An integrated oil filter assembly for a servo valve

A servo valve, oil filter technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of waste product production cycle, inability to meet matching requirements, and low qualification rate of oil filter components , to achieve the effect of improving the qualification rate of debugging, saving manpower and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

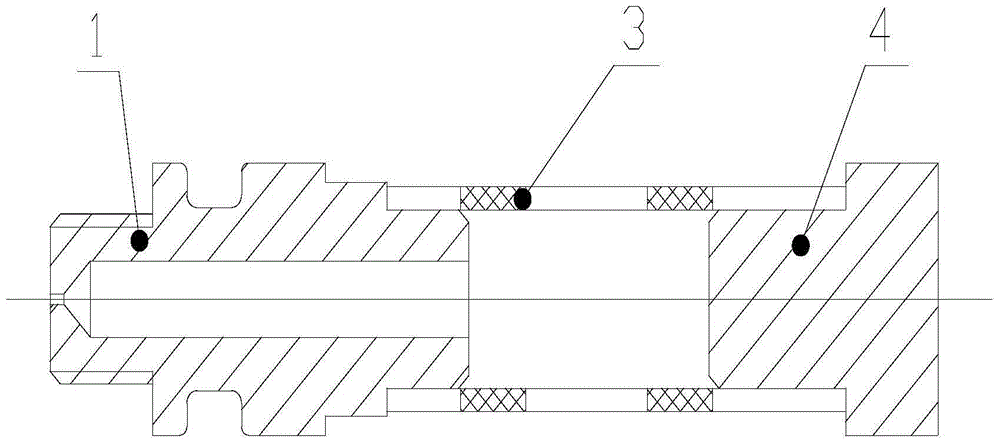

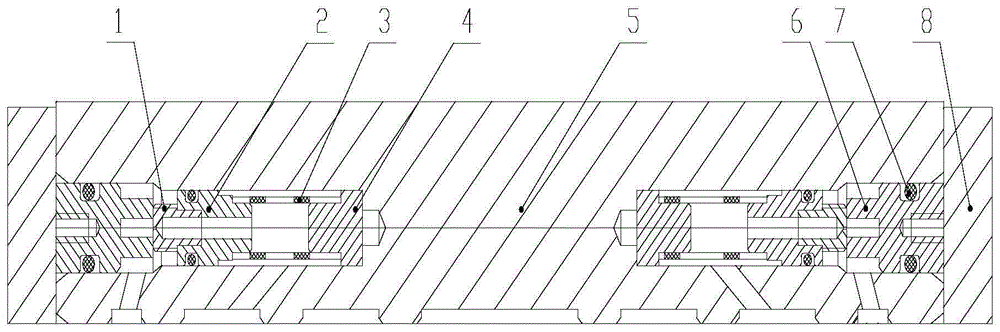

[0020] Such as figure 1 As shown, the oil filter assembly of the present invention includes an orifice 1, a filter tube 3 and an oil filter plug 4; one side of the orifice 1 is an external thread structure, the other side is welded with a filter tube 3, and the other side of the filter tube 3 is Welded oil filter plug 4; there is a cylindrical hole on the side of the throttle hole 1 close to the filter tube 3, and a conical hole on the side of the external thread structure, and the apex of the cone penetrates through a small hole. 5 are sealed by a radial sealing ring 7.

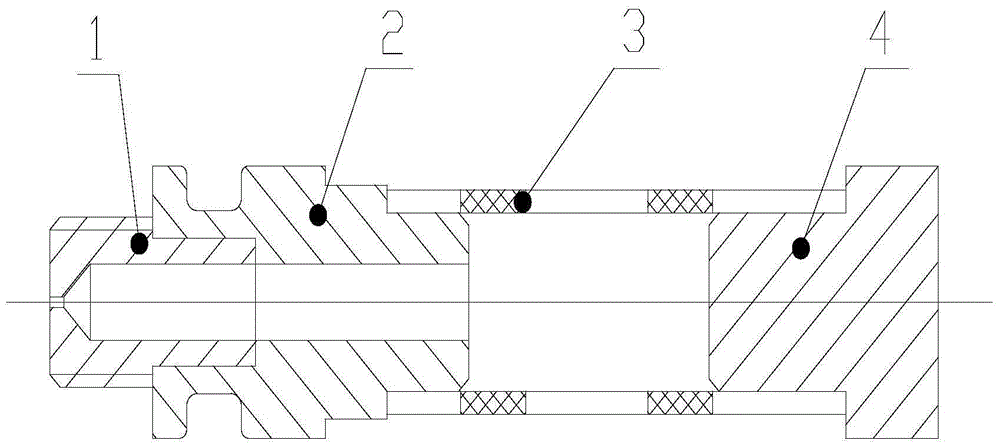

[0021] figure 2 Provides an integrated oil filter assembly that can quickly disassemble the throttle hole, including the throttle hole 1, the oil filter plug 2, the filter tube 3 and the oil filter plug 4; the two ends of the filter tube 3 are fixedly connected to the oil filter by welding The outer plug 2 and the oil filter plug 4; the through hole of the oil filter outer plug 2 is a stepped hole, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com