Automatic chip removal device for machine tool

An automatic discharge and machine tool technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of inconvenient collection of small debris, difficult to collect small debris, and inability to separate clean debris. , to achieve the effect of easy unified processing, novel structure design and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

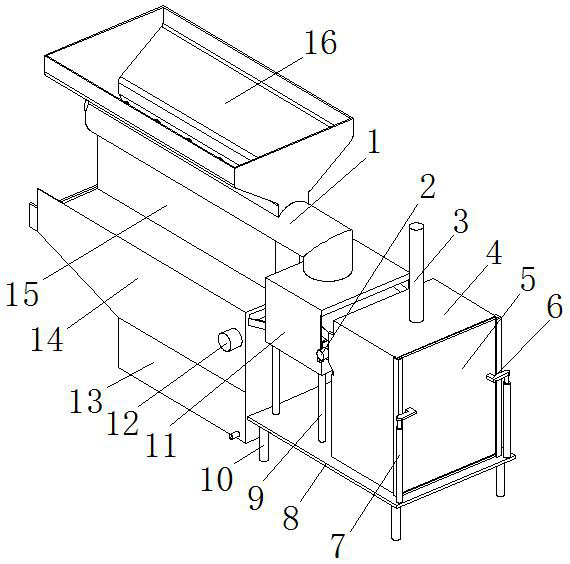

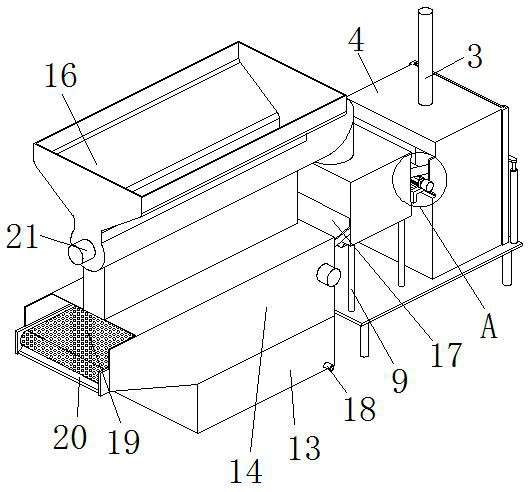

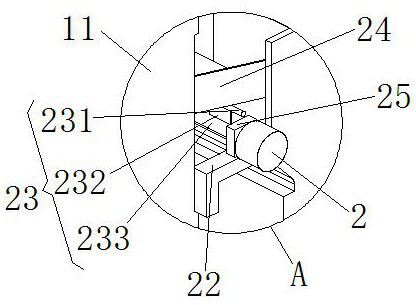

[0024] see Figure 1-6, the present invention provides a technical solution: an automatic chip removal device for machine tools, including a chip removal pipe 1, a chip compression box 4, a bottom plate 8, a slag-liquid separation box 11, a liquid storage box 13, a reciprocating swing mechanism 23 and a transmission frame 26. The inside of the chip discharge pipe 1 is provided with a screw discharge paddle 35, and the left end of the chip discharge pipe 1 is provided with a third motor 21. Connection, the chip discharge pipe 1 is provided with a debris collection tank 16, the discharge end of the chip discharge pipe 1 is connected with the slag-liquid separation box 11, the transmission frame 26 is set under the chip discharge pipe 1, and the transmission frame 26 is provided with a roller 28. A filter conveyor belt 19 is provided on the drum 28, a scraper 20 is provided at the left end of the transmission frame 26, one end of the scraper 20 is in contact with the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com