Glass substrate manufacturing method, glass substrate polishing method, glass substrate polishing apparatus and glass substrate

一种玻璃基板、研磨装置的技术,应用在研磨装置、制造基底层、磨削自动控制装置等方向,能够解决不能精度控制板厚、传感器检测部位污染等问题,达到提高品质特性和品质的稳定性、提高研磨加工精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

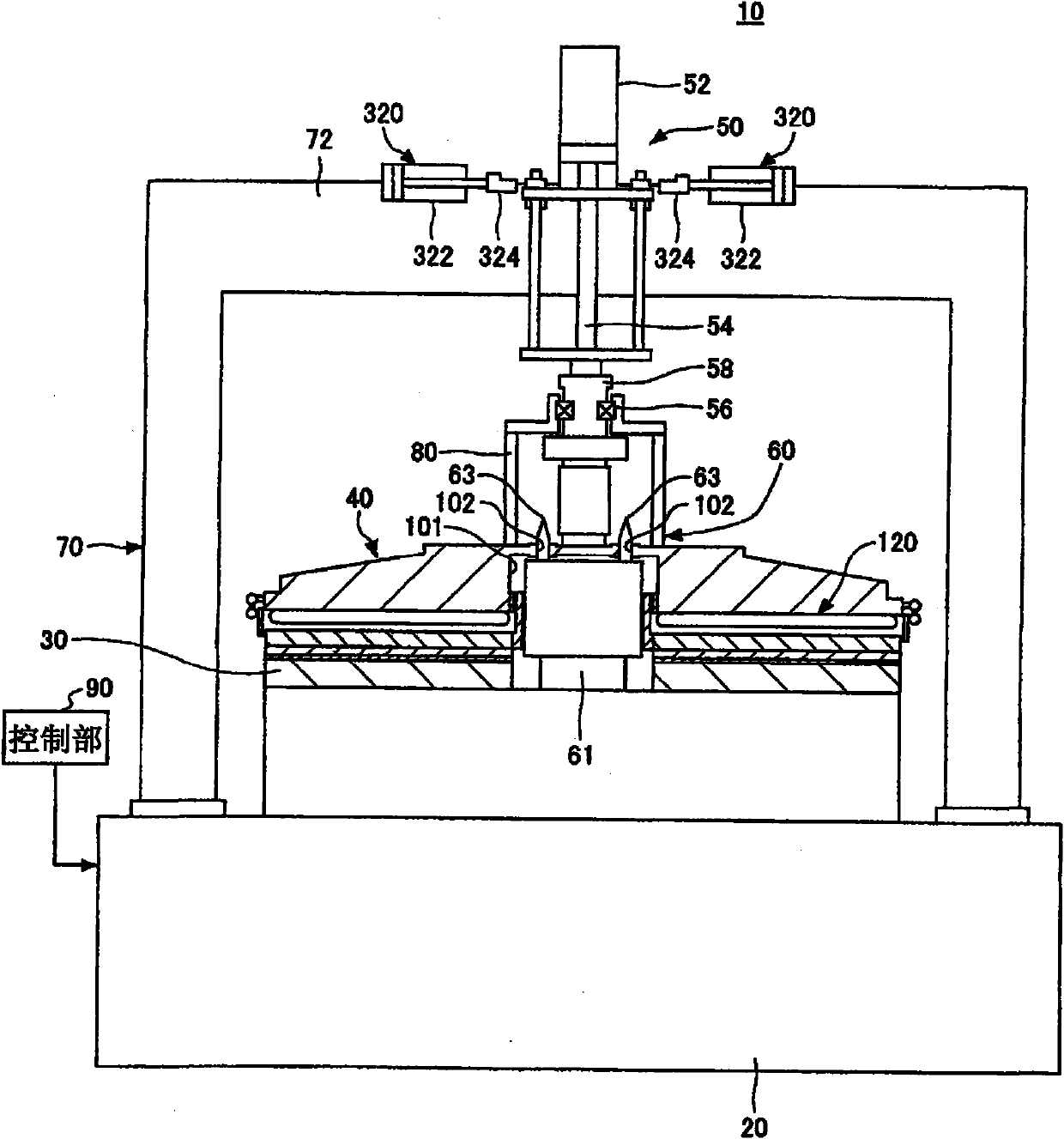

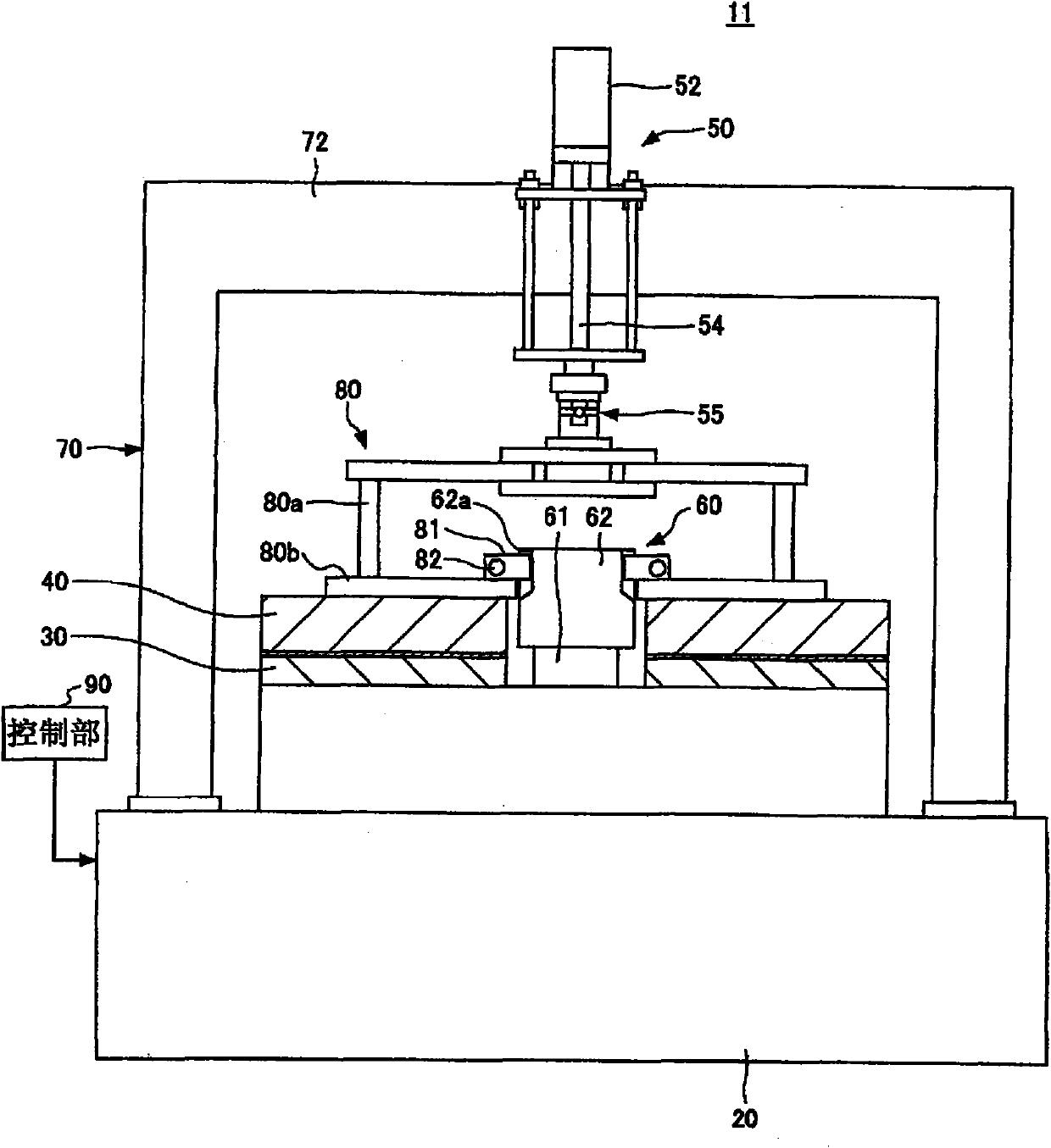

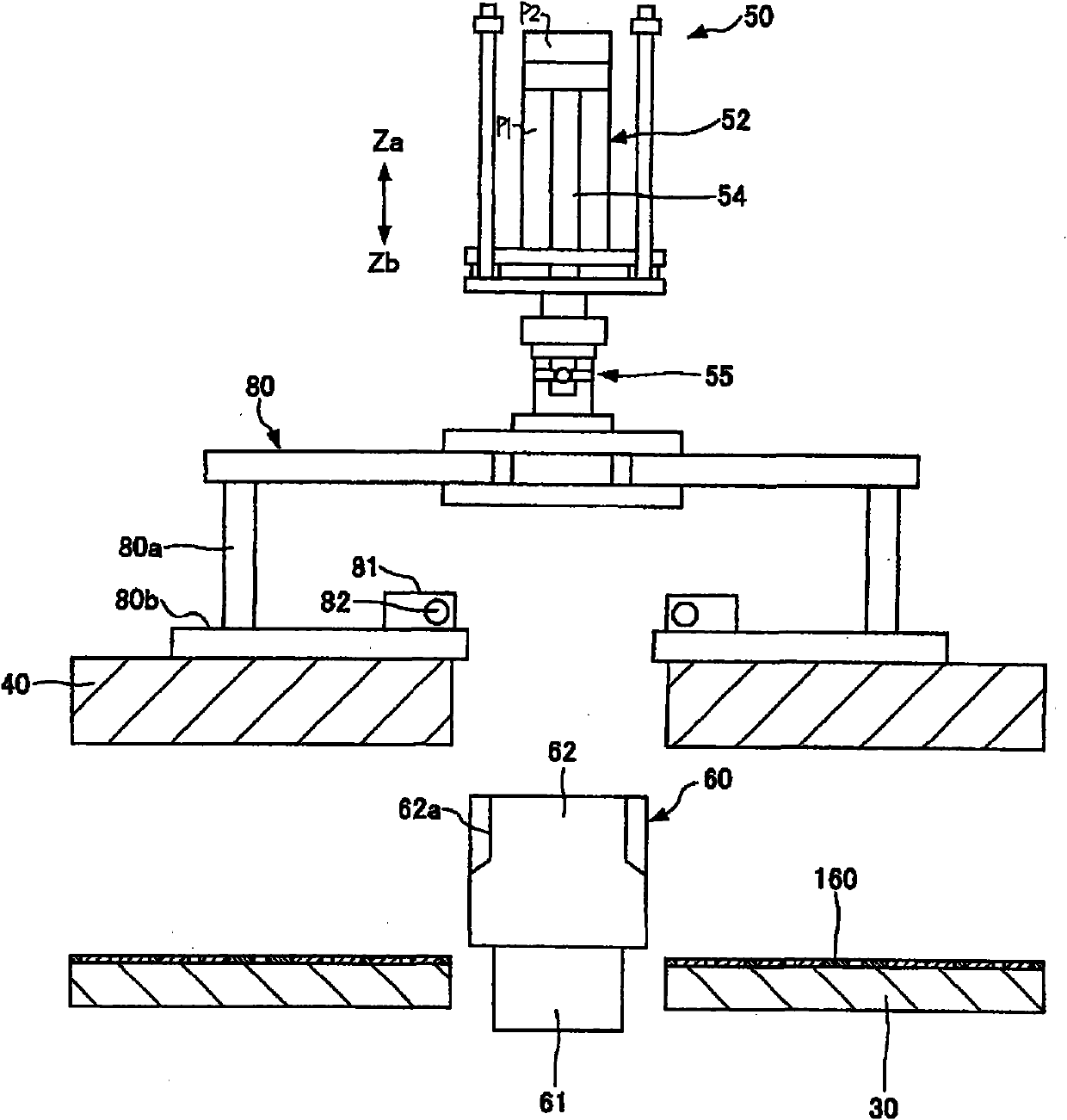

[0153] The following examples and comparative examples are given to further illustrate the present invention, but the present invention is by no means limited thereto. In this example, using Figure 1B The double-sided grinding device 11 of the key structure is shown.

[0154] Figure 9A This is the first example of a flowchart showing the manufacturing process of a glass substrate for a magnetic recording medium and a magnetic disk. The manufacturing process of the glass substrate for magnetic recordings is the process of P1-P9. At the end stage of process P9, the glass substrate for magnetic recording media which is the 1st final product is manufactured. And the magnetic disk which is the 2nd final product is manufactured by passing through the magnetic disk manufacturing process P10 about the glass substrate for magnetic recording media.

[0155] (Shaping process P1)

[0156] Process the silicate glass plate formed by the float method into a ring-shaped circular glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com