Transmission device of reduction gearbox of hollow cooling tower

A transmission device and cooling tower technology, applied in the direction of transmission device parts, belt/chain/gear, mechanical equipment, etc., can solve the vibration cracking at the connection between the fan helical blade and the drum, increase the equipment maintenance workload and maintenance cost, the main shaft Bearing large radial clearance and other problems, to solve the problem of frequent oil leakage, reduce equipment maintenance workload, and ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

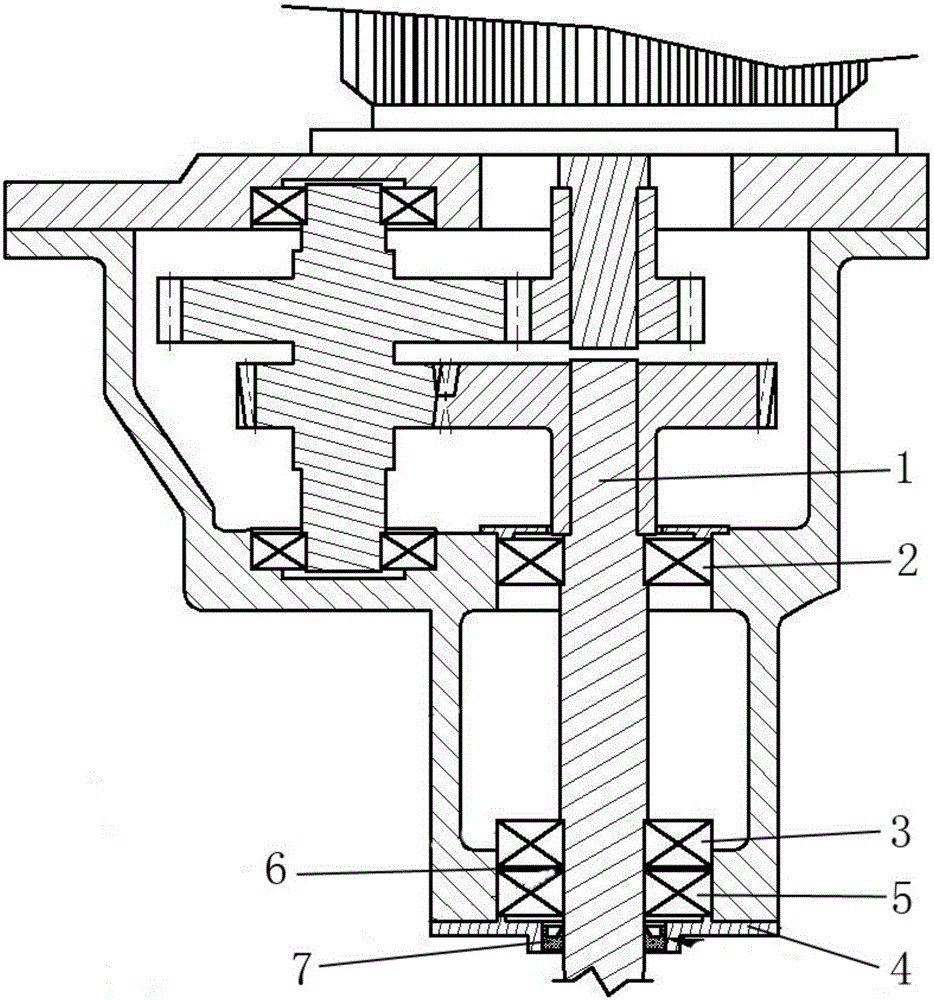

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0023] Please refer to figure 1 , the transmission device of the hollow cooling tower reduction box includes a gear box, a vertically arranged fan main shaft 1 is installed in the gear box, the lower end of the fan main shaft 1 extends to the outside of the gear box, and the upper and lower parts of the fan main shaft 1 are respectively set There are a first main shaft bearing 2 and a second main shaft bearing 3, the first main shaft bearing 2 and the second main shaft bearing 3 are respectively located in the upper mounting hole and the lower mounting hole of the gearbox, and the part of the blower main shaft 1 extending to the outside of the gearbox is covered with Bearing lower gland 4, the lower part of the fan main shaft 1 is also fitted with a third main shaft bearing 5, the third main shaft bearing 5 is located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com