Self-inductive-internal flushing liquid electric spark processing method for metal with insulating ceramic coating

A technology of insulating ceramics and processing methods, which is applied in the field of electric discharge machining and forming, can solve the problem that insulating ceramic coating metal materials cannot be processed with high quality and high efficiency, and achieve good chip removal and increase processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

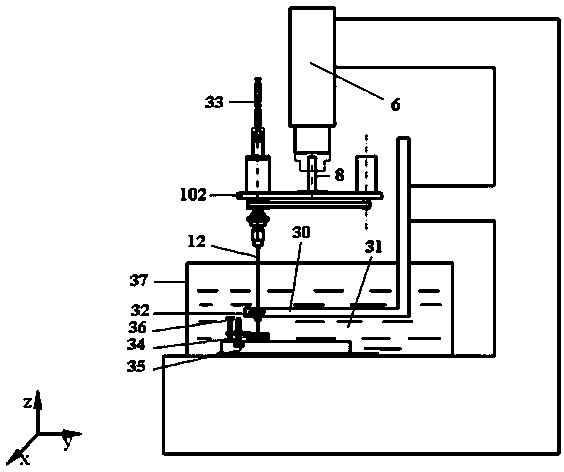

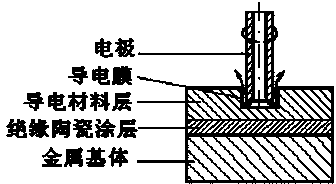

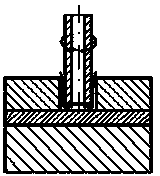

[0022] Specific implementation mode one: as figure 1 As shown, before processing, the electrode 12 is clamped by the electrode rotating and clamping device 102 , and the electrode 12 is terminated with the electrode guiding device 30 . The electrode rotation and clamping device 102 is fixed to the clamping head of the machine tool spindle 6 through the fixed block 8 on the epoxy resin beam base, and the machine tool spindle 6 drives the electrode rotation and clamping device 102 and then drives the electrode 12 to do vertical (Z axis) direction of movement. The weight of the entire device after assembly is about 1.5kg, which is far less than the maximum electrode weight of the machine tool 50kg, and will not affect the servo movement of the machine tool spindle 6, which is driven by the EDM machine tool spindle 6 to move up and down to provide progress during processing. Give movement. The electrode guide device 30 is installed at the bottom of the working fluid tank of the ...

specific Embodiment approach 2

[0025] Specific implementation mode two: as Figure 7-9As shown, this embodiment provides an electrode rotation and clamping device for electric discharge machining of insulating ceramic coated metal. The electrode rotation and clamping device includes an electrode rotation device 2, an insulating substrate 3, an electrode clamping device 5, Fixed block 8, synchronous belt transmission mechanism 9, DC geared motor 10 and electrode 12, electrode 12 adopts hollow tubular electrode, described electrode rotation device 2 includes pressure oil interface 13, upper end cover 14, spring 15, sealing block 16, sealing Assembly 17, upper bearing 18, base body 19, lower bearing 20, lower end cover 21, brush holder 22 and hollow shaft 23, the electrode holding device 5 includes an upper compression cover 25, a lower compression cover 27, a sealing plug 30. O-shaped sealing ring 28, tapered connecting shaft 29 and drill chuck 31, the first shaft hole and the second shaft hole are arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com