Quality property micro-adjustment structure of aircraft wind tunnel model formed by light curing and method

A technology of light-curing molding and quality characteristics, which is applied in the direction of instruments, control/adjustment systems, adaptive control, etc., and can solve problems such as process difficulties, operational difficulty of increasing adjustments, experience, and low degree of proficiency in automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with the accompanying drawings, the fine-tuning structure and method thereof for the quality characteristics of the aircraft wind tunnel model formed by light-curing molding of the present invention are described in detail:

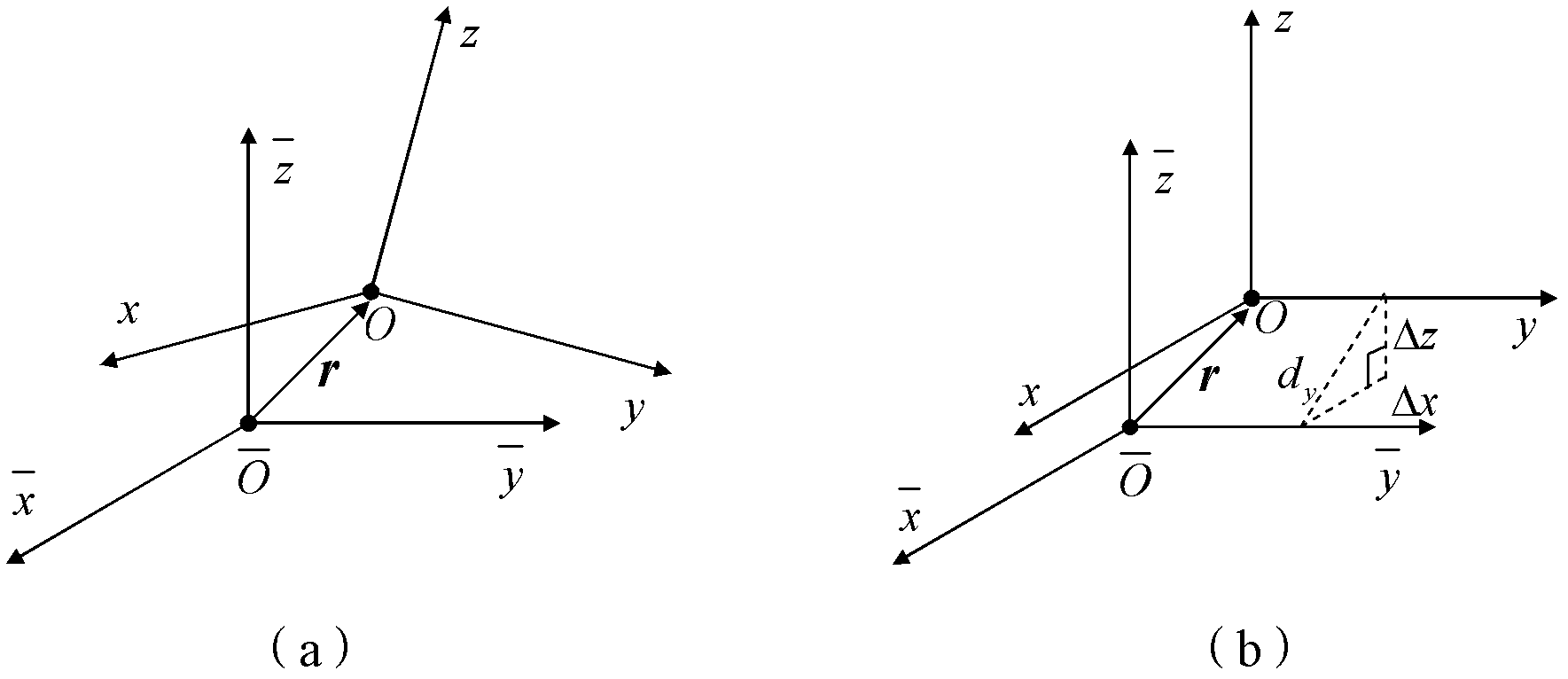

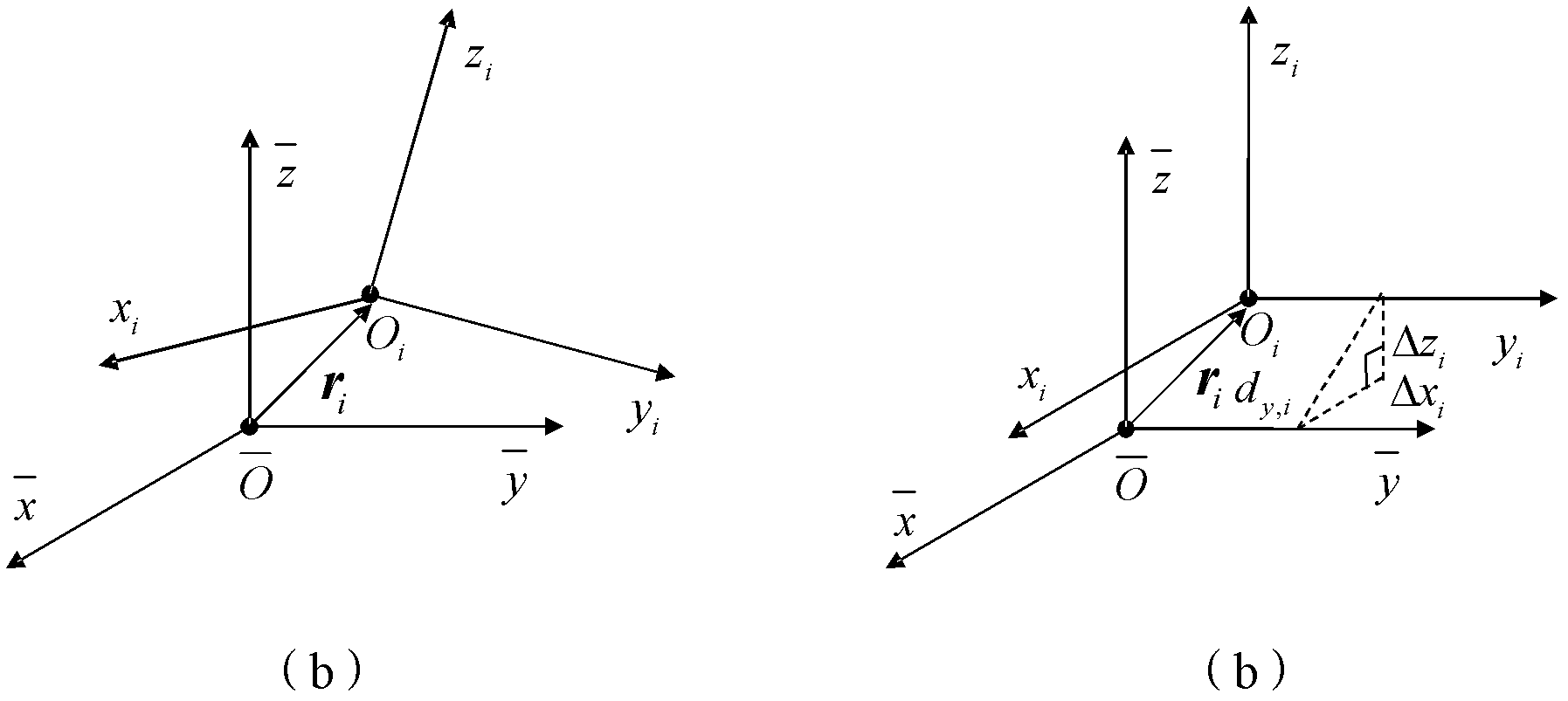

[0059] see Figure 1 to Figure 5 As shown, a method for fine-tuning the quality characteristics of an aircraft wind tunnel model formed by light curing of the present invention comprises the following steps:

[0060] 1. Pre-design and process "quality characteristic fine-tuning structure"

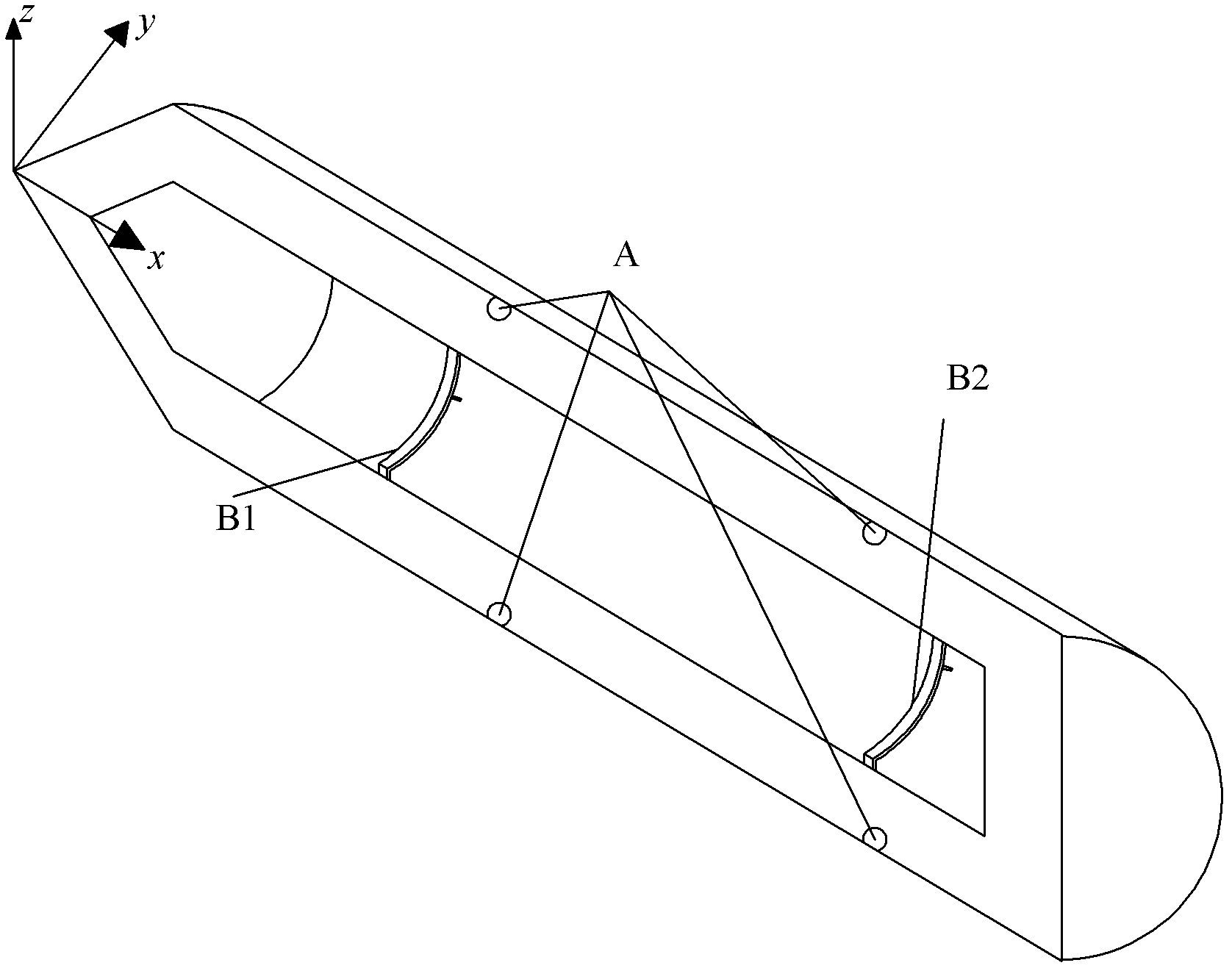

[0061] Such as image 3 Shown is a schematic diagram of the structure of the projectile aircraft model. The origin of the coordinate system is at the vertex of the model, the x-axis is parallel to the axis of the projectile aircraft model and points to the rear, the y-axis is perpendicular to the longitudinal symmetry plane of the fuselage and points to the right, and the z-axis is in the longitudinal symmetry plane of the fuselage and poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com