Method for preparing single-layer diamond abrasive tool through chemical vapor deposition

A chemical vapor deposition, single-layer diamond technology, used in manufacturing tools, grinding devices, metal processing equipment, etc., can solve the problem of brazing residual stress, the uneven thickness of the binder layer of the solder layer, the inability to prepare diamond abrasives, thermal expansion Coefficient of large difference and other problems, to achieve the effect of improving antioxidant capacity, reducing scratches, and high grain fullness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

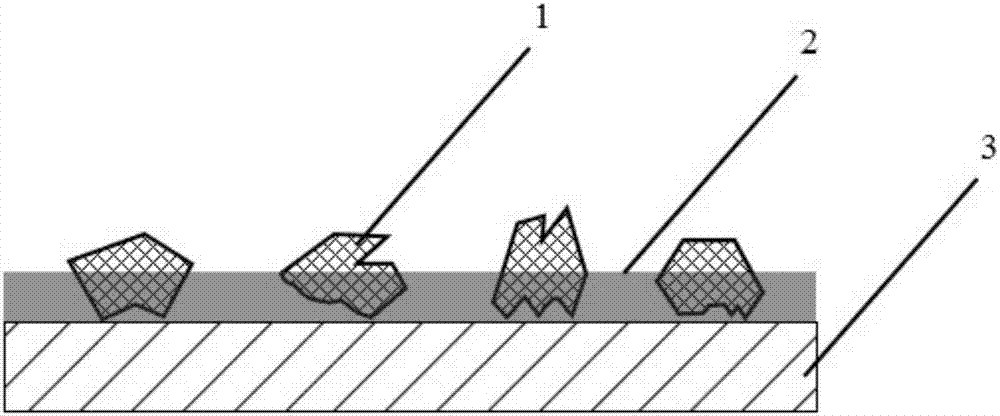

[0040] Specifically, the preparation method of the single-layer CVD diamond grinding tool that the present invention relates to comprises the steps:

[0041] In the first step, the diamond micropowder obtained by mechanically crushing large-grained high-temperature and high-pressure diamond abrasives is used as an abrasive (also called abrasive grains), and the particle size of the diamond micropowder is 5-100 μm. Ultrasonic vibration is used to make it fully mixed, and then the photoresist solution mixed with diamond micropowder is evenly spread on the surface of the substrate by using the glue-spinning technology.

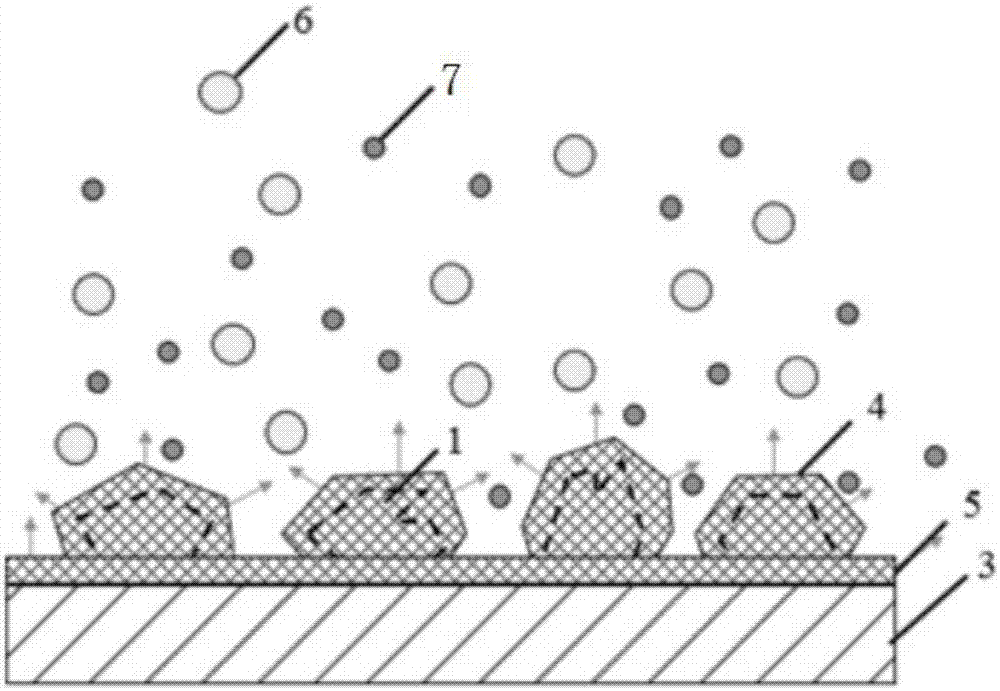

[0042] In the second step, a diamond coating is deposited on the surface of the silicon carbide substrate treated in the first step by hot wire chemical vapor deposition. The coating will be used as a bond diamond abrasive to connect with the substrate, and during the coating deposition process, The diamond abrasive will also grow homoepitaxially, so that the abr...

Embodiment 1

[0044] The substrate is silicon carbide, and the dimensions are 13mm×17mm×9mm.

[0045] The preparation method of a single-layer CVD diamond abrasive tool with a particle size of M4 / 8 is as follows: the diamond abrasive with a particle size of M4 / 8 prepared by a mechanical crushing method is mixed into a photoresist solution, and the concentration of the abrasive is 20mg / ml. Then the mixed solution was stirred rapidly, and it was subjected to 30min ultrasonic vibration treatment to eliminate the clusters of the diamond abrasive, so that the abrasive was evenly dispersed in the photoresist, and then the photoresist abrasive mixed solution was evenly dispersed on the substrate surface. Among them, the glue-spinning speed is 4000rpm, and the duration is 30s.

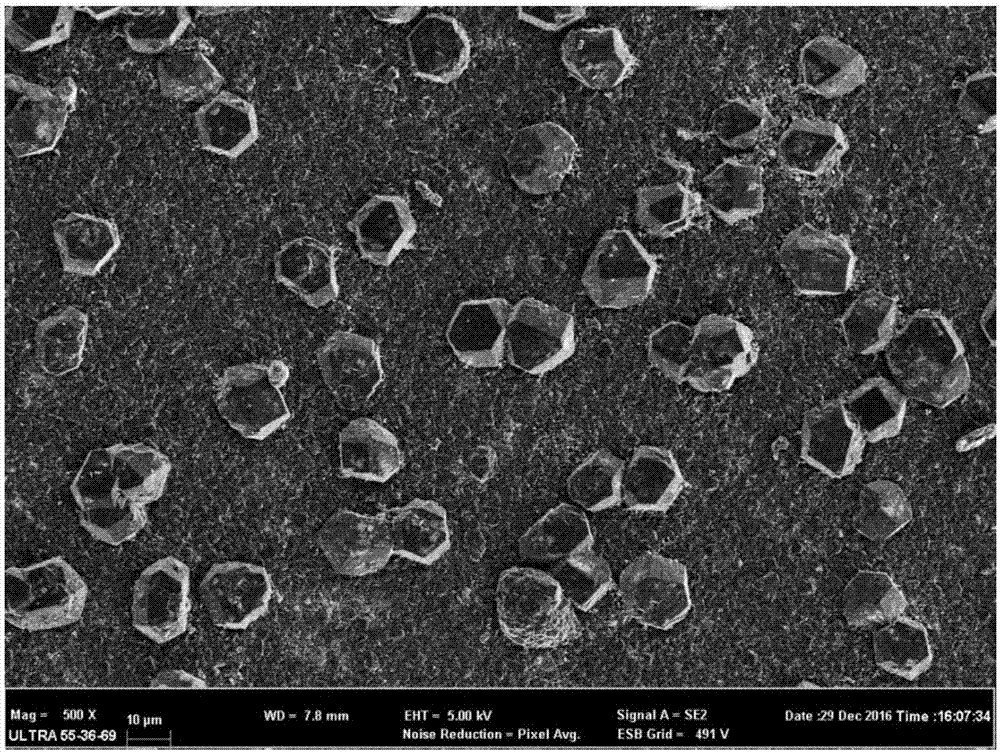

[0046] Finally, a layer of diamond coating is deposited on the surface of the substrate distributed with photoresist and diamond micropowder by hot wire chemical vapor deposition. The hot wire adopts a twisted-pair tantal...

Embodiment 2

[0050] The substrate is silicon carbide, and the dimensions are 13mm×17mm×9mm.

[0051] The preparation method of a single-layer CVD diamond abrasive tool with a particle size of M8 / 16 is as follows: the diamond abrasive with a particle size of M8 / 16 prepared by mechanical crushing is mixed into the photoresist solution, and the concentration of the abrasive is 60mg / ml. Then the mixed solution was stirred rapidly, and subjected to ultrasonic vibration treatment for 30 minutes, so that the abrasive was evenly dispersed in the photoresist, and then the mixed solution of photoresist abrasive particles was evenly spread on the surface of the substrate by using the glue-spinning technique. Among them, the glue-spinning speed is 4000rpm, and the duration is 40s.

[0052] Finally, a layer of diamond coating is deposited on the surface of the substrate distributed with photoresist and diamond micropowder by hot wire chemical vapor deposition. The hot wire adopts a twisted-pair tantal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com