Splicing device with single-spindle yarn suction nozzle structure and splicing method of splicing device

A yarn feeder and single-spindle technology, applied in the field of textile splicing equipment, can solve the problems of unsmooth running of the trolley, increased resistance of the trolley, and easy occurrence of yarn blocking, etc., and achieves the effect of simplifying the structure of the splicing trolley, simplifying the structure and increasing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

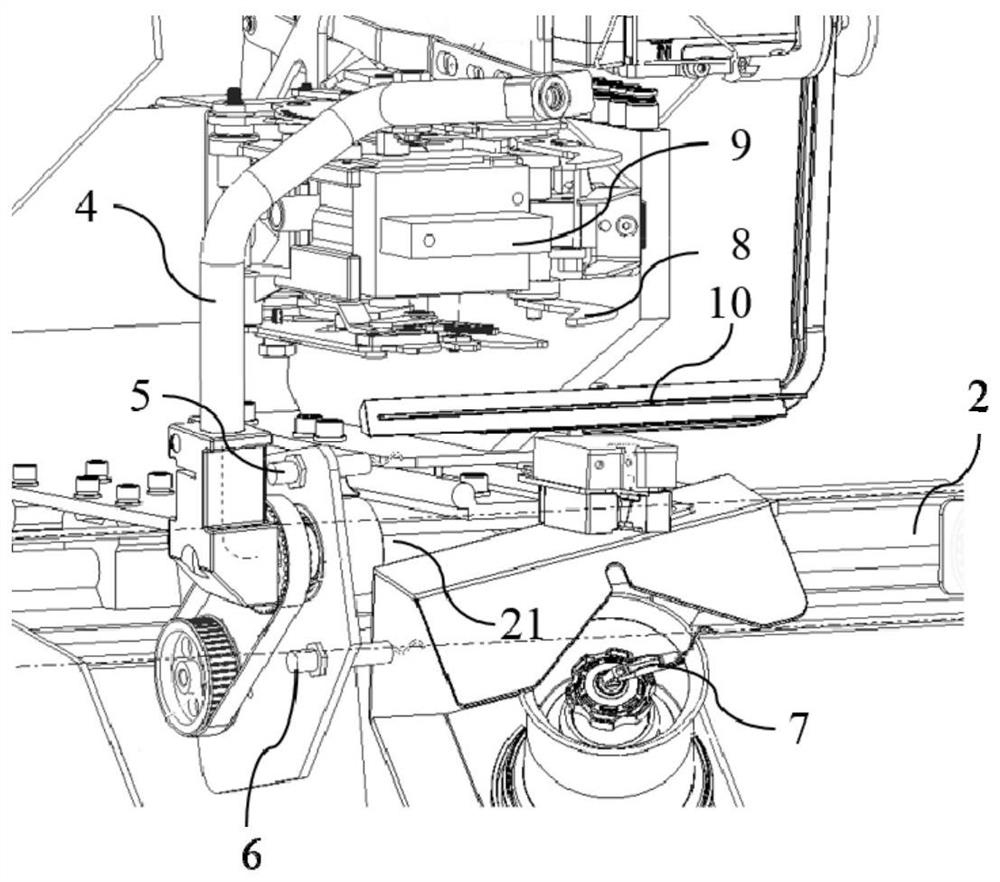

[0037] A splicing device with a single-spindle yarn suction nozzle structure in this embodiment, such as Figure 2~3 As shown, the single-spindle yarn suction nozzle 4 is included, and the single-spindle yarn suction nozzle 4 is fixedly installed on the wallboard of each spindle through the mounting seat 45 thereon; the single-spindle yarn suction nozzle 4 is connected with the upper The air door negative pressure air duct 21 is connected, and the negative pressure of the upper air door negative pressure air duct 21 is provided by the upper air duct 2, so that the distance between the single spindle yarn suction nozzle 4 and the upper air door negative pressure air duct 21 is relatively short, so there is no It is easy to cause yarn blocking phenomenon.

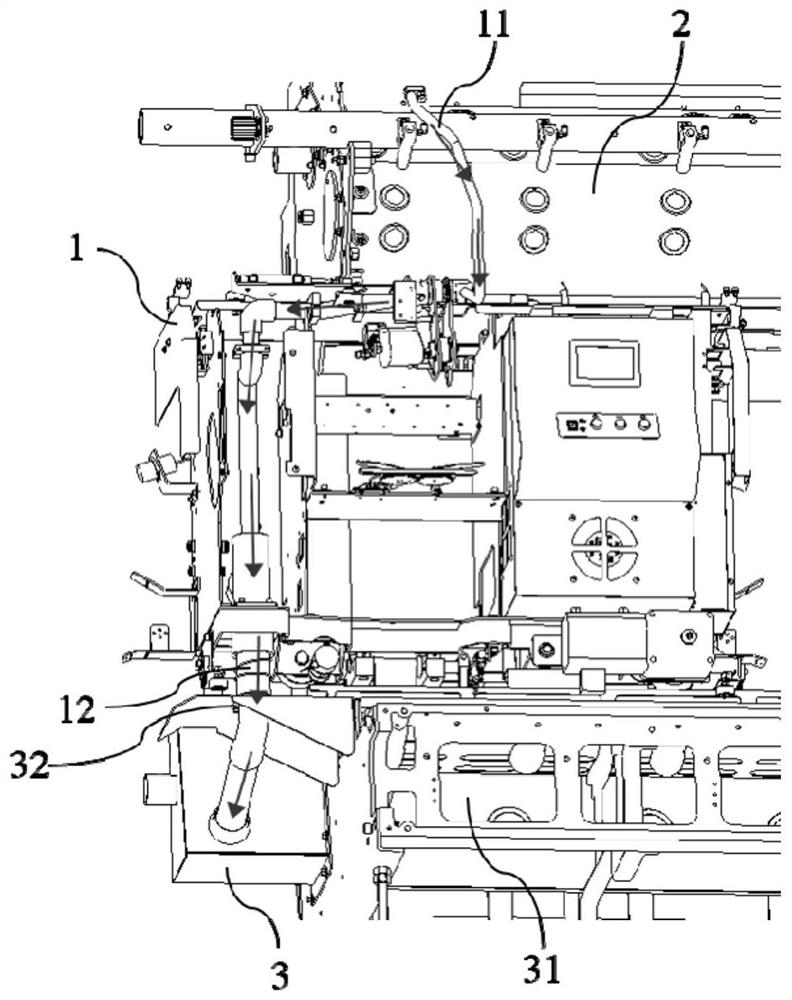

[0038]figure 1 It is a schematic diagram of the working state structure of the existing splicing trolley. After receiving the splicing signal, the splicing trolley 1 moves along the track to the spindle position that needs sp...

Embodiment 2

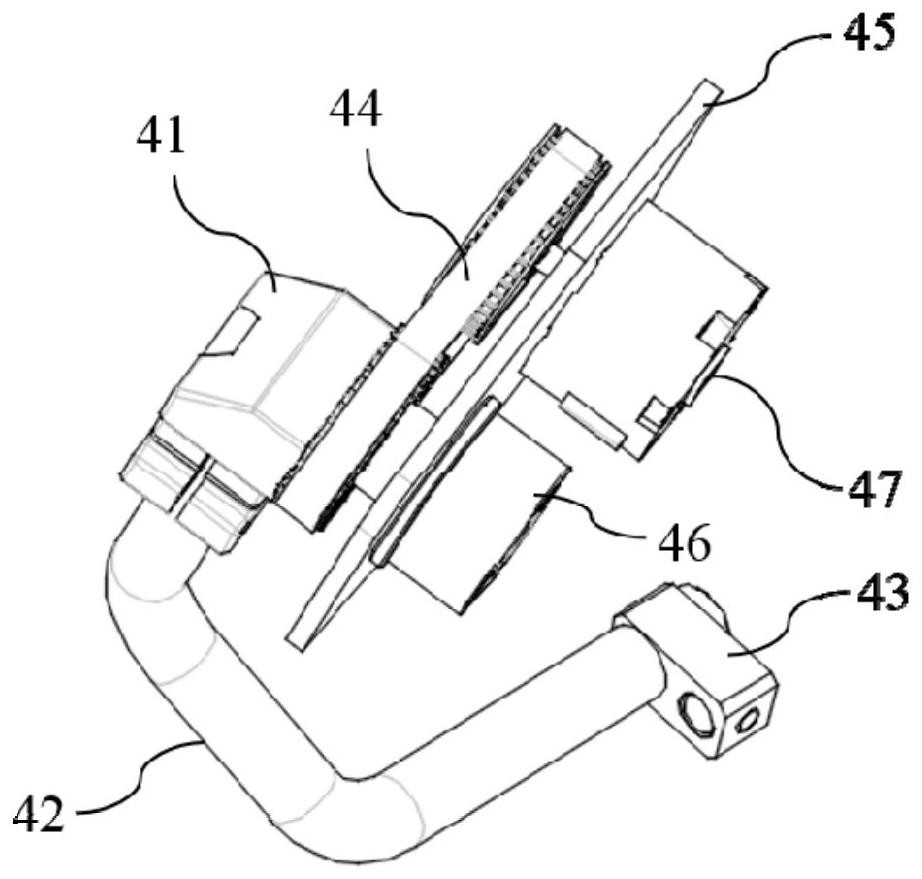

[0040] A splicing device with a single-spindle yarn suction nozzle structure in this embodiment, the basic structure is the same as that of embodiment 1, the differences and improvements are as follows: Figure 4 As shown, the single-spindle yarn suction nozzle 4 includes a suction nozzle elbow 41, a synchronous wheel 442 is installed inside the suction nozzle elbow 41, and a synchronous wheel shaft 443 is coaxially sleeved in the middle of the synchronous wheel 442. The wheel shaft 443 is also coaxially sleeved with a bearing 445, and each component is aligned with the axis of the connecting pipe 46 and is detachably installed on the mounting seat 45; the same side of the mounting seat 45 as the synchronous wheel 442 is also equipped with a driving wheel 441, the middle part of the drive wheel 441 is coaxially connected with a swing cylinder 47, thereby providing a drive source; the drive wheel 441 and the synchronous wheel 442 are sleeved with a synchronous belt 444 to realiz...

Embodiment 3

[0043] A splicing device with a single-spindle yarn suction nozzle structure in this embodiment, the basic structure is the same as that of embodiment 2, the differences and improvements are as follows: figure 2 As shown, the upper and lower zero sensors 5 and 6 are horizontally installed on the mounting base 45 respectively. Driven by a motor, the positioning of the sensors is required, so that the positioning of the swing cylinder 47 is accurate and the adjustment is simple.

[0044] In this example, if Figure 2~4 As shown, by starting the swing cylinder 47, the driving wheel 441 is driven to rotate forward or reversely, and then the synchronous wheel 442 is driven to rotate in the same direction through the synchronous belt 444 wound on it, so as to control the suction nozzle elbow 41 installed thereon. Rotate, and then drive the yarn suction nozzle 42 connected to the bottom of the suction nozzle elbow 41 to go down or up, and correspondingly drive the suction nozzle mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com