Patents

Literature

225results about How to "Good chip removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

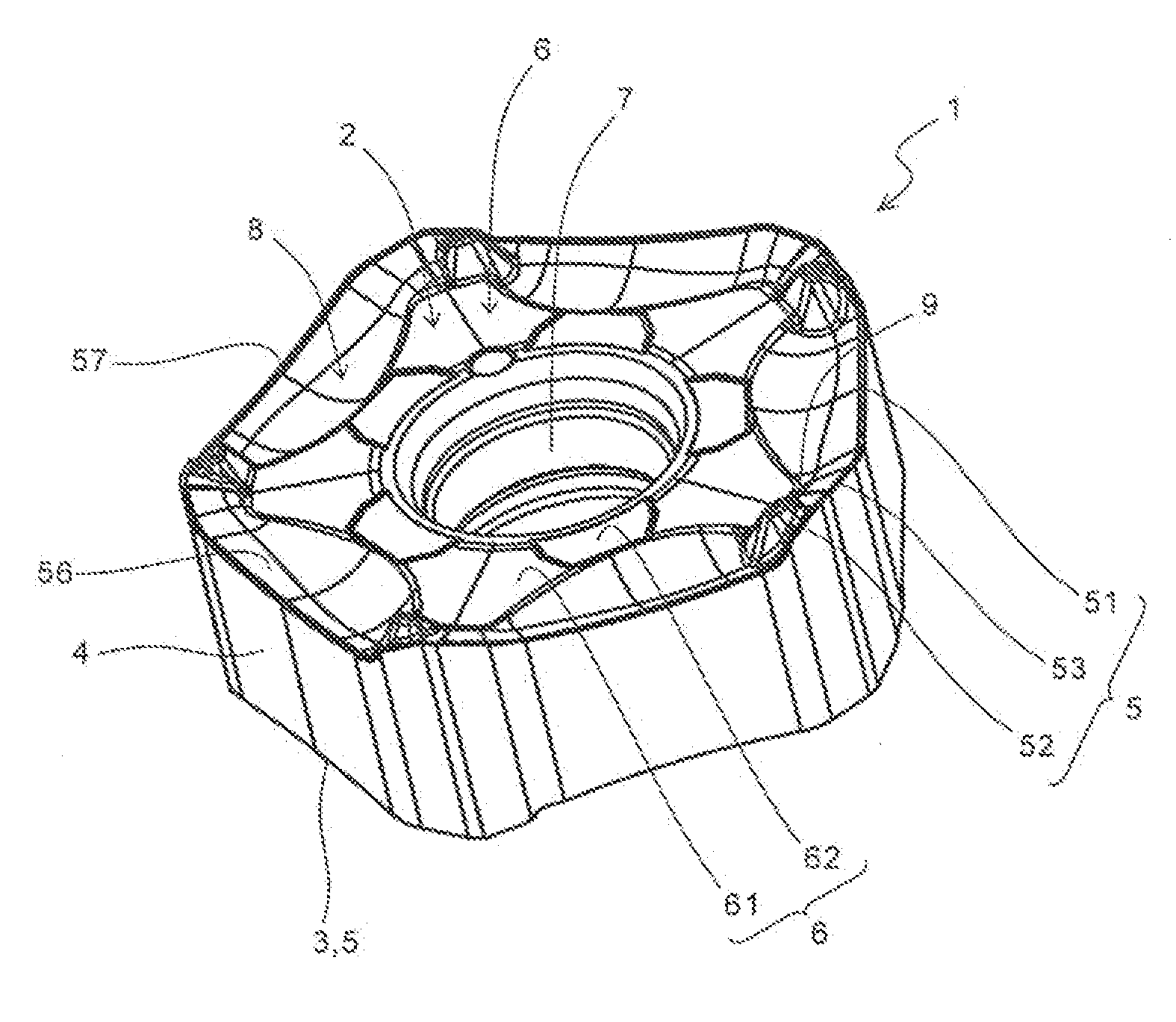

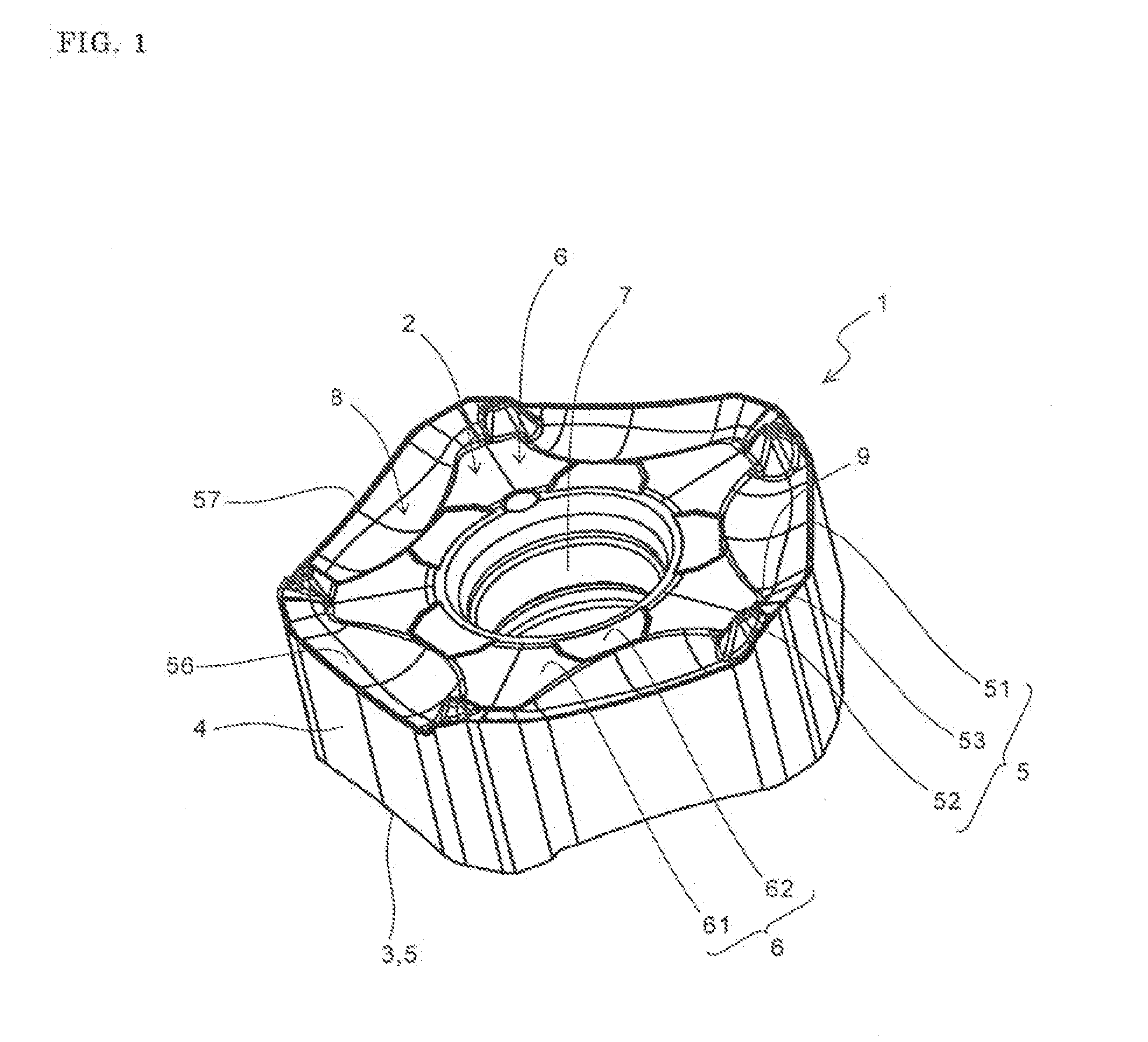

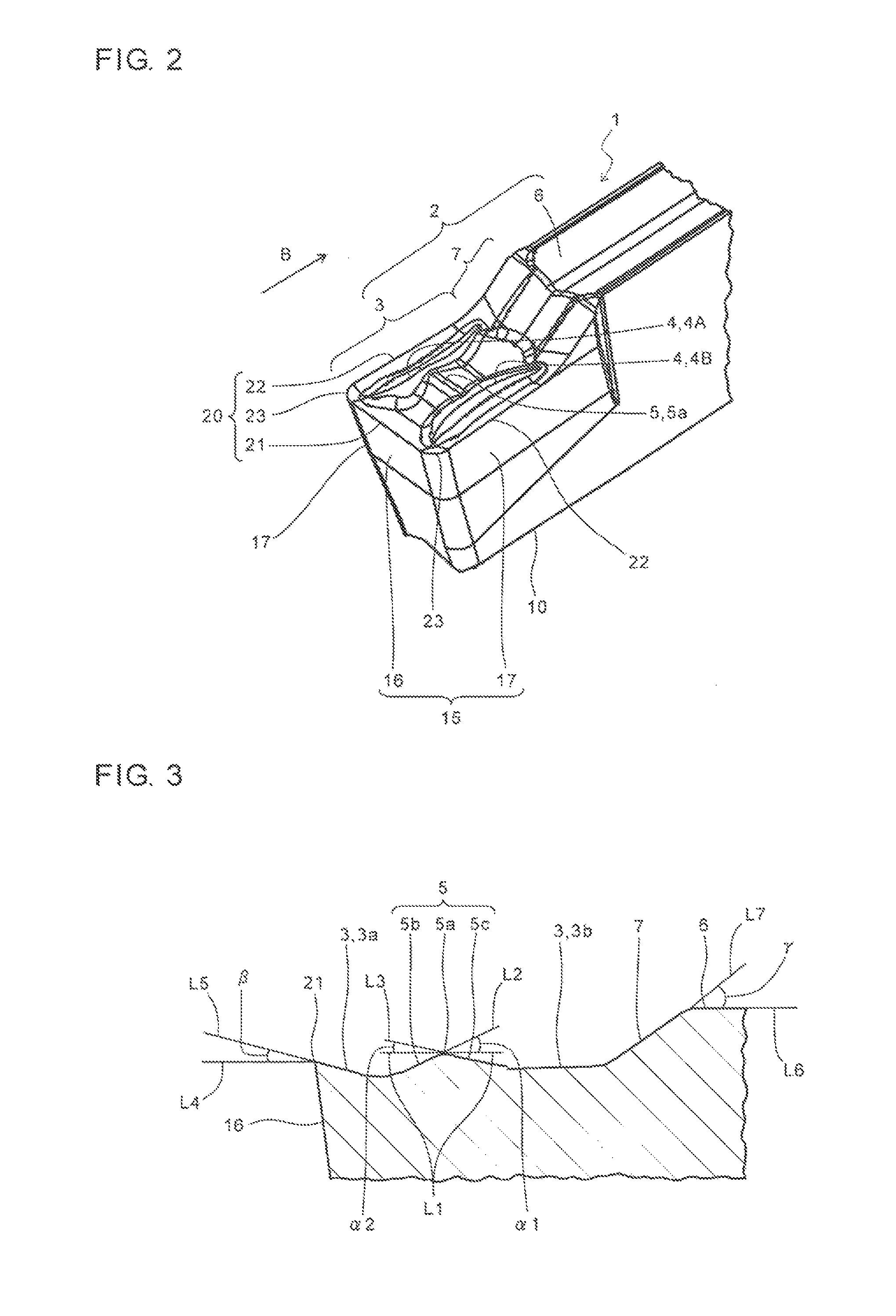

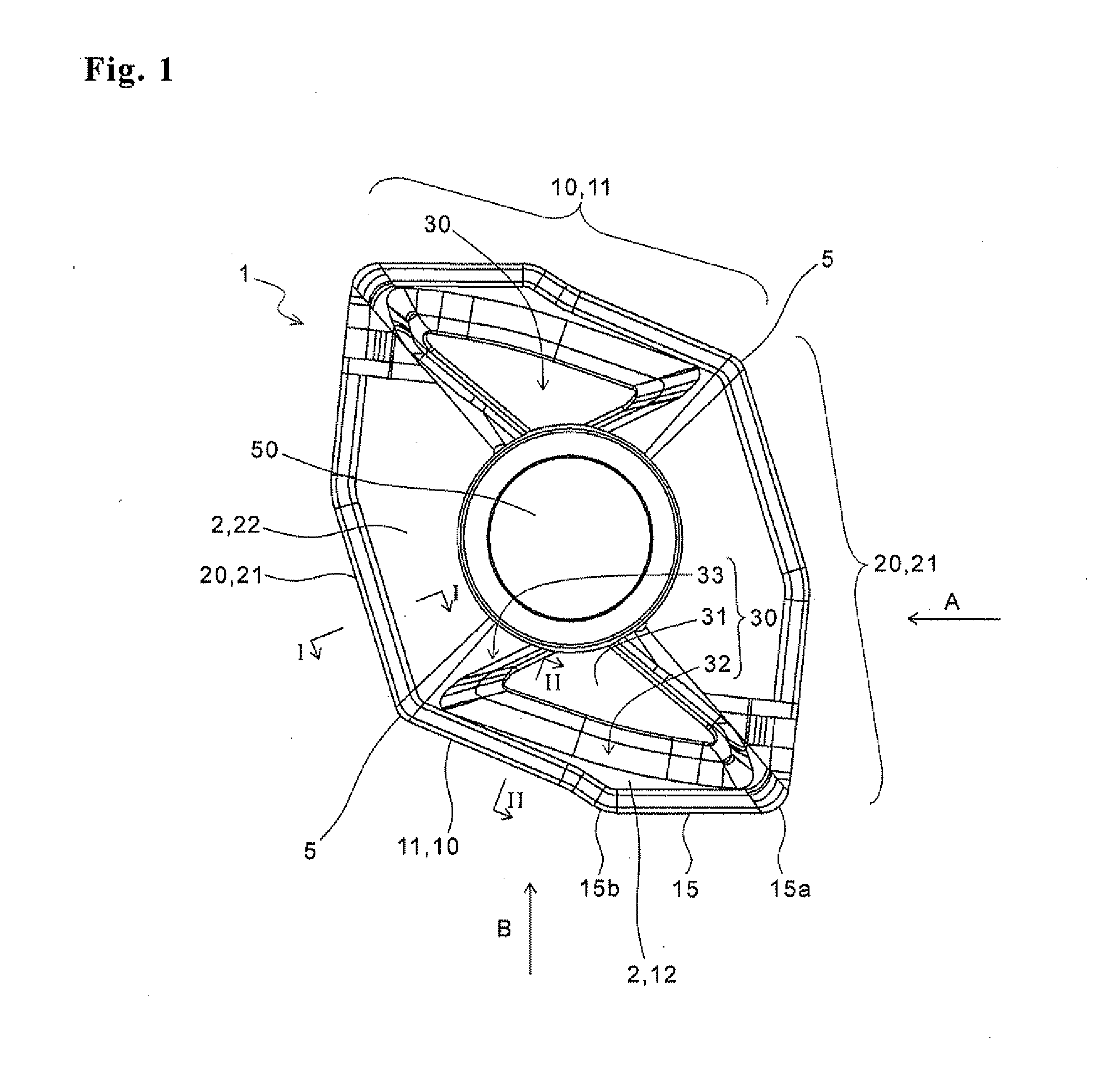

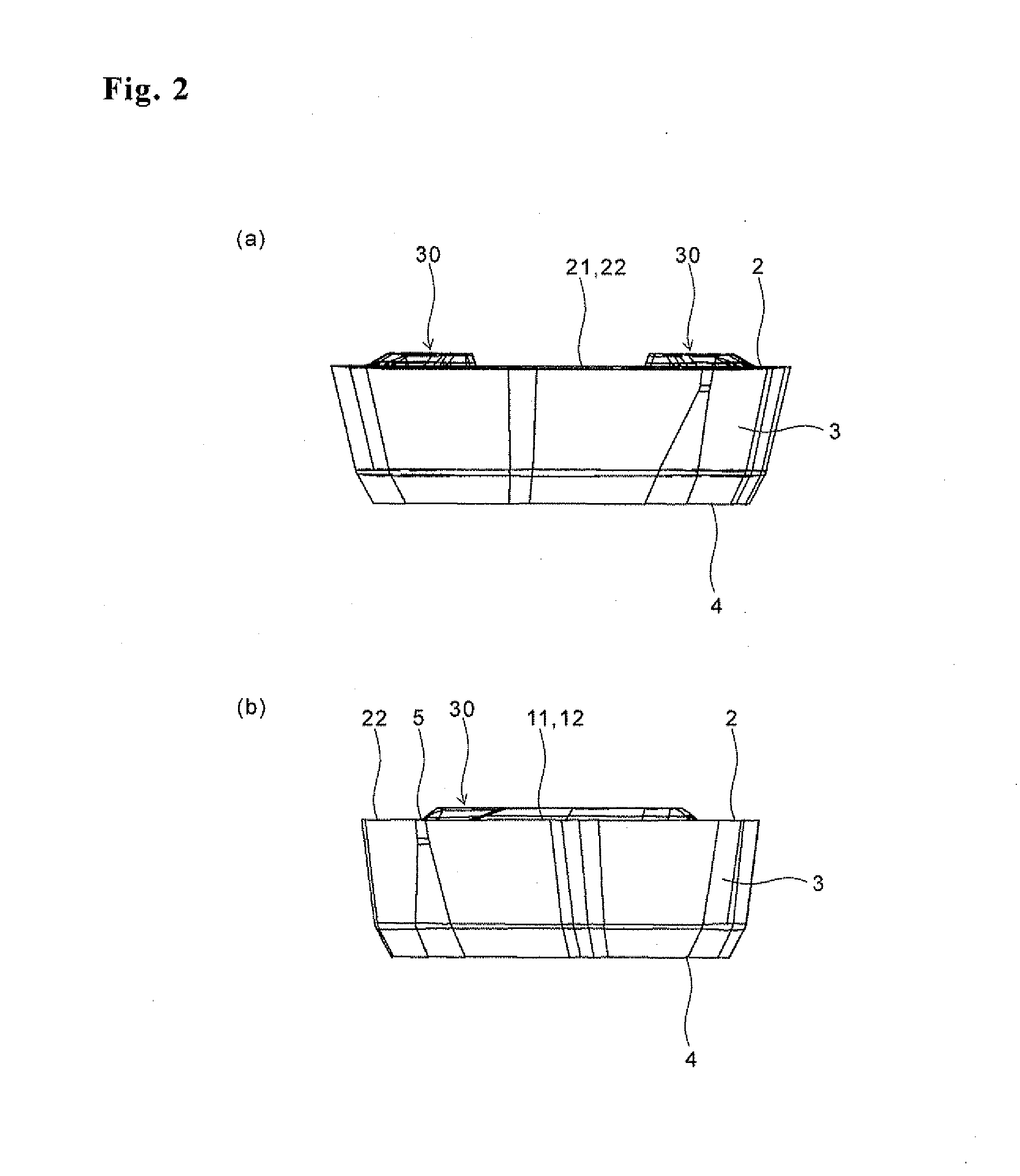

Cutting insert, cutting tool, and method of producing machined product using the same

ActiveUS20140298967A1Good chip removal effectCurl stableMilling cuttersShaping cuttersMechanical engineeringRake angle

A cutting insert comprises an upper surface sequentially including a first and second rake surface. The first rake surface is inclined toward the lower surface, going inward from the cutting edge at a first rake angle on a basis of a perpendicular plane perpendicular to a central axis extending between the upper surface and a lower surface. The second rake surface, located more inward than the first rake surface, is inclined toward the lower surface at a second rake angle different from the first rake angle on the basis of the perpendicular plane. An intersecting part of the first rake surface and the second rake surface includes a protruded part located at a highest position in a region of the intersecting part along the second side surface. A cutting tool with the cutting insert, and a method of producing a machined product using the cutting tool are provided.

Owner:KYOCERA CORP

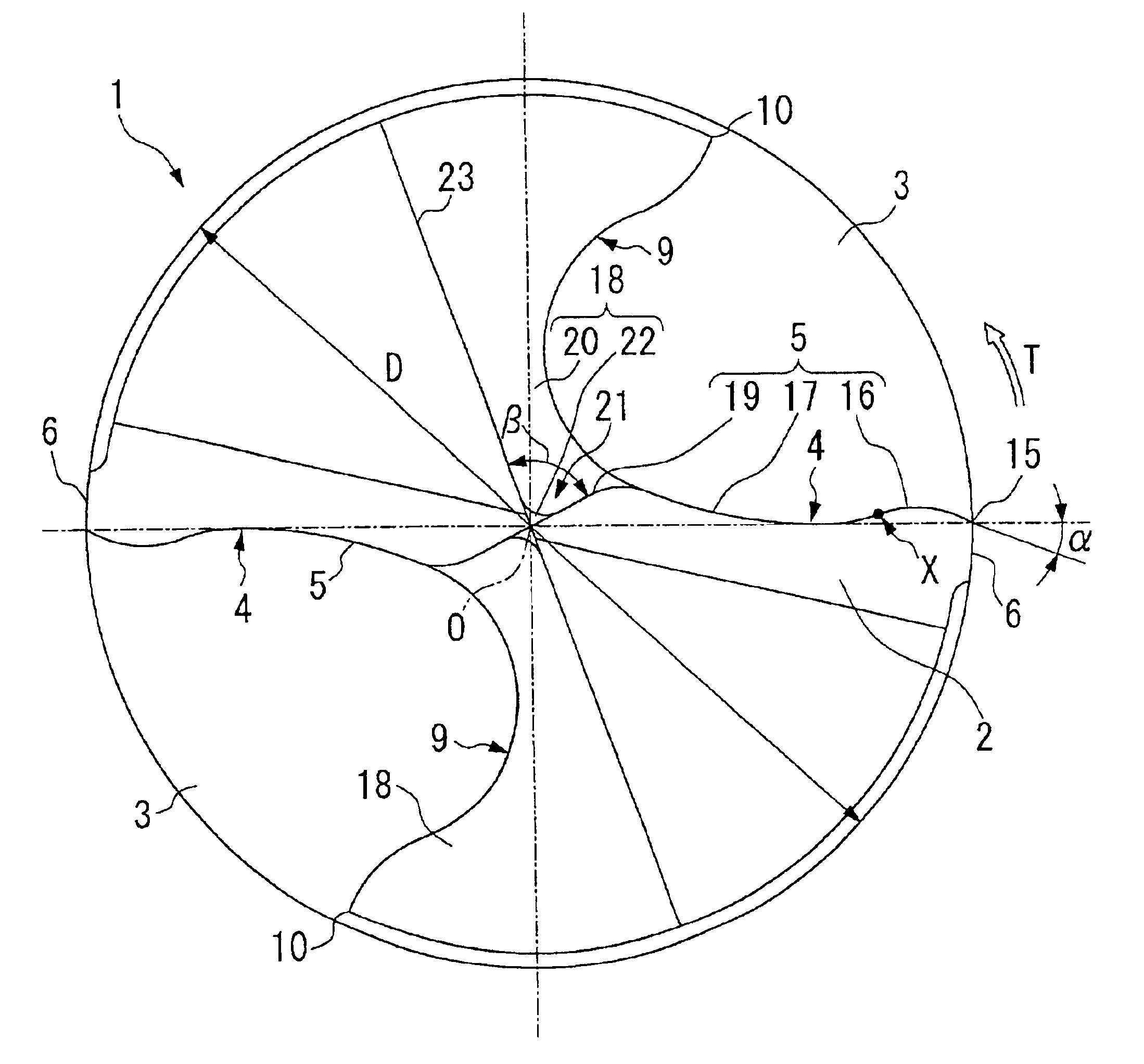

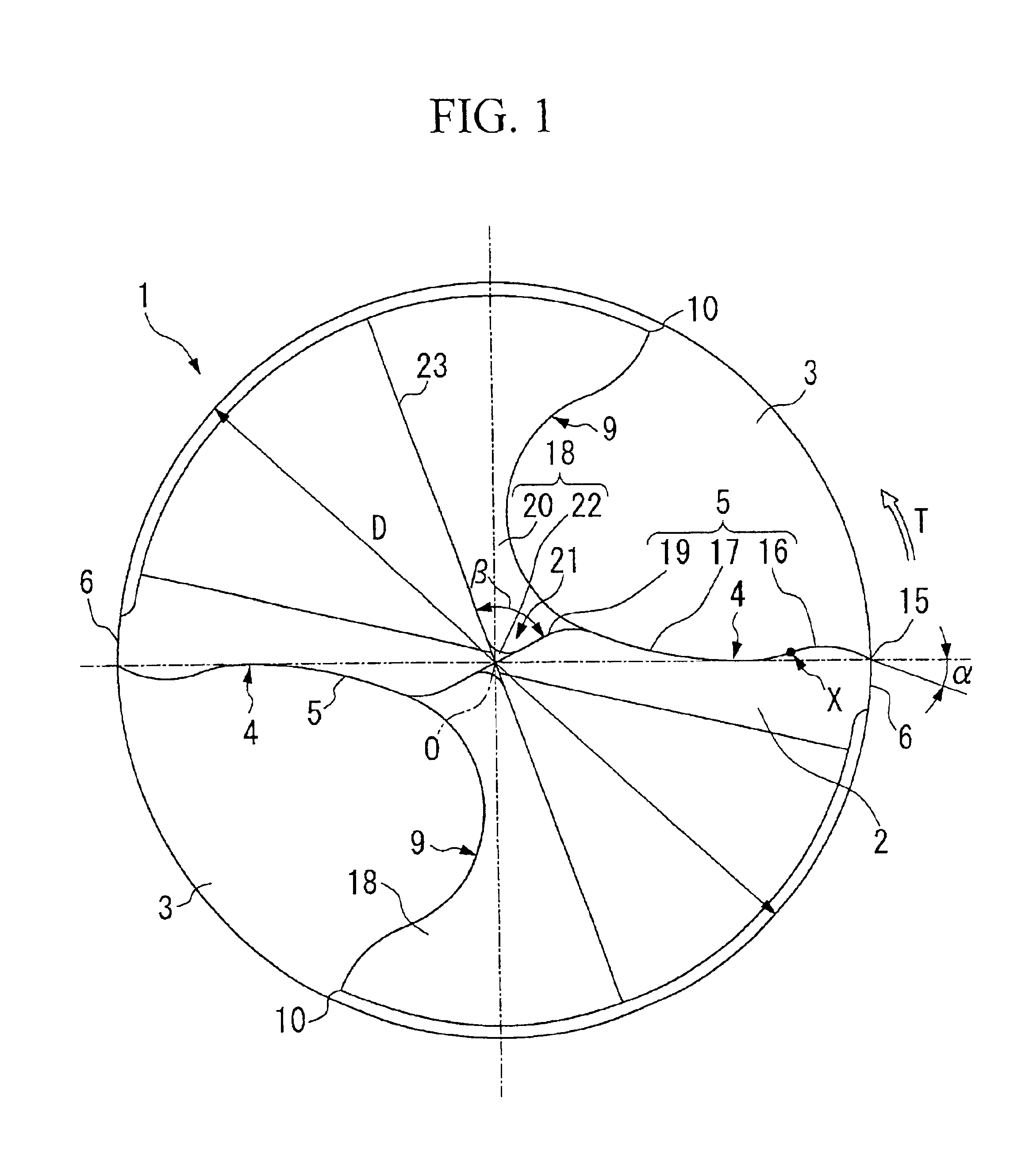

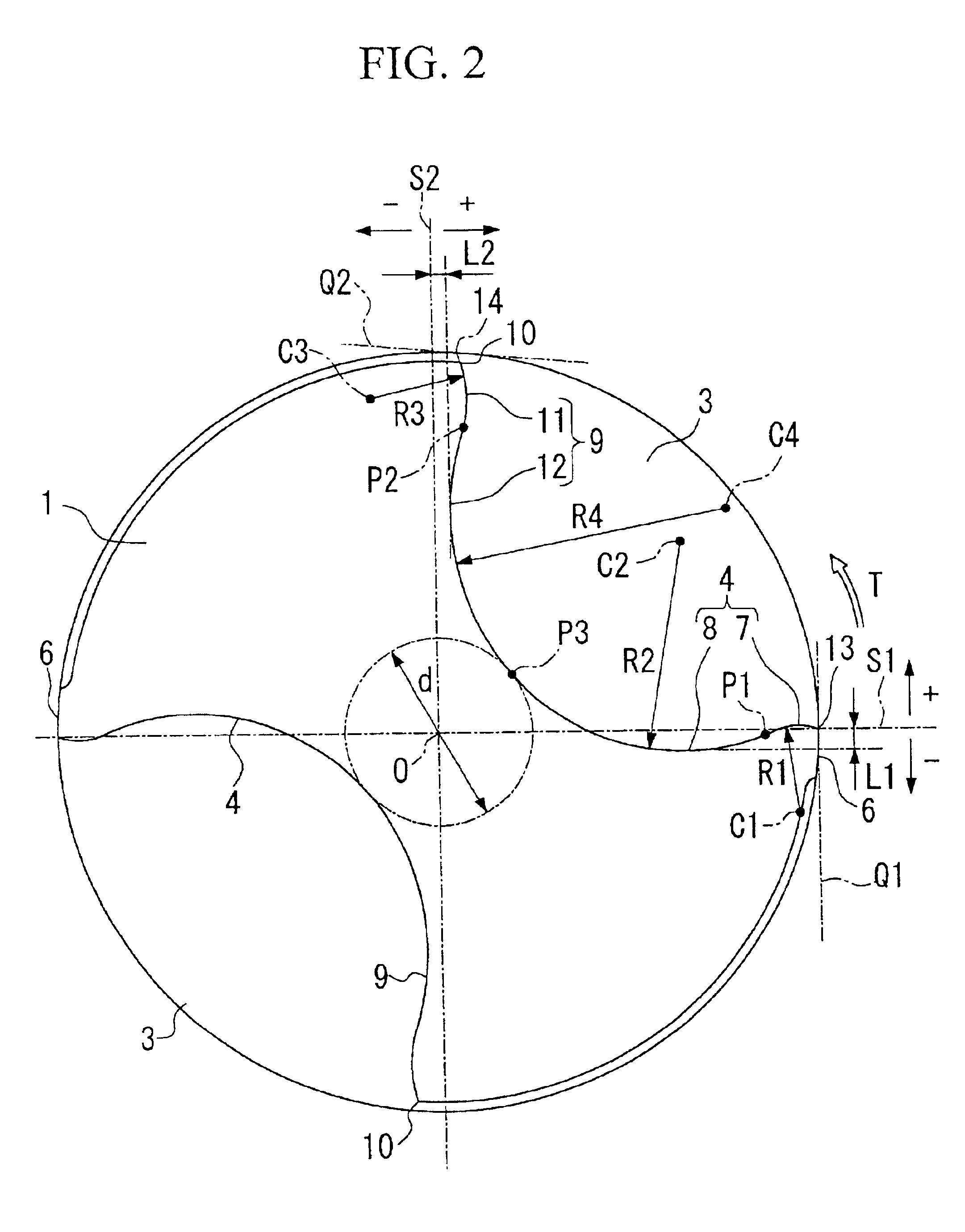

Drill

InactiveUS6916139B2Improve wear resistanceDegradation of the cutting ability all along the cutting edge is preventedWood turning toolsTransportation and packagingFluteEngineering

The present invention provides a drill comprising: a drill main body rotatable about an axis of rotation, and having a tip end with a tip flank and a shank; a chip discharge flute formed on a periphery of the drill main body, and extending from the tip end toward the shank of the drill main body; and a cutting edge formed along an intersecting ridge where a wall surface of the chip discharge flute facing in the direction of drill rotation intersects the tip flank of the drill main body, wherein the cutting edge comprises a convex cutting edge toward the periphery and a concave cutting edge smoothly extending from the convex cutting edge. When drilling work is performed with this drill, the chips are generally curled and can be smoothly discharged without being excessively abutted against the wall surface of the chip discharge flute; consequently, the chips can be smoothly discharged, and the drill main body is subjected to less frictional resistance, which leads to less wear on the drill and less driving torque for drilling. Therefore, the drill life can be preferably extended even under severe drilling conditions, such as during high speed drilling, and smooth and stable drilling can be performed.

Owner:MITSUBISHI MATERIALS CORP

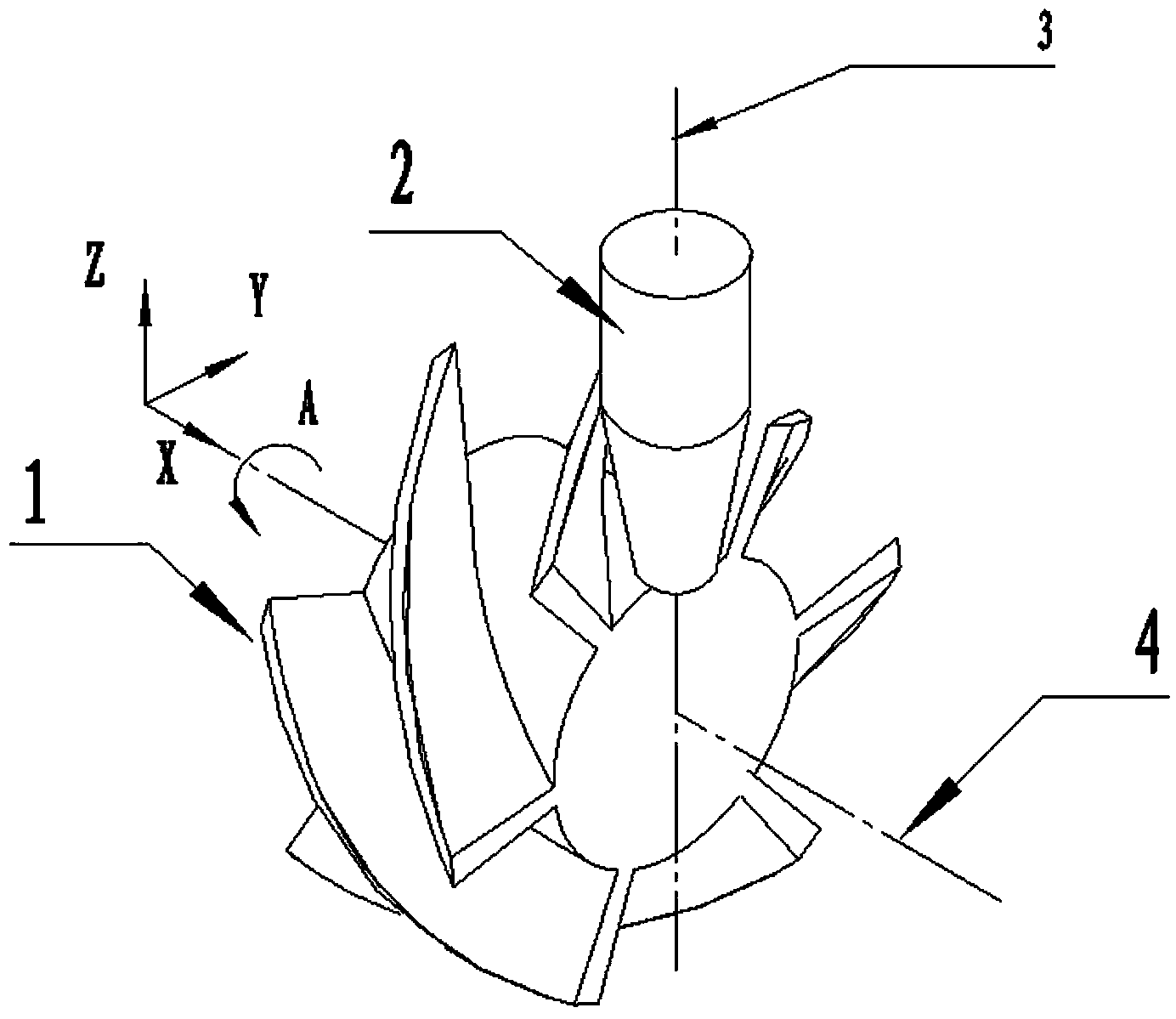

Method for processing integral impeller by using four-axis numerical-control milling machine

ActiveCN104384586AGood chip removal effectMilling cuttersMilling equipment detailsImpellerNumerical control

The invention discloses a method for processing an integral impeller by using a four-axis numerical-control milling machine. The method is high in cutting efficiency, helps to reduce processing cost, shorten processing time and simplify the number of movement shafts participating linkage when four-axis processing is performed. The method is realized through the following technical scheme: employing a lead reference line projection revolution processing manner in programming, so as to enable a milling cutter to perform multi-axis linked milling processing along with the impeller lead curvature change, and using a fixed-axis manner to arrange the cutter axis to be perpendicular to the processing path direction, so as to enable cutter path direction to superposed with the impeller revolution-shaft axial lead and generate a four-axis milling machine multi-axis linked processing digital control program; fixedly disposing an impeller part at the revolution shaft A center of the four-axis milling machine, calculating out the tapered angle of an impeller blade according to the lead and the diameter of the impeller, blade thickness and other parameters, arranging the processing direction of the tapered flat-bottom milling cutter to be X direction of the milling machine revolution shaft, and unchanging the revolution shaft axis position along Y direction during processing; and controlling the milling cutter to perform multi-axis linked milling processing along with the impeller lead curvature change.

Owner:四川泛华航空仪表电器有限公司

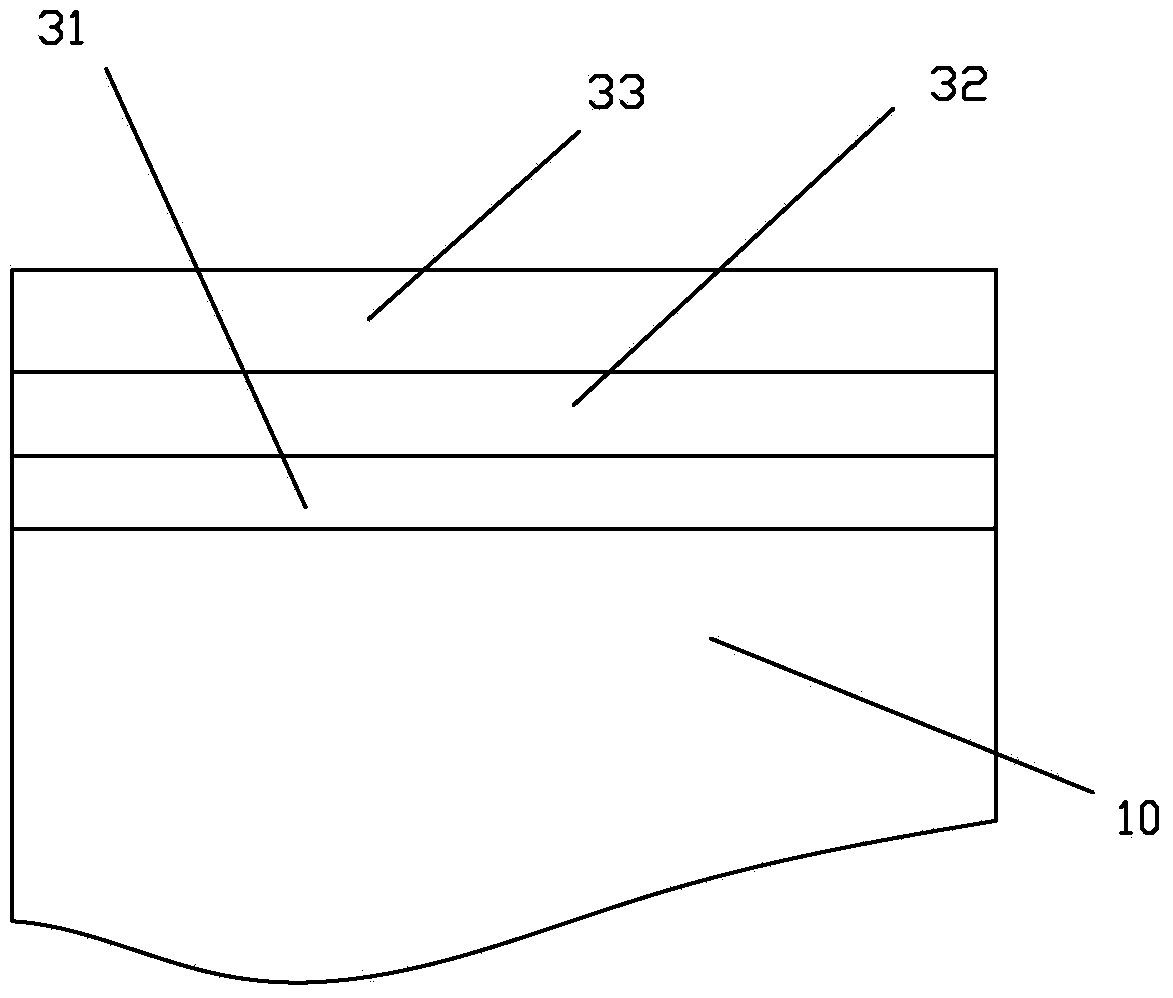

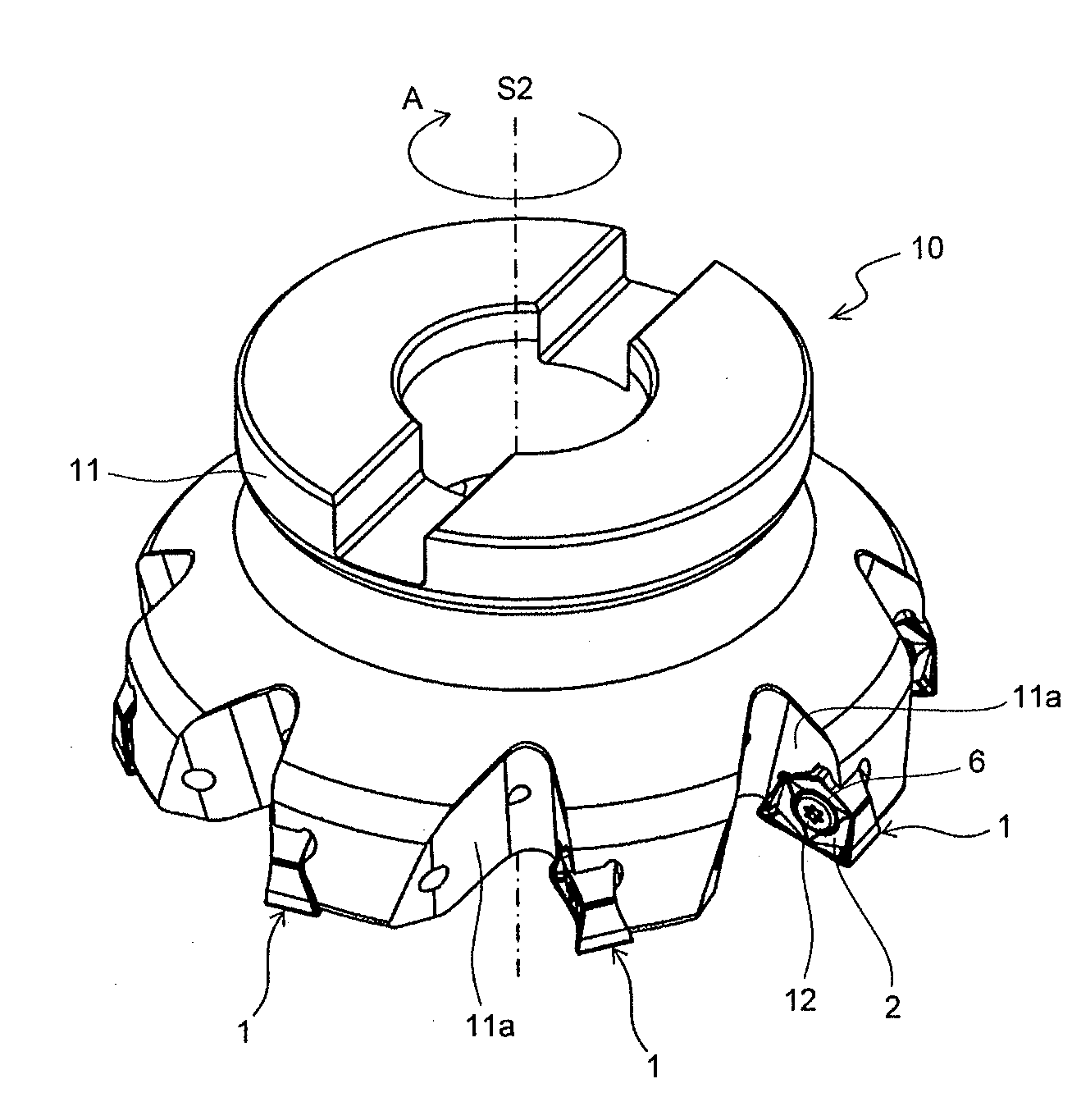

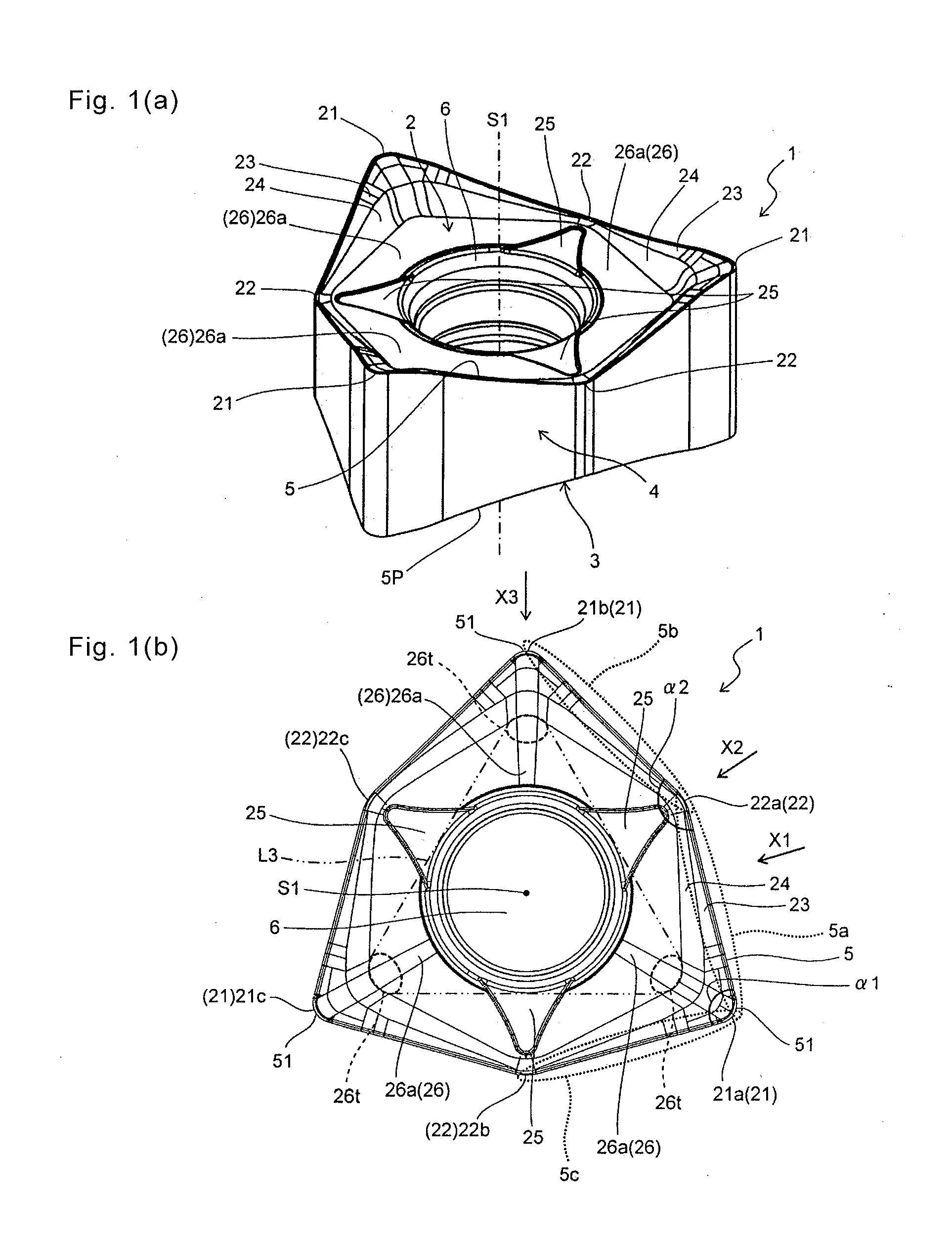

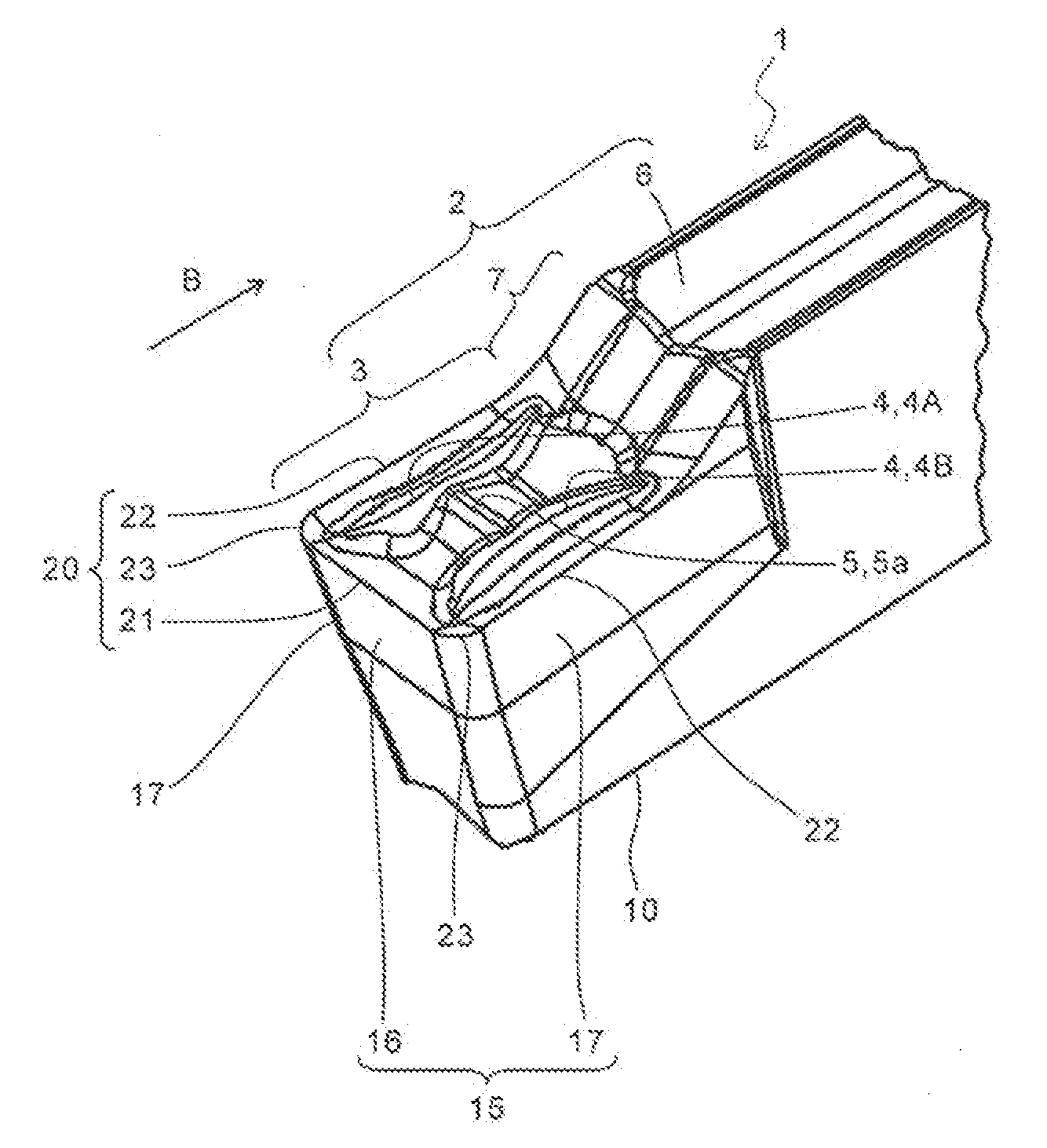

Cutting insert, cutting tool, and method of manufacturing machined product using the same

ActiveUS20120093596A1Reduce distortionLess susceptible to twistingTransportation and packagingMilling cuttersEngineeringKnife blades

A cutting insert of the present invention includes an upper surface; a lower surface; a side surface connected to the upper surface and the lower surface; and a cutting edge which is located along an intersection of the upper surface and the side surface, and includes a major cutting edge, a flat cutting edge, and a minor cutting edge located between the major cutting edge and the flat cutting edge. The upper surface includes a flat part located away from the cutting edge and being perpendicular to a central axis of the cutting insert, and a rake face inclined downward from the cutting edge to the flat part. In at least a part between the major cutting edge and the flat part, a groove part lies along the major cutting edge. The groove part includes the rake face and a rising face which is inclined upward from the rake face to the flat part and connects the rake face and the flat part. A connection part where the rake face and the flat part exist continuously extends from the minor cutting edge to a boundary of the minor cutting edge and the major cutting edge. A cutting tool including the cutting insert, and a method of manufacturing a machined product using the cutting tool are also provided.

Owner:KYOCERA CORP

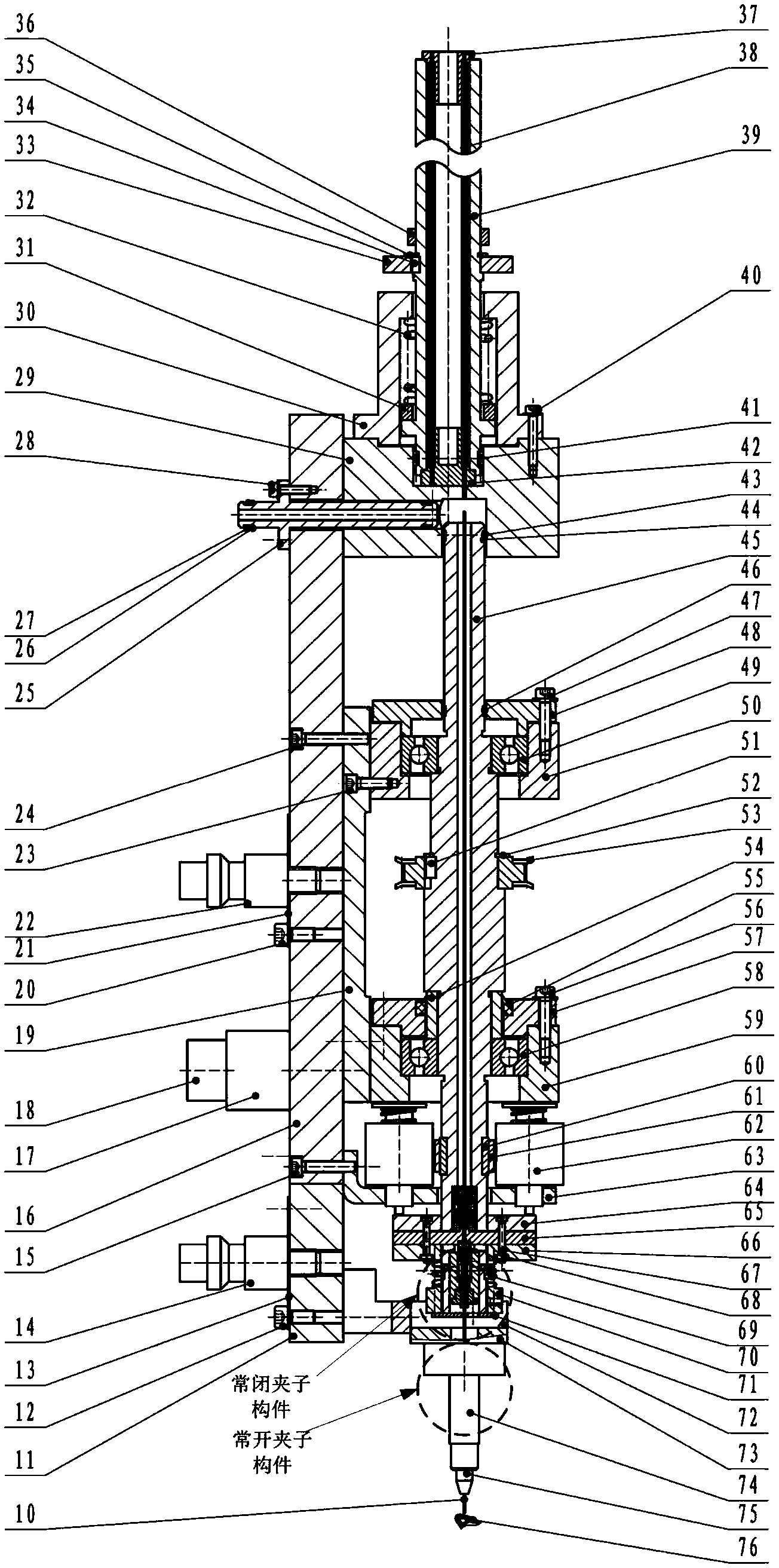

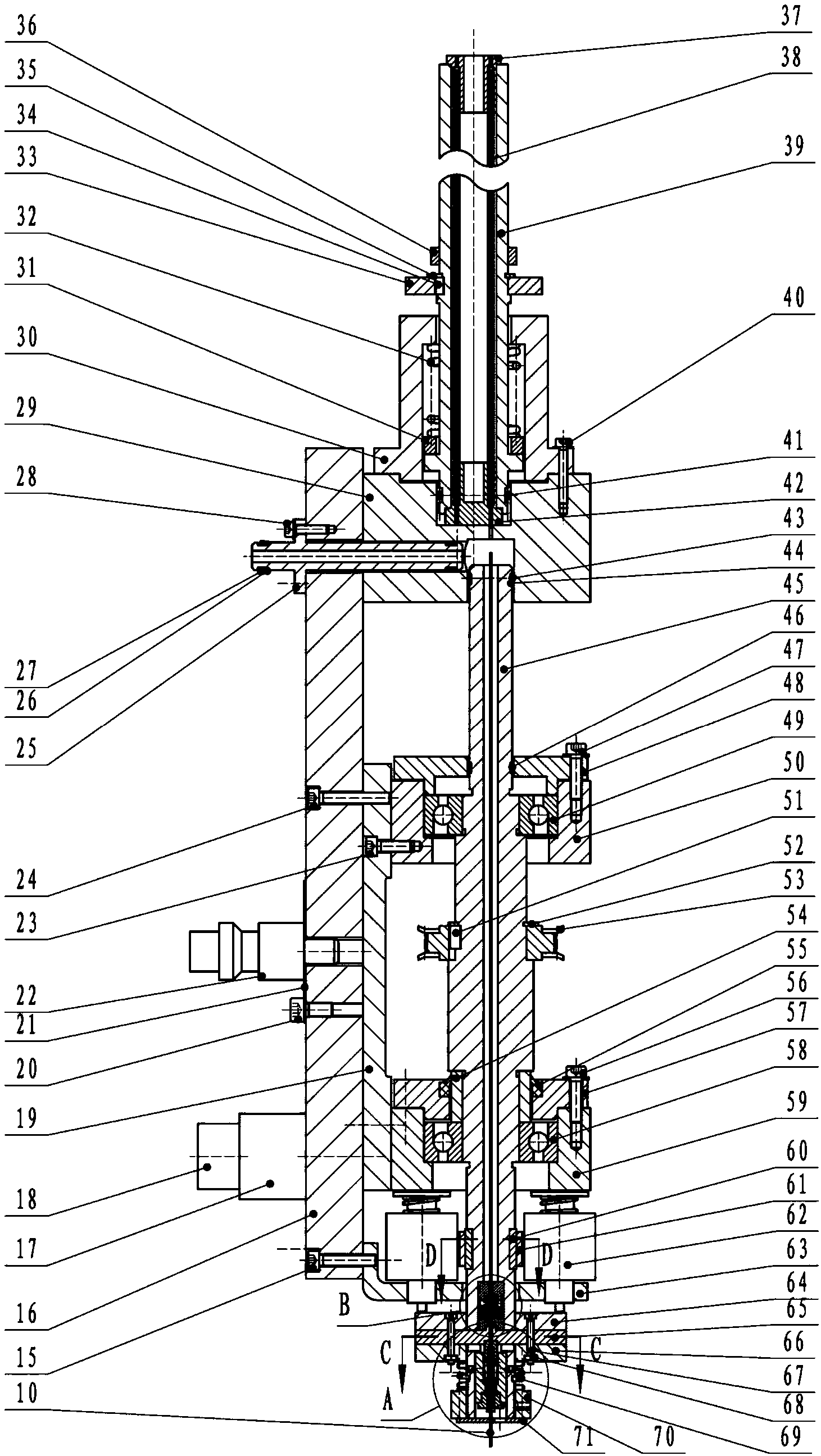

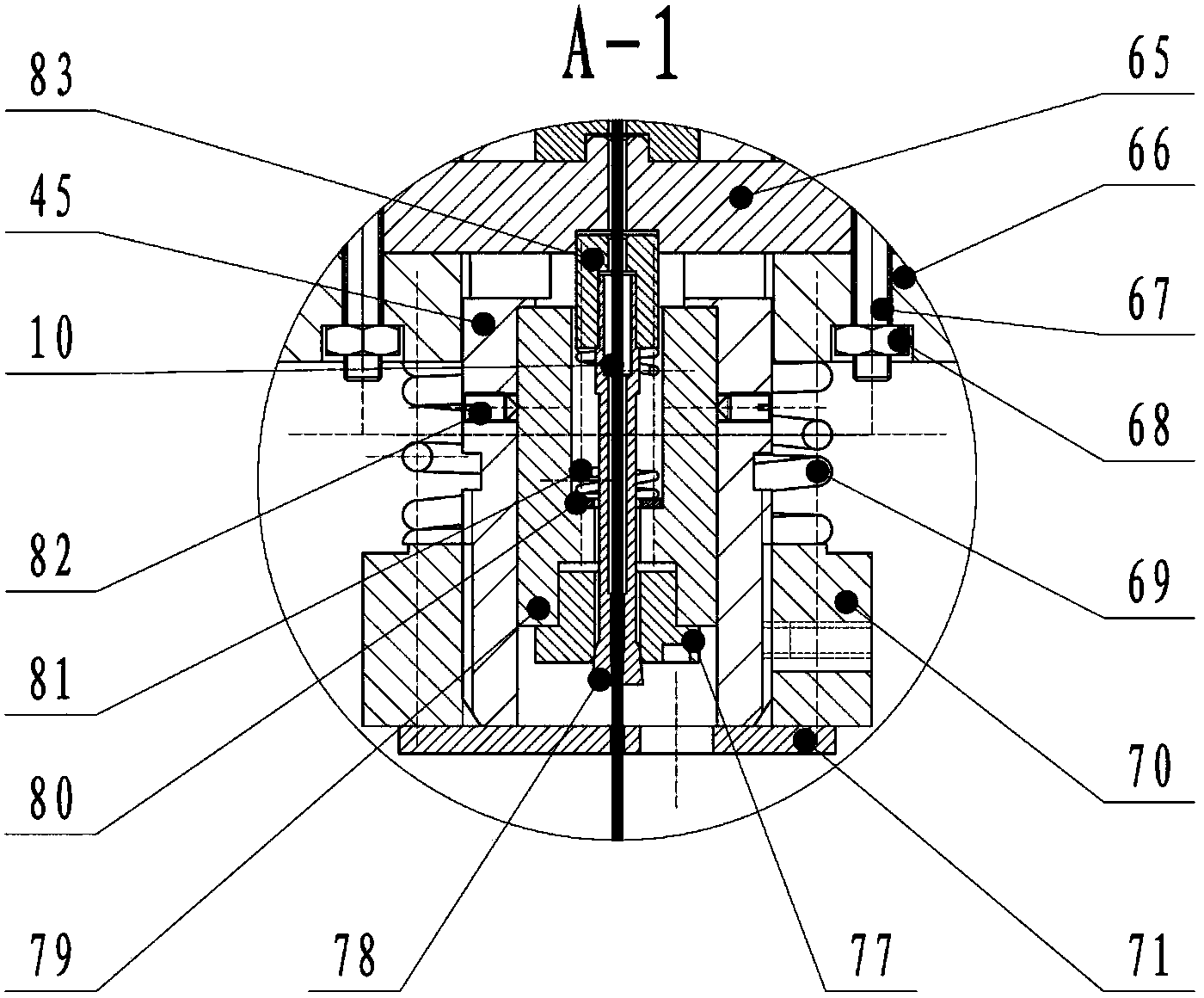

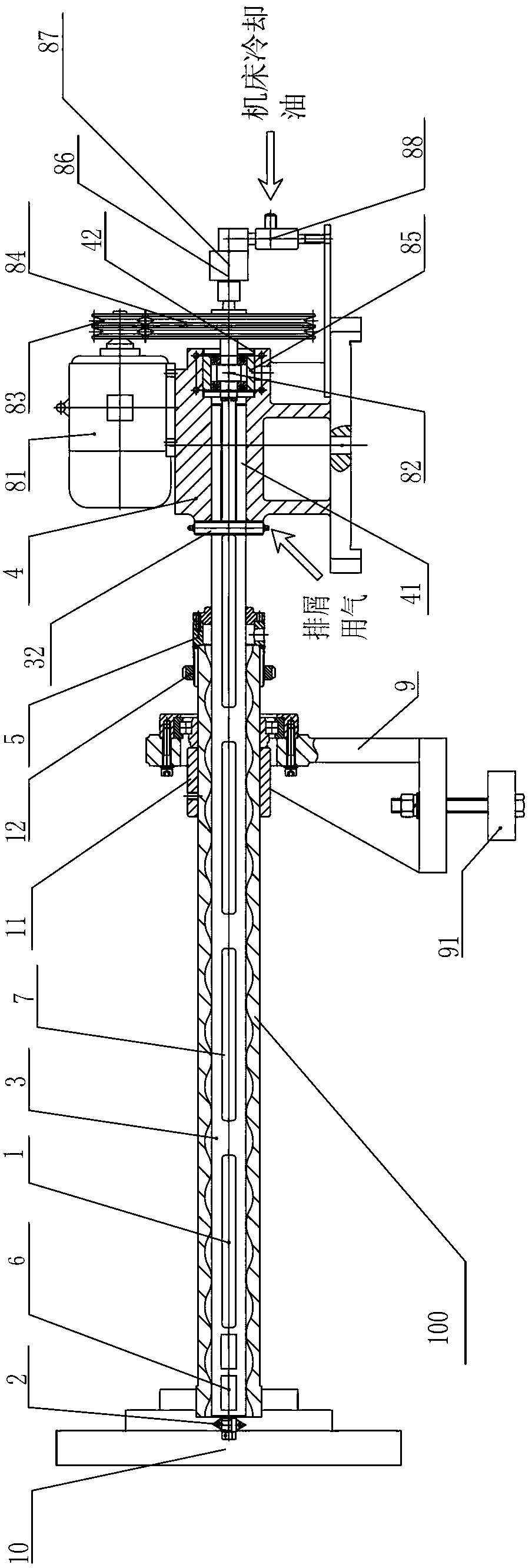

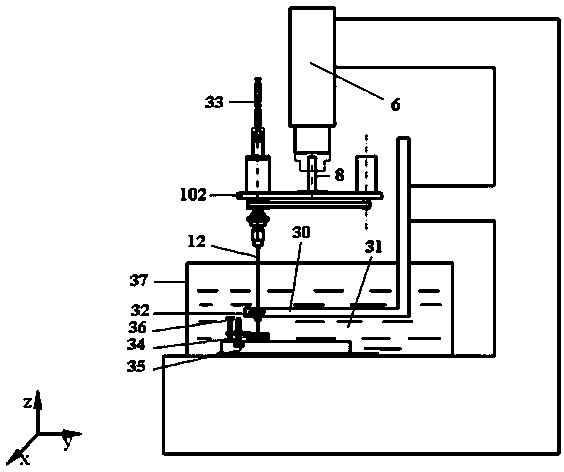

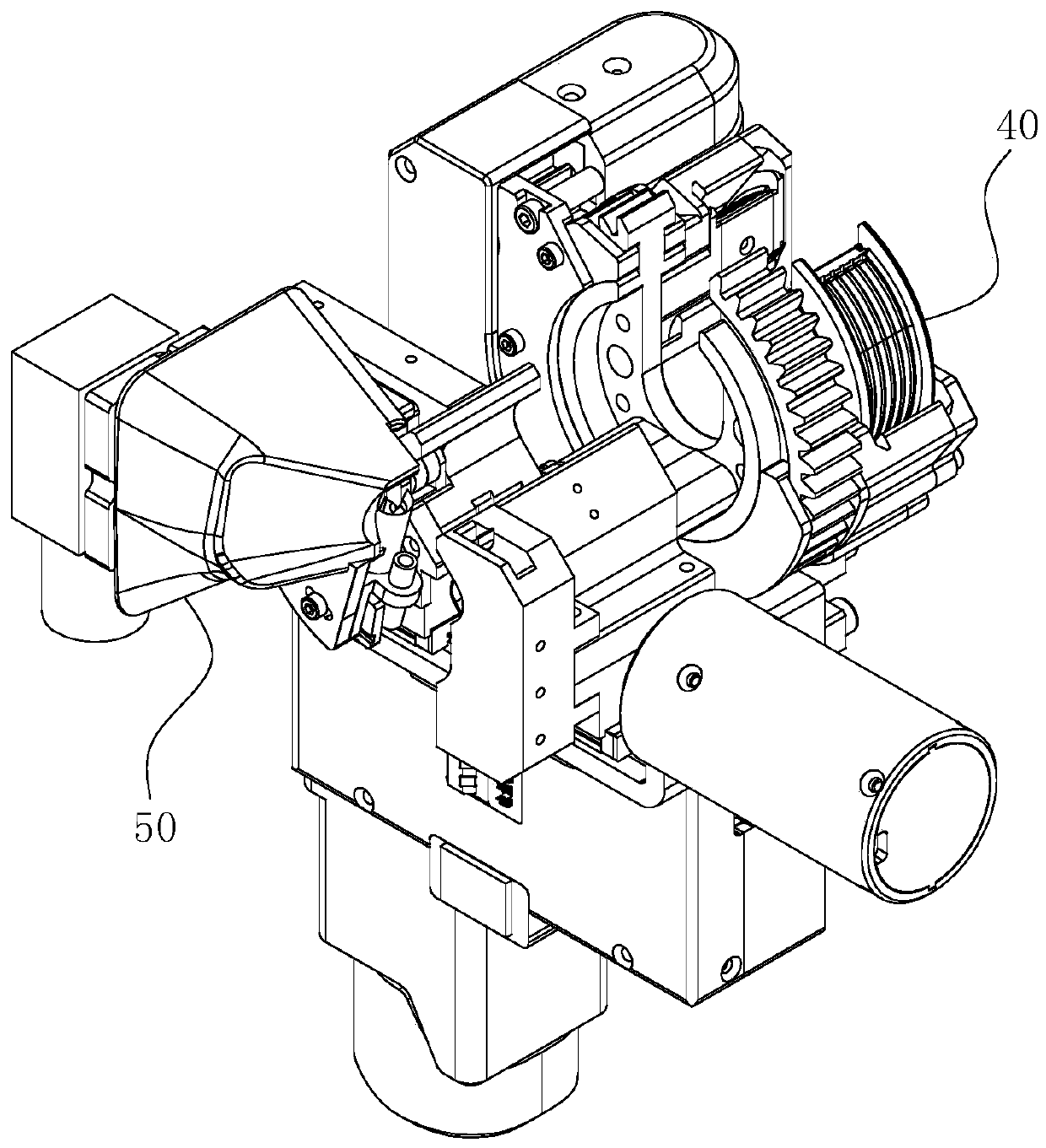

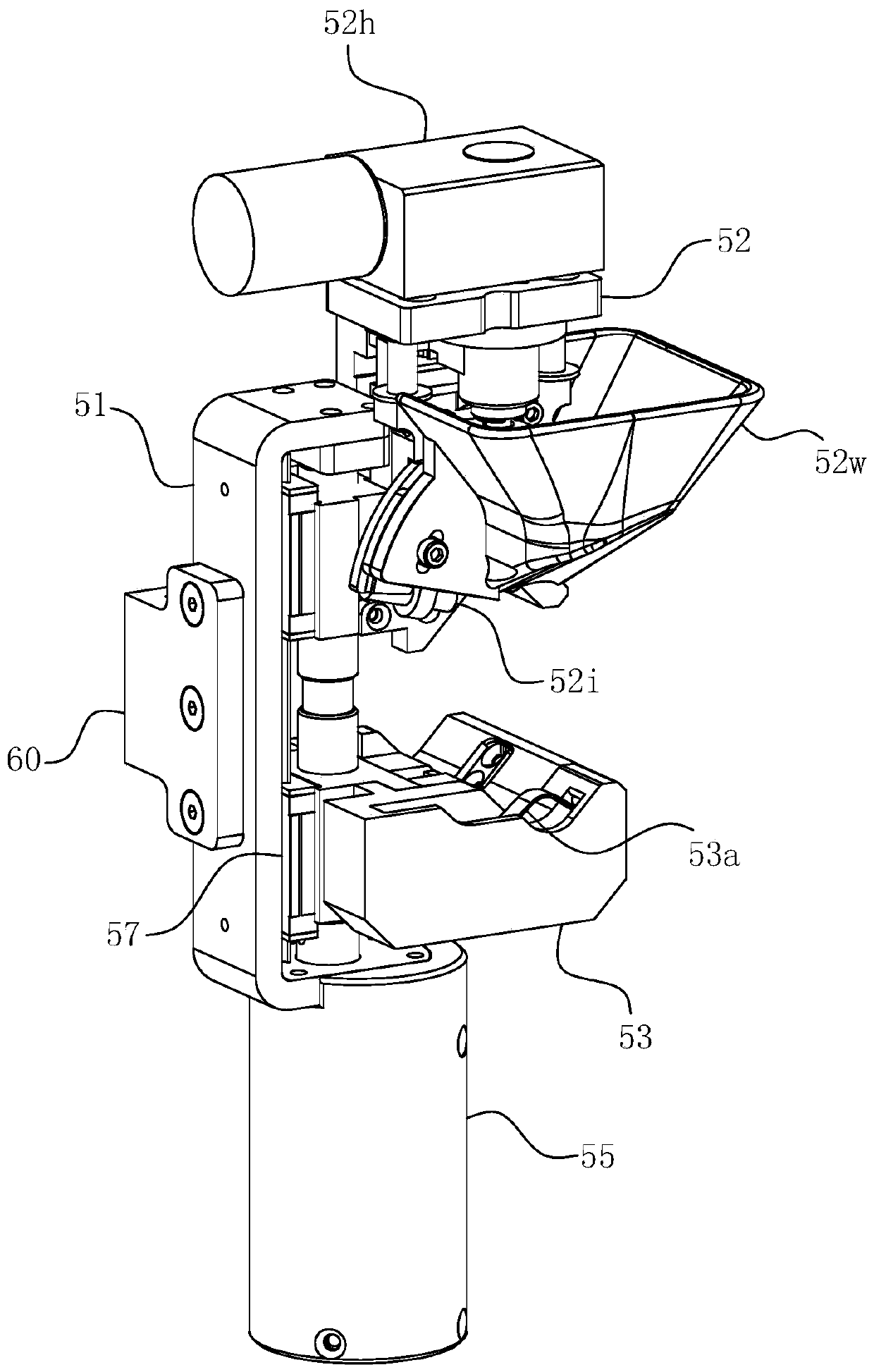

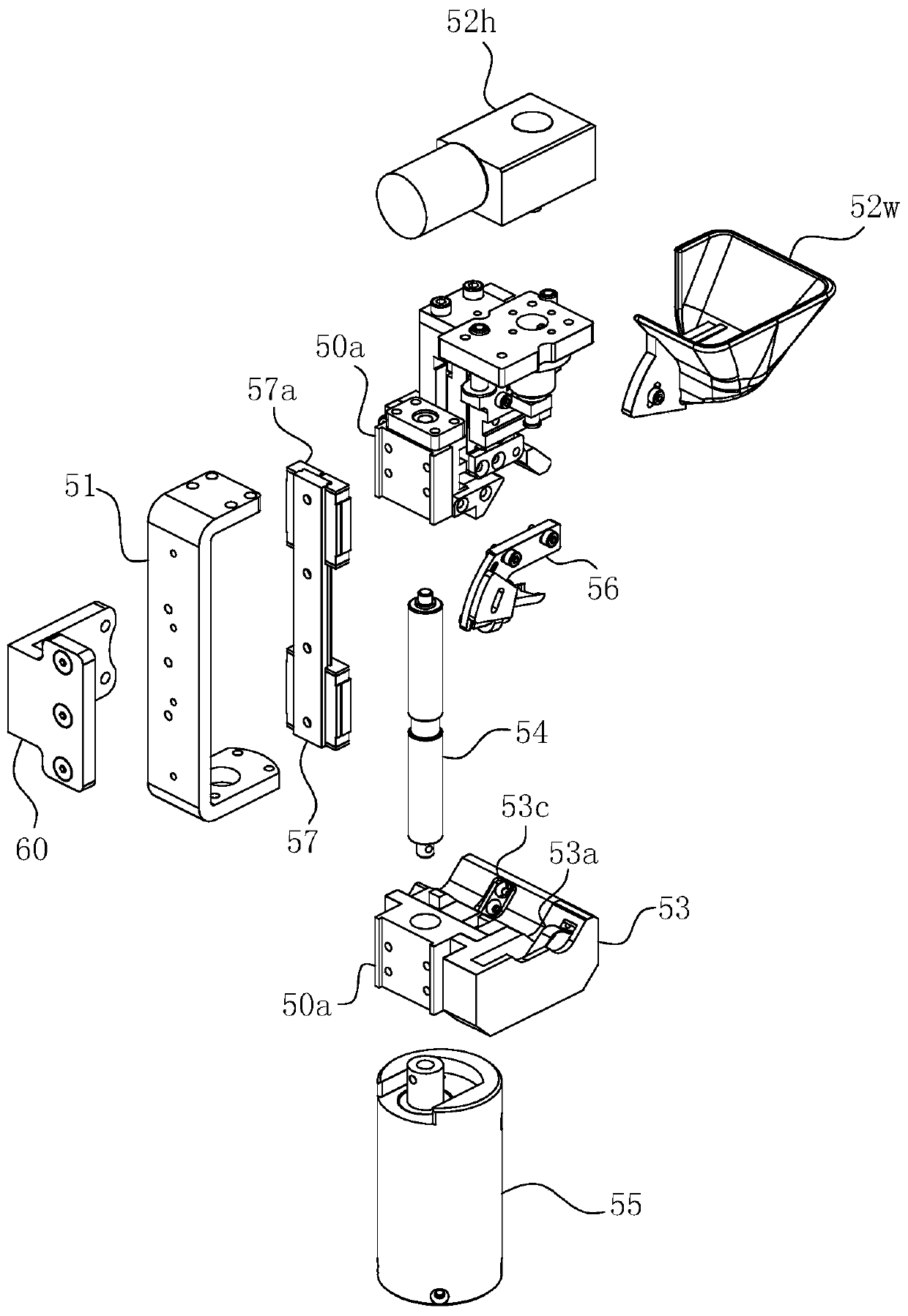

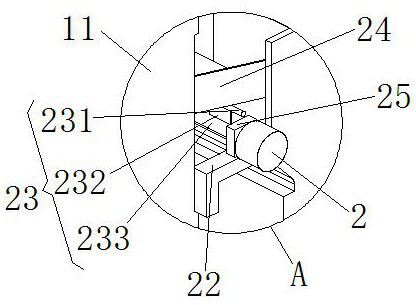

Multi-functional spindle mechanism used for small deep holes electrical discharge machining

InactiveCN103769705AImproved electrode feed stiffness and spindle servo stabilityImproved dimensional accuracy and aspect ratioElectrical-based auxillary apparatusGas turbinesEngineering

The invention discloses a multi-functional spindle mechanism used for the small deep holes electrical discharge machining, belonging to the technical field of micro non-traditional machining. The multi-functional spindle mechanism comprises a rotating spindle mechanism, a transmission mechanism, a normally closed clamp mechanism, a sealing mechanism, an electric brush mechanism, a wire replacing mechanism, a normally opened clamp mechanism, a guide mechanism and a connecting mechanism, wherein the rotating spindle mechanism, the transmission mechanism, the normally closed clamp mechanism, the sealing mechanism, the electric brush mechanism and the wire replacing mechanism are fixedly mounted on an upper mounting plate, and the normally opened clamp mechanism is mounted on a lower mounting plate; the upper mounting plate is connected to the lower mounting plate through the guide mechanism and a degree of freedom of relative movement in the z direction is kept; the upper mounting plate is connected to a z-axis top plate through the connecting mechanism, and the lower mounting plate is connected to a z-axis bottom plate through the connecting mechanism. The mechanism processes the film cooling group holes in the hot components of the aero-engines and the gas turbines, which can realize multiple functions of the forward pushing creep feed, the high precision rotation and the hollow high pressure flushing of the tool electrodes, and the on-line replacement of the electrodes.

Owner:TSINGHUA UNIV

Miniature PVD coat miller cutter for PCB, and making method thereof

InactiveCN103737092AReduce coefficient of frictionAnti-oxidation temperature is highMilling cuttersVacuum evaporation coatingMilling cutterWear resistant

The invention discloses a miniature PVD coat miller cutter for PCB, and a making method thereof. The miniature PVD coat miller cutter for PCB comprises a substrate and one or more layers of a hard and wear-resistant coat deposited on the substrate through a physical vapor deposition process; the hard and wear-resistant coat is an MeCxNyOz coat, Me is one or more of Al, Cr, Ti, Zr, Si, Hf, Nb, Ni, W, Ta, B, V, Y and Cu, and x+y+z is 1; and the total thickness of the one or more layers of the coat on the substrate is 0.1-10mum. The substrate is made by using a cemented carbide material, a ceramet material, a ceramic material, a cubic boron nitride based material or a high-speed steel material. By improving the structure of the PVD coat in the invention, a processing problem that printed circuit boards are difficult to process is overcome, and a problem that the service life of a common miniature milling cutter is short is prolonged.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

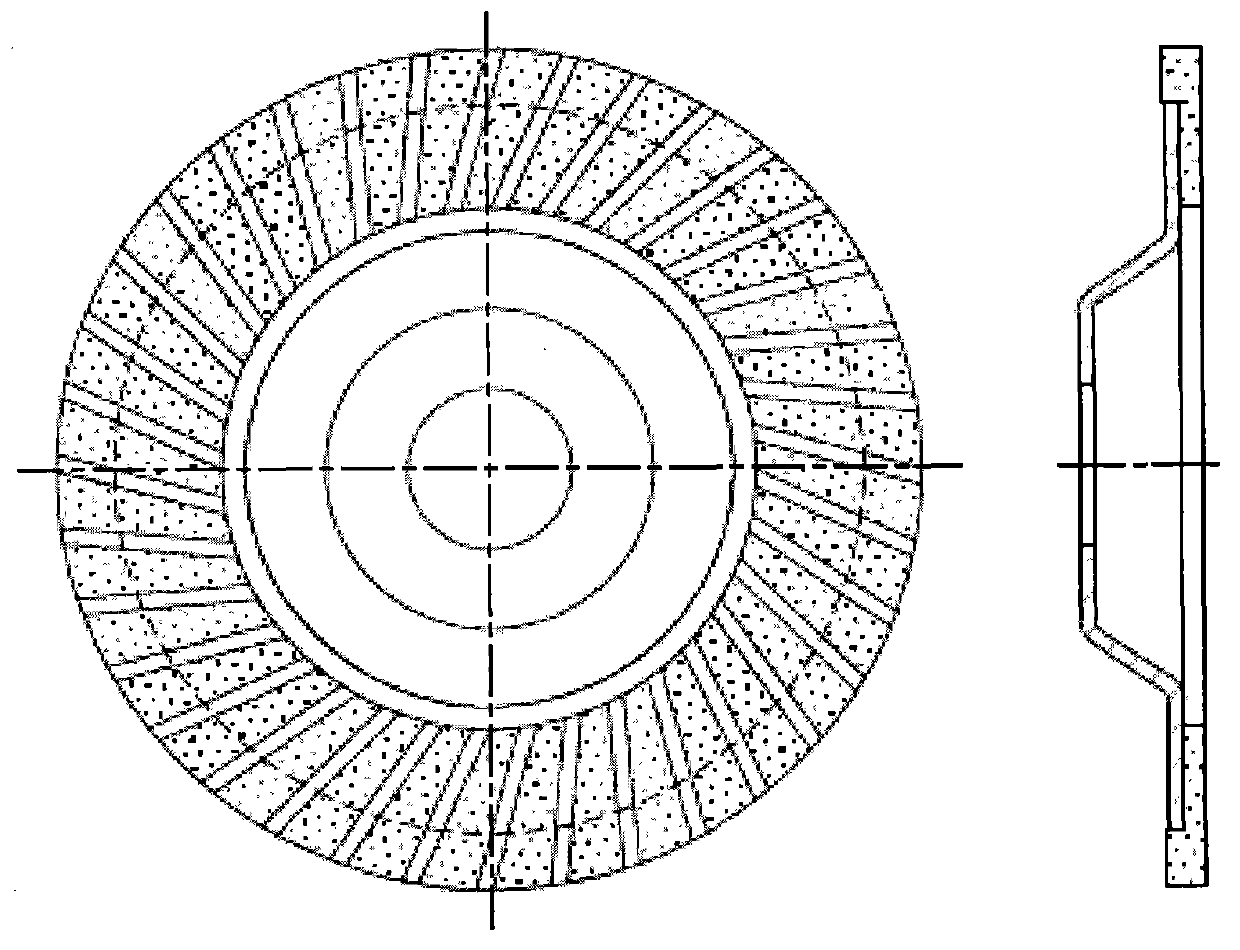

Preparation method for diamond cutting grinding piece

The invention relates to a preparation method for a diamond cutting grinding piece. The diamond cutting grinding piece comprises a diamond cutting grinding piece body arranged on a 65Mn steel substrate, and corrugated water channels are formed in the surface of the diamond cutting grinding piece body. The preparation method for the diamond cutting grinding piece comprises the steps of material mixture, substrate machining, compression forming, sintering and edge forming. The diamond cutting grinding piece produced through the preparation method for the diamond cutting grinding piece has the cutting effect and the grinding effect, and is safe and reliable in performance, simple and reasonable in structure, low in manufacturing cost, flexible in operation, good in sharpness of products and good in chip-removal performance.

Owner:JIANGSU FENGTAI TOOLS

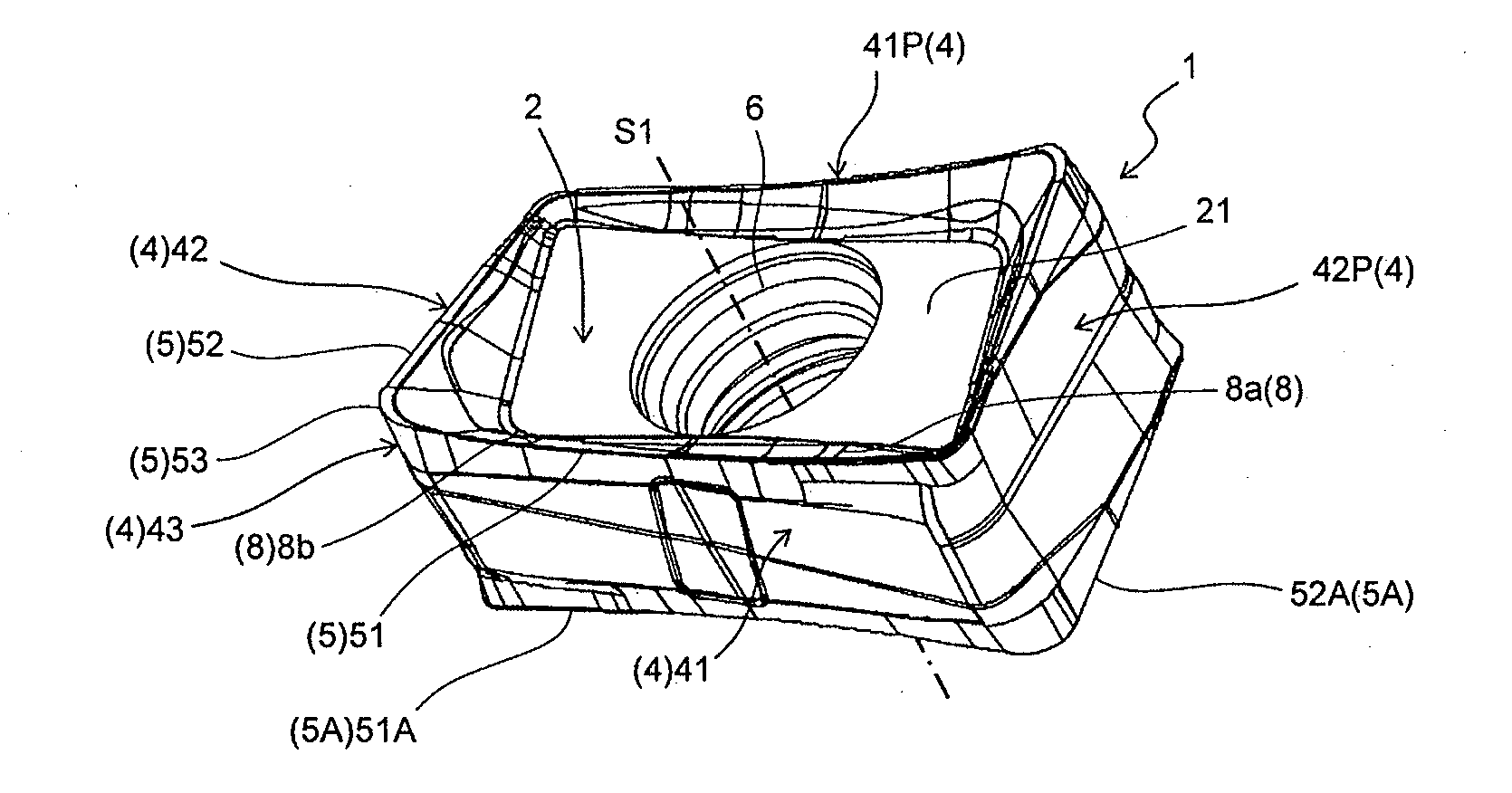

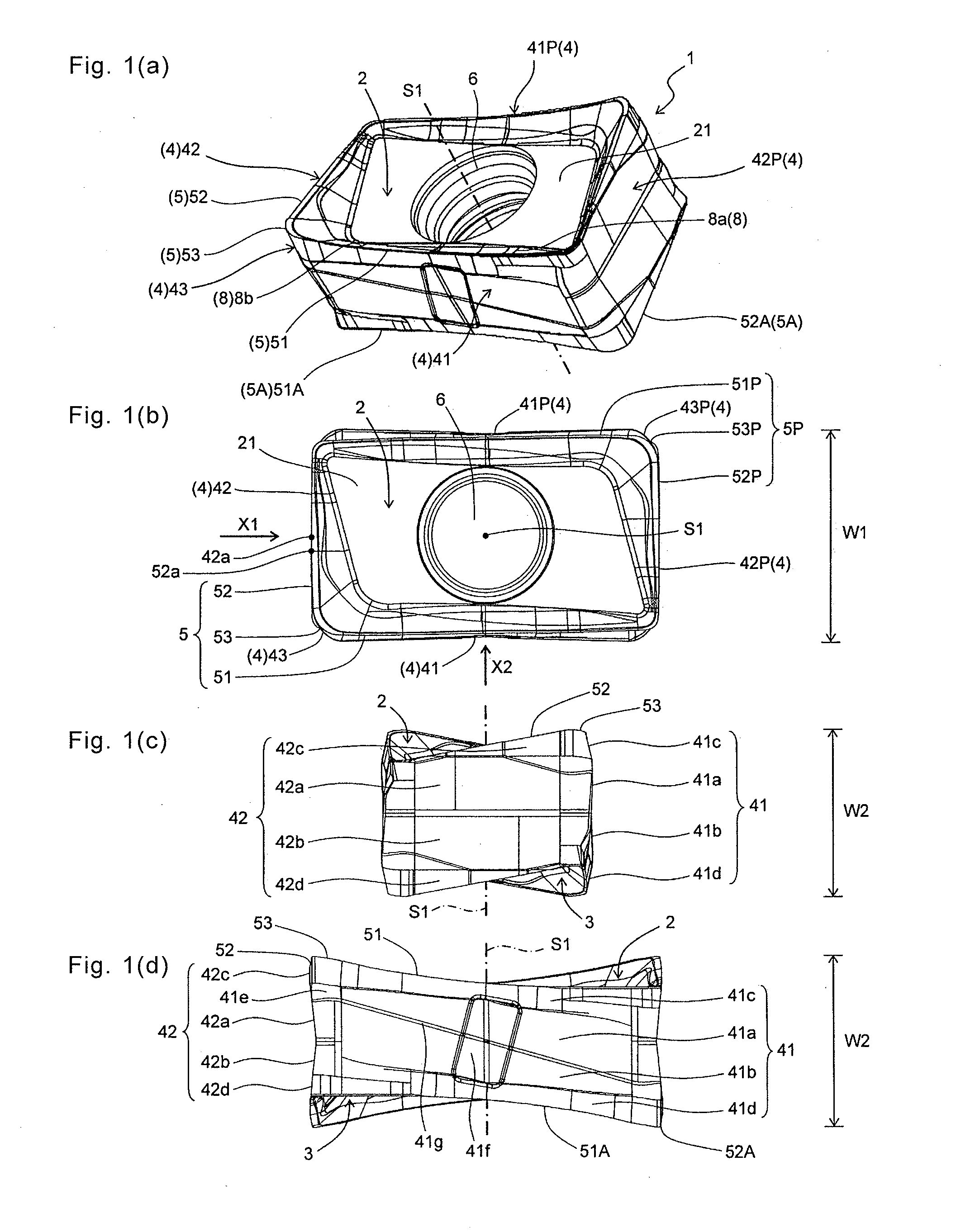

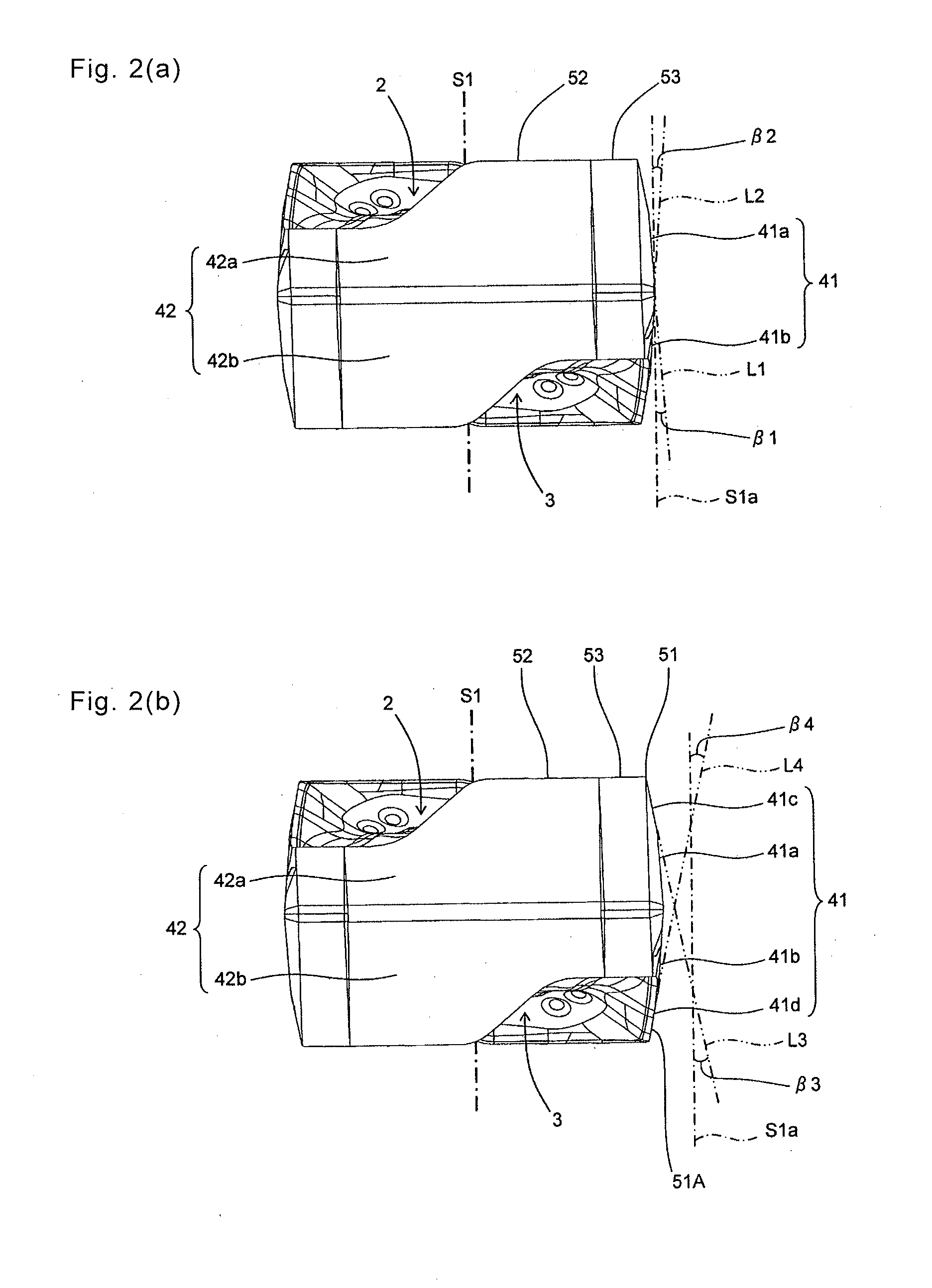

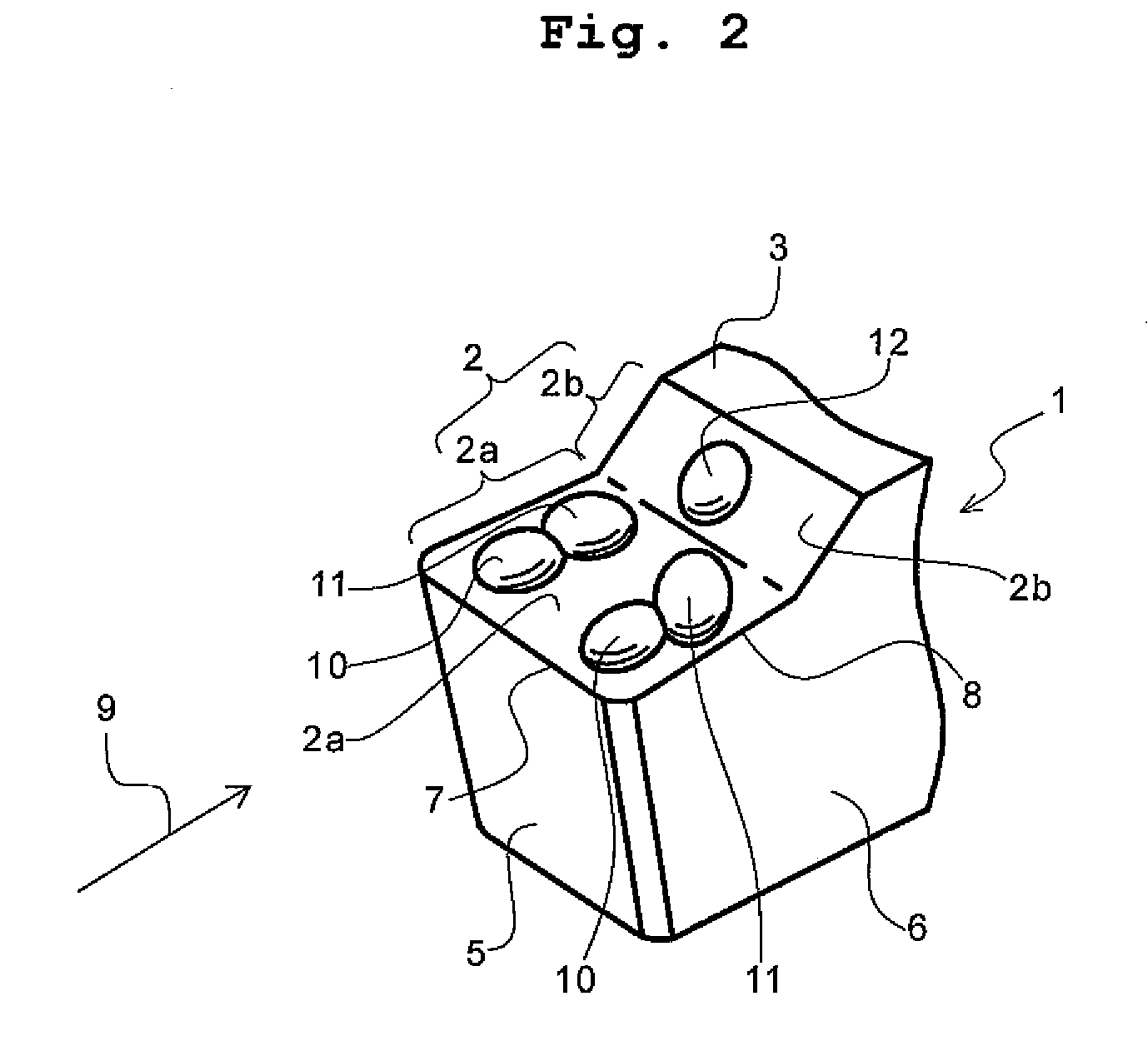

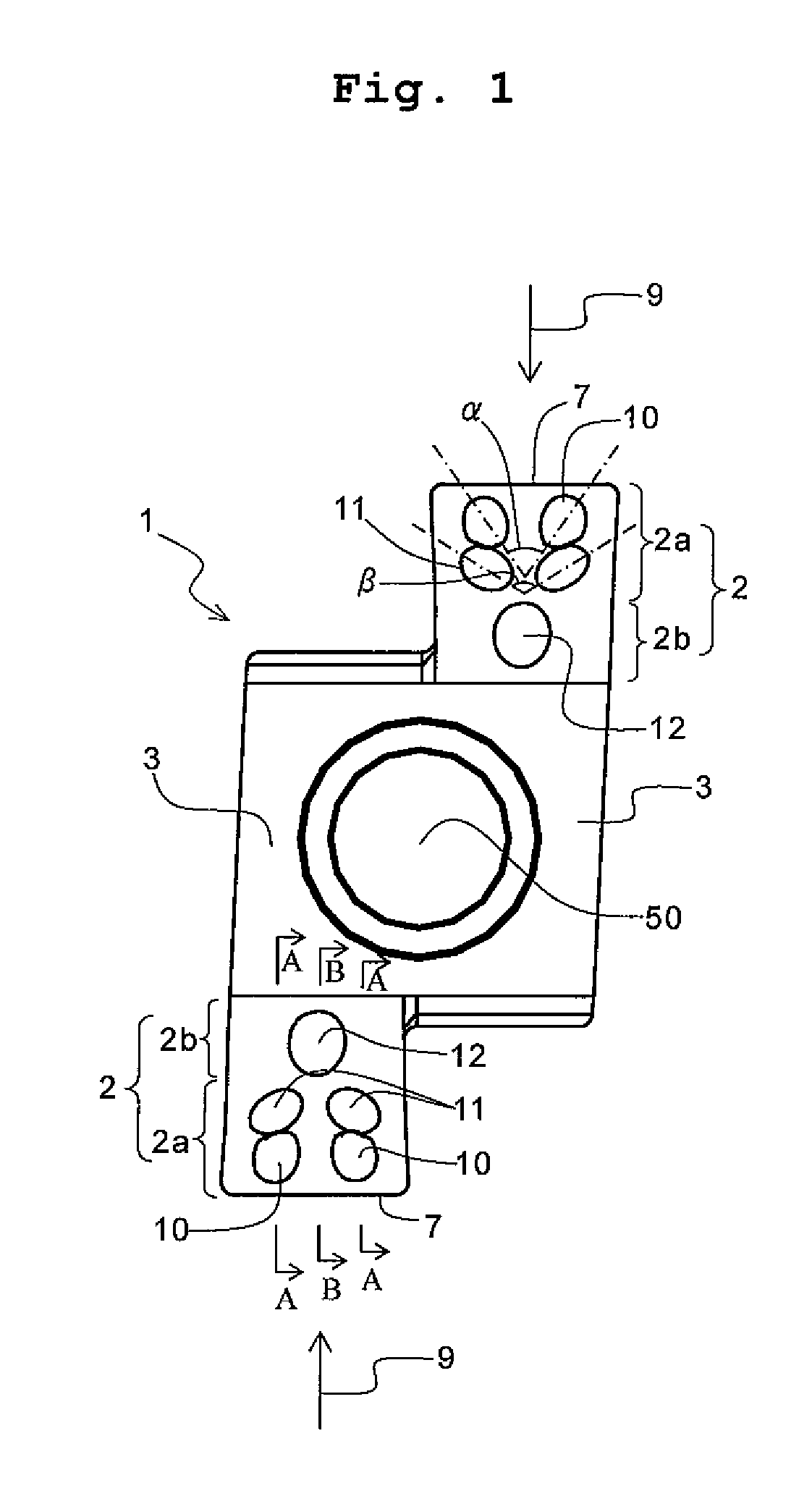

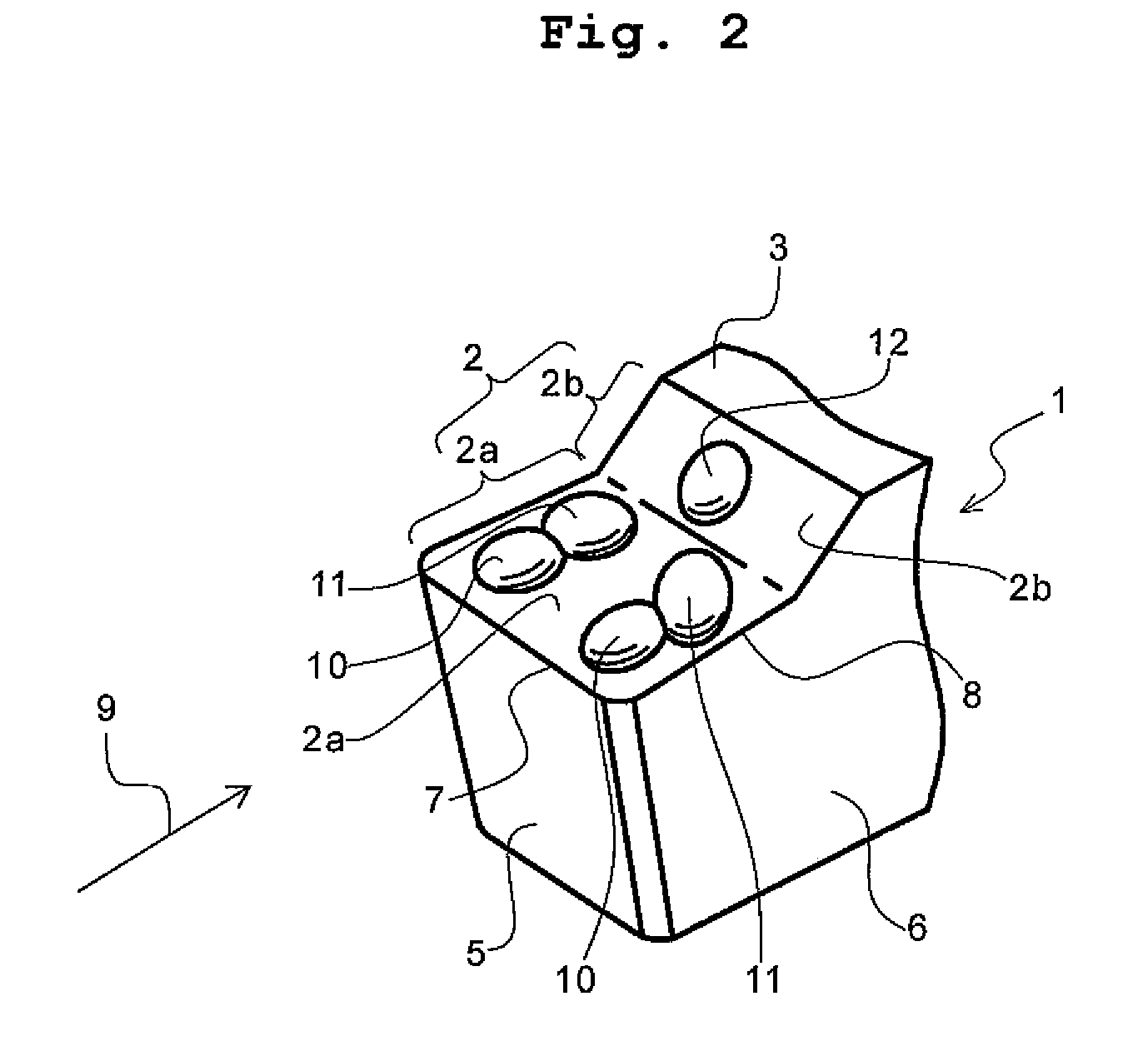

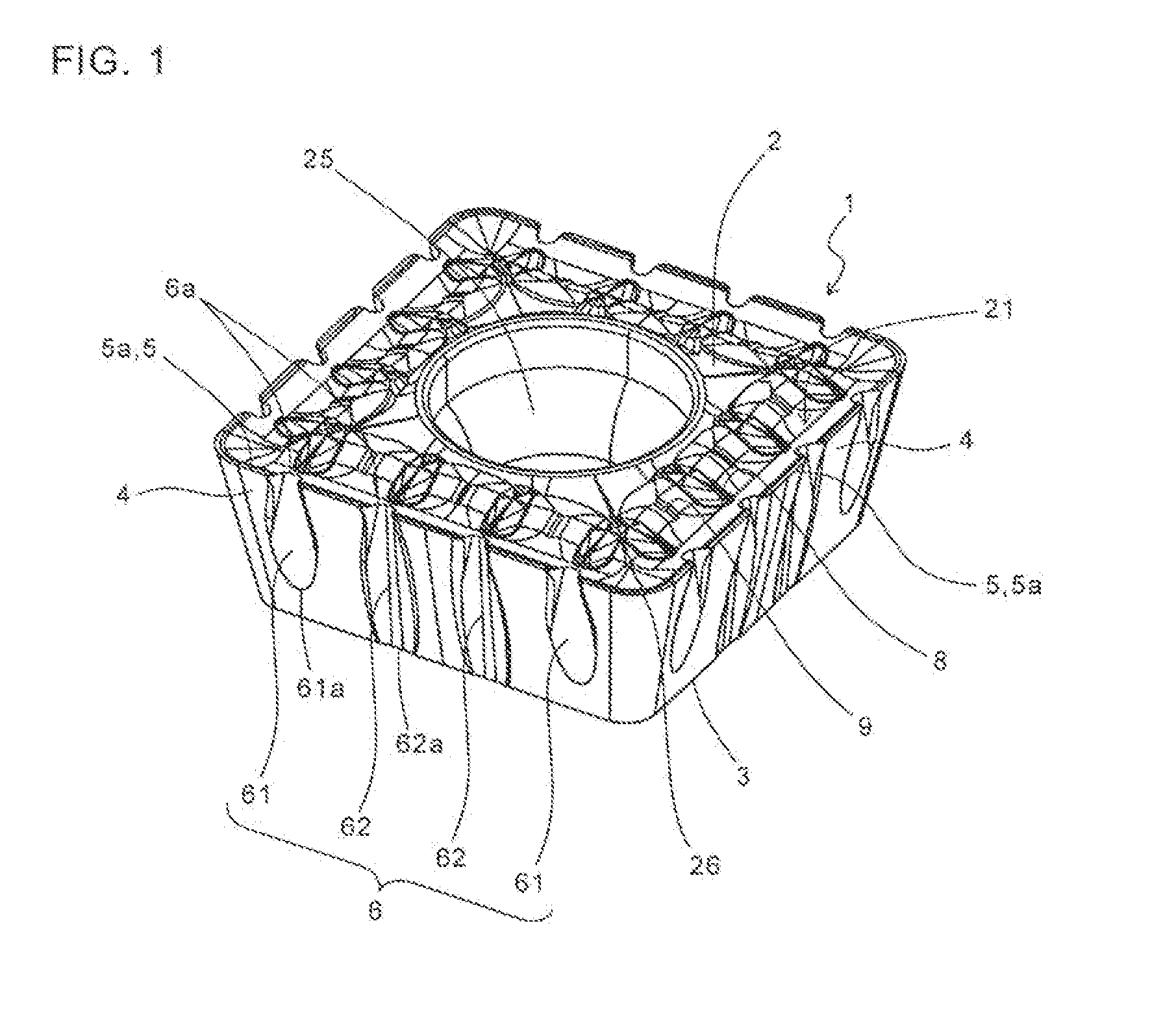

Cutting Insert

A cutting insert comprising a rake face region located on an upper surface, a flank located on a front surface, and a cutting edge located at an intersection between the rake face region and the flank. At least three types of projections having different distances from the cutting edge are located on the rake face region. When these three types of projections are arranged in the order of their increasing distance from the cutting edge, namely, a first projection, a second projection and a third projection, the top of the second projection is located lower than an imaginary straight line connecting the top of the first projection and the top of the third projection in the side view.

Owner:KYOCERA CORP

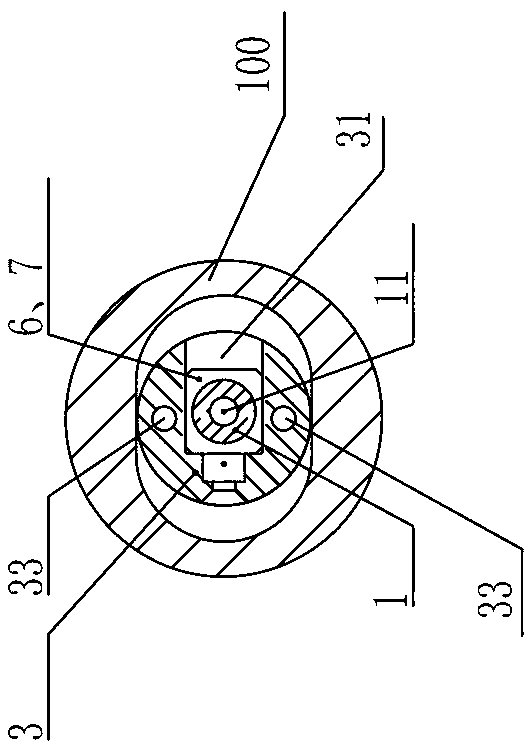

All-metal screw pump stator machining equipment

InactiveCN103008749AAvoid Hole DefectsExtend your lifeMilling cuttersAttachable milling devicesScrapStator

The invention discloses all-metal screw pump stator machining equipment. The all-metal screw pump stator machining equipment comprises a cutter bar, a cutter head, a guide rod, a supporting base, a workpiece fixing device and a cutter bar rotation driving device, wherein the supporting base is fixedly connected with a machine tool; a guide sleeve is arranged on the guide rod; a guide slot is formed on the guide rod; the guide rod is arranged on the supporting base; the cutter bar is arranged inside the guide slot through an adjustable shaft sleeve; the cutter head is arranged at the front end of the cutter bar; the back end of the cutter bar is connected with the cutter bar rotation driving device; the cutter bar is equipped with a translational mechanism moving in the radial direction of the guide slot; at least one axial air hole is formed on the guide rod; the outlet of the axial air hole is formed on the front end surface of the guide rod; the inlet of the axial air hole is connected with an air supplying device; an axially communicated cooling oil hole is formed in the center of the cutter bar; and a cooling oil supplying device is connected at the back end of the cooling oil hole. The all-metal screw pump stator machining equipment has the advantage as follows: metal scraps are discharged from a cutting point, thus avoiding the problems such as abrasion of the cutter head and blade flaking, and preventing defects of an internal hole caused by scratch of the internal hole by the metal scraps.

Owner:宁波正鼎石油机械设备制造有限公司

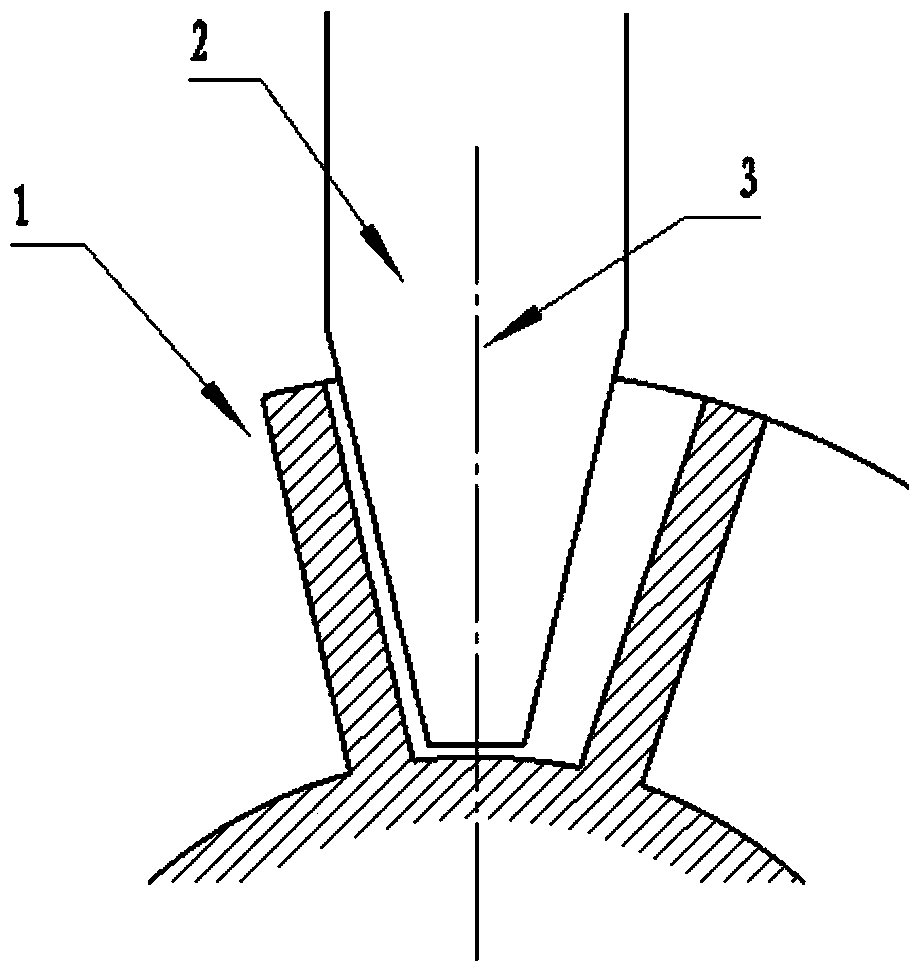

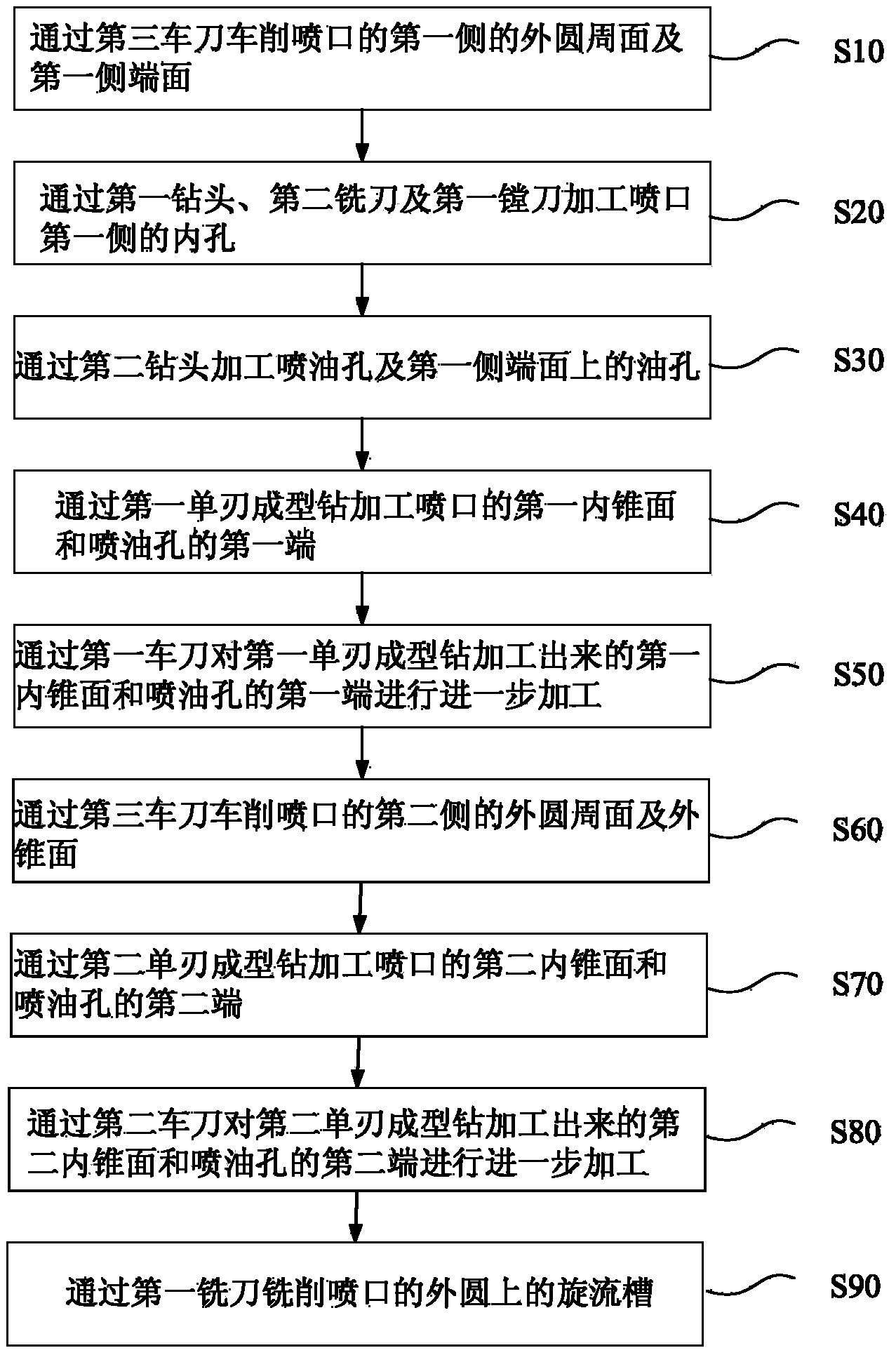

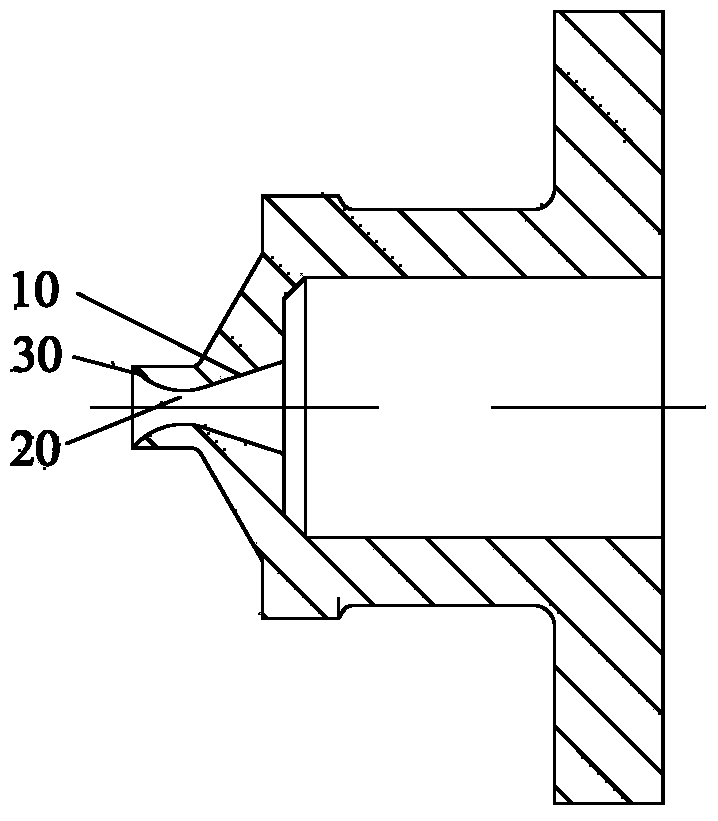

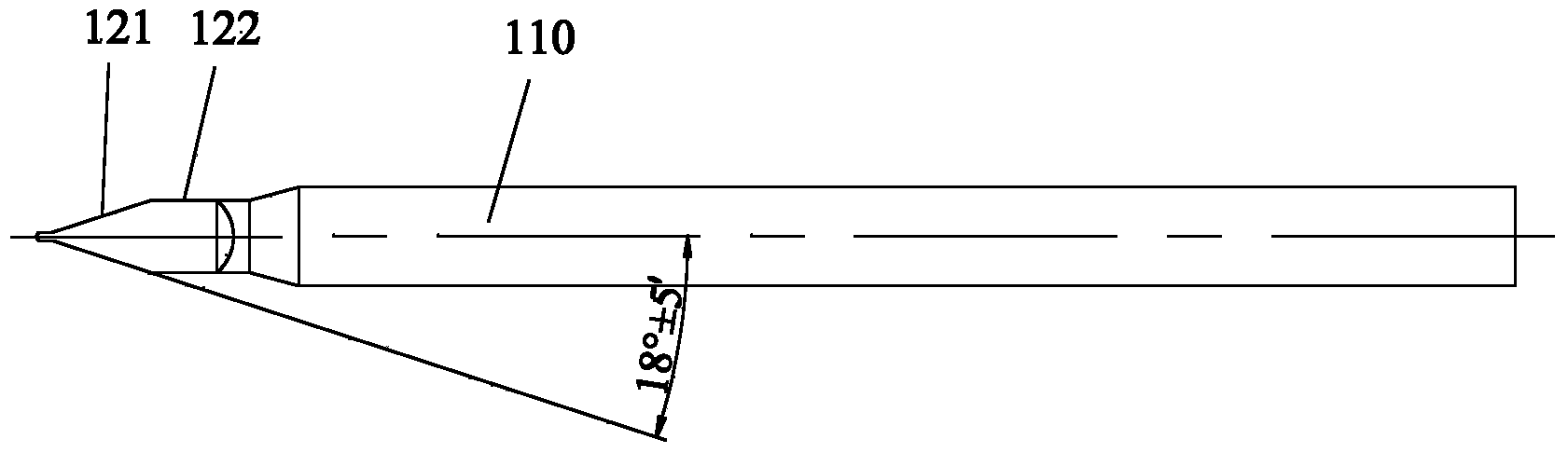

Machining method and machining device of jet nozzle

ActiveCN103586636AIncrease chip removal spaceImprove cooling effectTransportation and packagingMilling cuttersFistEngineering

The invention provides a machining method and a machining device of a jet nozzle. The machining method of the jet nozzle comprises the following steps that S40, the first end of a first inner conical surface (10) and the first end of an oil jet hole (20) of the jet nozzle are machined through a first single-blade forming drill; S70, the second end of a second inner conical surface (30) and the second end of the oil jet hole (20) of the jet nozzle are machined through a second single-blade forming drill; the first single-blade forming drill and the second single-blade forming drill respectively comprise a first cutter handle (110) and a first cutter head (120), each first cutter head (120) comprises a first conical section (121), each first conical section (121) is gradually contacted and extends outwards, a first cutting surface (1211) is formed on each first conical section (121) and provided with a fist scrap discharging portion, and one of two edges of each first cutting surface (1211) forms a cutting blade. According to the technical scheme, the machining method and the machining device effectively solve the problem that the inner conical surfaces of the jet nozzle are difficult to machine in the prior art.

Owner:CHINA HANGFA SOUTH IND CO LTD

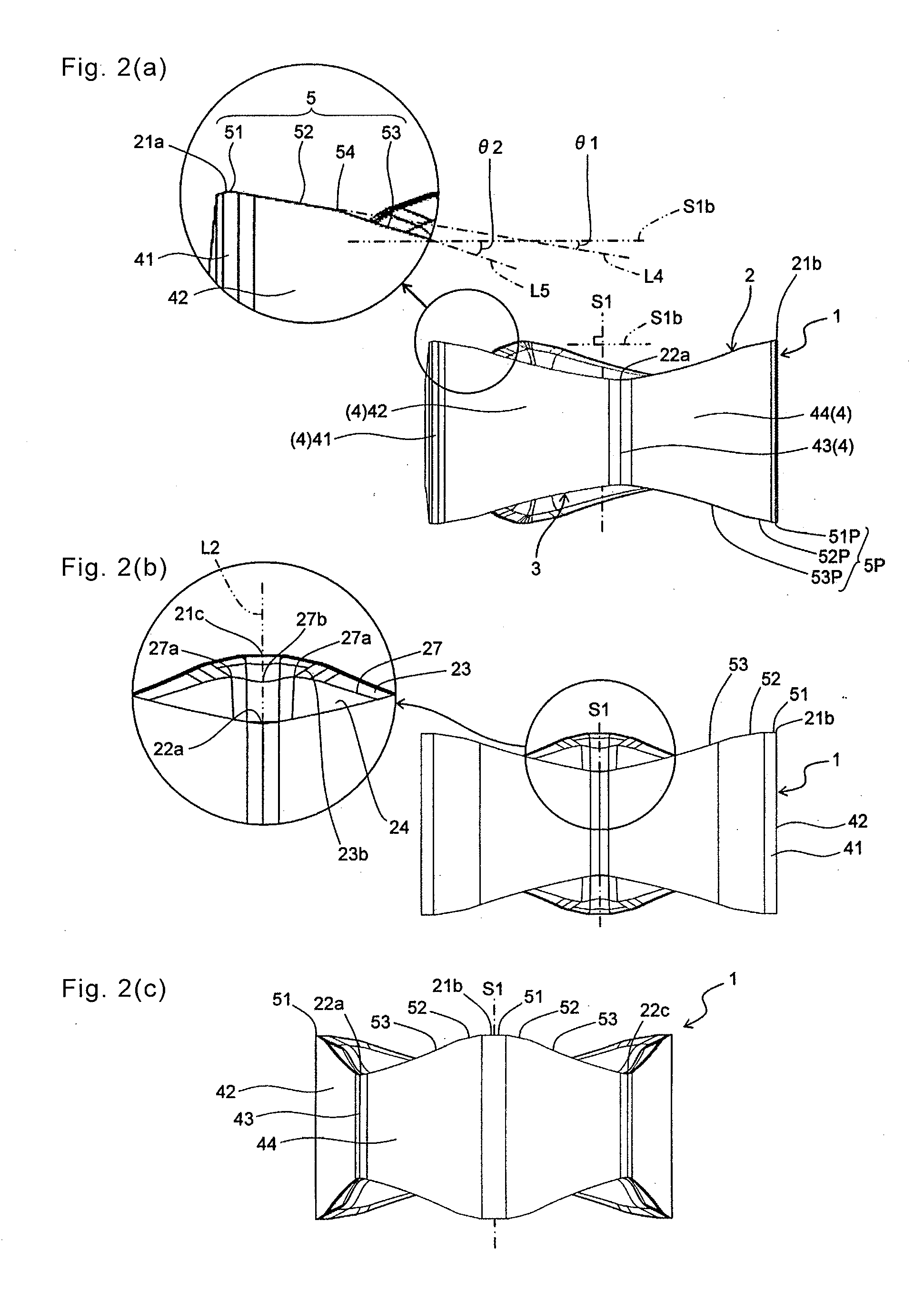

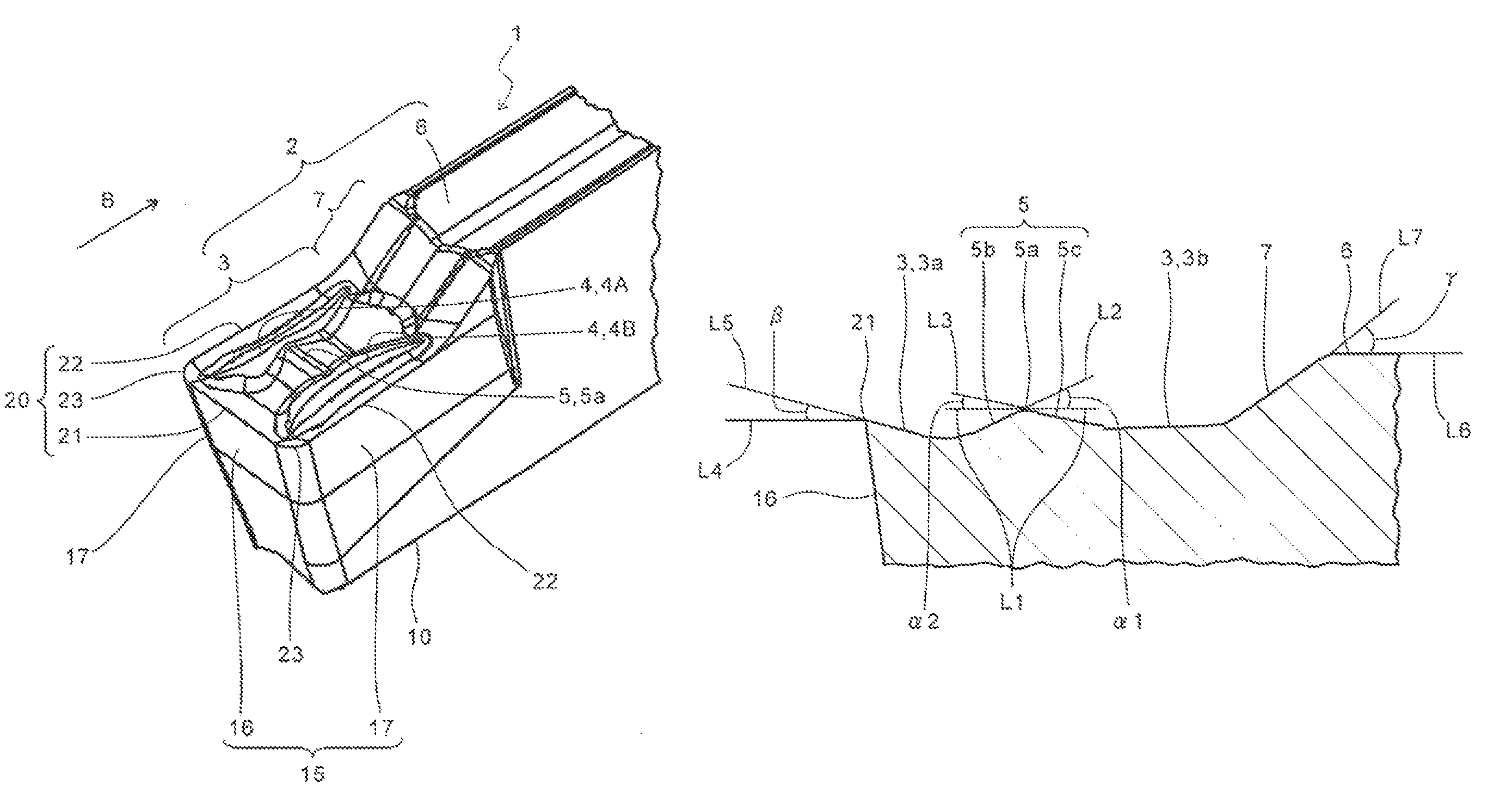

Cutting insert, cutting tool, and method of producing machined product using the same

ActiveUS20140314509A1Good chip removal effectCurl stableTransportation and packagingMilling cuttersEngineeringMechanical engineering

A cutting insert comprises an upper surface including a first corner, and a second and third corner, respectively, adjacent to both sides of the first corner. The upper surface sequentially includes a rake surface along an upper cutting edge, inclined toward a lower surface, going inward from the upper cutting edge at a rake angle on a basis of a perpendicular plane perpendicular to a central axis extending between the upper and lower surfaces, and a connection surface more inward than the rake surface, inclined toward the lower surface, going inward at a connection angle on the basis of the perpendicular plane. An intersecting part of the rake surface and the connection surface includes a highest position in a portion of the intersecting part corresponding to a minor rake surface. A cutting tool with cutting insert, and a method of producing a machined product using the cutting tool are provided.

Owner:KYOCERA CORP

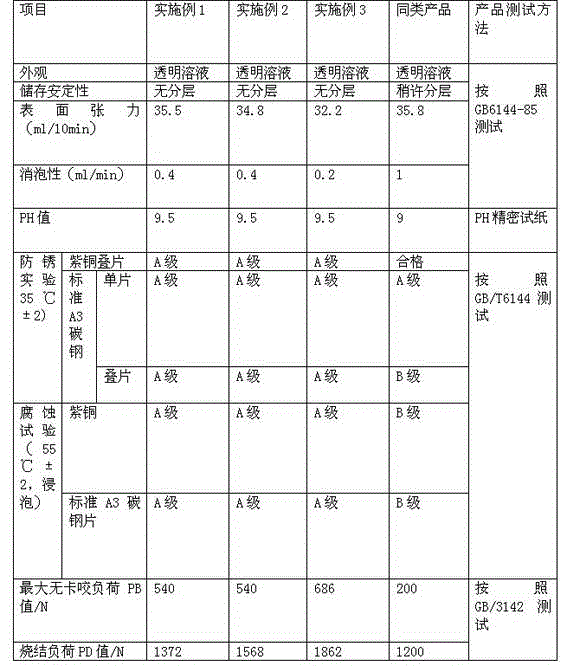

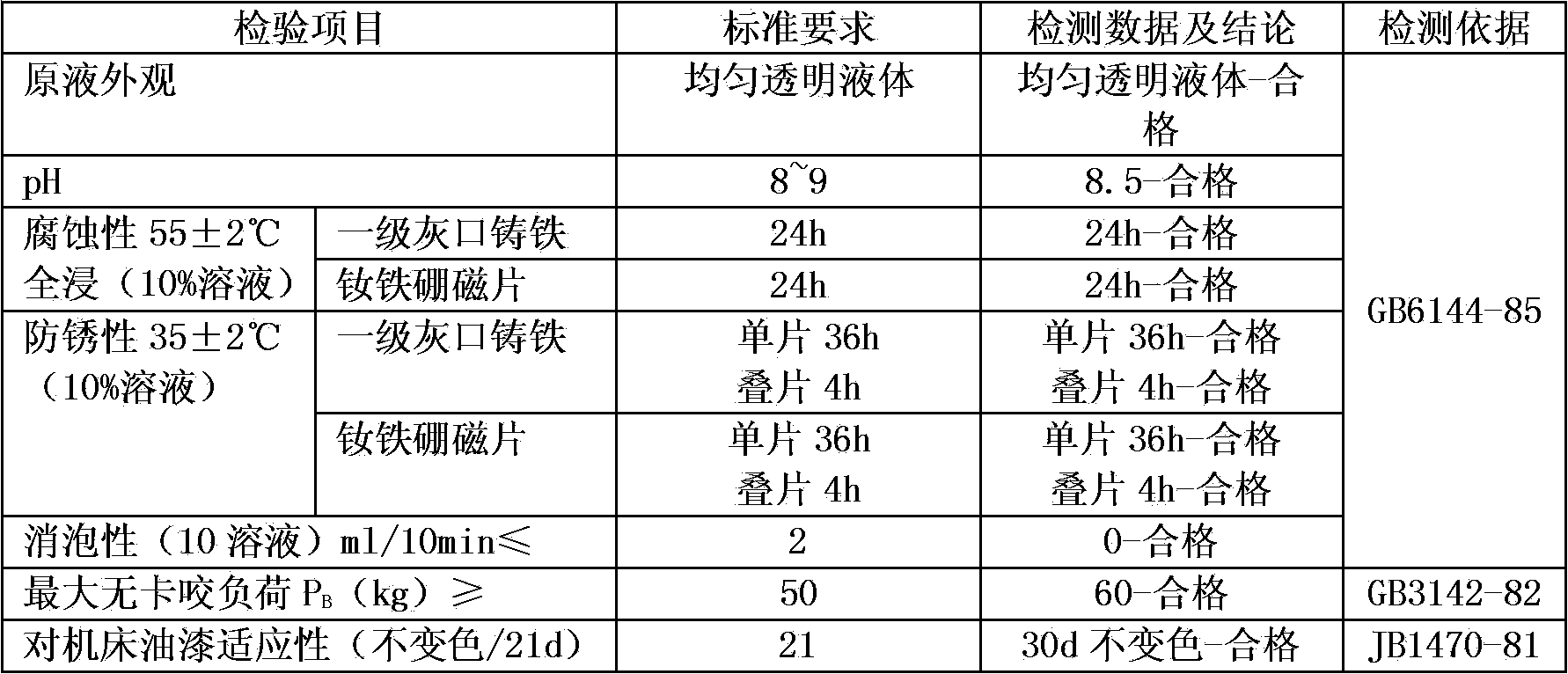

Total synthesis metal cutting solution and preparation method thereof

The invention discloses a total synthesis metal cutting solution comprising the following components by weight percent: 0.5-1% of pH regulator, 10-20% of antirust agent, 10-15% of mixed hydramine, 5-8% of lubricating agent, 0.1-0.3% of copper alloy corrosion inhibitor, 1-2% of sterilizing agent, 0.1-0.2% of defoaming agent, 0-0.5% of EDTA-4 sodium and the balance of water. The invention provides a preparation method of the total synthesis metal cutting solution. The total synthesis metal cutting solution is good in lubricating performance, and the use effect is superior to that of emulsification solution. By utilizing the total synthesis metal cutting solution, surface smoothness of a workpiece can be improved, a grinding wheel can not be sticked, and abrasion of the grinding wheel is reduced. The total synthesis metal cutting solution has a good sedimentation effect and is less in bubbles, long in service life and excellent in anti-rust property, cooling property, permeability and cleanability. By utilizing the total synthesis metal cutting solution, the service life of the grinding wheel can be effectively prolonged. The total synthesis metal cutting solution is suitable for materials, such as bearing steel, carbon steel and the like, the solution is colorless and transparent, and surface processing conditions are easy to observe. Meanwhile, the total synthesis metal cutting solution does not contain toxic and harmful substances, such as sodium nitrite, phenols and the like and is harmless to environment and operator health.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

Cutting insert

A cutting insert includes a rake face region located on an upper surface, a flank located on a front surface, and a cutting edge located at an intersection between the rake face region and the flank. At least three types of projections having different distances from the cutting edge are on the rake face region. When these three types of projections are arranged in the order of increasing distance from the cutting edge, namely, a first projection, a second projection and a third projection, the top of the second projection is lower than an imaginary straight line connecting the top of the first projection and the top of the third projection in the side view.

Owner:KYOCERA CORP

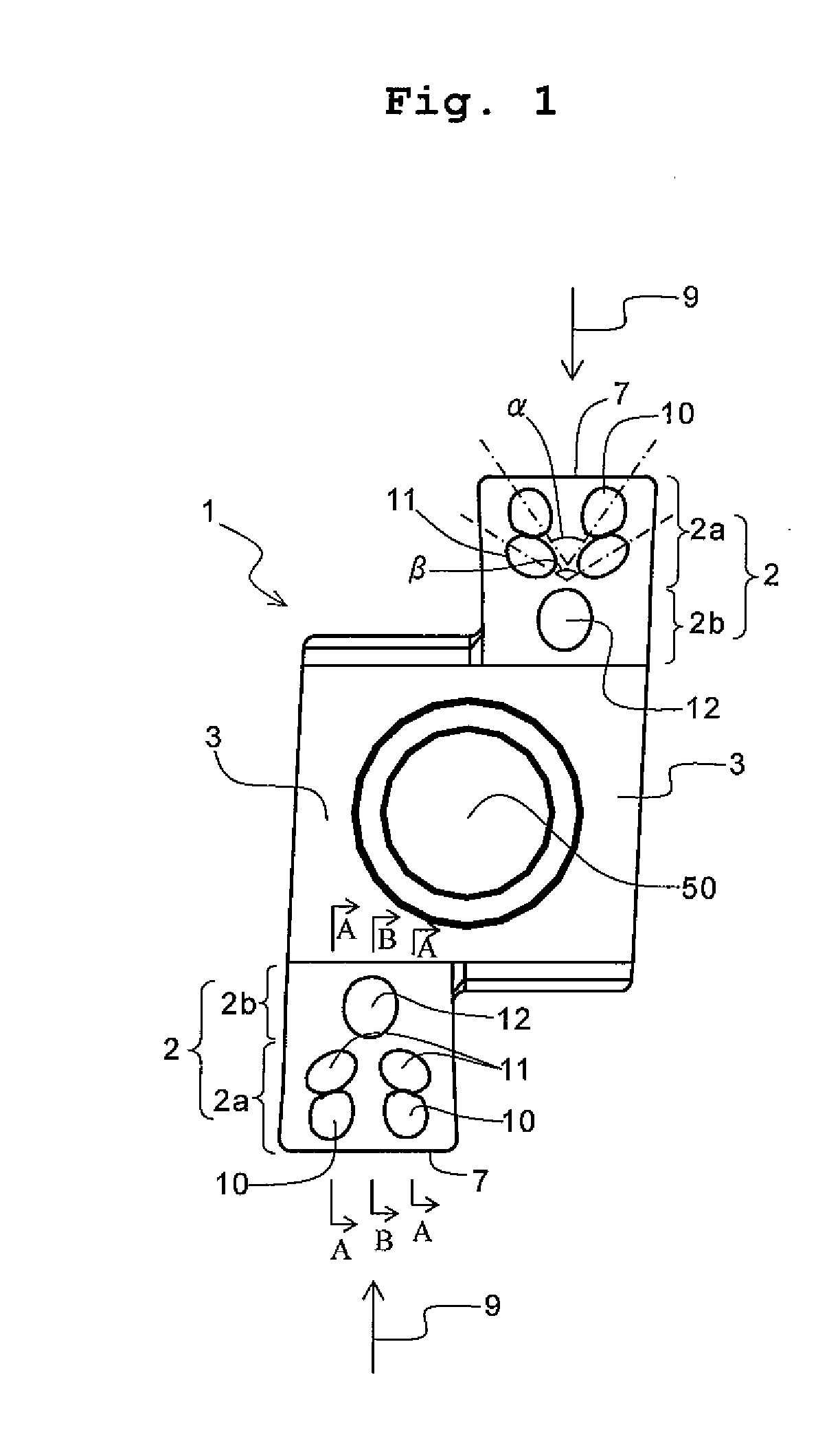

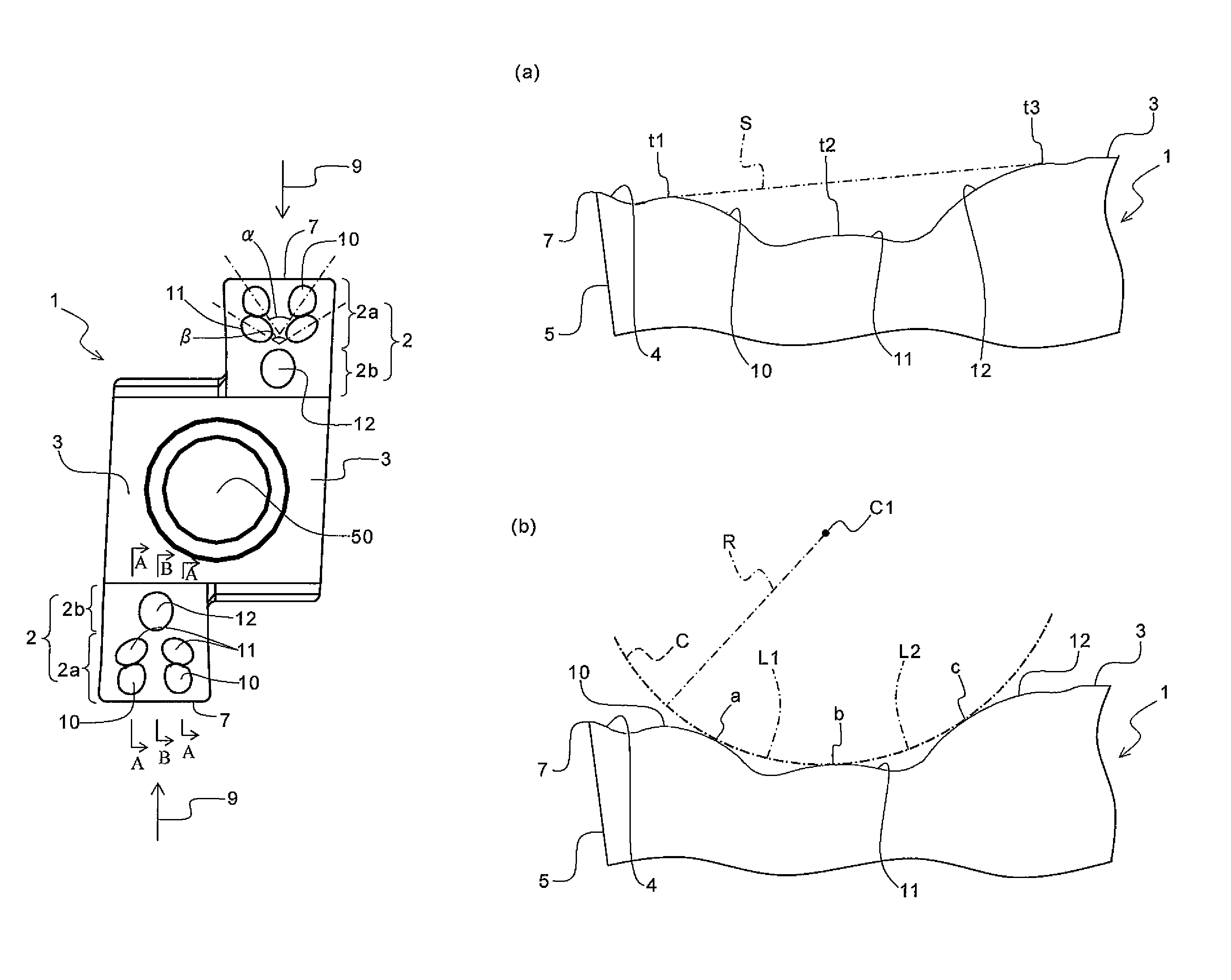

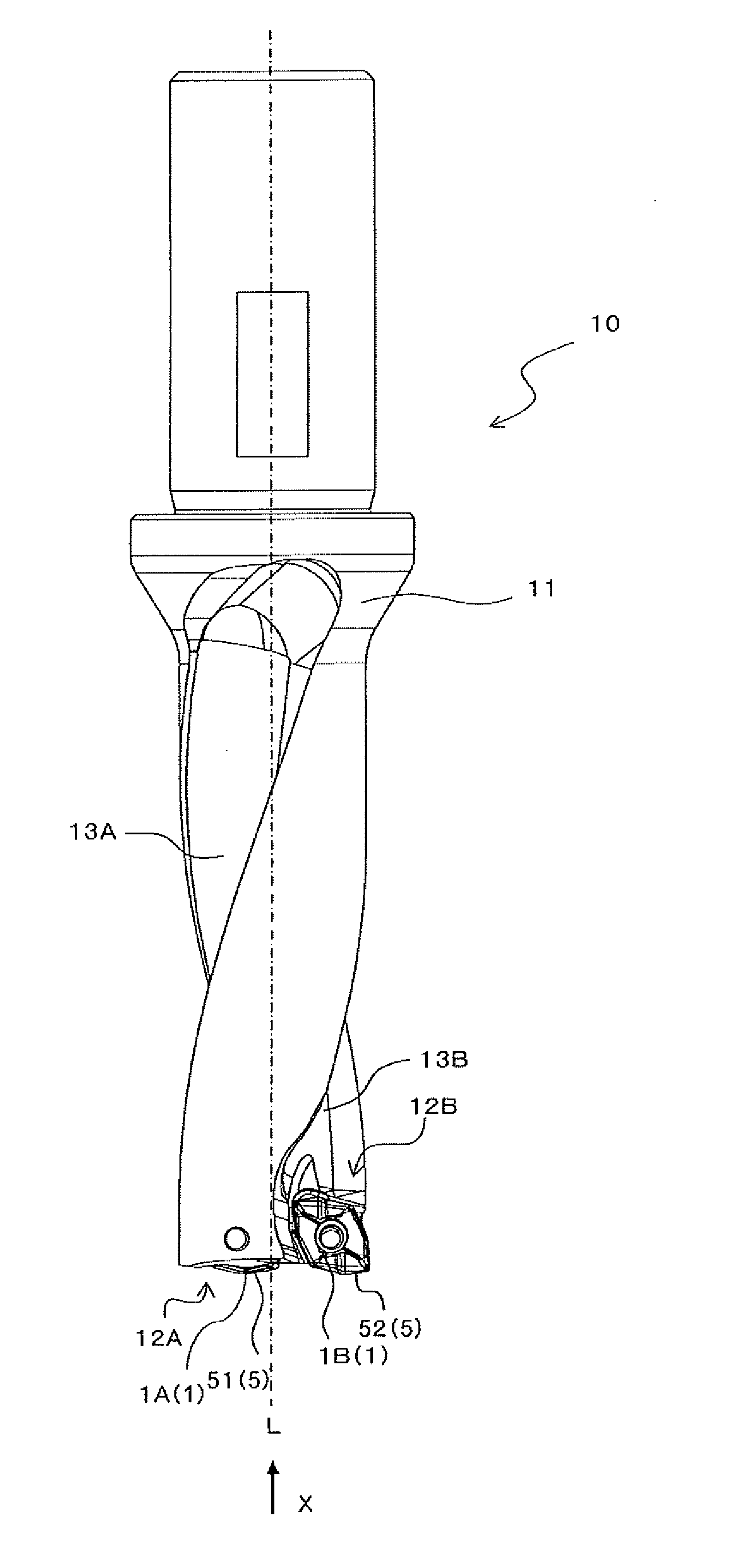

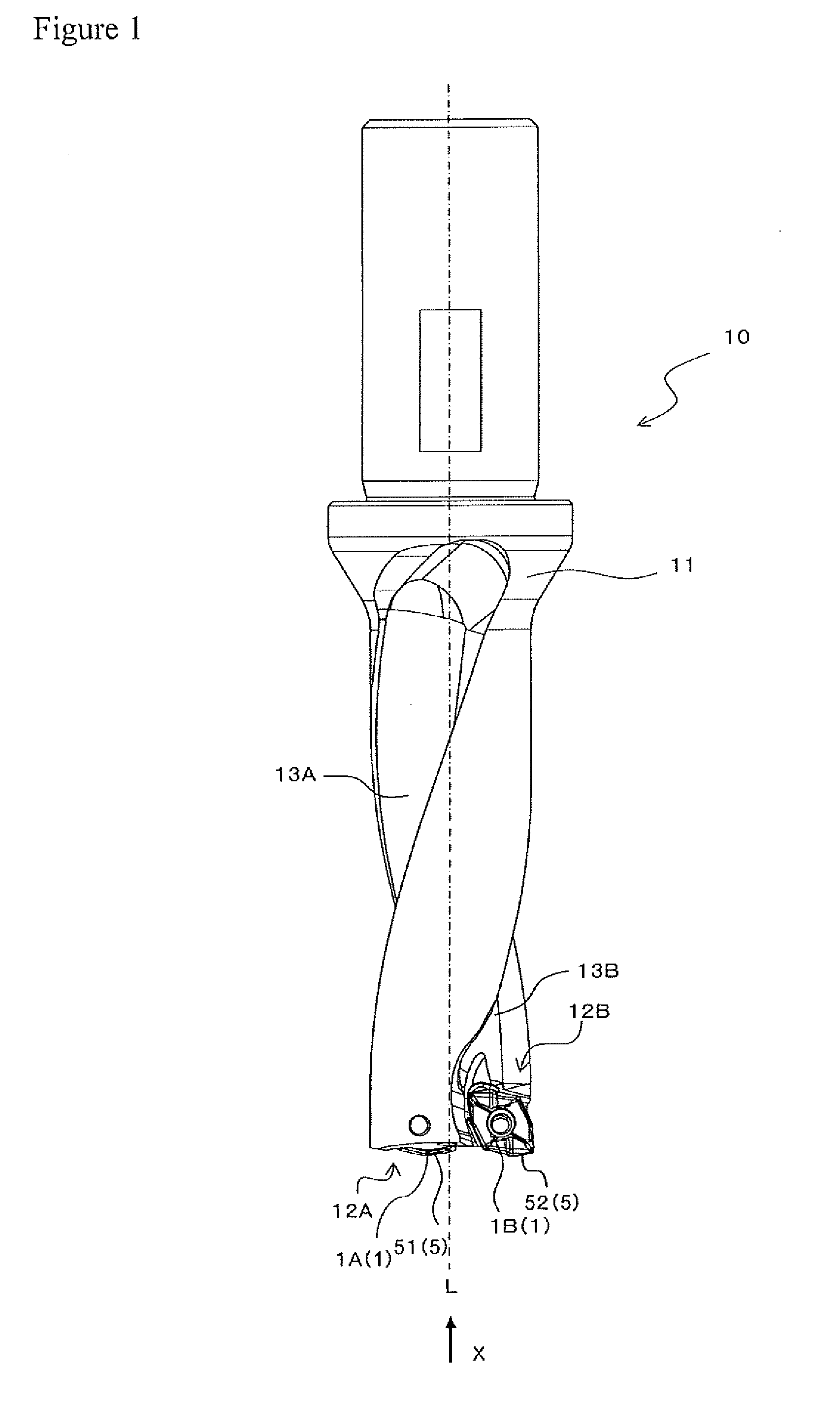

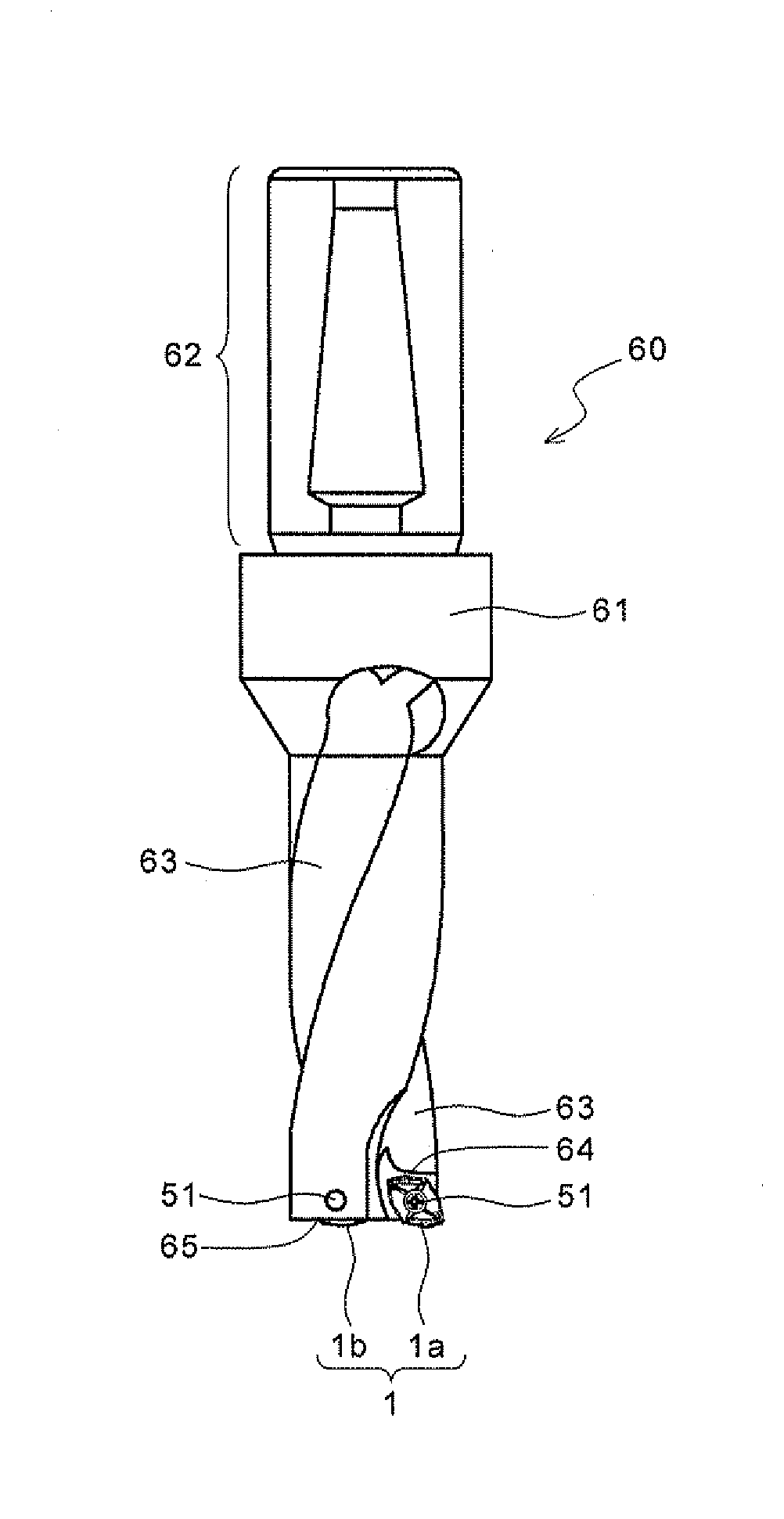

Drill, Cutting Insert, and Method of Manufacturing Cut Product

ActiveUS20110044776A1Good chip removal effectEasy to shapeThread cutting toolsWood turning toolsDrill bitEngineering

A drill, including: a substantially columnar drill holder including, at a front end portion thereof, a first insert pocket and a second insert pocket formed closer to the outer periphery of the drill holder than the first insert pocket; a first insert which is attached to the first insert pocket and includes a first cutting edge at an intersection of an upper face and a side face; and a second insert which is attached to the second insert pocket and includes a second cutting edge at an intersection of a upper face and a side face. The first insert pocket is located passing through a central axis of rotation of the drill holder. The second cutting edge has a concave shape when viewed from the front end side of the drill holder, and has a curved line at least a part thereof.

Owner:KYOCERA CORP

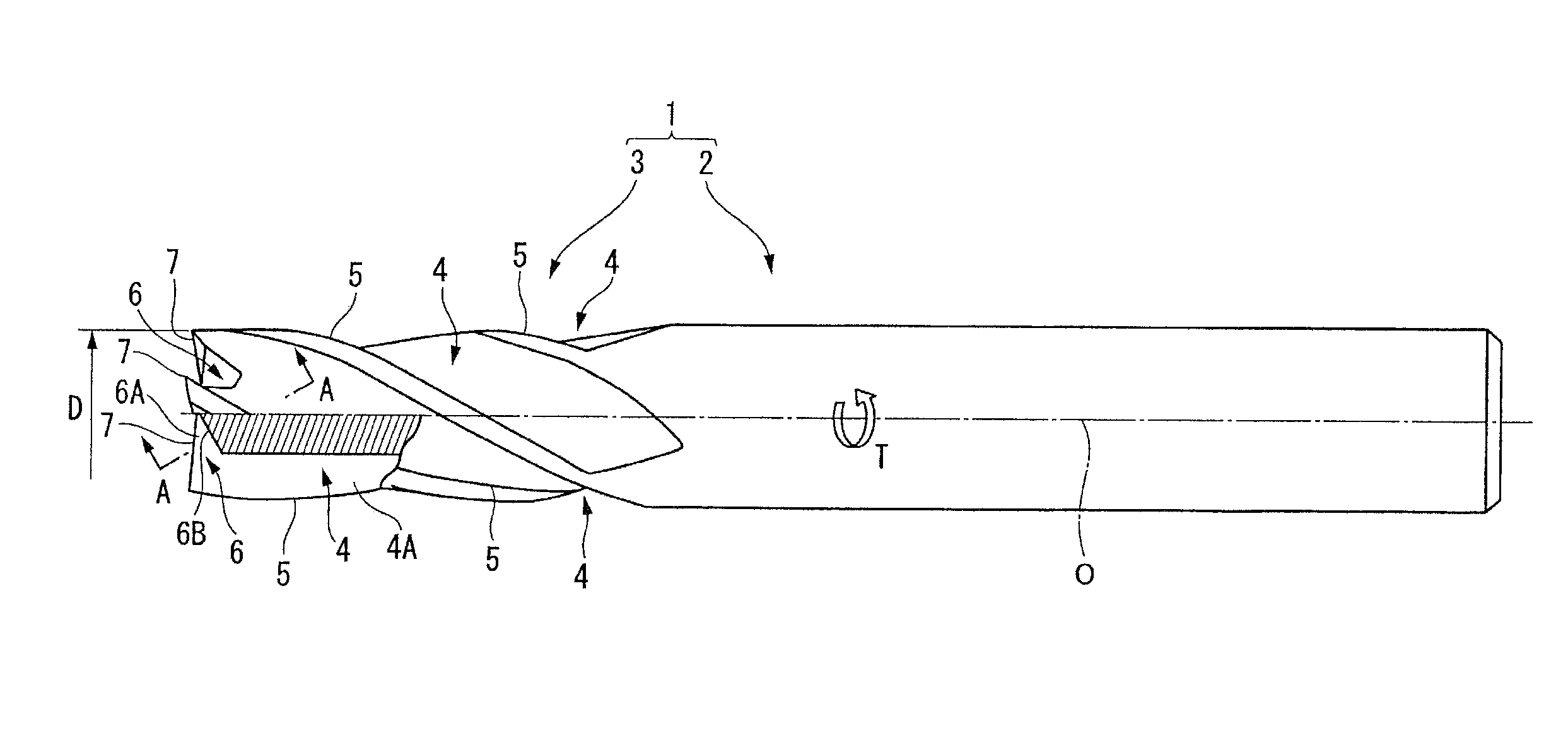

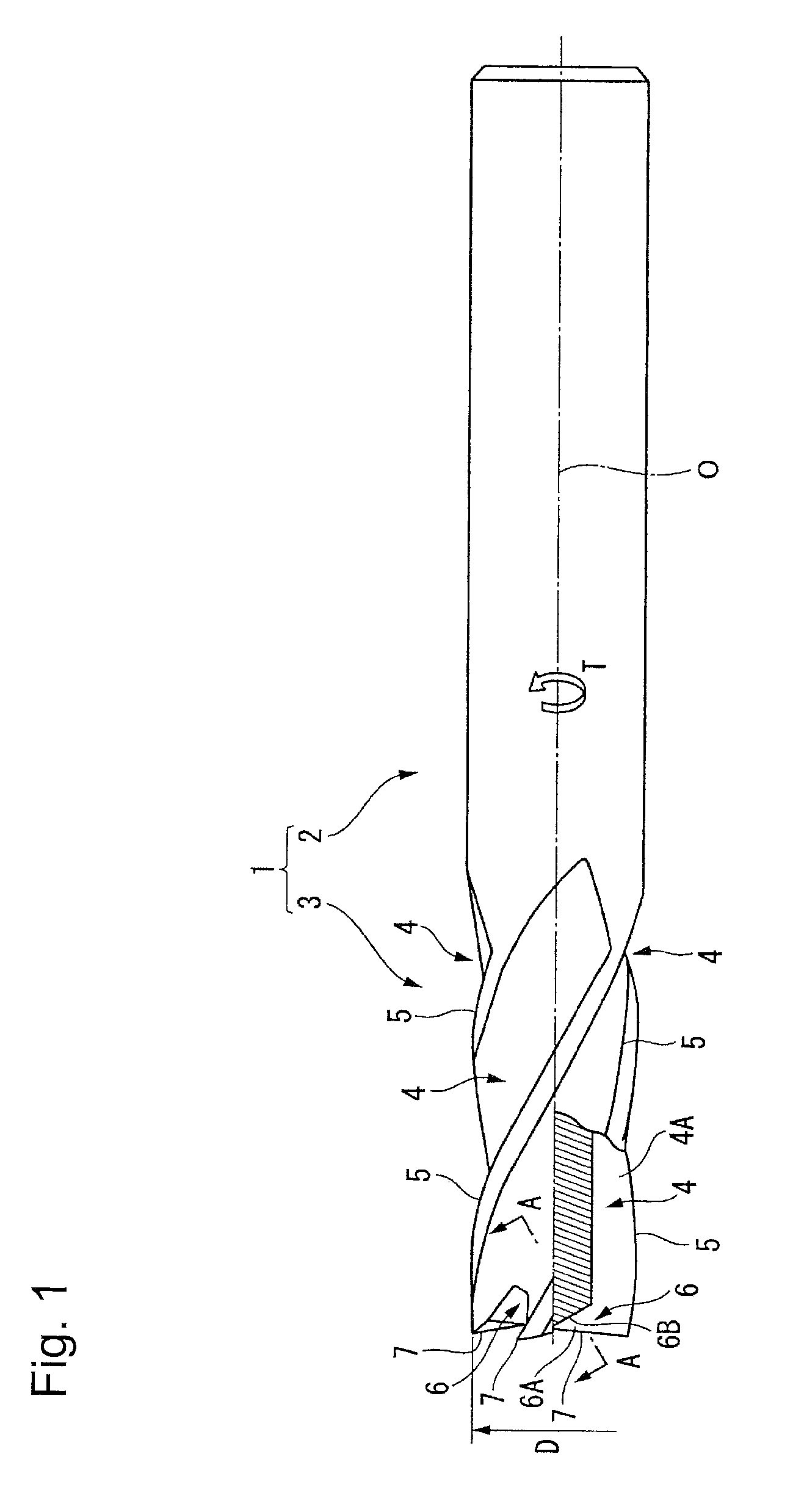

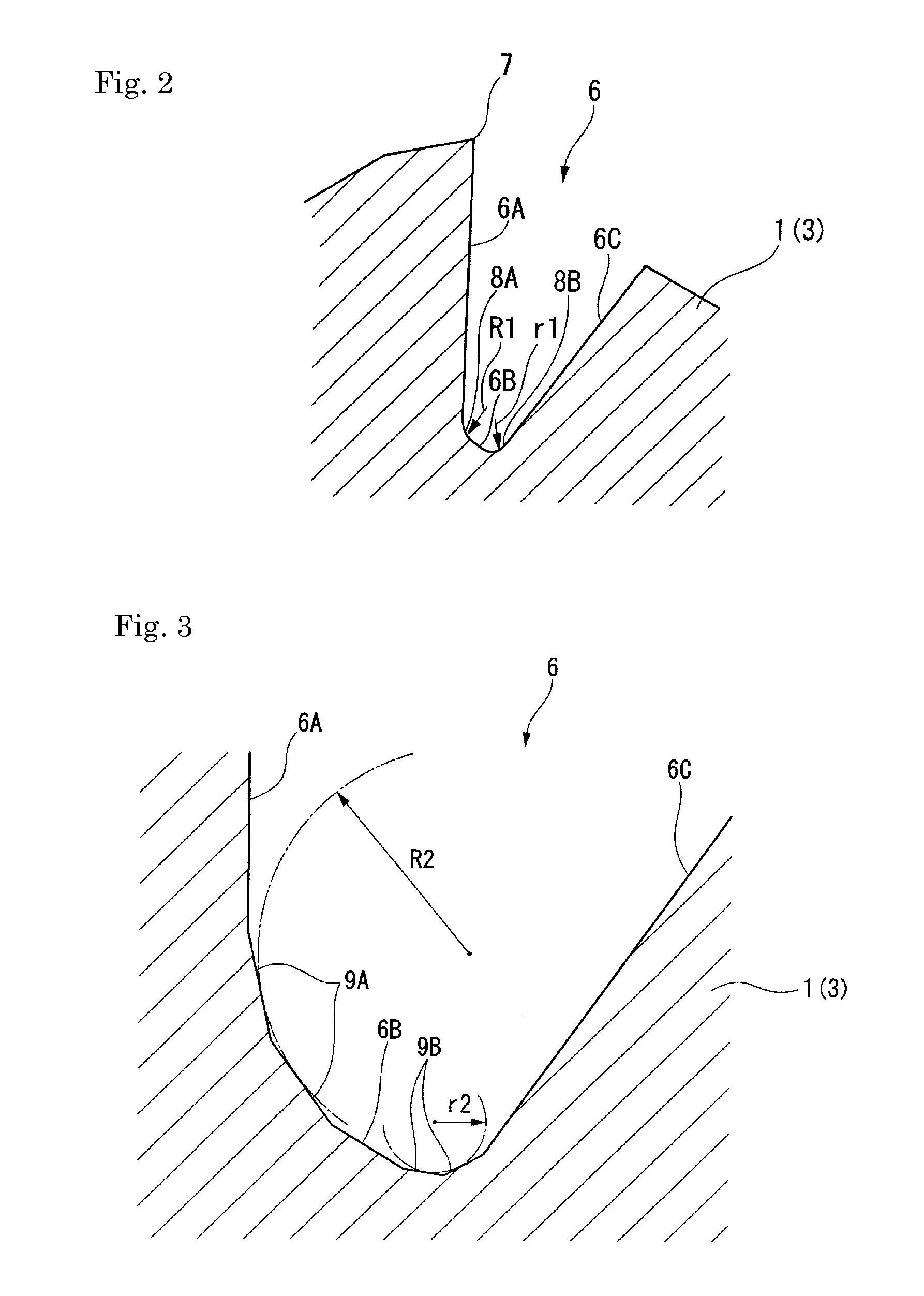

End mill

ActiveUS8277152B2Good chip removal effectAvoid stress concentrationMilling cuttersShaping cuttersEngineeringMechanical engineering

Owner:MITSUBISHI MATERIALS CORP

Cutting insert, cutting tool, and method of manufacturing machined product using the same

ActiveUS8784014B2Good chip removal effectEasy to splitCutting insertsTurning toolsEngineeringKnife blades

Owner:KYOCERA CORP

Yttrium modified chromium aluminium carbonitride/silicon nitride nano composite coating and deposition method thereof

ActiveCN103436841AHigh bonding strengthGood heat matchingLayered productsVacuum evaporation coatingRare-earth elementAlloy

The invention relates to a yttrium modified chromium aluminium carbonitride / silicon nitride nano composite coating and a deposition method thereof. Chromium aluminium carbonitride and silicon nitride are subjected to nano composite design to form a nano composite structure with nanocrystal chromium aluminium carbonitride implanted into amorphous silicon nitride, so that the rigidity of the coating is improved; the toughness of the coating and bonding strength of the coating and a matrix are both considered; a rare earth element Y is introduced simultaneously, so that the mechanical property and high-temperature oxidation resistance of the coating are further improved; and the nano composite coating which is strong in bonding force, high in rigidity, good in toughness, low in friction coefficient and prominent in thermostability and is used for high-speed steel and hard alloy cutters and molds is obtained. The coating comprises a chromium-aluminum-yttrium bonding layer, a chromium-aluminum-yttrium nitride transition layer and a nano composite layer; the membrane / matrix bonding strength of the obtained coating reaches 40-90N; the surface composite strength under 10g load reaches 40-65 GPa; and the friction coefficient is 0.2-0.5 when matched with GCr15.

Owner:JIANGXI SCI & TECH NORMAL UNIV

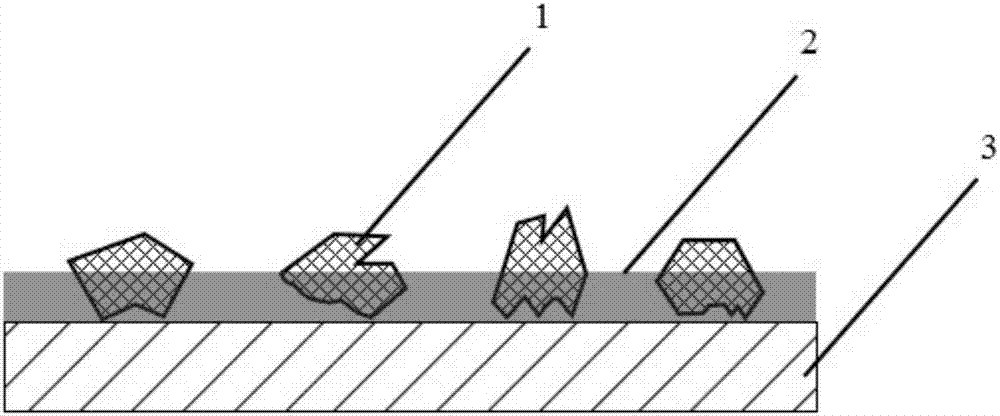

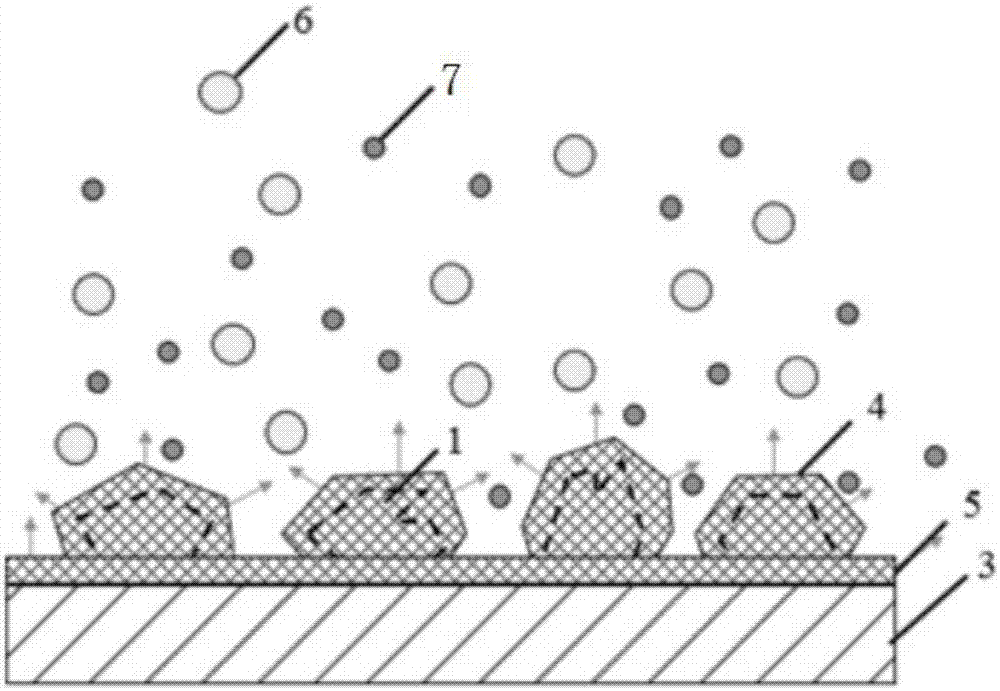

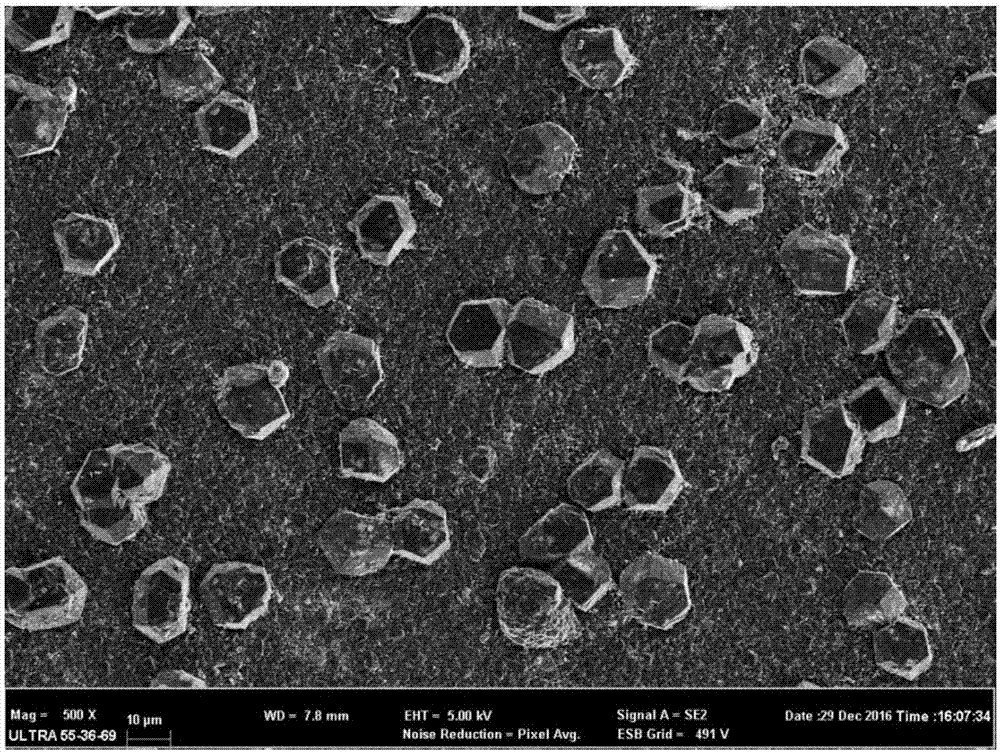

Method for preparing single-layer diamond abrasive tool through chemical vapor deposition

The invention discloses a method for preparing a single-layer diamond abrasive tool through chemical vapor deposition. According to a silicon carbide base body, a diamond abrasive material is mixed into a photoresist solution and is subject to ultrasonic vibration, rotating whirl coating is used for evenly dispersing diamond abrasive particles, uniform distribution of the particles on a base body substrate can be achieved, the CVD method is adopted to enable the diamond coating bonding agent to be subject to deposition between the diamond abrasive particles and the silicon carbide base body, the abrasive material and the base body are firmly connected together, and meanwhile, the abrasive particles grow to become high-grade cubic octahedral single-crystal particles. The prepared single-layer diamond abrasive tool is high in abrasive particle holding force, the exposure height is large, the chipping containing space is large, defects of electroplating and brazing single-layer diamond abrasive tools are overcome, and the method is suitable for preparing fine granularity (five micrometers to 100 micrometers) single-layer diamond abrasive tools. The prepared single-layer diamond abrasive tool has the wide application prospect in high-precise grinding fields of crisp and hard materials of semiconductors, optical crystals, artificial sapphire, glass and the like

Owner:SHANGHAI JIAO TONG UNIV +1

Water-soluble and oil-soluble diamond grinding liquid and preparation method thereof

The invention discloses water-soluble and oil-soluble diamond grinding liquid, and belongs to the field of precise finishing and polishing processing. The liquid is prepared by the following raw materials in percentages by weight: 54-87% of base oil, 5-15% of an emulsifier, 5-10% of a co-emulsifier, 0.1-1% of an anti-aging agent of oil products, 0.05-5% of a diamond abrasive, and the balance being water. The invention also discloses a preparation method of the water-soluble and oil-soluble diamond grinding liquid, and the method comprises the following steps: (1) the base oil, the emulsifier, the co-emulsifier and the anti-aging agent of oil products are mixed and poured into a reaction vessel, and heating is carried out with stirring at 70 DEG C for 10-20 minutes; (2) the diamond abrasive is added into water and placed in supersonic wave with stirring for 10 minutes, and mixed liquor is obtained; (3) the mixed liquor with dispersed diamond abrasive is slowly added into a reaction vessel, temperature is raised to 70 DEG C with stirring for 30 minutes, temperature is reduced to room temperature with stirring, and the water-soluble and oil-soluble diamond grinding liquid is obtained.

Owner:HENAN UNION ABRASIVES

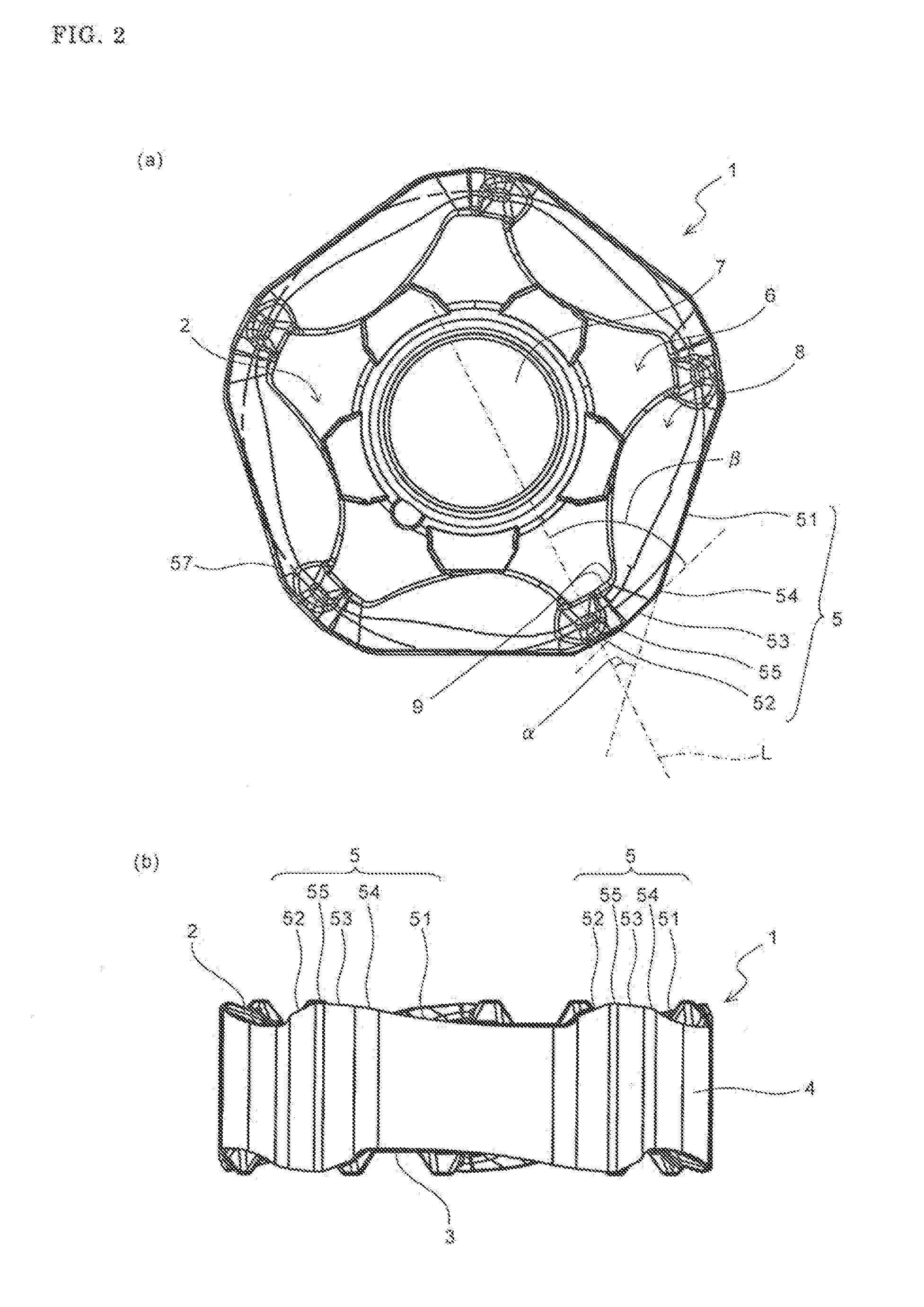

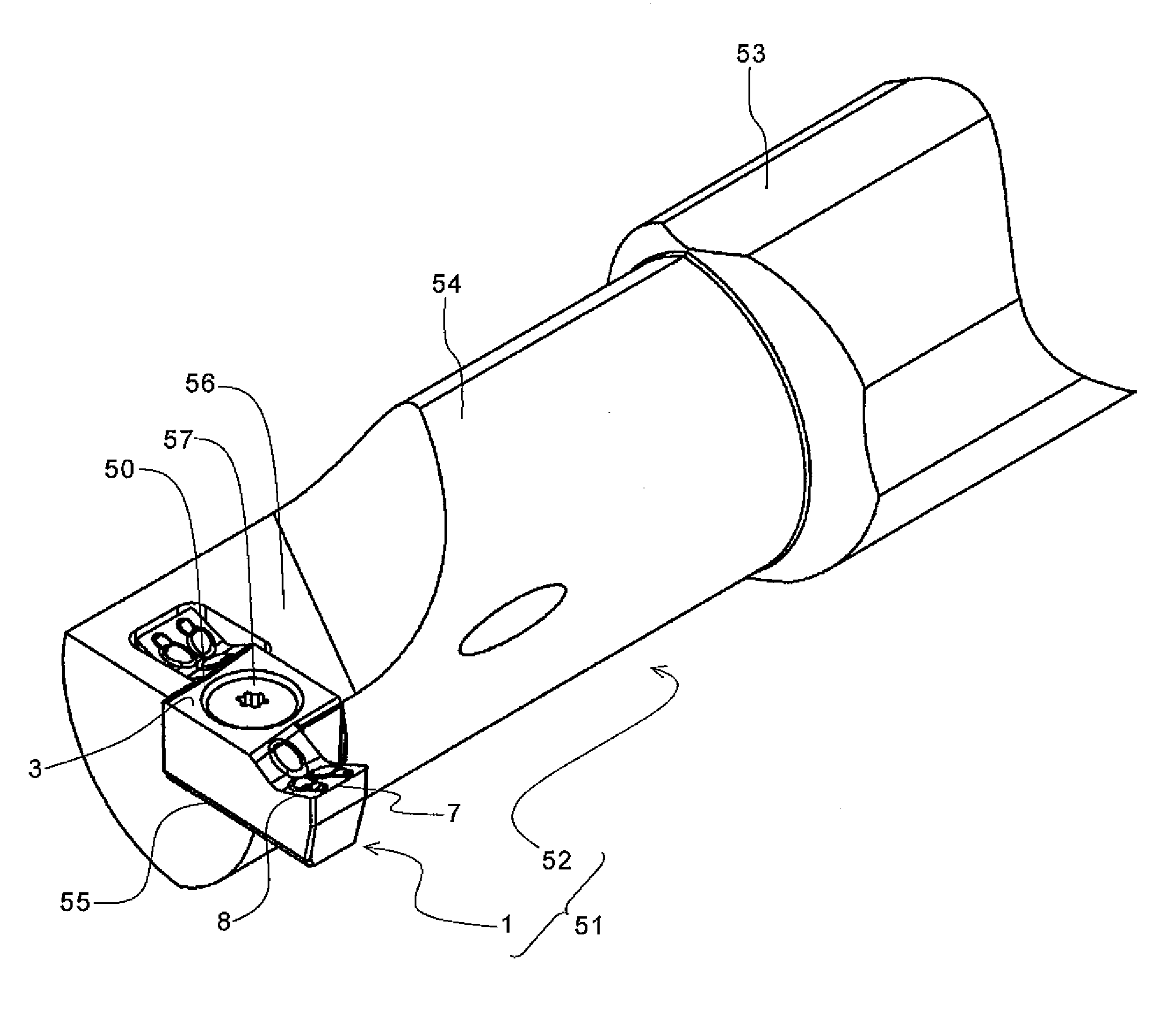

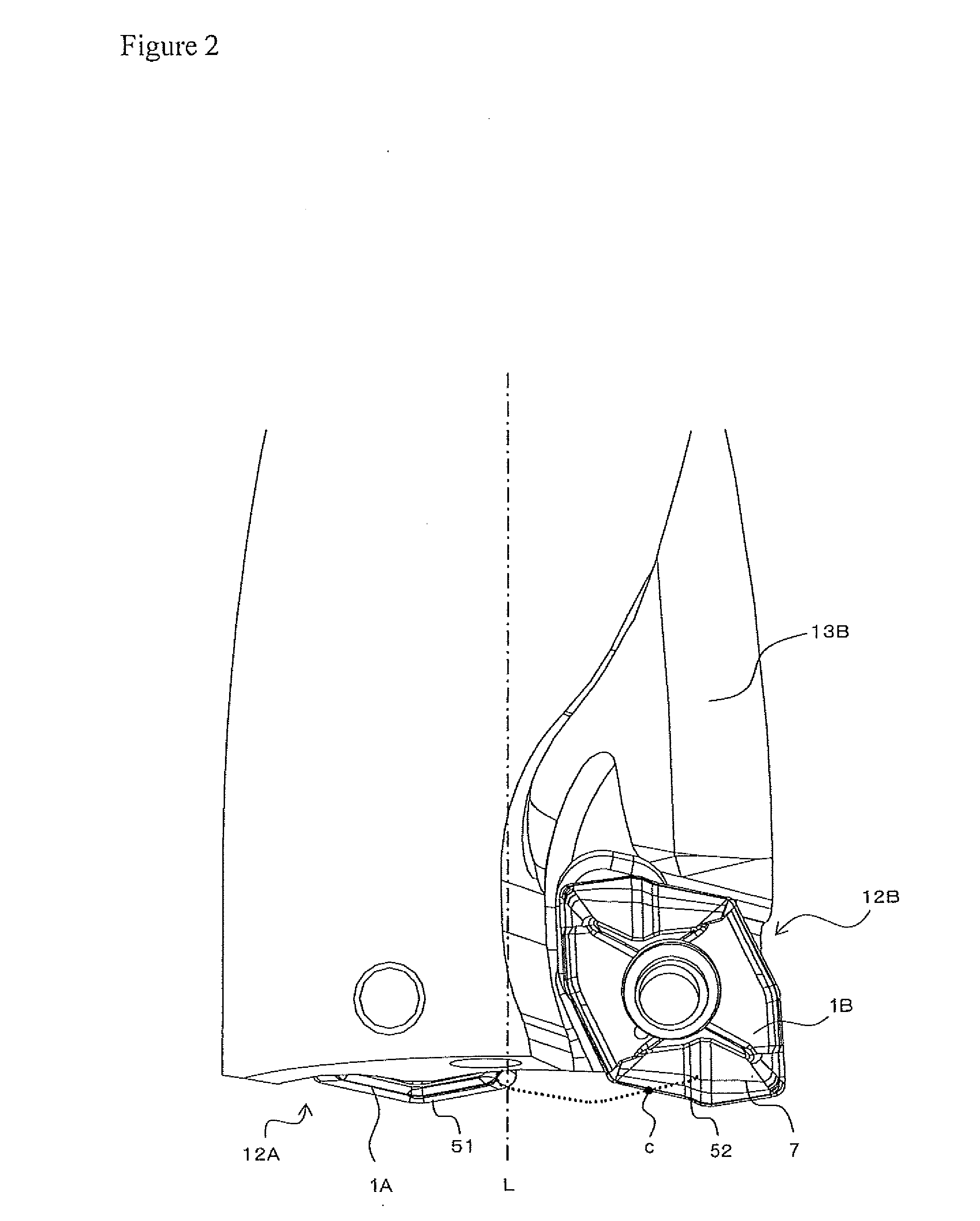

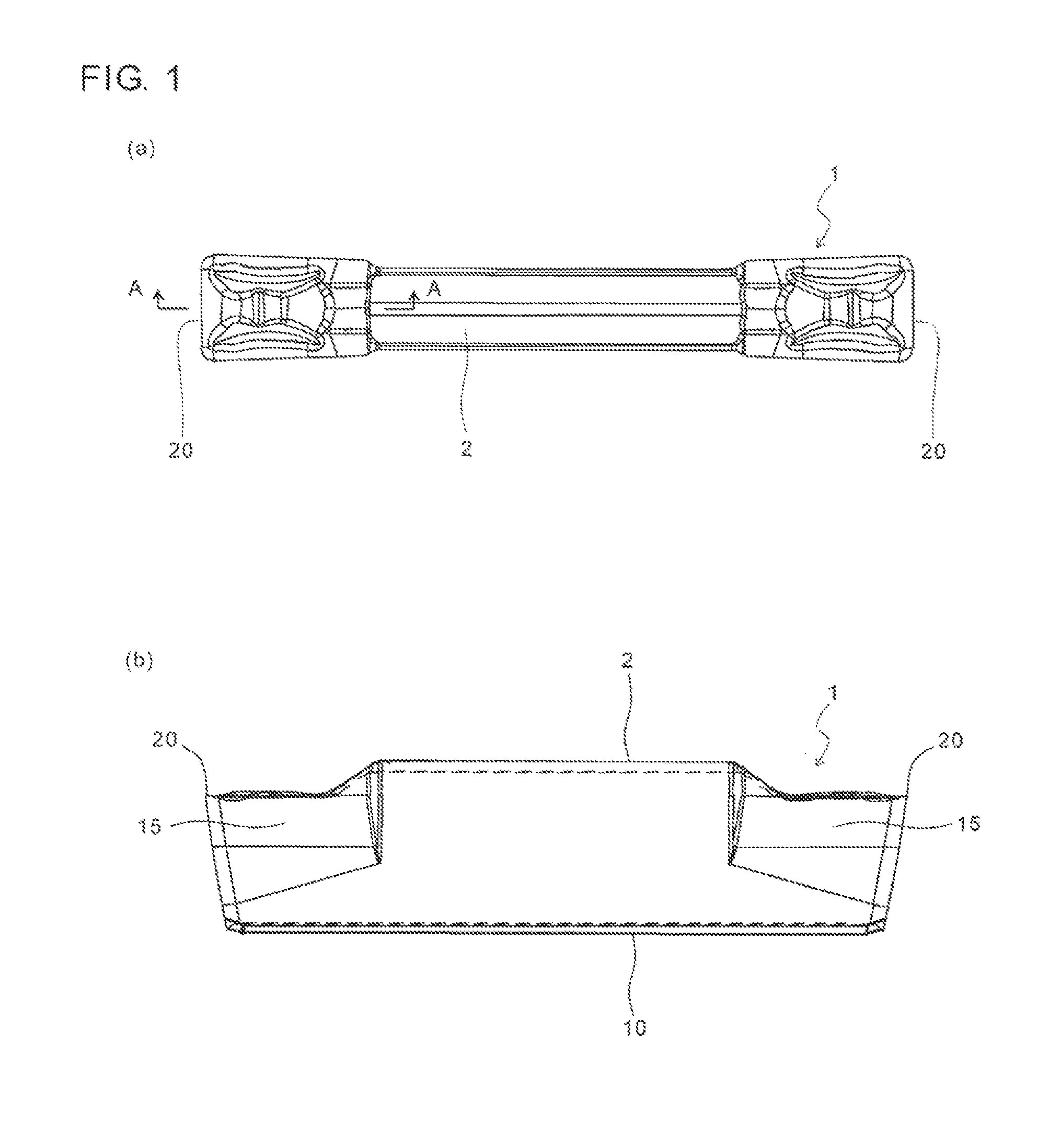

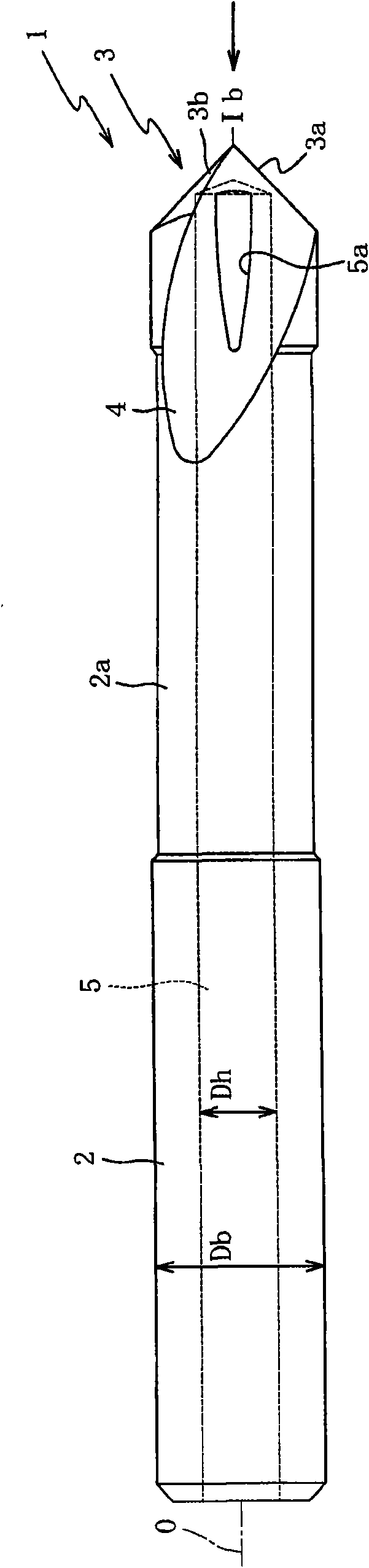

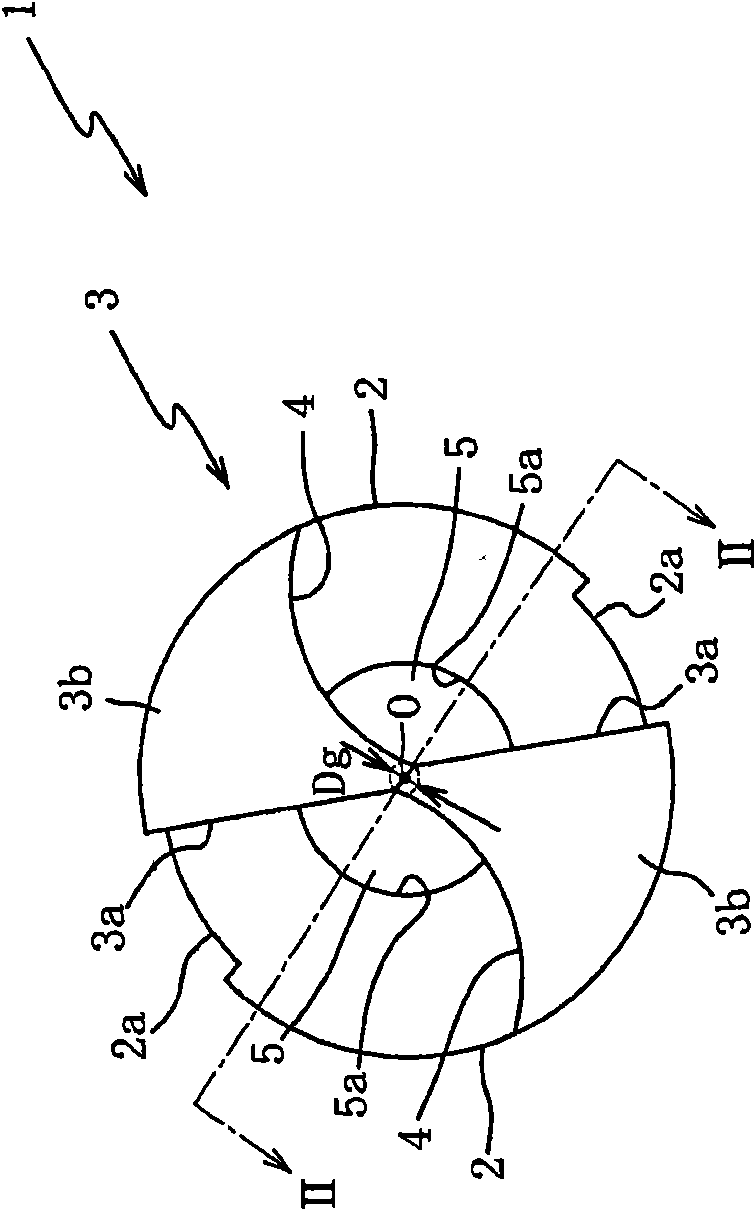

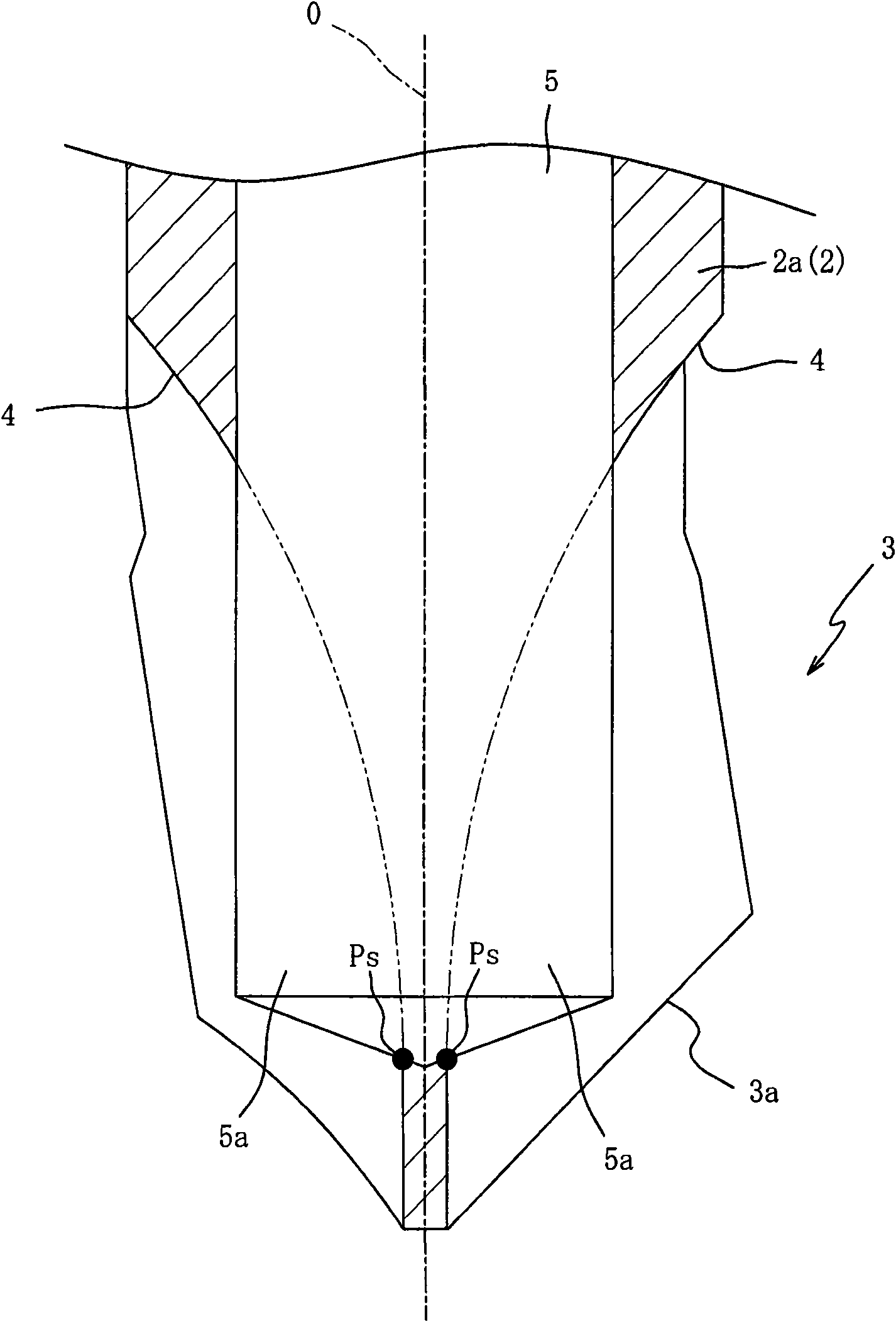

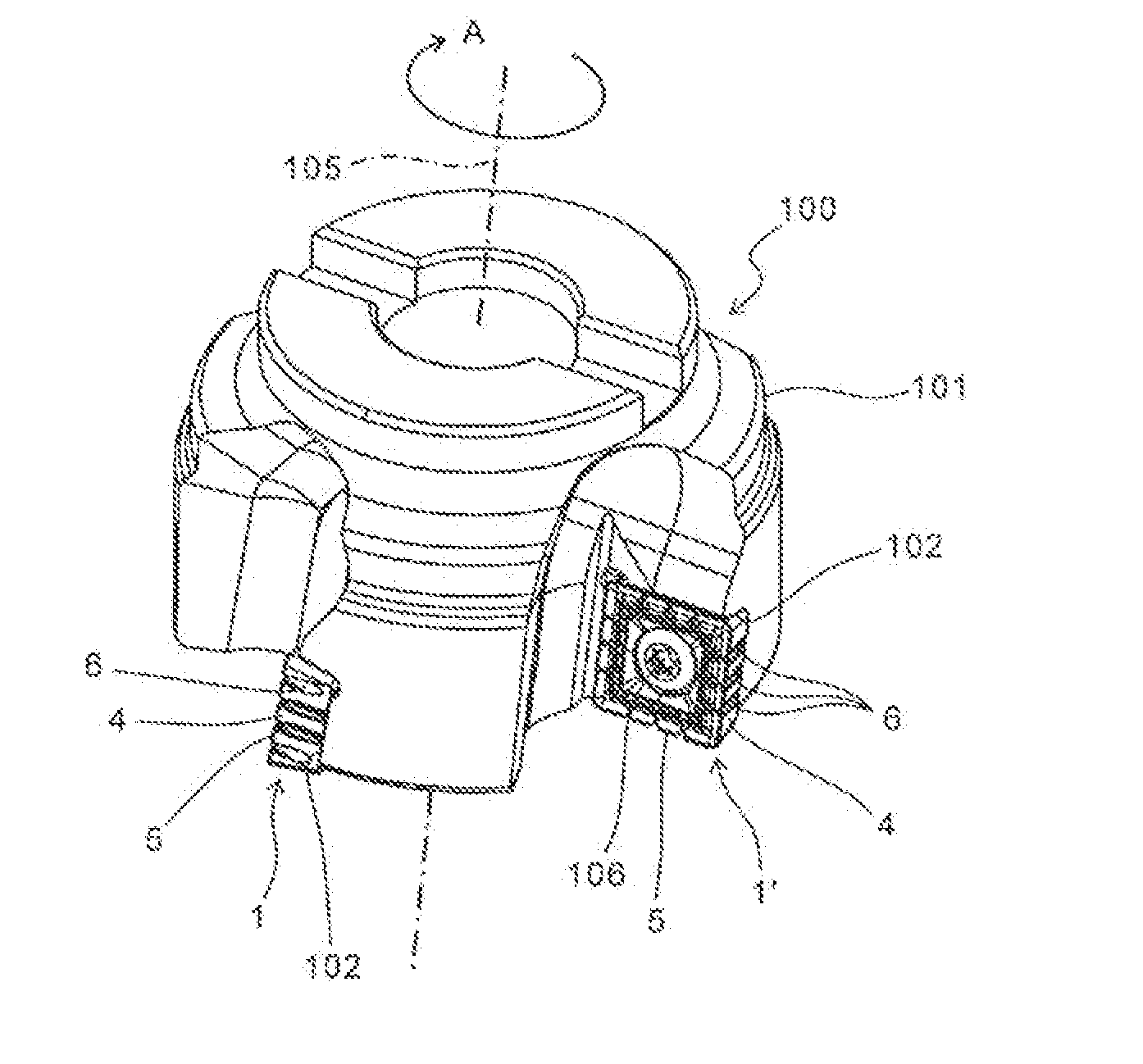

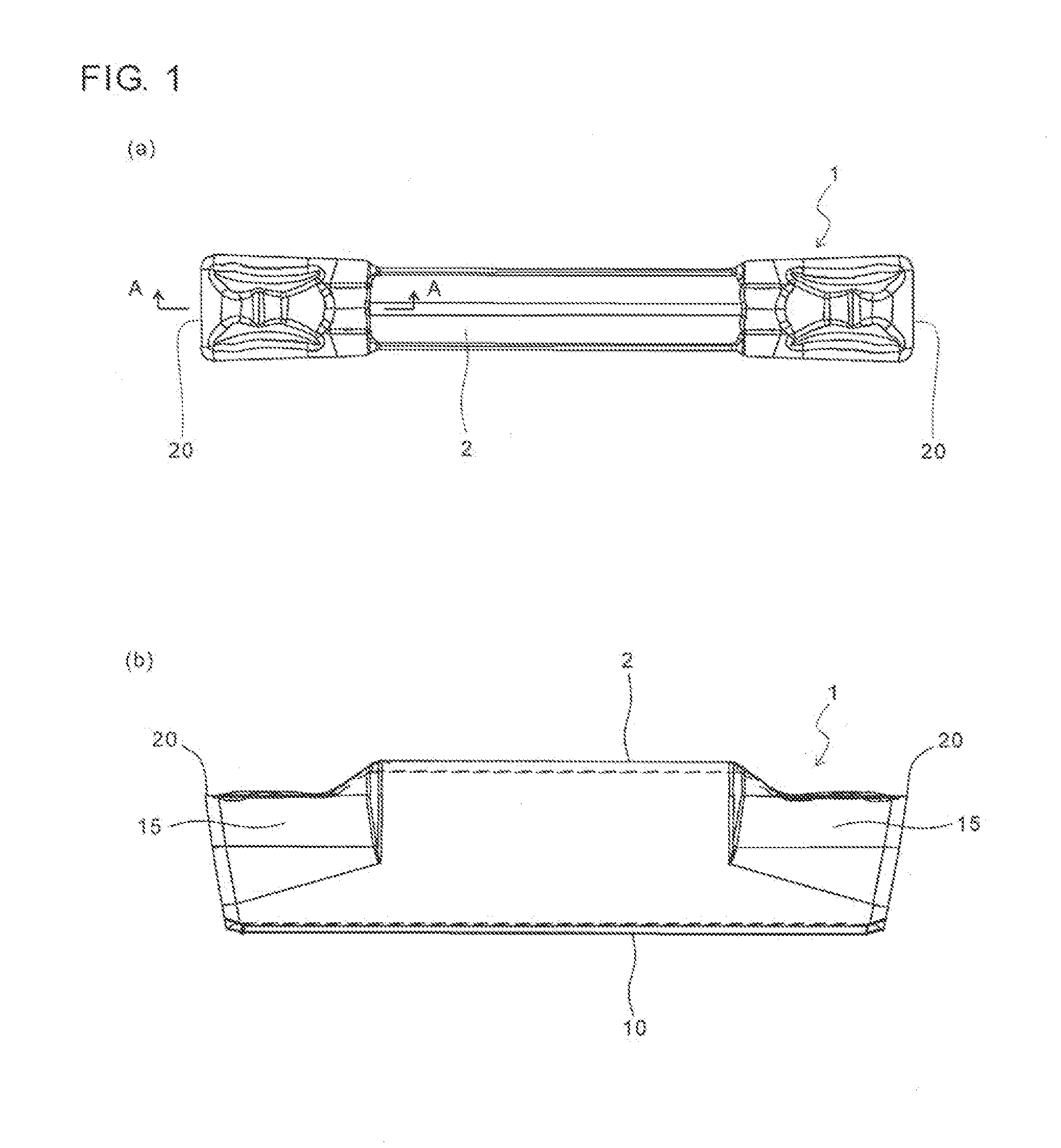

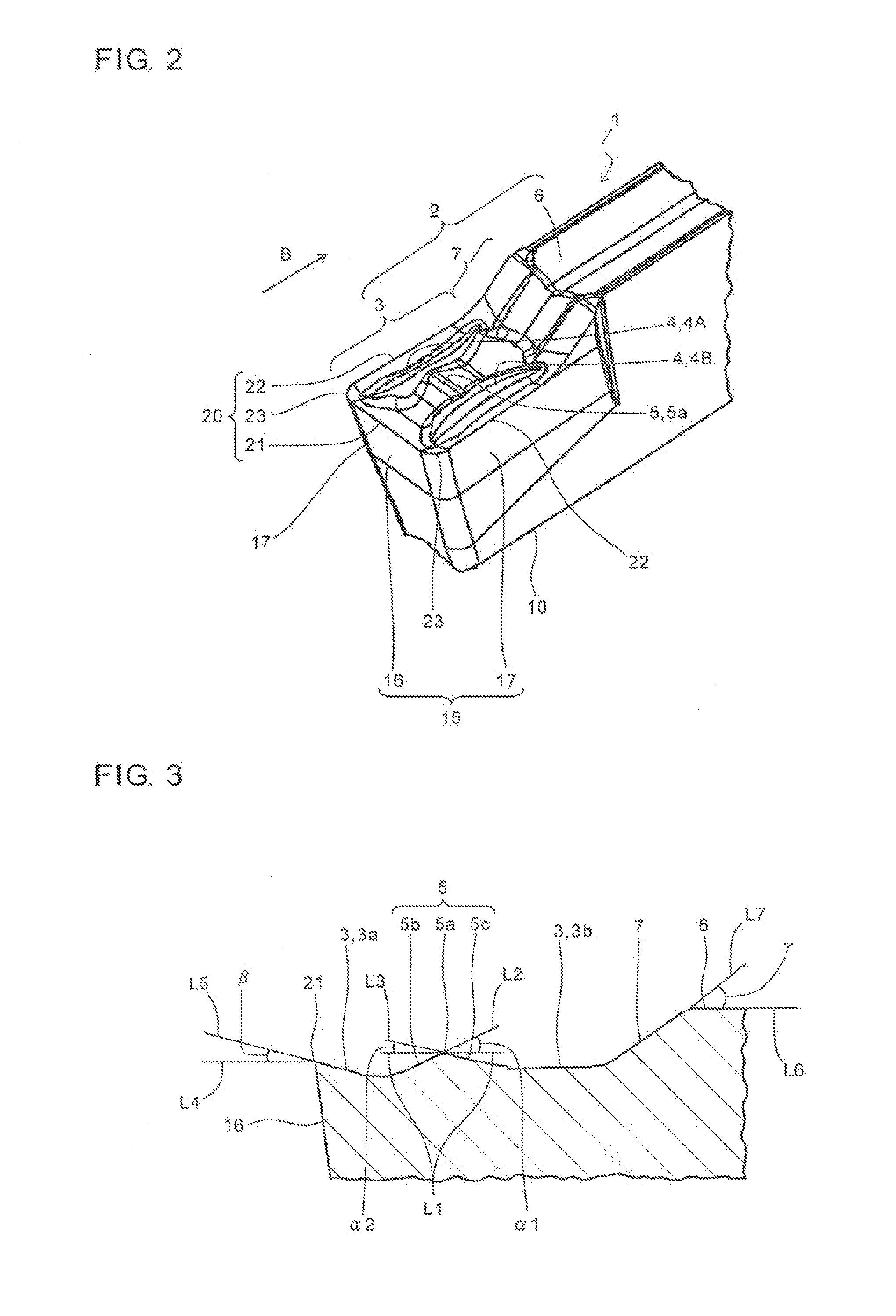

Drill

ActiveCN101528394AAvoid pollutionReduce processing costsTransportation and packagingMetal working apparatusEngineeringDrill

The present invention provides a drill that by forcibly suctioning and discharging of chips, attaining not only prevention of environmental pollution but also simplification of cleaning operation. Drill (1) has air suction hole (5) provided with aperture (5a). Accordingly, by air suctioning through the air suction hole (5), any chips generated at cutting processing can be forcibly suctioned from the aperture (5a). Thus, as the chips can be discharged without the use of cutting liquid, there can be attained prevention of environmental pollution. Further, as not only can the chips be forcibly suctioned from the aperture (5a) but also the chips having been suctioned from the aperture (5a) can be discharged through the air suction hole (5), scattering of the chips on the workpiece can be avoided to thereby attain simplification of cleaning operation.

Owner:OSG

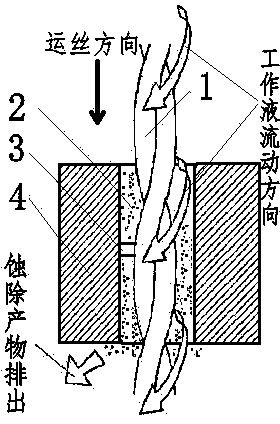

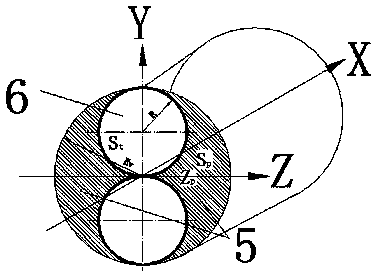

Efficient long-service-life stranded electrode wire for EDM wire

ActiveCN103990877AImprove cutting efficiencyHigh-speed reciprocating wire EDM and low cutting efficiencyElectrical-based machining electrodesCooling effectElectrical and Electronics engineering

An efficient long-service-life stranded electrode wire for an EDM wire is characterized by being formed by stranding at least two electrode wire bodies. Concave cavity grooves and convex discharging joint points are formed on the surfaces of the stranded electrode wire bodies. The concave cavity grooves are not only containing spaces for a working solution but also discharging spaces for inter-electrode corrosion removal products. In addition, feeding of the working solution and the discharging of the corrosion removal products are respectively performed in a spiral mode, and then the inter-electrode cooling effect and the deionization ability are improved. The discharging joint points can form regular discharging, and a discharging pulse interval can be indirectly prolonged. As the surfaces of the electrode wire bodies are provided with the concave parts which serve as the chip containing spaces, the working solution can be fed into inter-electrode in a promoted mode; meanwhile the discharging of the inter-electrode corrosion removal products is accelerated, so that the inter-electrode discharging conditions are improved; due to the regular convex points on the surfaces of the stranded electrode wire bodies, the discharging rule is easier to control. Accordingly, machining efficiency can be enhanced, and surface quality can be improved. Besides, the volume of the chip containing spaces of the stranded electrode wire bodies can be controlled according to the diameter of the electrode wire bodies and the pitch of the stranded wire bodies.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

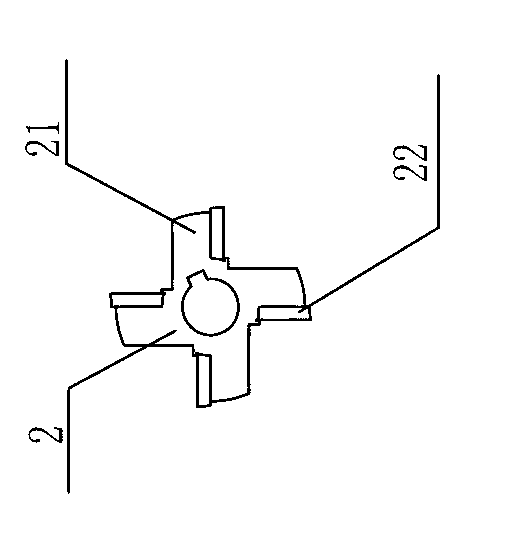

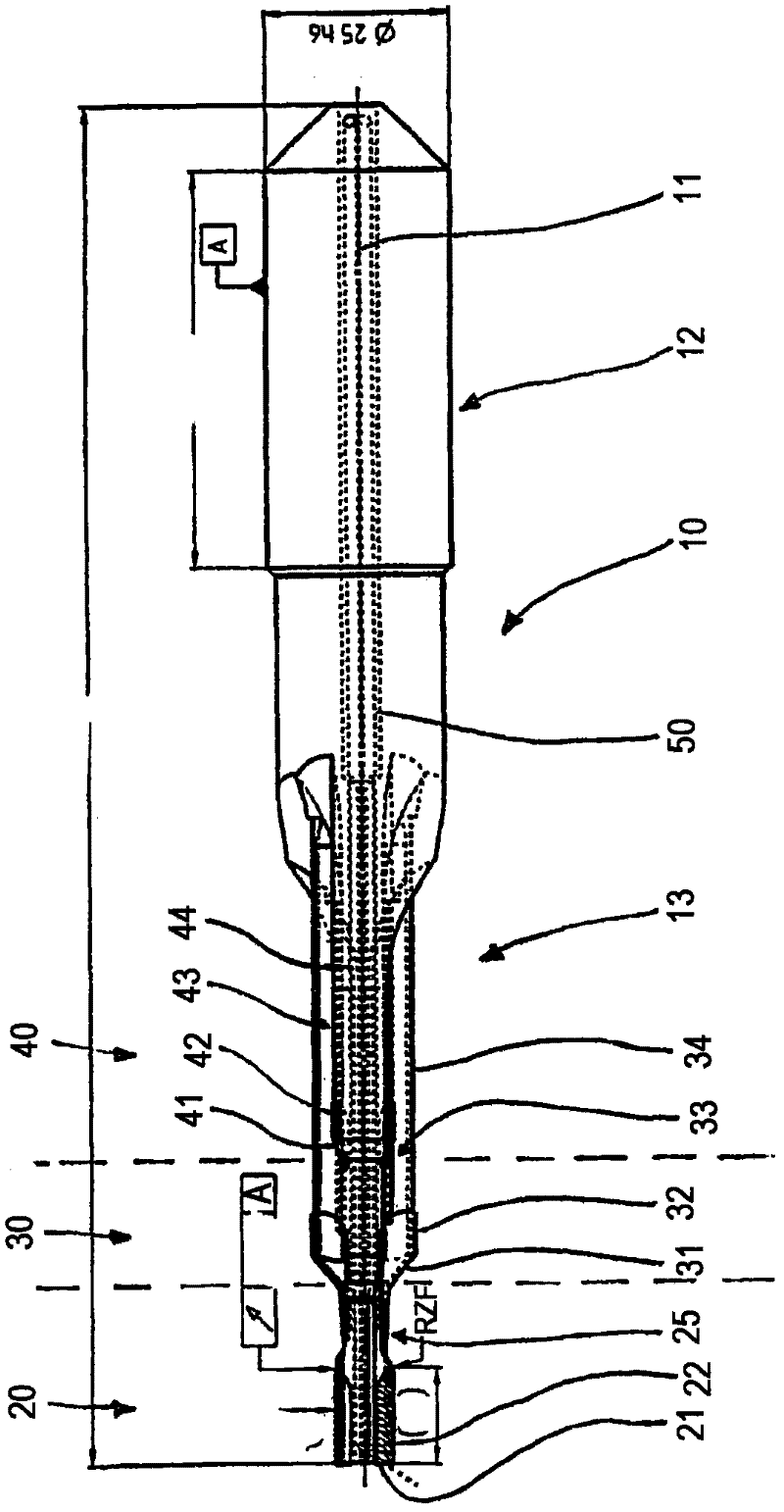

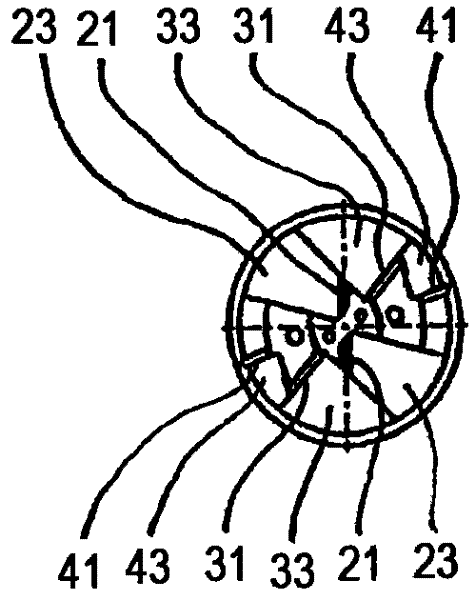

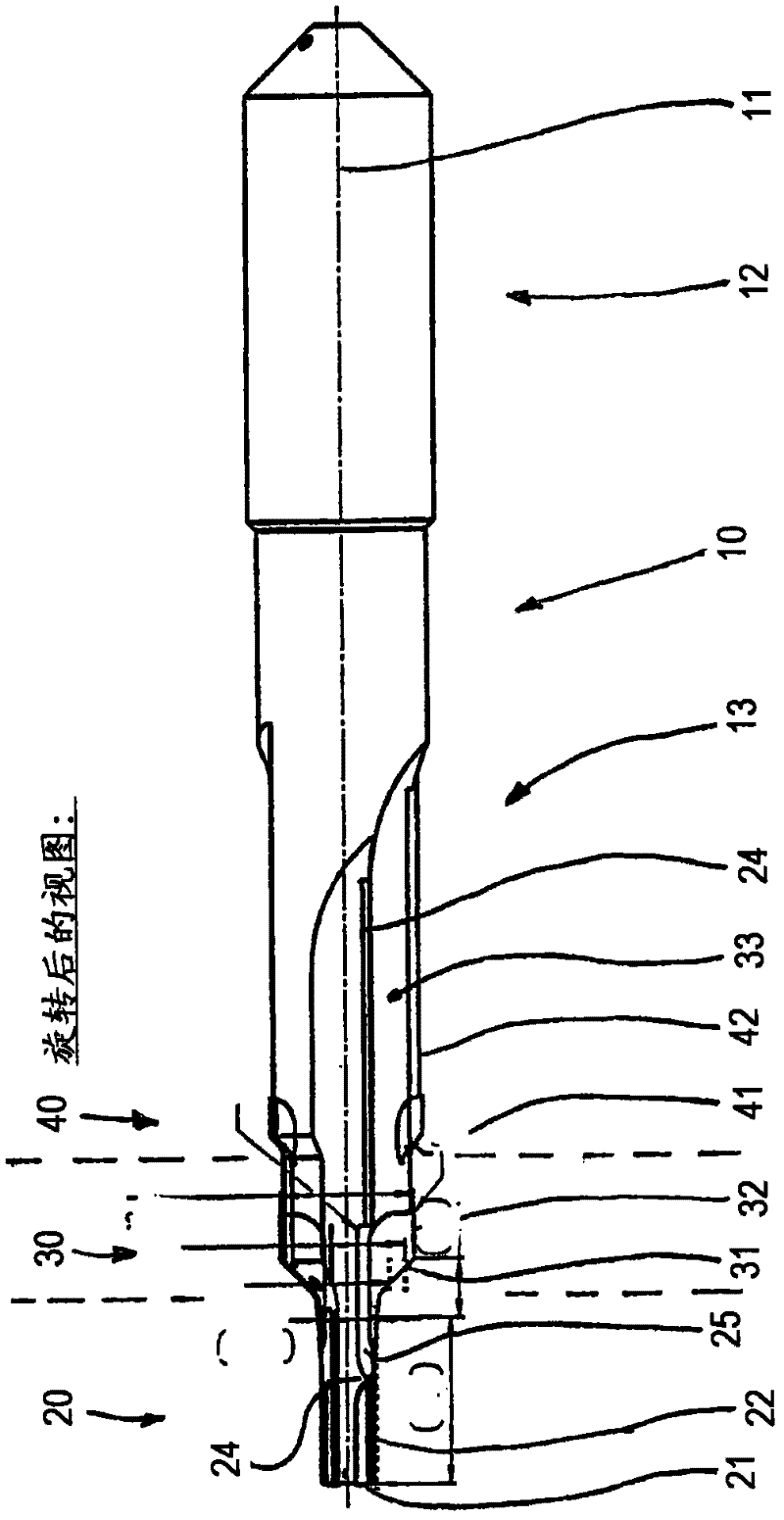

Rotationally driven multi-bevel step tool

InactiveCN102448646AIncrease the lengthIncreased usable chip removal volumeTransportation and packagingWorkpiecesFluteEngineering

The invention relates to a rotationally driven multi-bevel step tool, particularly a step drill for drilling into solid material, comprising a plurality of one-edged or multi-edged cutting steps which are arranged in a staggered manner in the cutting and advancing directions and each have a number of flutes that corresponds to the number of edges. Flutes (23, 33) adjoining each other in the circumferential direction are separated from each other by a web (24). According to the invention, the flues (23, 33) adjoining each other in the circumferential direction of two consecutive cutting steps (20, 30) in the cutting and advancing directions are connected to each other by a metal-cutting window (25) that is open on the circumferential side and interrupts the interposed web (24).

Owner:GUEHRING OHG

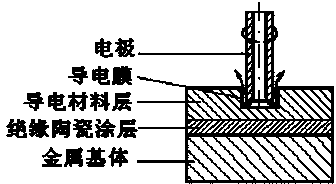

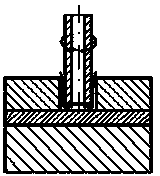

Self-inductive-internal flushing liquid electric spark processing method for metal with insulating ceramic coating

ActiveCN103433576AEasy processing conditionsGood chip removal effectChemical reactionCeramic coating

The invention relates to a self-inductive-internal flushing liquid electric spark processing method for metal with an insulating ceramic coating, belonging to the technical field of electric spark processing and forming. In order to solve the technical problem that the metal with the insulating ceramic coating cannot be processed with high quality and high efficiency, the invention provides the self-inductive electric spark processing method, and on the basis, a processing form of the internal flushing liquid of a rotating electrode is adopted. The whole processing process is carried out in an oil-base working liquid. The tubular electrode rotates around the axis and is assisted by a high pressure flushing liquid in an inner hole of the electrode, and flushing by the working liquid has good chip removal effect. A conductive material is arranged on the surface of the insulating ceramic coating, and the conductive material is connected to the positive electrode of a power supply. In the initial processing stage, according to the thermal chemical reaction of electrical discharge processing, a workpiece discharging area is self-induced to generate conductive films which are continuously produced in the processing process, and the process is continuously carried out, so that the insulating ceramic is processed. According to the self-inductive-internal flushing liquid electric spark processing method for the metal with an insulating ceramic coating provided by the invention, micropores of the metal material with the insulating ceramic coating can be processed with high precision and high efficiency.

Owner:HARBIN INST OF TECH

Automatic stripper

PendingCN110676767ALow rotational resistanceImprove convenienceApparatus for removing/armouring cablesElectric machineryEngineering

The invention belongs to the technical field of cable stripping, and particularly relates to an automatic stripper. The automatic stripper comprises a stripping clamp and a driving unit, wherein the stripping clamp comprises a rack, an upper clamp base and a lower clamp base; threaded holes are vertically formed in the upper clamp base and the lower clamp base in a penetrating mode, and vertical approaching and separating actions of the upper clamp base and the lower clamp base are achieved through rotating actions of two-way lead screws after the two-way lead screws are in threaded fit with threaded holes and opening and closing driving motors located at the ends of the two-way lead screws; the upper clamp base comprises a zero position reference sliding plate, a cutter depth adjusting sliding block, a pressing plate, a cutter depth adjusting threaded base, an elastic compression damping piece, a cutter depth adjusting bolt, a rotating sleeve, a cutter depth adjusting motor and a wirecore detection sensor. Thus, the purposes of self-adaptive adjustment of the feed amount of the cutter and adaptive opening adjustment of the stripping clamp can be flexibly realized, so that the stripping reliability and the stripping efficiency of the cable are greatly improved.

Owner:HEFEI CAS LANRUI TECH CO LTD +2

Cutting insert, cutting tool, and method of manufacturing machined product using the same

ActiveUS20120294686A1Reduce lateral vibrationReduce resistanceTransportation and packagingMilling cuttersMechanical engineering

A cutting insert according to an embodiment of the present invention includes an upper surface; a lower surface; a side surface located between the upper surface and the lower surface; at least one concave part extending in a thickness direction in the side surface, and having one end thereof located at the upper surface; and a cutting edge which is located at an intersection region of the upper surface and the side surface, and is divided into a plurality of divided cutting edges with the at least one concave part interposed therebetween. The upper surface includes a first raised part located inwardly of the at least one concave part, and a plurality of second raised parts respectively located inwardly of the plurality of divided cutting edges. The plurality of the second raised parts are located inward compared to one end of the first raised part close to the cutting edge in a top view. A cutting tool including the cutting insert, and a method of manufacturing a machined product using the cutting tool are also provided.

Owner:KYOCERA CORP

Cutting insert, cutting tool, and method of manufacturing machined product using the same

ActiveUS20120210834A1Improve wear resistanceEasy to splitCutting insertsTurning toolsEngineeringKnife blades

A cutting insert according to an embodiment of the present invention includes an upper surface; a side surface; and a cutting edge located at an intersection region of the upper surface and the side surface. The upper surface includes a rake surface continuous with the cutting edge; and a rising surface inclined and lying at a higher position as going inward from the rake surface. The rake surface includes a pair of first raised parts respectively extending inward from near both ends of the cutting edge in a top view; and a second raised part extending from one of the pair of first raised parts to the other. A cutting tool including the cutting insert, and a method of manufacturing a machined product by using the cutting tool are also provided.

Owner:KYOCERA CORP

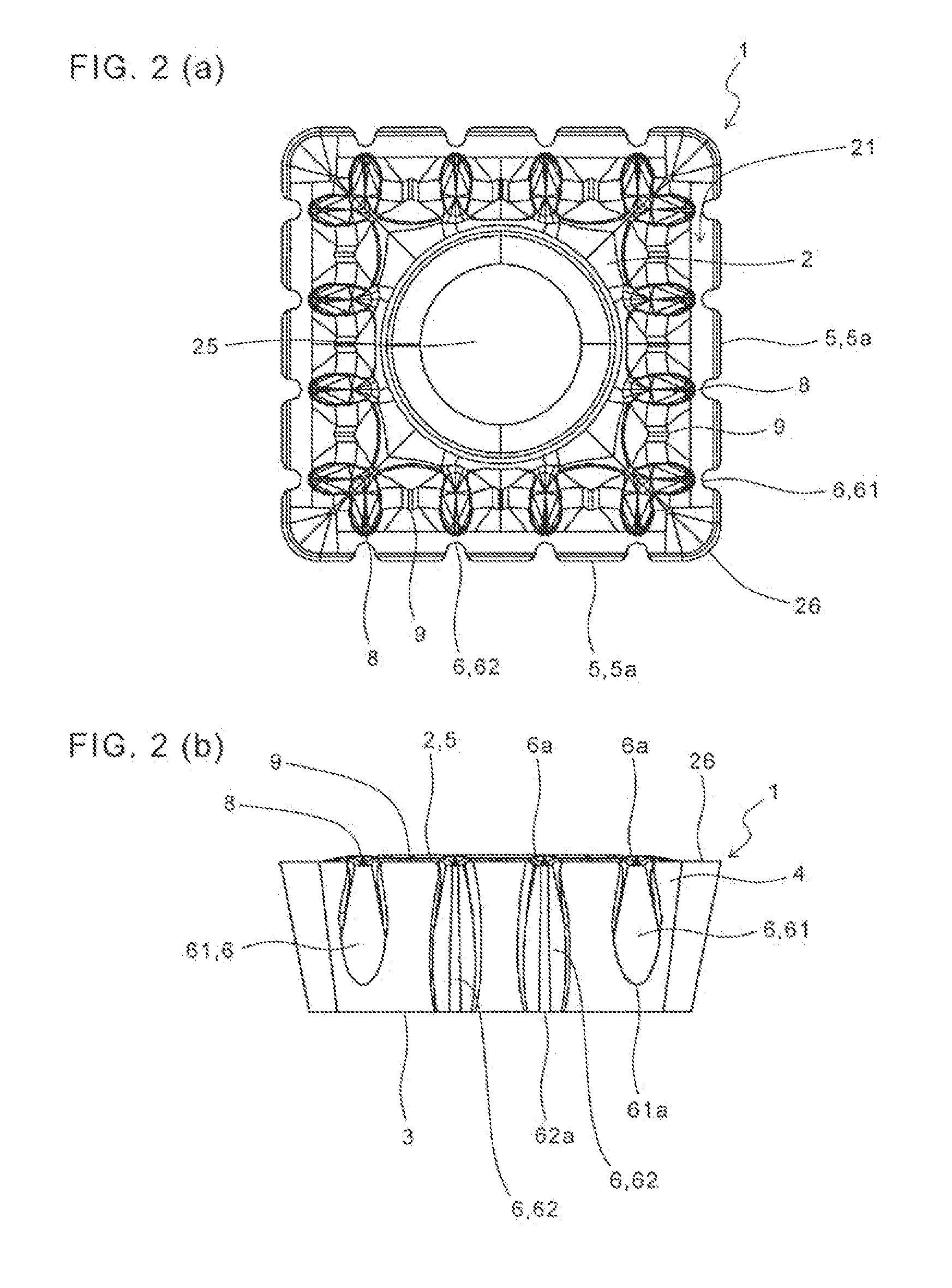

Insert for drill

ActiveUS20110164936A1Good chip removal effectWide spaceThread cutting toolsWood turning toolsMechanical engineeringEngineering

A drill insert of the present invention comprises a corner part, and an upper face having a first side and a second side disposed on both sides of the corner part, respectively. The drill insert comprises a first cutting edge formed along the first side; a second cutting edge formed along the second side; a first region of the upper face located along the first cutting edge;a second region of the upper face located along the second cutting edge; and a first raised part disposed in the first region so as to lie at a higher position than the second region. The first raised part has an upper portion; a breaker portion configured to be inclined so as to become at a lower position as the first raised part extends from the upper portion; and a side portion configured to be inclined so as to become at a lower position as the side portion extends from the upper portion. The first raised part is disposed at a position closer to the first cutting edge than a bisector of the corner part when viewed from above.

Owner:KYOCERA CORP

Method for manufacturing pre-deformation line diamond line saw through powder metallurgy

InactiveCN102218537AImprove gripExtended service lifeMetal sawing toolsStone-like material working toolsBLENDER/MIXERPre deformation

The invention provides a method for manufacturing a pre-deformation line diamond line saw through powder metallurgy, comprising the following steps: basic line manufacturing: selecting metal wires, stranding at least two metal wires into a line, and deforming the stranded line by a deformer to obtain a pre-deformation base line; powder preparation: weighing metal powder, a binder and diamond by mass percent, and adding the mixture into a blender mixer to evenly mixing; line blank manufacturing: putting the base line and powder into a mould, and taking the pre-deformation base line as a center to prepare a line blank by using a forming technology; and line saw manufacturing: putting the line blank to a sintering furnace for sintering, and cooling with the furnace to obtain the line saw. The manufacturing method provided by the invention has the advantages of simple process, low cost and high production efficiency. The produced line saw has excellent performance, high strength, good flexibility, high hold to diamonds, stable cutting performance, good chip discharging performance and long service life, and is not easy to crack.

Owner:长沙和谦新材料科技有限公司

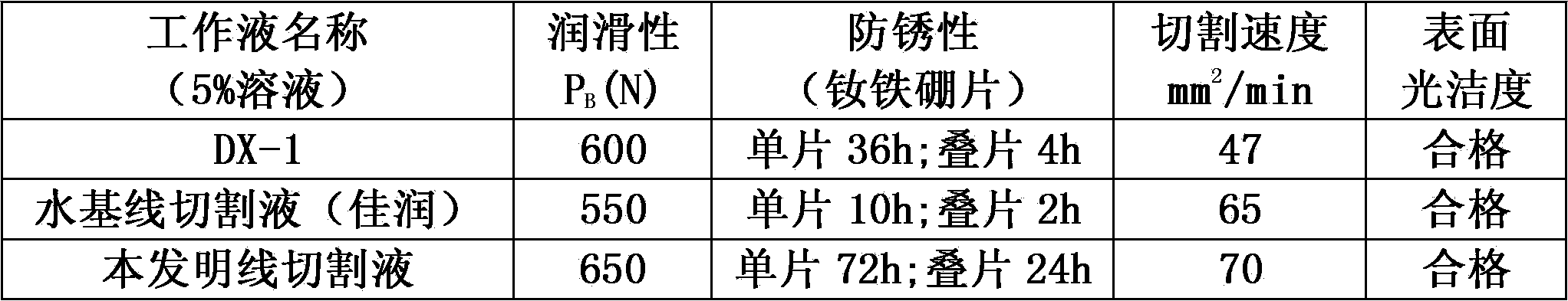

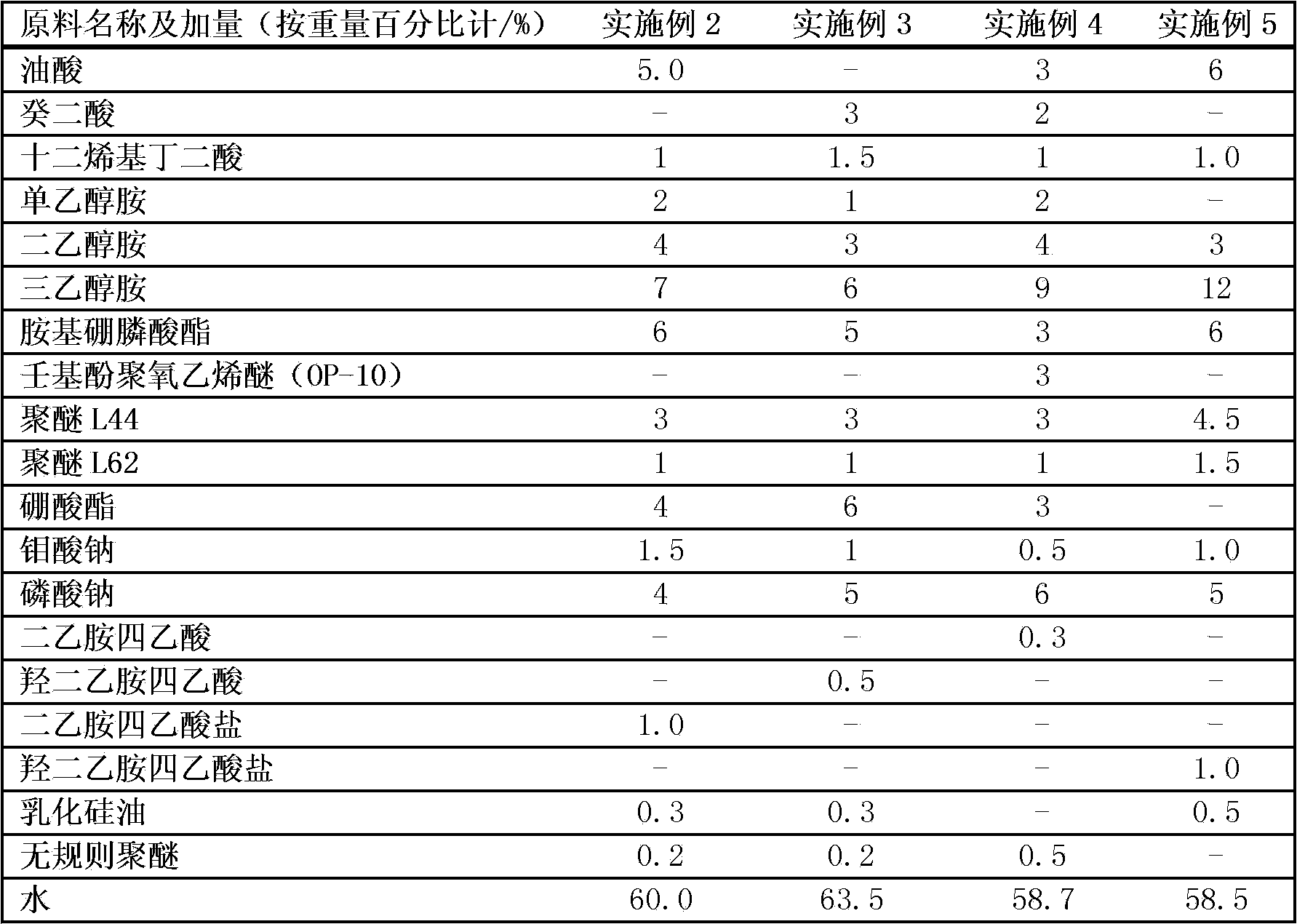

Linear cutting fluid for neodymium-iron-boron permanent magnet material

InactiveCN103725387AImprove conductivityImprove the lubrication effectLubricant compositionHard waterMaterials processing

A linear cutting fluid for a neodymium-iron-boron permanent magnet material is characterized by comprising the compositions in percent by weight: 3%-9% of an aliphatic acid, 10%-15% of ethanolamine, 3%-6% of an amino boron phosphate, 5%-10% of a cleaning agent, 6%-9% of an antirust agent, 0.3%-1.0% of a hard water resistant agent, 0.3%-1.0% of an antifoaming agent and the balance water. The preparation method of the linear cutting fluid comprises: adding the aliphatic acid into a reaction kettle according to the amount of the formula, heating to 60-70 DEG C, adding ethanolamine with stirring, continuing to heat to 120-150 DEG C and reacting for 2 h, then cooling to 80 DEG C, successively adding the amino boron phosphate, the cleaning agent, the antirust agent, the antifoaming agent, the hard water resistant agent and water, and continuing to stir for 2 hours to obtain the finished product. The linear cutting fluid provided by the invention is low in cost, can realize long-acting antibiosis, belongs to environment-friendly product, is specially used in neodymium-iron-boron permanent magnet material processing technology, and has good cutting, cooling and rust resisting effects.

Owner:SHENYANG POLYTECHNIC UNIV

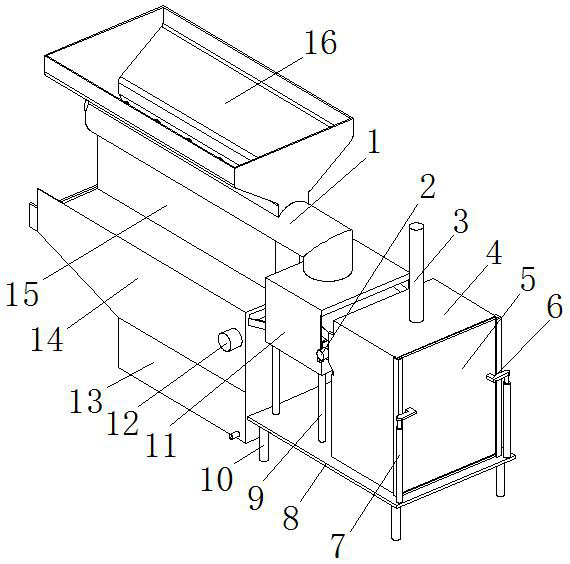

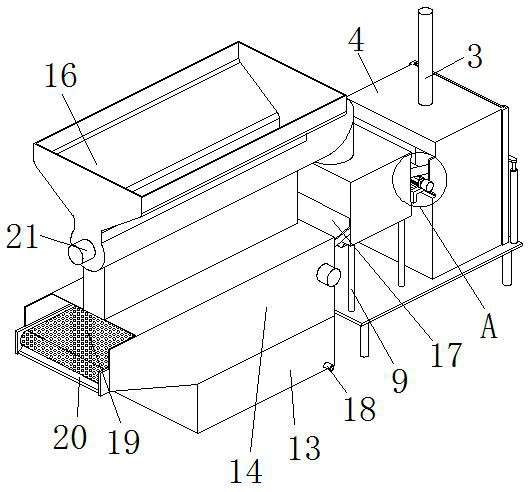

Automatic chip removal device for machine tool

ActiveCN112453994AAchieve up and down swingEasy to deal withMaintainance and safety accessoriesComputer hardwareElectric machinery

The invention discloses an automatic chip removal device for a machine tool. The device comprises a chip removal pipe, a chip compression box, a bottom plate, a slag-liquid separation box, a liquid storage box, a reciprocating swing mechanism and a conveying frame. A spiral discharging paddle is arranged in the chip removal pipe, a third motor is arranged at the left end of the chip removal pipe,and an output shaft of the third motor penetrates into the chip removal pipe and is connected with the spiral discharging paddle. A chip collecting groove is formed in the chip removal pipe, and the discharging end of the chip removal pipe is connected with the slag-liquid separation box. The conveying frame is arranged below the chip removal pipe, a roller is arranged on the conveying frame, a filtering conveying belt is arranged on the roller, cooling liquid and small-particle chips are separated through the filtering conveying belt, and the small-particle chips are conveyed out. A scrapingplate is arranged at the left end of the conveying frame. The automatic chip removal device for the machine tool is novel in structural design and good in chip removal effect, chip particles can be classified, separated treatment is facilitated, large chips are compressed, space is saved, frequent chip treatment is avoided, and time is saved.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com