Precise grinding and polishing machine for sealed end face of airplane engine

A technology for aircraft engines and sealing ends, which is applied in the field of grinding machines, can solve problems such as high labor intensity, unsatisfactory flatness, and low work efficiency, and achieve the effect of improving grinding accuracy and facilitating subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

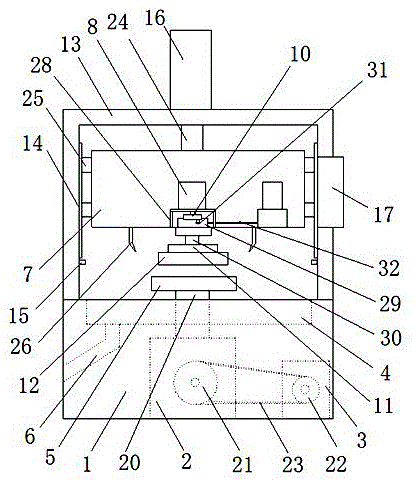

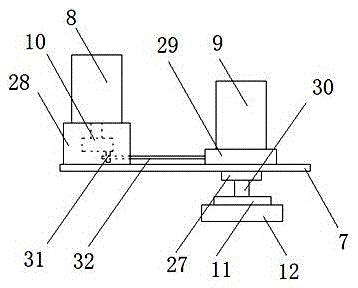

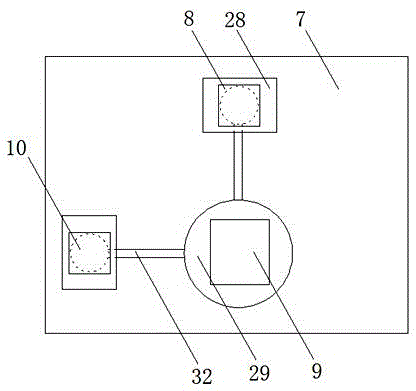

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0019] as attached Figure 1-6 As shown, a precision grinding and polishing machine for the sealing end face of an aircraft engine includes a housing 1, a gearbox 2, a motor 3, a grinding liquid tank 4, a bearing plate 5, a drain pipe 6, a bearing box 7, and a motor 2 8. Motor three 9, runner 10, grinding disc mounting block 11 and grinding disc 12, characterized in that: the housing 1 is provided with a support beam 13, and the support beam 13 is provided with a guide rail 14, an inductor 15. The cylinder 16 and the controller 17 can control the flatness and parallelism of the grinding disc 12 through the sensor 15, thereby improving the grinding accuracy of the workpiece. The controller 17 is provided with a parameter display 18 and a control button 19, The operator's work is facilitated by the parameter display 18 and the control button 19. The gearbox 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com