Interior decoration parts for automobiles and its manufacturing method

A technology for automotive interiors and manufacturing methods, applied in decorative art, decorative structures, etc., can solve the problems of heavy product weight, high injection pressure, low productivity, etc., achieve good appearance performance, strengthen joint strength, and realize lightweight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

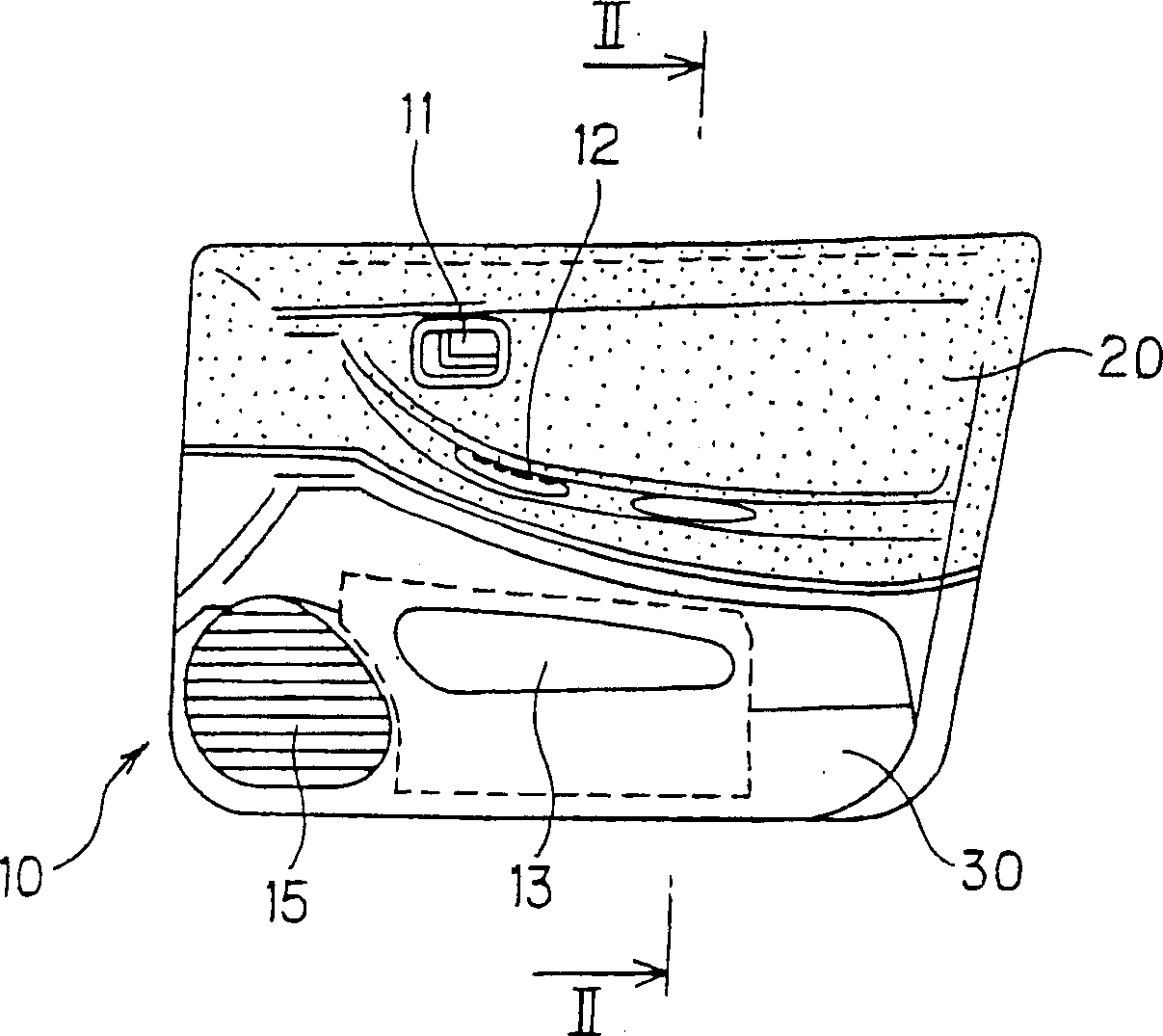

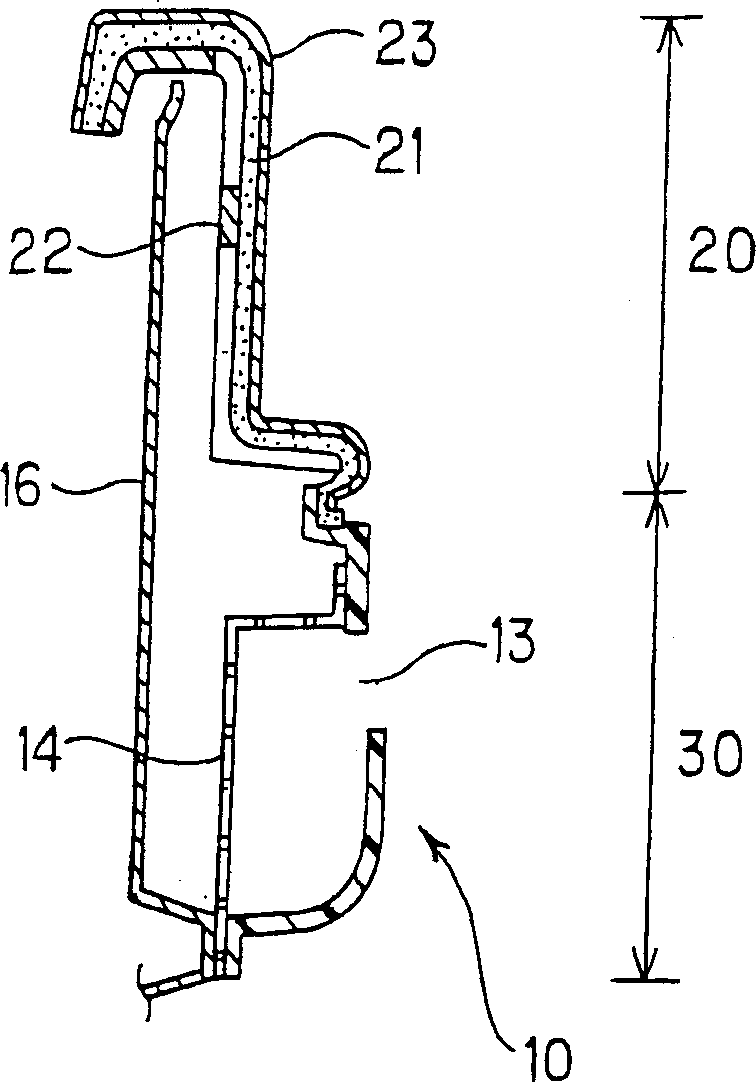

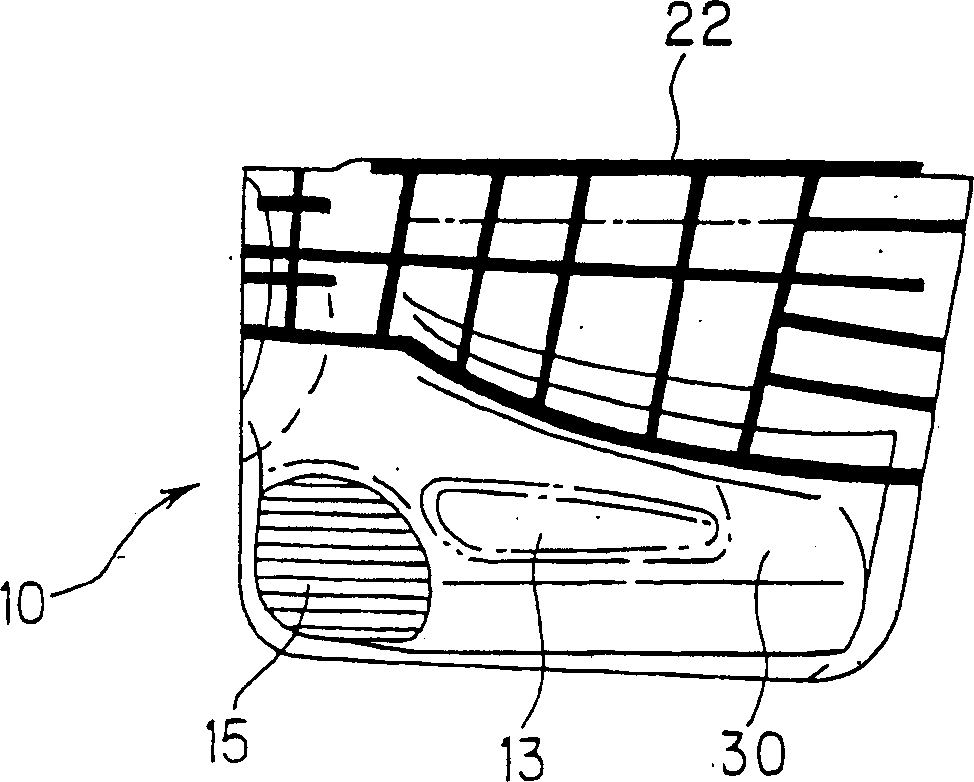

[0072] Figure 1 to Figure 7 Shows the first embodiment of the present invention applied to the interior trim of a two-color automobile door, figure 1 It is a front view of the door interior trim for a two-color type car, figure 2 is a cross-sectional view showing the composition of the interior door trim for the automobile, image 3 It is a front view showing the resin rib on the upper part of the door interior and the lower part of the door interior in the door interior for this automobile, Figure 4 It is an explanatory drawing showing the outline of the manufacturing method of the automotive interior part of the present invention, Figure 5 to Figure 7 It is an explanatory drawing of each process of the manufacturing method of the automotive interior part of this invention.

[0073] exist figure 1 , figure 2 Among them, the two-color type automotive door interior trim 10 is composed of upper and lower door interior trim parts 20 composed of a laminated structure a...

Embodiment 2

[0096] Figure 8 , Figure 9 Shows the second embodiment of the present invention applied to the door interior trim of a two-color type automobile, Figure 8 It is a sectional view showing the composition of the door interior trim. Figure 9 It is an explanatory drawing showing the outline of the manufacturing method of the door interior trim. In addition, the same parts as those in the first embodiment are assigned the same symbols, and detailed description thereof will be omitted.

[0097] In the second embodiment, the door interior trim 10 for an automobile is also composed of upper and lower door interior trim parts 20 and lower door trim parts 30, which is the same as the first embodiment. In other words, the door trim upper part 20 is formed in a desired curved shape, and is roughly composed of a shape-retaining foamed resin base material 21 and a reinforcement layer integrated on the inner side of the foamed resin base material 21 . The resin rib 22 and the decorati...

Embodiment 3

[0103] Figure 10 , Figure 11 Shows the third embodiment in which the present invention is applied to a two-color type automobile door interior decoration, Figure 10 It is a cross-sectional view showing the structure of the door interior, Figure 11 It is an explanatory drawing showing the outline of the manufacturing method of the door interior trim. In this third embodiment, the same parts as those in the first embodiment are assigned the same reference numerals, and description thereof will be omitted.

[0104] In this third embodiment, the structure of the decorative member 23 of the upper door interior trim 20 is different from that of the first and second embodiments, in other words, as Figure 10 As shown, the decorative member 23 is characterized in that it is composed of a three-layer laminated structure of a top layer 23a, a buffer layer 23b, and a back non-woven fabric layer 23c starting from the product surface side.

[0105] In addition, the third embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com