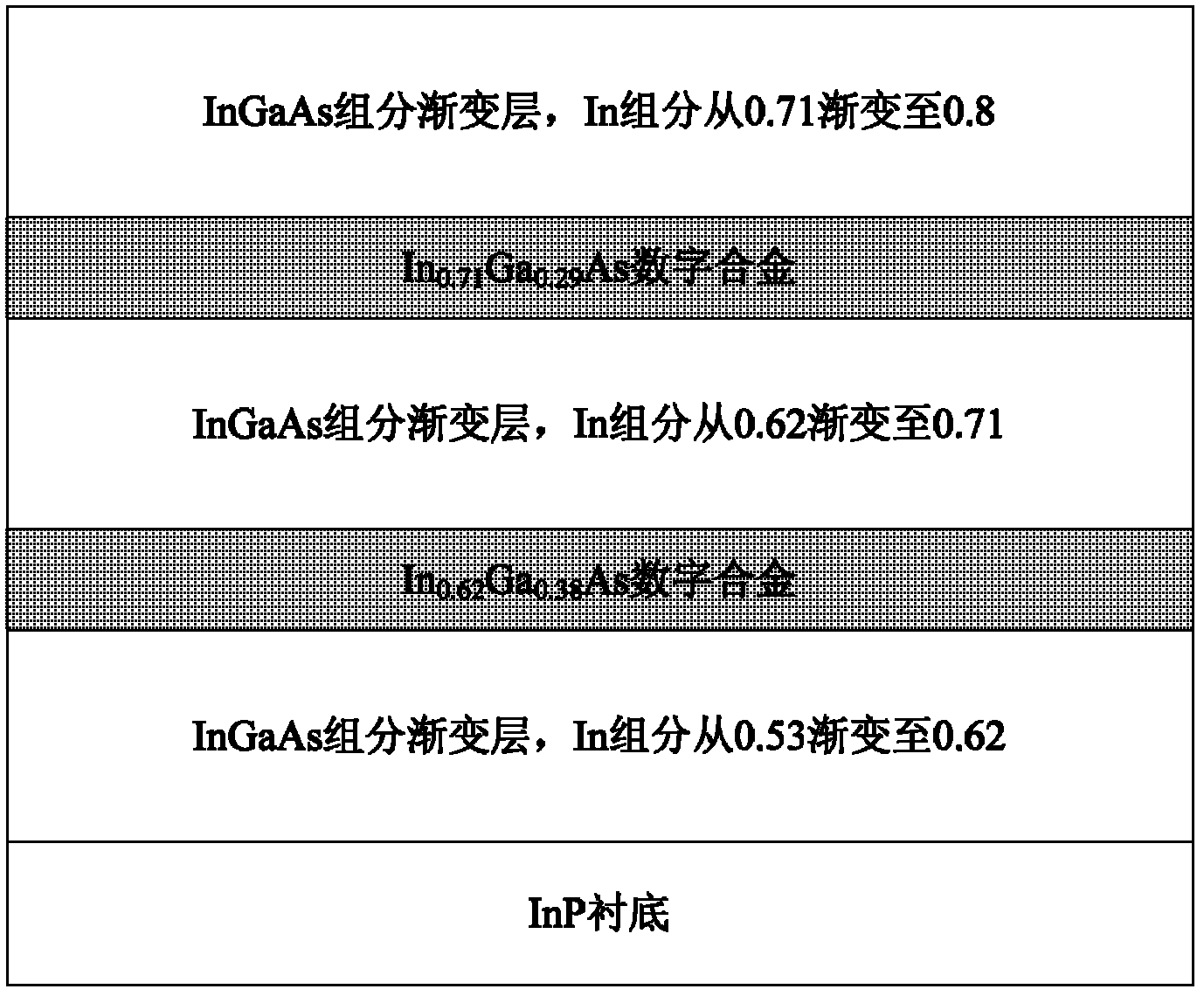

Macrolattice mismatch epitaxial buffer layer structure containing digital dislocation separating layers and preparation method thereof

InactiveCN102254954AReduce threading dislocation densityImproved lattice quality and optoelectronic propertiesFinal product manufactureSemiconductor devicesDislocationBeam source

The invention relates to a macrolattice mismatch epitaxial buffer layer structure containing digital dislocation separating layers and a preparation method thereof. The structure is characterized in that n layers of digital alloy dislocation separating layer materials are inserted into an ingredient gradual changing buffer layer. The preparation method comprise the following steps: adjusting beam source temperature, growing a ingredient gradual changing buffer layer on a substrate, and according to present gradual changing ingredient, forming a digital alloy dislocation separating layer through growing short period superlattice; adjusting the beam source temperature again, growing a ingredient gradual changing buffer layer, regrowing a digital alloy dislocation separating layer according to present gradual changing ingredient; regrowing a ingredient gradual changing buffer layer in above sequence until the buffer layer ingredient gradually changes to a desirable value to obtain the macrolattice mismatch epitaxial buffer layer structure. According to the invention, the macrolattice mismatch epitaxial material takes place relaxation and releases stress rapidly and effectively in the buffer layer and isolates penetrating dislocation, thus penetrating dislocation density of the epitaxial material on the buffer layer is reduced, and crystal lattice quality and photoelectric characteristic of the macrolattice mismatch epitaxial material on the buffer layer are improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Hybrid maize plant and seed 32A85

ActiveUS6927326B1Good colorEasy to standPlant genotype modificationPlant cellsHybrid seedGenetic Materials

According to the invention, there is provided a hybrid maize plant, designated as 32A85, produced by crossing two Pioneer Hi-Bred International, Inc. proprietary inbred maize lines. This invention relates to the hybrid seed 32A85, the hybrid plant produced from the seed, and variants, mutants, and trivial modifications of hybrid 32A85. This invention also relates to methods for producing a maize plant containing in its genetic material one or more transgenes and to the transgenic maize plants produced by that method. This invention further relates to methods for producing maize lines derived from hybrid maize line 32A85 and to the maize lines derived by the use of those methods.

Owner:PIONEER HI BRED INT INC

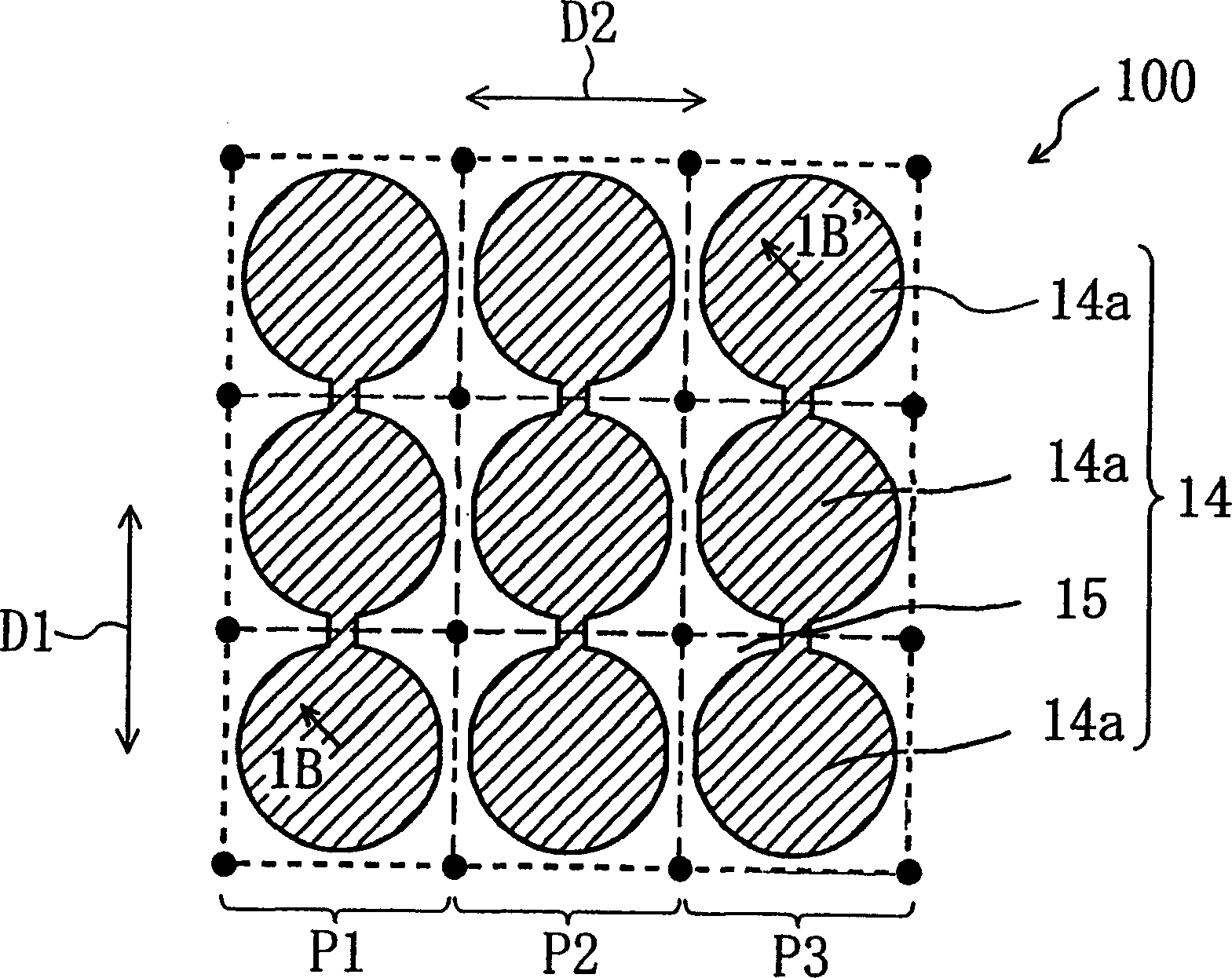

Liquid crystal display

InactiveCN1477428AStable Radial Tilt OrientationImprove stabilityStatic indicating devicesNon-linear opticsVertical alignmentElectrical polarity

A liquid crystal display device includes picture element regions defined each by a first electrode and a second electrode opposing the first electrode via the liquid crystal layer therebetween. The first electrode includes, in each picture element region, a plurality of unit solid portions arranged in a first direction, whereby the liquid crystal layer takes a vertical alignment in the absence of an applied voltage, and forms a liquid crystal domain taking a radially-inclined orientation in each unit solid portion by an inclined electric field produced around the unit solid portion in response to an applied voltage. The picture element regions are arranged in a matrix pattern including a rows extending in the second direction different from the first direction and columns extending in the first direction, and picture elements adjacent to each other in the second direction are driven with voltages of opposite polarities in each frame.

Owner:SHARP KK

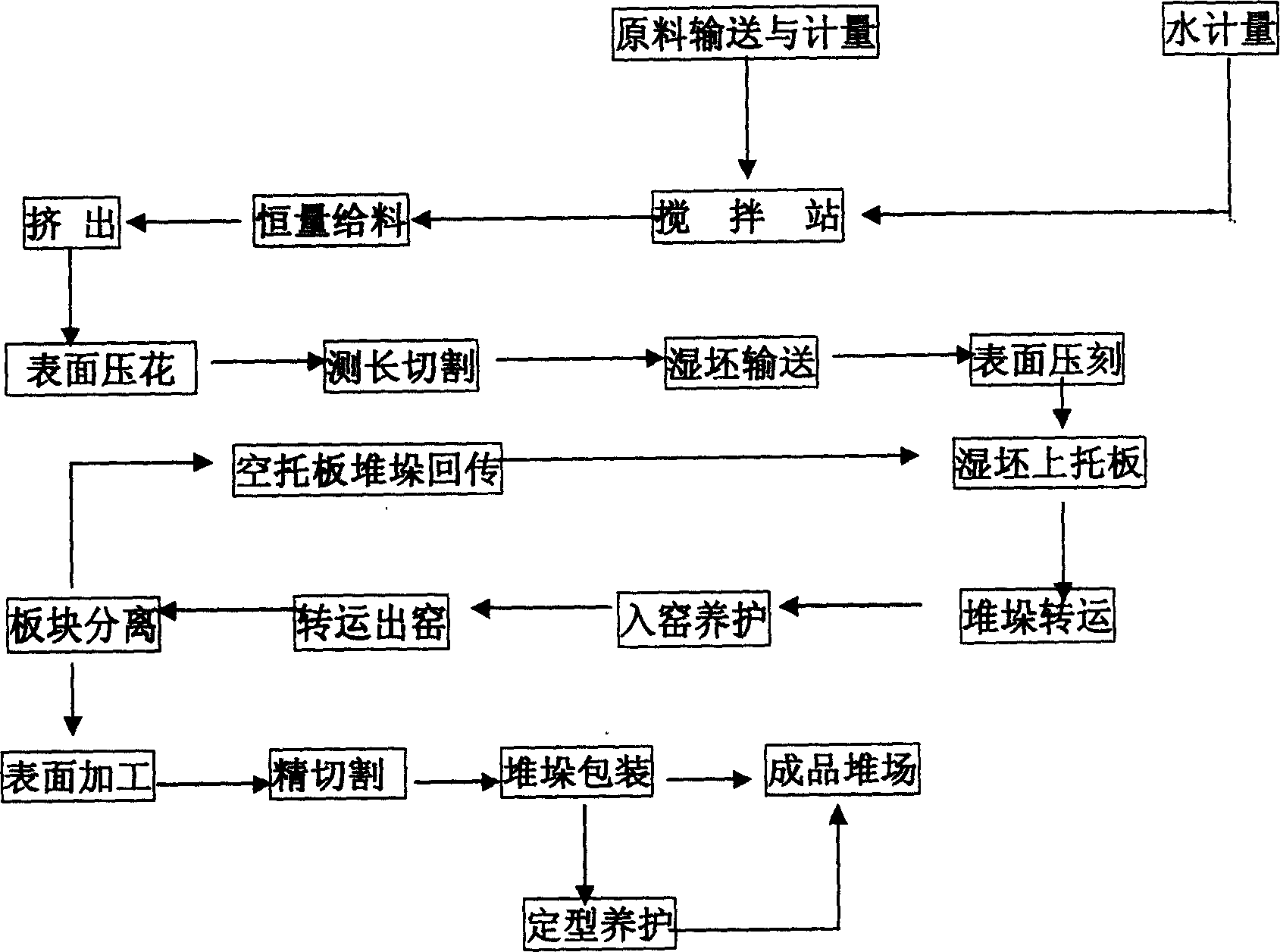

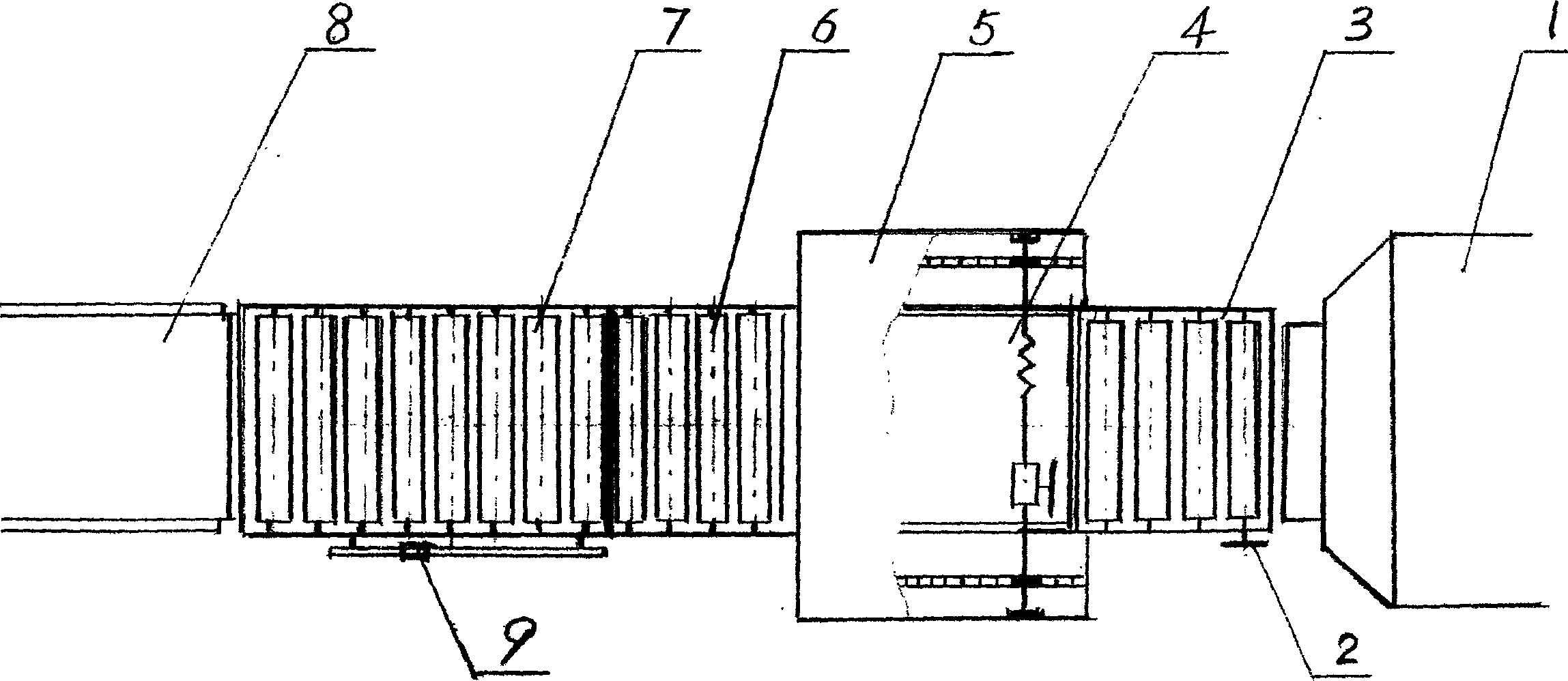

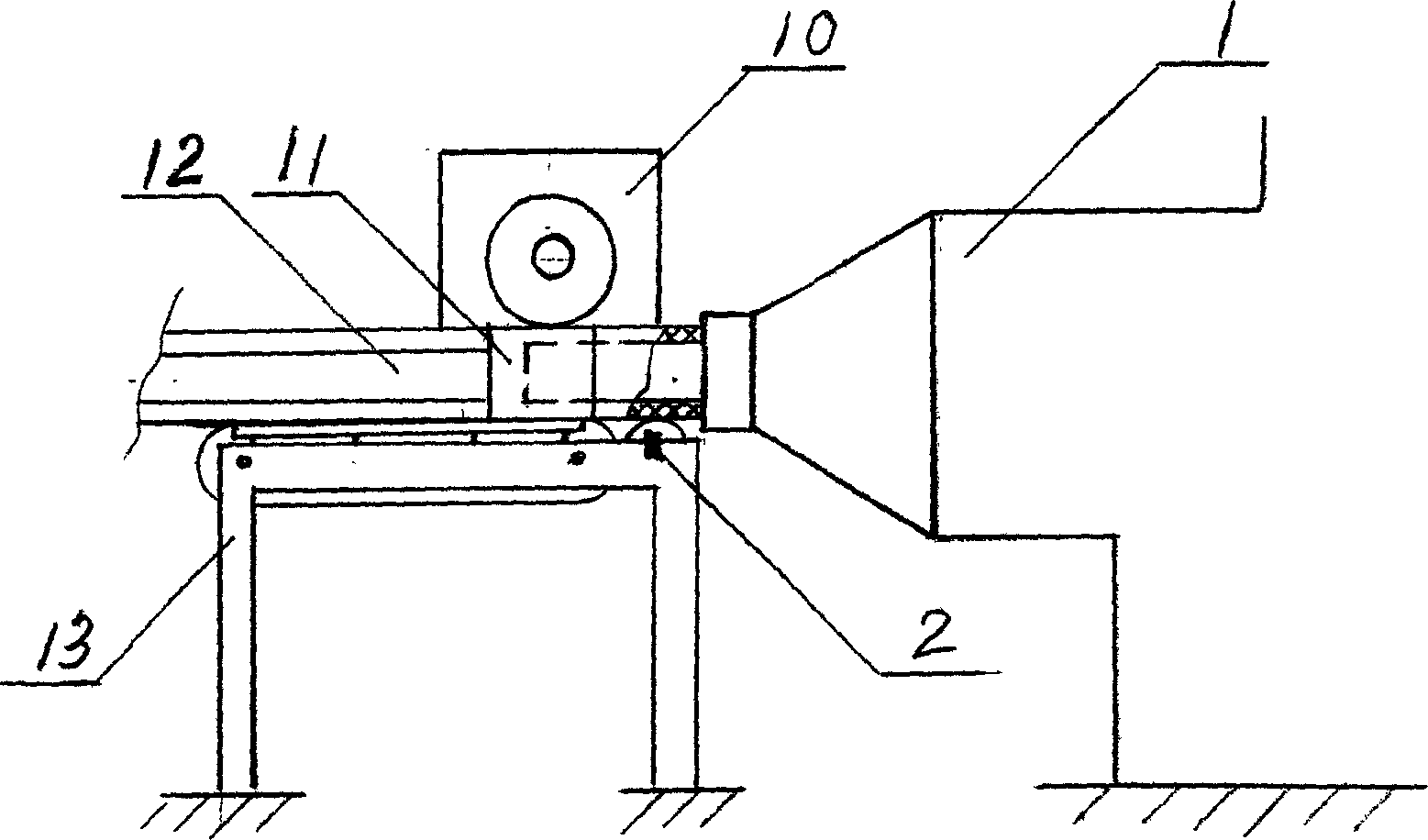

Light-duty high-strength fabric cement fly ash construction wallboard and complete set equipment for making same

ActiveCN1632258ASimple and fast constructionReduce the use of areaConstruction materialCeramic shaping apparatusThermal insulationNoise barrier

A light high-strength fiber cement fly ash building wallboard and its complete set of equipment, which use cement, silica powder, fly ash, plant fiber, methylcellulose (MC) and water as raw materials, and the wallboard can not only be used in construction Inner partition walls, and can be used for building exterior walls, exterior decorative walls, and public facilities such as sound insulation walls, firewalls, retaining walls, enclosures, etc., and can also produce such as L-shaped, baseboards, mirror lines, etc. The special-shaped board avoids the low technical index and the singleness of product types in the traditional wallboard production. It has high strength, exquisite and beautiful appearance, not easy to deform, and has outstanding performances such as bending resistance, anti-corrosion, anti-ultraviolet radiation, anti-freezing and thawing, machinability, heat preservation, sound insulation, and fire prevention.

Owner:项宏疆 +1

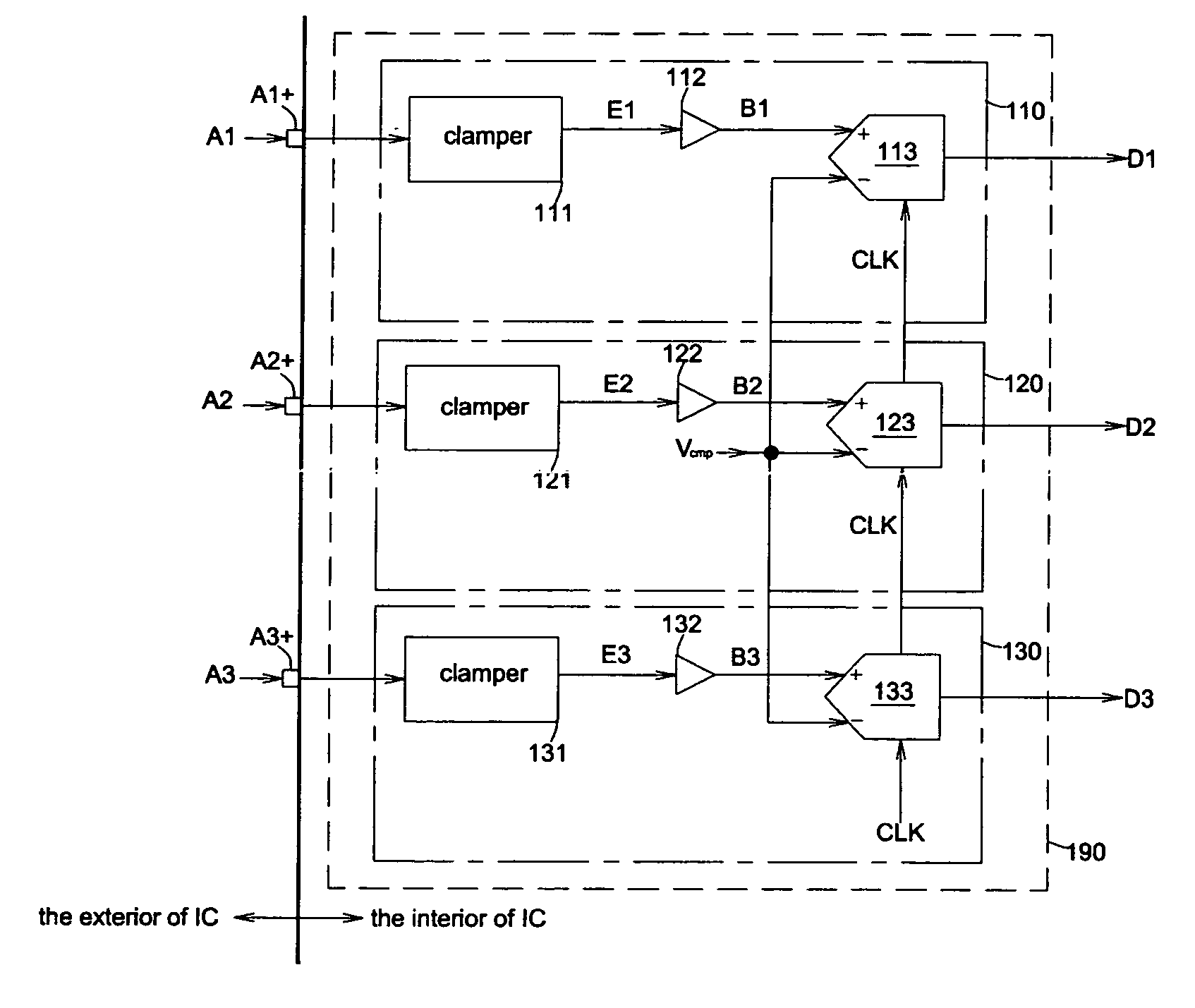

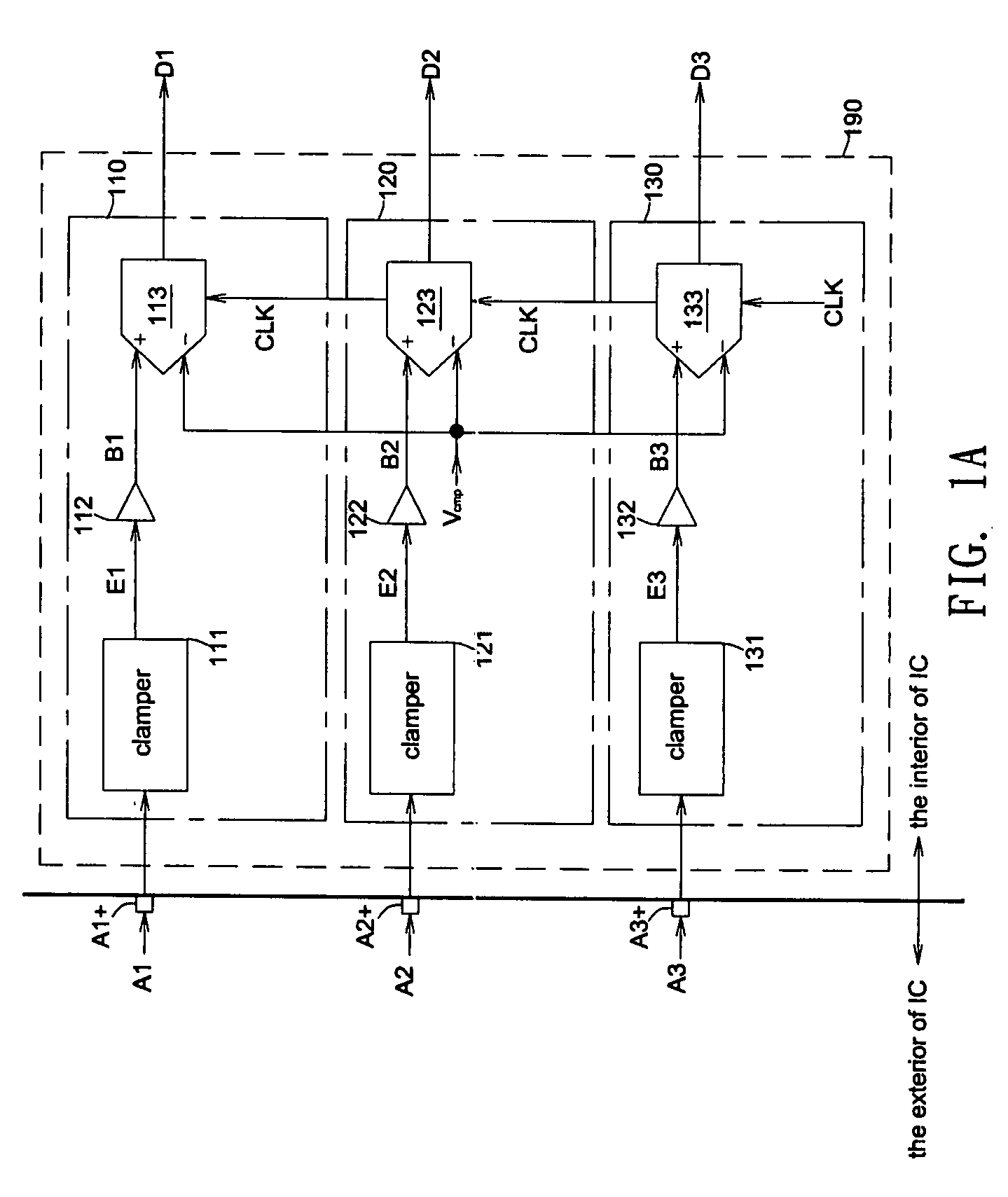

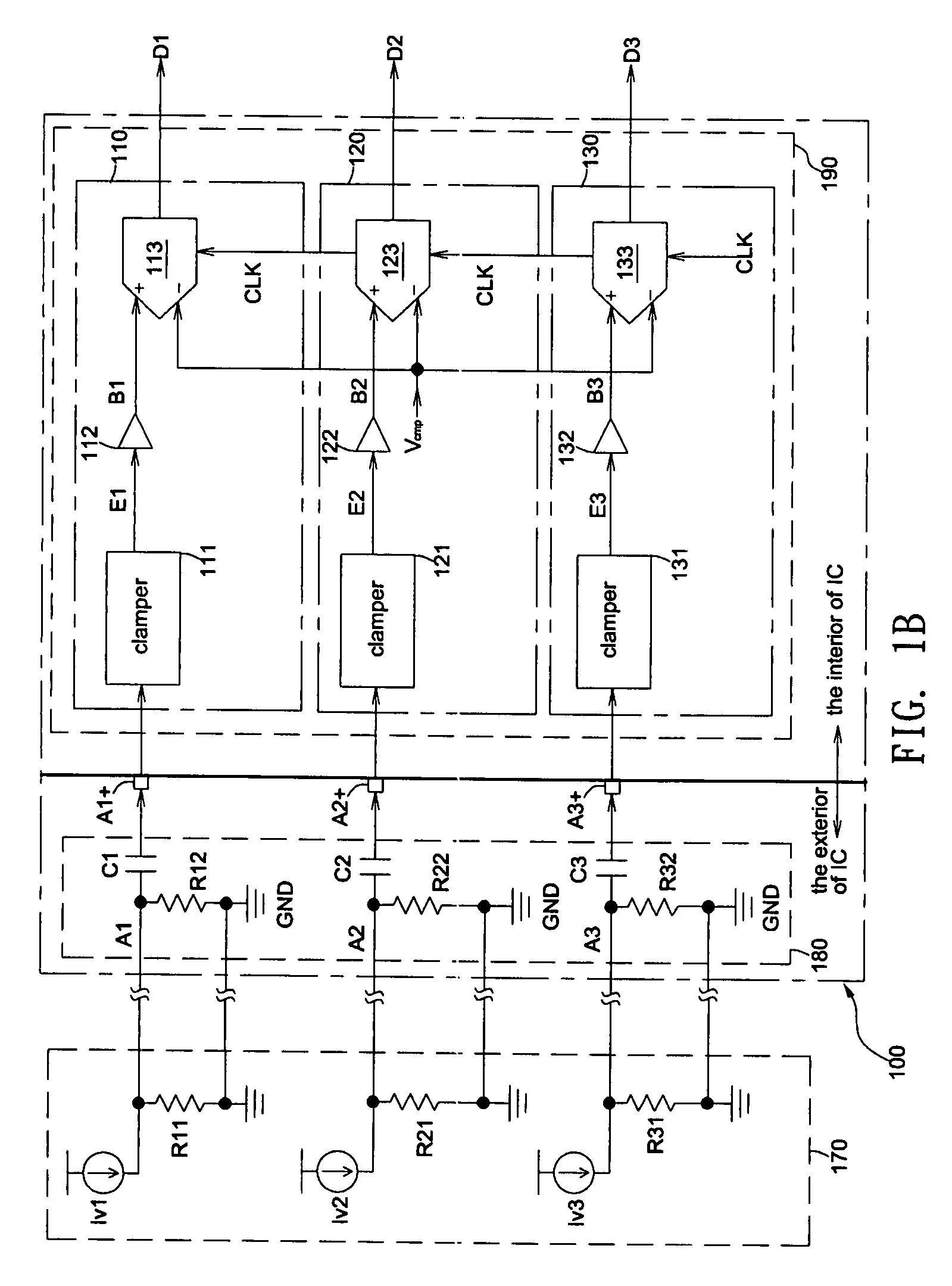

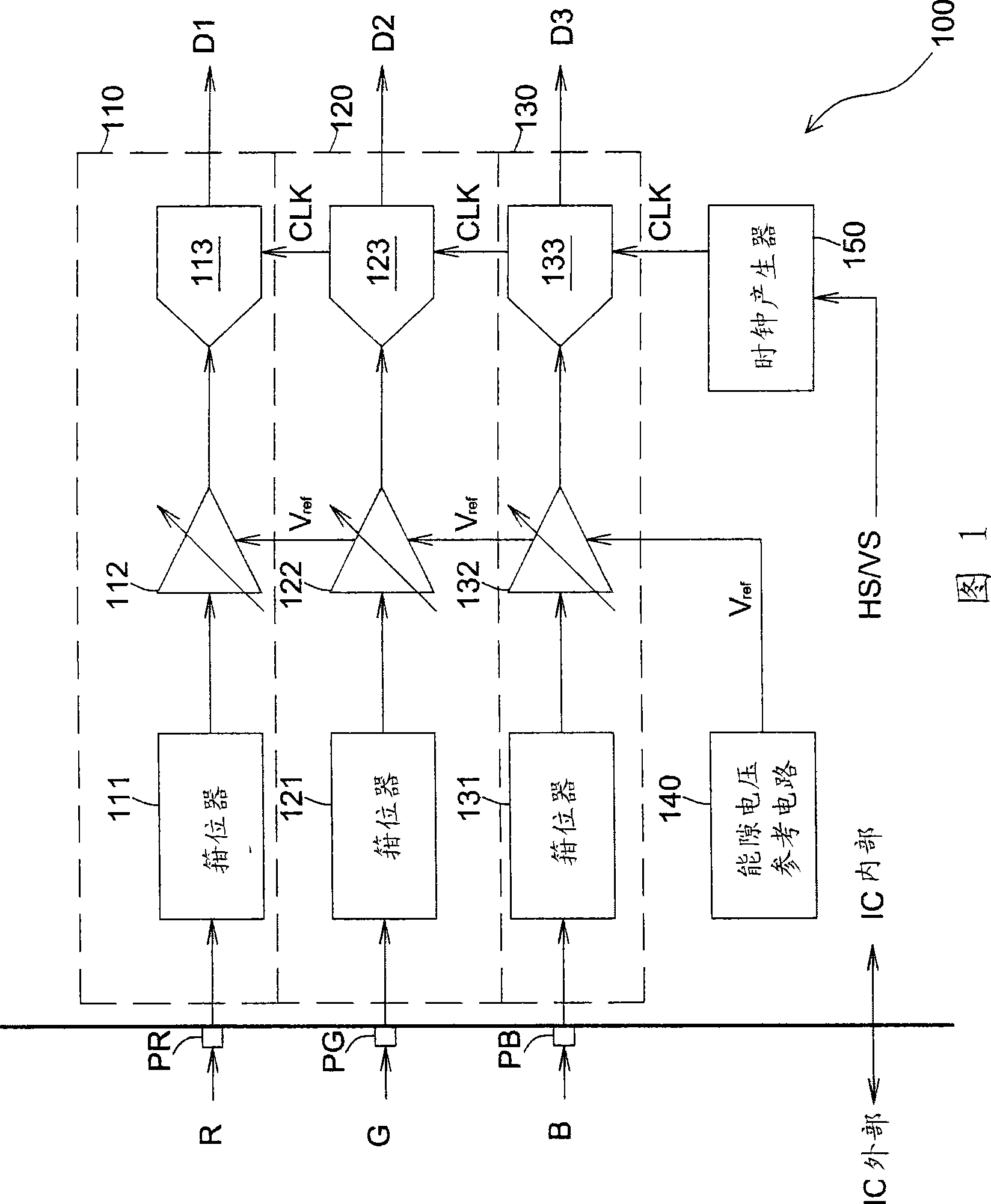

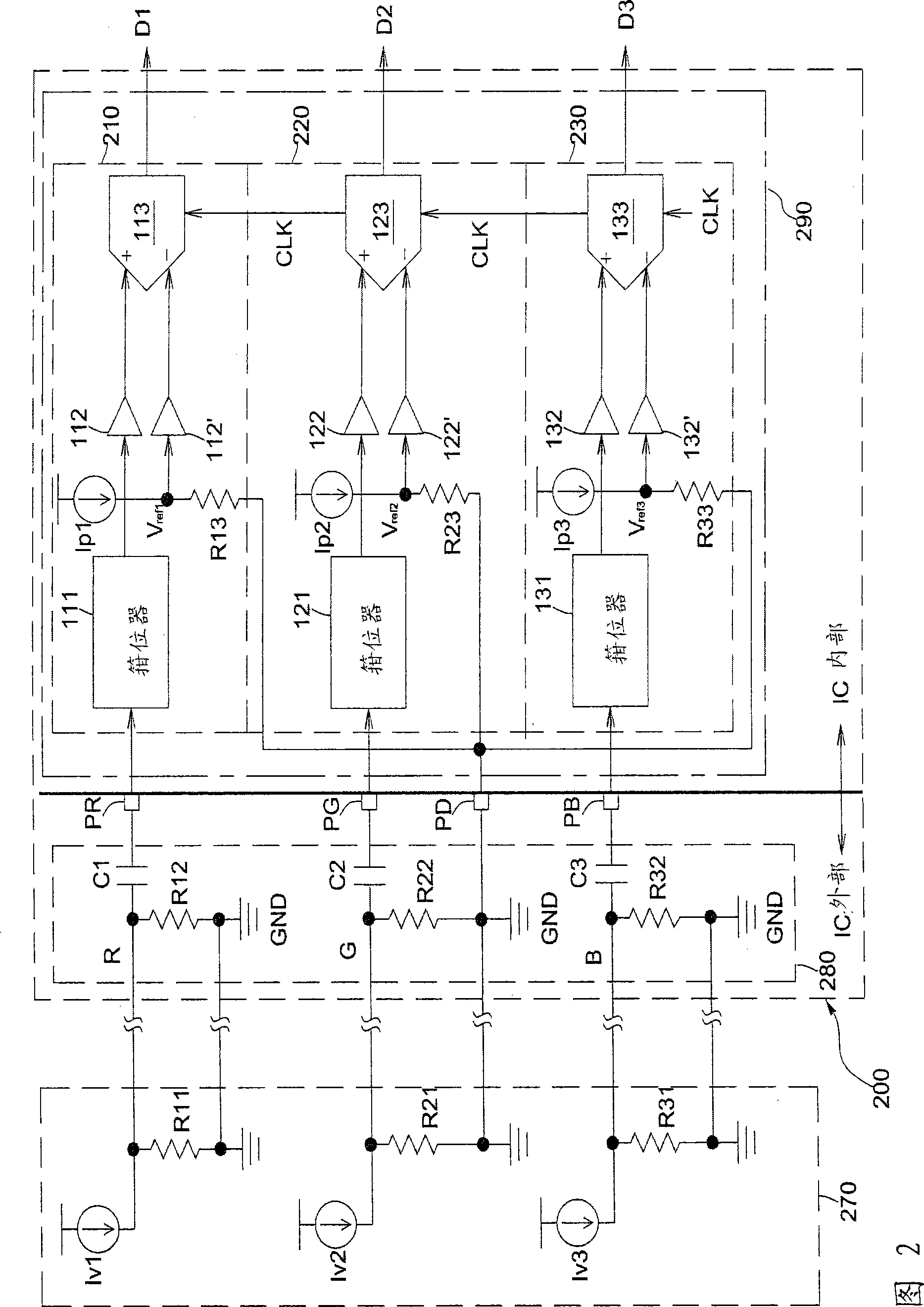

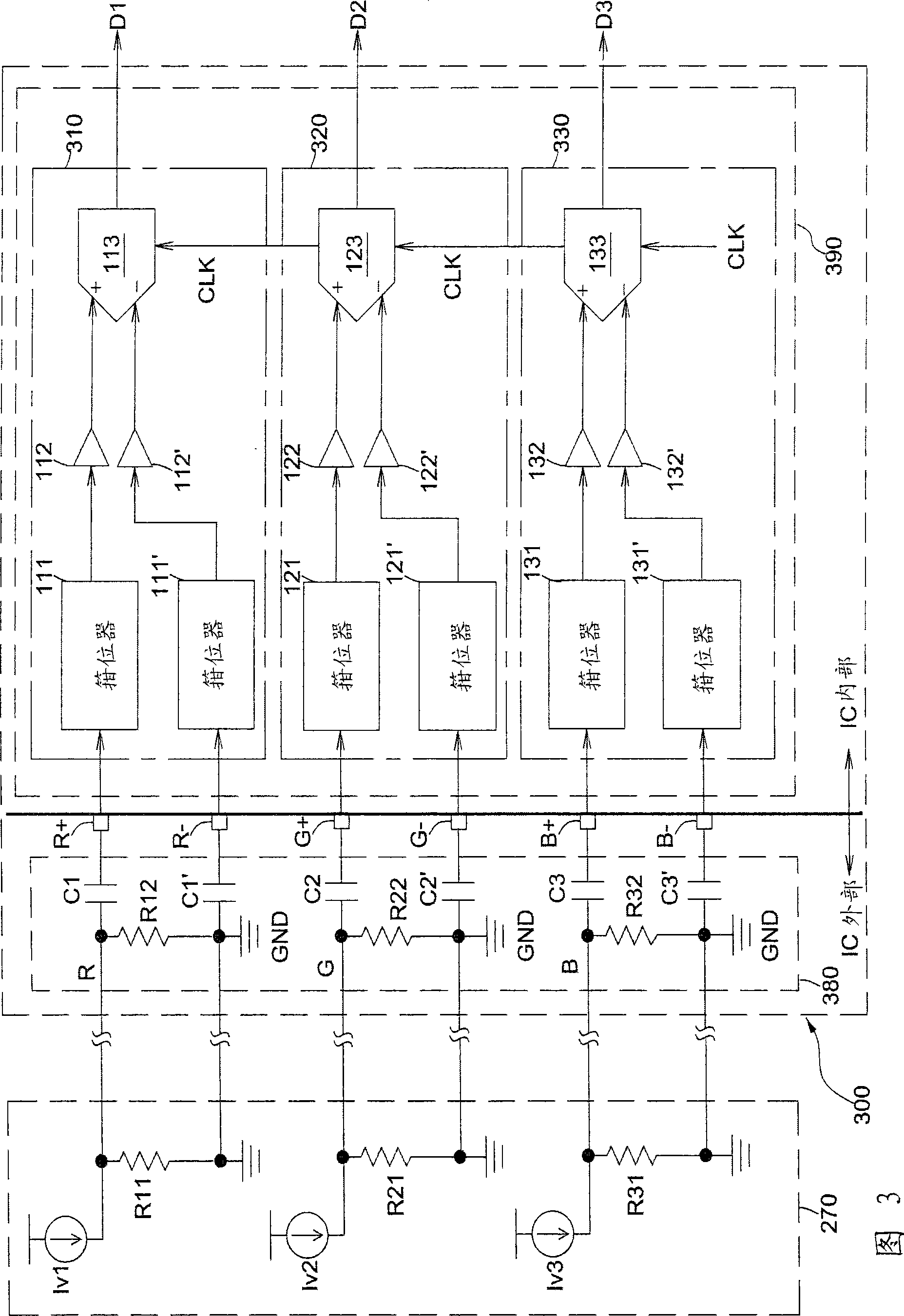

Pseudo-differential analog front end circuit and image processing device

ActiveUS20080036640A1Reduce decreaseImprove quality characteristicsElectric signal transmission systemsCathode-ray tube indicatorsImaging processingAnalog signal

An image processing device is provided which includes a pseudo differential analog front end circuit for receiving at least one image analog signal and generating at least one digital signal. The pseudo differential analog front end circuit includes at least a converting circuit, each of which includes a clamper, an input buffer and an analog-to-digital converter. All of the analog-to-digital converters receive a common comparing voltage if the number of the converting circuits is greater than one.

Owner:REALTEK SEMICON CORP

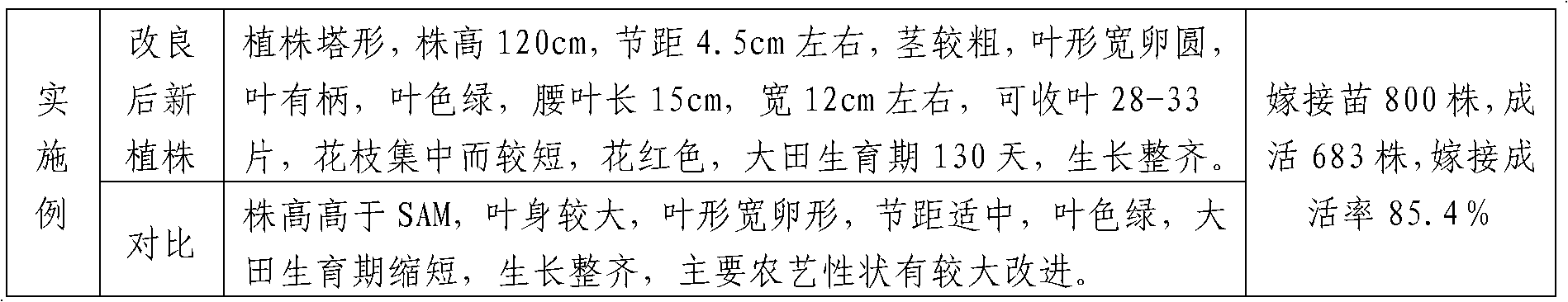

Method for improving aromatic tobacco variety SAM (Samsun)

InactiveCN102487731APromote gene infiltrationImprove quality characteristicsHorticultureAxillary budDisease

The invention discloses a method for improving an aromatic tobacco variety SAM (Samsun). The method comprises the following steps of: on the basis of selecting flue-cured tobacco CB-1 as understock and a seedling of the aromatic tobacco variety SAM as scion, grafting at the first ten-day period of April by adopting a cleft grafting method, i.e. vertically cutting the understock to reach the depth of 1-1.5cm from the middle of a stem, and inserting the scion into the cut of the understock, wherein an axillary bud with a growing point is selected as the scion; and after grafting is successful, transplanting plants into a large field. According to the method, a grafting culture technical method for different aromatic tobacco varieties and flue-cured tobacco varieties is achieved for the first time, The gene seepage and exchange of different varieties can be artificially promoted, and a new tobacco plant variety can be created; and the new plant variety has self characteristics, also has the unique quality characteristic of the flue-cured tobacco CB-1, and has the advantages that the fragrance quality is improved, the harmony among the internal chemical compositions of tobacco is increased, and the stress resistance and the disease resistance are improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

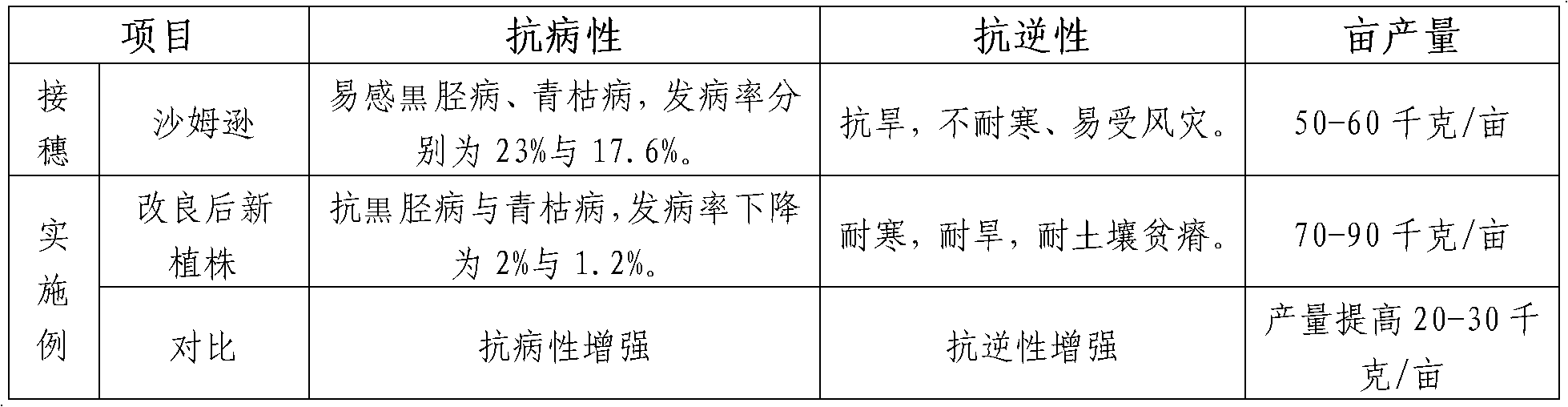

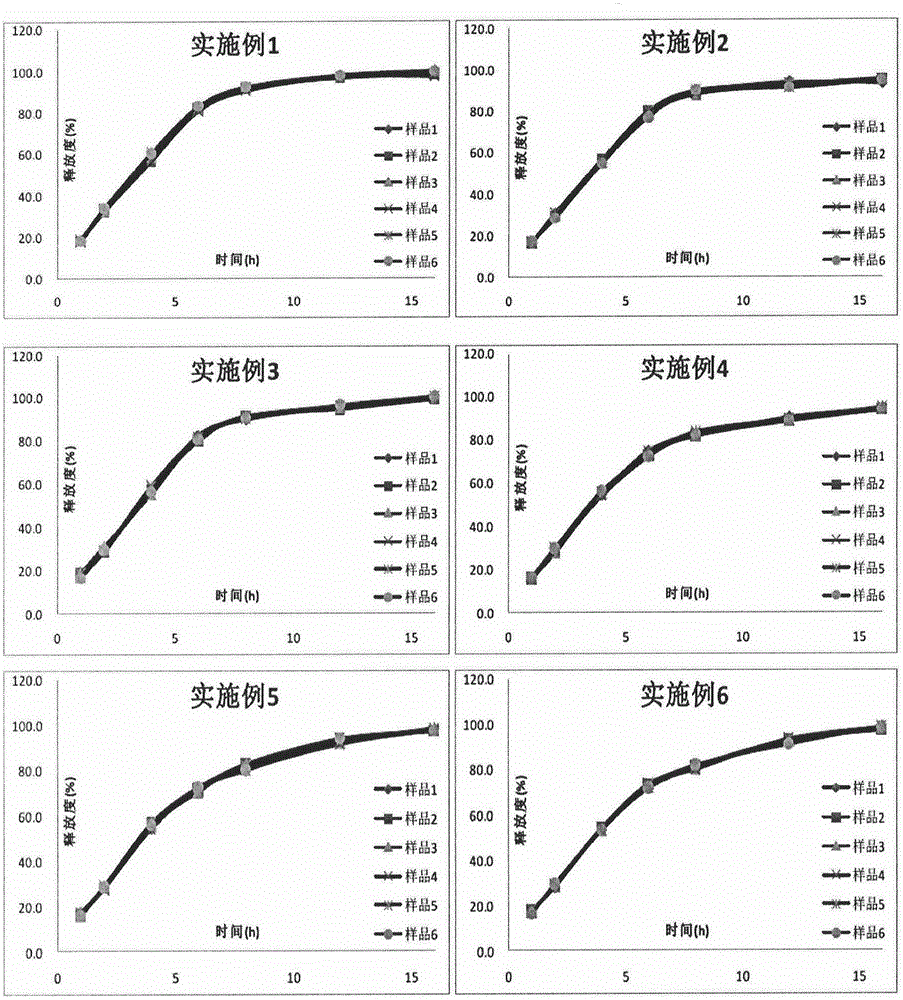

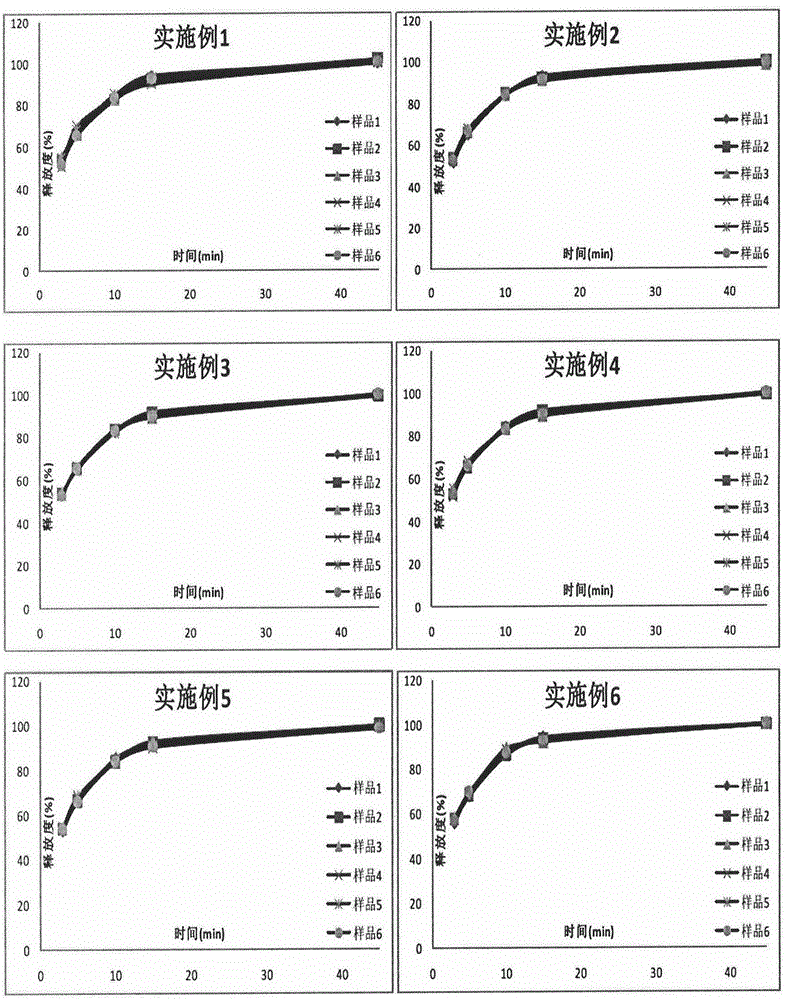

Controlled-release preparation containing metformin hydrochloride and glimepiride and preparation method of controlled-release preparation

ActiveCN105878256AImprove release uniformityImproved controlled releaseMetabolism disorderSulfonylurea active ingredientsMedicineMetformin Hydrochloride

The invention relates to the field of pharmaceutical preparations, and in particular discloses a compound controlled-release preparation of metformin hydrochloride and glimepiride and a preparation method of the controlled-release preparation. The controlled-release preparation disclosed by the invention consists of an internal controlled-release tablet which contains the metformin hydrochloride and an external drug-loaded coating which contains the glimepiride, wherein the internal controlled-release tablet which contains the metformin hydrochloride comprises a tablet core, an insoluble semipermeable coating film and drug-release small pores. The controlled-release preparation disclosed by the invention can significantly improve the linearity and the uniformity of drug release, the process (the preparation method) is simple and easy to implement, and the tablet is better in compressibility; and the glimepiride, without micronizing treatment or other special treatment, is excellent in dissolving effect.

Owner:HEFEI LIFEON PHARMA

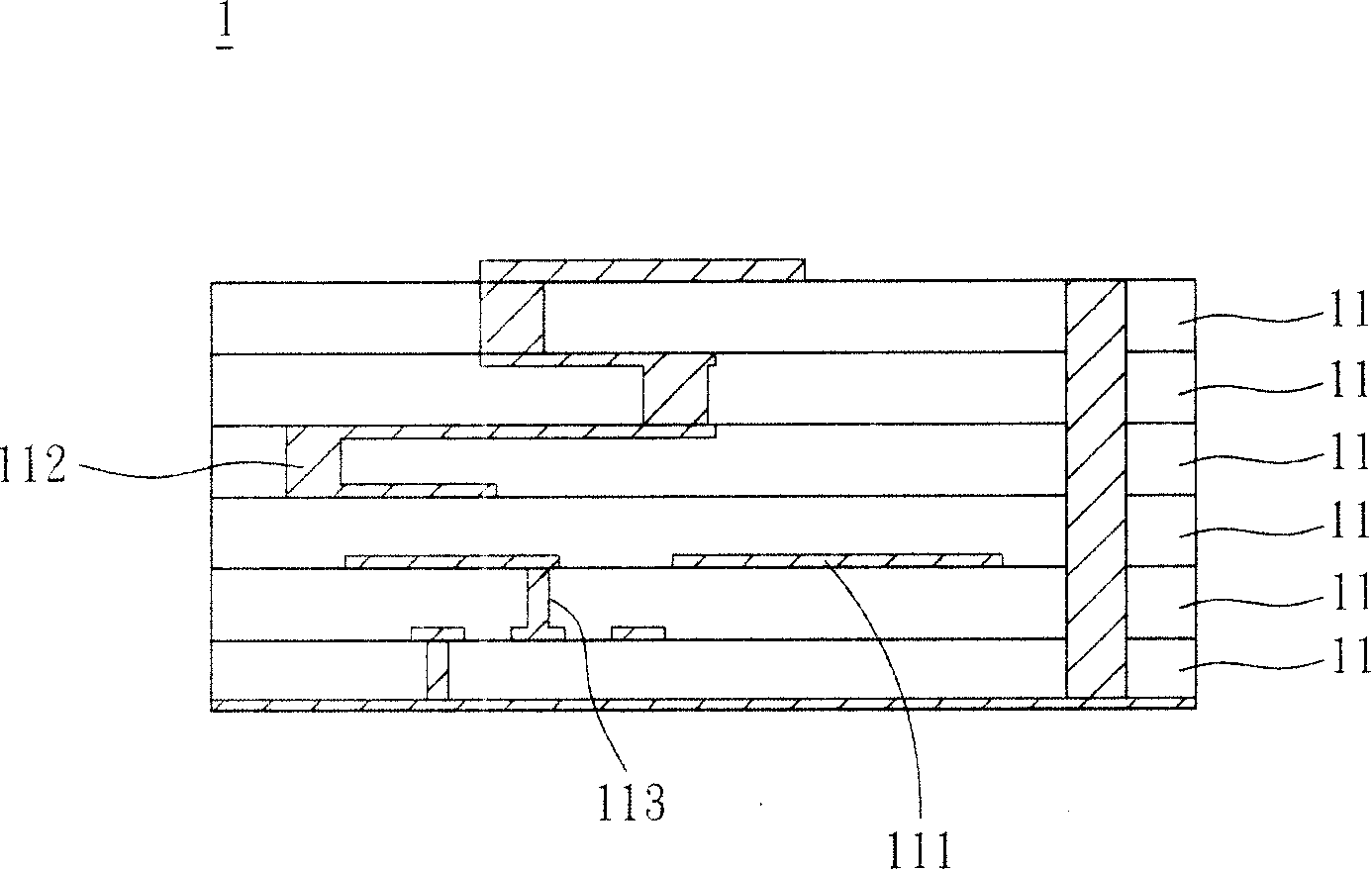

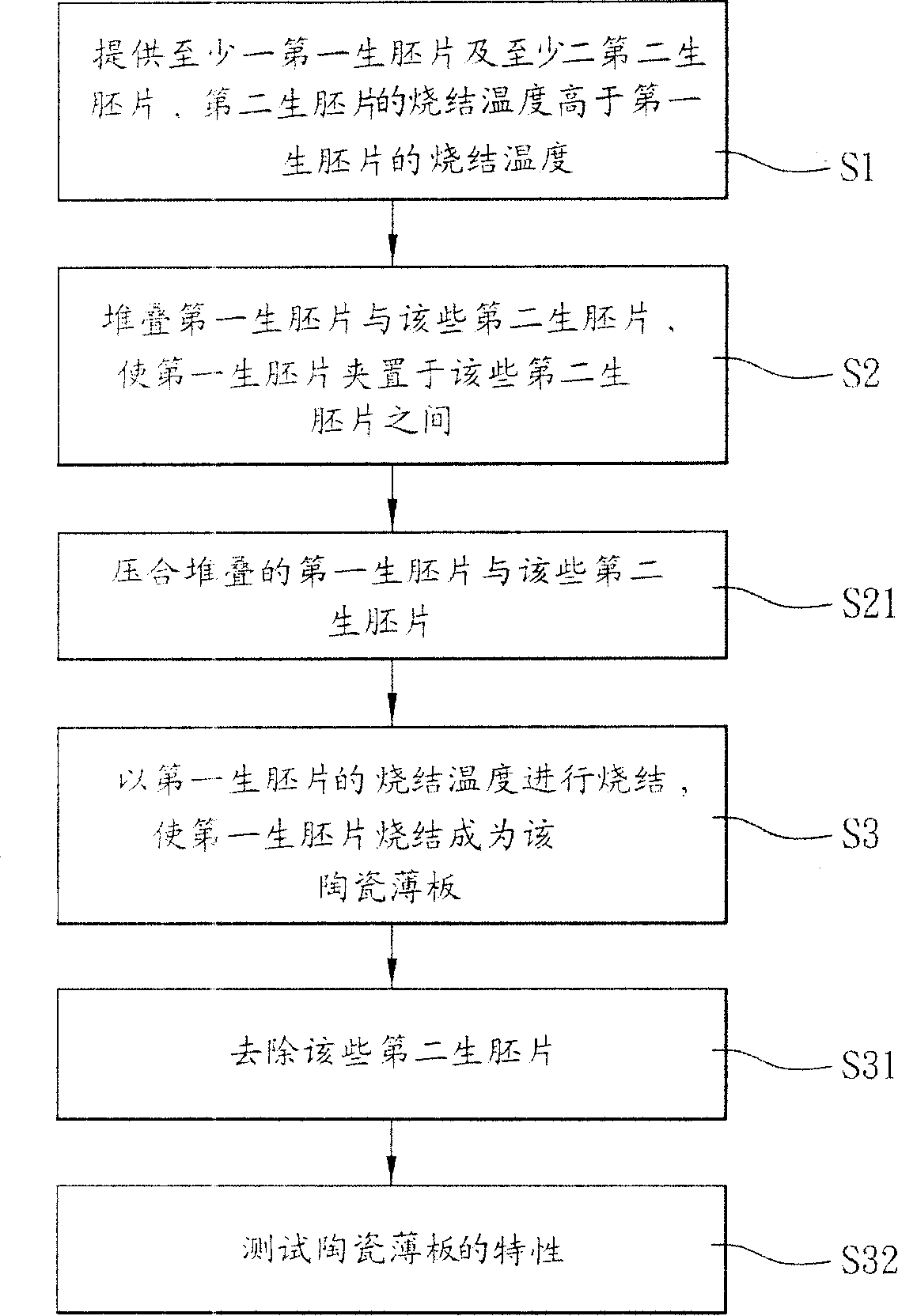

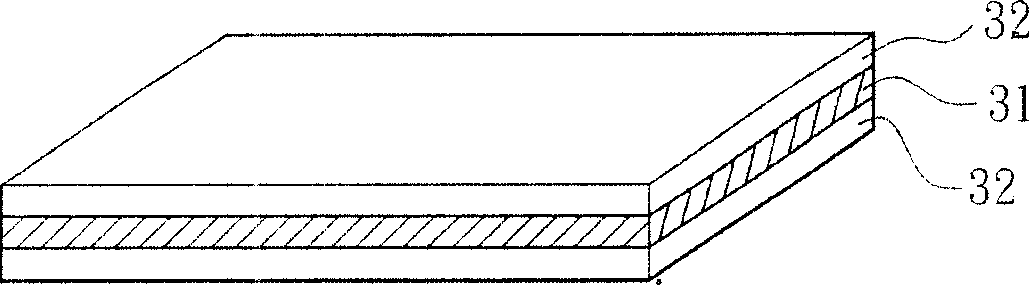

Method for preparing ceramic sheet

InactiveCN101161606AInhibition affects flatnessPrevent warpageCeramic shaping apparatusCeramic layered productsMetallurgyThin sheet

The invention discloses a method for manufacturing ceramic sheets. The method comprises the following steps that: at least one first blank sheet and at least two second blank sheets are provided, and the sintering temperature of the second blank sheets is higher than that of the first blank sheet; the first blank sheet and the second blank sheets are stacked to allow the first blank sheet to be placed among the second blank sheets; the first blank sheet is sintered into a ceramic sheet by the sintering temperature of the first blank sheet.

Owner:DELTA ELECTRONICS INC

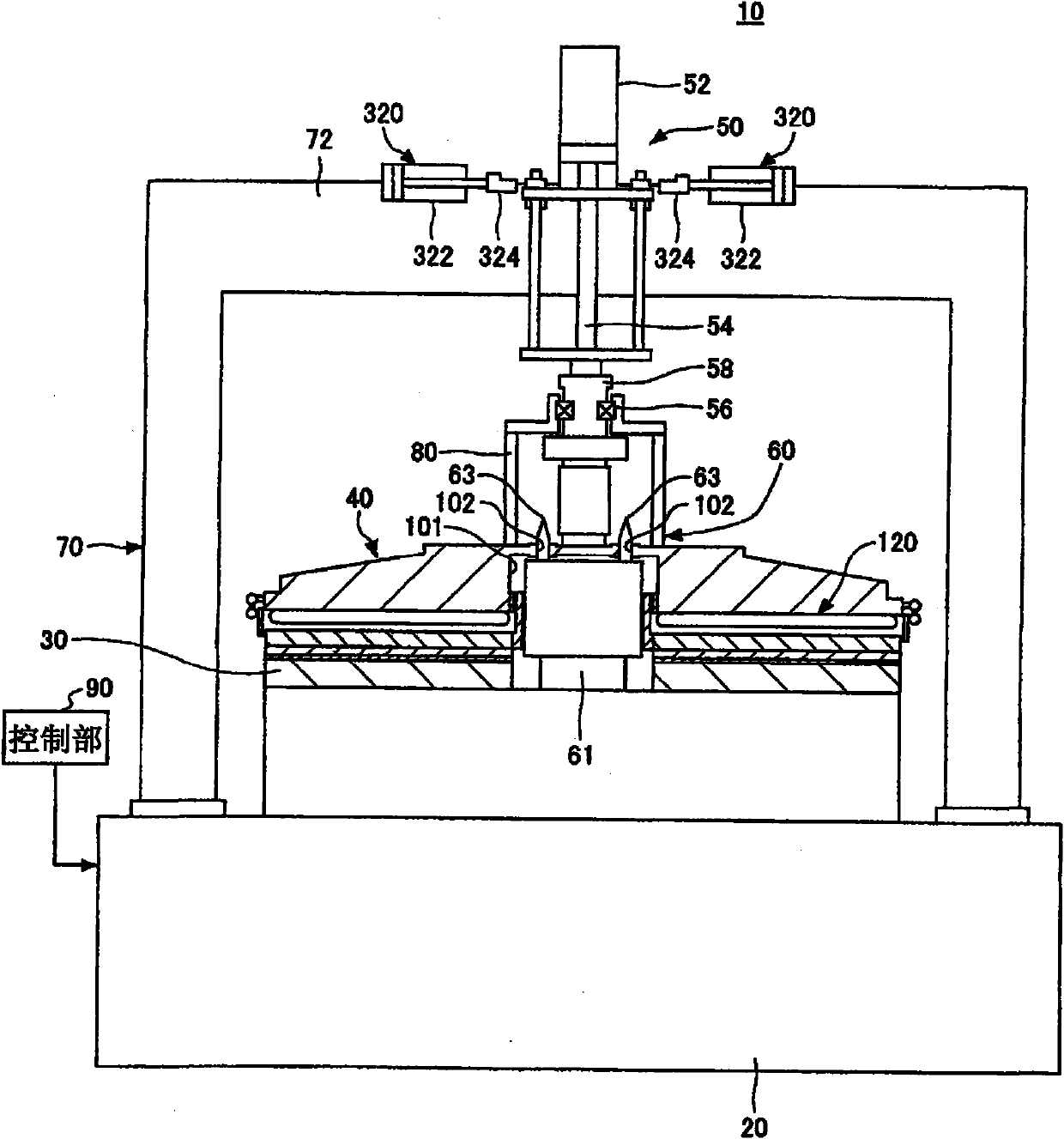

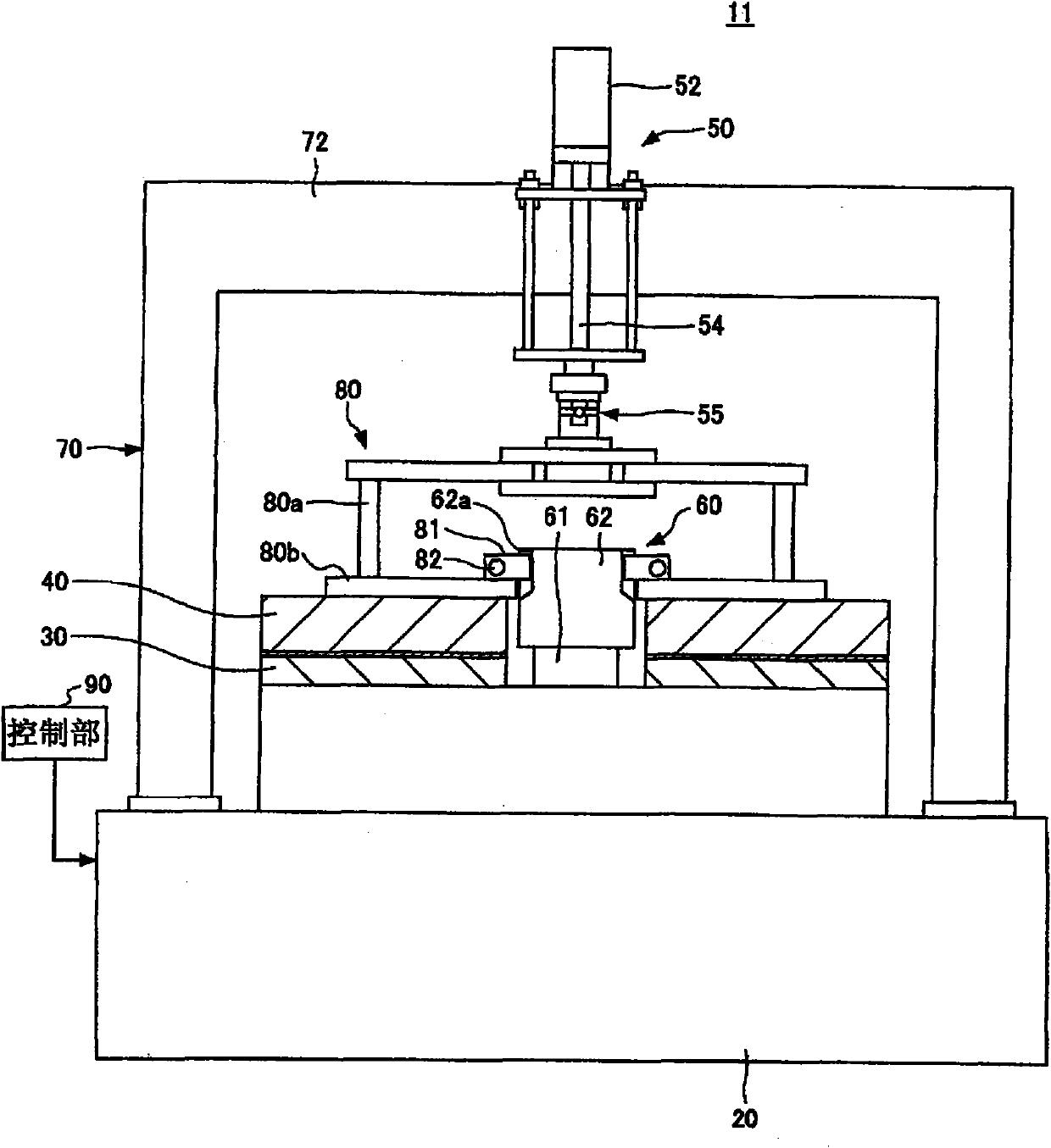

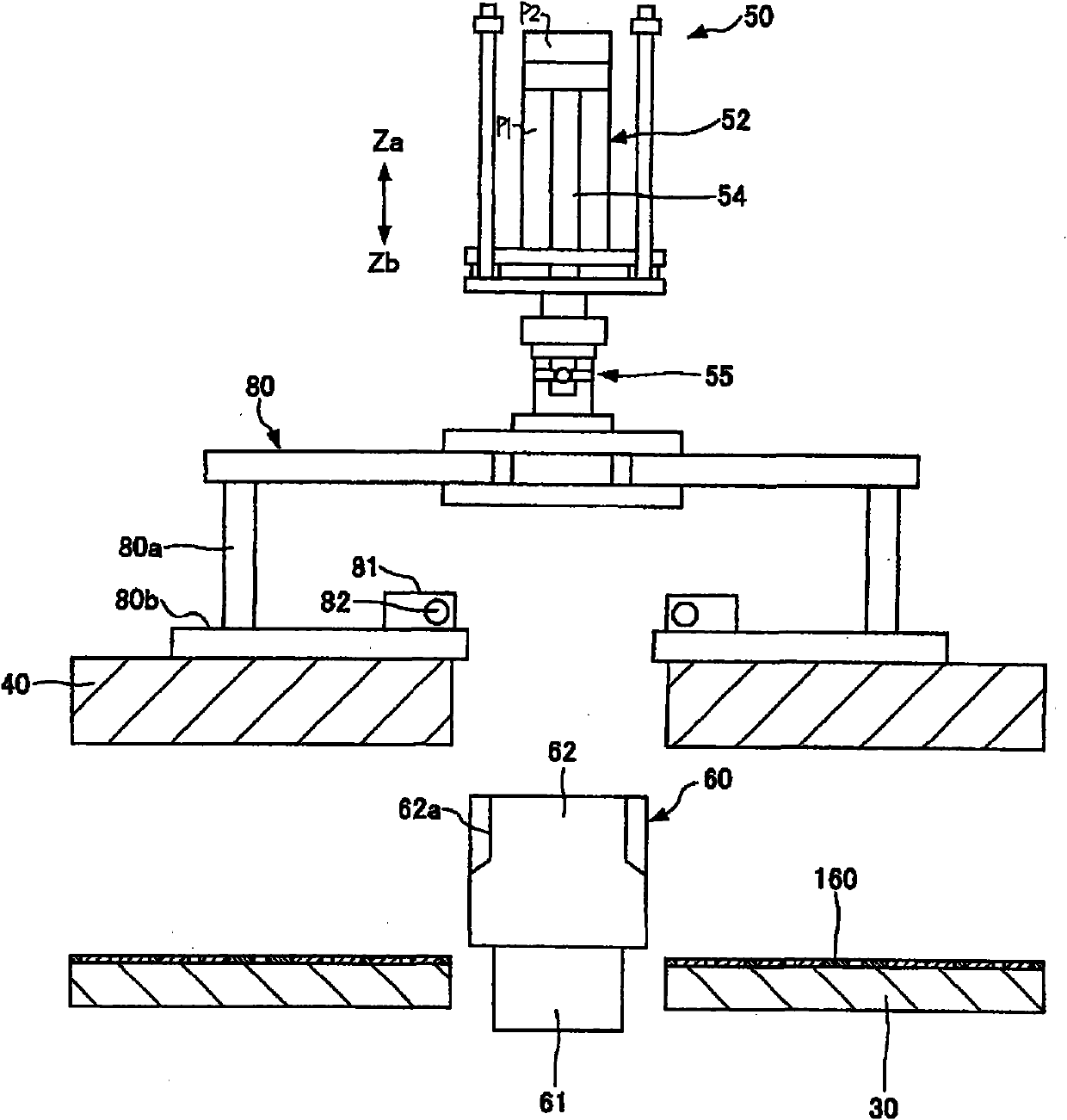

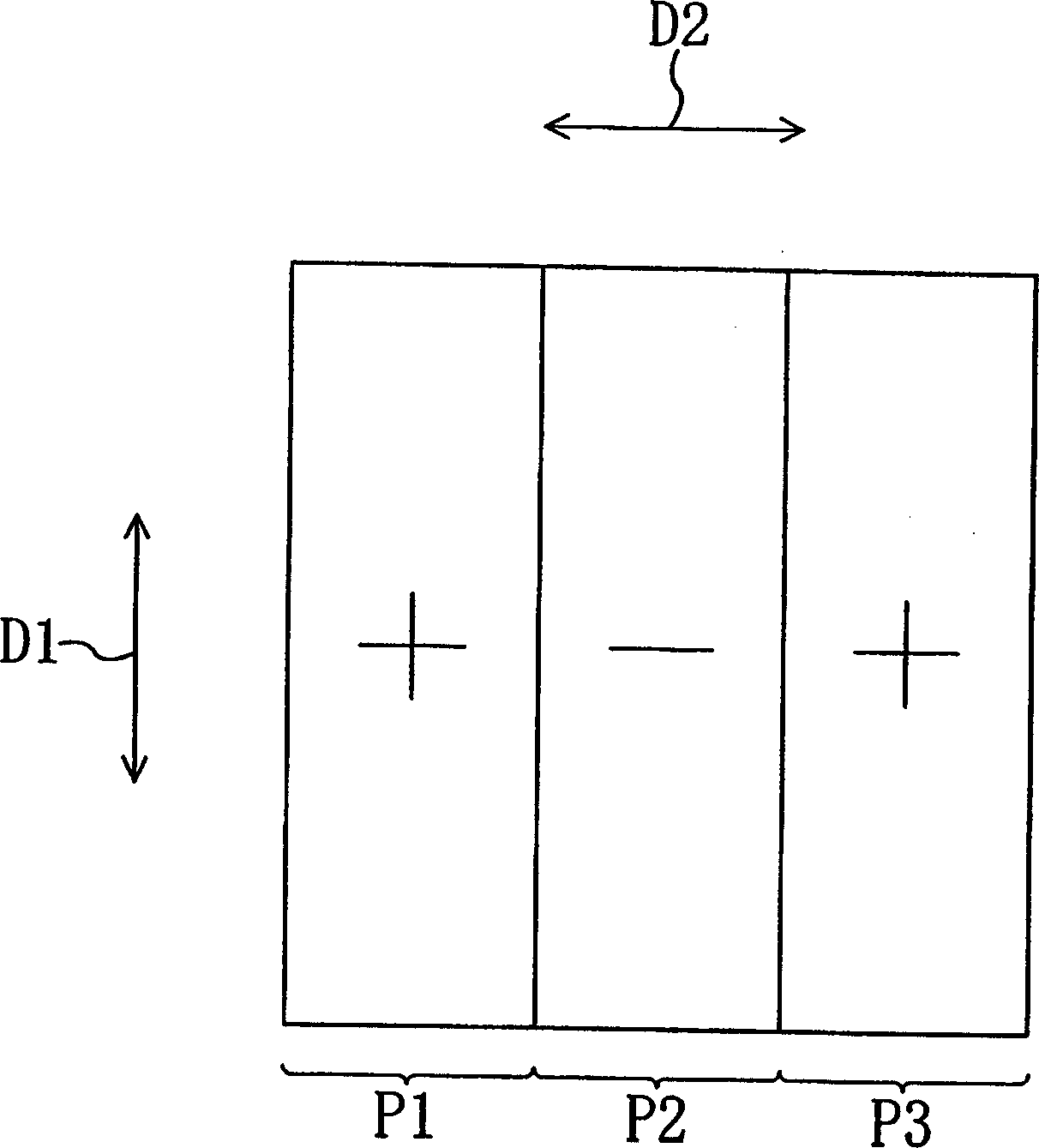

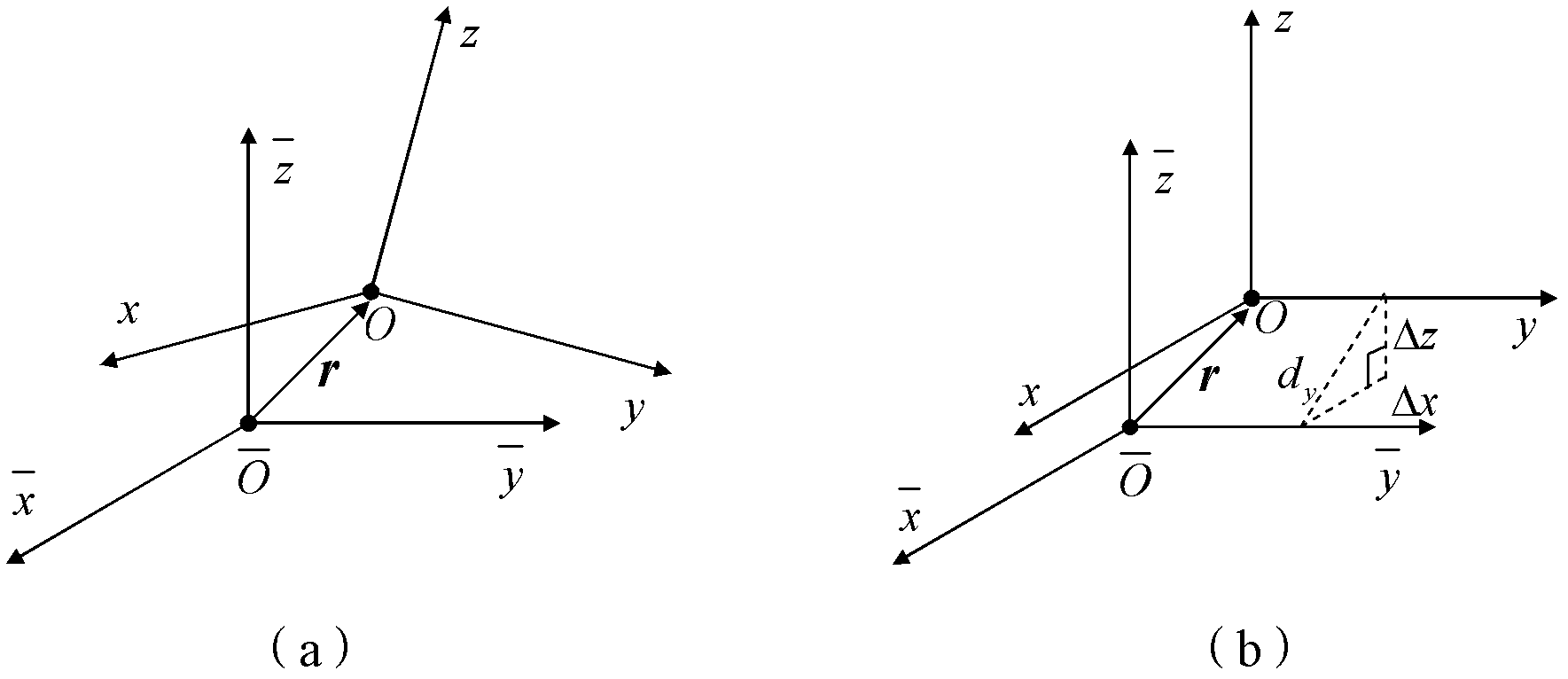

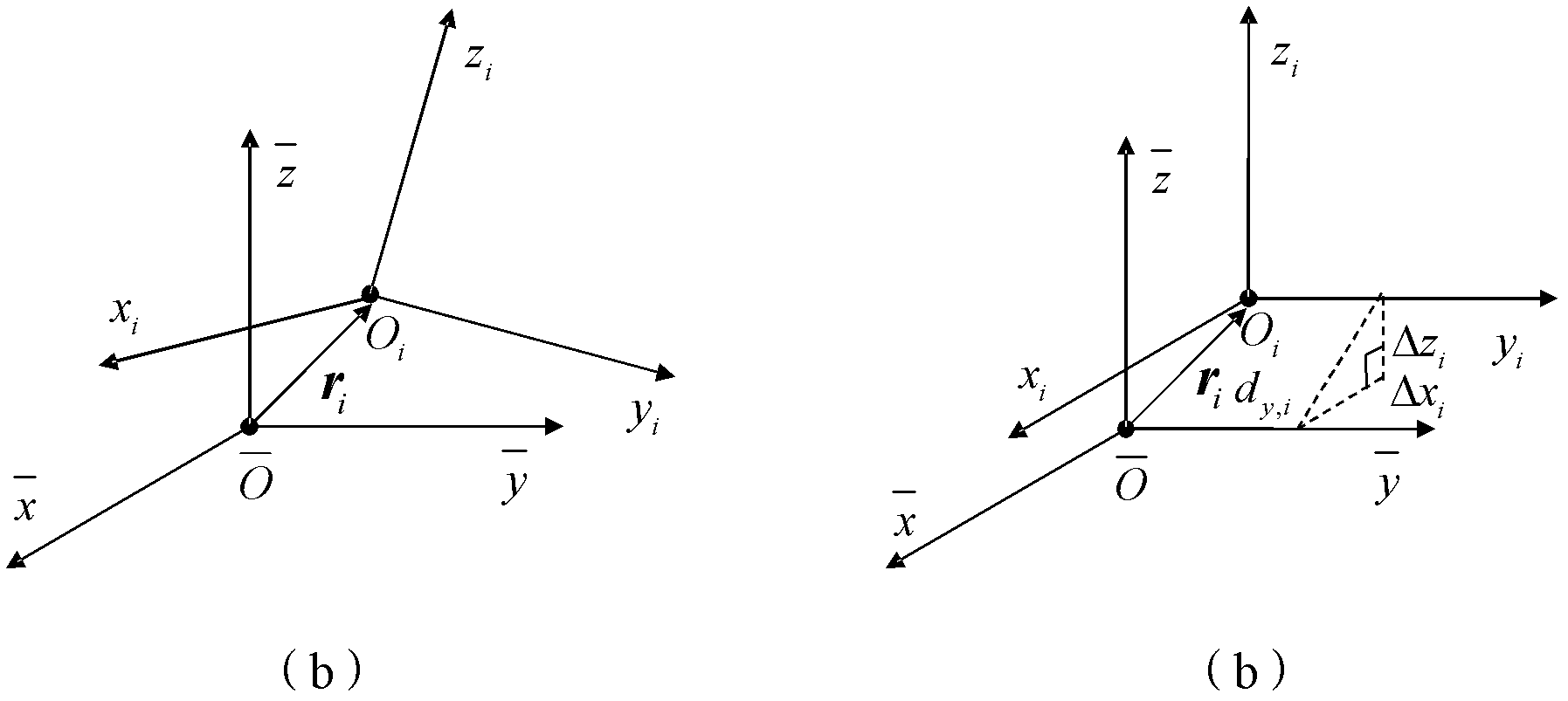

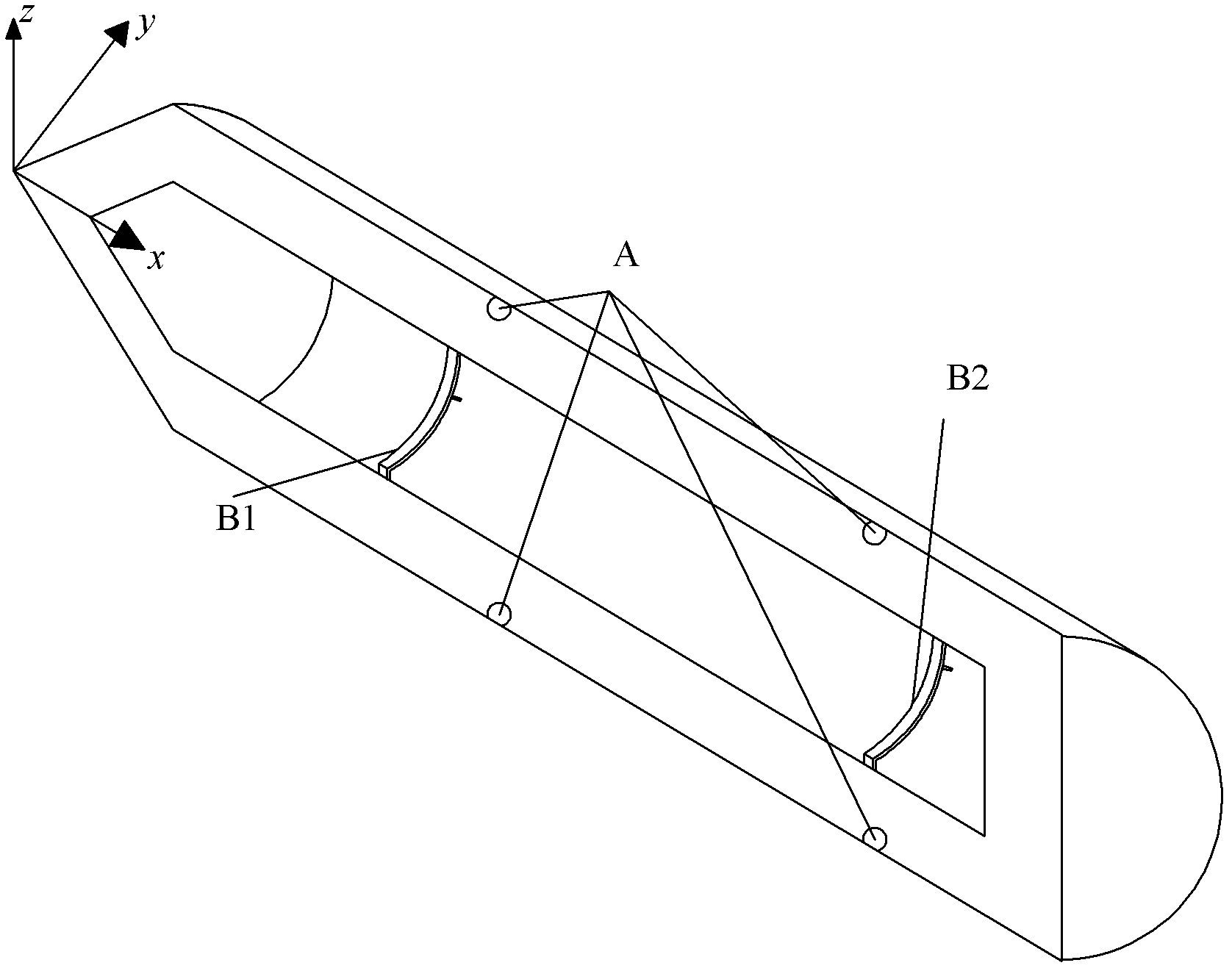

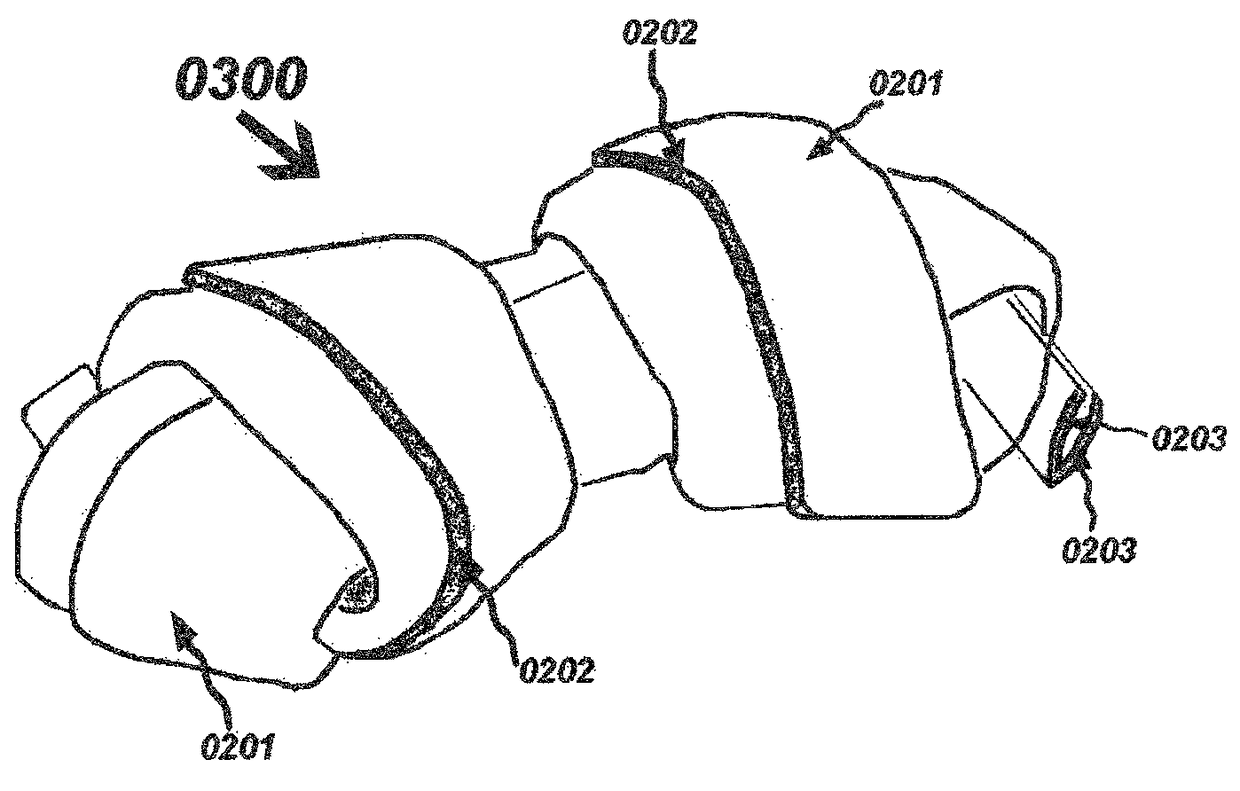

Quality property micro-adjustment structure of aircraft wind tunnel model formed by light curing and method

InactiveCN102314151AImprove quality characteristicsReduce the difficulty of operationAdaptive controlComputer-aidedObject function

The invention provides a quality property micro-adjustment structure of an aircraft wind tunnel model quickly formed based on light curing and a method; the method comprises the steps that: 1. the aircraft wind tunnel model in the micro-adjustment structure is designed and processed in advance; 2. an optimal quality property micro-adjustment scheme is obtained through computer-assisted optimization: the quality property parameter of the aircraft wind tunnel model after being processed is measured and compared with a design value, and an error value is calculated as a target function; portfolios which are added or removed from the micro-adjustment structure serve as optimization variables; and an optimal quality property micro-adjustment scheme is obtained through computer-based automatic optimization. The invention provides the quick and automatic quality property micro-adjustment method which can provide the quality property simulation precision of the model.

Owner:XI AN JIAOTONG UNIV

Cysteine Protease from Ginger (Zingiber) as a Food Improver and Anti-Inflammatory

InactiveUS20070264311A1Improve filtration efficiencyImprove hydrolysis efficiencyBiocidePeptide/protein ingredientsFood technologyWaste treatment

The present invention relates generally to plant extracts and / or components isolated therefrom which exhibit desirable properties in relation to therapy and / or food technology. More particularly, the present invention relates to extracts and components isolated thereof from the plant genus Zingiber and in particular from the rhizome of the species Zingiber officinale (also known as ginger) which comprise activities having broad applicability in the fields of research reagents, inter alia pharmaceutical and / or nutraceutical product development, manufacture of improved high-value food and feed products, production of alcohol from cereals and waste treatment.

Owner:NATBIO

Factory cutting seedling raising method for pinus elliottii

InactiveCN107853046ASolve the technical problems of perishable deteriorationReduce high temperaturePlanting bedsGrowth substratesShootPeat

The invention discloses a factory cutting seedling raising method for pinus elliottii. The method comprises the steps of building a greenhouse, dressing cutting beds, preparing a matrix and seedling raising containers, placing the seedling raising containers, subjecting the cutting beds and the cutting matrix to sterilization and disinfection, scissoring and treating cutting slips, disinfecting the cutting slips, carrying out cutting, building low arched sheds and carrying out later-stage management, wherein the later-stage management comprises the steps of (1) sterilization, (2) water and fertilizer management and (3) light, humidity and temperature control. The method is characterized in that basal planes of the cutting beds are transparent, the cutting matrix is prepared from coco coir,peat, vermiculite and pearlite, the seedling raising containers are bottomless coverless cylindrical bodies, and the cutting slips are one-year-old semi-lignified tree shoots. The method has the advantages that the survival rate of cutting is high, the root system is developed, the cutting management is convenient, the labor intensity is low, the transportation of nursery-grown plants is portableduring afforestation, and the survival rate of afforestation is high due to lightweight-matrix-carrying transplanting; and excellent quality characteristics are maintained, so that the method is applicable to large-scale factory seedling raising, and the positive effect of meeting the requirements of man-made pinus elliottii forests on improved variety is achieved.

Owner:吉安市林业科学研究所

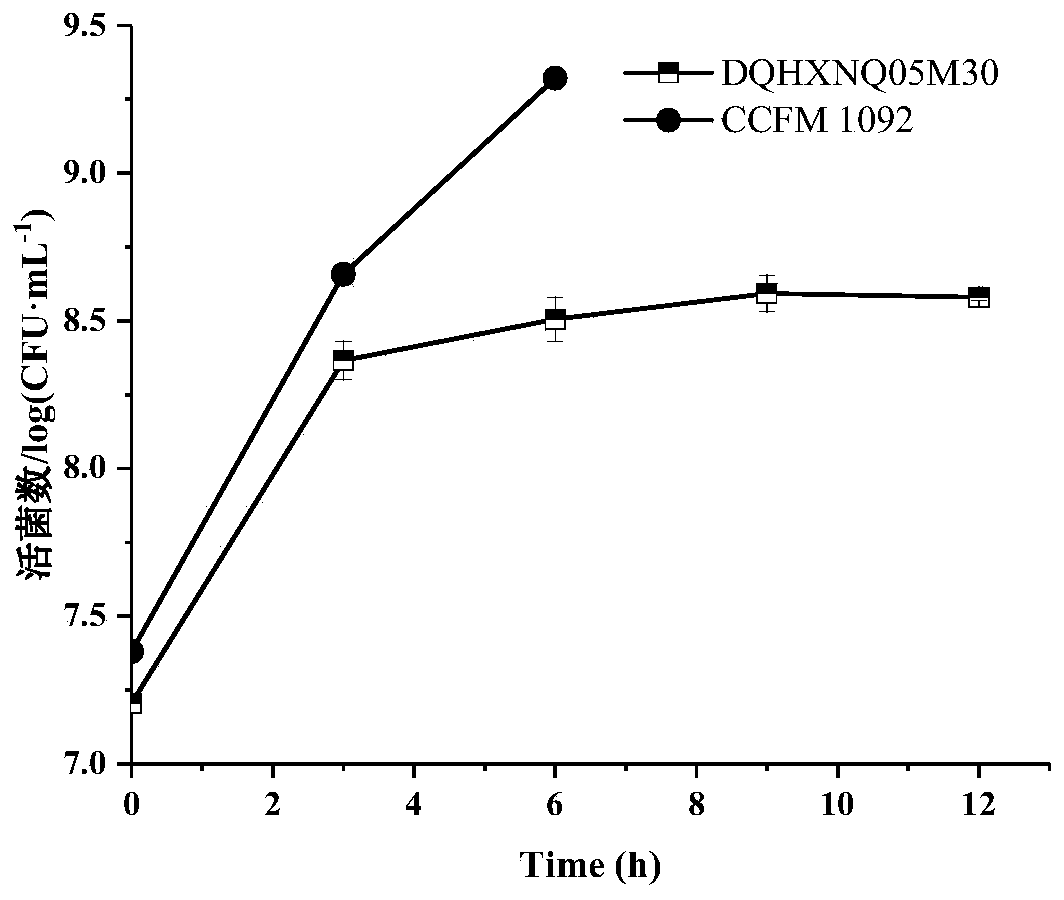

Lactococcus lactis subsp. lactis and application thereof in preparation of soybean milk

ActiveCN111206001AMethod safety and healthEfficient use ofBacteriaMicroorganism based processesBiotechnologyStaphylococcus lactis

The invention discloses Lactococcus lactis subsp. lactis and application thereof in preparation of soybean milk, and belongs to the technical field of microbiology. The Lactococcus lactis subsp. lactis CCFM 1092 has the following properties that (1) strains grow fast, and enter a stable period in 8 h in MRS, and the increment of the viable count can reach 2 orders of magnitude in 6 h in the soybean milk, and the strains are suitable for industrial fermentation; (2) the strains have a high speed of acid production, and the soybean milk curds and reaches the end of fermentation when the strainsare applied to fermentation of the soybean milk, so that production of curd and flavor substances is facilitated; and (3) the strains have a high yield of 3-methyl butanol, and 476.05 [mu]g / kg of 3-methyl butanol can be produced in 6 h. When the Lactococcus lactis subsp. lactis CCFM 1092 is used as a fermentation agent for food fermentation, the fruit flavor of the fermented soybean milk can be improved, and a very broad application prospect is achieved.

Owner:JIANGNAN UNIV

Method for determining cigarette paper smolder speed

InactiveCN101226186BGood repeatabilityTruly reflect the quality characteristicsChemical analysis using combustionPaper testingProcess engineeringIndustrial engineering

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Virtual differential analog front end circuit and image processing apparatus

ActiveCN101452678AReduce power consumptionReduce areaStatic indicating devicesLogic circuits coupling/interface using field-effect transistorsDigital down converterImaging processing

The invention provides an image processing device, which comprises a virtual differential analog front end circuit. The front end circuit is used for receiving at least one image analog signal, and generates at least one digital signal. The virtual differential analog front end circuit comprises at least one conversion circuit, each conversion circuit comprises a clamper, an input buffer and an analog-to-digital converter, wherein when the number of the conversion circuits is larger than 1, various analog-to-digital converters receive the same comparative voltage.

Owner:REALTEK SEMICON CORP

Health and safe preservation technology of tomatoes

ActiveCN108651613AEasy to operateExtend freshnessFruits/vegetable preservation by irradiation/electric treatmentFood thermal treatmentPre treatmentRefrigeration

The present invention discloses a health and safe preservation technology of tomatoes. The health and safe preservation technology comprises the following steps: I, pretreatment; II, pre-cooling; III,preservation treatment; IV, sterilization; and V, refrigeration. The health and safe preservation technology of the tomatoes is simple in process steps, environmentally protective and safe, can effectively reduce the nutrient loss of the tomatoes, delays occurrence of cold damage symptoms of the post-harvested tomato fruits, inhibits the decay and deterioration of the tomato fruits, and prolongsthe shelf life of the tomatoes.

Owner:海南农佳佳科技发展有限公司

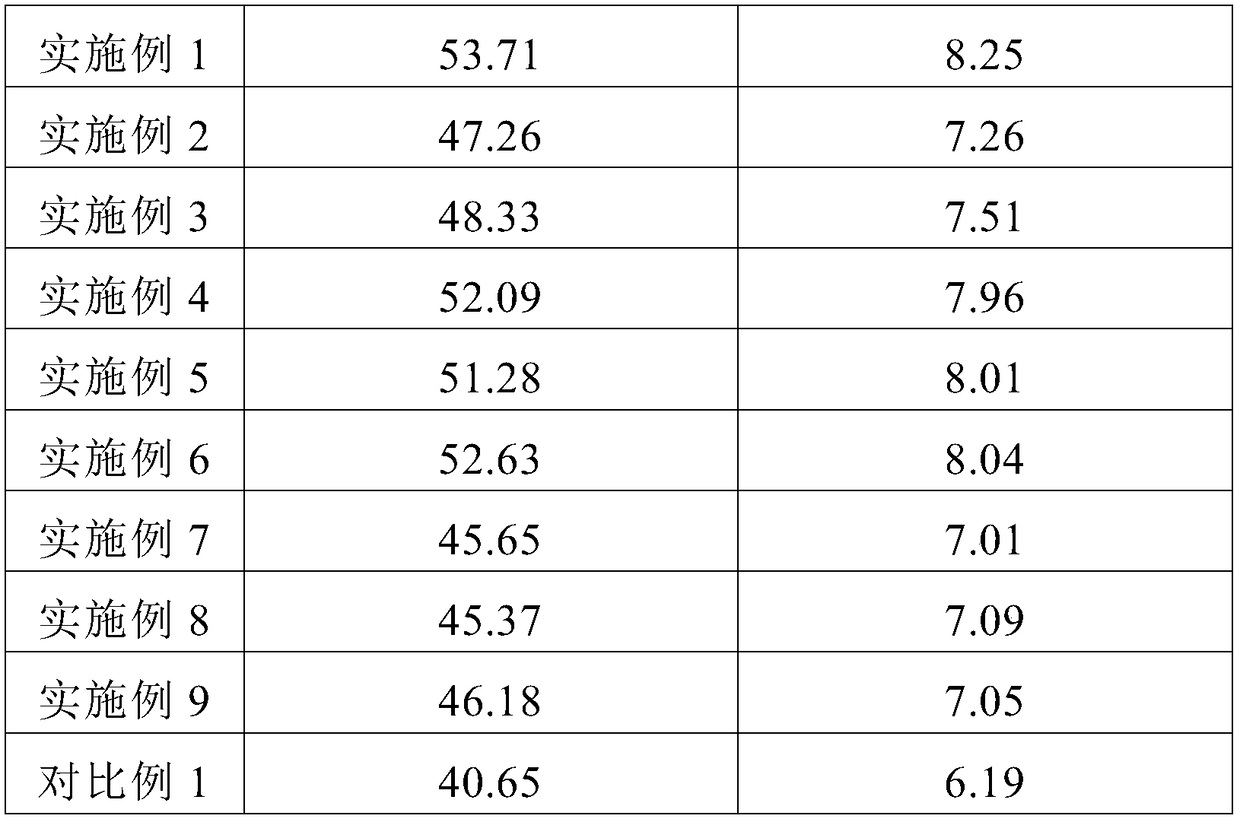

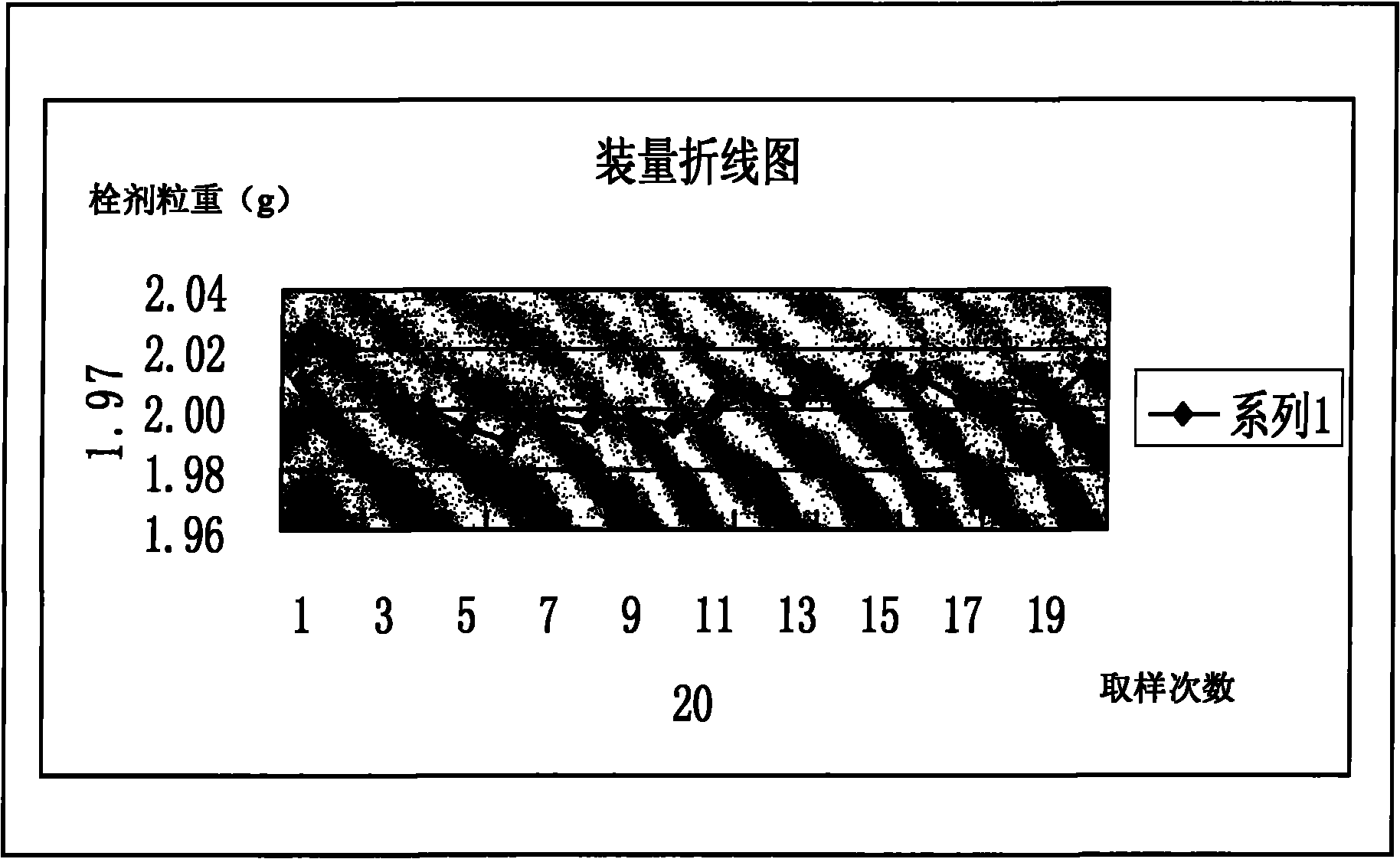

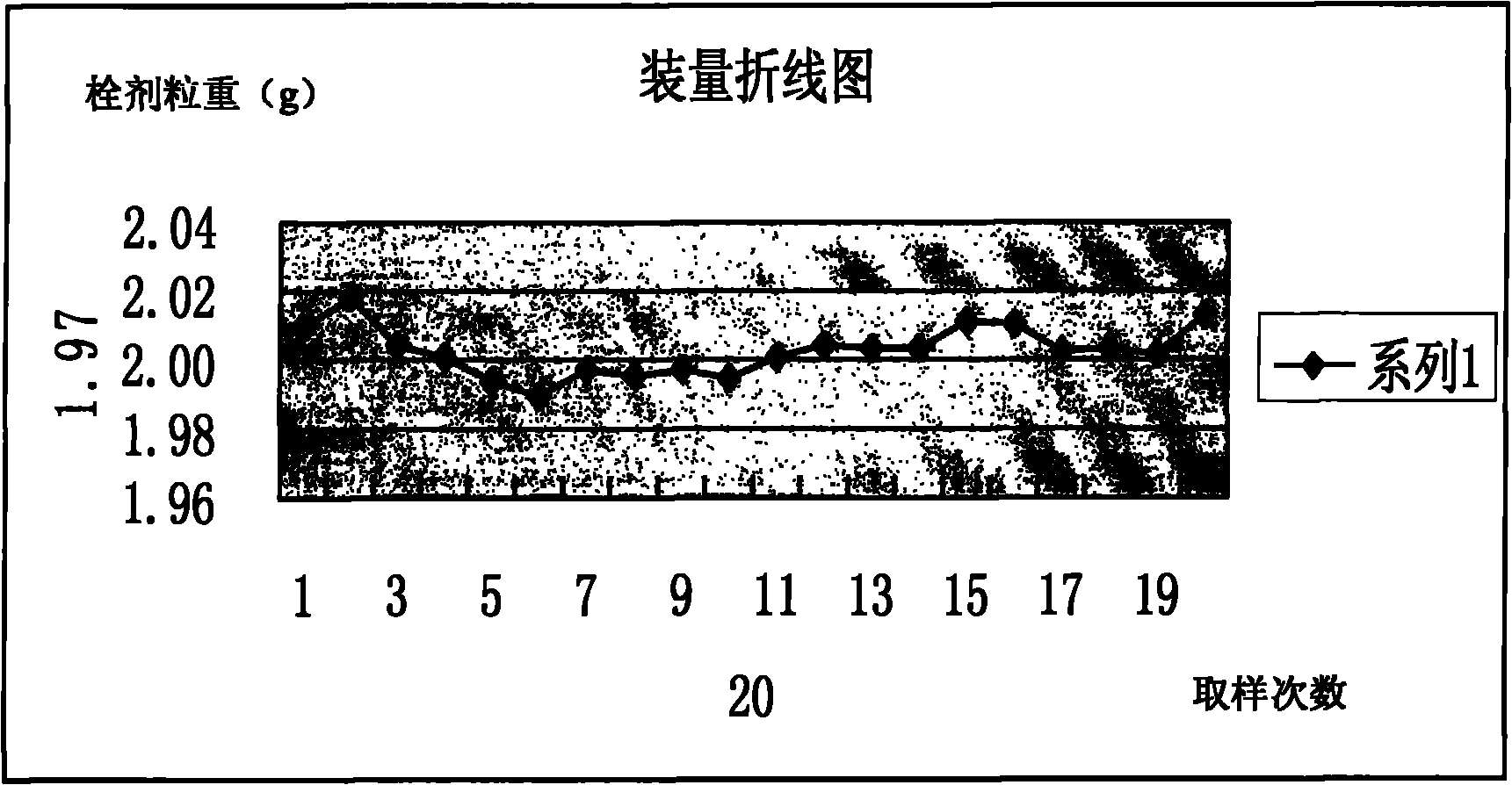

Matrix of suppository or paste medicine for treating prostatitis and preparation method thereof

ActiveCN101797388AImprove fluencyImprove quality characteristicsAerosol deliverySuppositories deliverySuppositoryPolyethylene glycol

The invention provides a matrix for a suppository or a paste medicine and a method preparing the suppository or the paste containing the matrix. The matrix comprises (1) fat soluble matrix and (2) polyethylene glycol fatty acid ester. The invention also provides application of the matrix on preparing the suppository or the paste medicine for treating prostatitis. When being used to manufacture the suppository or the paste, the matrix of the invention can carry high dose and at the same time the suppository or the paste containing the matrix can bear high temperature in the transportation process and keep good stability.

Owner:LIVZON PHARM GRP INC +1

Edible pet chew and method for making the same

ActiveUS9770044B2Improve quality characteristicsSimple structureAnimal feeding stuffWorking-up animal fodderAnimal scienceUltimate tensile strength

Owner:SHANGHAI SUNLIGHT INNOV TRADING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com