Device for grinding sealing face of valve seat of high temperature and high pressure valve

A high-pressure valve and grinding device technology, which is applied to seat surface grinders, grinders, grinding/polishing equipment, etc., can solve the problems of difficult manufacturing, transportation, difficult maintenance and grinding progress, and long grinding period, so as to shorten the grinding period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

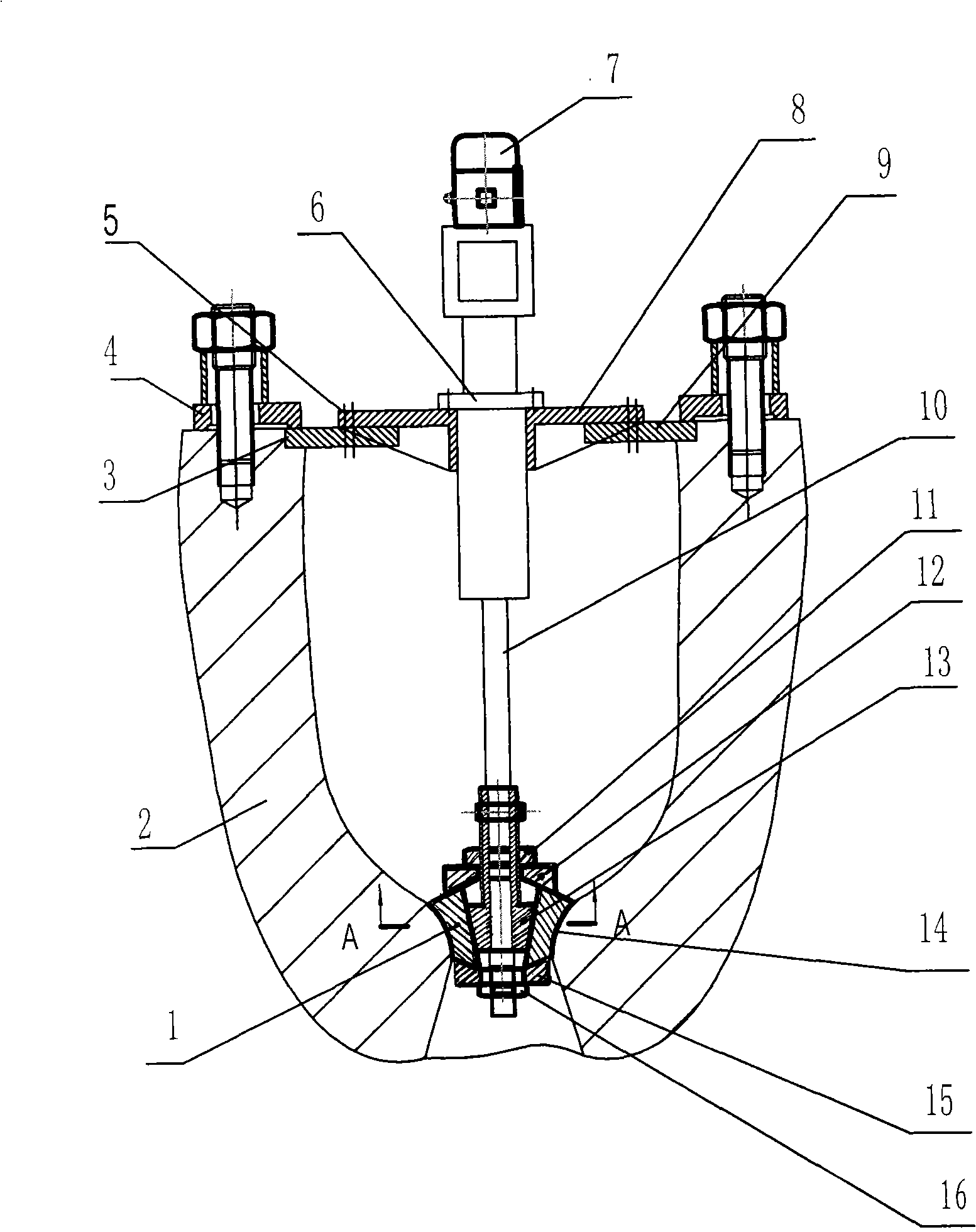

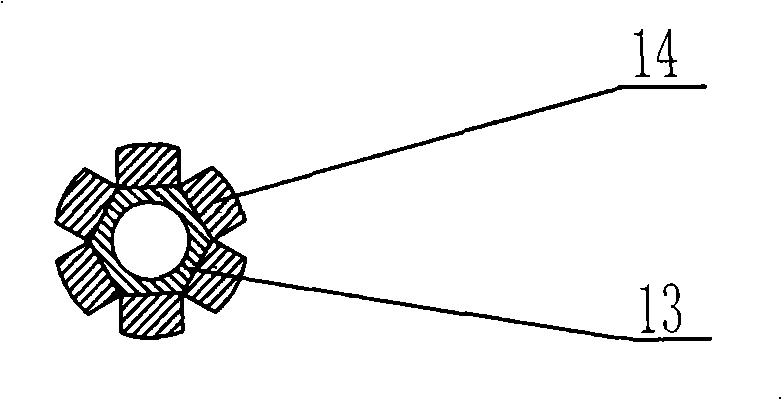

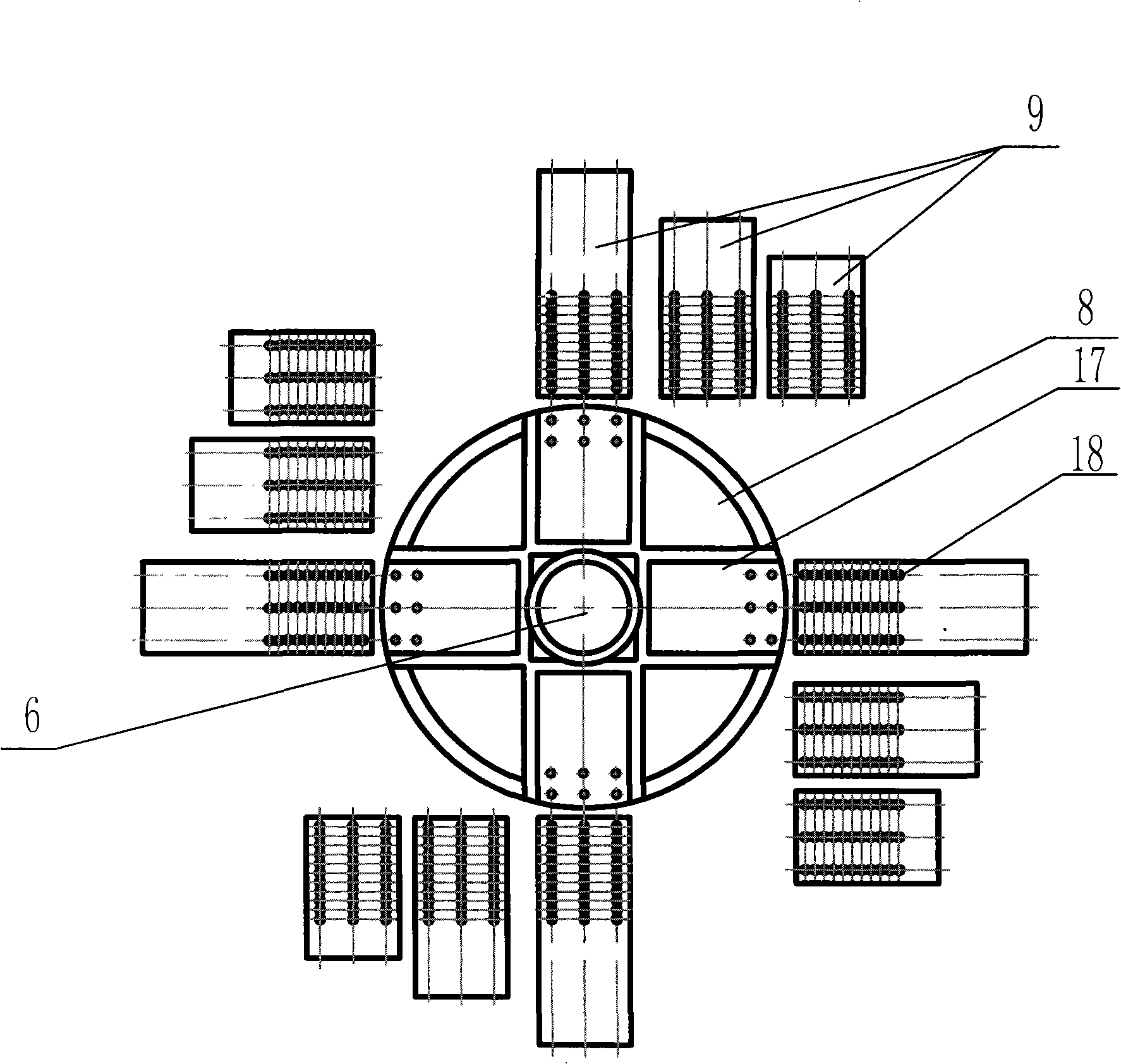

[0012] See Figure 1-3 , the specific technical solution of the present invention is as follows: the outer peripheral surface of the mounting seat 13 is composed of six tapered planes, the mounting seat 13 is fixedly connected to the grinding rod 10, and six grinding blocks 1 are assembled on the outer periphery of the mounting seat 13. The upper and lower ends of the three grinding blocks 1 are conical after the combination of the outer peripheral surfaces of the mounting seat 13, and the outer peripheral surfaces of the six grinding blocks 1 are curved surfaces 14 (coinciding with the sealing profile of the valve seat 2), and the upper and lower pressure discs 12, 15 and the upper and lower conical surfaces of the six grinding blocks 1 are also conical surfaces, and the upper and lower pressure discs 12 and 15 are threadedly connected to the grinding rod 10, and the grinding head combined with the six grinding blocks 1 is fixed on the grinding On the rod 10, upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com