Determination method of content of urea in water-based adhesive

A technology of urea content and determination method, which is applied in the field of physical and chemical inspection of water-based adhesive materials, can solve the problems of analysts’ health and environmental hazards, difficulty in purchasing reagents, and long time-consuming, etc., to achieve short detection time, easy operation, and high recovery rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

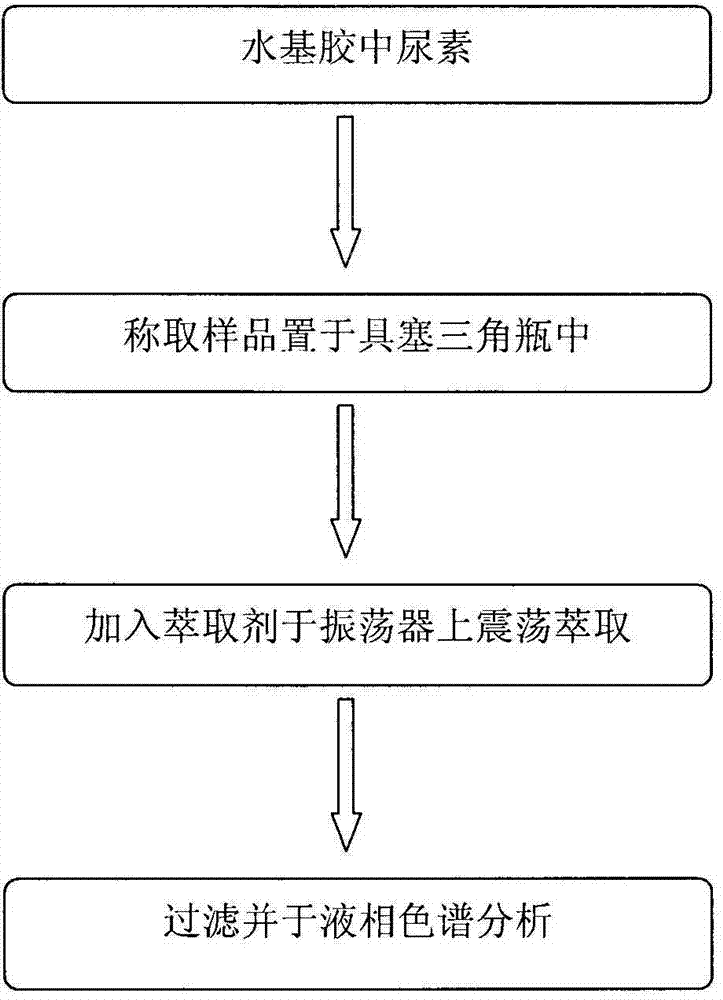

[0026] The present embodiment is as follows to the assay method of urea content in water-based glue (the flow chart of described detection method is as follows figure 1 shown)

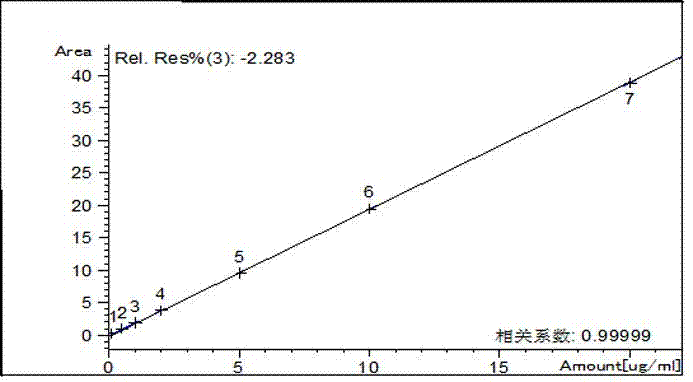

[0027] (1) Preparation of standard solution: Weigh 10mg of urea (accurate to 0.1mg), dissolve it with ultrapure water and transfer it to a 100mL volumetric flask, set the volume to the mark and shake well, as the primary mother solution; take 1mL of the primary mother solution to In a 50mL volumetric flask, dilute to the mark with ultrapure water, as the secondary mother liquor; store at 2°C-8°C, valid for 1 month. Accurately pipette 10 μL, 50 μL, 100 μL, 200 μL, 500 μL and 1000 μL of the secondary mother liquor into 10 mL volumetric flasks, and dilute to the mark with ammonium dihydrogen phosphate solution to obtain a series of standard working solutions, which are prepared and used immediately.

[0028] (2) Preparation of sample solution: Weigh 1.0g sample into a 50mL Erlenmeyer flask, add 25mL ultr...

Embodiment 2

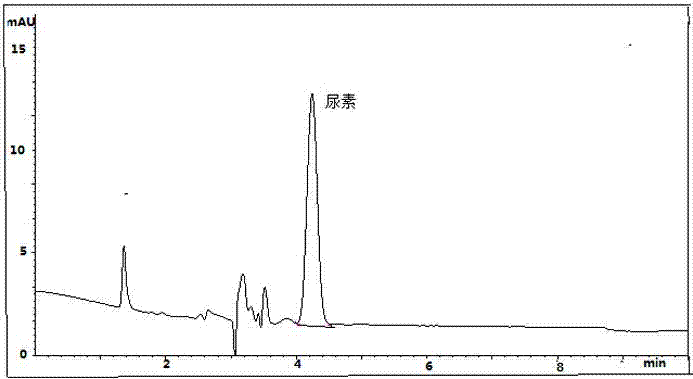

[0042] The present embodiment is as follows to the detection method of the repeatability of the inventive method and the standard addition recovery rate

[0043] Adopt the sample standard addition recovery rate test, add the standard solution of three different concentrations of low, medium and high respectively in the sample and carry out standard addition rate test, each sample measures 5 times respectively, the condition of chromatographic analysis is the same as embodiment 1, calculates according to analysis result The standard addition recovery of urea in the water-based glue of this method and the relative standard deviation of measured value after the standard addition, the results are shown in table 2;

[0044]

[0045] As can be seen from Table 2, on the 3 levels of standard addition, the average recovery rate of urea in the water-based glue detected by this method is 92.01%, and the average relative standard deviation of the sample test results is 0.33%, indicating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com