Valve sealing surface grinding miller

A sealing surface and grinding machine technology, which is applied in the direction of grinding machine tools, grinding devices, seat surface grinding machines, etc., can solve the problem of low product precision, difficulty in achieving ideal precision for valve seat sealing surfaces, and manual grinding efficiency of valve discs, valve plates, and gates Low-level problems, to achieve the effect of high grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

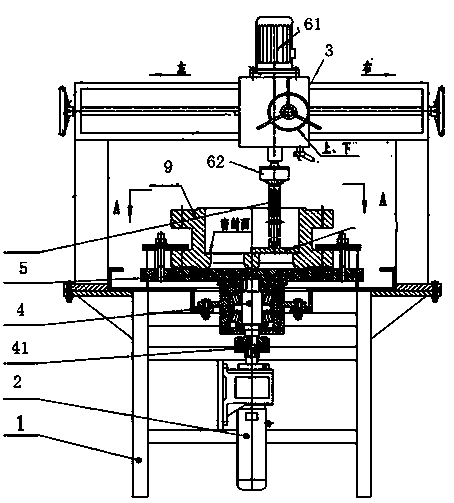

[0030] Such as figure 1 As shown, a valve sealing surface grinding machine is used to grind the sealing surface of the workpiece 9. The sealing surface of the workpiece 9 is the sealing surface of the valve seat in the valve body, including a frame 1 and a motor 2 vertically installed on the frame 1. , and the feed mechanism 3 installed on the top of the frame 1, the feed mechanism 3 can move left and right, up and down, the grinding machine also includes: the main shaft 4, which is connected with the output shaft of the motor 2 through a coupling 41; the grinding disc ( 5) It is horizontally arranged on the main shaft 4 through the flange; the drive assembly is fixed on the feed mechanism 3, and the spatial position of the drive assembly is adjusted through the feed mechanism 3. The drive assembly includes a drive motor 61, and The chuck 62 connected to the output shaft of the driving motor 61, the driving motor 61 is matched with a gearbox with multiple sets of exchanging ge...

Embodiment 2

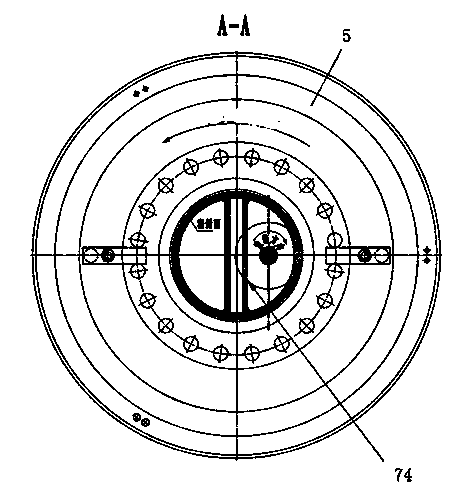

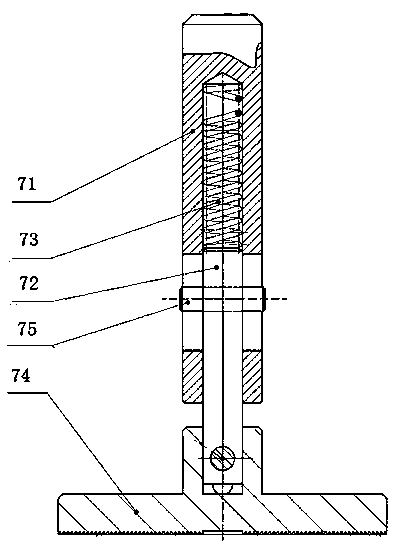

[0034] Such as Figure 4 , 5 As shown, a valve sealing surface grinding machine is used to grind the sealing surface of the workpiece 9. The sealing surface of the workpiece 9 is a valve disc and a valve plate sealing surface, including a frame 1 and a motor vertically installed on the frame 1. 2, and the feeding mechanism 3 installed on the top of the frame 1, the feeding mechanism 3 can move left and right, up and down, the grinding machine also includes: the main shaft 4, which is connected with the output shaft of the motor 2; the grinding disc 5, which is arranged horizontally On the main shaft 4, there are alveolar grooves or flat threads on the surface of the grinding disc 5; the drive assembly is fixed on the feed mechanism 3, and the spatial position of the drive assembly is adjusted by the feed mechanism 3, and the drive assembly includes a drive Motor 61, the chuck 62 that links to each other with drive motor 61 output shafts; 3 sleeve grinding assemblies, its circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com