Auxiliary overlap joint hydraulic match grinding process for spool valve of servo valve

A technology of spool valve pair and servo valve, which is applied in the field of matching grinding process of servo valve spool valve pair overlap, which can solve the problems of no curve interpretation, complex structure of servo valve, not easy to block, etc., and achieve equipment testing The effect of faster speed, less repeated testing, and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The hydraulic matching grinding process of the lap joint of the servo valve spool valve pair is as follows:

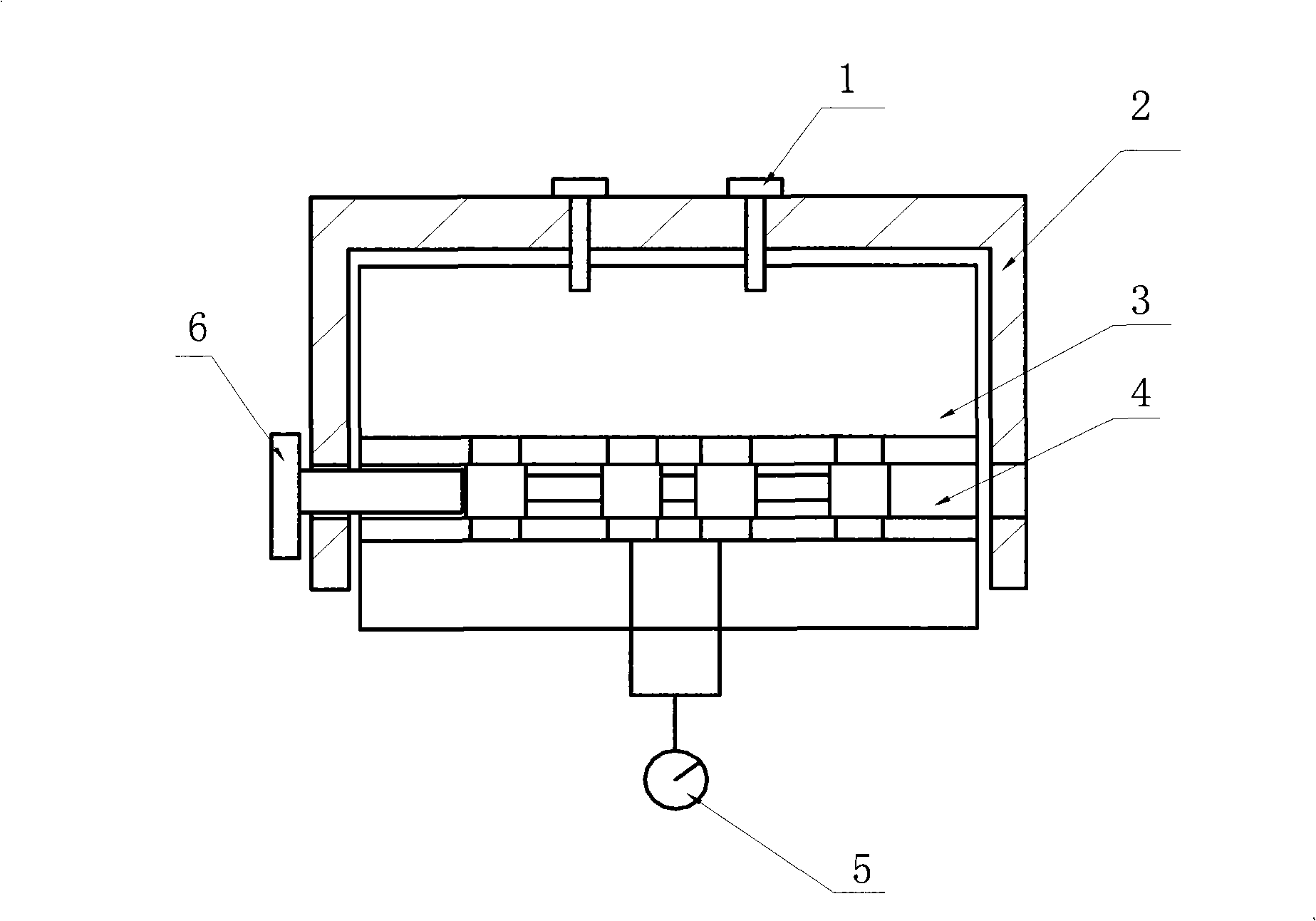

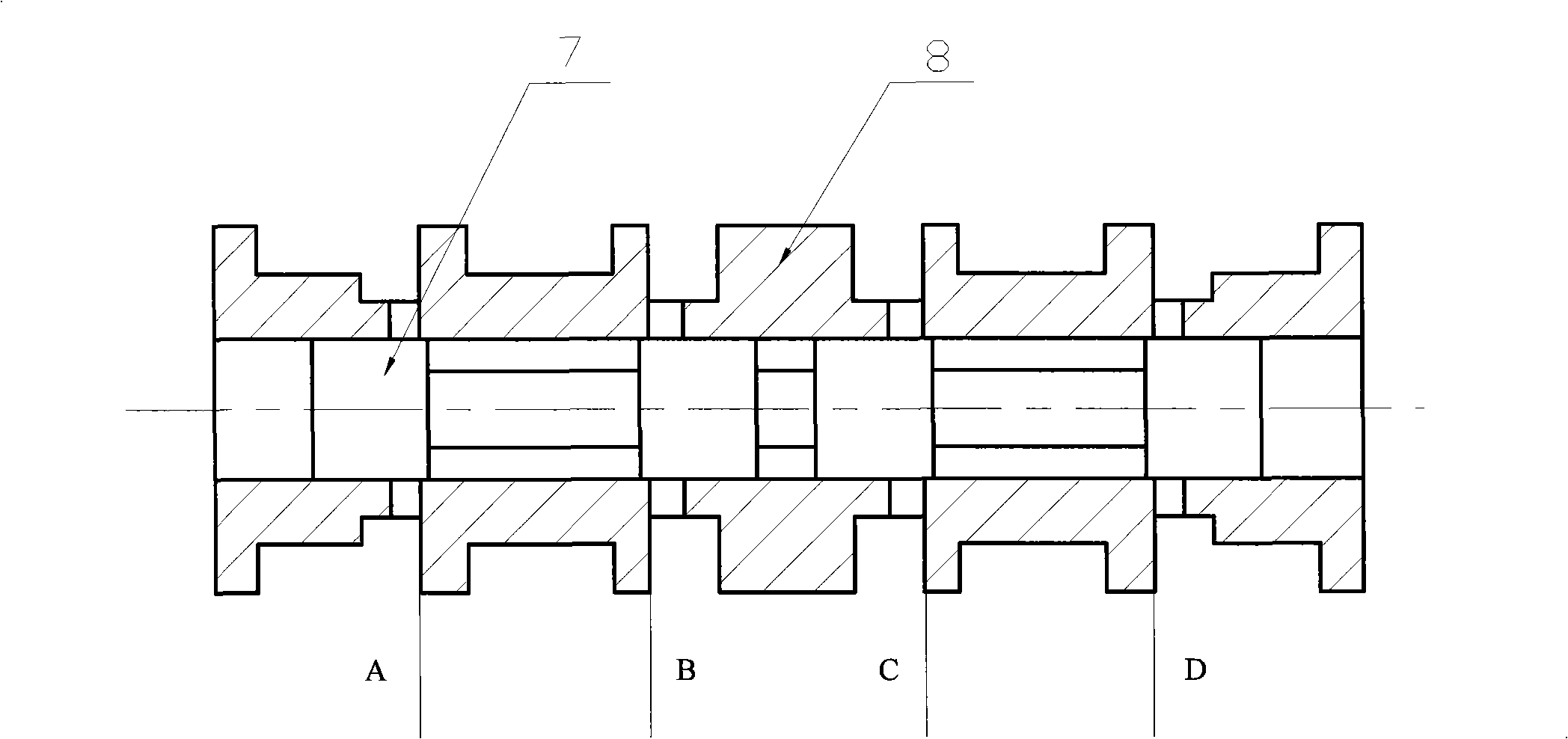

[0022] (1) if figure 1 As shown, the servo valve spool pair 4 is installed in the process shell 3, and the oil passages on the process shell 3 are sealed by using the sealing plug and the integral pressure sleeve 2, and the integral pressure sleeve 2 and the process shell 3 It is fixed by the fastening screw 1, the displacement sensor 6 is installed at one end of the servo valve spool, and the flow sensor 5 is installed in the feedback chamber of the spool valve pair. The schematic diagram of the spool valve pair is as follows figure 2 As shown, where A, B, C, D represent the working side of the slide valve pair;

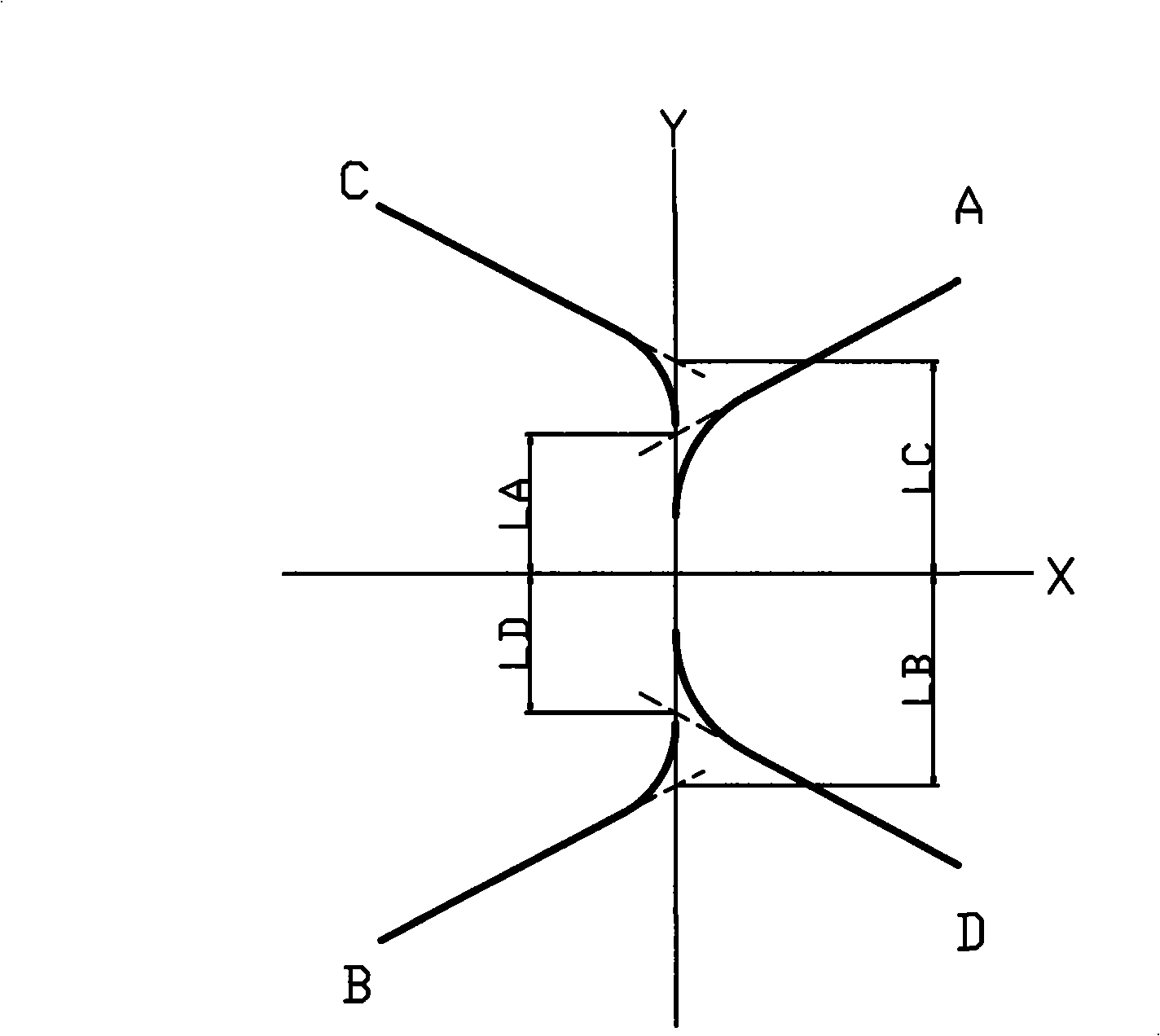

[0023] (2) supply oil to the spool valve pair 4, start the test, drag the servo valve spool 7 back and forth, draw the matching grinding curve of the spool valve pair 4 working side according to the displacement sensor 6 and the flow sensor 5 collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com