Grinding tool for sealing face of safety valve

A technology for grinding tools and sealing surfaces, which is applied in the field of grinding tools for sealing surfaces of safety valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

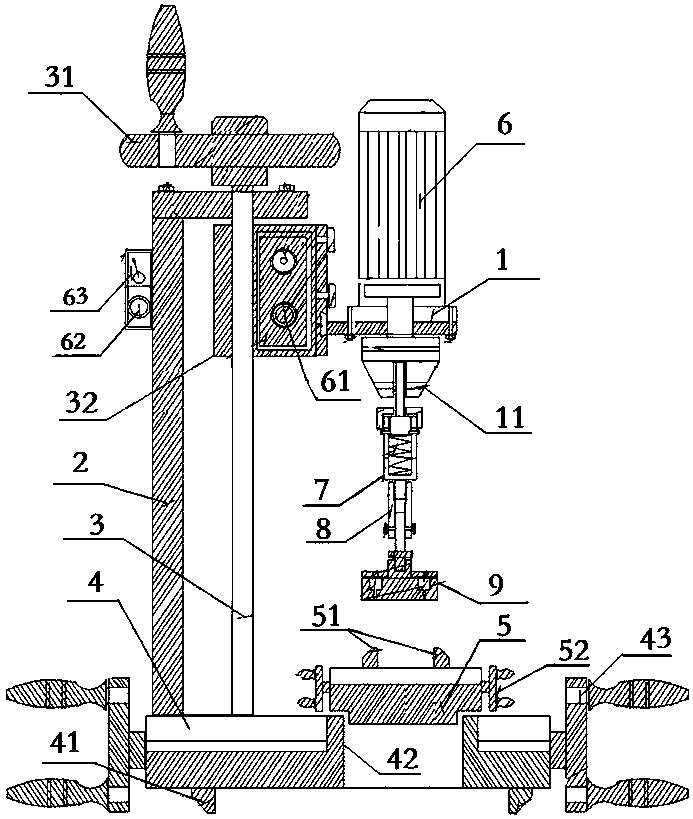

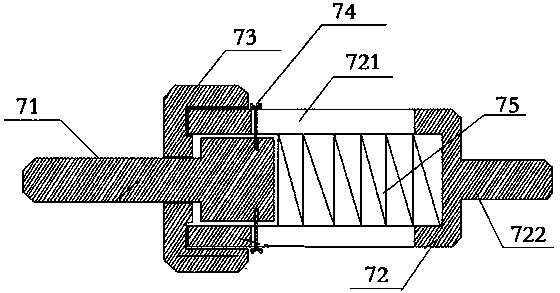

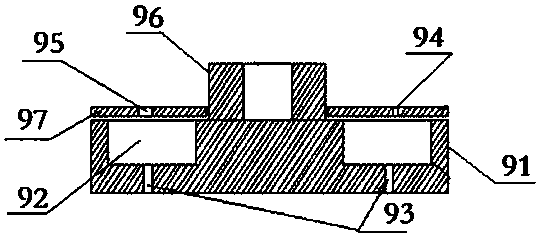

[0020] Such as figure 1 As shown, a safety valve sealing surface grinding tool includes a fixed wall 2, a grinding motor 6, a grinding head 9 and a preload disc, the grinding motor 6 is a low-speed grinding motor and is installed on the fixed wall 2, and the grinding motor The motor switch 61 of 6 is fixed on the lifting block 32, is also provided with the speed control knob 62 that controls the grinding motor 6 rotating speeds and the current pointer meter 63 that shows the grinding motor 6 current, the speed regulation knob 62 and the current pointer meter 63 are all fixed on the fixed On the wall 2, the grinding head 9 is installed on the output shaft of the grinding motor 6, and there are two types of grinding heads 9, namely, the valve seat grinding head and the disc grinding head, such as image 3 As shown, the grinding disc 91 in the valve seat grinding head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com