Patents

Literature

436results about "Seat surface grinding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

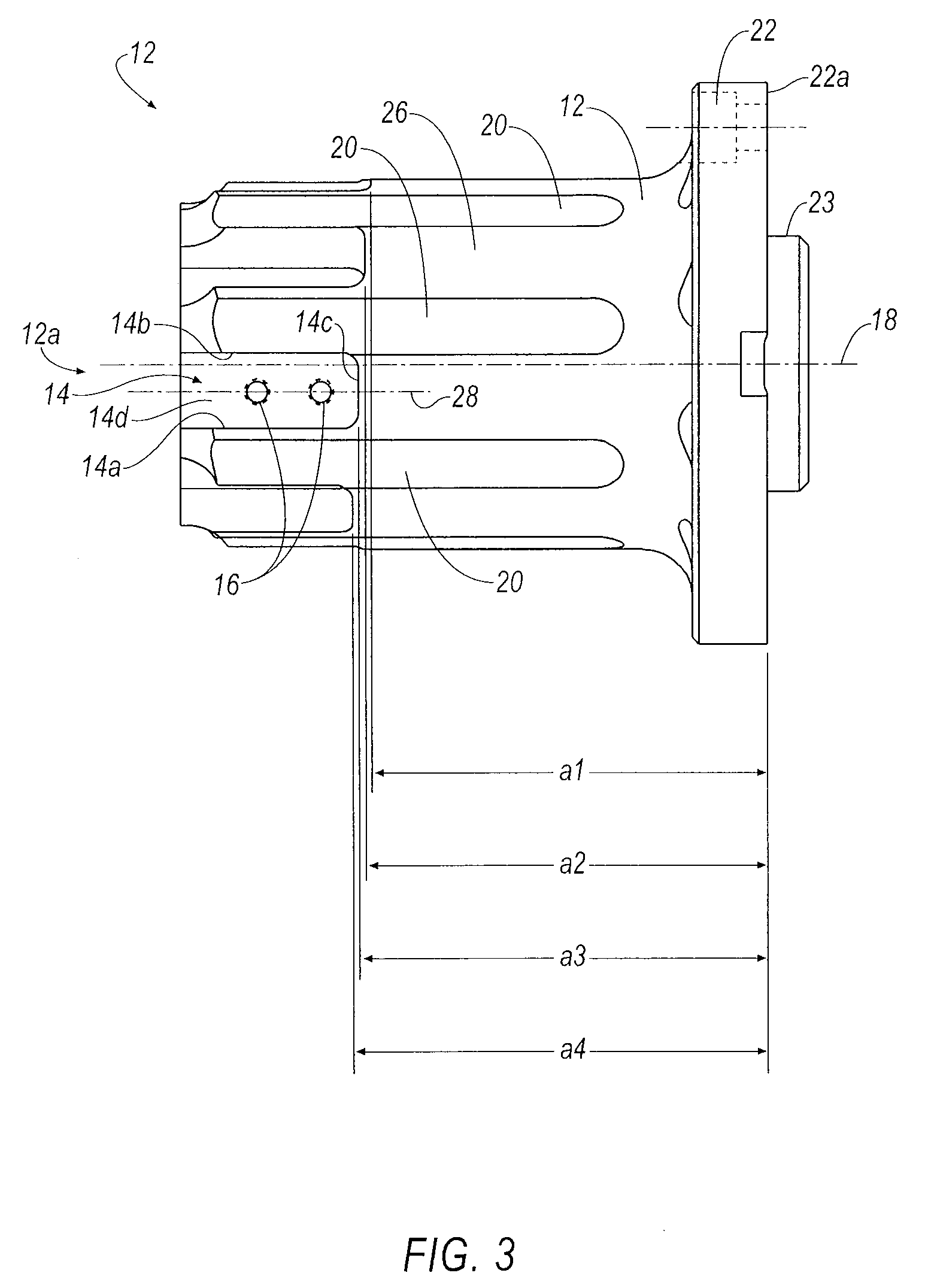

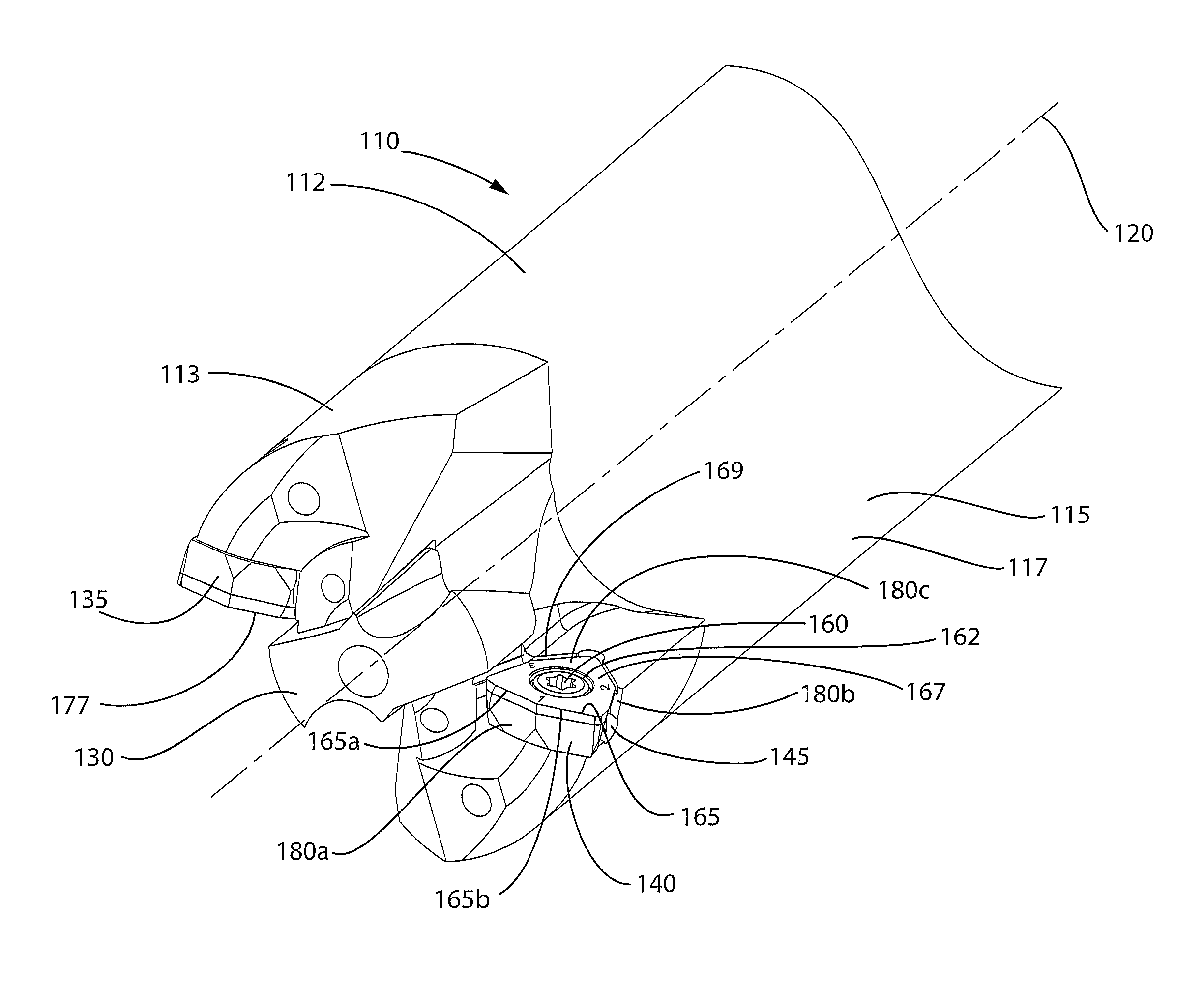

Power Drill Alignment and Depth Measurement Device

InactiveUS20150165580A1Efficient and economical for alignmentEfficient and economicalDrilling/boring measurement devicesThread cutting machinesMeasurement deviceSignal source

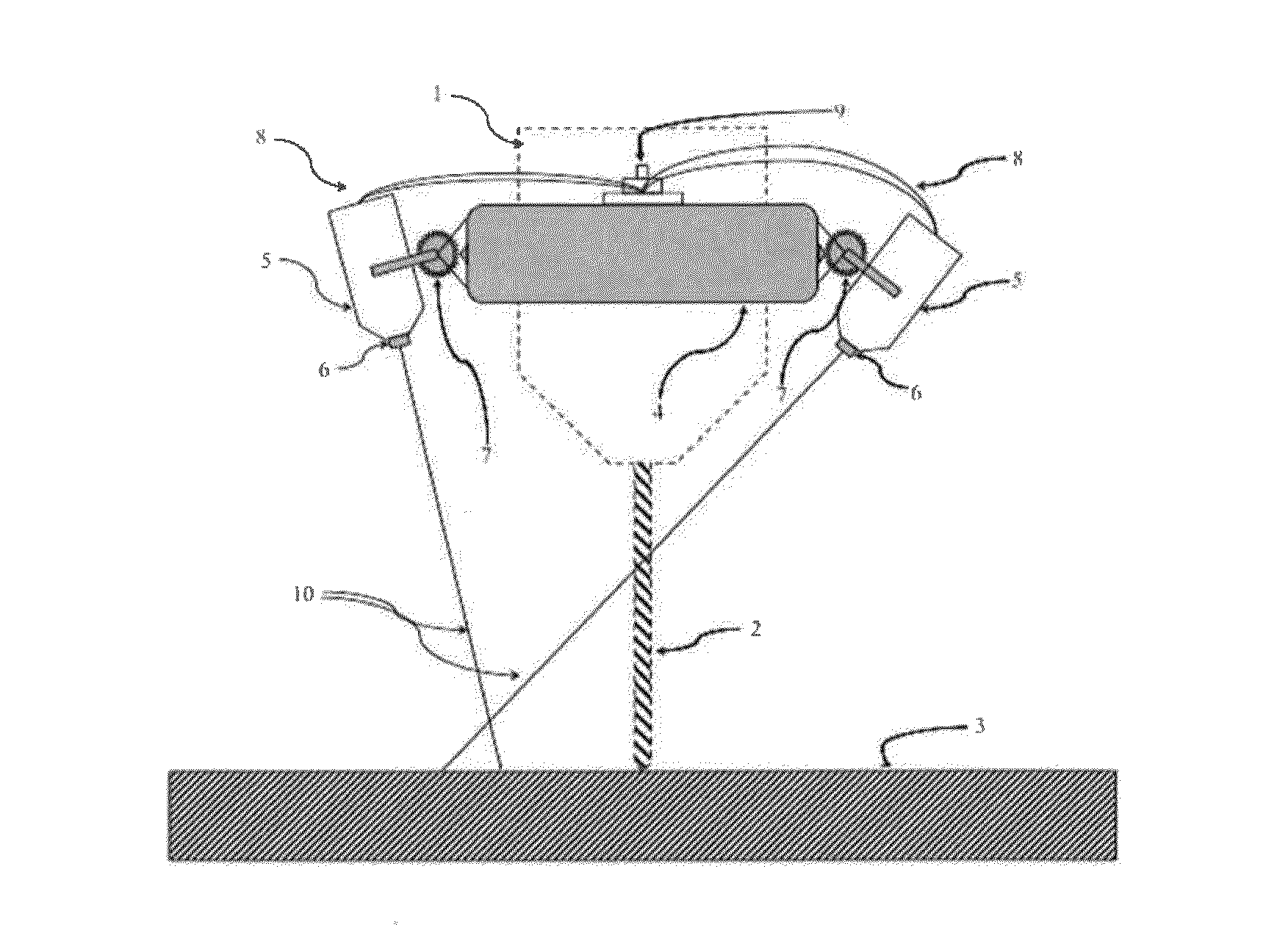

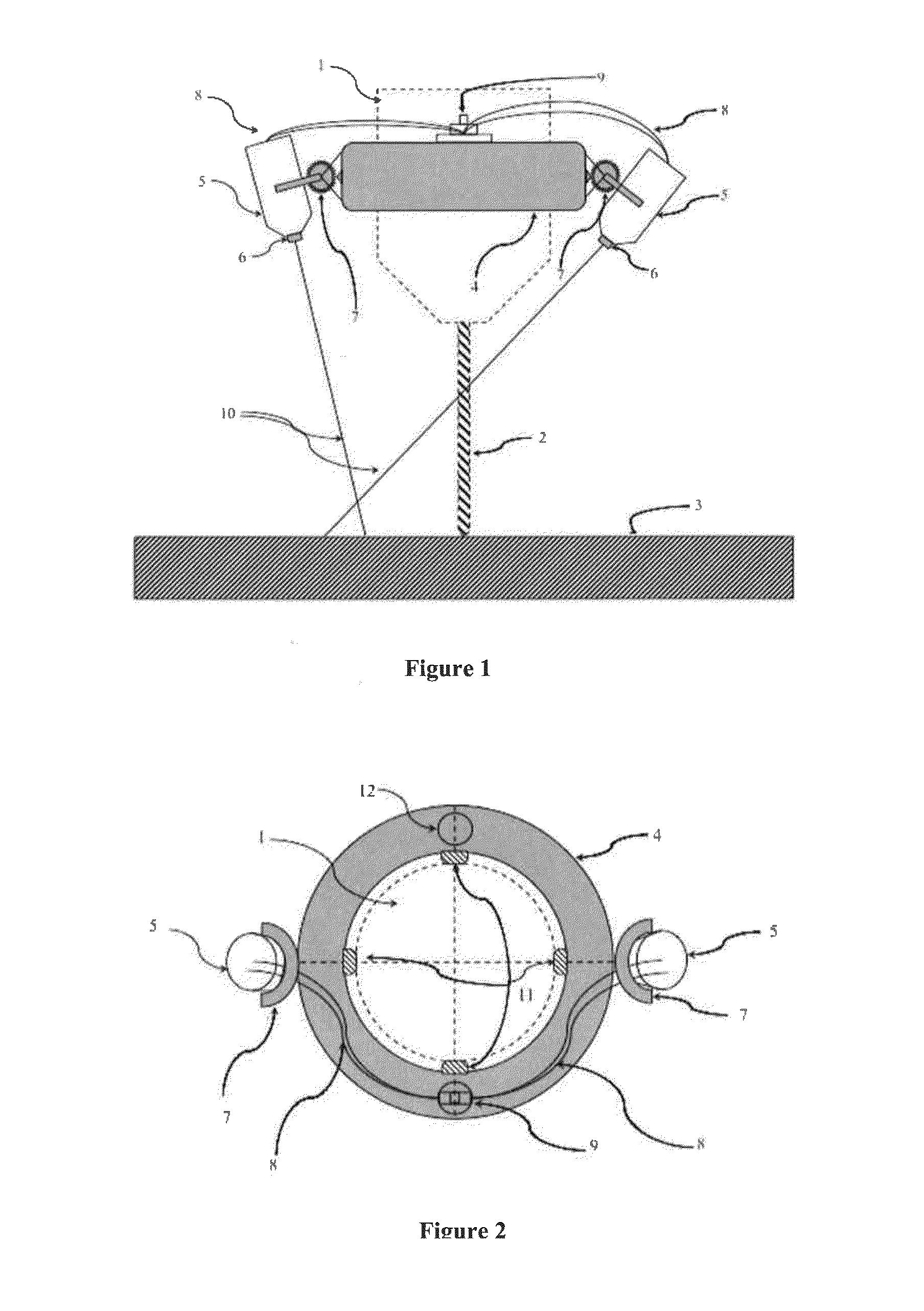

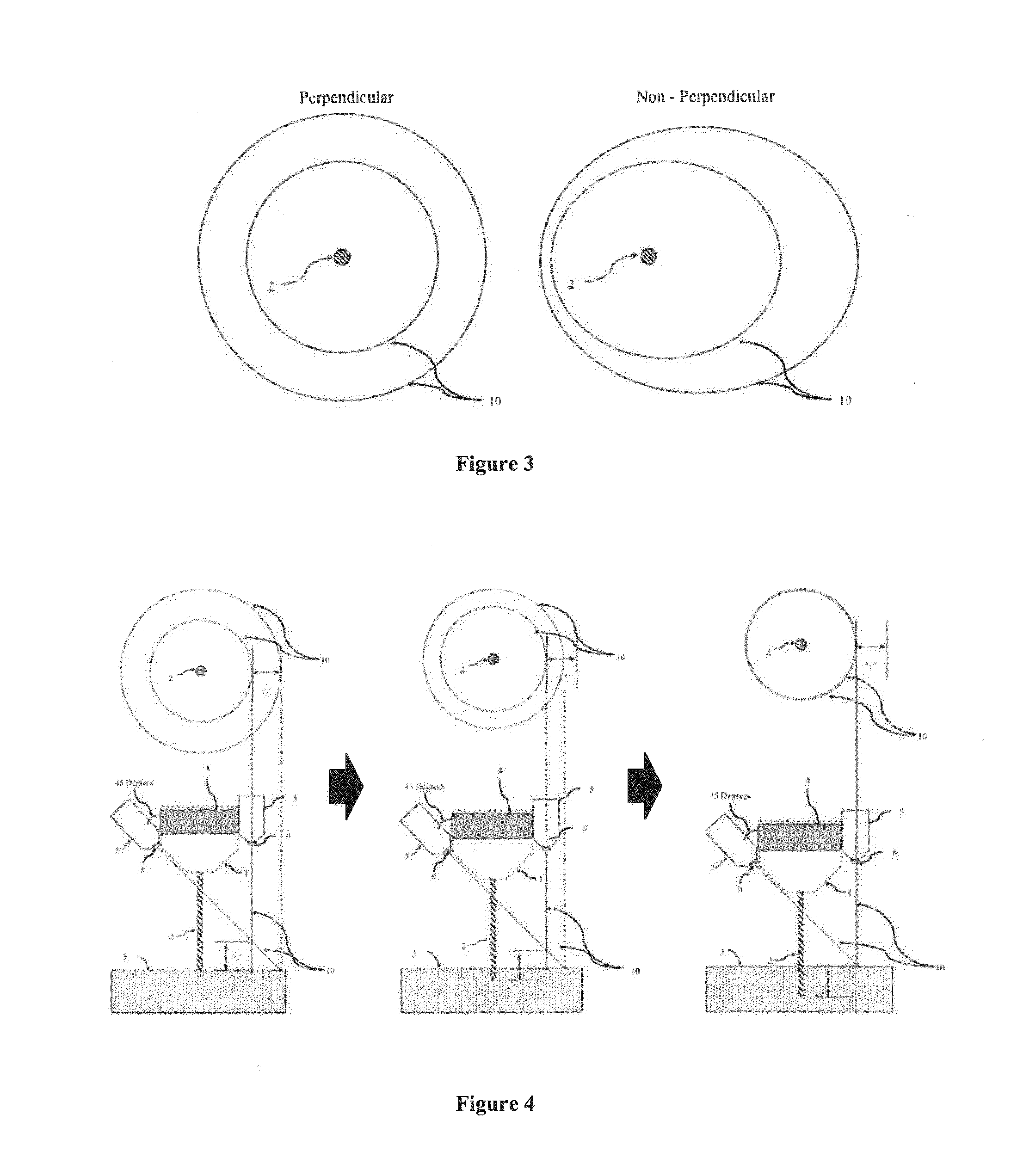

The present invention provides a device and method for aligning a drill bit of a hand drill to a specific angle—typically, perpendicular to the surface to be drilled. Concurrently, the invention provides a method to measure the depth of the drilled hole. The device of the invention comprises: (a) a signal source that generates a signal (typically a light pattern) that varies in response to changes in angle or depth of the drill bit; and (b) a holder to which the signal source is attached, the holder is mounted to the drill chuck of the drill and moves with its rotation. By using of the present invention, an image is generated that changes with angle or depth changes of the drill bit. This image is used by the operator to orient the angle of the drill bit or to determine the depth of the hole drilled.

Owner:HOLLAND JAMES

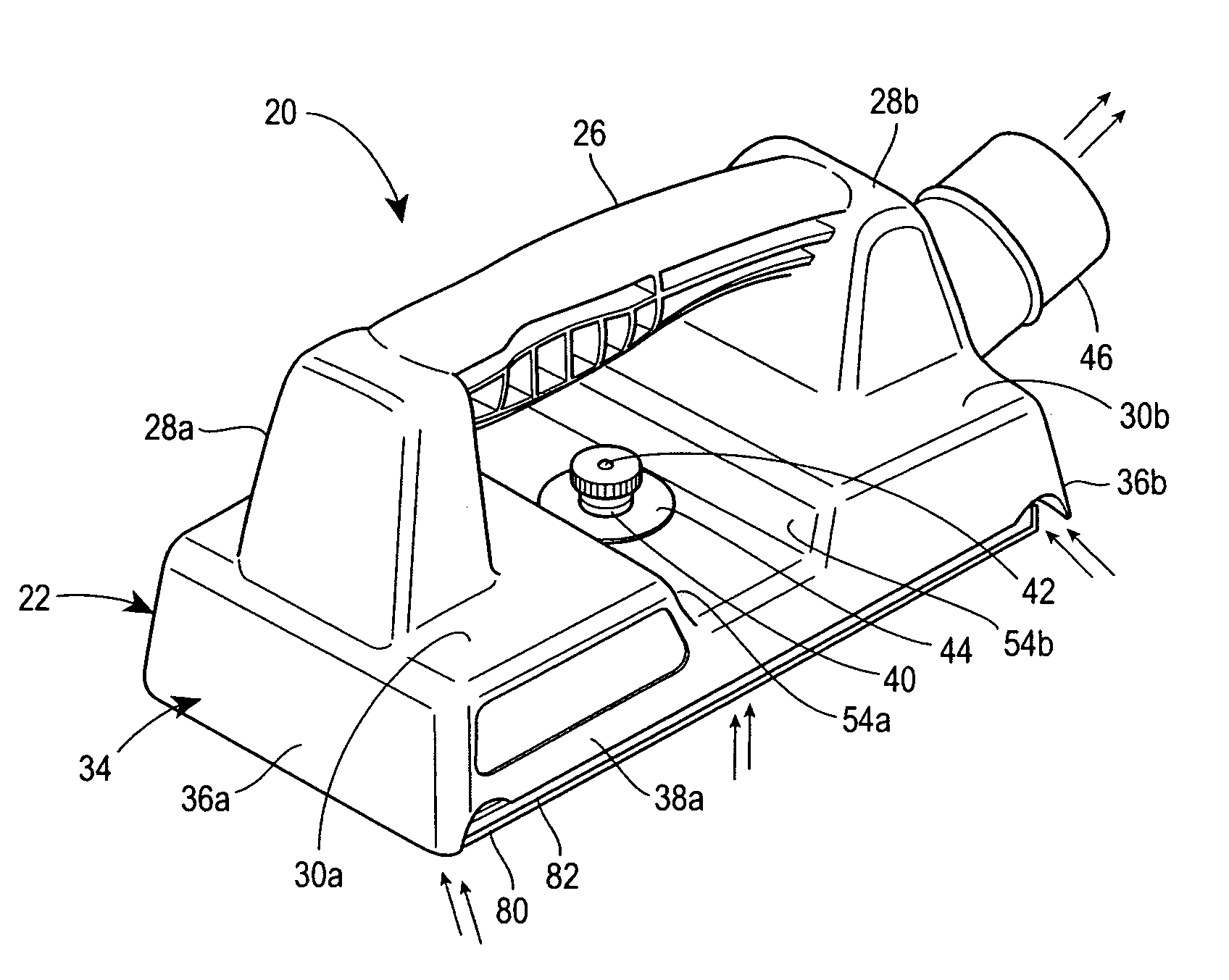

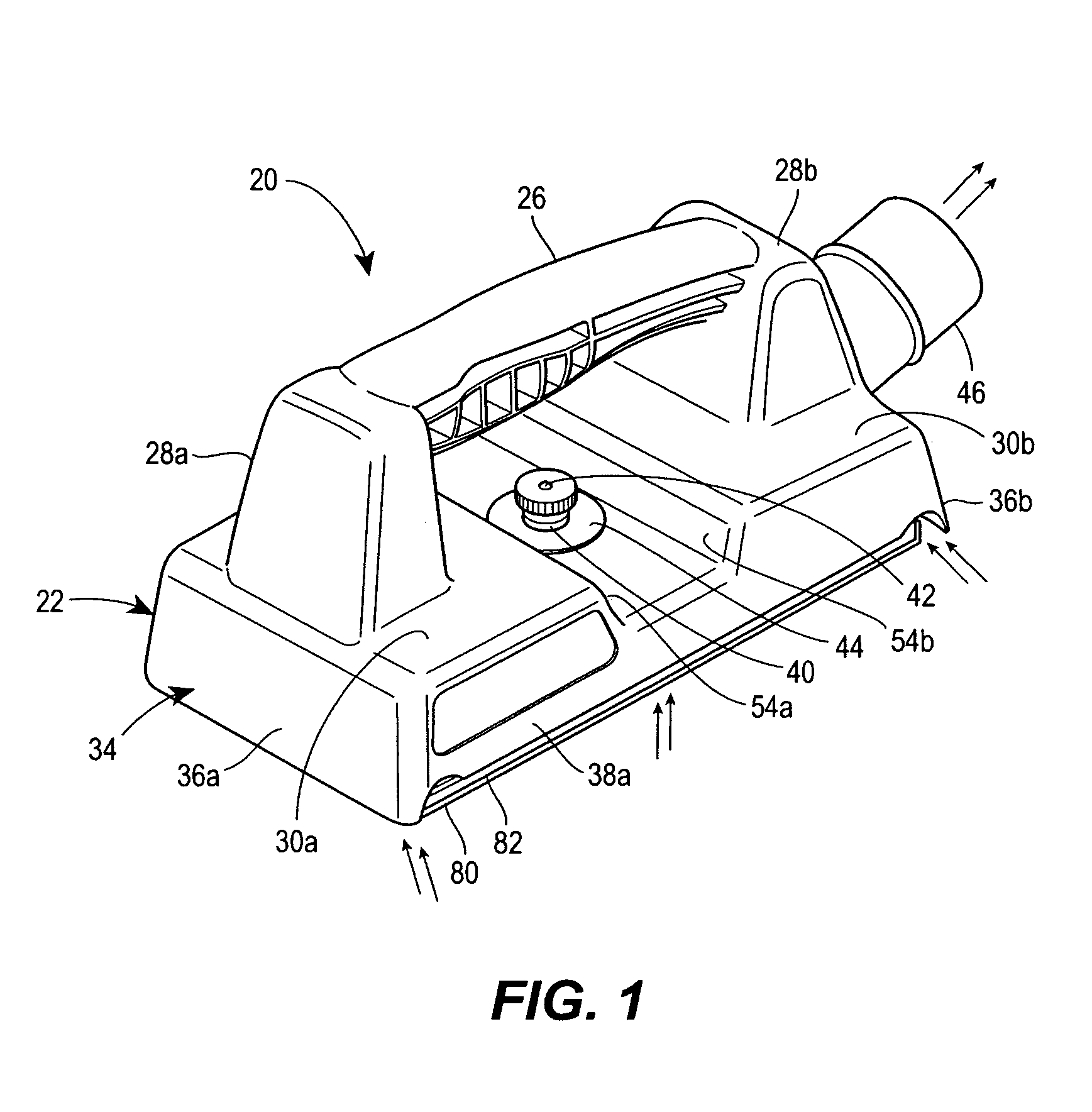

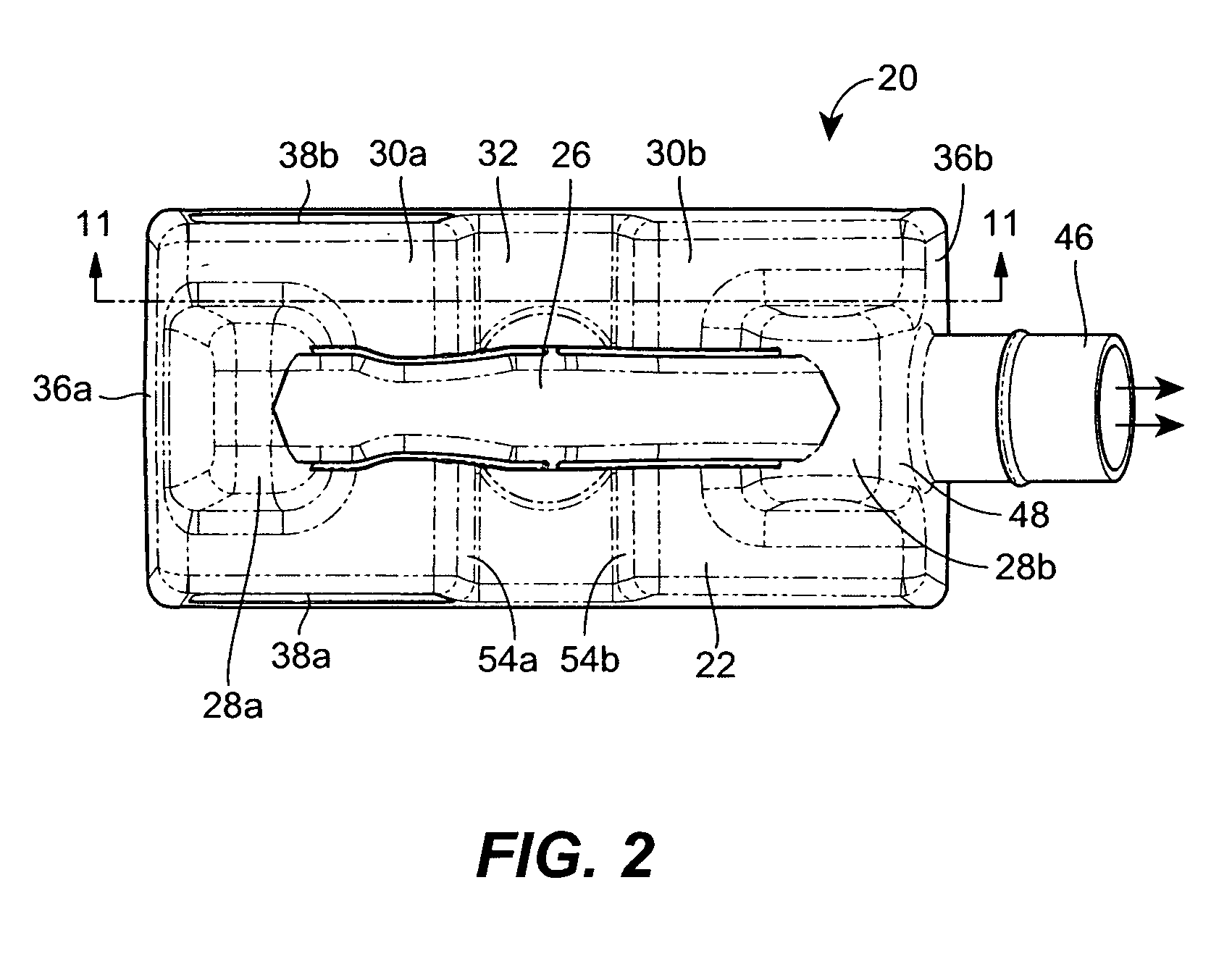

Hand sander vacuum attachment

A manual sander vacuum attachment, providing edge sanding and multiple positioning capabilities, having a lower sanding backer plate member, which carries a soft sanding pad and secures the sandpaper sheet, and an upper housing portion, having a generally horizontal platform with two vertically-extending stanchion supporting a handle therebetween, with a vacuum fitting for connection to a hose for a vacuum air source, and a peripheral skirt surrounding the backer plate member, whereby all vacuum air flow of sanded debris travels about periphery of sander backing plate up into interior of the housing portion.

Owner:SHOP VAC

Method for preparing heat-not-burn tobacco bases containing active carbon

ActiveCN105747264AReduce the impactIncrease loadTobacco preparationTobacco treatmentActivated carbonFlavor

The invention discloses a method for preparing heat-not-burn tobacco bases containing active carbon.The method comprises the following steps that active carbon is weighed and mixed with water, defibering and pulping are conducted, and active carbon pulp is obtained; tobacco raw materials are weighed, soaked, filtered and pulped so that tobacco pulp can be obtained; by weight, 50-80 parts of tobacco pulp, 8-25 parts of wood pulp, 10-30 parts of active carbon pulp and 4-8 parts of adhesive are weighed and evenly mixed; the mixture is formed and dried so that the tobacco bases are obtained; by weight, 1-40 parts of tobacco essential oil, 2-20 parts of tobacco flavor material and 40-80 parts of atomization agent are weighed and evenly mixed so that coating liquid can be obtained; the coating liquid is sprayed to the tobacco bases, standing is conducted for 40-48 h under the constant-temperature and constant-humidity conditions, and finally the heat-not-burn tobacco bases containing active carbon are obtained.Cigarettes prepared from the tobacco bases are put in a smoking set to be used, good satisfaction can be brought to consumers, the amount of smoke is large, the fragrance concentration is high, and the quality of heat-not-burn cigarettes is improved better.

Owner:CHINA TOBACCO GUIZHOU IND

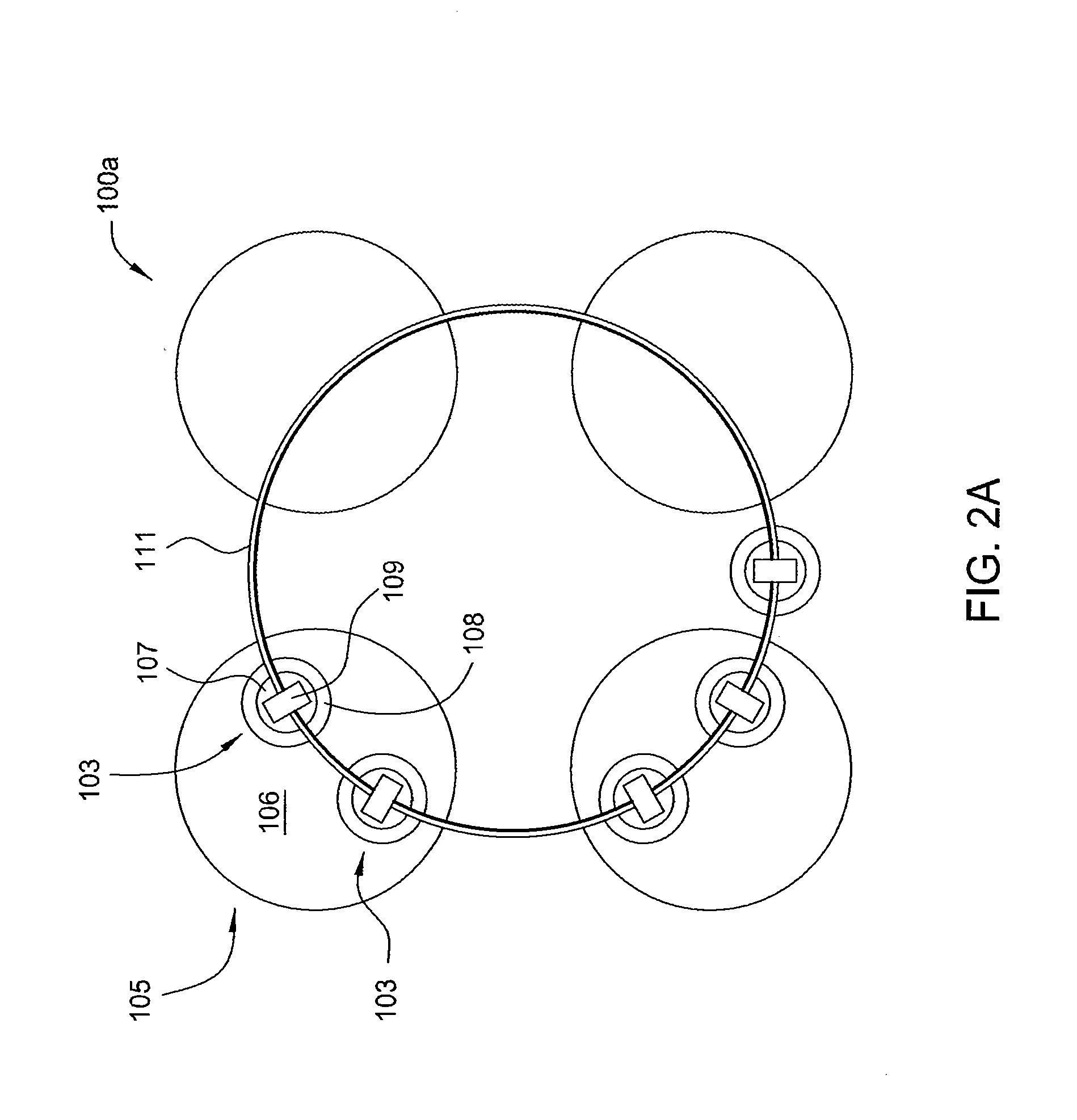

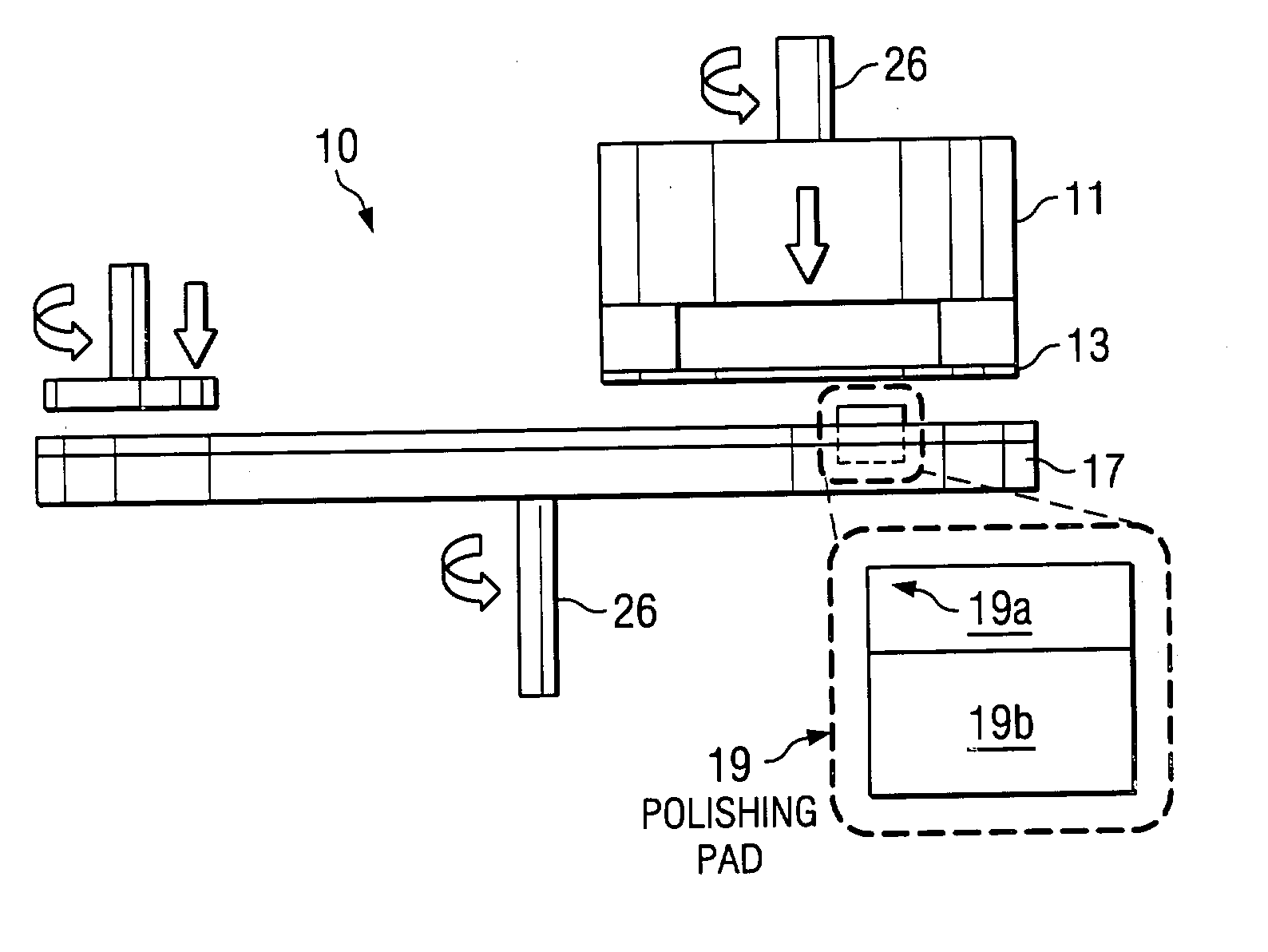

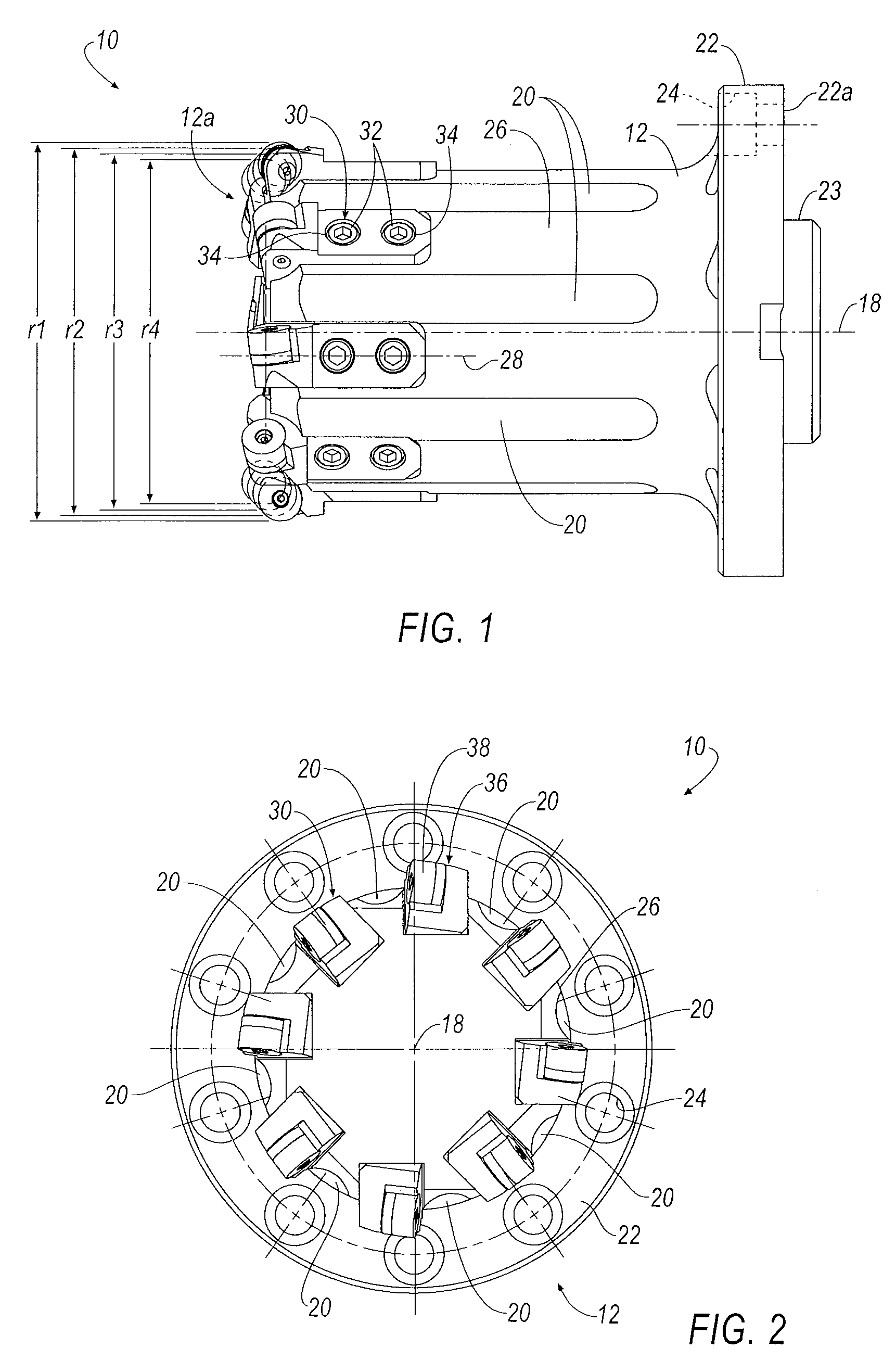

Polishing system having a track

InactiveUS20090258574A1Provide rigidityAvoid enteringGrinding wheel securing apparatusGrinding carriagesEngineering

Embodiments described herein relate to a track system in a polishing system. One embodiment described herein provides a track system configured to transfer polishing heads in a polishing system. The track system comprises a supporting frame, a track coupled to the supporting frame and defining a path along which the polishing heads are configured to move, and one or more carriages configured to carry at least one polishing head along the path defined by the track, wherein the one or more carriages are coupled to the track and independently movable along the track.

Owner:APPLIED MATERIALS INC

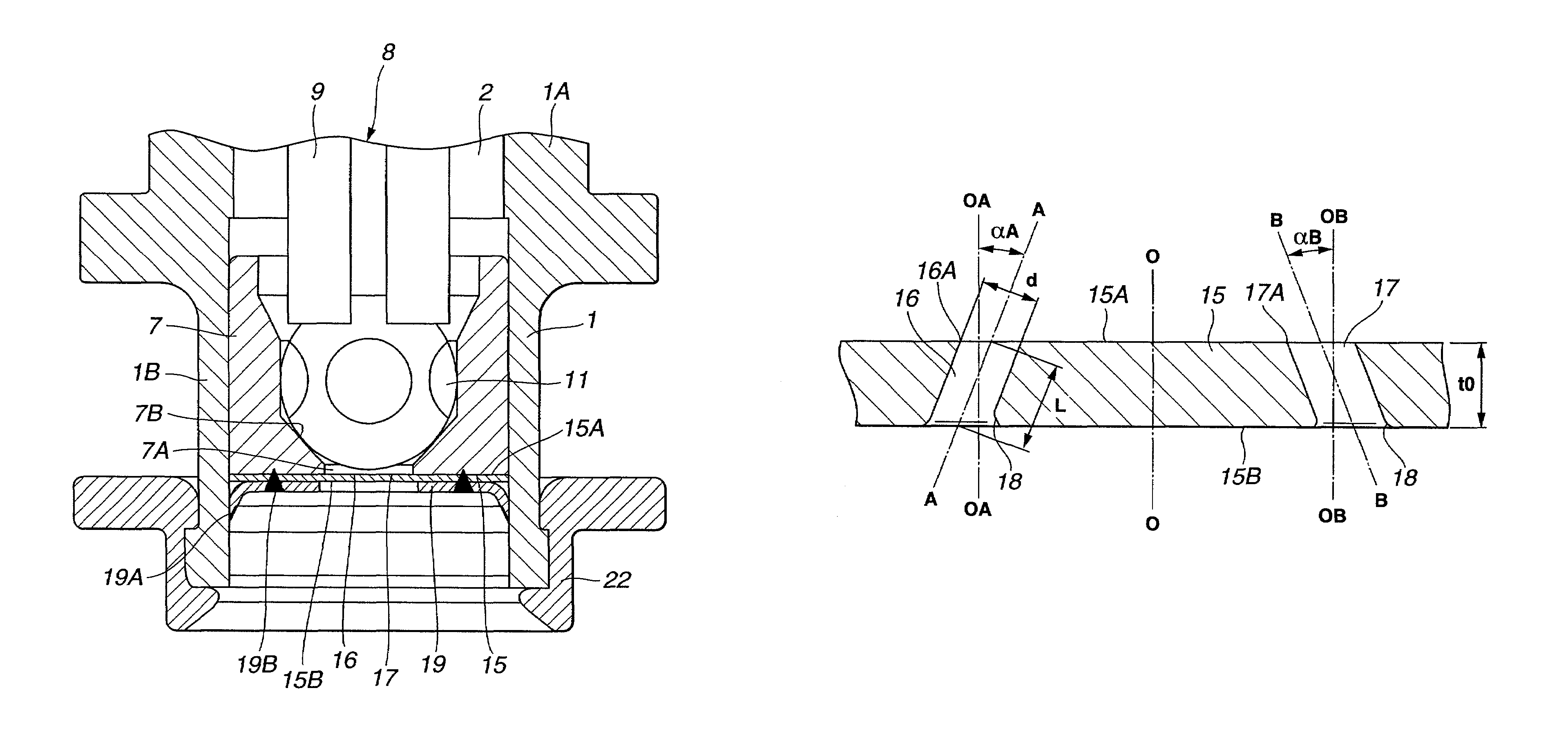

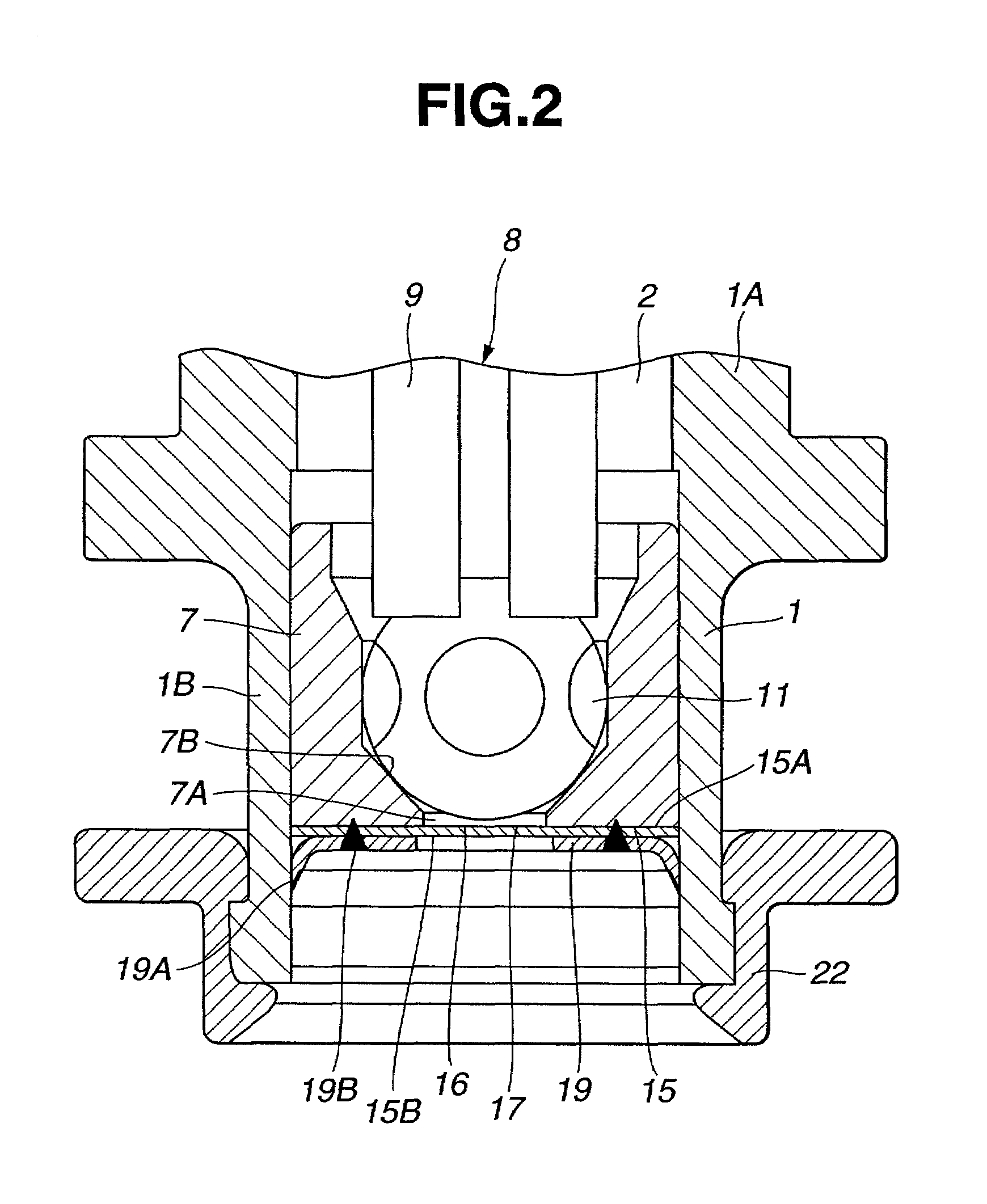

Engine fuel injection valve and manufacturing method for nozzle plate used for the same injection valve

InactiveUS6991188B2Improve flammabilityEasy to clogEdge grinding machinesPolishing machinesEngineeringMotor fuel

In a fuel injection valve, a substantially arc-shaped chamfered portion in a substantially arc shape of cross section is formed on an edge of an inner wall portion of each opening end of a corresponding nozzle hole of a nozzle plate to further expand a whole diameter of an injection stream of fuel passed through a plurality of obliquely penetrated nozzle holes. In a manufacturing method for the nozzle plate, circulating a fluid mixed with an abrasive through each nozzle hole is carried out to polish opening ends of the respective nozzle holes which are faced against the external of the fuel injection valve in a form of substantially arc shape of cross section with the abrasive. Furthermore, grinding the respective major surfaces of a punched plate material which becomes the nozzle plate together with vicinities to the respective opening ends of the nozzle holes is carried out.

Owner:HITACHI LTD

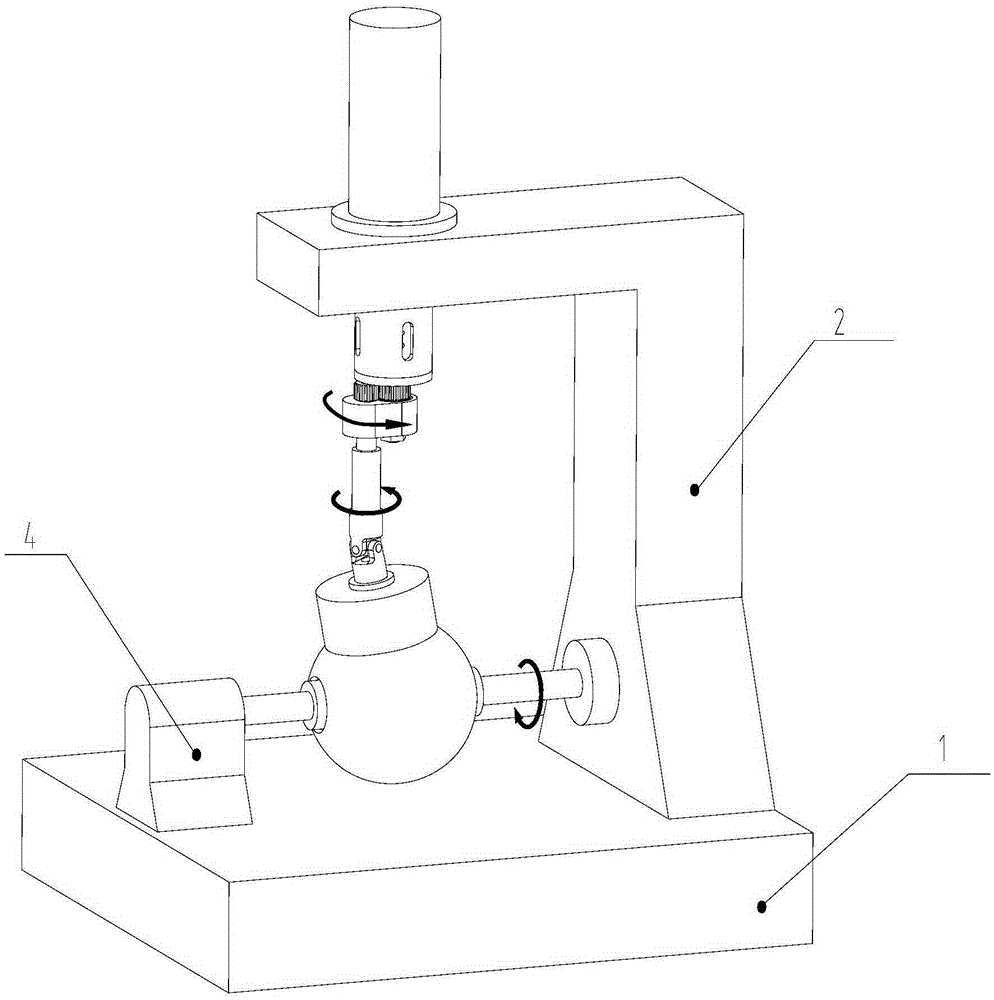

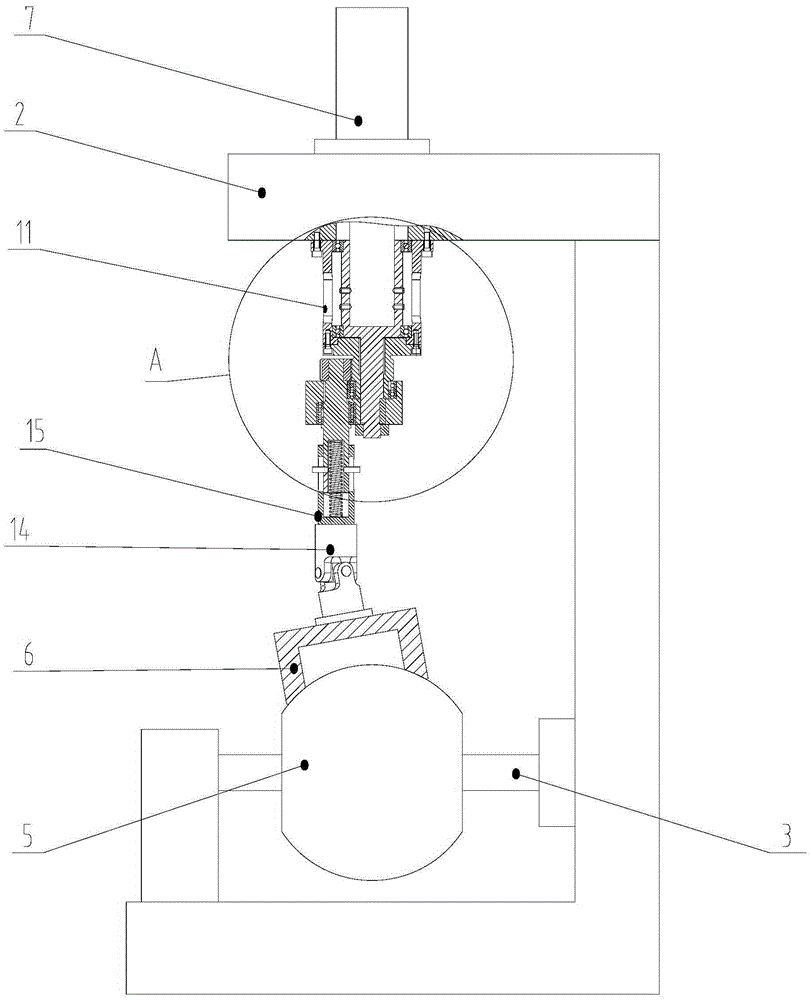

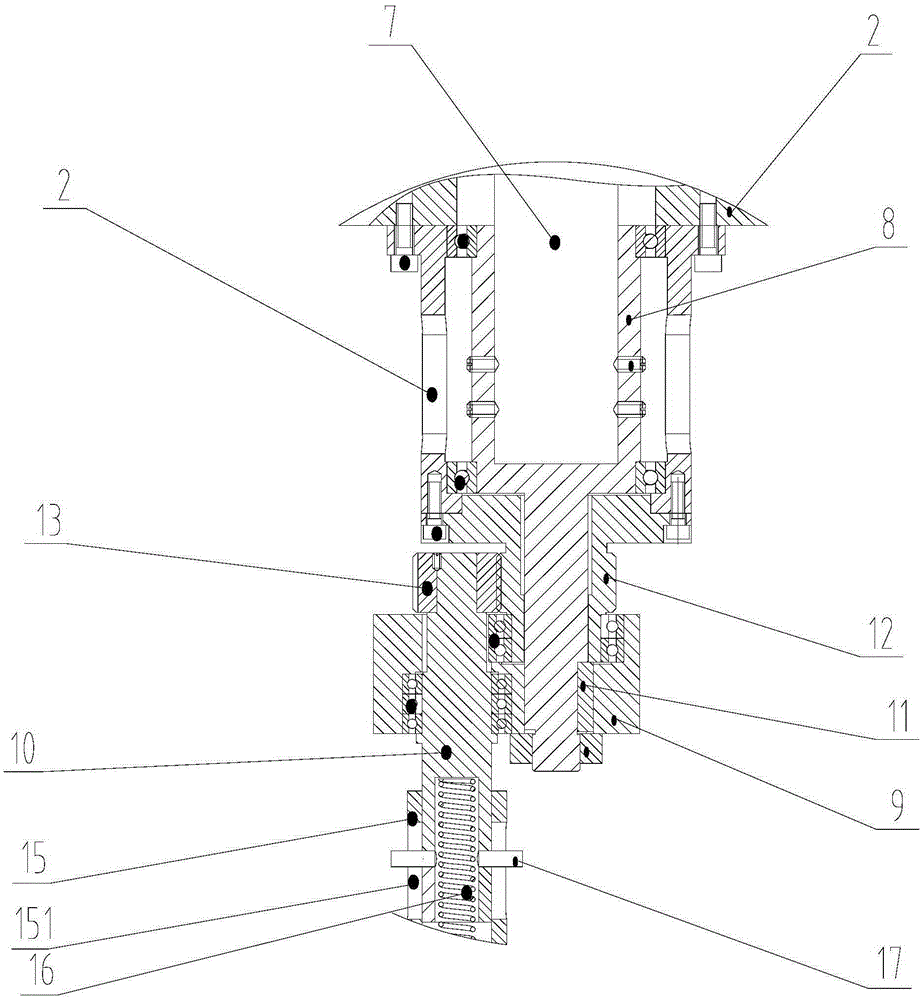

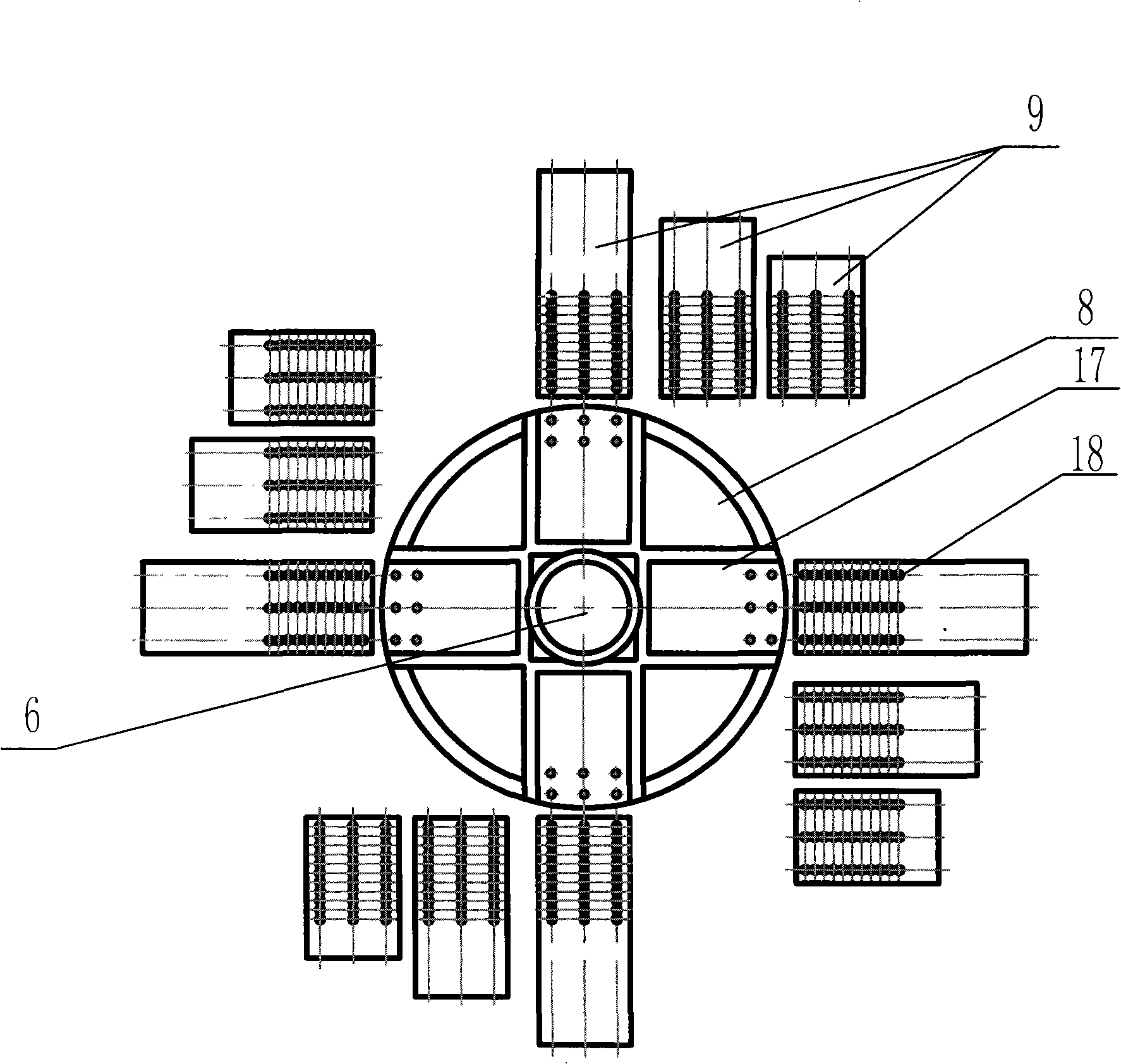

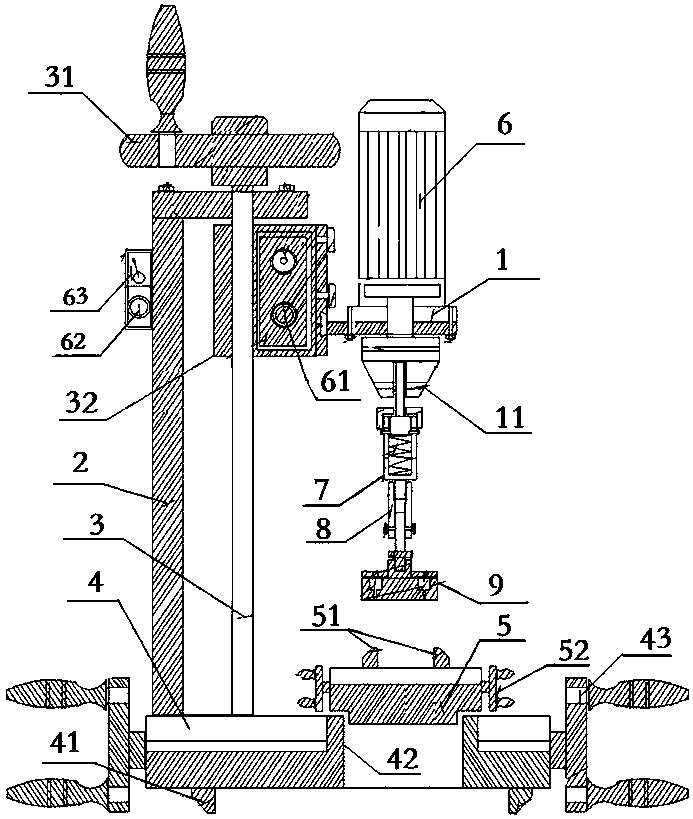

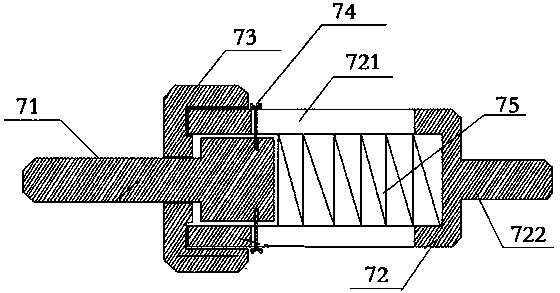

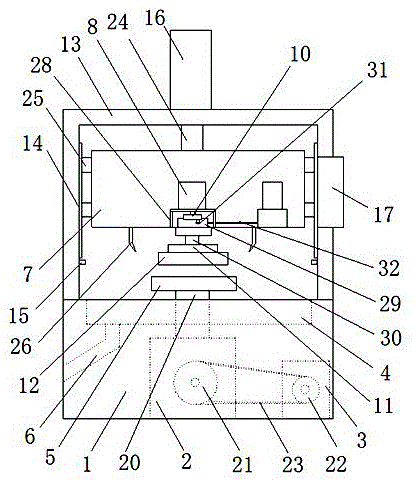

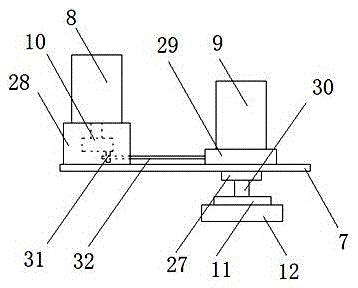

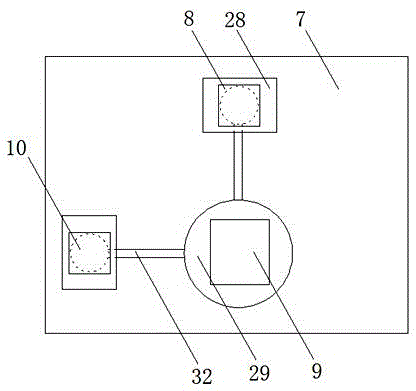

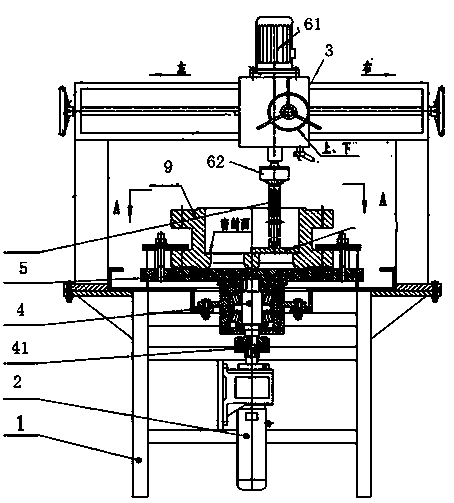

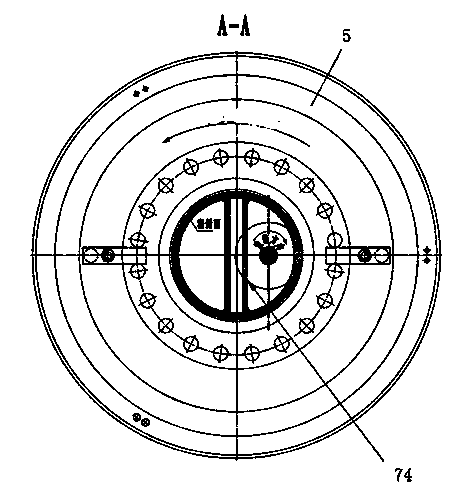

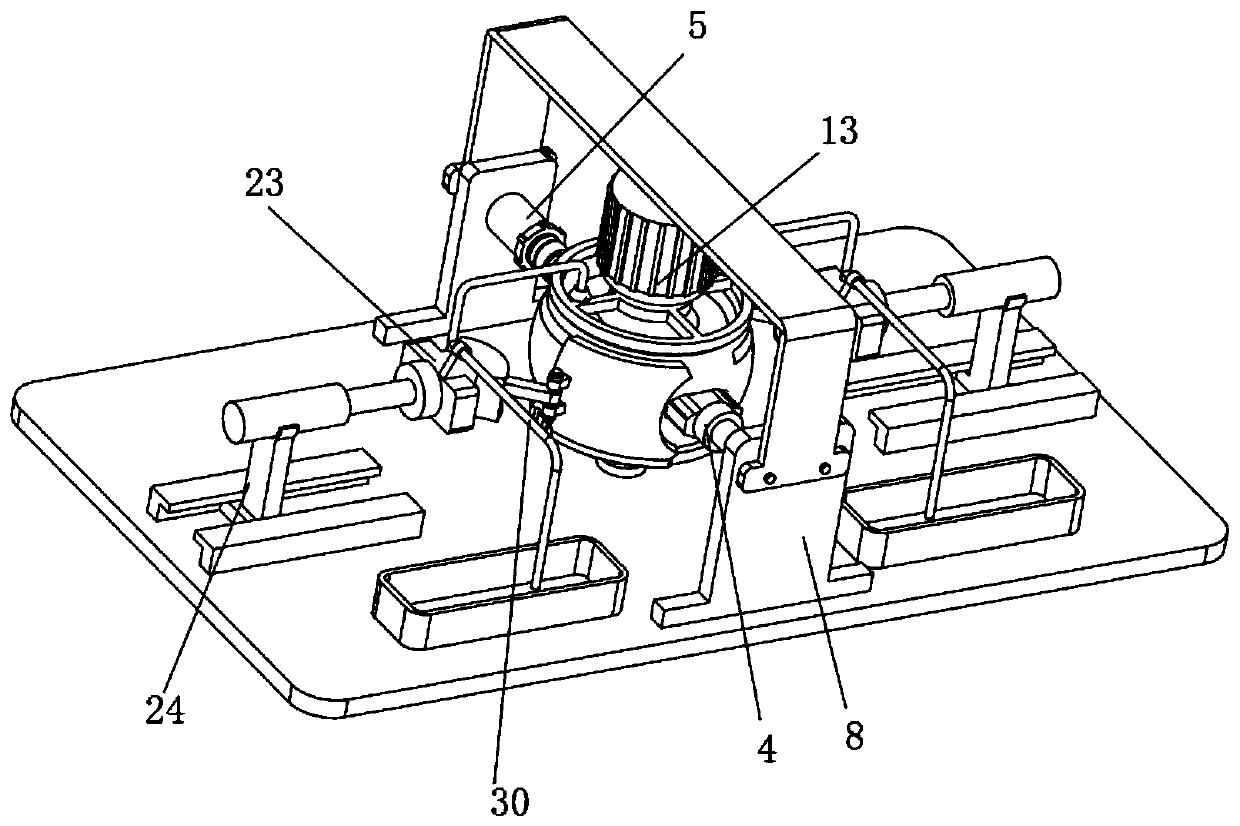

Efficient ball core grinding device

InactiveCN105252380AAchieve rotationIncrease relative grinding speedGrinding drivesSeat surface grinding machinesUniversal jointEngineering

The invention relates to the technical field of ball core grinding, in particular to an efficient ball core grinding device. The efficient ball core grinding device comprises a base, a rack, a positioning mandrel, a mandrel driving motor, a ball core, a grinding disc and a grinding driving device, and the grinding driving device is used for driving the grinding disc to revolve and rotate around the surface of the ball core to conduct grinding. The rack and the mandrel driving motor are both fixed to the base. One end of the positioning mandrel is mounted on the rack, and the other end of the positioning mandrel is connected with the mandrel driving motor. The positioning mandrel is sleeved with the ball core. According to the efficient ball core grinding device, the grinding disc can rotate on the ball core, and moreover the grinding disc can revolve, so that the relative grinding speed of the grinding disc is increased, and accordingly the grinding efficiency is improved; through the arrangement of a swing shaft height adjusting device and a universal joint, uniform grinding pressure can be guaranteed while the grinding speed is increased, and the grinding disc is prevented from flying out when the rotating speed of the grinding disc is high and is made to adapt to changes of the surface of the ball core in the grinding process.

Owner:WUZHONG INSTR

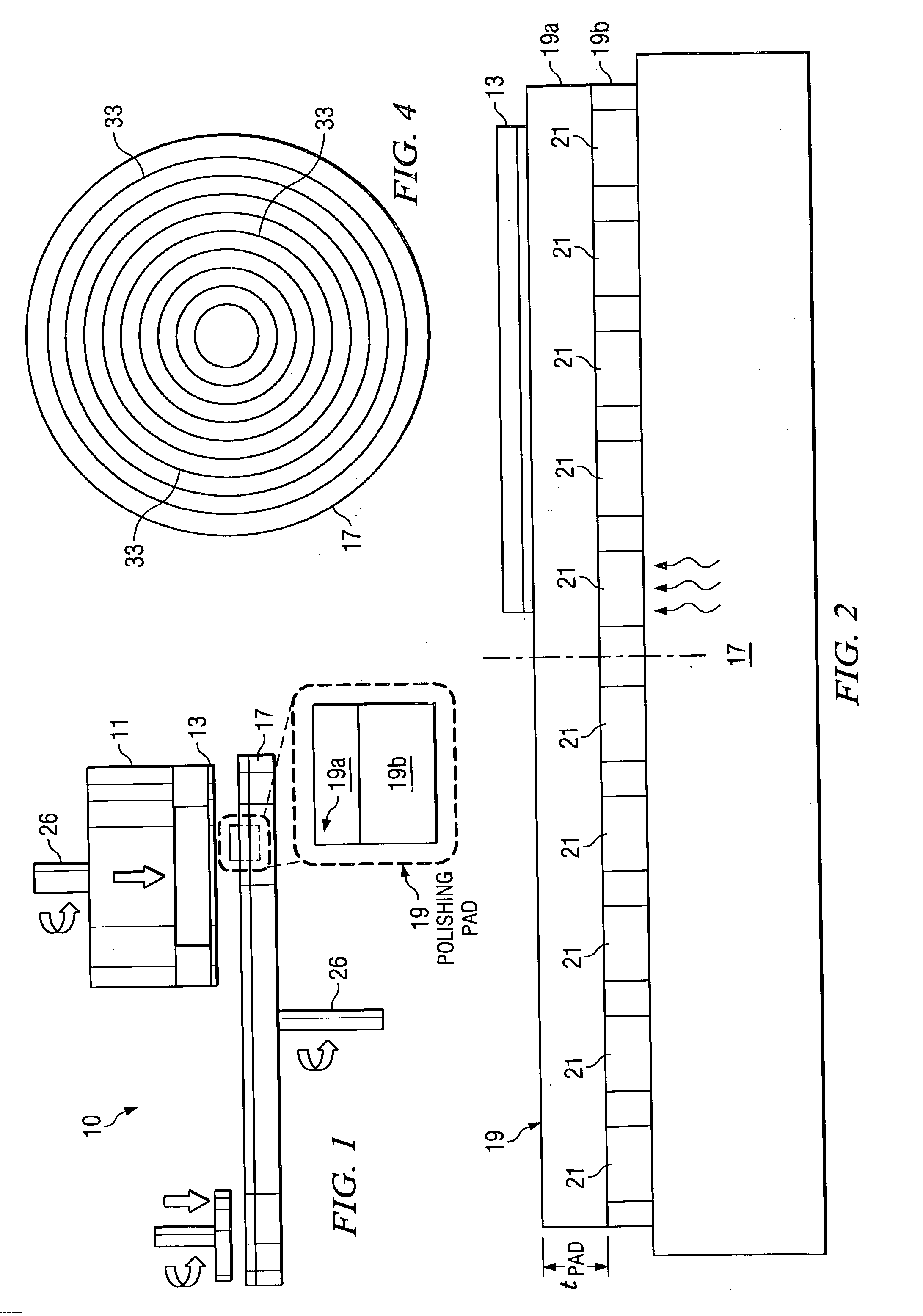

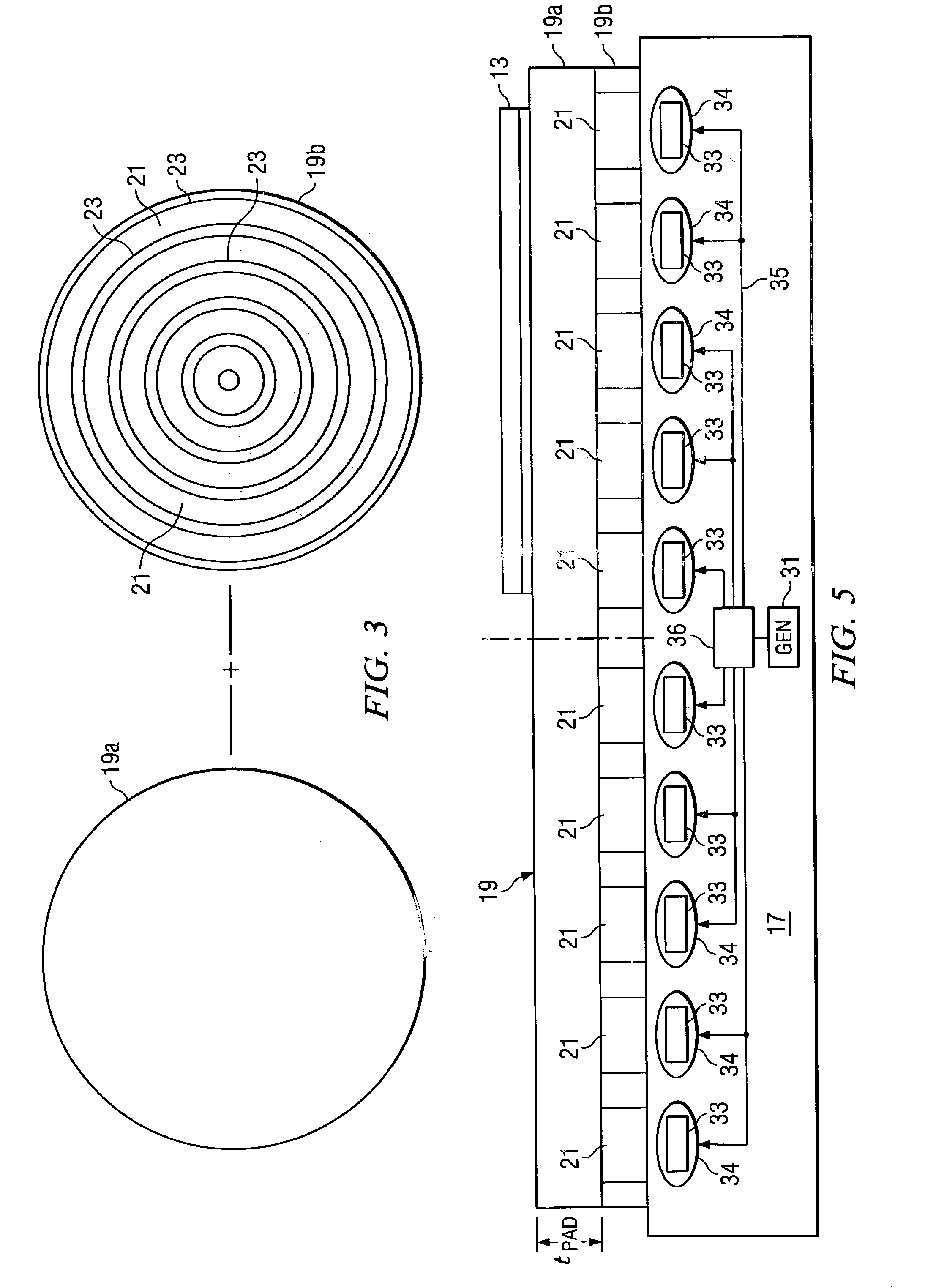

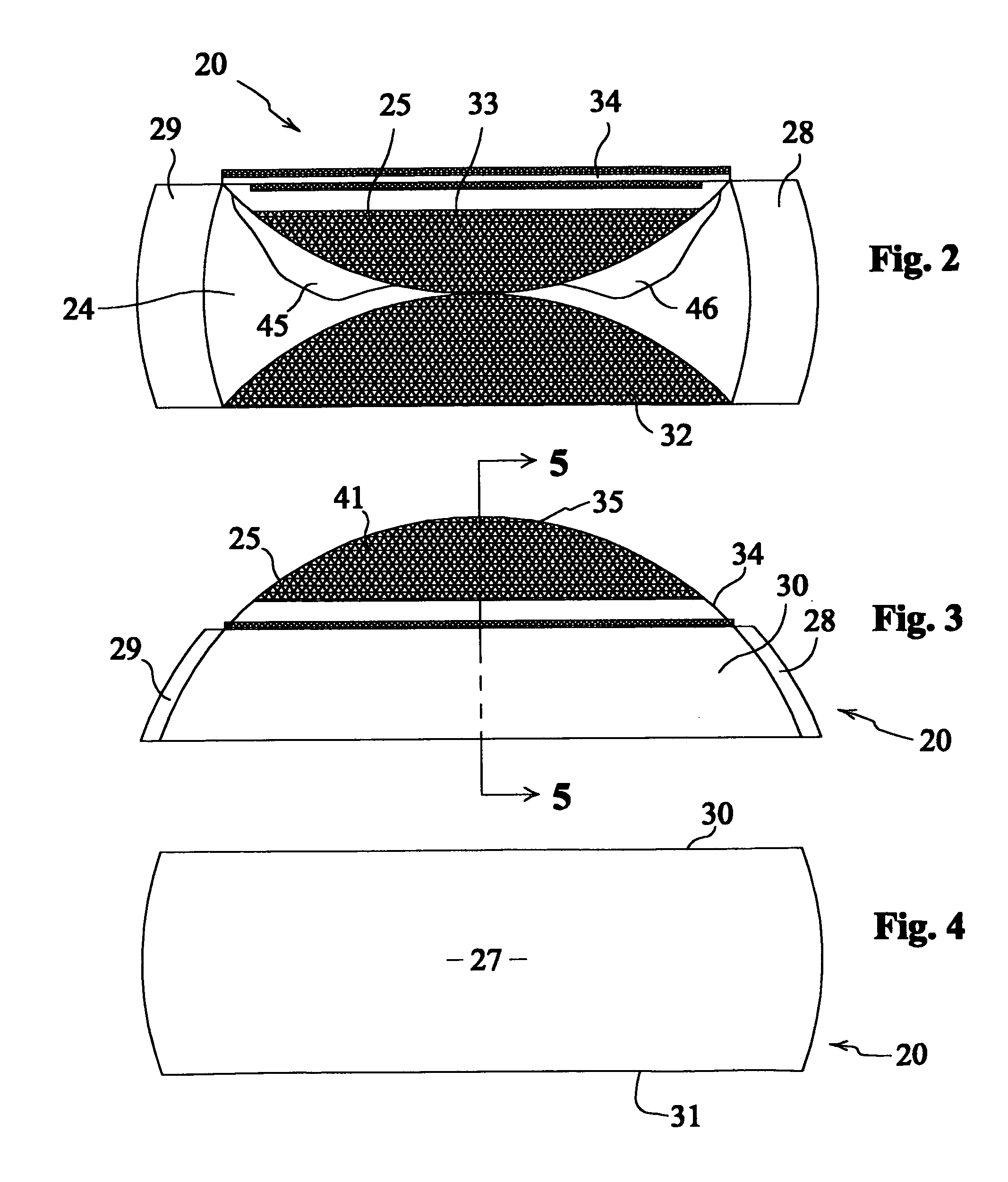

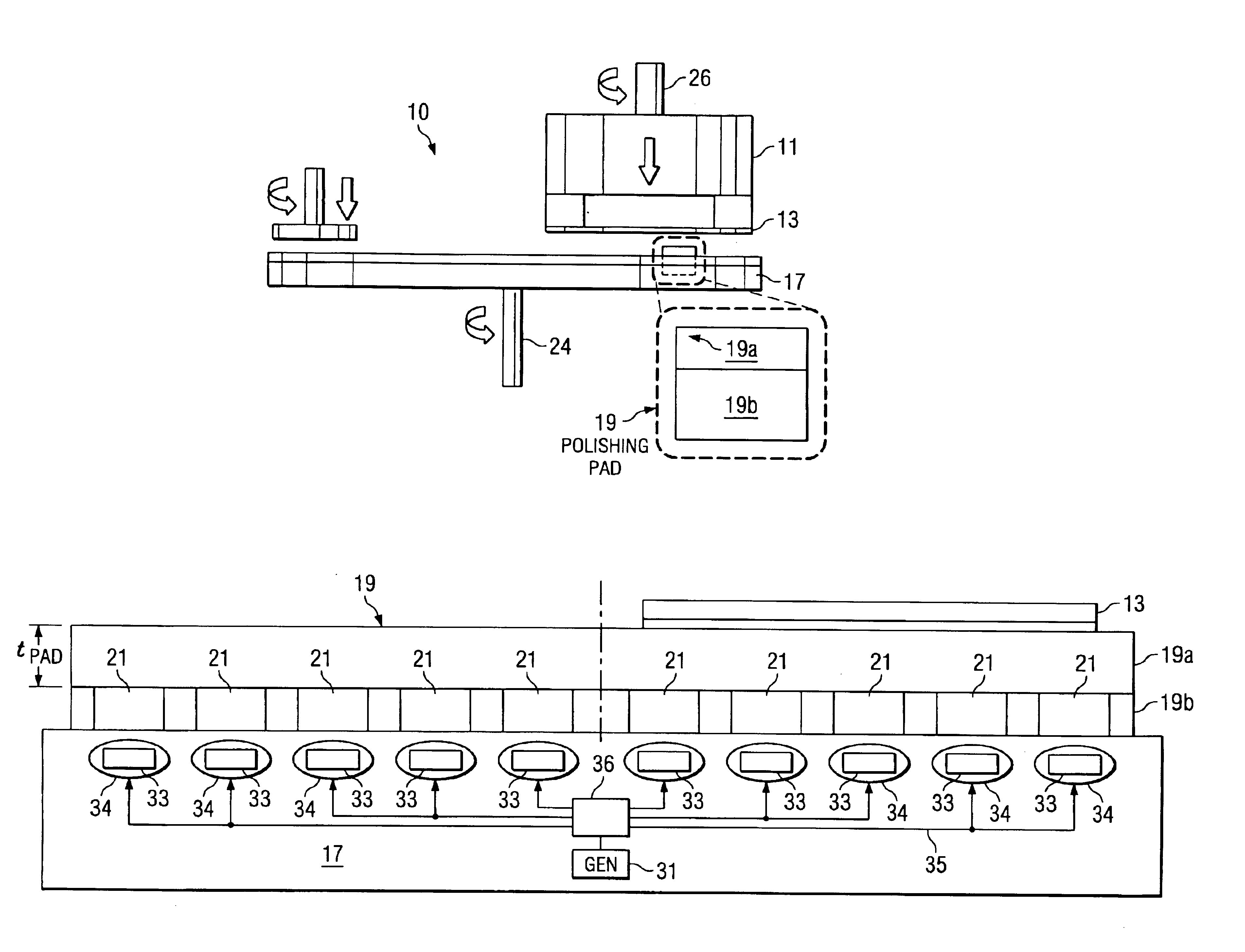

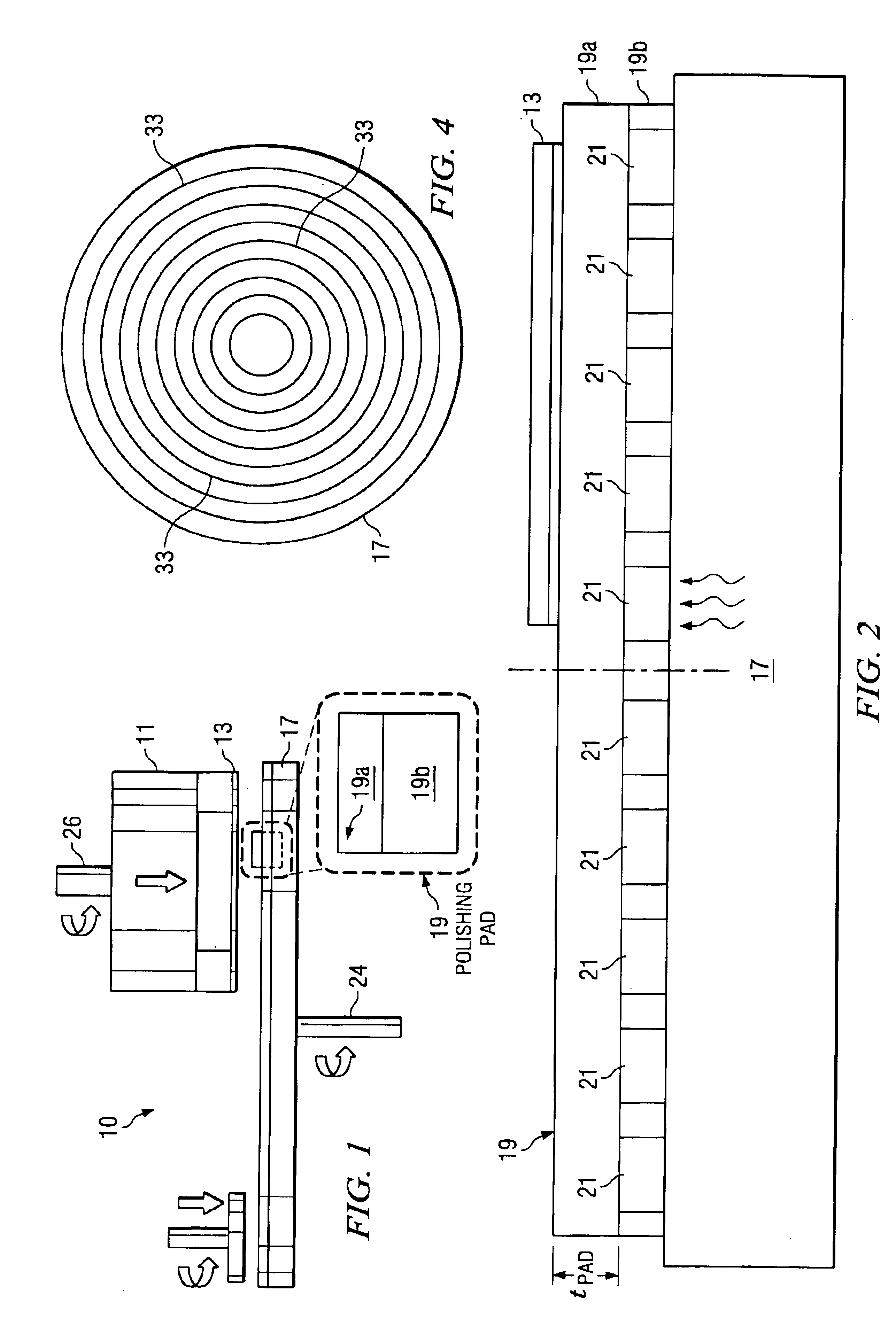

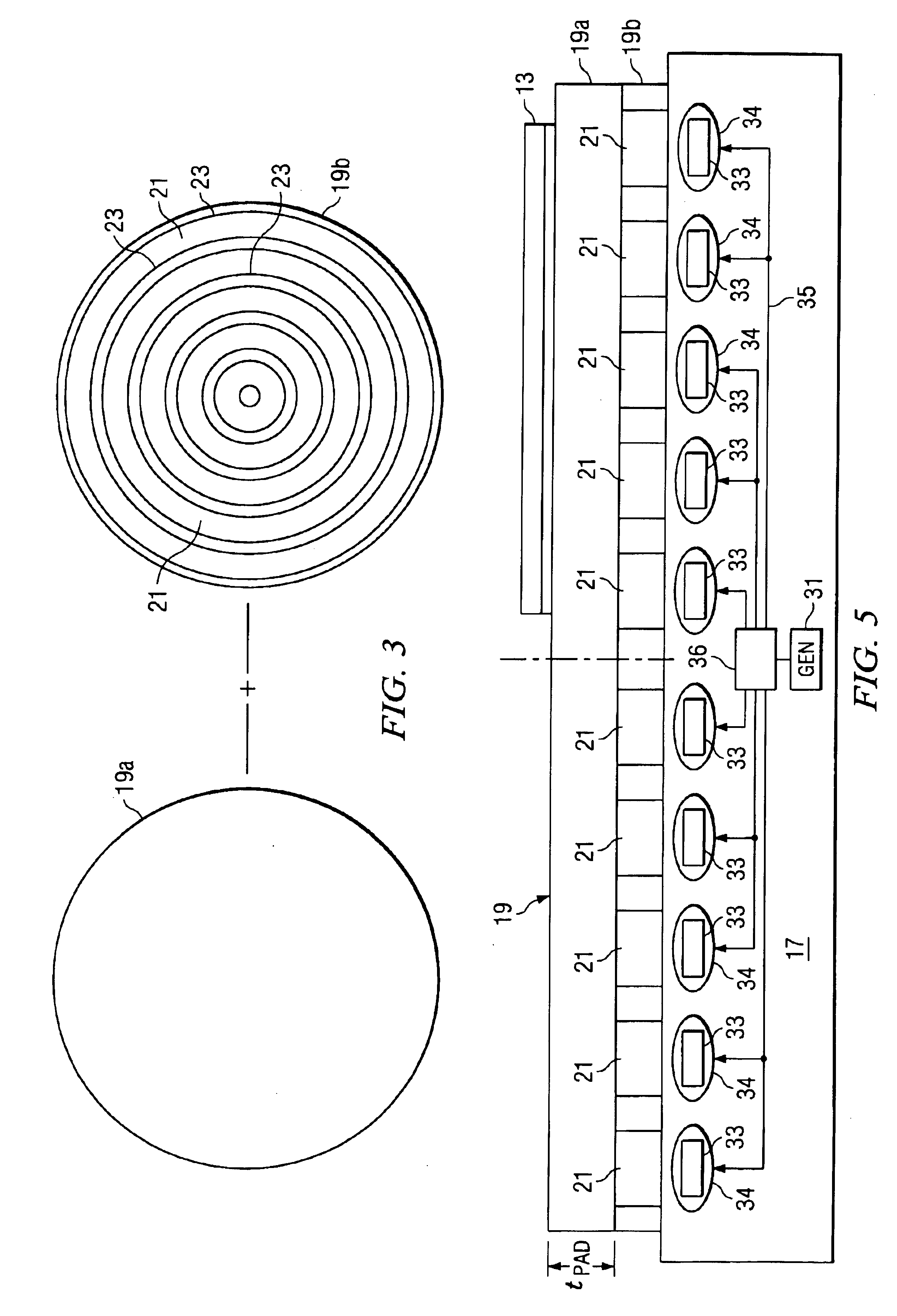

Real-time polishing pad stiffness control using magnetically controllable fluid

InactiveUS20040077292A1Limited stiffnessLiquid processingDecorative surface effectsMagnetic currentMagnetorheological fluid

A method of CMP polishing of a semiconductor wafer is described that includes using a polishing pad on a platen / table with the polishing pad including a sub-pad containing pockets of magnetorheological fluid. The stiffness of the sub-pad is controlled by selectively applying a magnetic field at selective pockets containing magnetorheological fluid to change the viscosity of the magnetorheological fluid. The changing stiffness increases the polishing rate of the pad in the areas of the magnetic field.

Owner:TEXAS INSTR INC

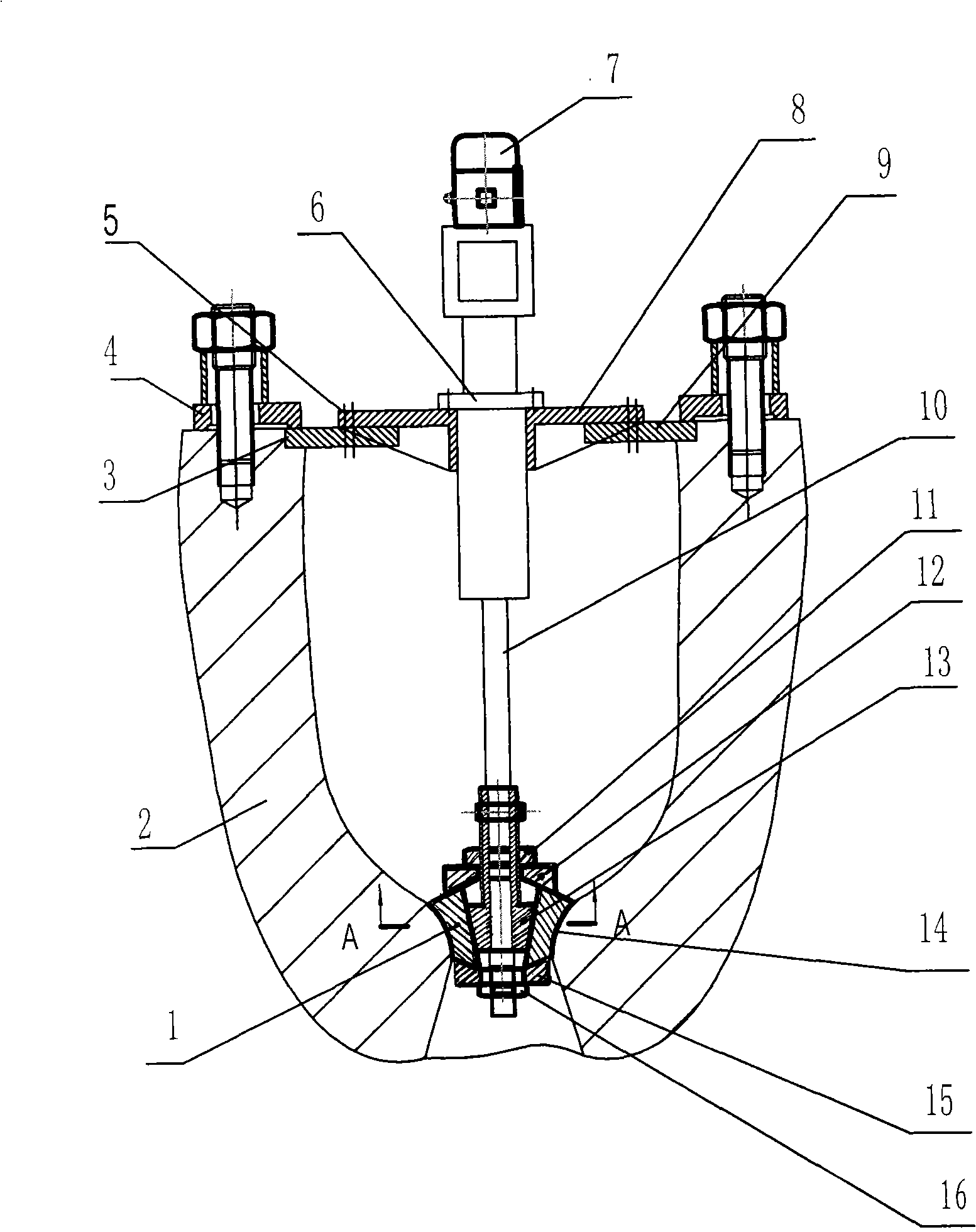

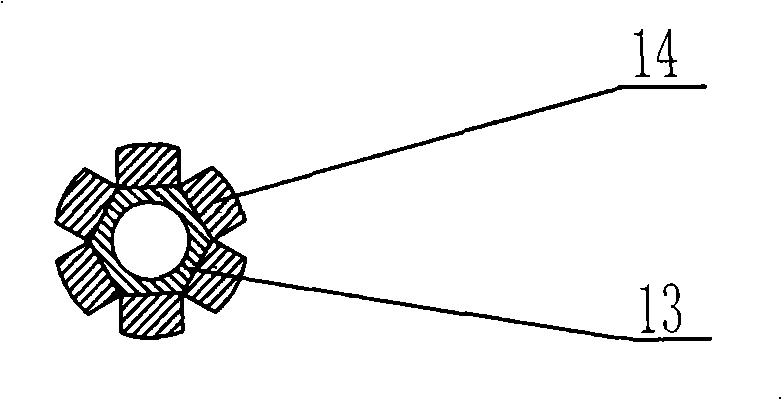

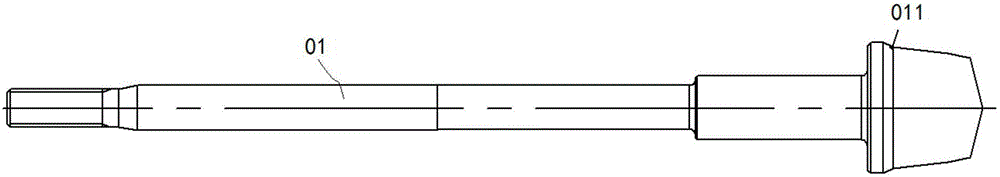

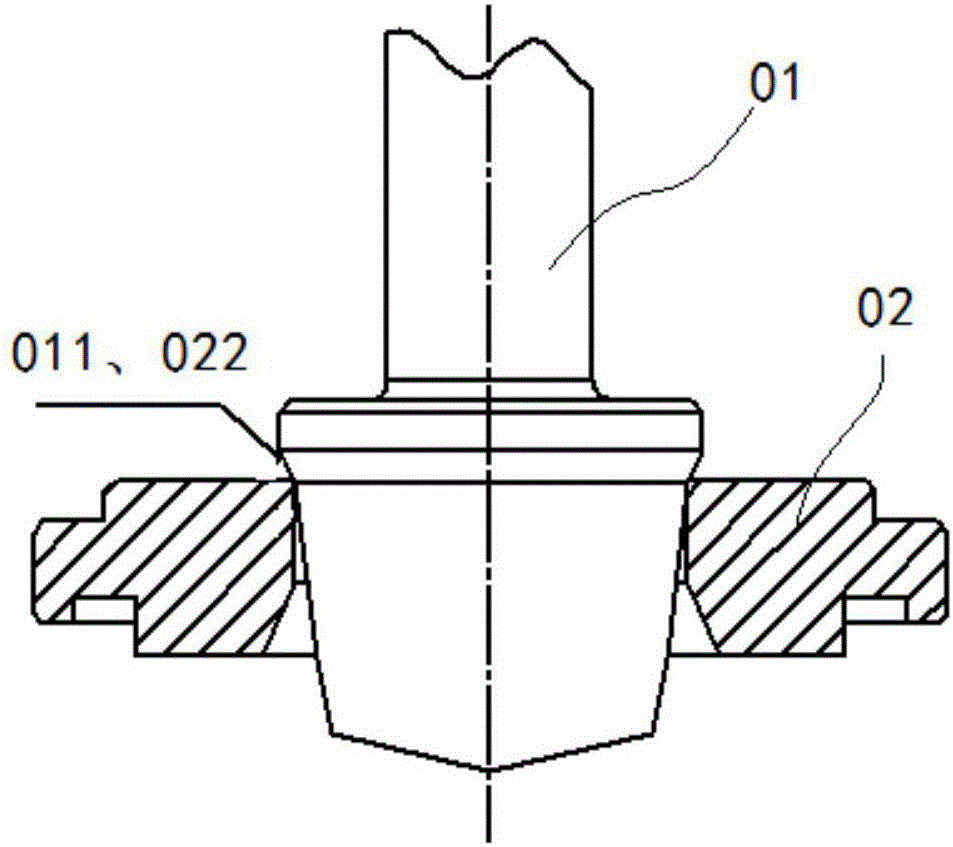

Device for grinding sealing face of valve seat of high temperature and high pressure valve

InactiveCN101407036AQuick changeAdapt to the technical requirements of quick maintenanceSeat surface grinding machinesPower stationHigh pressure

The invention relates to a sealing face grinding device for a valve seat of a high-temperature and high-pressure valve, which comprises a grinding rod, a main support positioning disk, a mounting seat and a grinding block, and is characterized in that the mounting seat the outer peripheral face of which has taper is connected to the grinding rod through a connecting piece; a plurality of grinding blocks are combined and arranged at the periphery of the mounting seat, the upper end and the lower end of the combined grinding blocks are conical surfaces, the outer peripheral surface of the grinding block is a curved surface and is fixed by an upper compaction disk and a lower compaction disk with matched conical surfaces; and the grinding rod is movably sleeved with the connecting piece which is connected with the main support positioning disk, four orientations of the main support positioning disk are connected with supporting plates through bolts, and the outer edges of the supporting plates are fixed and assembled on a flange mouth of the valve through compaction blocks. The sealing face grinding device has the advantages that a main bearing part can be adjusted, the grinding face of a grinding head can be adjusted according to requirements, the grinding block can be replaced quickly, and the sealing face grinding device can shorten the grinding period remarkably and is suitable for the technical requirement of quick maintenance for a power plant.

Owner:SHENYANG BEILING DUOYUAN MECHANICAL & ELECTRICAL RES INST

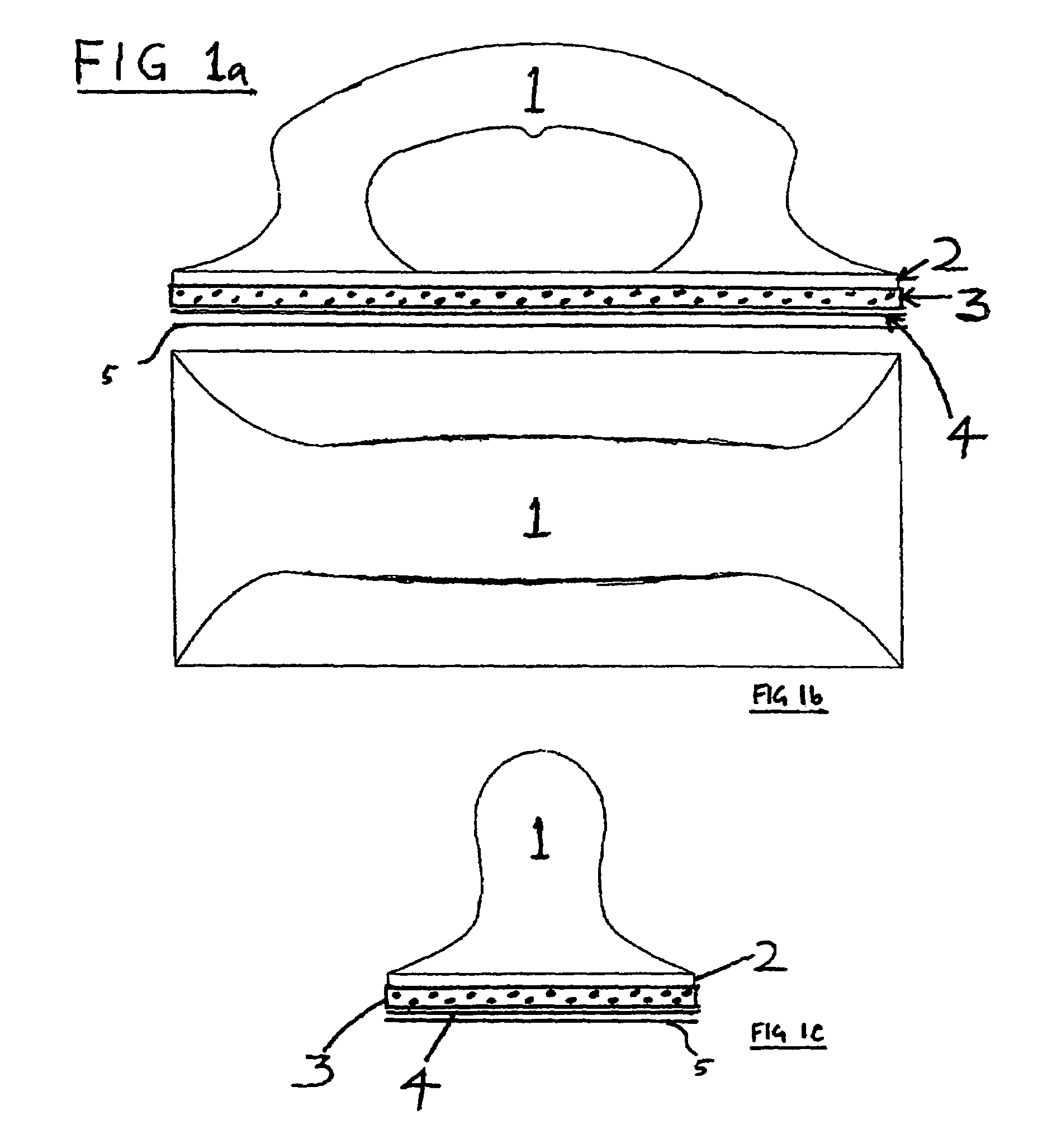

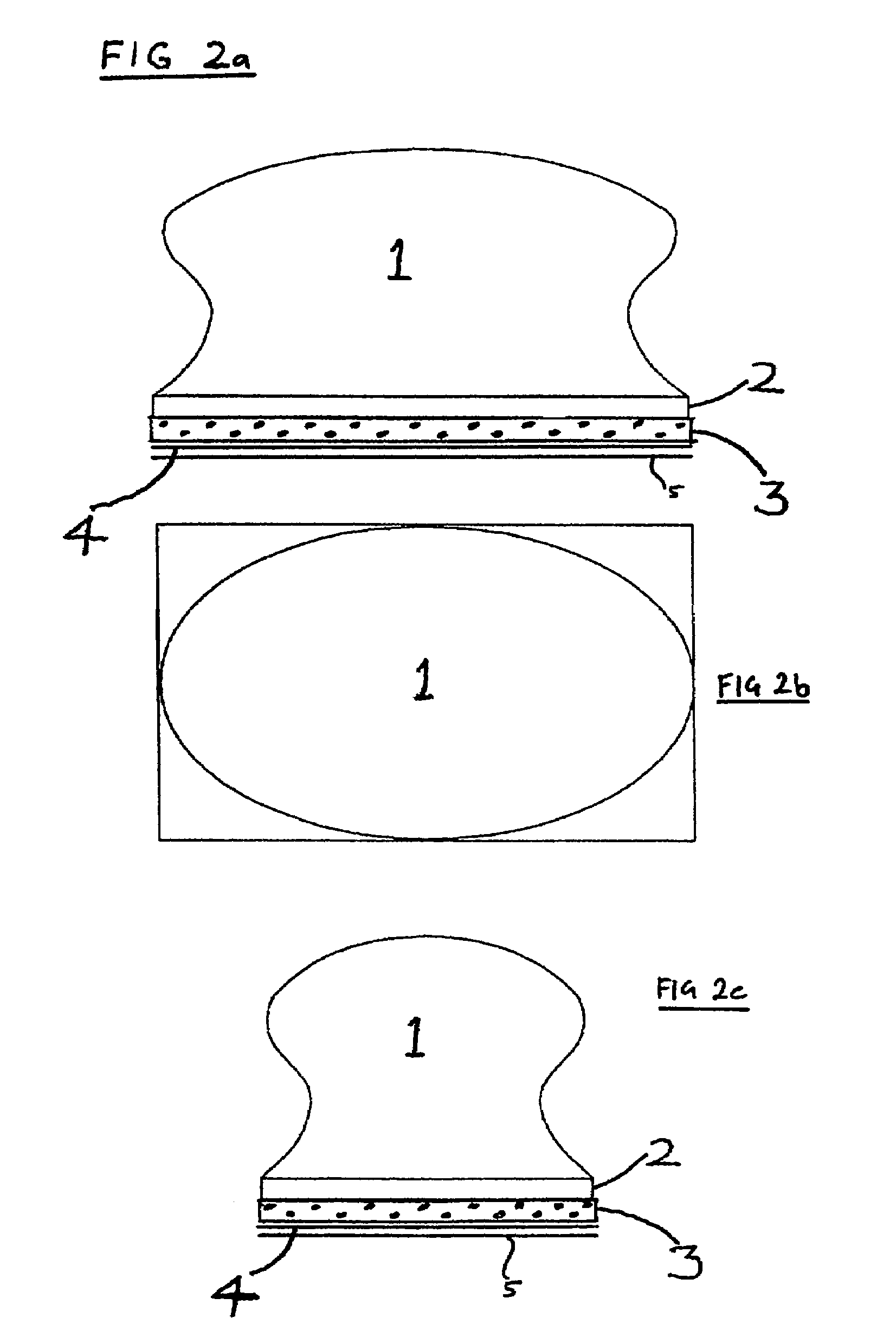

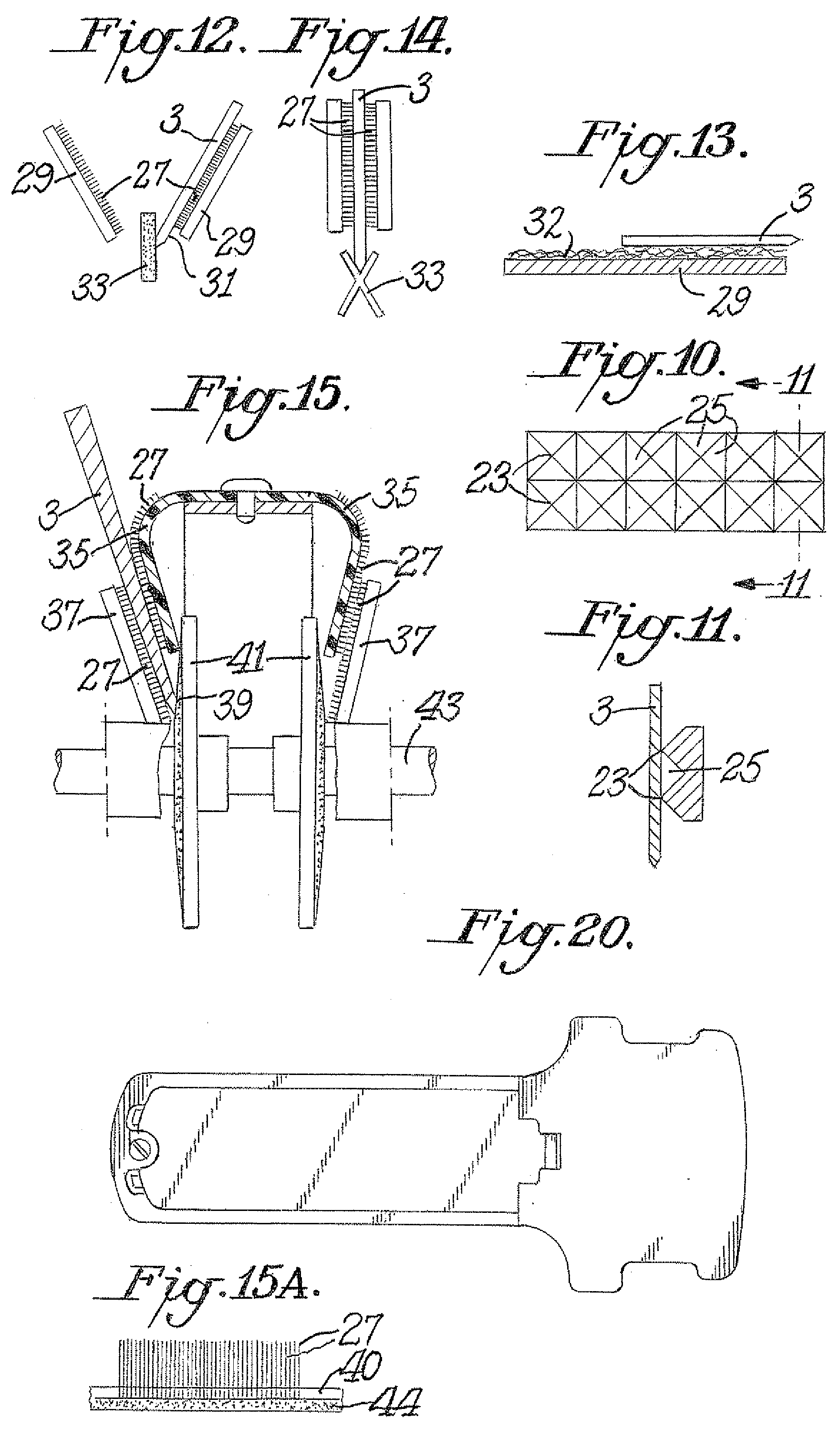

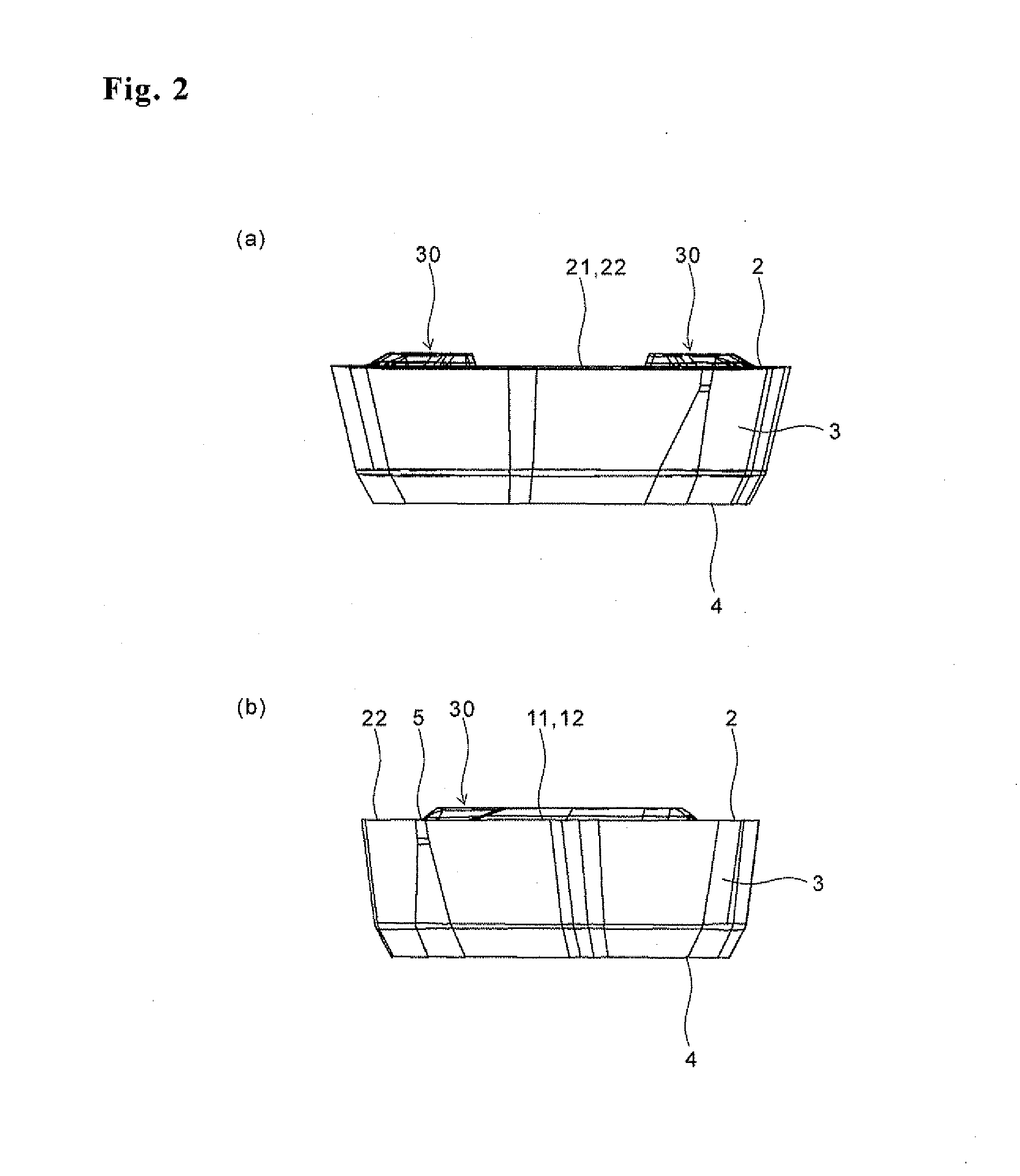

Abrasive holder

An abrasive tool comprising of a base portion (2), having a foam layer (3) affixed to the abrasive tool base portion, and a plastic film layer (4) affixed, bonded or glued to the foam layer. This tool is adapted to receive an abrasive material layer (5) or sand paper or other abrasive material having a pressure sensitive adhesive applied to one side of the abrasive material, to allow said abrasive material to be stuck and affixed to the abrasive tool. The abrasive tool may be hand operated, or operated by electric power, air power, or other motive power.

Owner:RED DEVIL SANDFAST

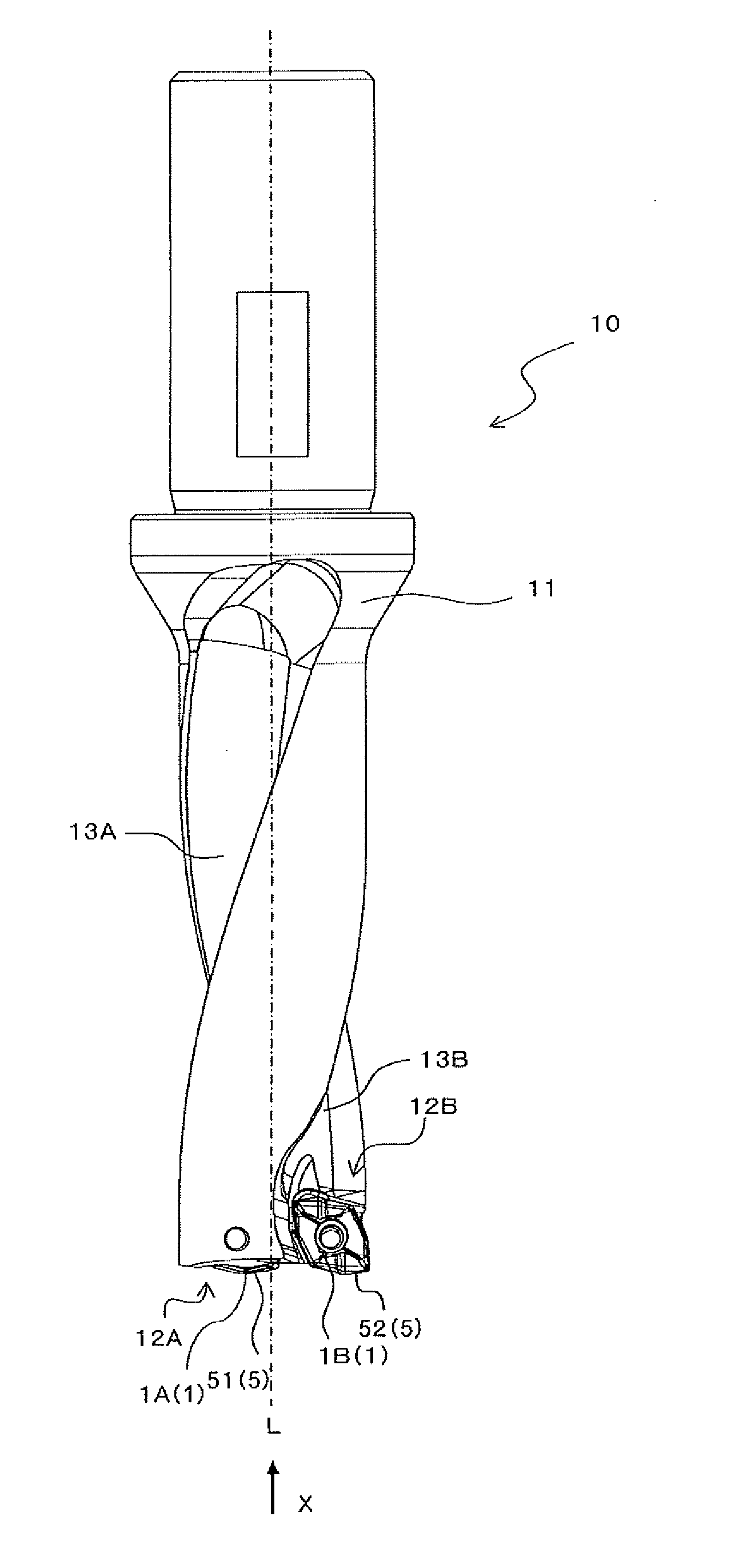

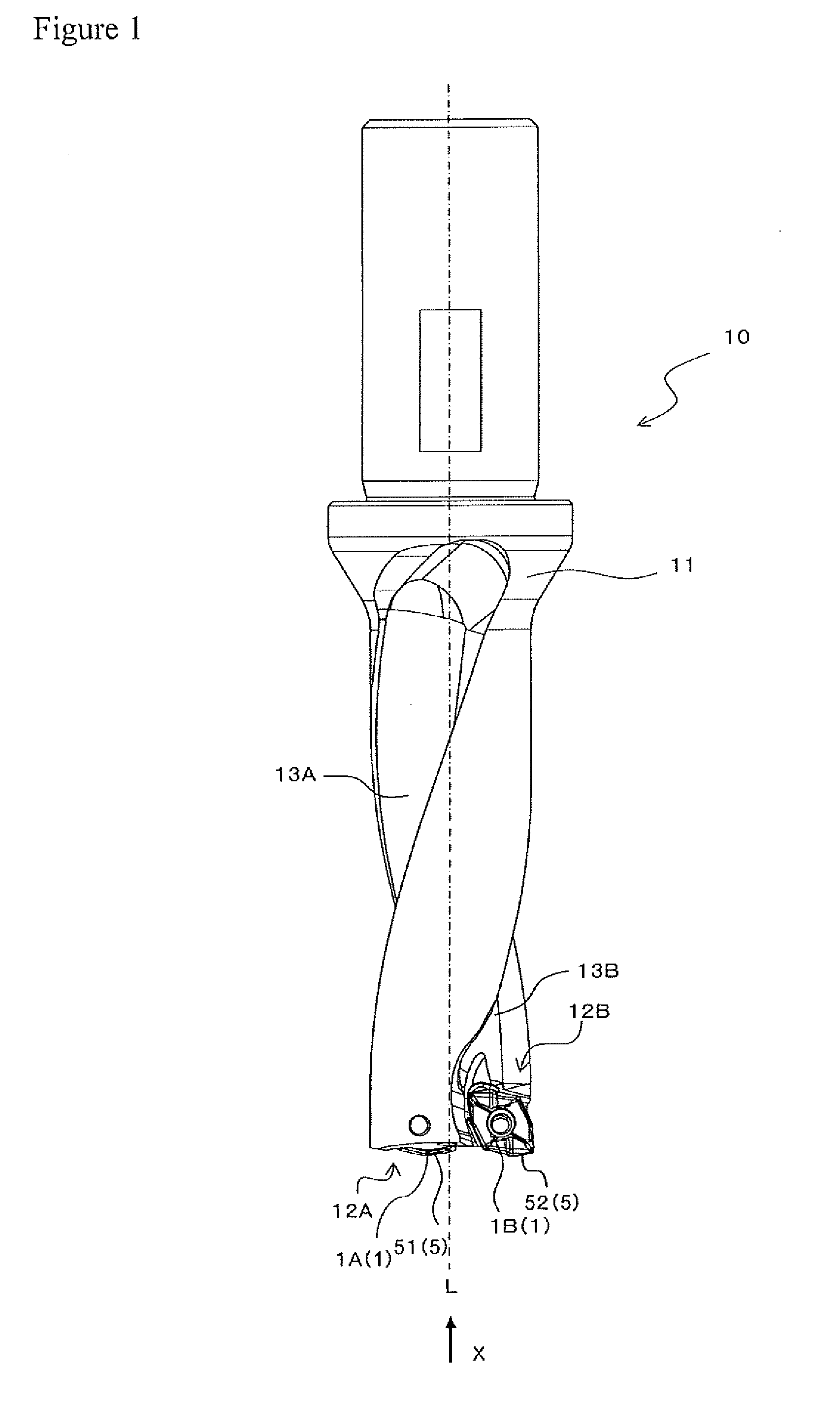

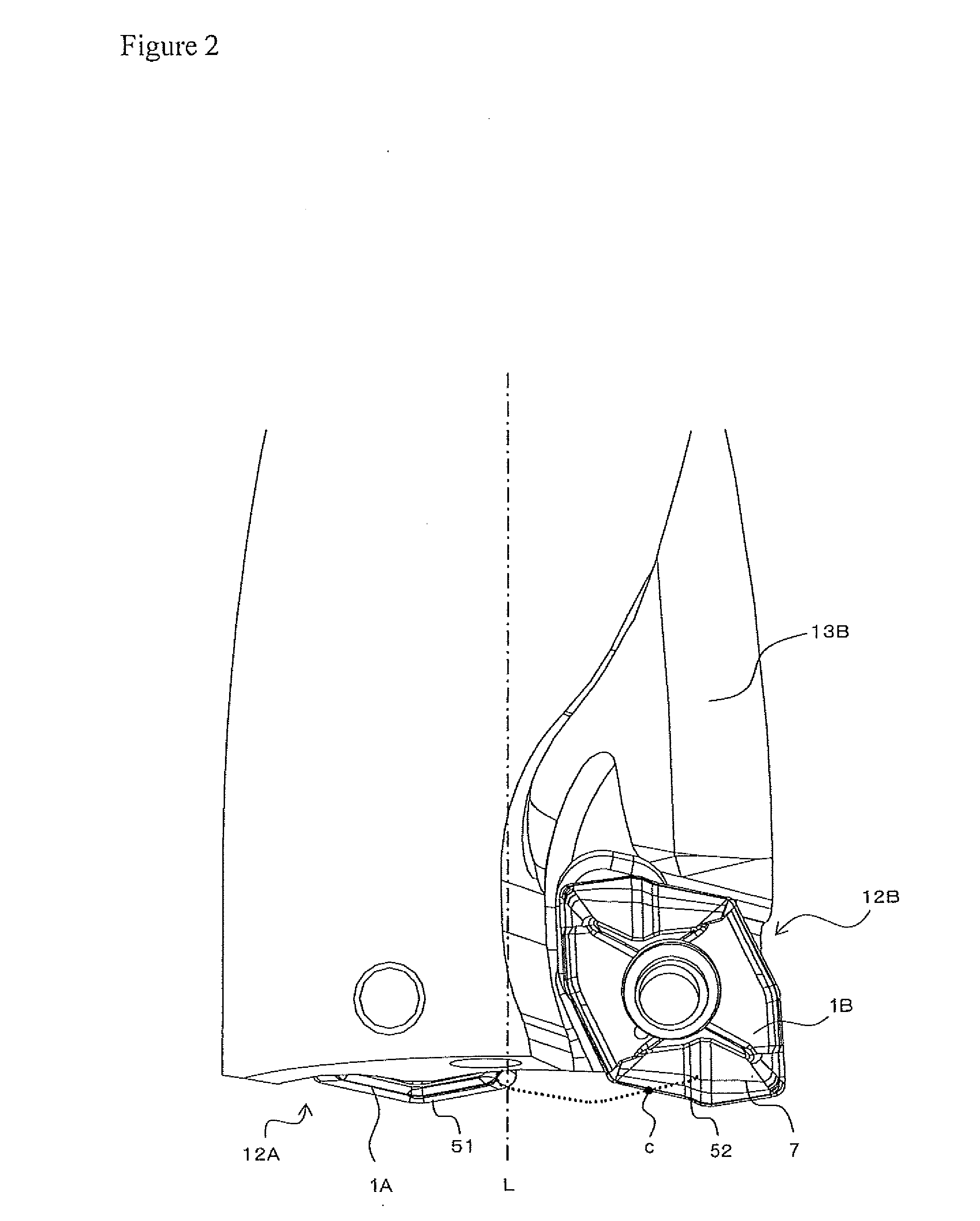

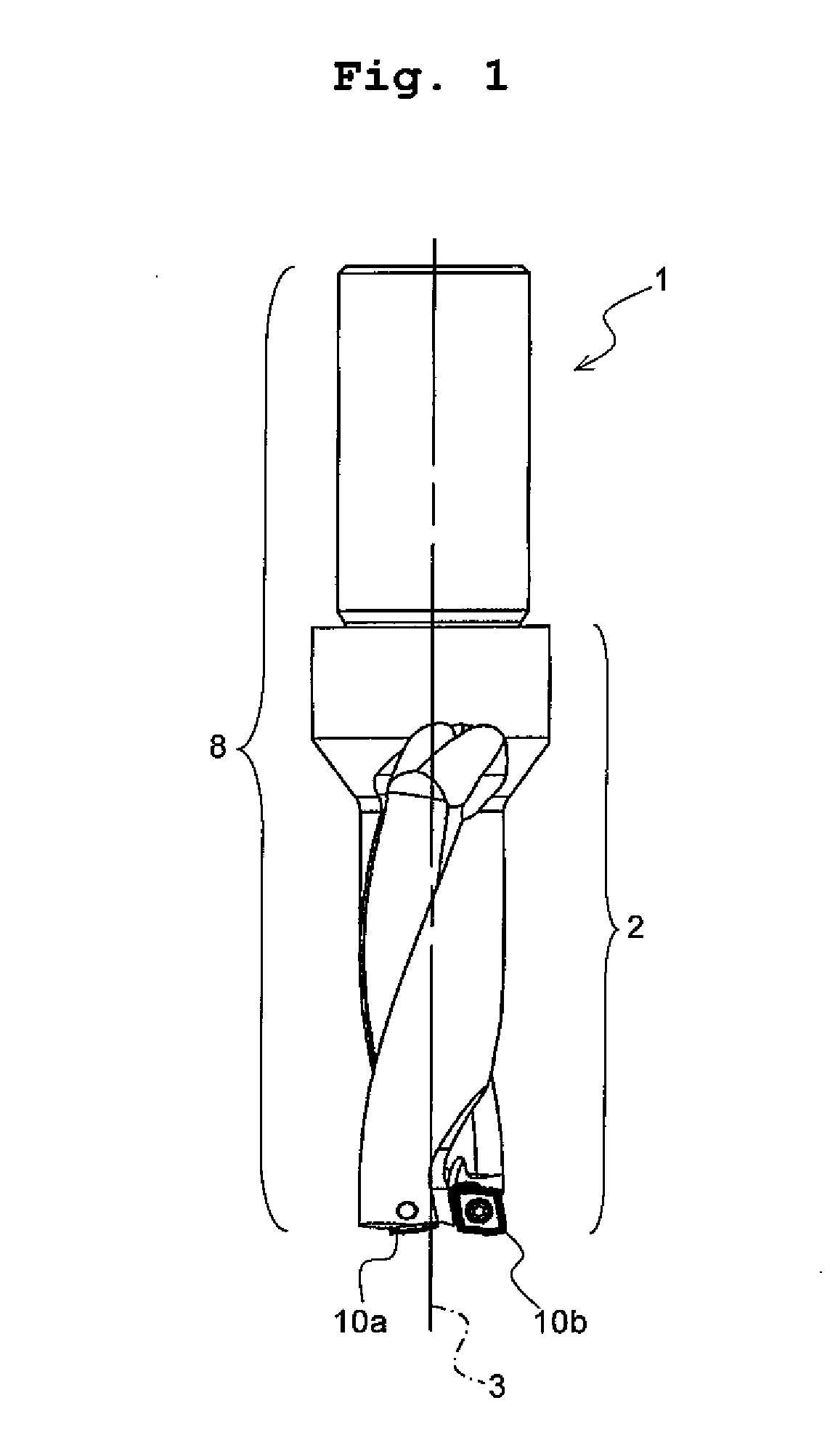

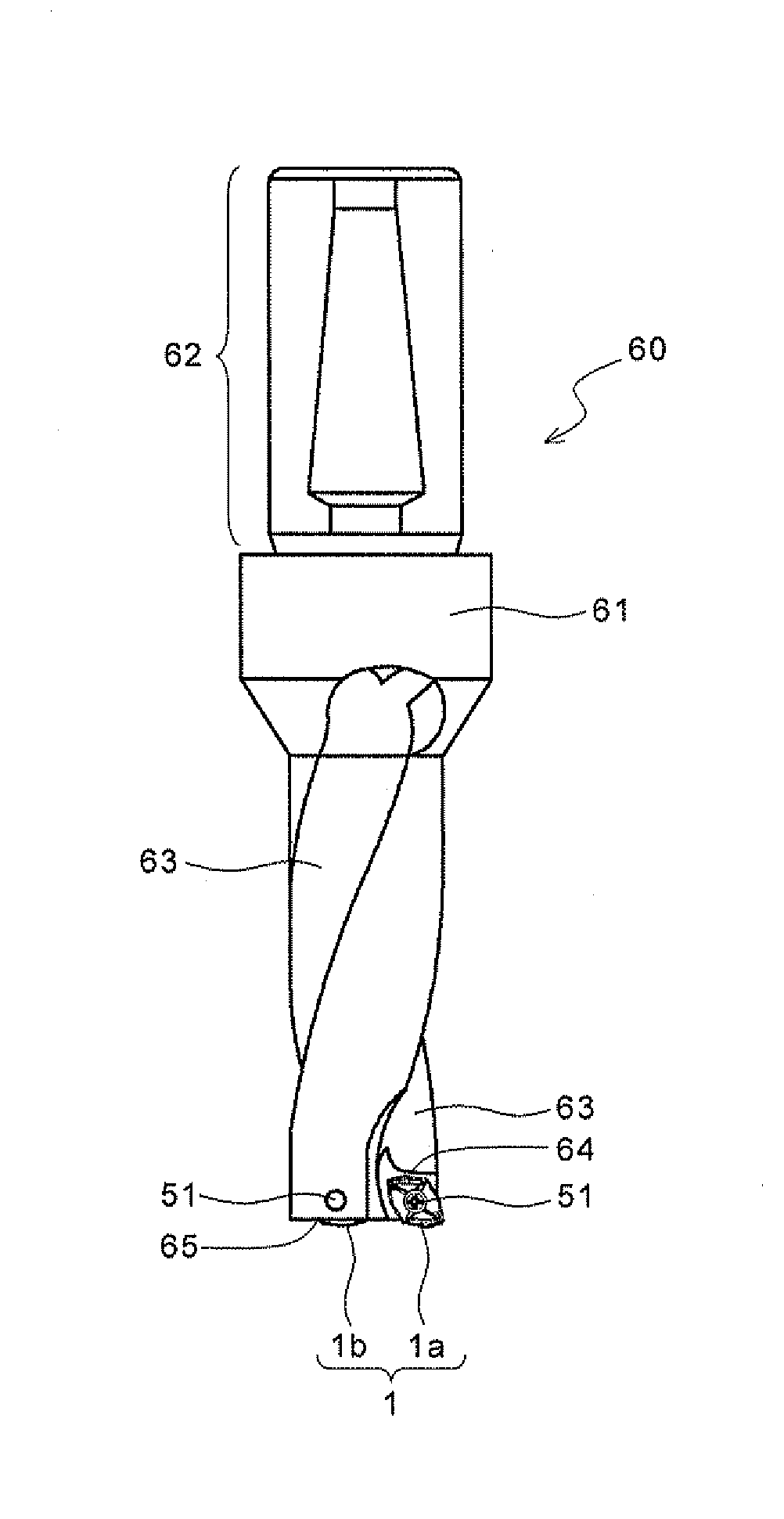

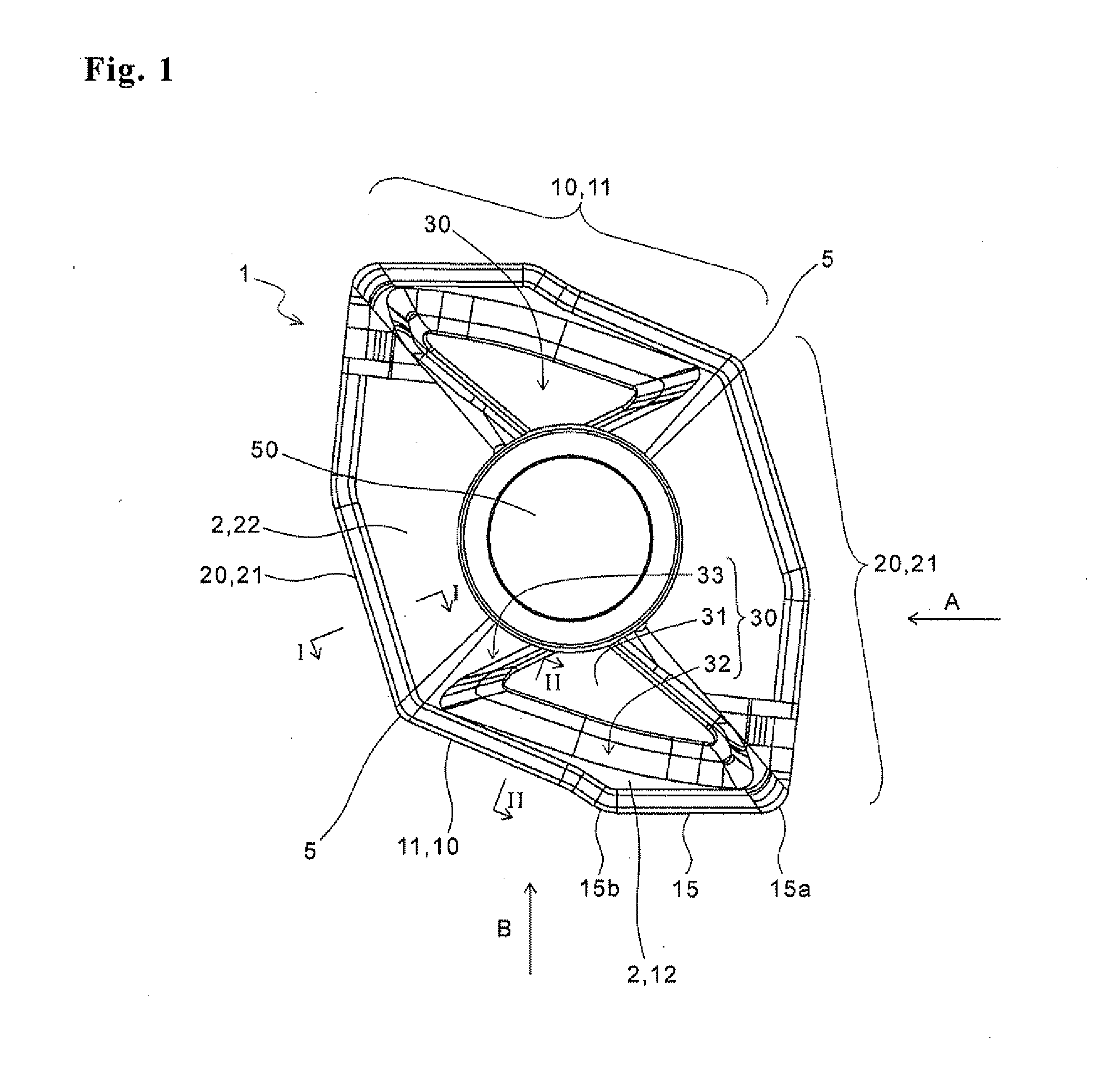

Drill, Cutting Insert, and Method of Manufacturing Cut Product

ActiveUS20110044776A1Good chip removal effectEasy to shapeThread cutting toolsWood turning toolsDrill bitEngineering

A drill, including: a substantially columnar drill holder including, at a front end portion thereof, a first insert pocket and a second insert pocket formed closer to the outer periphery of the drill holder than the first insert pocket; a first insert which is attached to the first insert pocket and includes a first cutting edge at an intersection of an upper face and a side face; and a second insert which is attached to the second insert pocket and includes a second cutting edge at an intersection of a upper face and a side face. The first insert pocket is located passing through a central axis of rotation of the drill holder. The second cutting edge has a concave shape when viewed from the front end side of the drill holder, and has a curved line at least a part thereof.

Owner:KYOCERA CORP

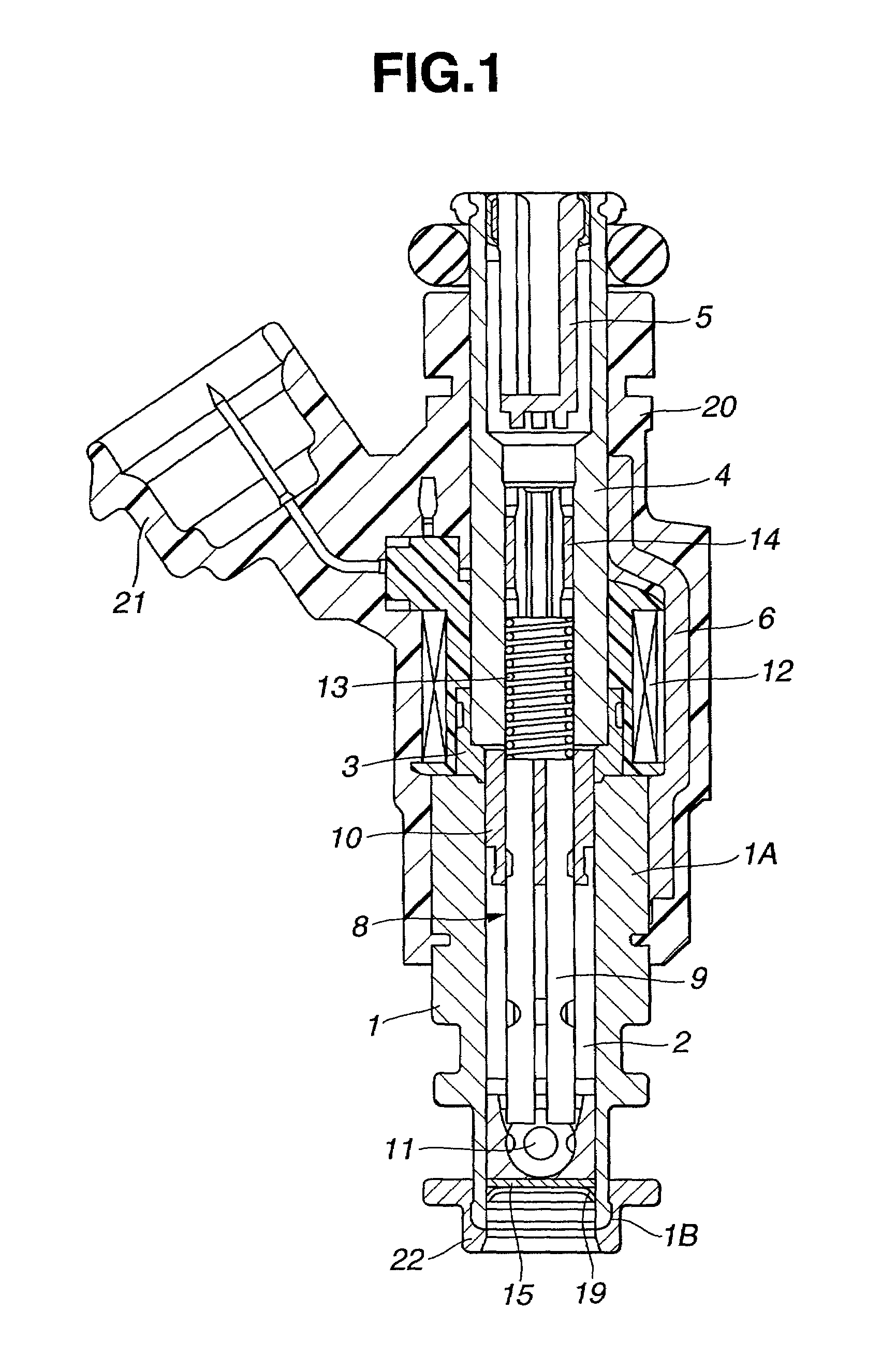

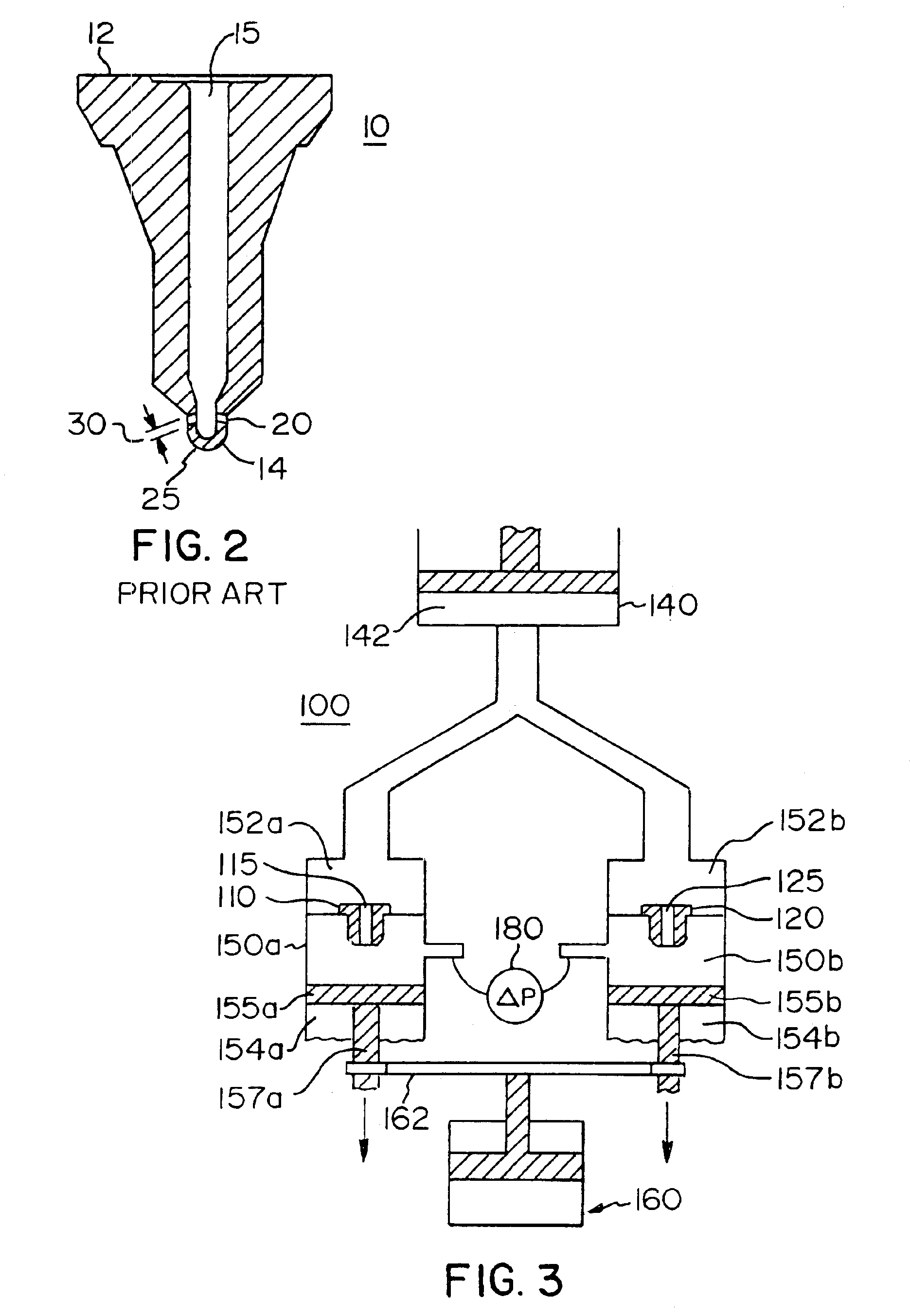

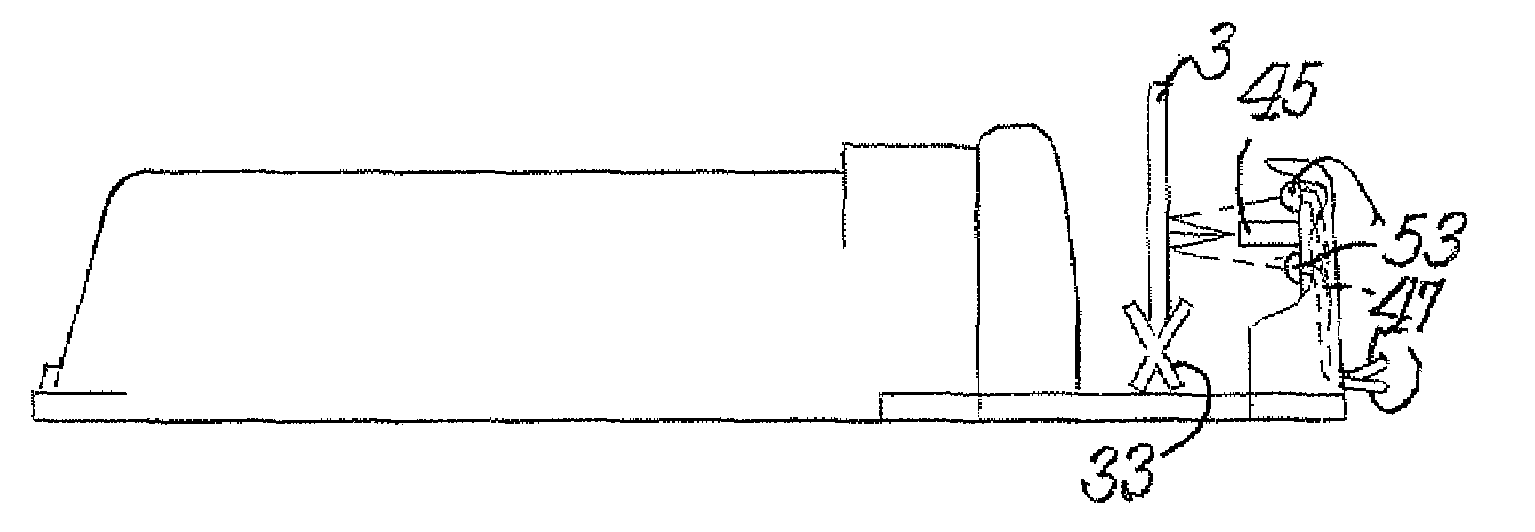

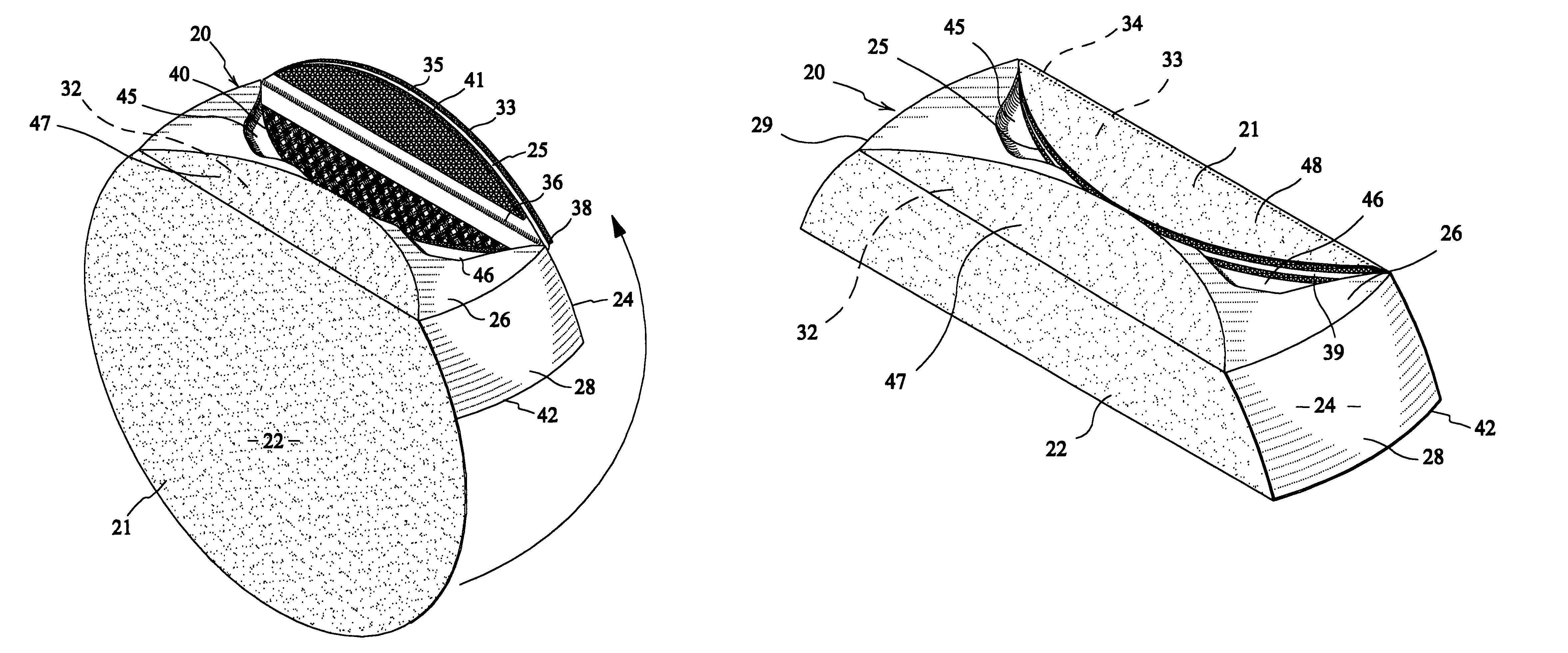

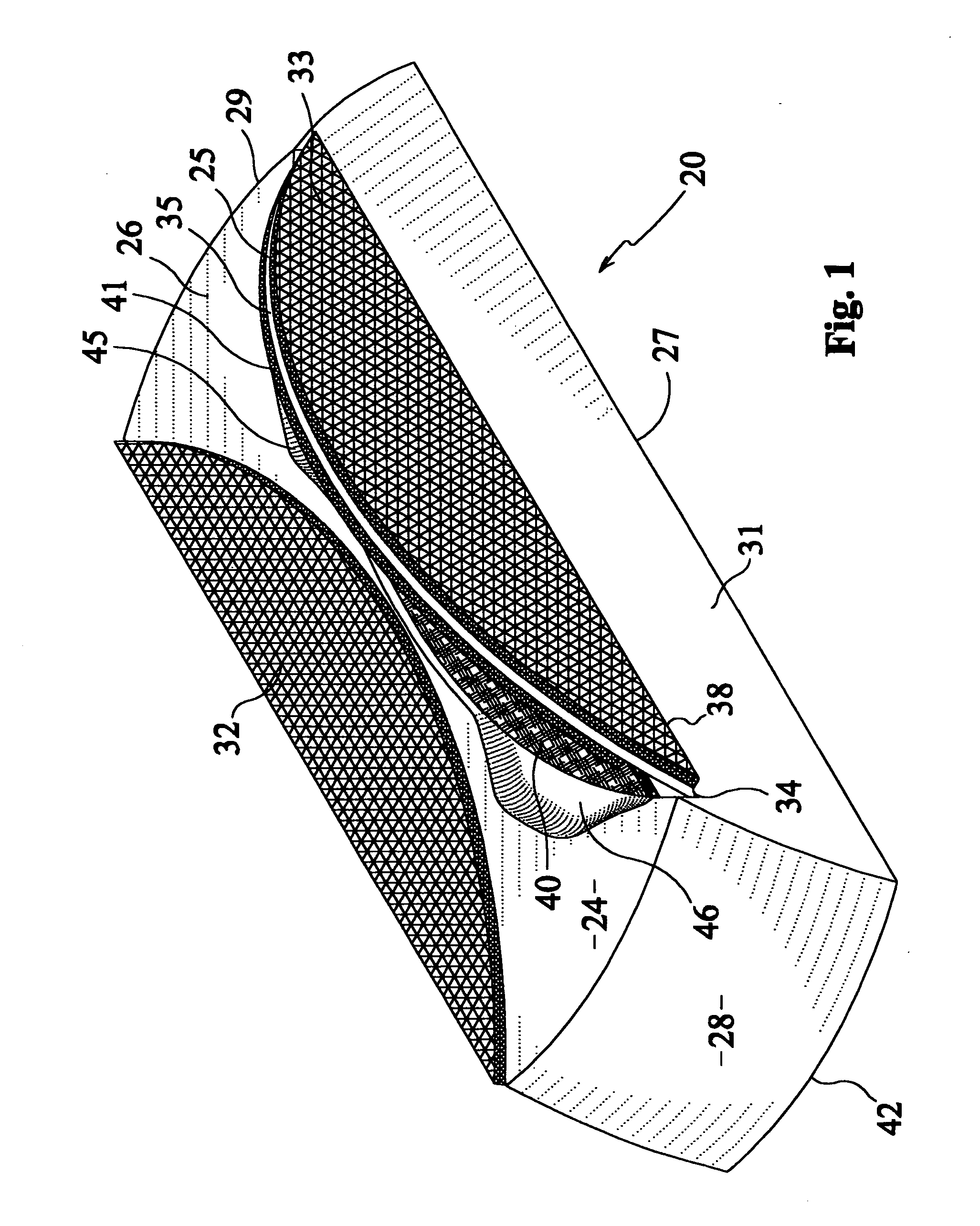

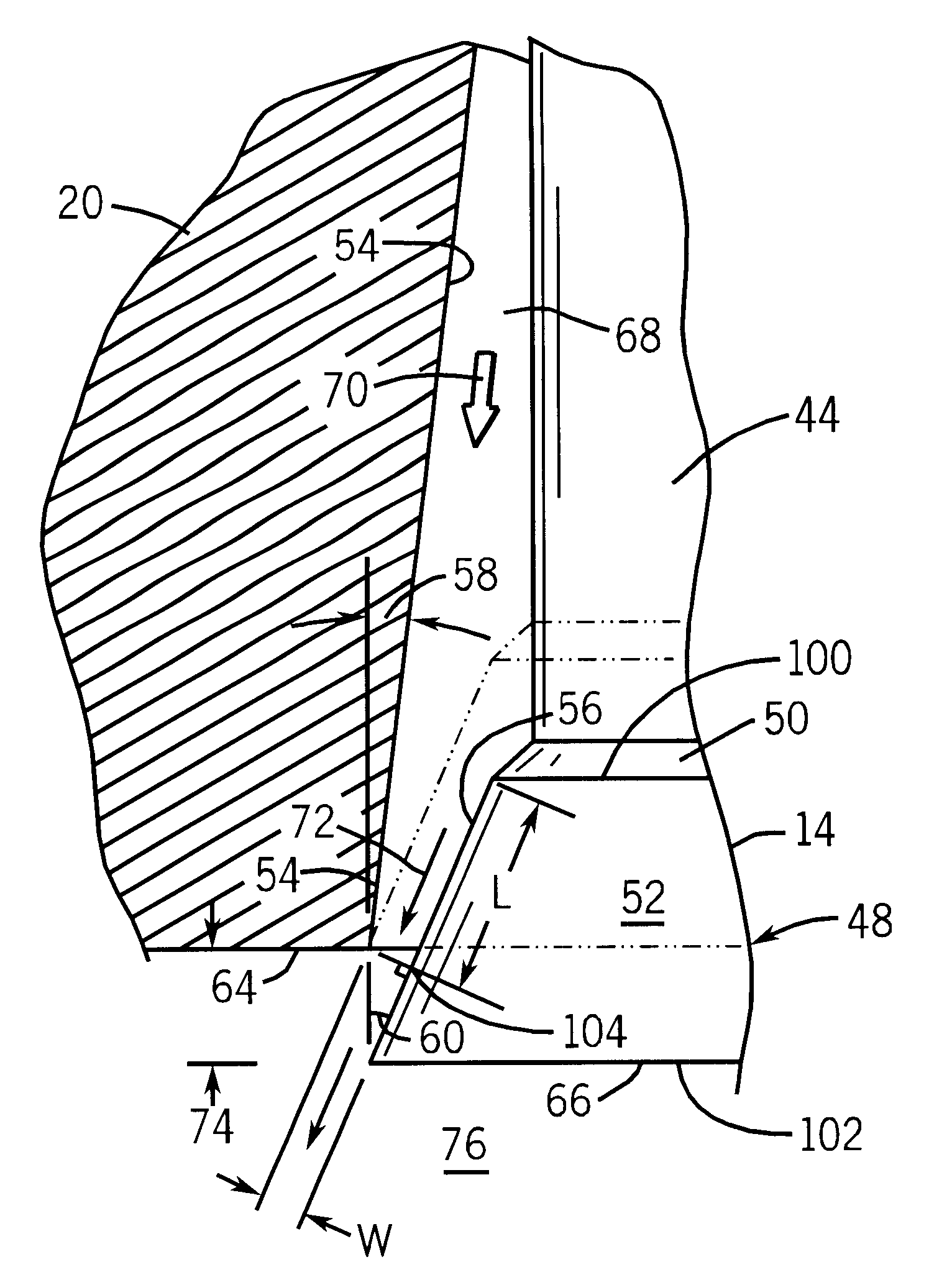

Fuel injector for internal combustion engines and method for making same

InactiveUS6109549APromote atomizationReduce manufacturing costSeat surface grinding machinesFuel injection apparatusInjector nozzleReciprocating motion

A fuel injector nozzle includes a nozzle body and a poppet disposed in the body for reciprocating movement. The body has an internal bore surrounding the poppet. The internal bore tapers in a constant angle of taper from a front seating region to a fuel reservoir region. The poppet has a corresponding surface which diverges slightly from the bore. The surfaces of the bore and poppet form flow control surfaces which terminate in a sharp-edged orifice at the front face of the nozzle. When the poppet is displaced to an open or flow position, fuel is accelerated to the orifice and atomized into a combustion chamber.

Owner:OUTBOARD MARINE +2

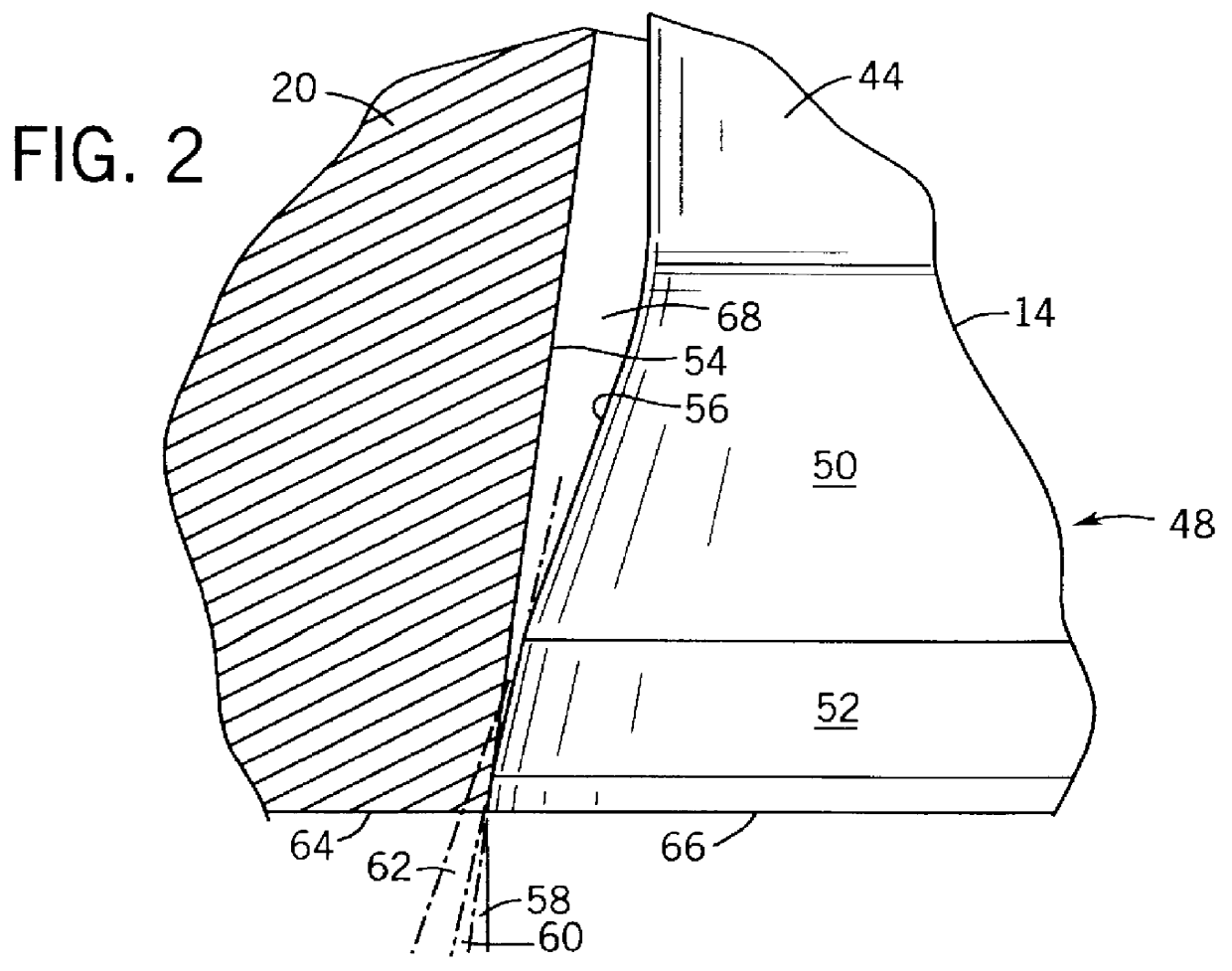

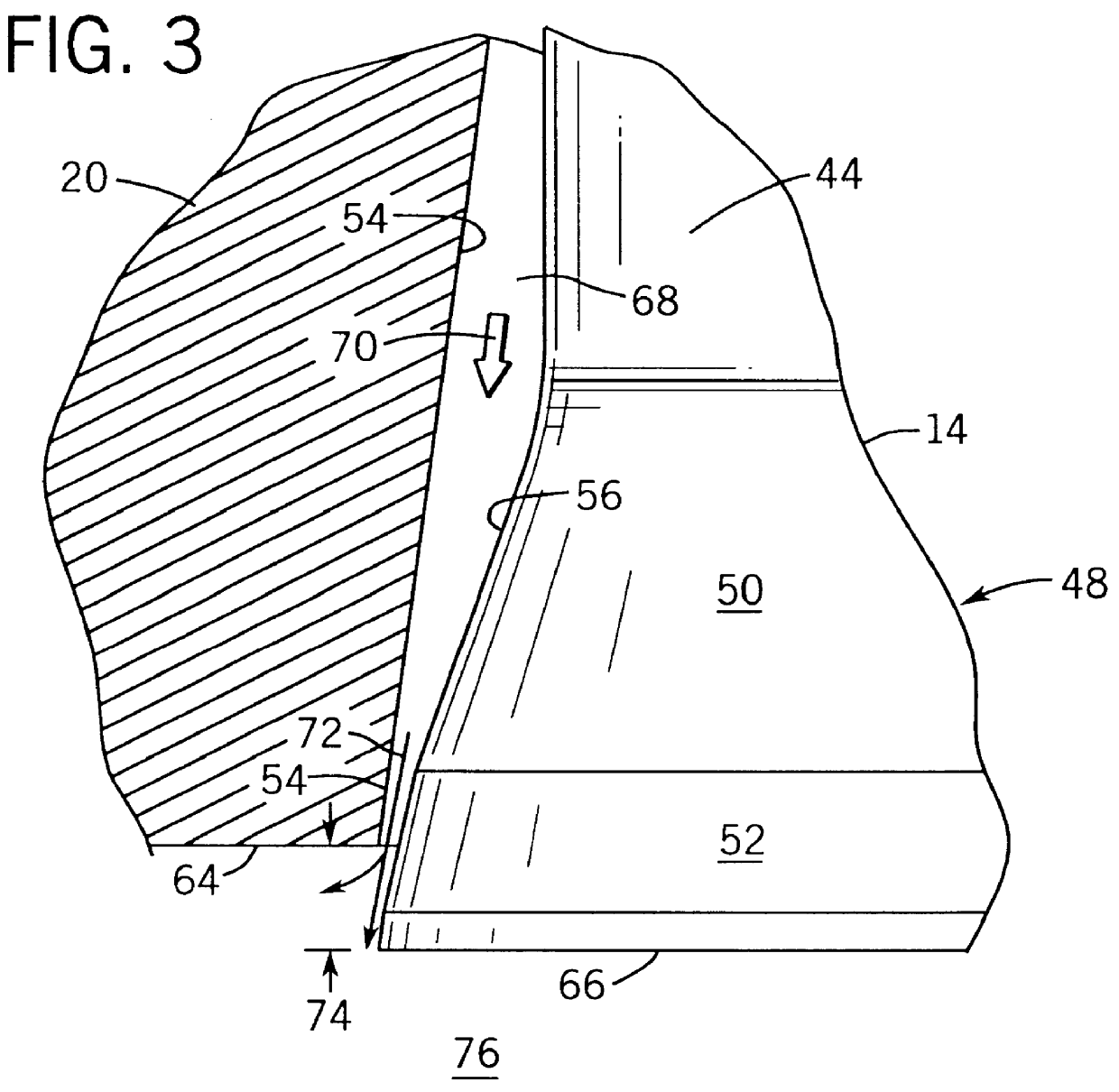

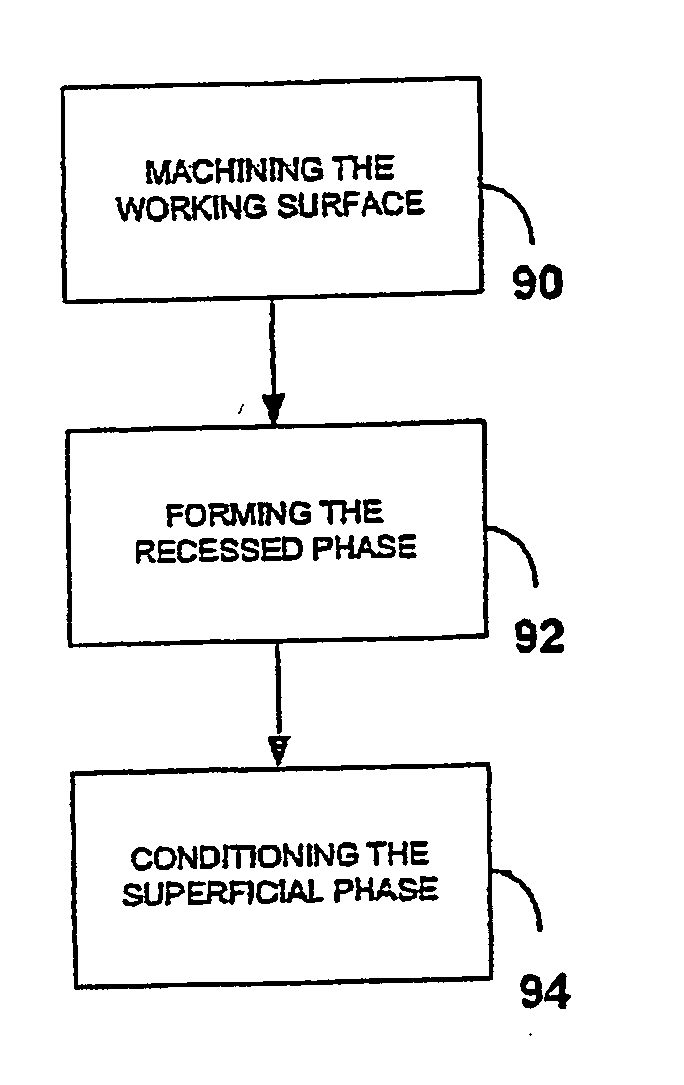

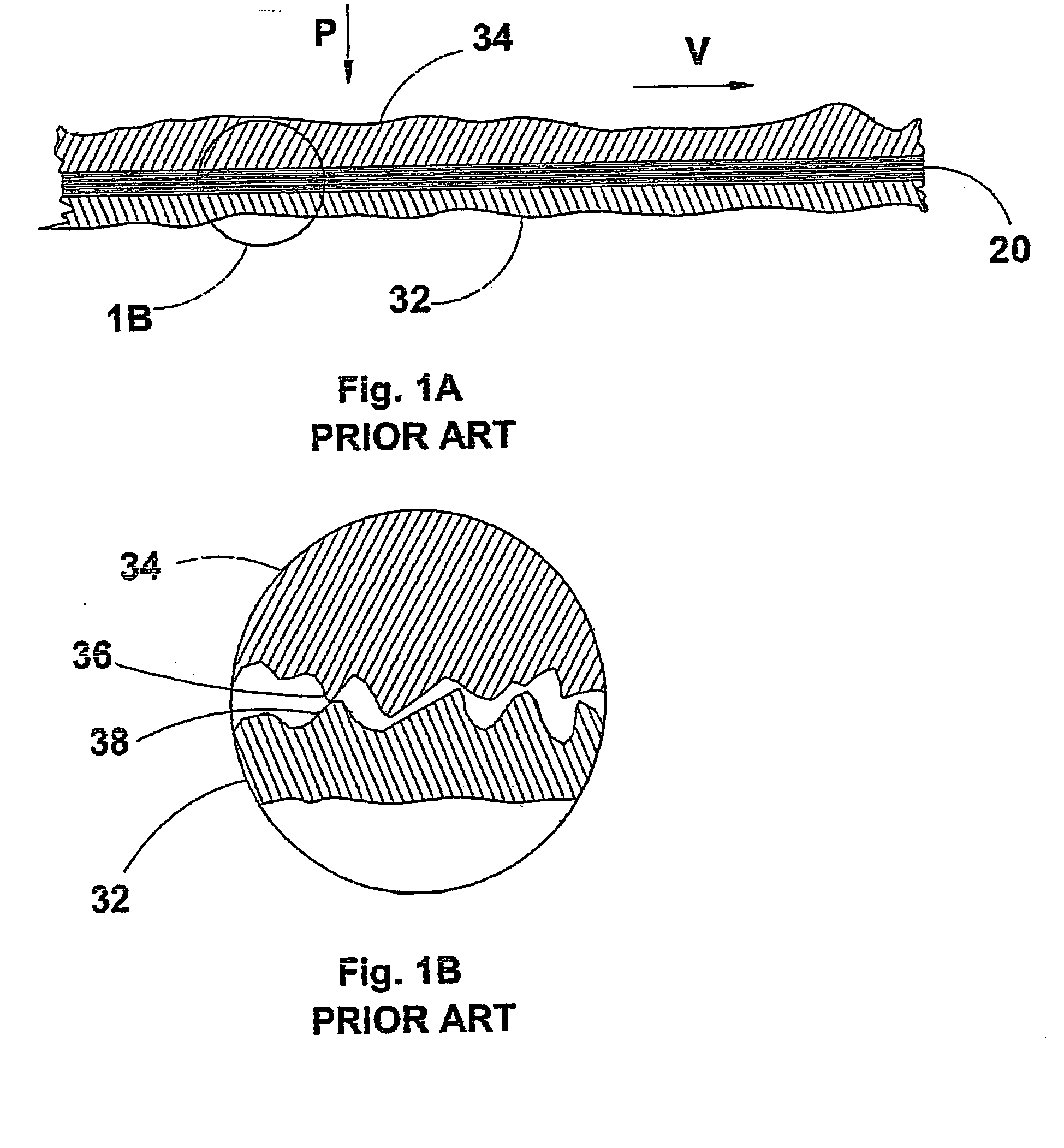

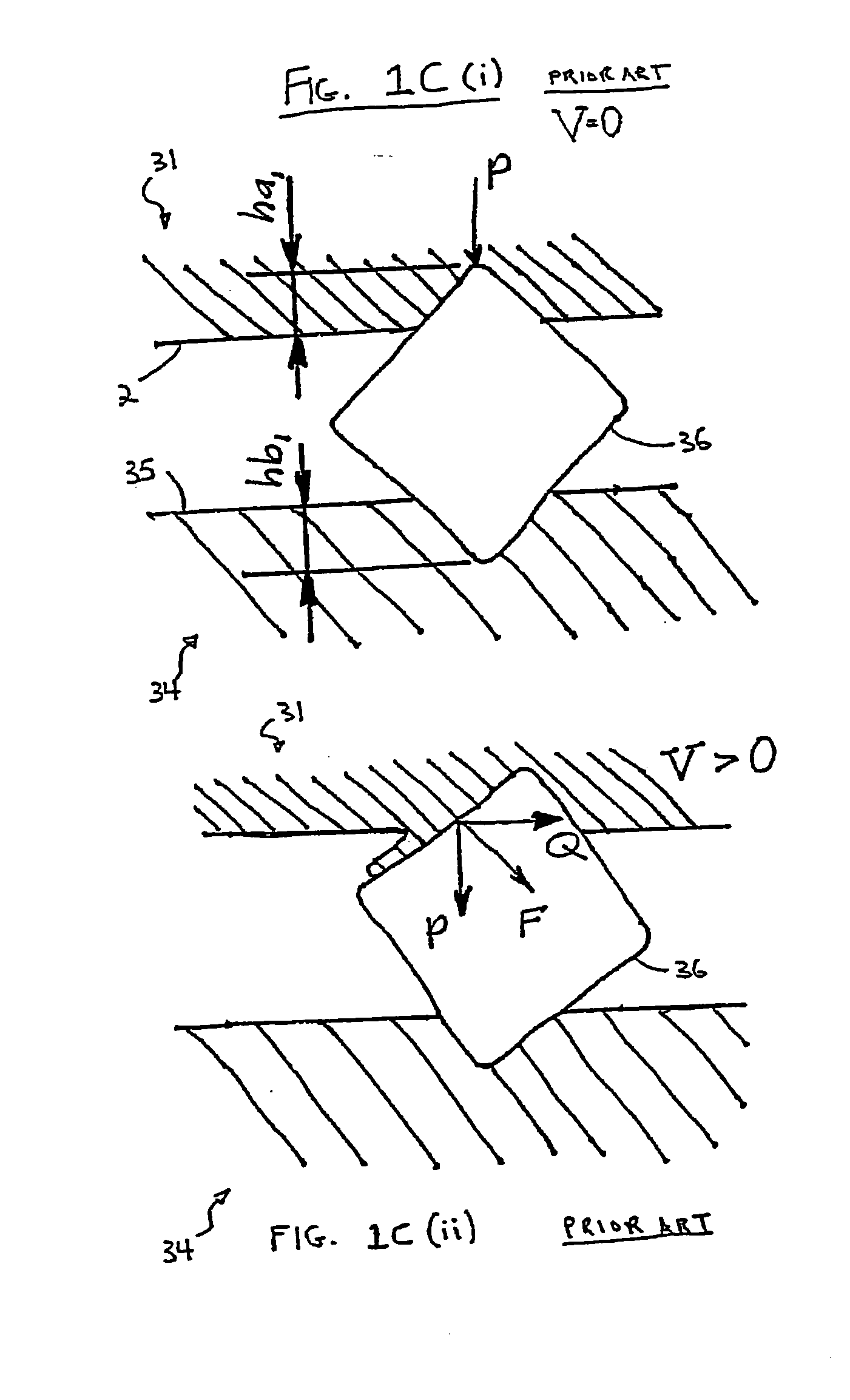

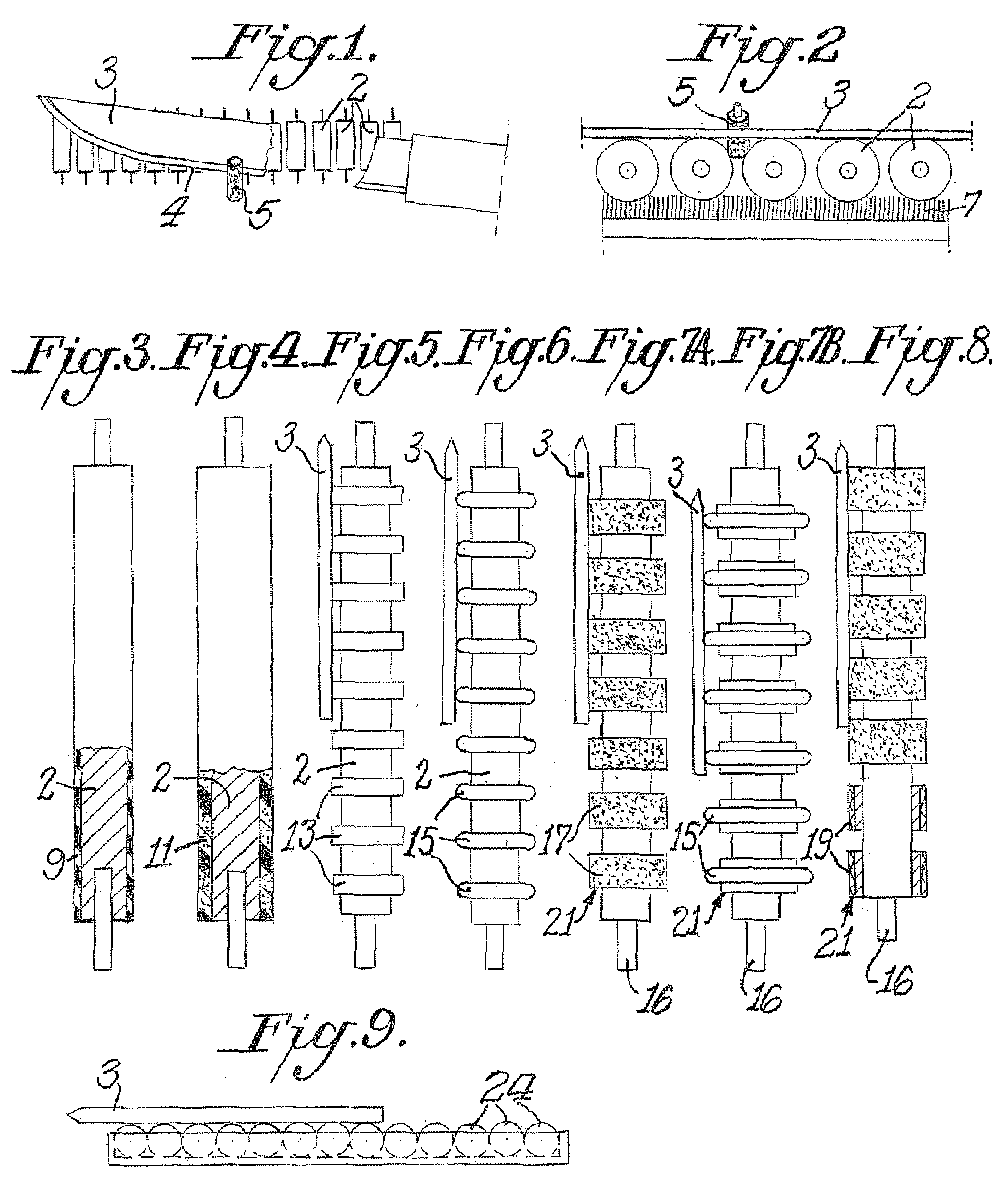

Incorporation of particulate additives into metal working surfaces

InactiveUS20070123152A1Improve tribological propertiesEdge grinding machinesPolishing machinesParticulatesEngineering

A mechanical device for lapping, and a method therefor, the device including: (a) a metal workpiece having a metal working surface; (b) a contact surface, disposed generally opposite the working surface, for moving in a relative motion to the working surface; (c) abrasive particles disposed between the contact surface and the working surface, and (d) a mechanism, associated with the working surface and / or the contact surface, for applying the relative motion, and for exerting a load in a substantially normal direction to the contact surface and the working surface, the contact surface for providing an at least partially elastic interaction with the plurality of abrasive particles, wherein, associated with the contact surface is a particulate additive, and wherein, upon activation of the mechanism, the relative motion under the load causes a portion of the abrasive particles to penetrate the working surface, and wherein the relative motion under the load effects incorporation of a portion of the particulate additive into the metal working surface.

Owner:FRICSO

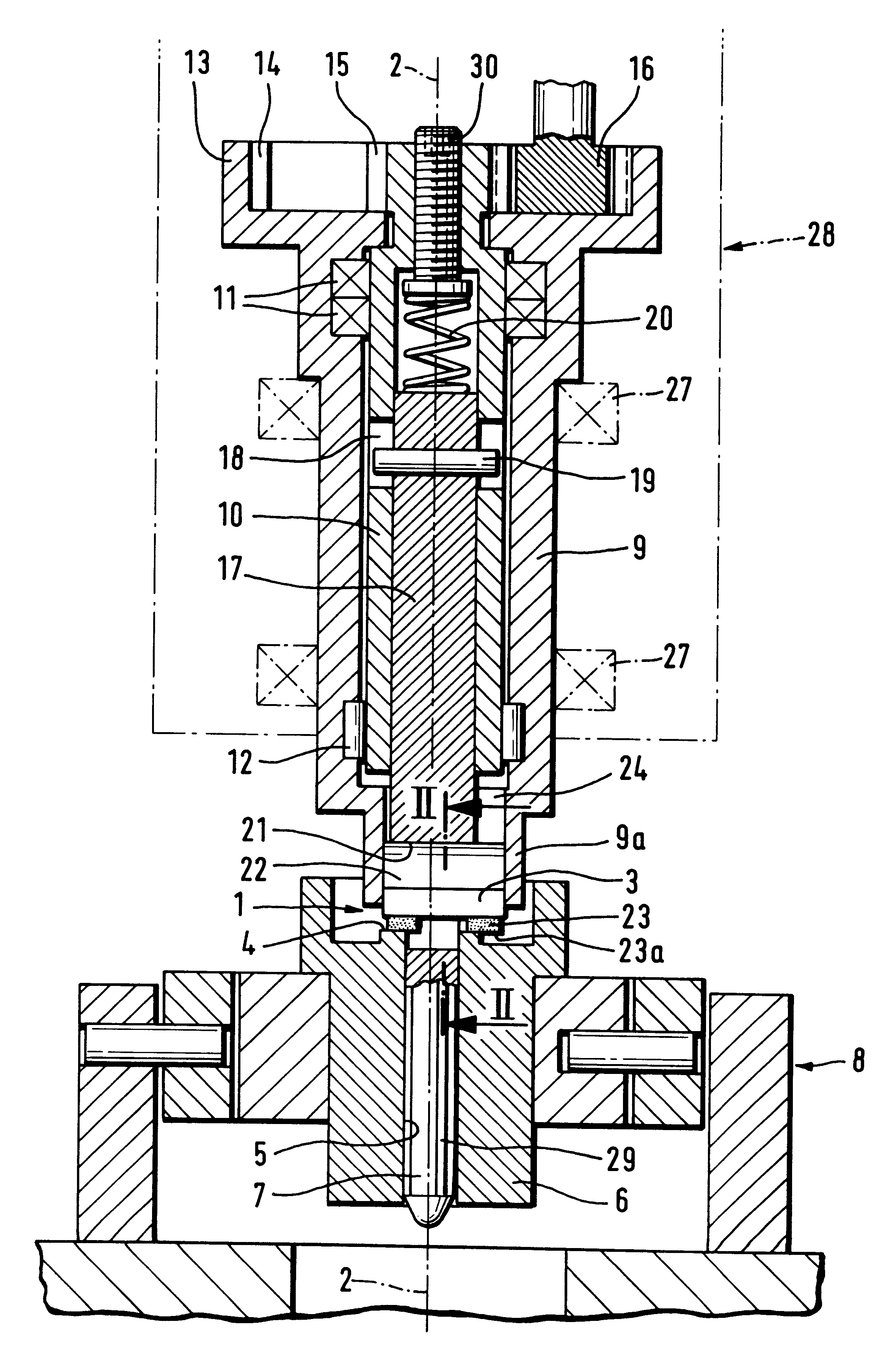

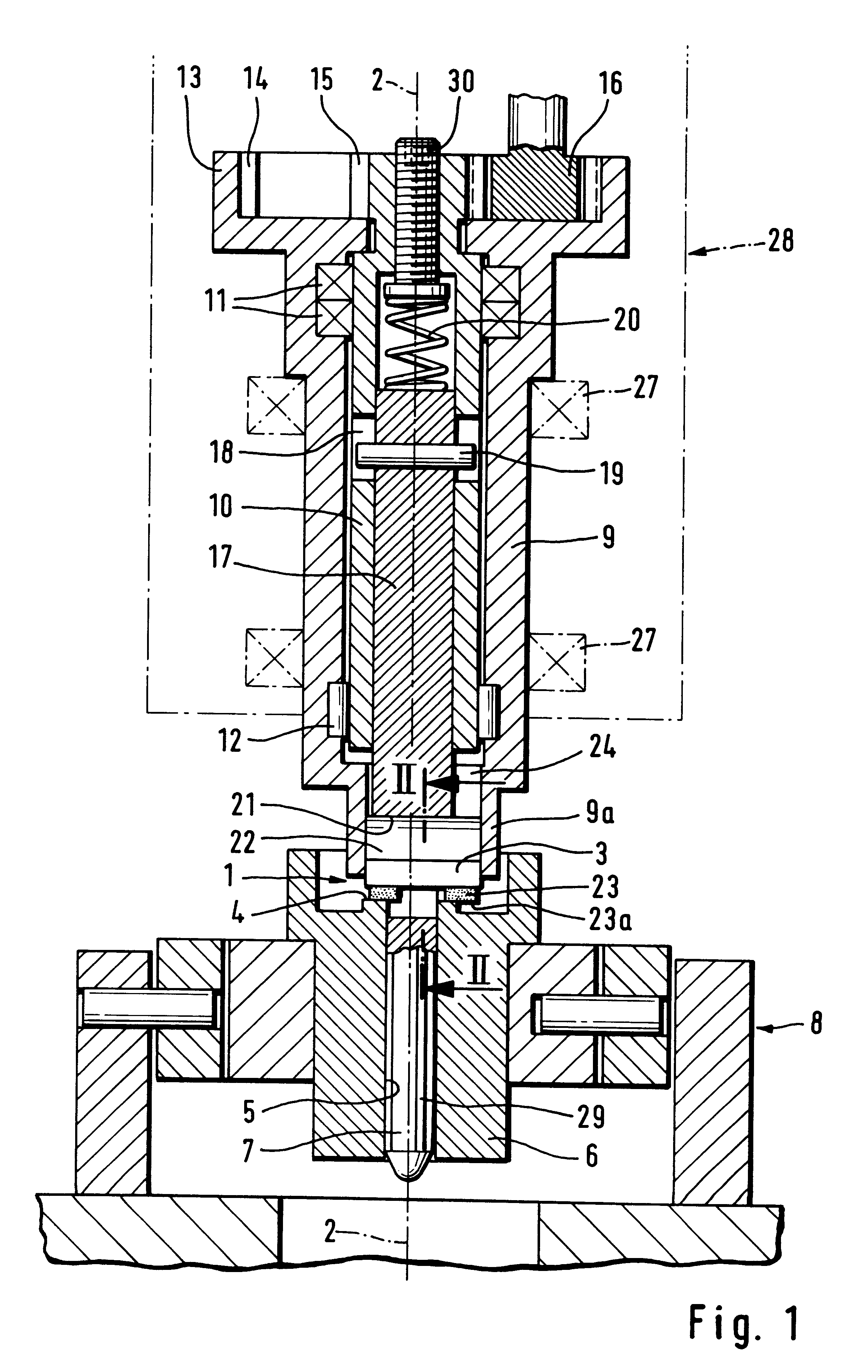

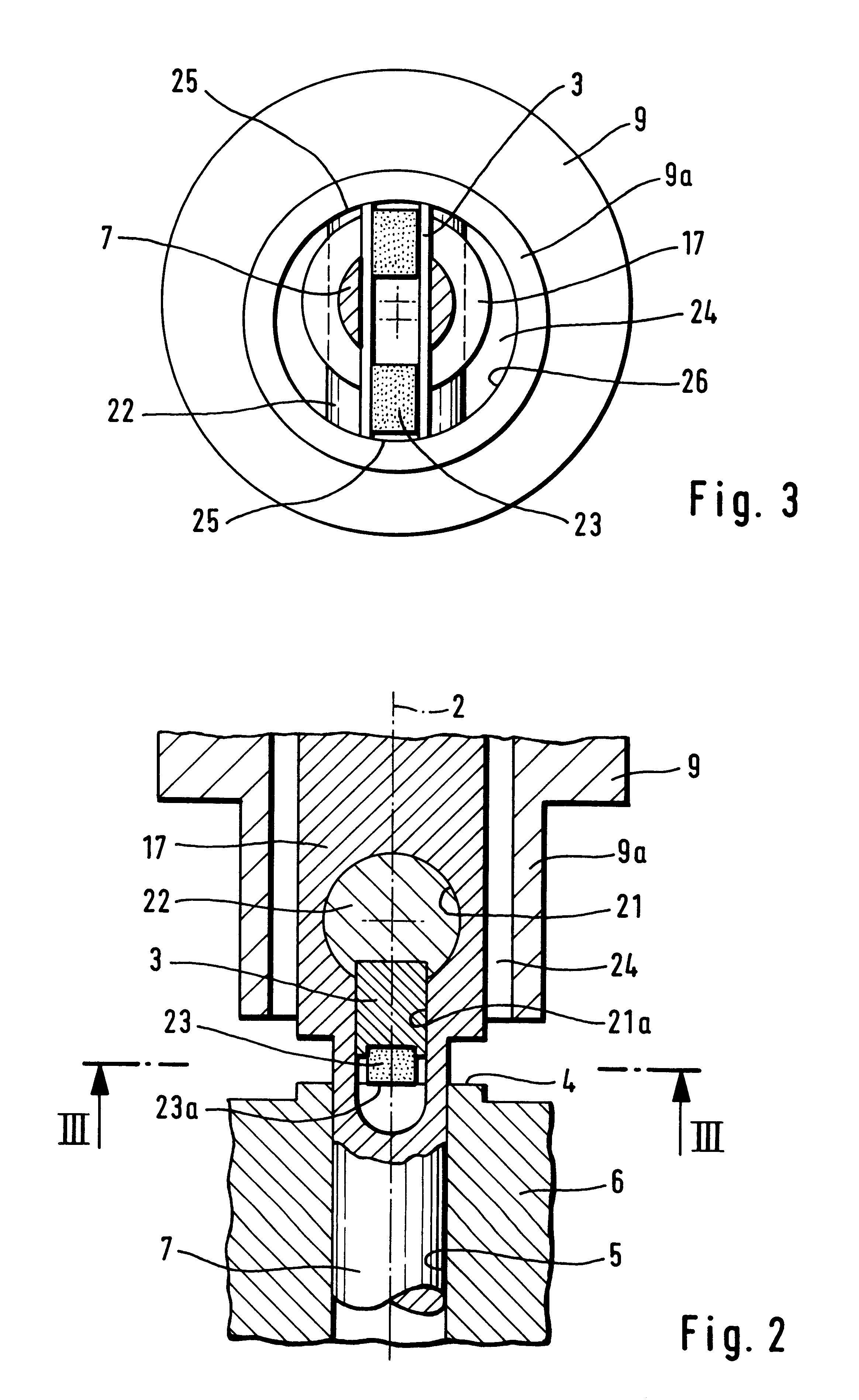

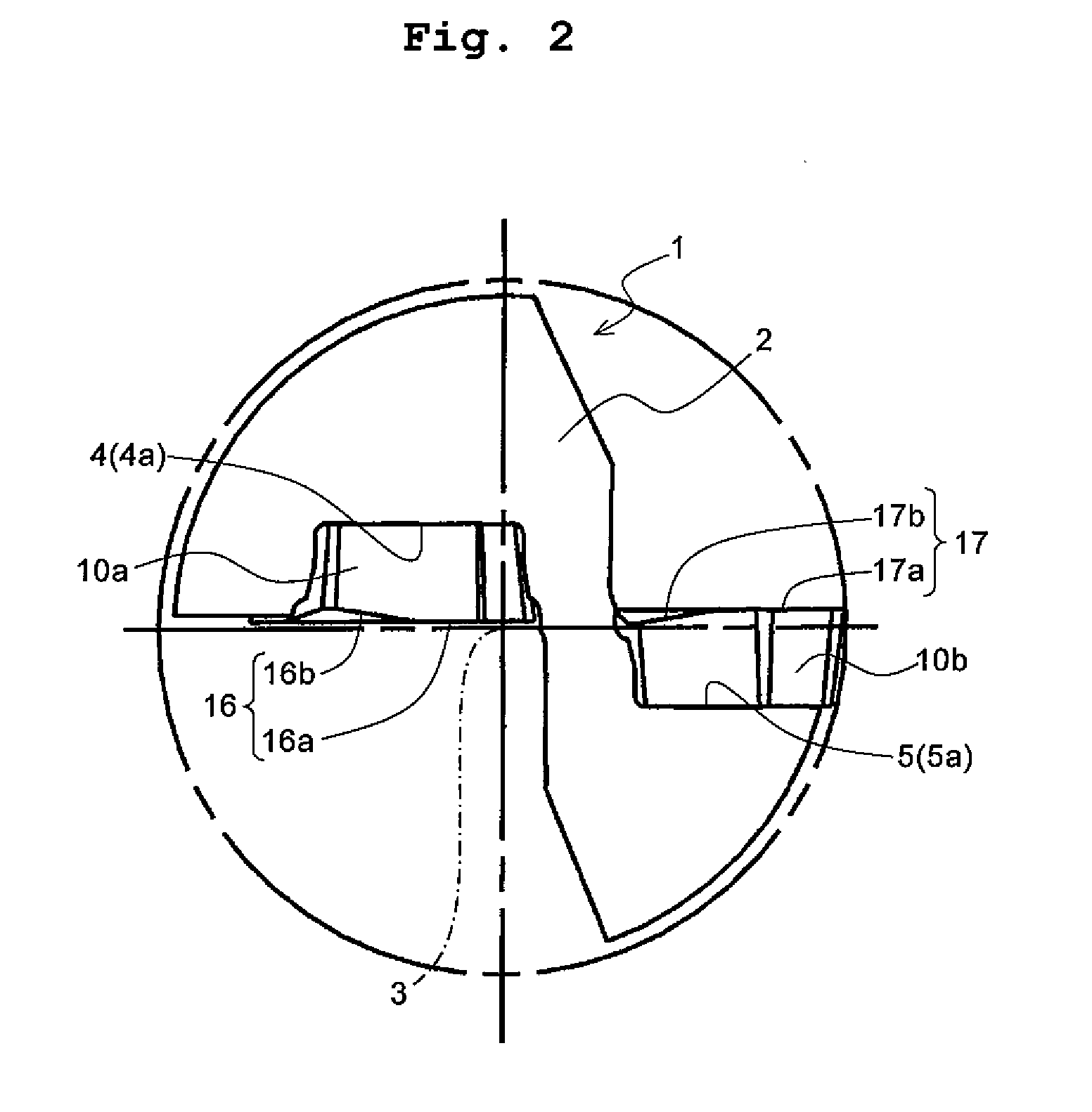

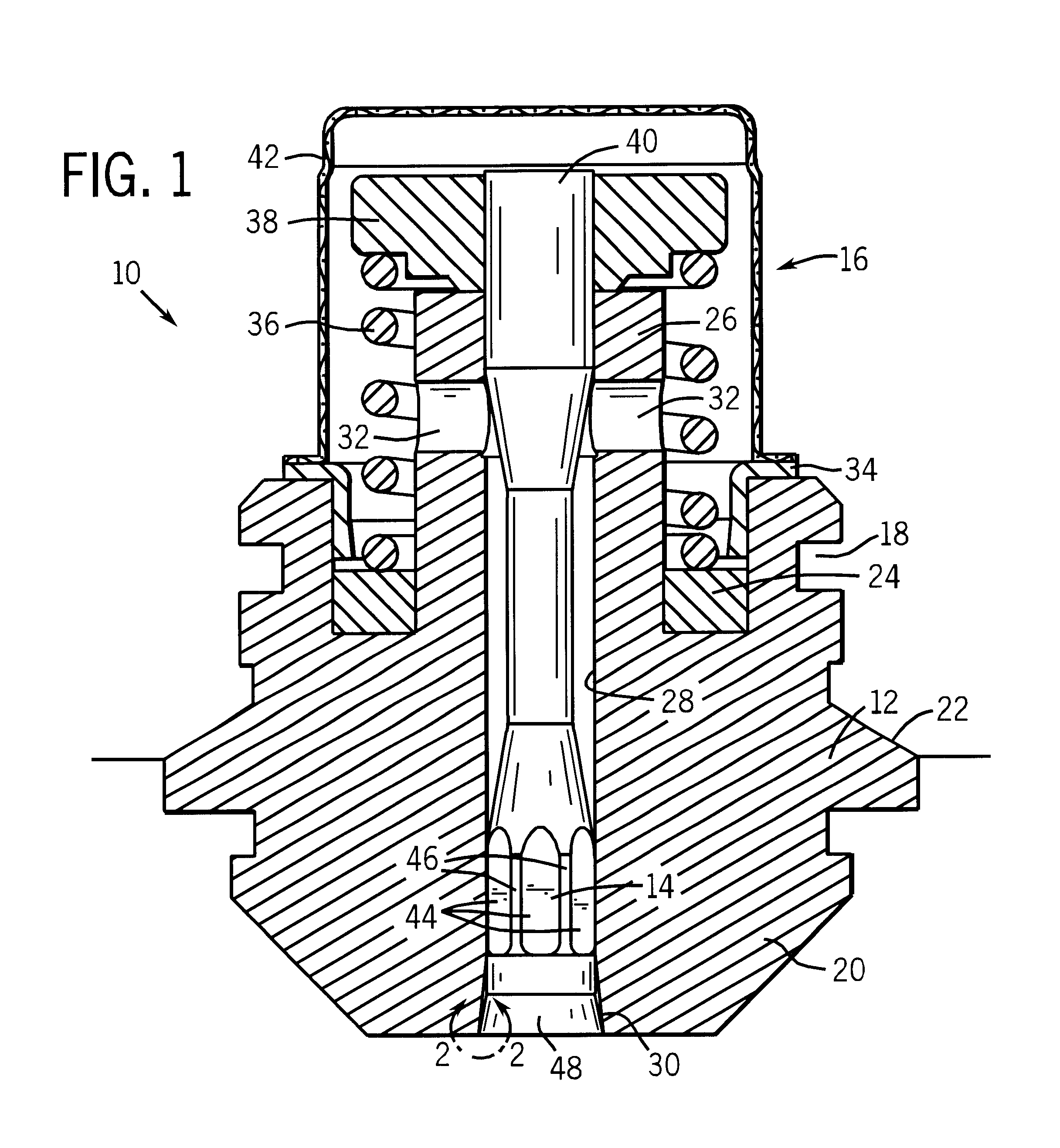

Device for grinding an end face, especially an annular surface at the edge of a workpiece bore

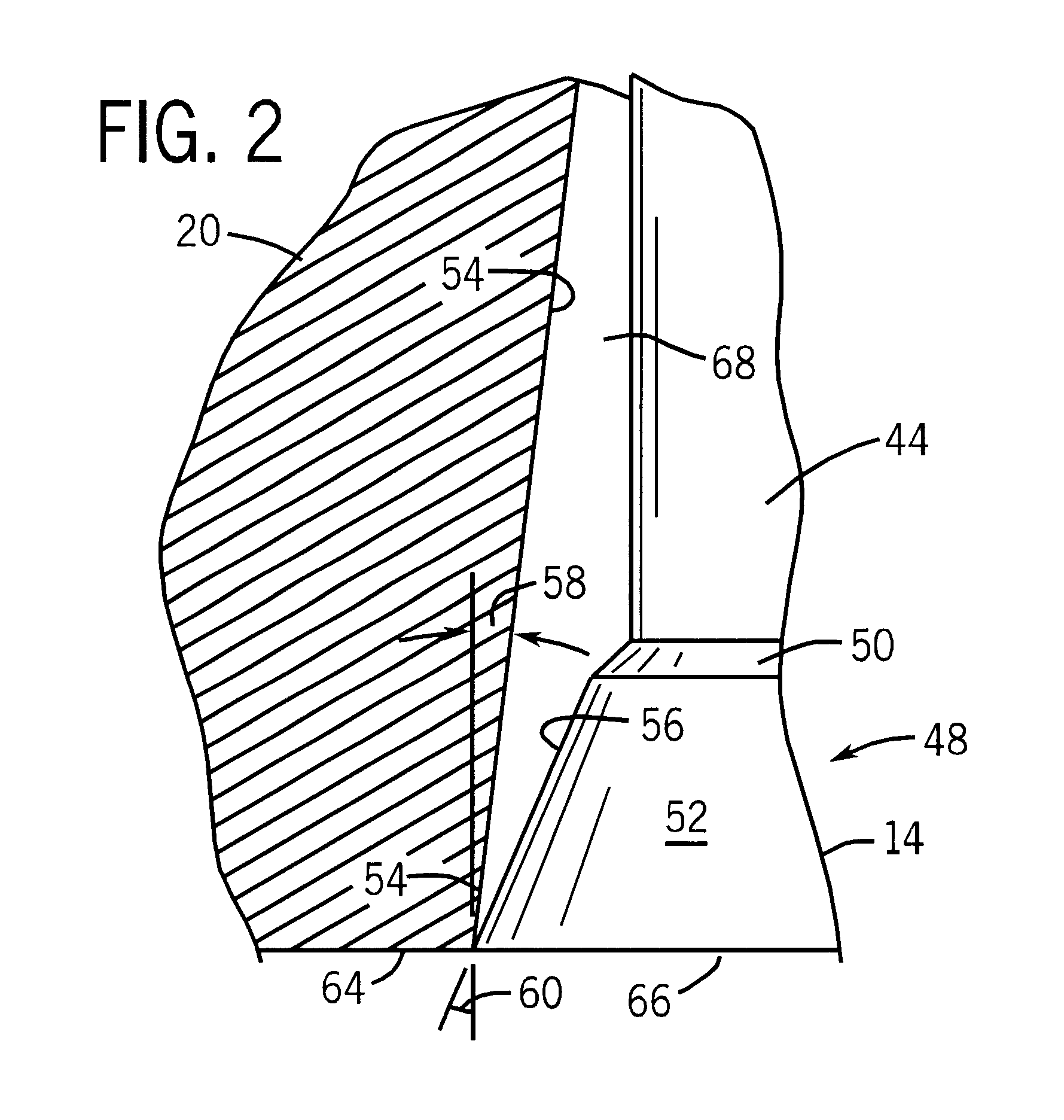

InactiveUS6267653B1High precisionQuality improvementEdge grinding machinesSeat surface grinding machinesMechanical engineeringEngineering

A device for grinding an end face at an edge of a workpiece bore of a workpiece has a driven grinding tool and a guide pin, connected to the grinding tool, for insertion into the workpiece. The guide pin is dimensioned so as to precisely match the workpiece bore. The guide pin has a central axis. The grinding tool has a grinding surface extending angularly to the central axis. The grinding tool is periodically displaceable transverse to the central axis.

Owner:MASCHFAB GEHRING +1

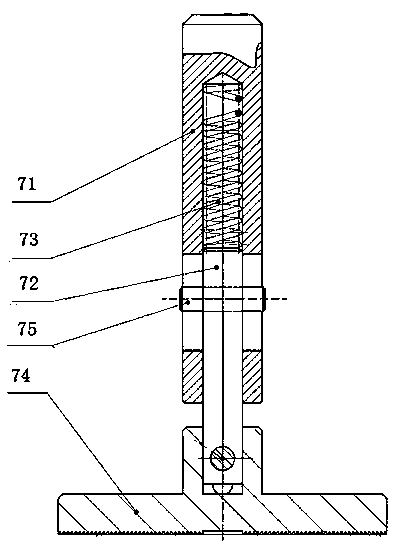

Grinding tool for sealing face of safety valve

PendingCN108032177APrevent vibration crackingAvoid being damagedGrinding carriagesSeat surface grinding machinesElectric machineryEngineering

The invention provides a grinding tool for a sealing face of a safety valve. The grinding tool is high in operability, simple to operate and high in adaptability. In the grinding process, secondary damage to the sealing face of the safety valve can be avoided effectively. A grinding head is mounted on an output shaft of a grinding motor; the grinding head faces the middle part of a pre-tighteningdisc; a transmission, a grinding buffer and a telescopic rod assembly are successively arranged between the grinding motor and the grinding head; the pre-tightening disc comprises a valve seat pre-tightening disc and a valve clack pre-tightening disc; a valve seat pre-tightening block of the valve seat pre-tightening disc is located on the lower surface of the valve seat pre-tightening disc; a processing through hole is formed in the middle of the valve seat pre-tightening disc; and the valve clack pre-tightening disc is locked on the valve seat pre-tightening disc by matching a locking tablewith the processing through hole; the buffer can avoid or reduce vibration caused by grinding of the motor and the grinding disc, so that the sealing face of the valve body is prevented from being vibrated or damaged; an oil storage room and an oil leakage hole are formed in the grinding disc, so that high temperature of the sealing face which is ground is reduced, and the sealing face is prevented from being stretched or being heated at the high temperature form a crack.

Owner:新乡中新化工有限责任公司

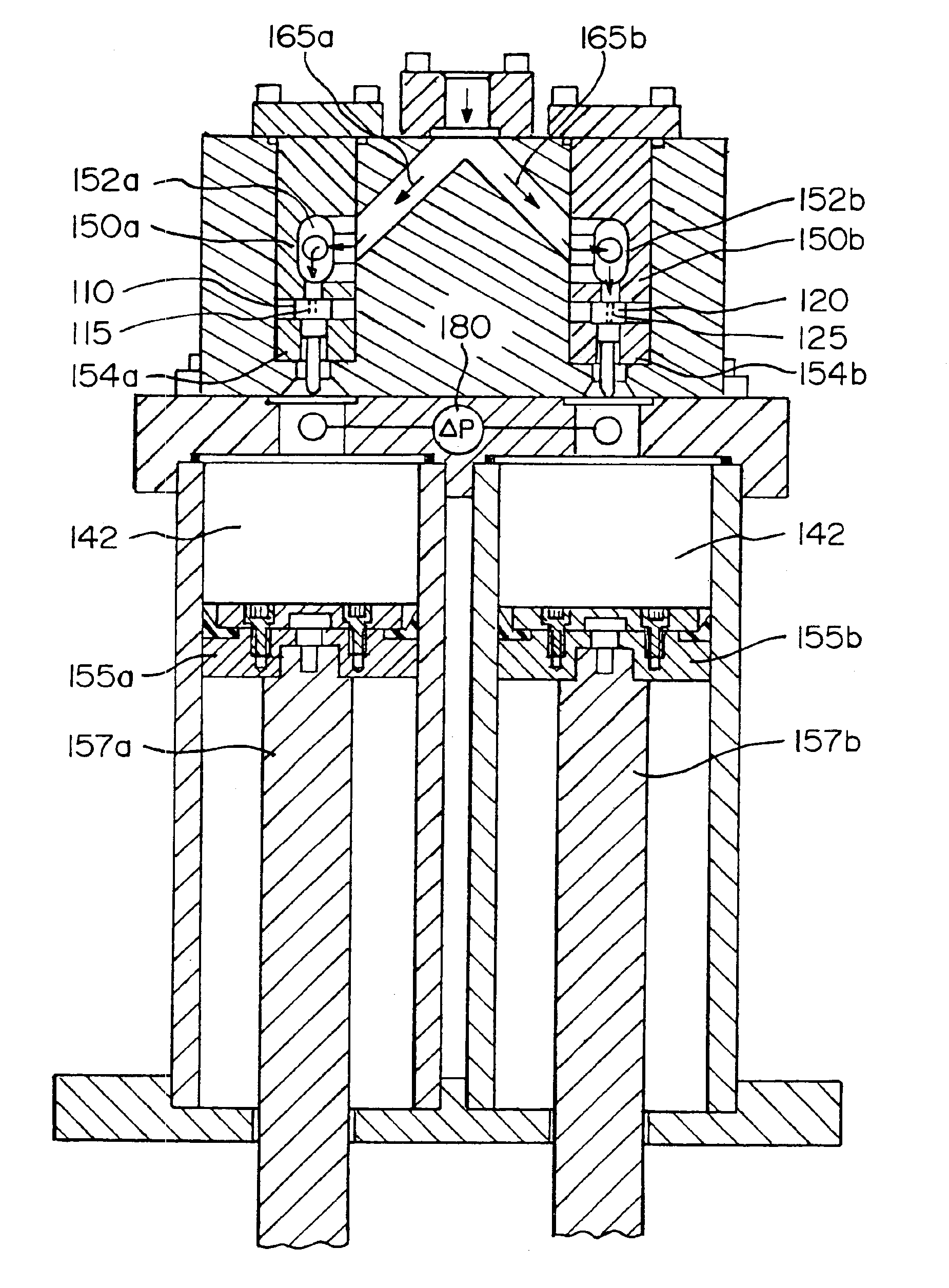

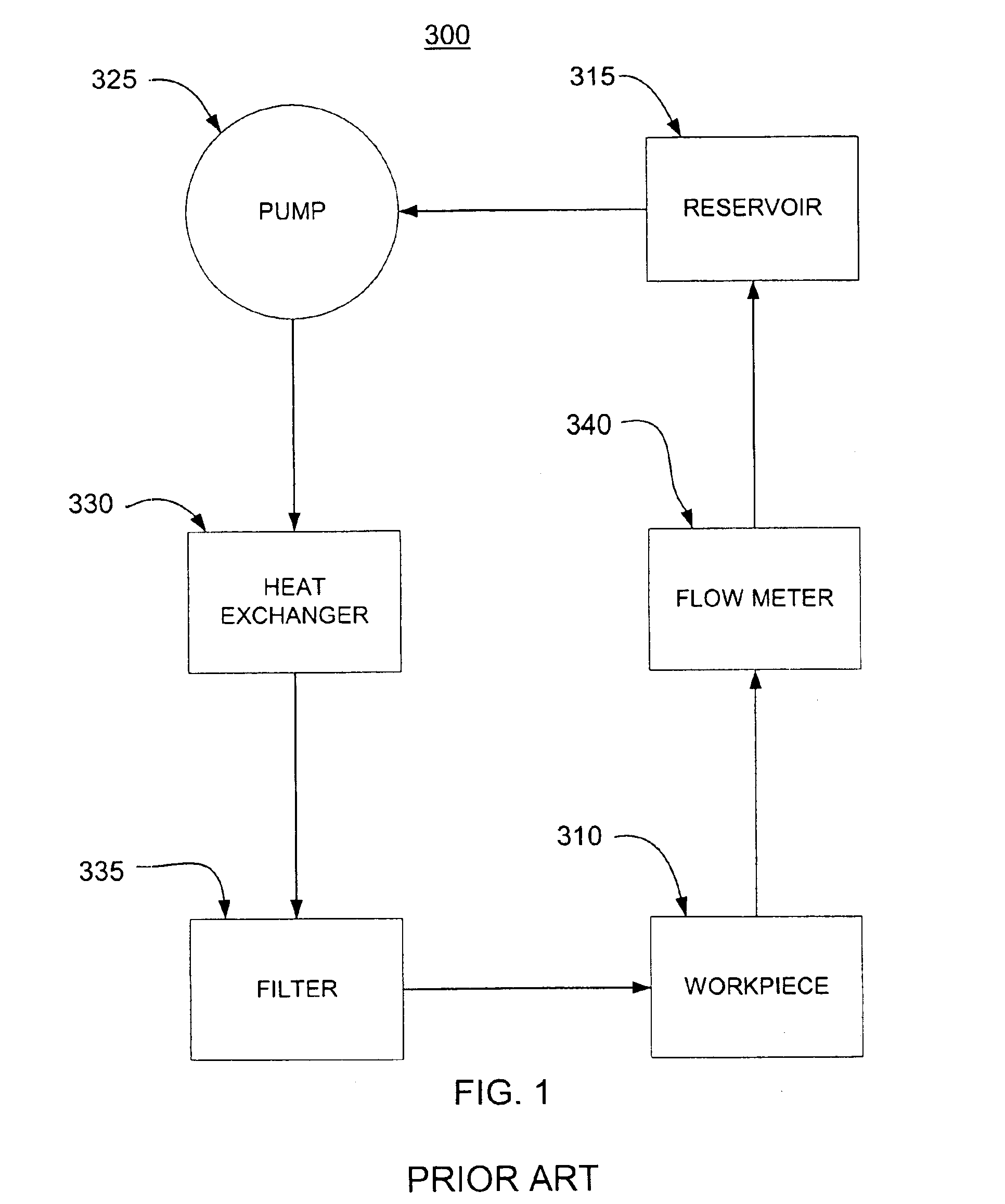

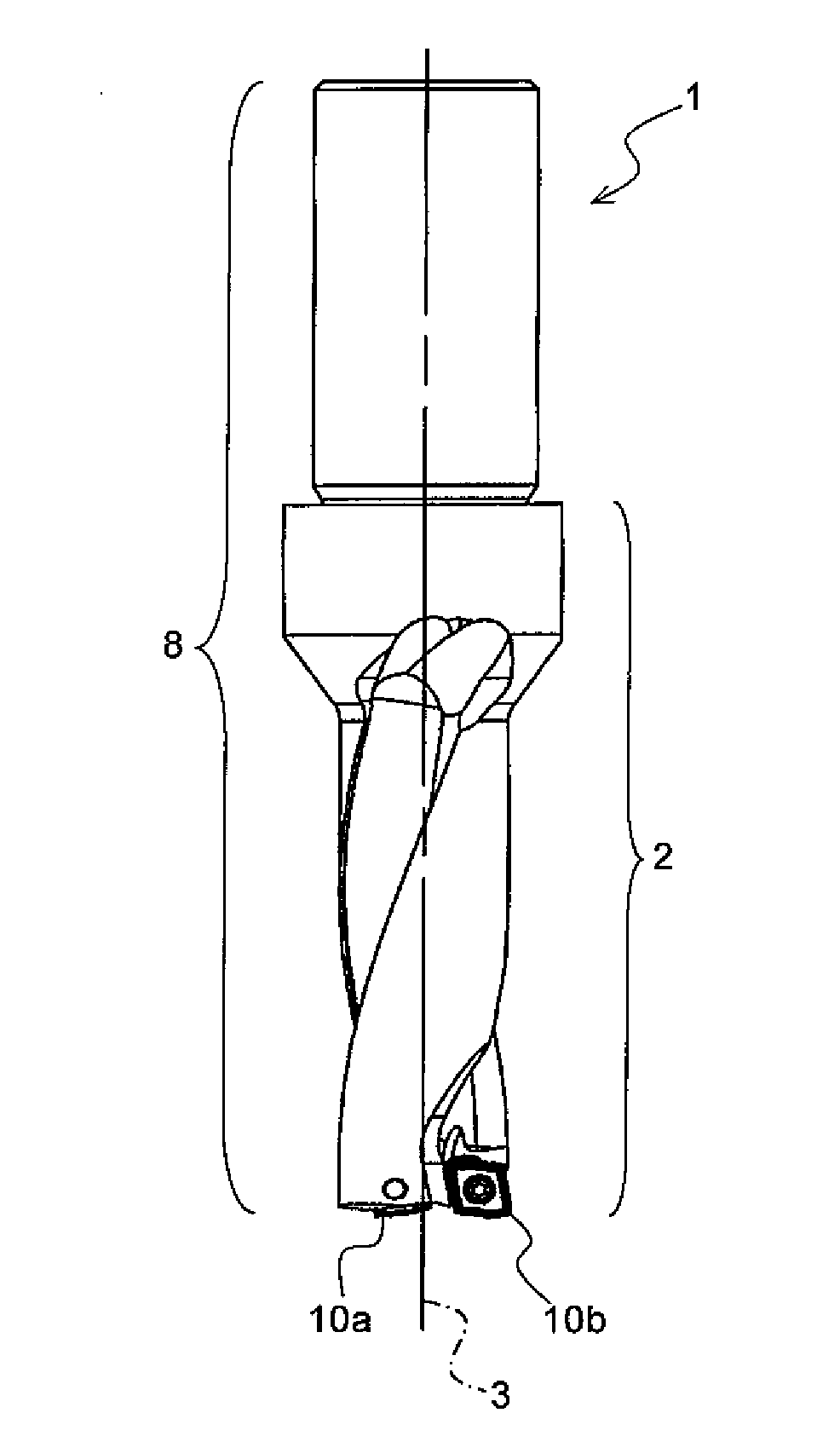

Method and apparatus for measuring flow rate through and polishing a workpiece orifice

A method and apparatus for comparing the flow rate through an orifice within a master part with the orifice within a workpiece by subjecting each orifice to an identical fluid at an identical temperature, under an identical pressure, and comparing the downstream pressures of the fluid exiting these orifices when the upstream pressure is constant or comparing the upstream pressure when the downstream pressure is constant. For purely measurement purposes, the fluid may be a non-abrasive media, however, in the event the workpiece orifice must be machined, it is possible to introduce a flowable abrasive media, and pass this media through the orifices until the desired pressure difference is achieved. With additional flow characteristics of the master part, it is also possible to calculate the flow rate through the workpiece orifice using only the pressure differential at the exits of the workpiece and the master part.

Owner:EXTRUDE HONE CORP

Throwaway Drill, Insert of Throwaway Drill and Cutting Method Using the Same

InactiveUS20100166514A1Cutting force balanceThread cutting toolsWood turning toolsEngineeringDrill bit

A throwaway drill, an insert provided on the throwaway drill, and a cutting method using the same. The throwaway drill has a throwaway drill holder including an inner edge insert pocket having a seat, formed on a central axis side of a tip end of a drill main body, and an outer edge insert pocket having a seat, formed on the outer peripheral side of the tip end; an inner edge insert fixed to the seat of the inner edge insert pocket; and an outer edge insert fixed to the seat of the outer edge insert pocket. When viewed from the tip end side of the drill main body, the inner cutting edge of the inner edge insert includes: a first inner cutting edge provided on the central axis side of the drill main body, being parallel to at least part of the outer cutting edge of the outer edge insert; and a second inner cutting edge provided on the outer peripheral side of the drill main body, being inclined to the seat of the inner edge insert pocket in a direction toward the outer peripheral side, with respect to the first inner cutting edge.

Owner:KYOCERA CORP

Knife sharpener with improved knife guides

ActiveUS20070197148A1Eliminate burnishingEliminate scratchesEdge grinding machinesRevolution surface grinding machinesKnife sharpenerKnife blades

Owner:EDGECRAFT

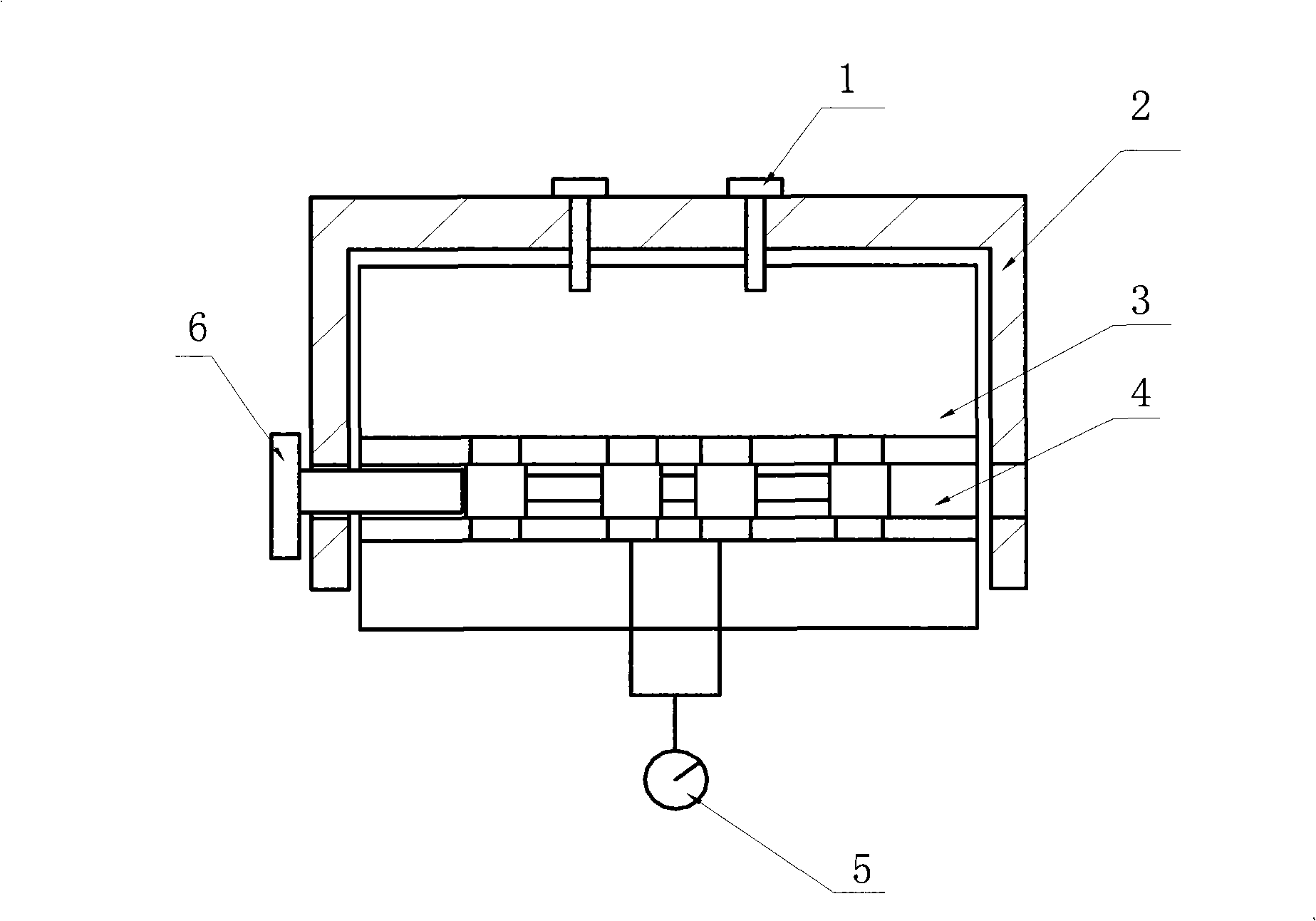

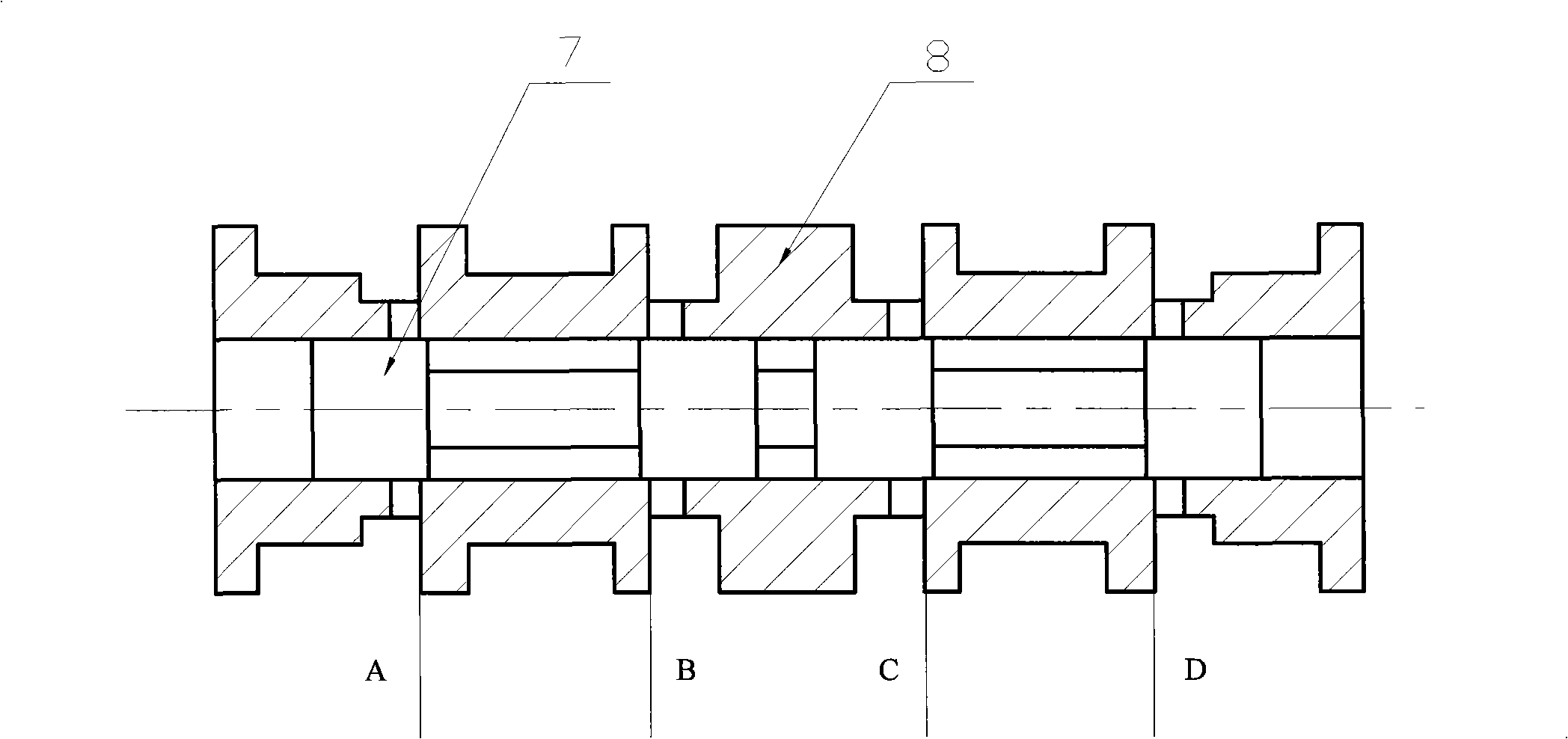

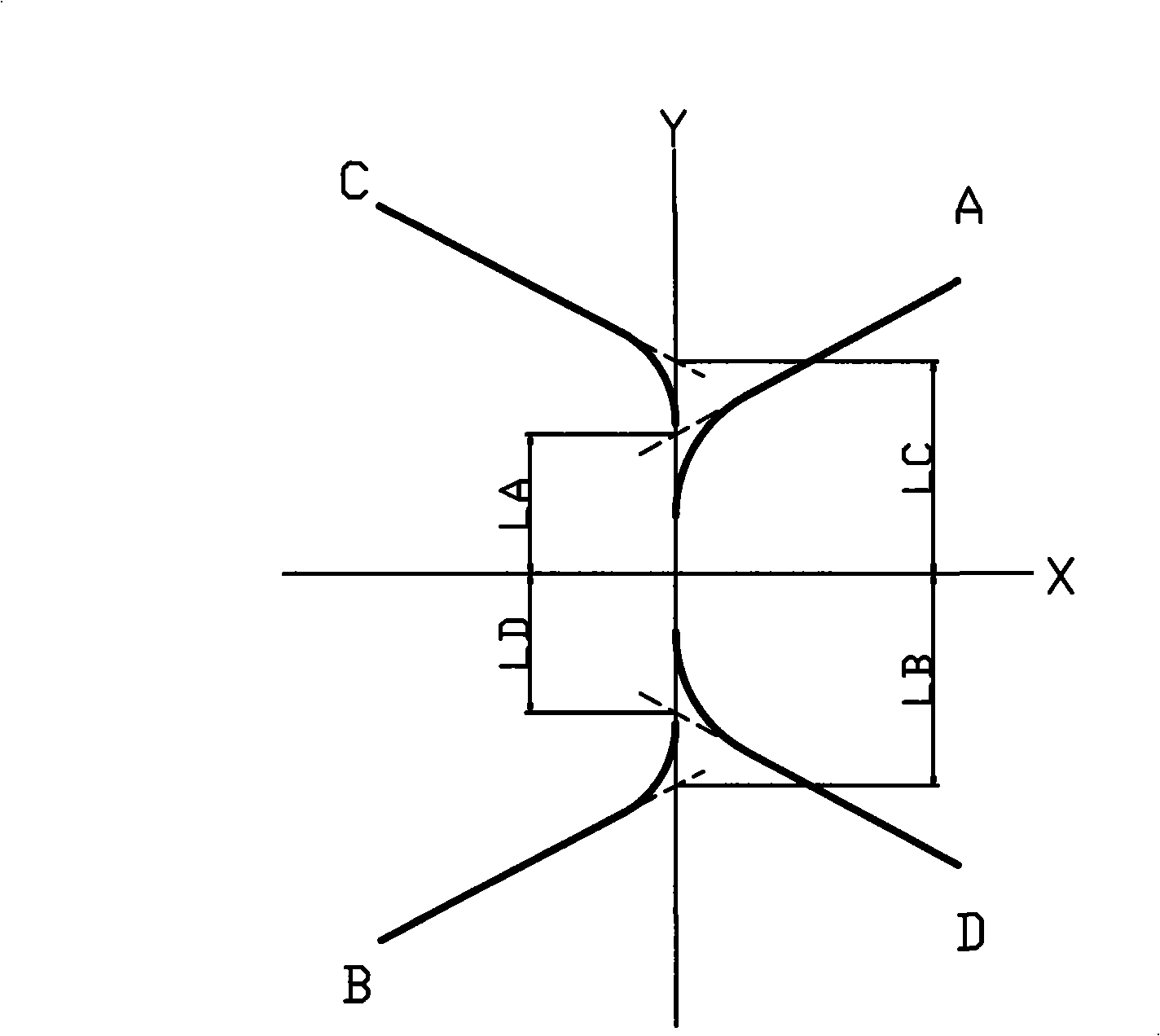

Auxiliary overlap joint hydraulic match grinding process for spool valve of servo valve

ActiveCN101402180AImprove debugging pass rateImprove pass rateSeat surface grinding machinesSpool valveEngineering

The invention relates to a hydraulic match grinding process for the lap amount of a slide valve pair of a servo valve. The process comprises the following steps: (1). the slide valve pair of the servo valve is arranged in a process shell; a sealing gland and a whole pressing sleeve are adopted to seal each oil circuit of the process shell; a displacement sensor is arranged on one end of a valve core of the servo valve; and a flow sensor is arranged in a feedback cavity of the slide valve pair; (2). oil is supplied to the slide valve pair; when a test is begun, the valve core of the servo valve is dragged to and fro; and according to collecting values of the displacement sensor and the flow sensor, a match grinding curve of a working side of the slide valve pair is drawn; (3). the match grinding curve is judged and read; a value of the lap amount of the working side of the slide valve side is judged and is compared with the design requirement of the servo valve; and the working side corresponding to the value larger than the design requirement is sharpened and grinded; and (4). the steps from the step (2) are carried out repeatedly till the slide valve pair meets the design requirement.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

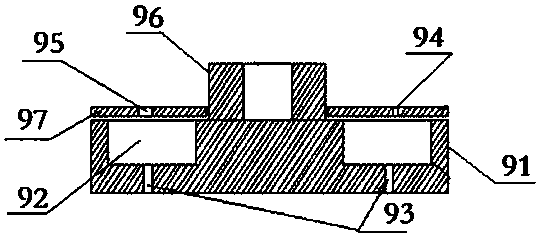

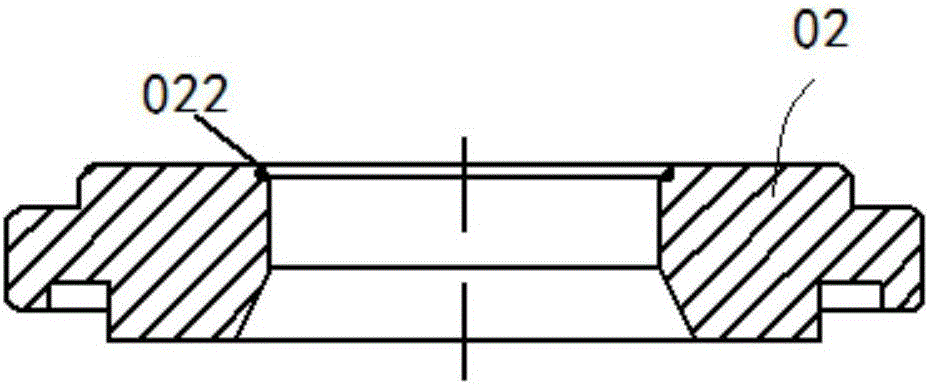

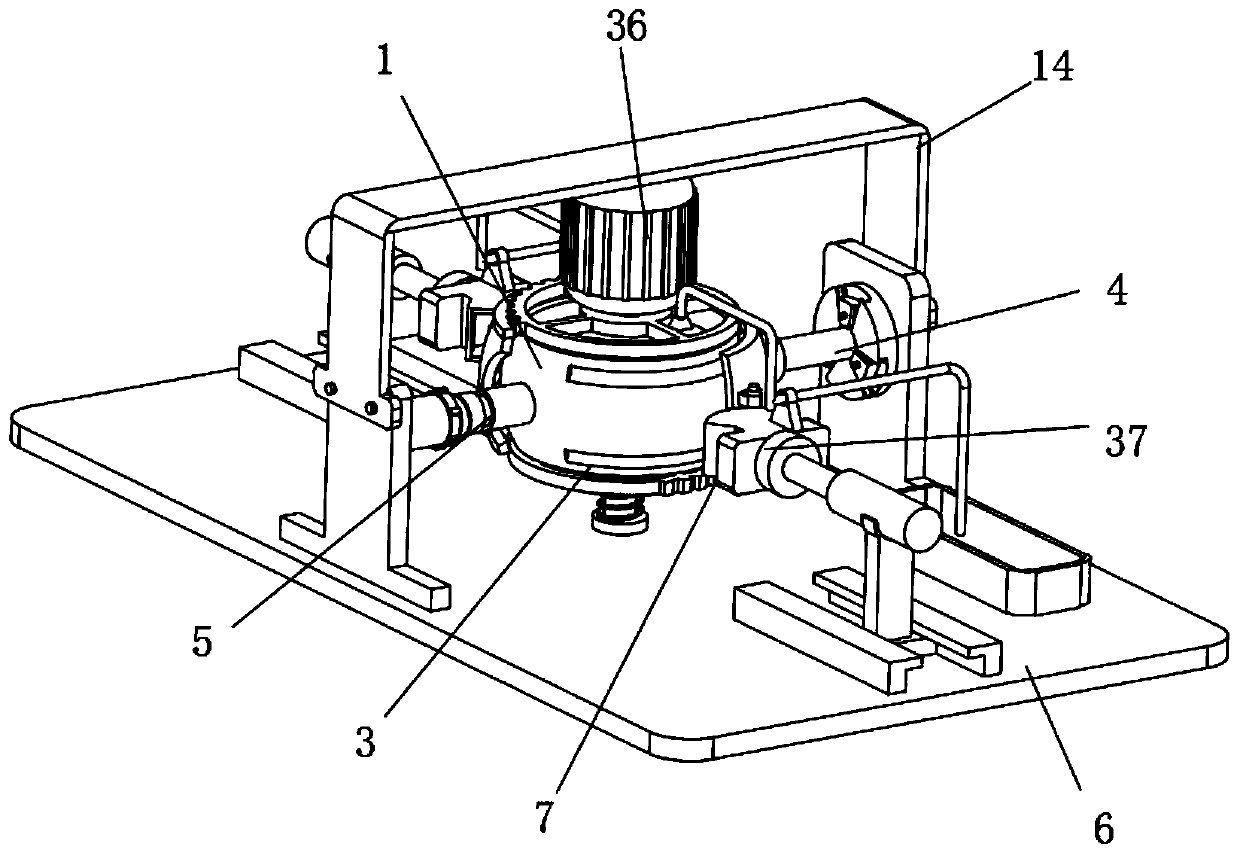

Grinding mechanism for valve core and valve seat

ActiveCN105729270AEasy to detectGuaranteed sealing performanceSeat surface grinding machinesGrinding feed controlButt jointEngineering

The invention provides a grinding mechanism for a valve core and a valve seat. The grinding mechanism comprises a first installation rack, a second installation rack and a driving structure; the first installation rack is provided with first installation space suitable for installing the valve seat and a first air hole communicating with the first installation space and the atmosphere; the second installation rack is provided with second installation space suitable for installing the valve core and a second air hole communicating with the second installation space and the atmosphere; the first installation rack and / or the second installation rack can move oppositely and / or towards the other one so that the first installation space and the second installation space can form closed space in a butt joint mode, the first installation space and the second installation space only can communicate through a hole to be ground of the valve seat when the valve seat is installed, and the valve core is inserted into the hole to be ground for being connected to the valve seat in a matched mode when the valve core is installed; the driving structure is used for driving the valve core or the valve seat to rotate relative to the other one so that the sealed contact surface of the valve core and the valve seat can be ground. According to the grinding mechanism, the valve core and the valve seat can be controlled to be automatically ground, the sealing performance between the valve core and the valve seat can be detected, and the production efficiency is high.

Owner:NEWAY VALVE SUZHOU

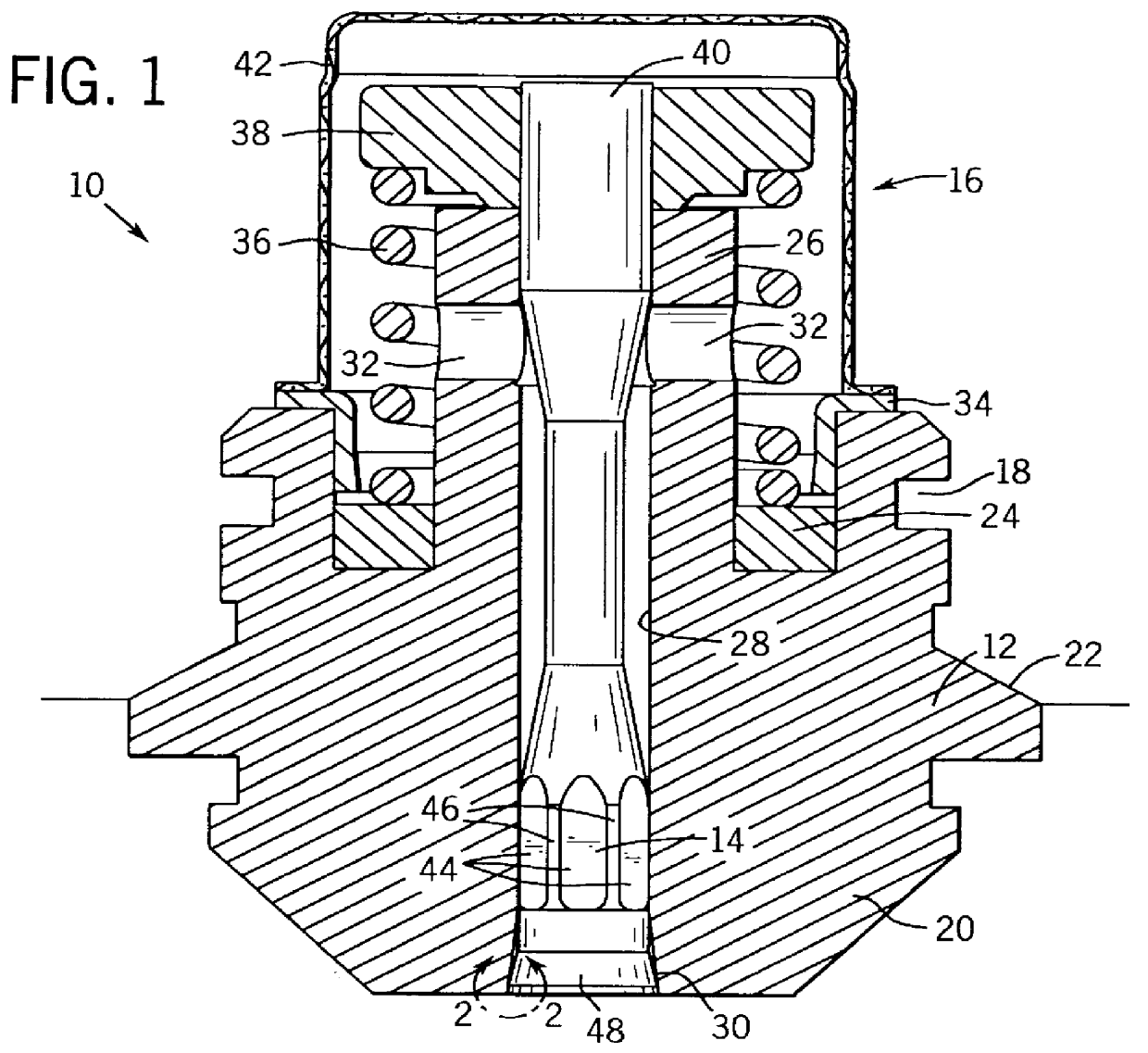

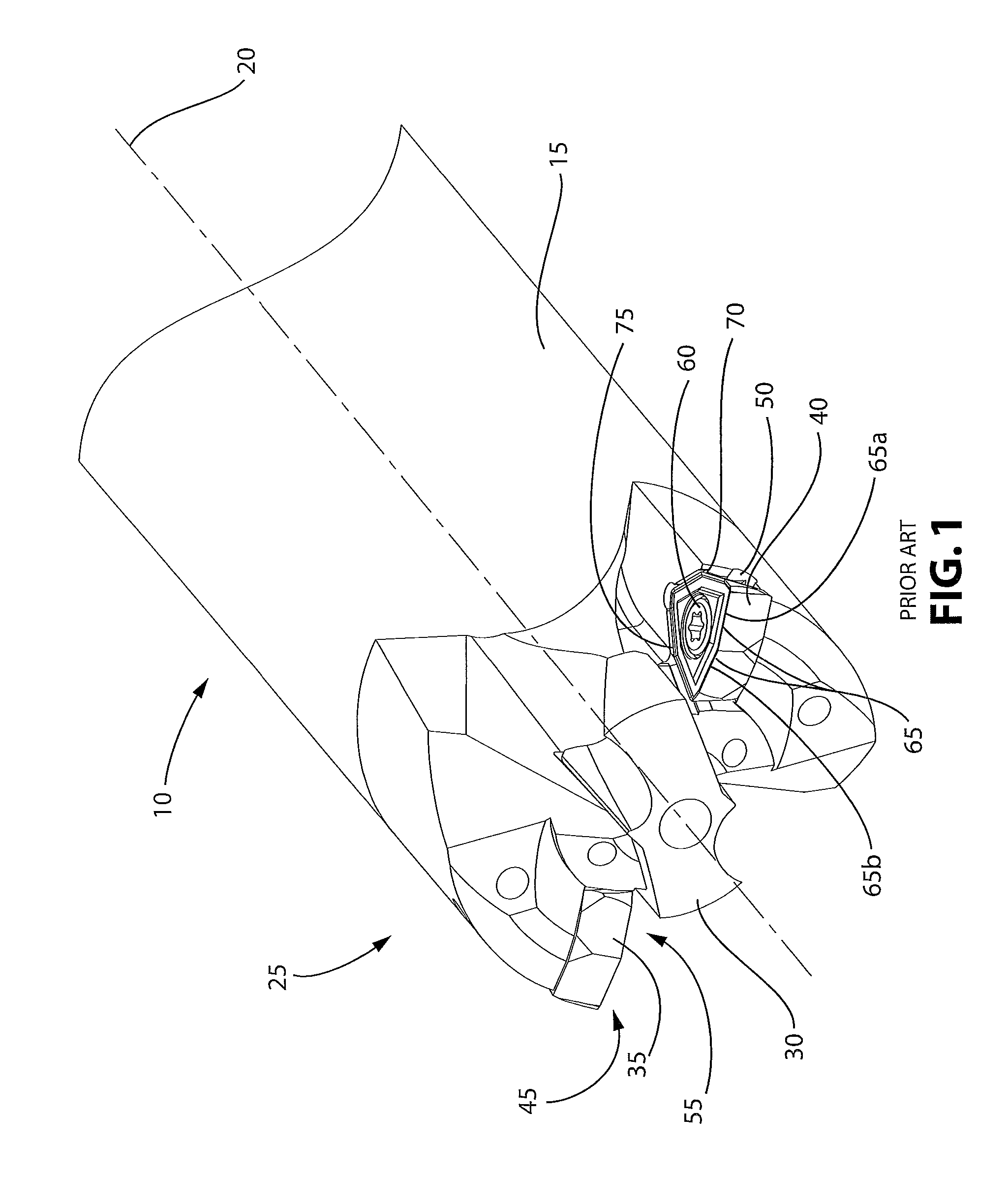

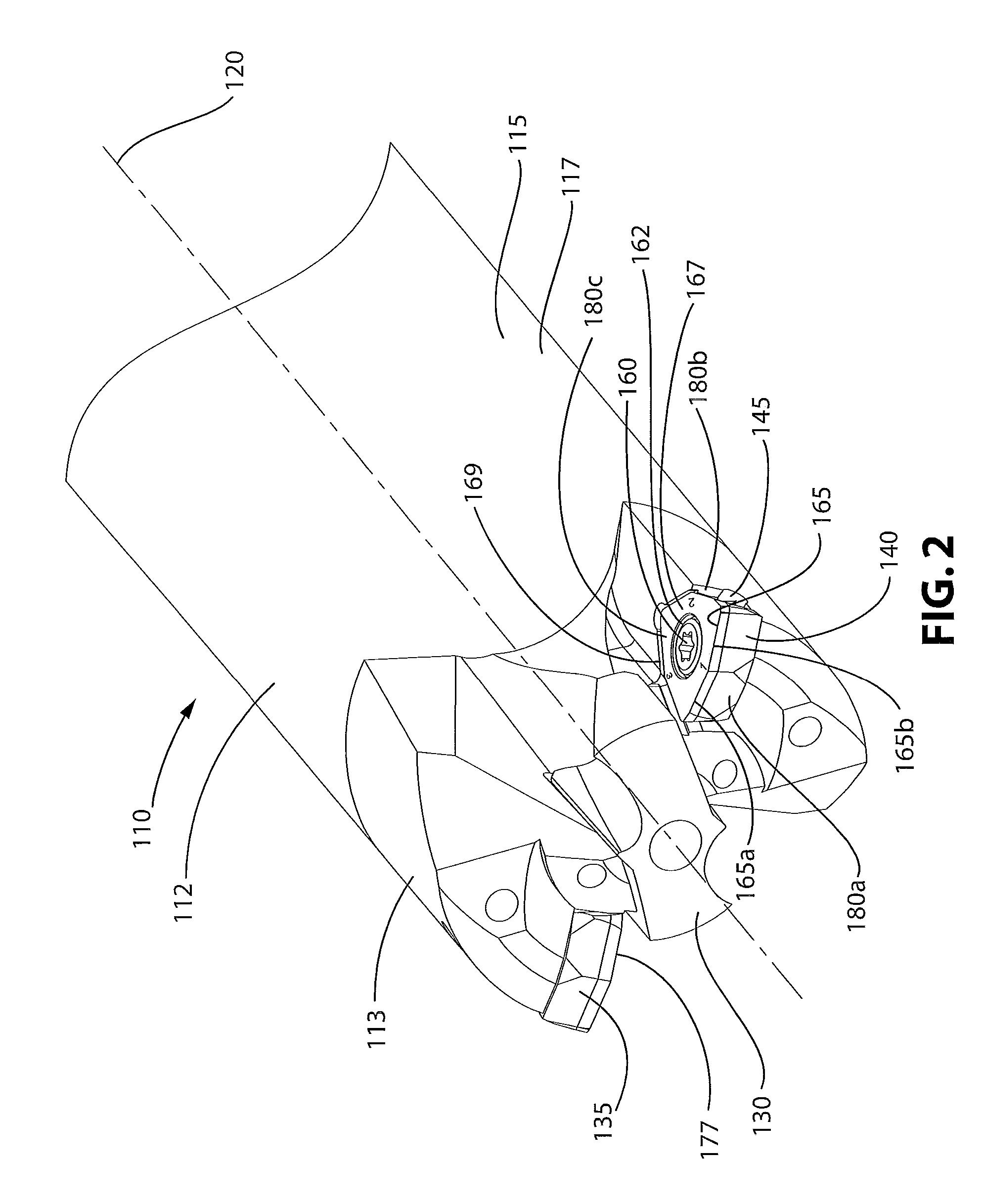

Multi-cartridge cutting tool and railway wheel boring assembly

A multi-cartridge cutting tool includes a body with a plurality of cartridge-receiving pockets, and a plurality of insert-receiving cartridges mounted to a respective pocket. A round cutting insert is mounted to each cartridge. The pockets are formed at predetermined distances from a central, longitudinal axis of the body to form a first group and a second group of cutting inserts such that the cutting edges of the first group of cutting inserts and the cutting edges of the second group of cutting inserts are located at different axial and radial distances from the central, longitudinal axis of the body to perform different machining operations. A third group of cutting insert(s) may exist for cutting tools with an odd number of cutting inserts. The different types of machining pockets allow for high feed rates, while greatly improving the life of the cutting insert as compared to conventional cutting tools. A railway wheel boring assembly is also disclosed.

Owner:KENNAMETAL INC +1

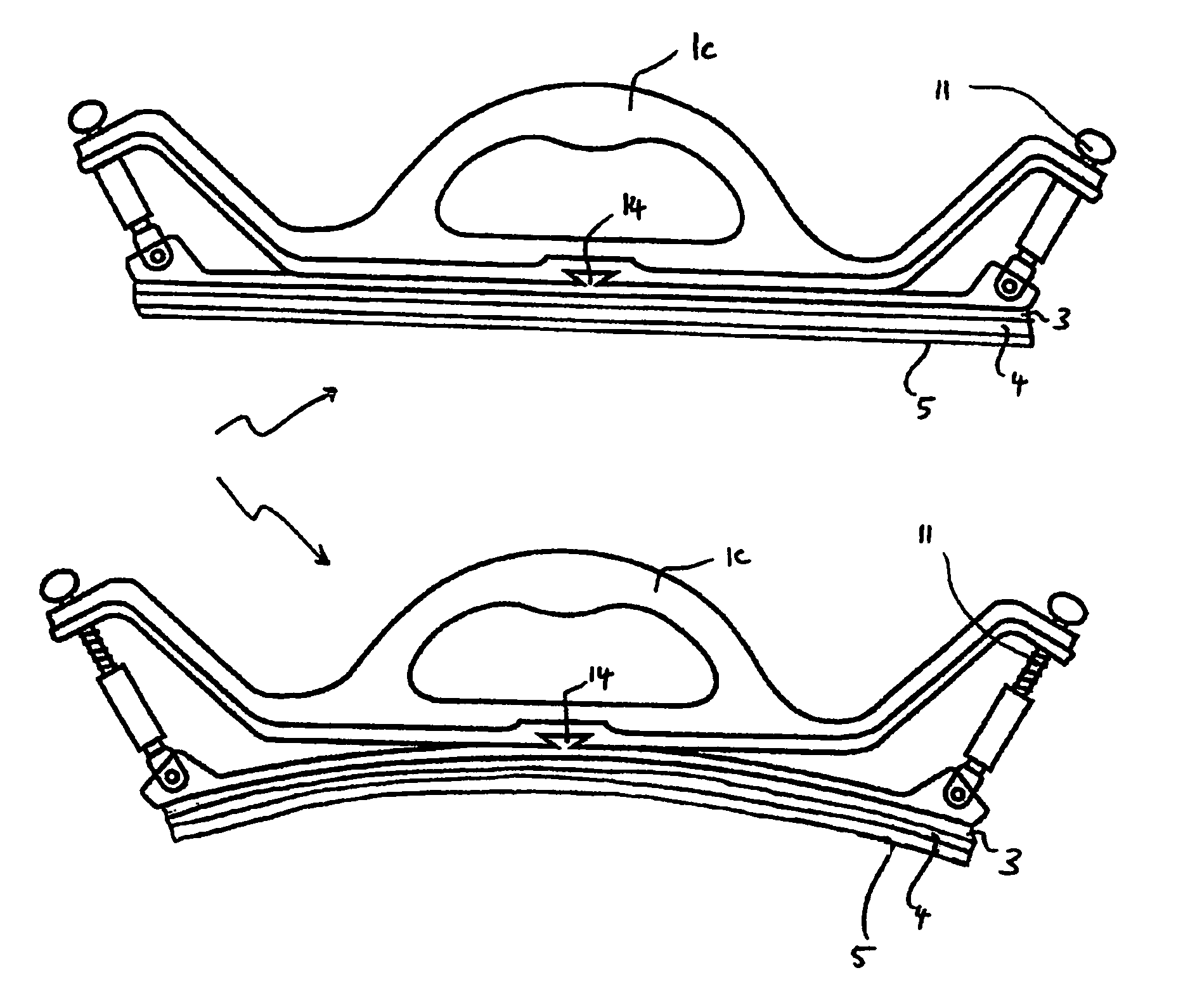

Sanding block

InactiveUS6960125B2Simple structureQuick and easy changeSeat surface grinding machinesGrinding/polishing hand toolsClassical mechanicsHand held

A sanding block for hand held use has a main body with a bottom side providing a surface for pressing a portion of a circular sheet of sandpaper against an article to be sanded. A first hook and loop-type fastener is secured to the top side of the main body for coupling with a corresponding material covering a backside of the sandpaper. A flap member is secured to the main body and is swingable between first and second positions. A second hook and loop-type fastener is secured to the flap member for coupling with the material covering the backside of the sandpaper. The flap member and the second fastener are arranged to pull the sheet of sandpaper taut across the bottom side when the flap member is moved from its first position to its second position. A closure system is provided for holding the flap member in its second position.

Owner:MICK JERRY

Precise grinding and polishing machine for sealed end face of airplane engine

ActiveCN105598824AControl FlatnessControl parallelismSeat surface grinding machinesLapping machinesJet aeroplaneElectric machinery

The invention discloses a precise grinding and polishing machine for the sealed end face of an airplane engine. The precise grinding and polishing machine comprises a shell, a gearbox, a first motor, a grinding liquid tank, a bearing plate, a liquid discharge pipe, a bearing box, a second motor, a third motor, a rotating wheel, a grinding plate installation plate and a grinding plate, and is characterized in that a supporting beam is arranged on the shell and provided with a guide rail, a sensor, a cylinder and a controller, the bearing box is connected with the cylinder through a lifting rod, a slide block, a spray nozzle and a stabilizer are arranged on the outer wall of the bearing box, a cushion block and a movable block are arranged in the bearing box, the second motor is arranged on the cushion block, and the third motor is arranged on the movable block. The grinding plate grinds a workpiece according to the track shaped like the Arabic number '8' under the effect of the second motor and the third motor, the grinding plate is prevented from making complete contact with the workpiece, the ground workpiece can be rapidly cooled, and meanwhile the grinding precision of the workpiece can be improved.

Owner:ANHUI GENAN MULLERS

Real-time polishing pad stiffness-control using magnetically controllable fluid

A method of CMP polishing of a semiconductor wafer is described that includes using a polishing pad on a platen / table with the polishing pad including a sub-pad containing pockets of magnetorheological fluid. The stiffness of the sub-pad is controlled by selectively applying a magnetic field at selective pockets containing magnetorheological fluid to change the viscosity of the magnetorheological fluid. The changing stiffness increases the polishing rate of the pad in the areas of the magnetic field.

Owner:TEXAS INSTR INC

Fuel injector for internal combustion engines and method for making same

InactiveUS6349885B1Promote atomizationReduce manufacturing costFuel-injection pumpsSeat surface grinding machinesCombustion chamberInjector nozzle

Owner:BRP US

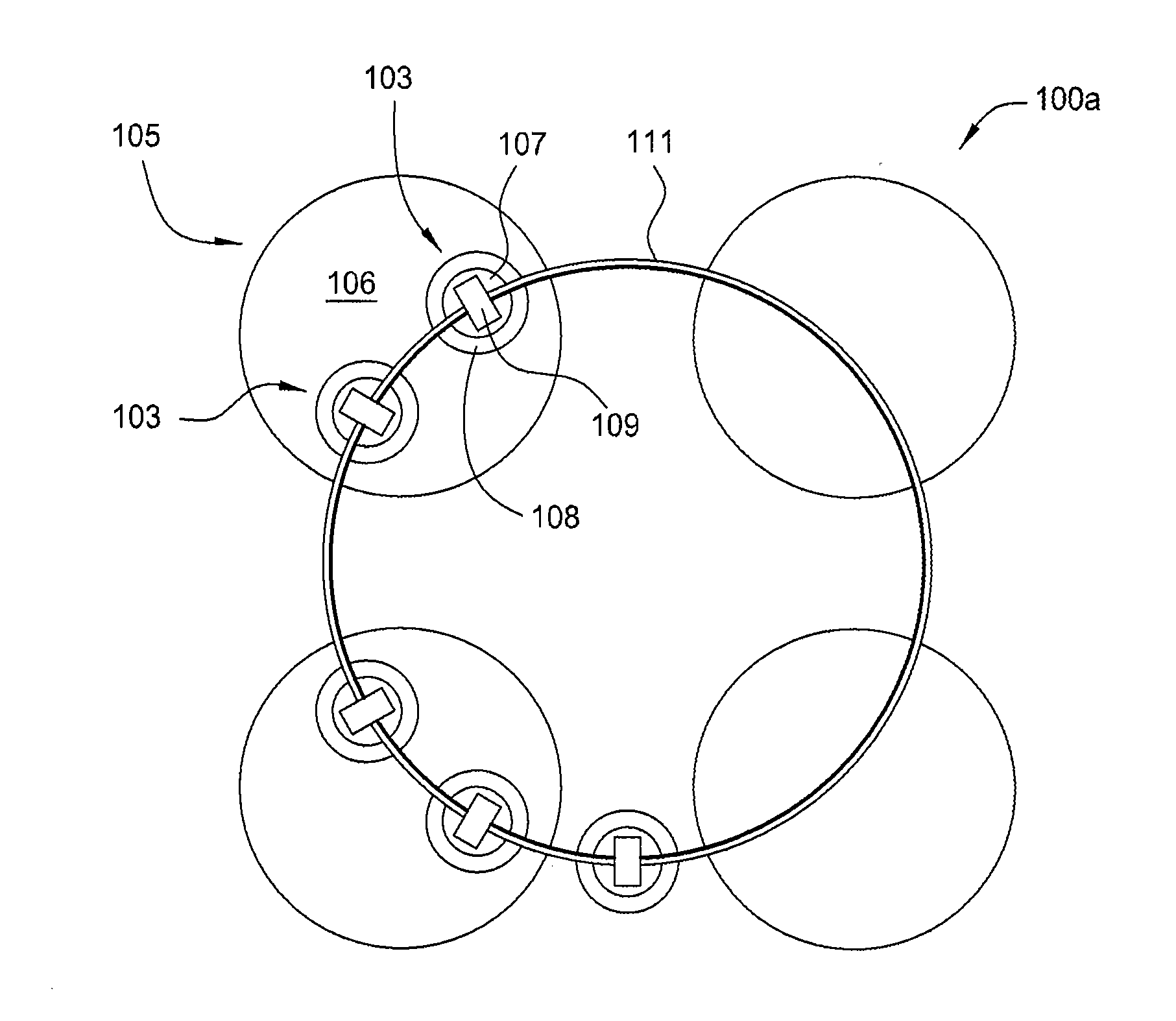

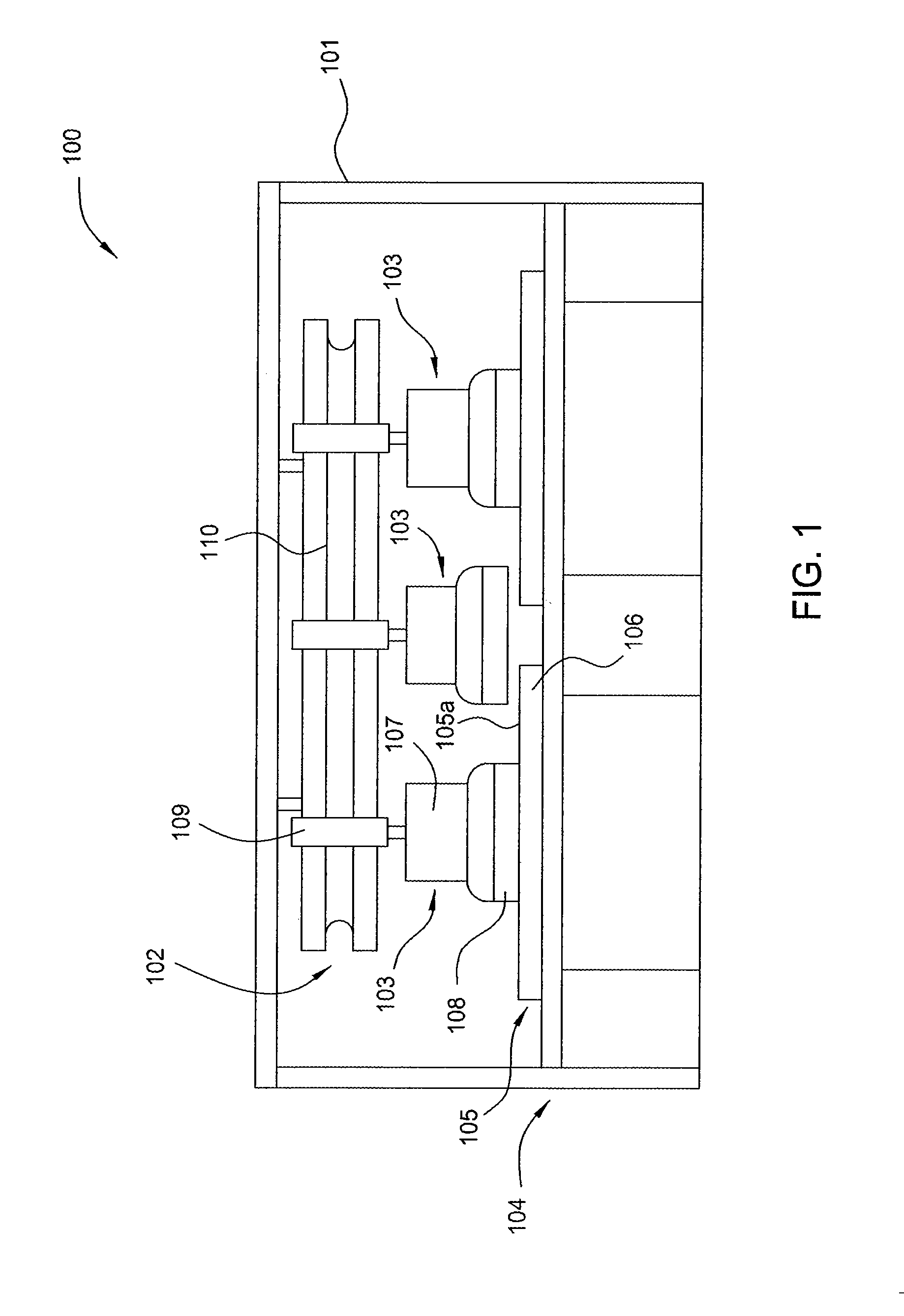

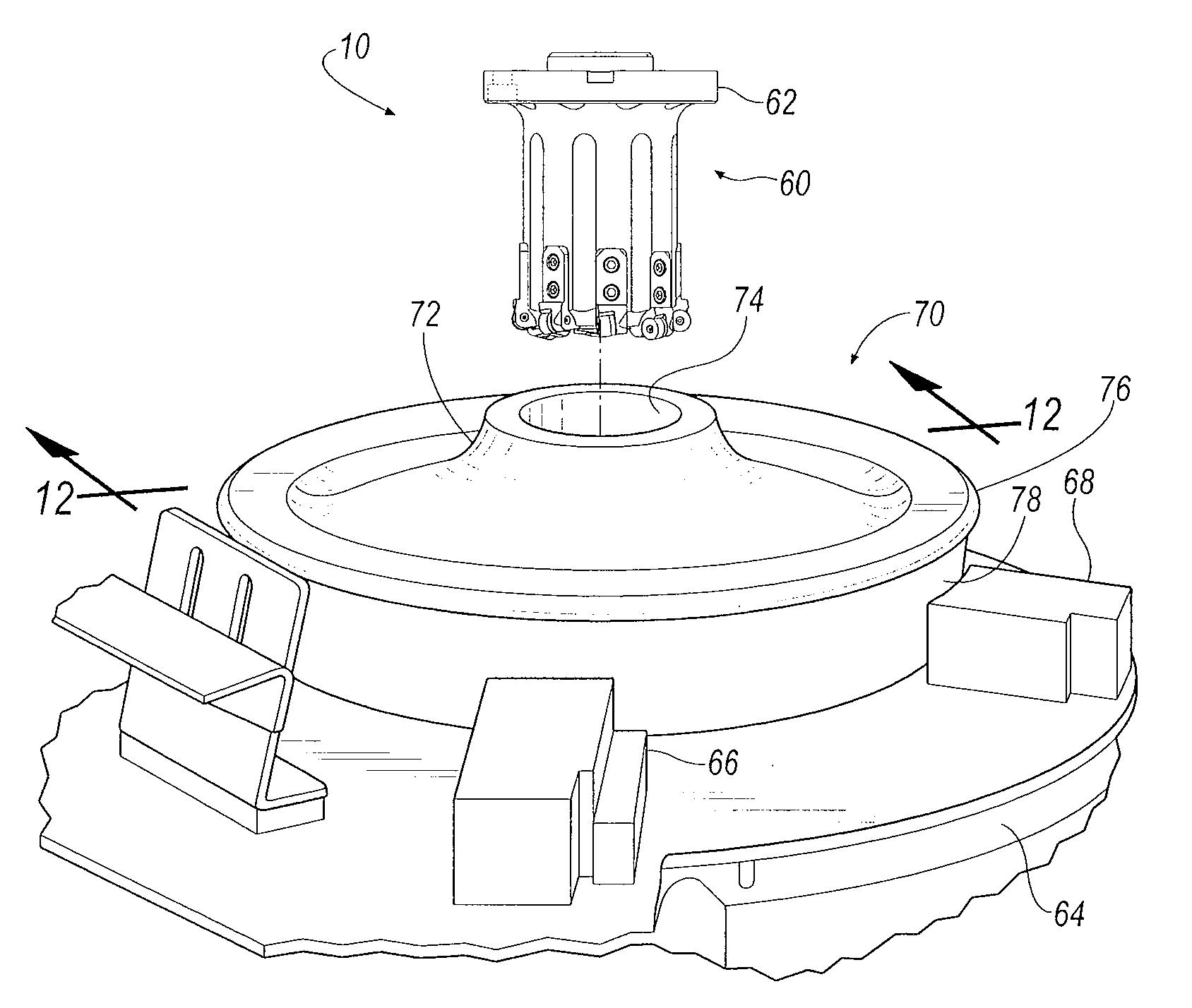

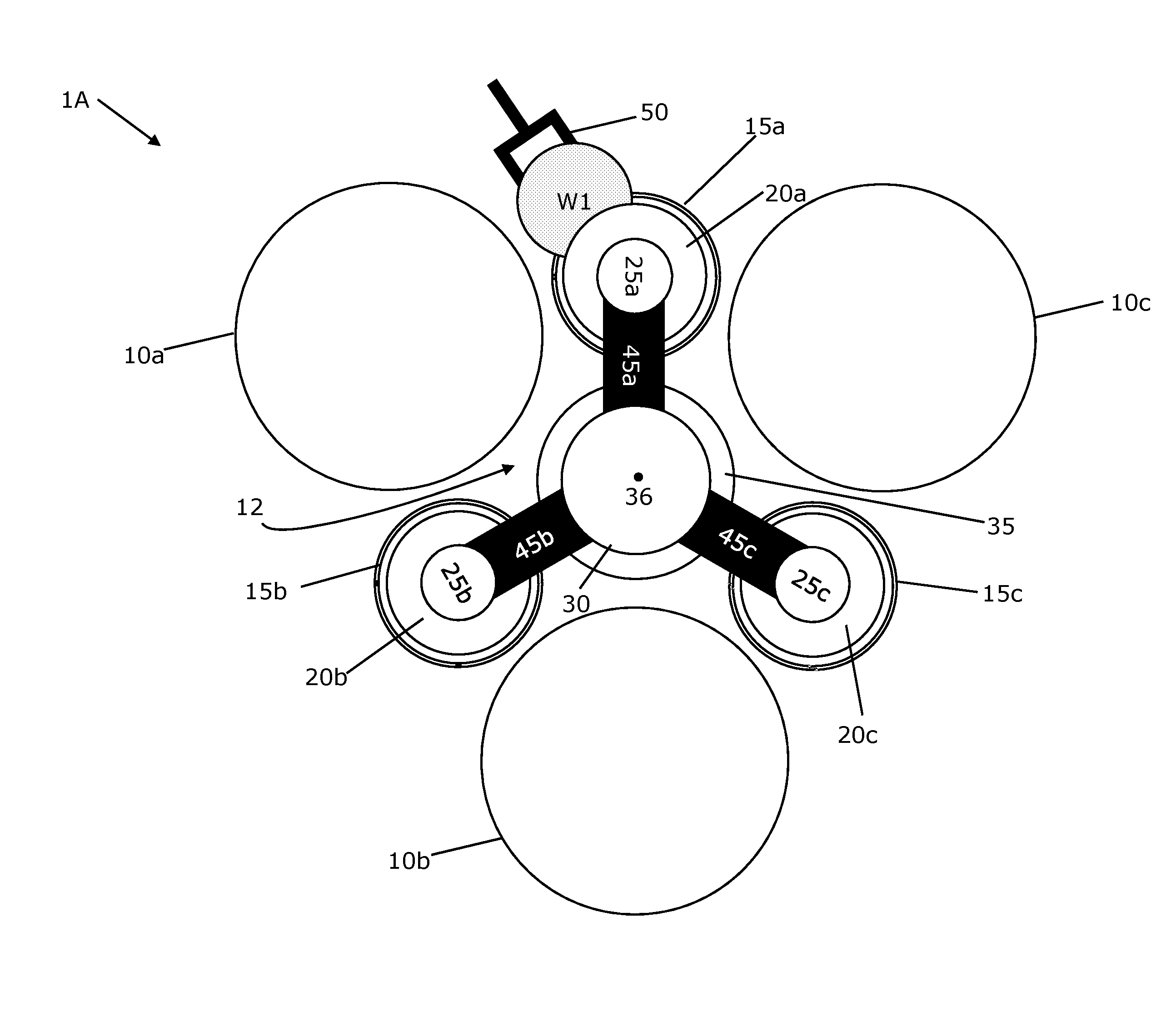

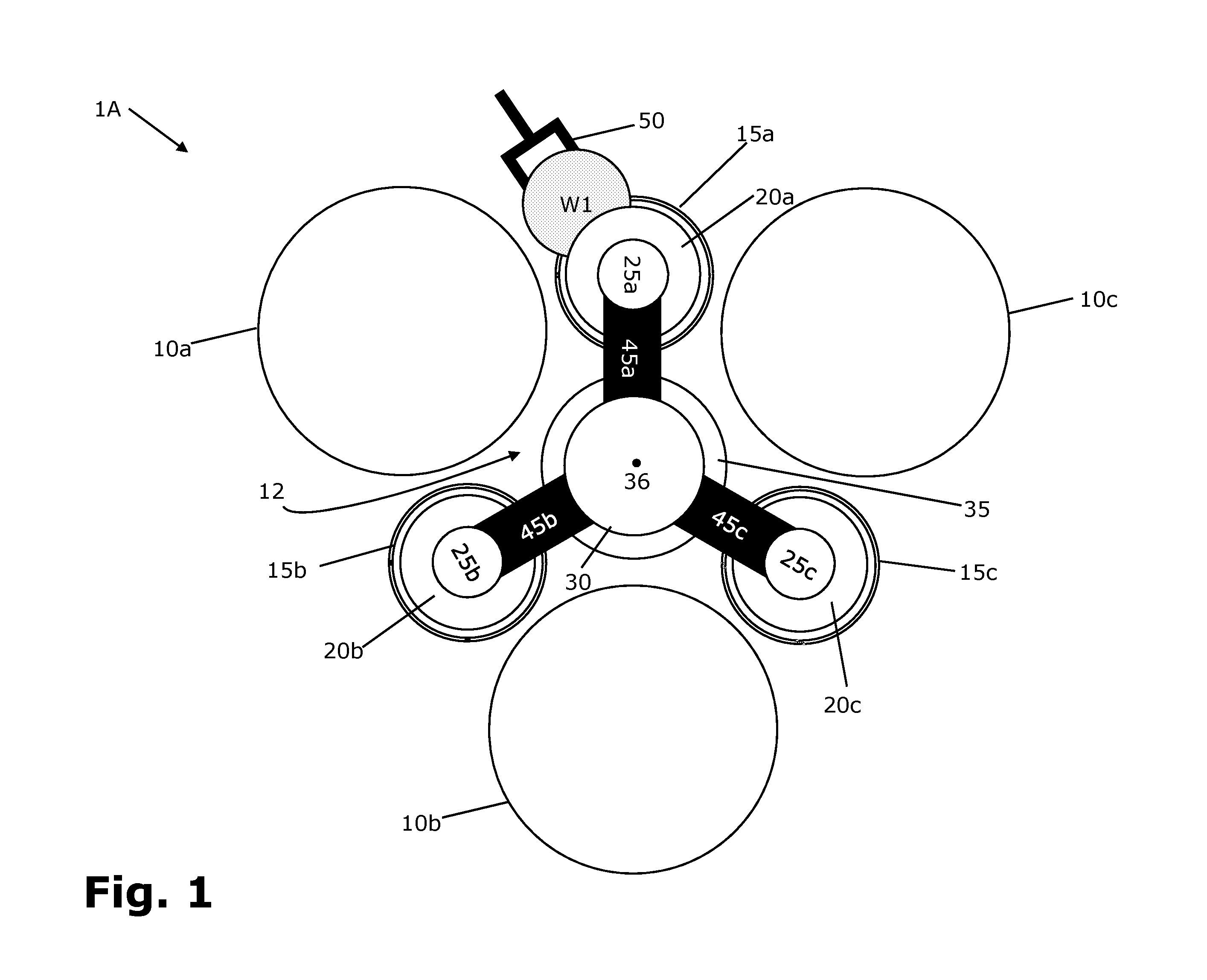

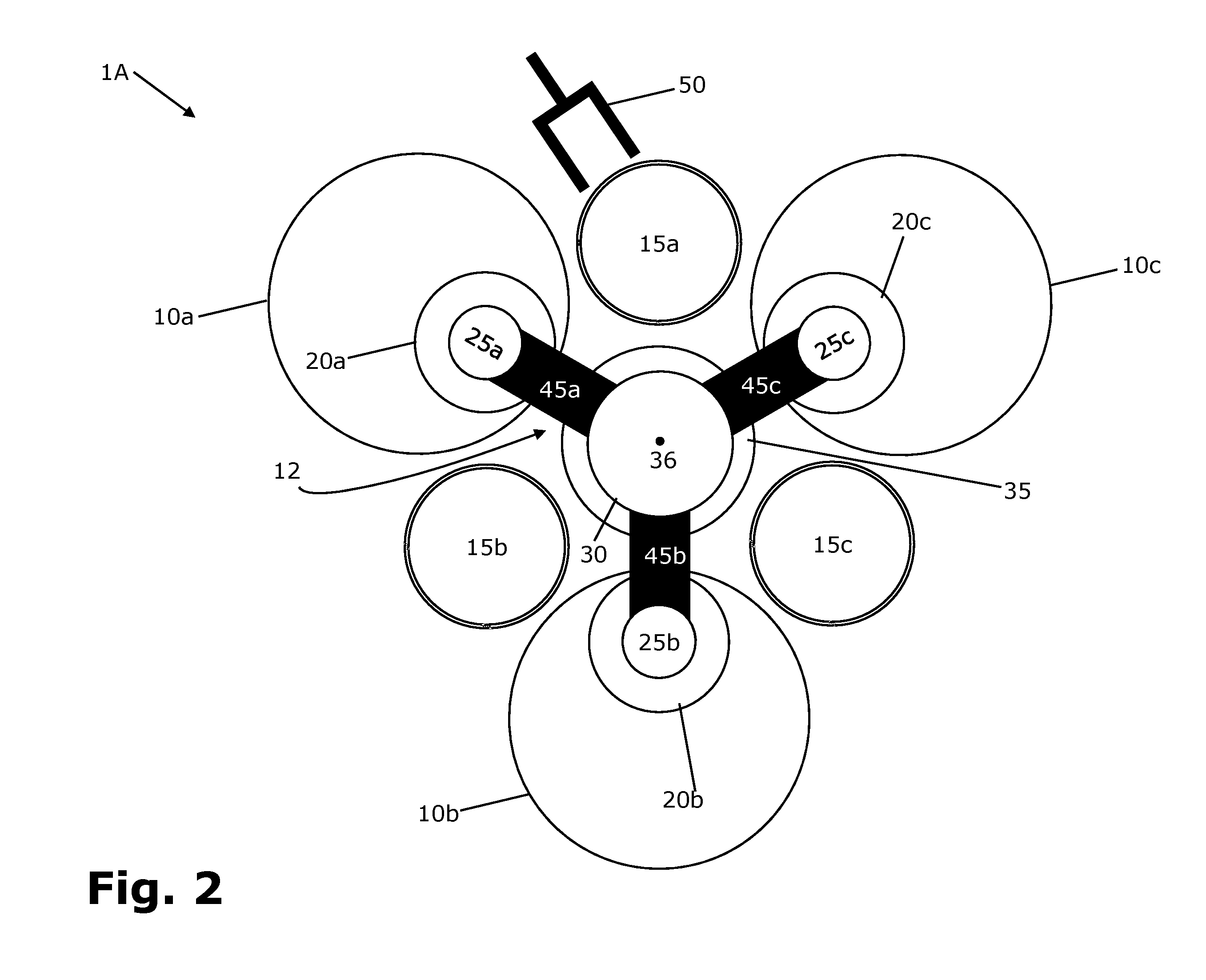

Apparatus and method for polishing semiconductor wafers

InactiveUS20080038993A1Seat surface grinding machinesLapping machinesSemiconductorElectrical and Electronics engineering

An apparatus and method for polishing semiconductor wafers uses multiple polishing surfaces, multiple polishing heads and multiple wafer stations to sequentially polish the semiconductor wafers. The wafer stations includes at least one wafer load-unload station to transfer the semiconductor wafers between the wafer load-unload station and the polishing heads.

Owner:KOMICO TECH

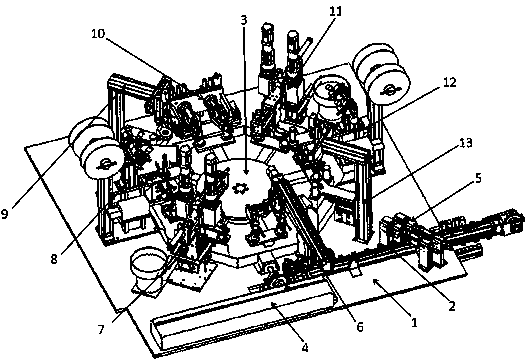

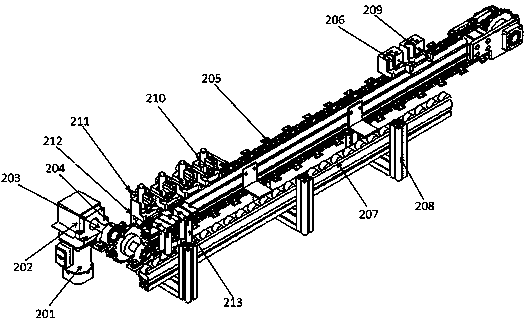

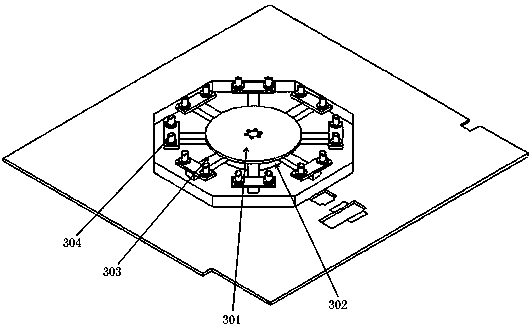

Automatic welding device for four-way valve end cap

ActiveCN108890057AReduce volumeImprove welding efficiencySeat surface grinding machinesGrinding feed controlFour-way valveEngineering

The invention discloses an automatic welding device for a four-way valve end cap. The automatic welding device consists of a supplied material delivery module, a capillary tube reshaping module, a turntable delivery module, a workpiece feeding and discharging module, a welding ring positioning and containing module, an automatic end cap welding module, a cooling and grinding detection module and aworkpiece overturning and reversing module. The modules perform independent actions, and coordination actions are achieved through a programmable controller. The automatic welding device can achieveautomatic welding of 1-2 products, the production takt is that welding of one product needs 5 seconds, the modules perform parallel actions, and the production efficiency is high only through linkageof the supplied material delivery module, the turntable delivery module and the workpiece feeding and discharging module. The automatic welding device for the four-way valve end cap is a full-automatic device, and the working efficiency and the stability of product quality are greatly improved.

Owner:CHINA JILIANG UNIV

Modular drill with diamond cutting edges

ActiveUS20120189393A1Thread cutting toolsDrilling/boring measurement devicesDiamond cuttingEngineering

A modular drill for machining applications includes a central pilot drill made of cemented carbide and outboard radial inserts having cutting edges with a diamond surface. Additionally, the diamond surface associated with the cutting edges includes indicia identifying each cutting edge, such that indexing of the inserts is made easier. To ensure the indicia withstands the harsh machining environment, the indicia is laser etched onto the diamond surface of the insert

Owner:KENNAMETAL INC

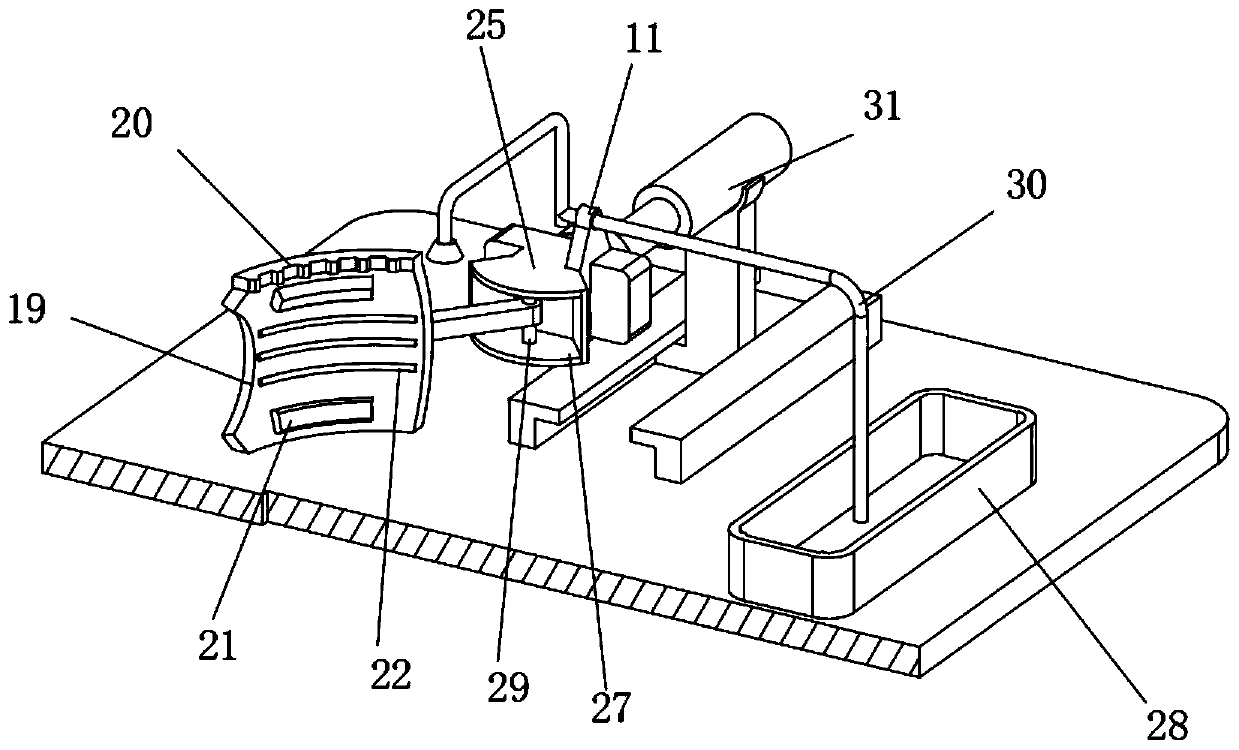

Valve sealing surface grinding miller

InactiveCN103962934AImprove grinding precisionReasonable grinding movementSeat surface grinding machinesLapping machinesEngineeringDrive motor

The invention discloses a valve sealing surface grinding miller used for grinding a workpiece. The valve sealing surface grinding miller comprises a rack, a motor vertically mounted on the rack, and a feed mechanism mounted at the top part of the rack. The feed mechanism can move left and right as well as up and down; the grinding miler further comprises a main shaft connected with an output shaft of the motor, a grinding disc horizontally arranged on the main shaft, and a drive component fixed on the feed mechanism and used for regulating the space position of the drive component through the feed mechanism. The drive component comprises a drive motor, and a chuck connected with an output shaft of the drive motor. The valve sealing surface grinding miller can realize multiple functions, and can grind a sealing surface of a valve plate or a valve clack as well as a sealing surface of a valve seat in a valve body. The grinding precision is high, and the grinding movement, the grinding speed and the grinding force are more reasonable.

Owner:SHANGHAI PUDONG HANWEI VALVE

Ball valve and processing equipment thereof

PendingCN111306315AImprove grinding efficiencyImprove sealingPlug valvesSpherical surface grinding machinesEngineeringMaterials science

The invention discloses a ball valve and processing equipment thereof. The ball valve comprises a ball valve ball body, a channel is arranged in the ball valve ball body, two sealing clamping groovesare symmetrically formed in the outer side of the ball valve ball body, a valve rod is connected to one end of the ball valve ball body, a rotary rod is connected to the other end of the ball valve ball body, a working table for placing is arranged at the bottom of the ball valve ball body, the rotary rod and the valve rod are correspondingly connected with the two sides of the working table, anda polishing piece used for polishing the ball valve ball body is connected to the working table. The two sealing clamping grooves are formed in the outer side of the ball valve ball body, and the sealing of the ball valve ball body and a ball valve body during sealing is helped to be improved; meanwhile, when the ball valve ball body is produced, a radial piece and an axial piece correspondingly arranged in the polishing piece simultaneously polish the ball valve ball body, and the polishing processing efficiency during ball valve ball body production is conveniently improved; and meanwhile, when the ball valve ball body is polished, a spraying piece performs cooling processing on the surface of the ball valve ball body and the polishing piece, and the protection of the ball valve ball body and the polishing piece is facilitated.

Owner:VALVE BIWEI VALVE CO LTD

Insert for drill

ActiveUS20110164936A1Good chip removal effectWide spaceThread cutting toolsWood turning toolsMechanical engineeringEngineering

A drill insert of the present invention comprises a corner part, and an upper face having a first side and a second side disposed on both sides of the corner part, respectively. The drill insert comprises a first cutting edge formed along the first side; a second cutting edge formed along the second side; a first region of the upper face located along the first cutting edge;a second region of the upper face located along the second cutting edge; and a first raised part disposed in the first region so as to lie at a higher position than the second region. The first raised part has an upper portion; a breaker portion configured to be inclined so as to become at a lower position as the first raised part extends from the upper portion; and a side portion configured to be inclined so as to become at a lower position as the side portion extends from the upper portion. The first raised part is disposed at a position closer to the first cutting edge than a bisector of the corner part when viewed from above.

Owner:KYOCERA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com