Grinding mechanism for valve core and valve seat

A technology of grinding mechanism and valve seat, which is applied in the direction of seat surface grinder, grinding machine parts, grinding machine, etc., can solve the problems of low production efficiency and inability to detect the tightness of valve core and valve seat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

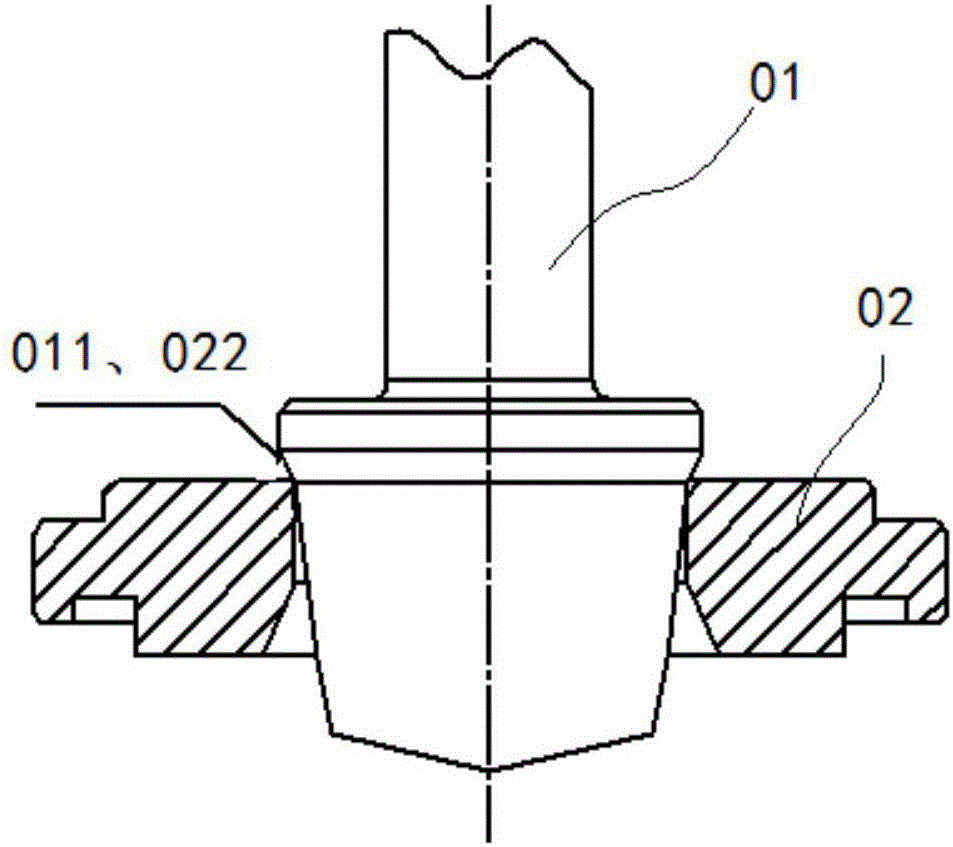

[0048] This embodiment provides a valve core valve seat grinding mechanism, such as image 3 shown, including:

[0049] The first installation frame 1 has a first installation space 31 suitable for installing the valve seat 5, and a first air hole 41 communicating with the first installation space 31 and the atmosphere;

[0050] The second installation frame 2 has a second installation space 32 suitable for installing the valve core 6, and a second air hole 42 communicating with the second installation space 32 and the atmosphere;

[0051] The first installation frame 1 can move toward the direction close to the second installation frame 2, so that the first installation space 31 and the second installation space 32 are butted to form a closed space, when the valve seat is installed 5, the first installation space 31 and the second installation space 32 can only communicate through the hole 50 of the valve seat 5 to be ground; when the valve core 6 is installed, the valve cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com