Grinding device using ultrasonic vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The grinding machine of the invention is described below, referring to the attached drawings.

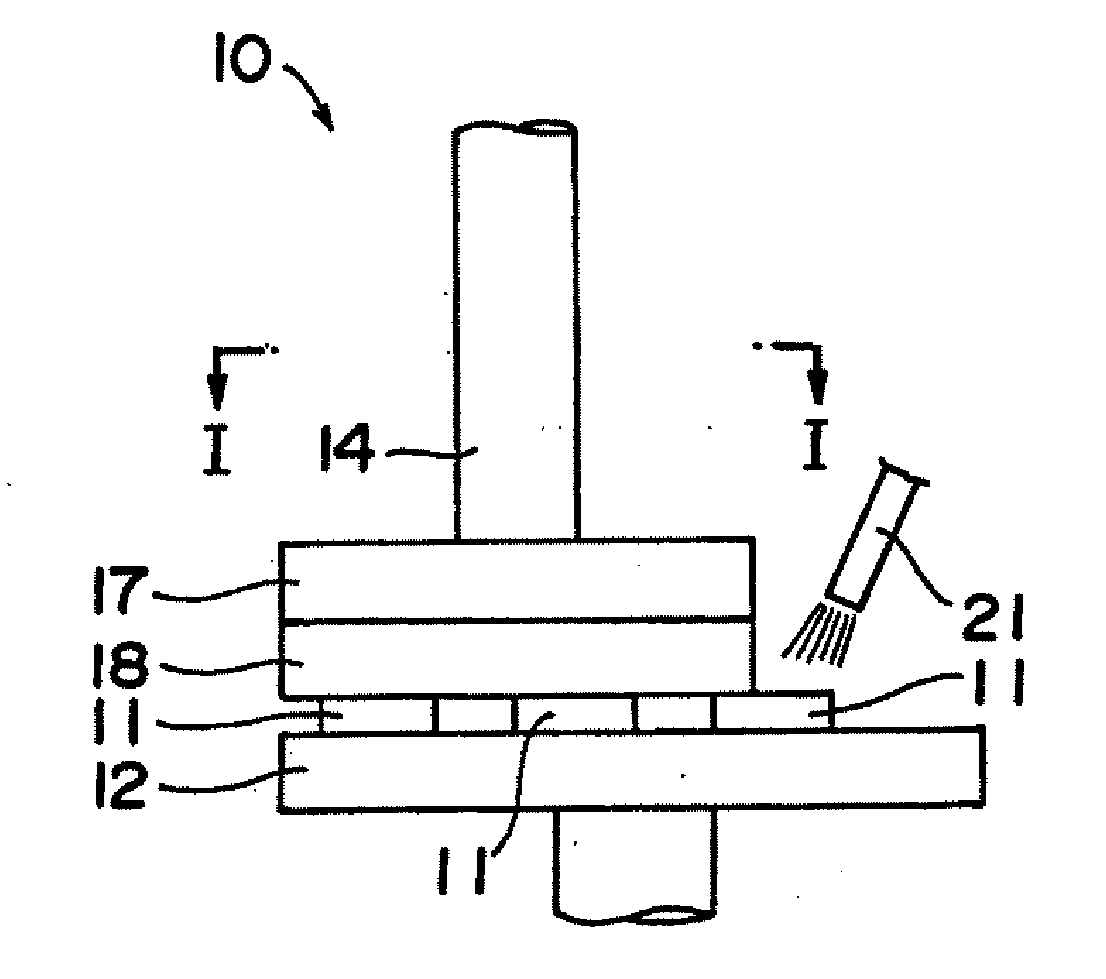

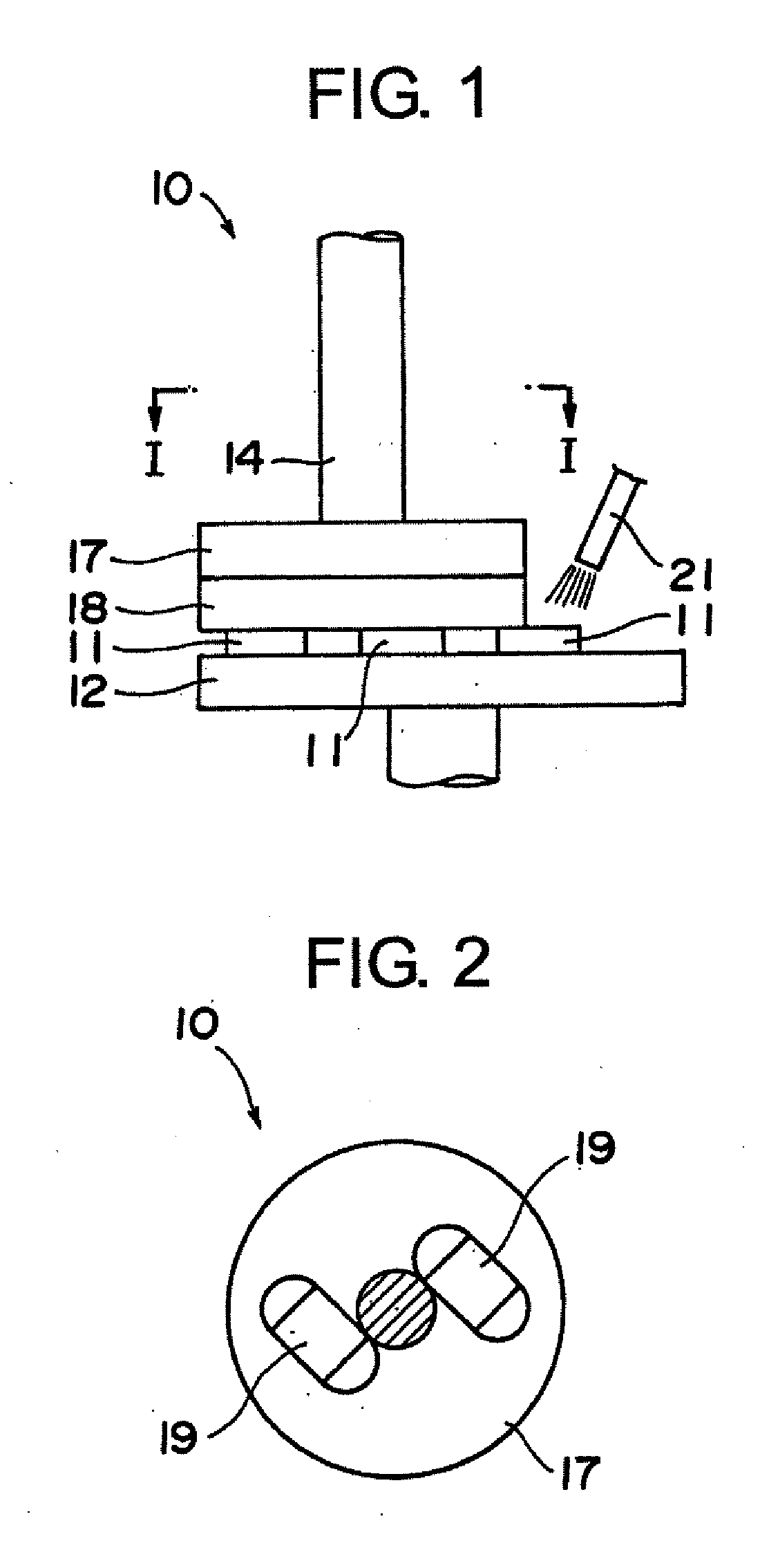

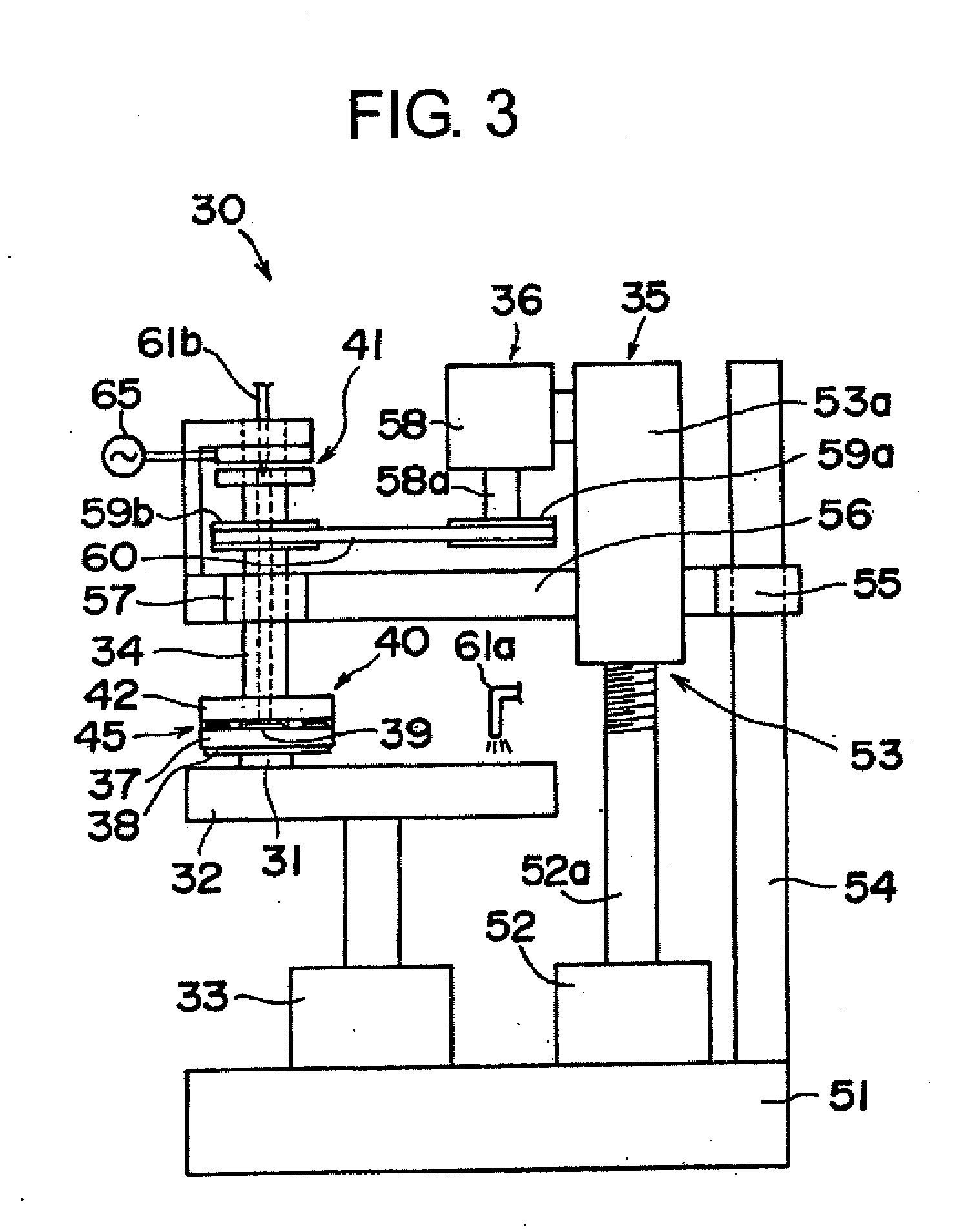

[0050]FIG. 3 is a front view of a grinding machine according to the invention. FIG. 4 is an enlarged view illustrating the grinding tool 40 of the grinding machine 30 of FIG. 3 which comprises a connection plate 42, connection means 45, annular elastic body 37, ultrasonic vibrators 39 and grind stone 38. FIG. 5 is a perspective exploded view of the grinding tool 40 of FIG. 4. FIG. 6 is a top view illustrating the annular elastic body 37, ultrasonic vibrators 39 and grind stone 38 which constitute the grinding tool 40 of FIG. 4. FIG. 7 is a sectional view illustrating the annular elastic body 37, ultrasonic vibrators 39 and grind stone 38 taken along the line II-II shown in FIG. 6.

[0051]As is illustrated in FIGS. 3 to 7, the grinding machine 30 comprises a support table 32 on which an object 31 to be ground is supported and fixed, a vertically movable rotating shaft 34 arranged above th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric energy | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com