Method of measuring residual amount of 4-aminoazobenzene in paper for cigarettes

A technology of aminoazobenzene and a determination method, which is applied in the field of determination of 4-aminoazobenzene residues in cigarette paper, can solve the problems of poor qualitative ability, poor chromatographic peak shape, poor thermal stability and the like, and achieves rapid Simple Sensitivity, Avoidance of Matrix Effects, Reduced Interference Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

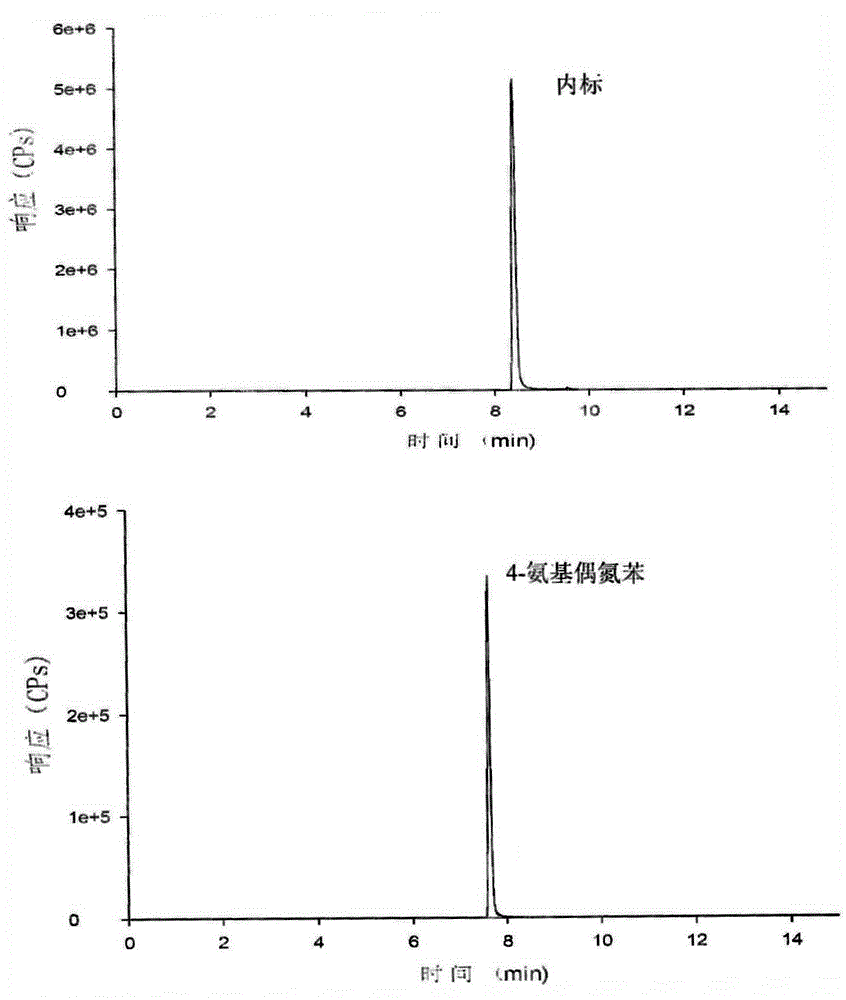

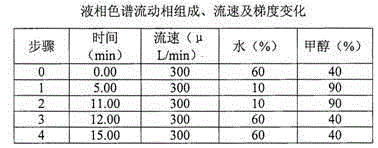

Examples

example 1

[0033] 1. Instruments and reagents:

[0034] Tert-butyl methyl ether and methanol are chromatographic grade reagents, sodium hydroxide and sodium sulfate are analytical reagents; distilled water meets the requirements of first-grade water in GB / T6682.

[0035] API4000 quadrupole tandem mass spectrometer; water bath constant temperature oscillator; Swiss Mettler AE163 electronic balance (sensitivity: 0.0001g).

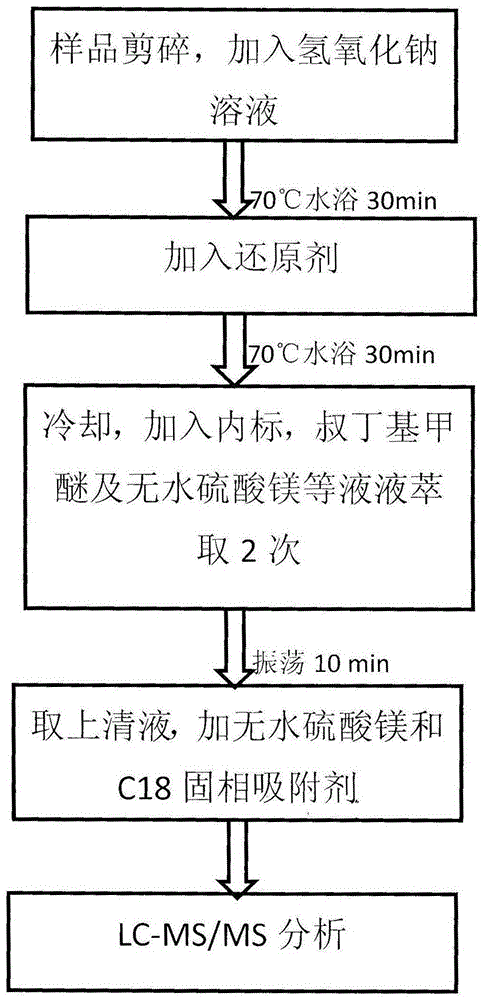

[0036] 2. Sample handling:

[0037] Cut the sample first: the cutting method of tipping paper for cigarettes is carried out in accordance with the regulations of YC171-2008, that is, to accurately cut a sample of tipping paper with a length of 200mm and a width of 40mm (should include a single side); The cutting method is carried out in accordance with the provisions of YC264-2008, that is, the cutting area is about 170cm 2 (That is equivalent to the area of the lining paper used in ordinary cigarette soft box packaging); the cutting method of cigarette rods and b...

example 2

[0044] According to the determination method described in Example 1, another cigarette tipping paper sample was selected, and 4-aminoazobenzene was not detected in the sample.

example 3

[0046] According to the determination method described in Example 1, another inner liner paper sample for cigarettes was selected, and 4-aminoazobenzene was not detected in the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com