Patents

Literature

246 results about "Cleanability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleanability is a term used in clean productions (e.g. to assess the cleanability of technical surfaces). In order to ensure optimum cleanability of the surfaces of machines and equipment, they must fulfil certain requirements. Where surfaces come into contact with media, no deposits may be formed which could impair product quality. Therefore, the surface roughness of such areas should be below 0.8 µm (see EHEDG doc. 8). If the degree of roughness is exceeded, resistances may develop during disinfection processes. These occur when microorganisms only come into contact with disinfectants but are not killed by them. When ascertaining the cleanability of a surface with regard to particles, the analysis can be carried out in correlation with the surface cleanliness classes described in VDI 2083 Part 9.1. Surface roughness can be measured, for example, using profile methods (DIN EN ISO 11562) or AFM (atomic force microscope). However, no norm is currently in existence which describes a standardised AFM procedure.

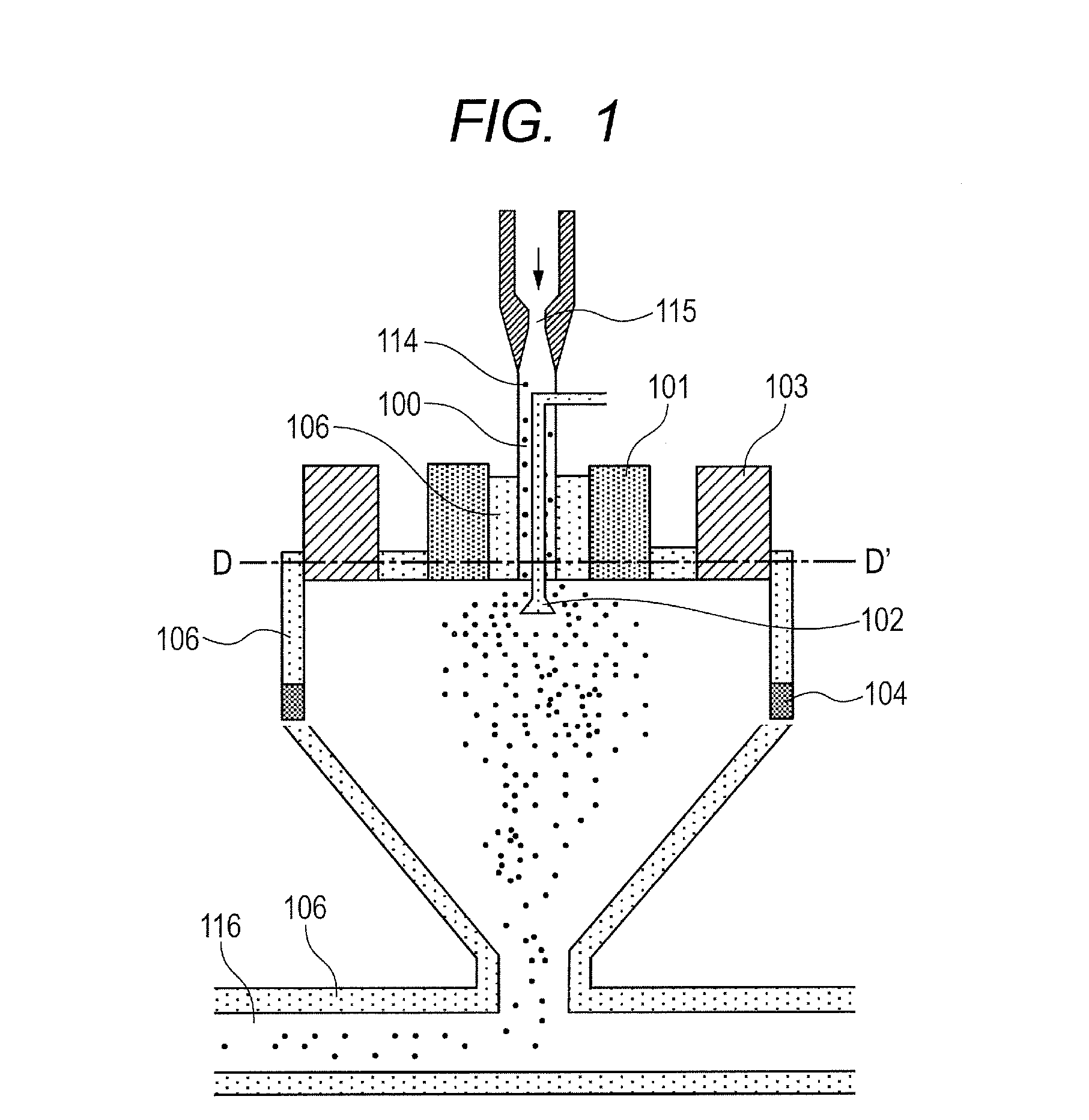

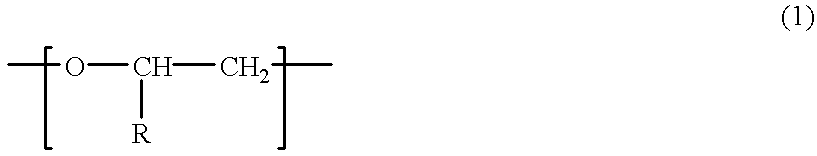

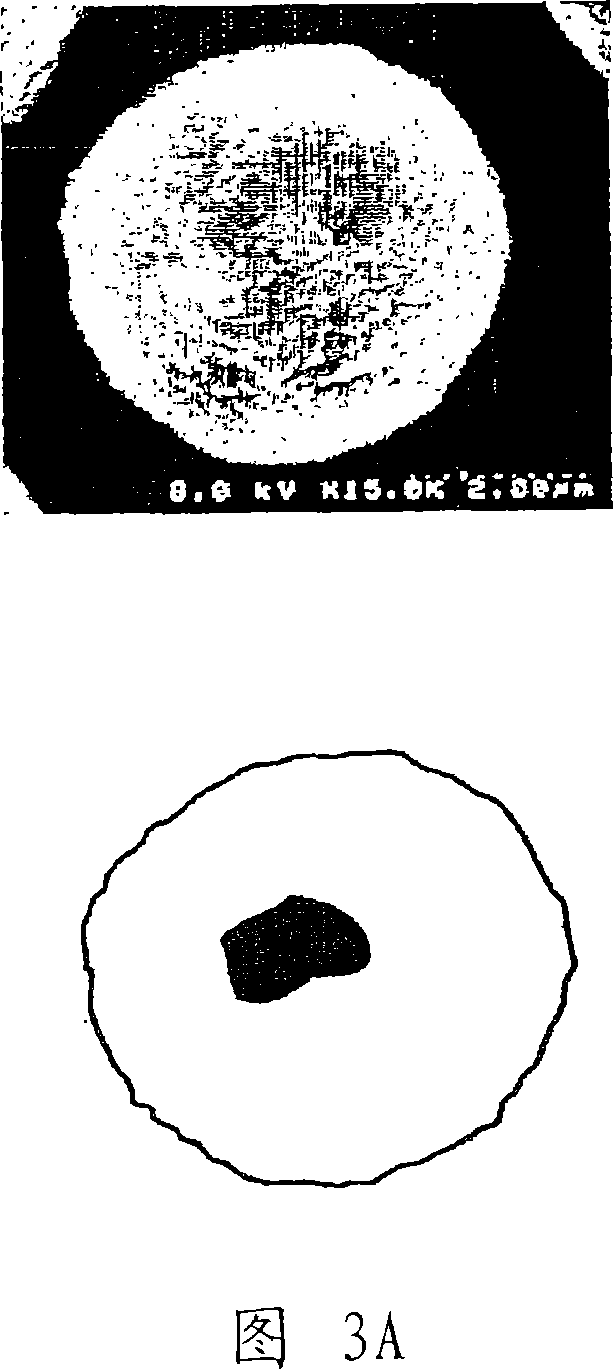

Resin particle and process of producing the same

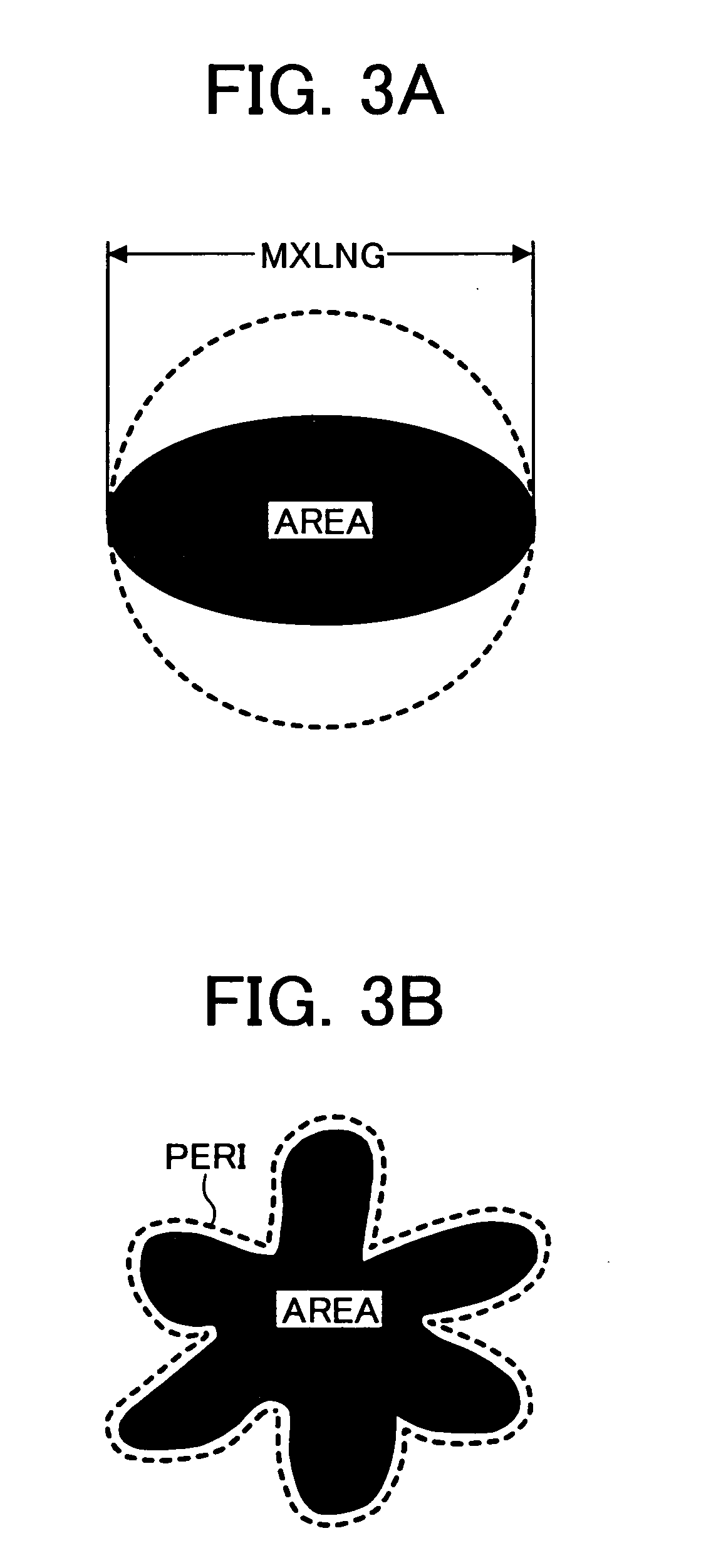

ActiveUS20060165989A1Improve wear resistanceExcellent in anti-hot offset propertyPretreated surfacesGranulation by liquid drop formationVolume averageWear resistance

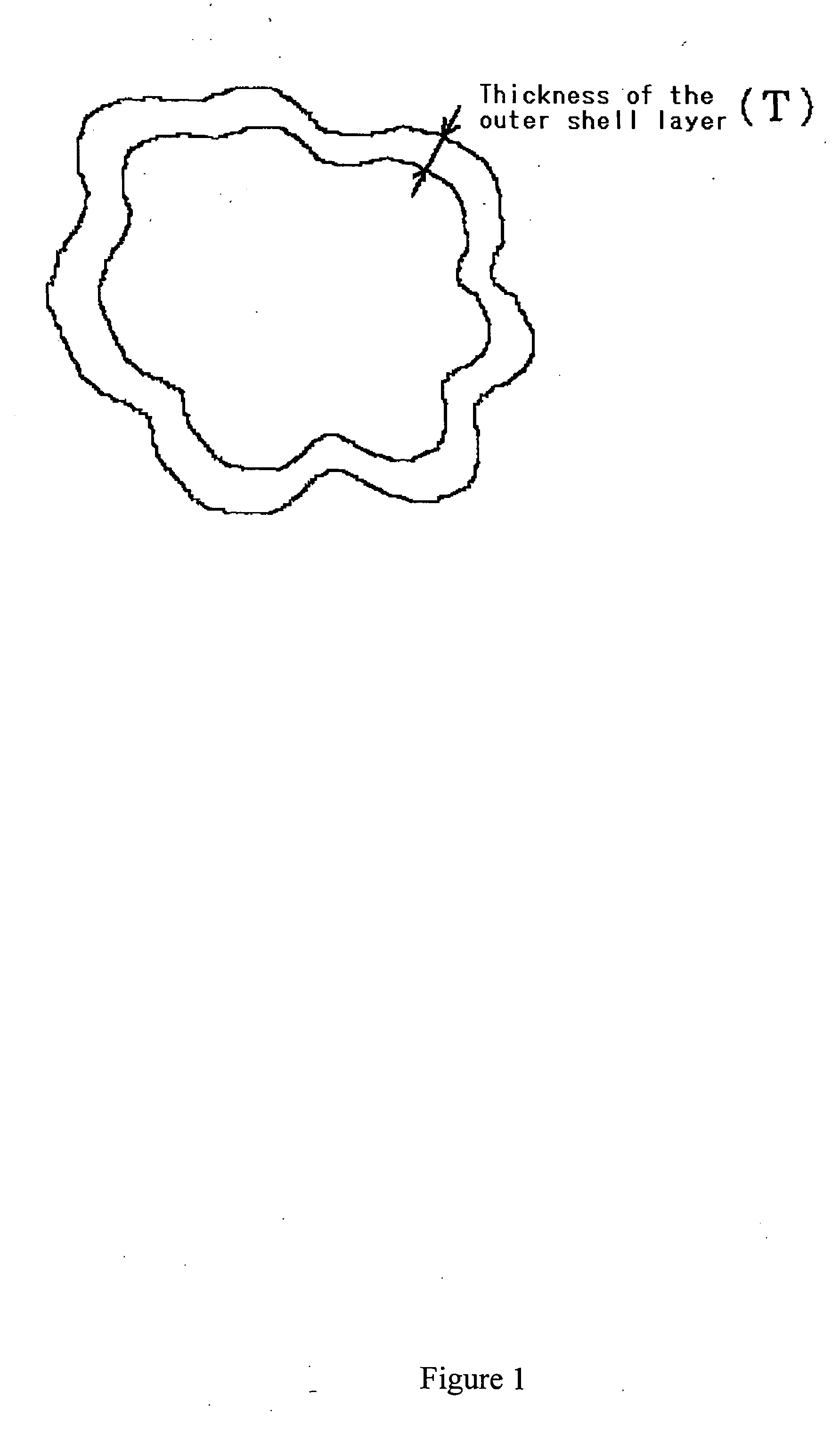

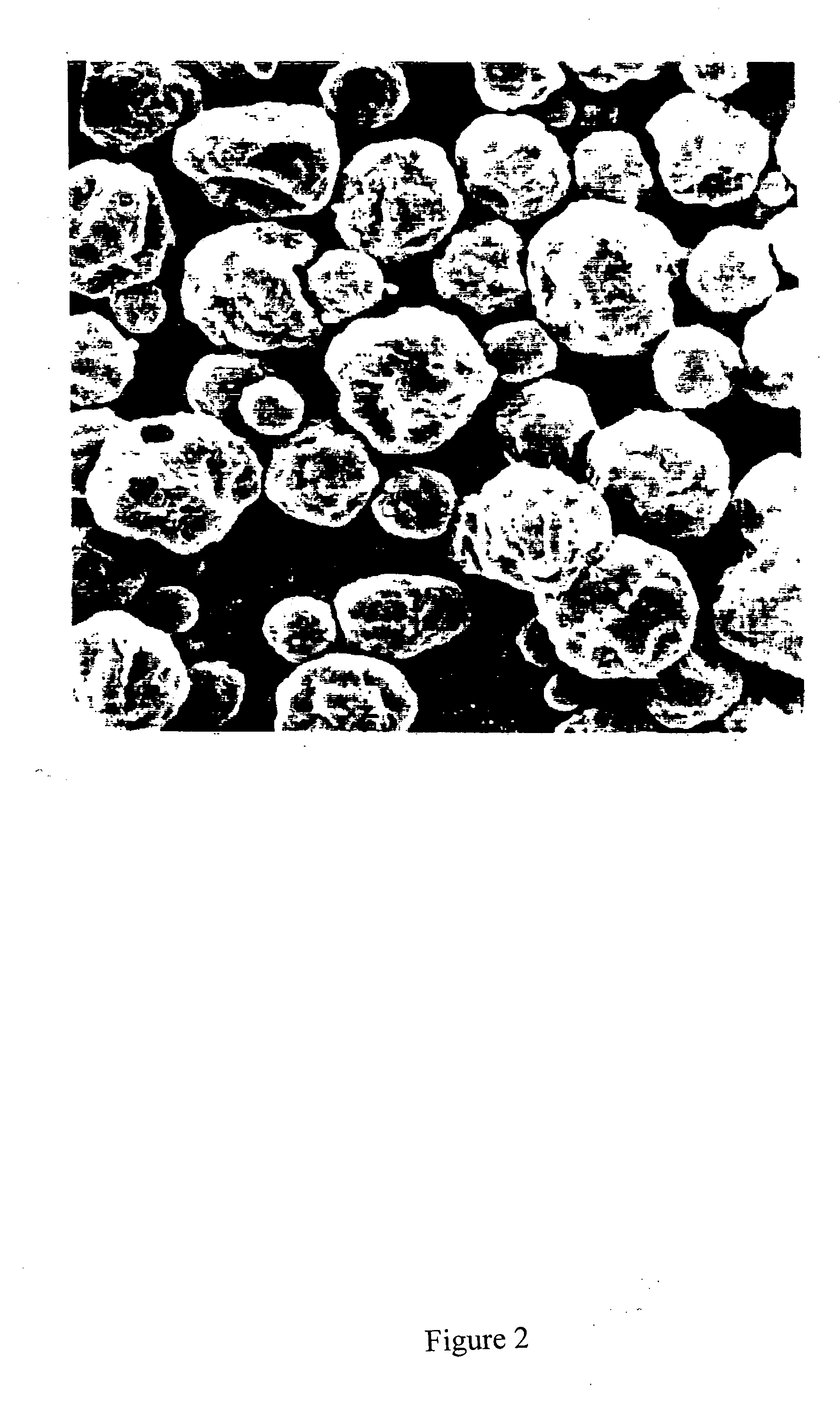

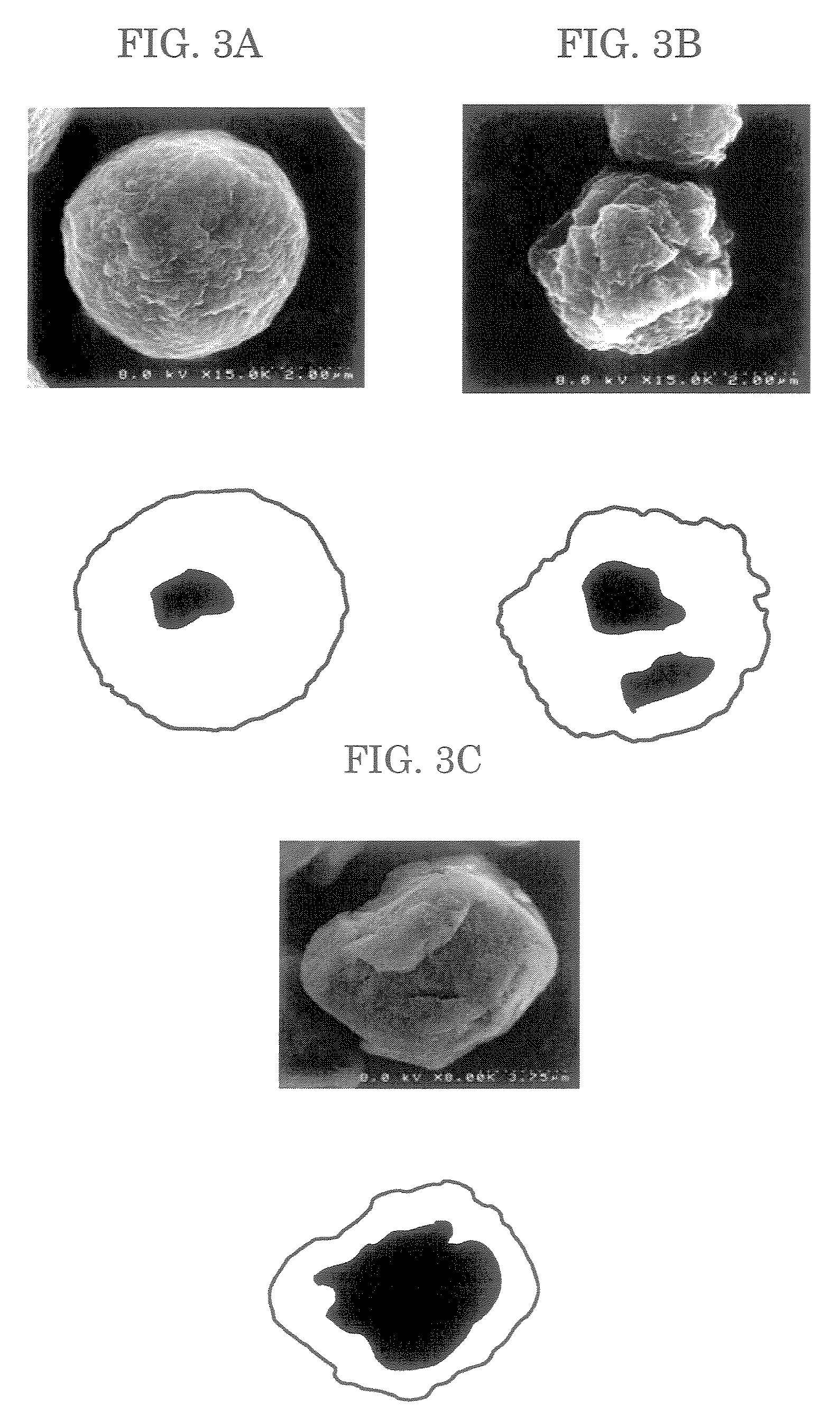

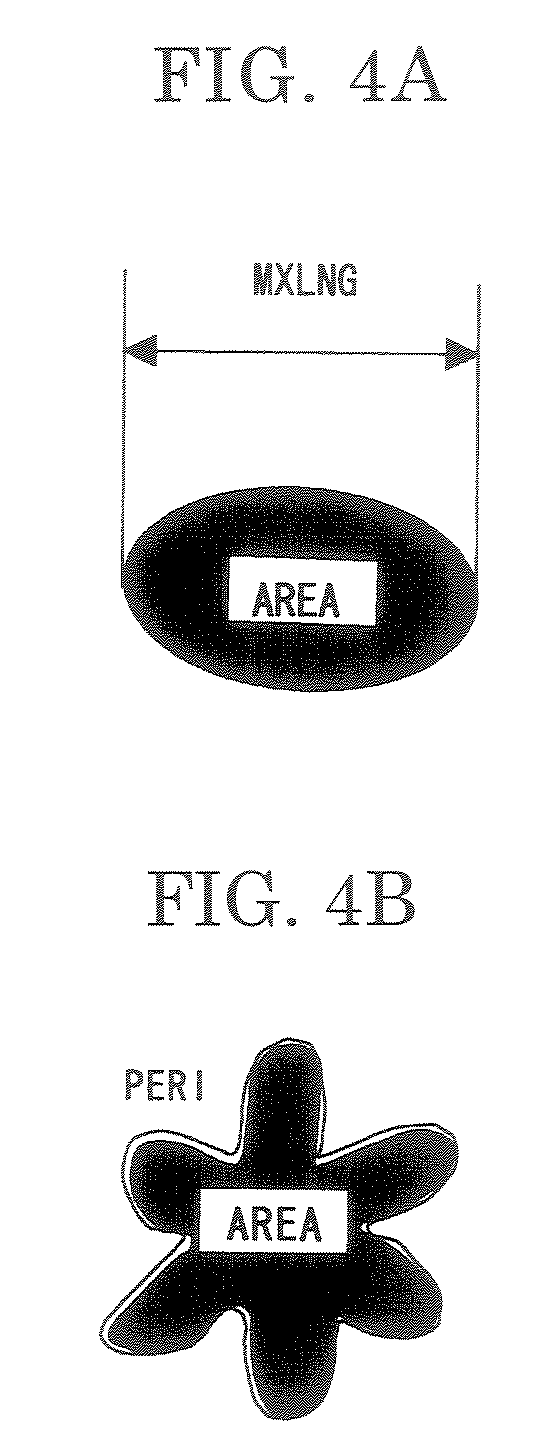

Provided is a resin particle comprising a resin (a) and a filler (b) contained in the particle; the particle has a volume average particle diameter of from 0.1 to 300 μm and a shape factor of from 110 to 300; the particle has an outer shell layer (S) comprising at least a portion of the filler (b); the layer (S) is at least 0.01 μm thick and has a thickness that is ½ or less of the maximum inscribed circle radius of the particle cross section. When used as a toner resin, it is excellent in blade cleaning properties and wide in the fixation temperature range; when employed as a paint additive or a cosmetics additive, it is excellent in masking properties; when used as paper coating additive, it is excellent in ink retention; when utilized as an abrasive, it is excellent in abrasion.

Owner:RICOH KK +1

Pulverized toner

ActiveUS20070212630A1Improve release abilityExcellent in ability cleaning abilityElectrographic process apparatusDevelopersMass ratioEngineering

To provide a pulverized toner excellent in the releasing ability and cleaning ability, and an image-forming apparatus for one-component developer, and a process cartridge using the pulverized toner. The pulverized toner contains a toner base particle containing at least a binder resin, a colorant, and a releasing agent, the mass ratio of the releasing agent to the binder resin is 3.0% to 6.0%, the adhesive force among the pulverized toners at 25° C. to 55° C. is 20 g to 80 g, and the pulverized toner is used for the image-forming apparatus for one-component developer containing the cleaning unit configured to dispose an elastic blade adjacent to the surface of the image bearing member so as to clean the surface.

Owner:RICOH KK

Liquid composition for making pigment fixed, ink set, method for producing ink jet recorded matter on fabric and ink jet recorded matter on fabric

InactiveUS20090226678A1Improve wear resistanceGood dry-cleanabilityLayered productsDecorative surface effectsHigh resistanceColor intensity

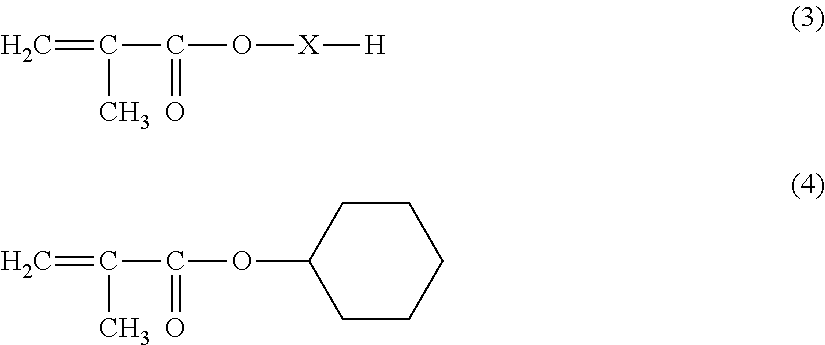

There are provided a liquid composition for making pigment fixed having a high resistance to rubbing and a good dry-cleanability; an ink set including the liquid composition for making pigment fixed and an ink composition excellent in terms of color intensity, discharge stability, and adhesiveness; and a method for producing ink-jet-recorded matter on a fabric having a high resistance to rubbing and good dry-cleanability using the liquid composition for making pigment fixed and the ink composition.The liquid composition for making pigment fixed according to the present invention contains at least a reactant and polymer fine particles synthesized from an alkyl (meth)acrylate and / or cyclic alkyl (meth)acrylate, the glass transition temperature and acid value of the liquid composition being equal to or lower than −10° C. and equal to or lower than 100 mg KOH / g, respectively.

Owner:SEIKO EPSON CORP

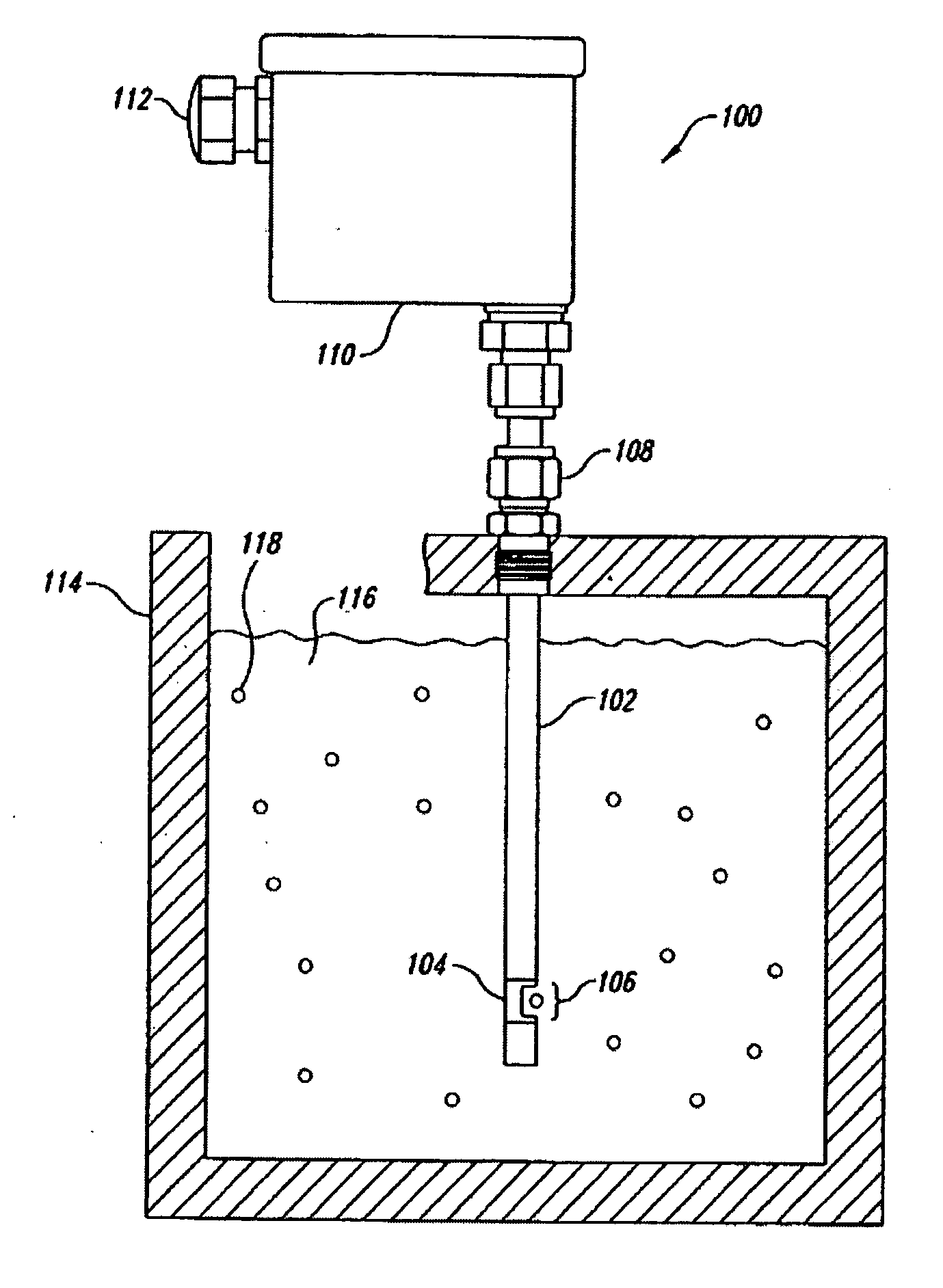

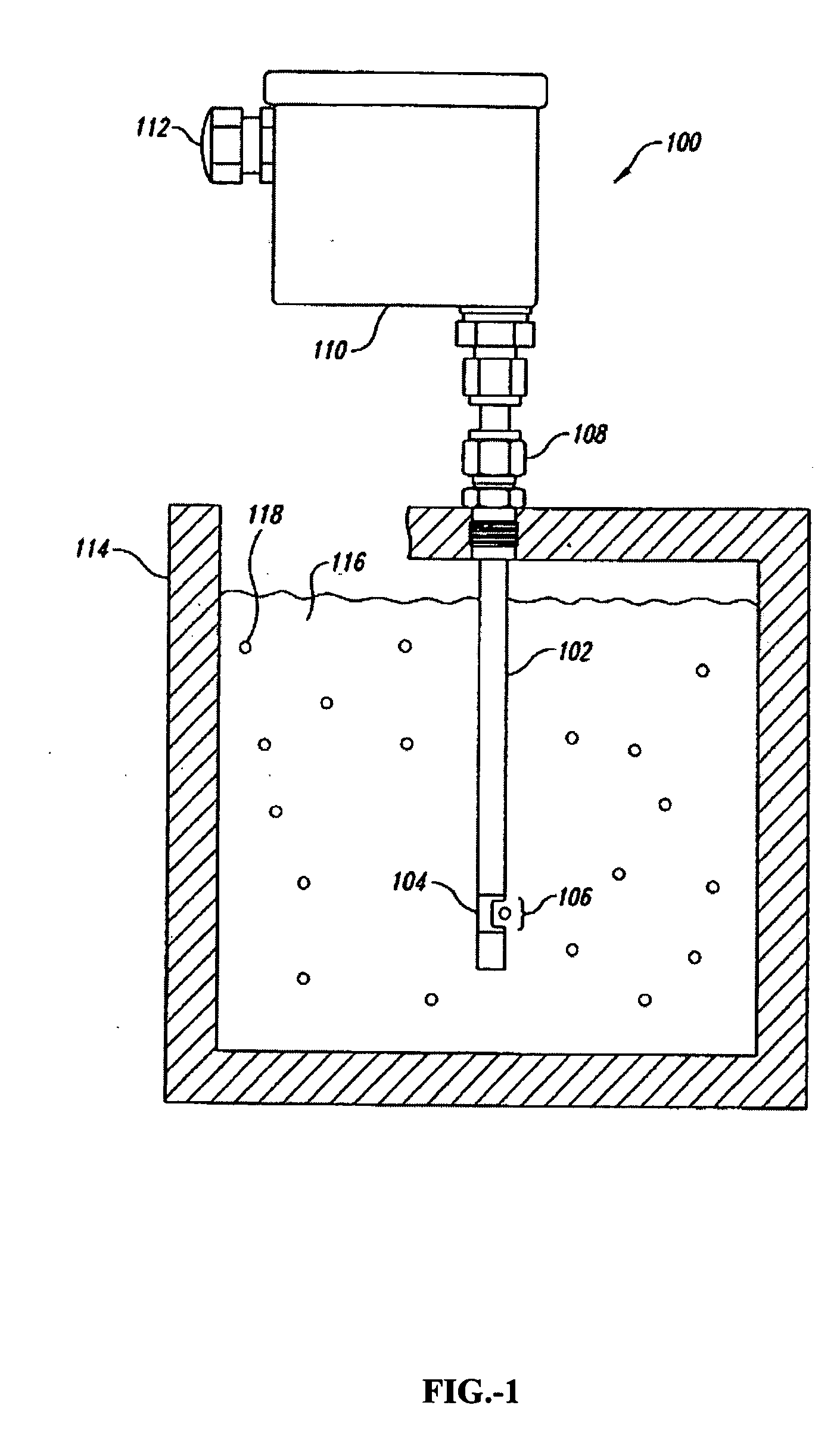

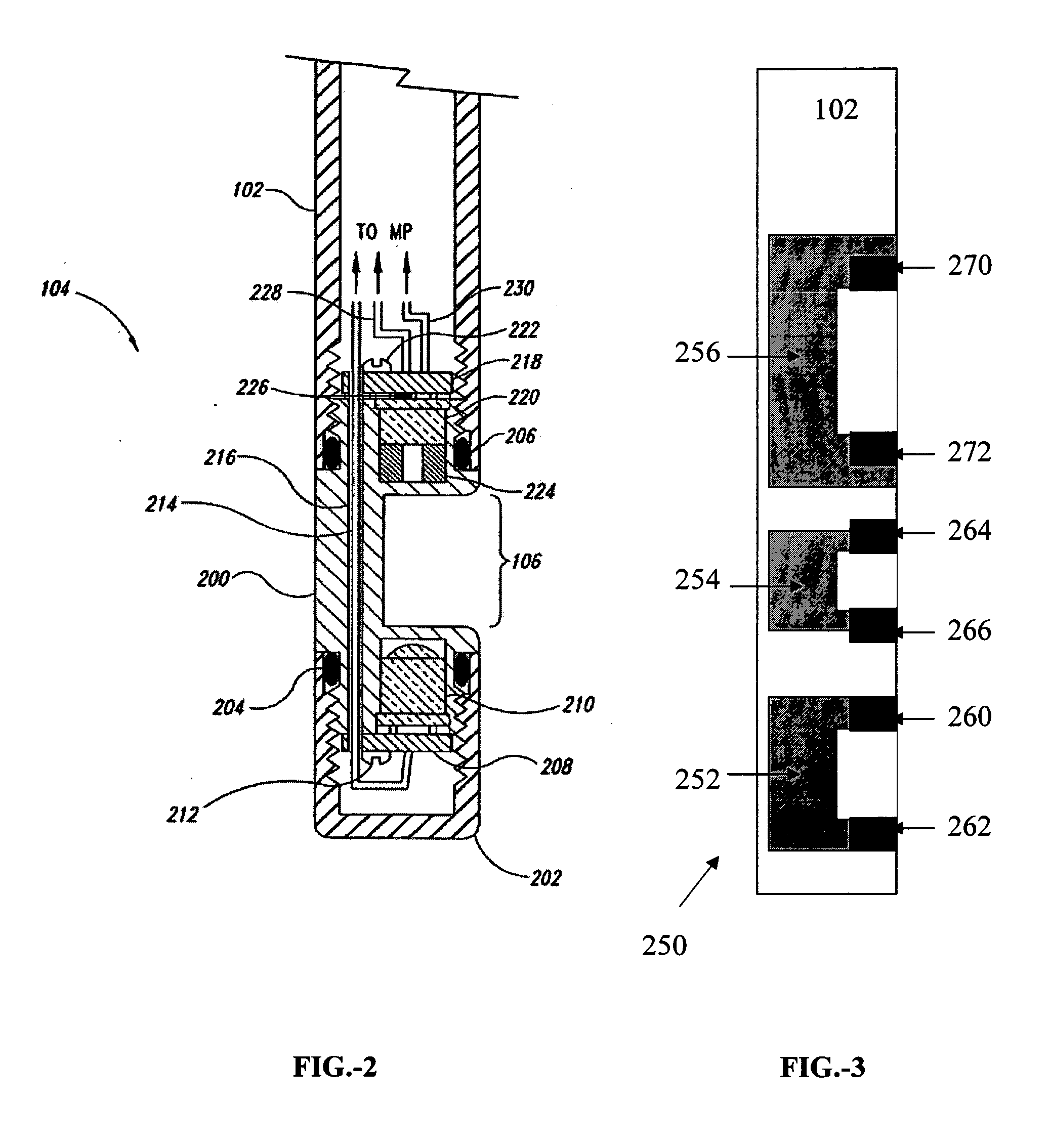

Systems and methods for in situ spectroscopic measurements

ActiveUS20050264817A1Investigating moving fluids/granular solidsScattering properties measurementsVertical-cavity surface-emitting laserBiotechnology

A circularizated semiconductor laser diode (CSLD), such as for example a vertical cavity surface emitting laser (VCSEL) may be used for optical measurements. The CSLD may be used in a cell density probe to perform cell density determination and / or turbidity determination, such as in a biotech, fermentation, or other optical absorbance application. The cell density probe may comprise a probe tip section made from a polytetrafluoroethylene material, which provides sealability, ease of manufacture, durability, cleanability, optical semi-transparency at visible and near infrared wavelengths, and other advantages. The probe tip advantageously provides an optical gap that allows for in situ measurements of optical measurements including but not limited to absorbance, scattering, and fluorescence.

Owner:FINESSE SOLUTIONS +1

Toner and image forming method

InactiveUS6156471AImprove development performanceHigh densityDevelopersElectrographic process apparatusLatent imageAmorphous silicon

An electrophotographic toner showing good cleanability and is suitable for use in developing an electrostatic latent image formed on an amorphous-silicon photosensitive member is provided. The toner includes toner particles each comprising a binder resin and a colorant, and inorganic fine powder A. The inorganic fine powder A contains 88.0-97.0 wt. % of a rare earth compound comprising a rare earth oxide. The rare earth compound contains 40.0-65.0 wt. % of Ce (calculated as CeO2), 25.0-45.0 wt. % of La (calculated as La2O3), 1.0-10.0 wt. % of Nd (calculated as Nd2O3) and 1.0-10.0 wt. % of Pr (calculated as Pr6O11). The rare earth compound contains further a fluorinated rare earth compound in such an amount as to provide the inorganic fine powder A with a fluorine content of 2.0-11.0 wt. %.

Owner:CANON KK

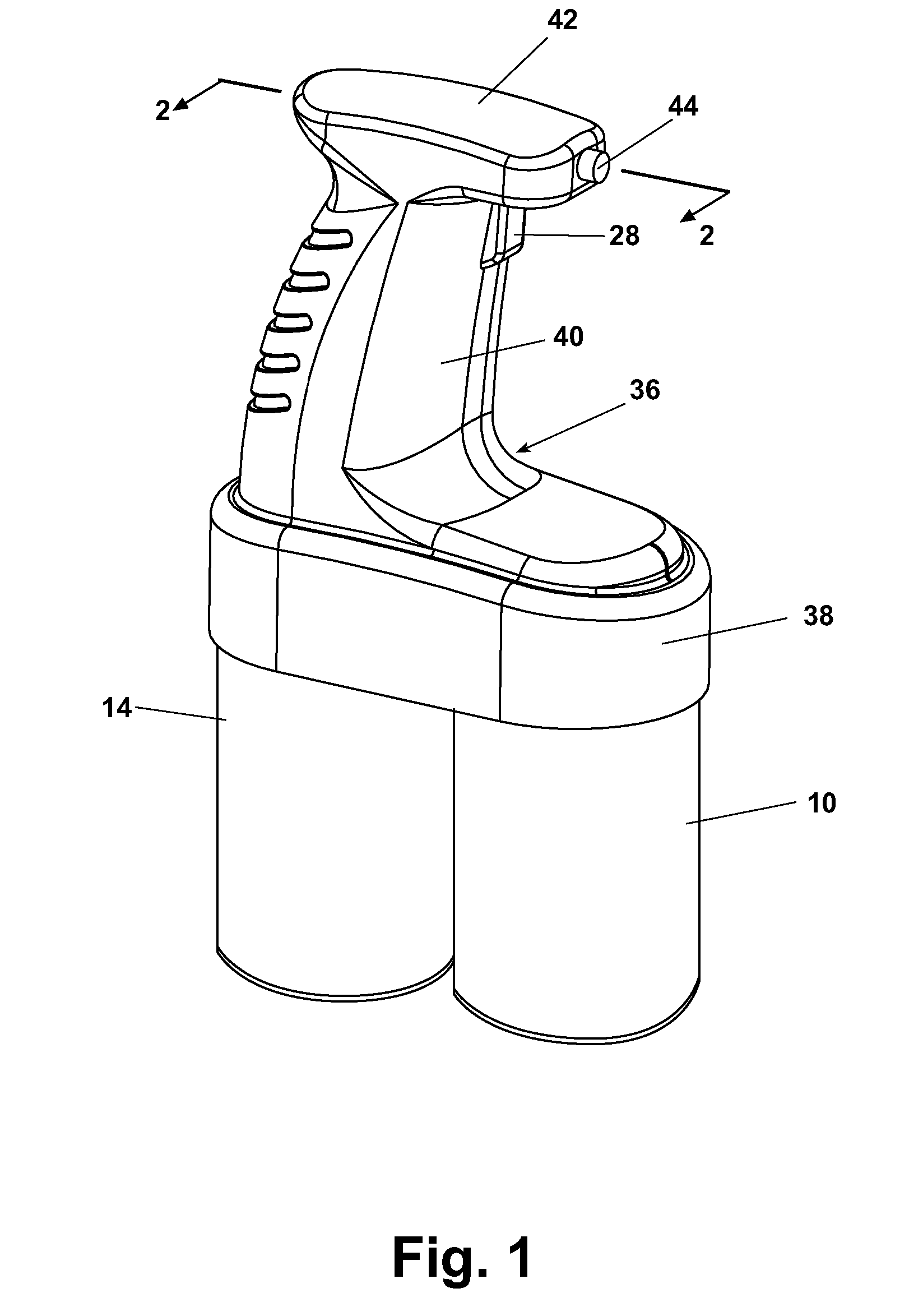

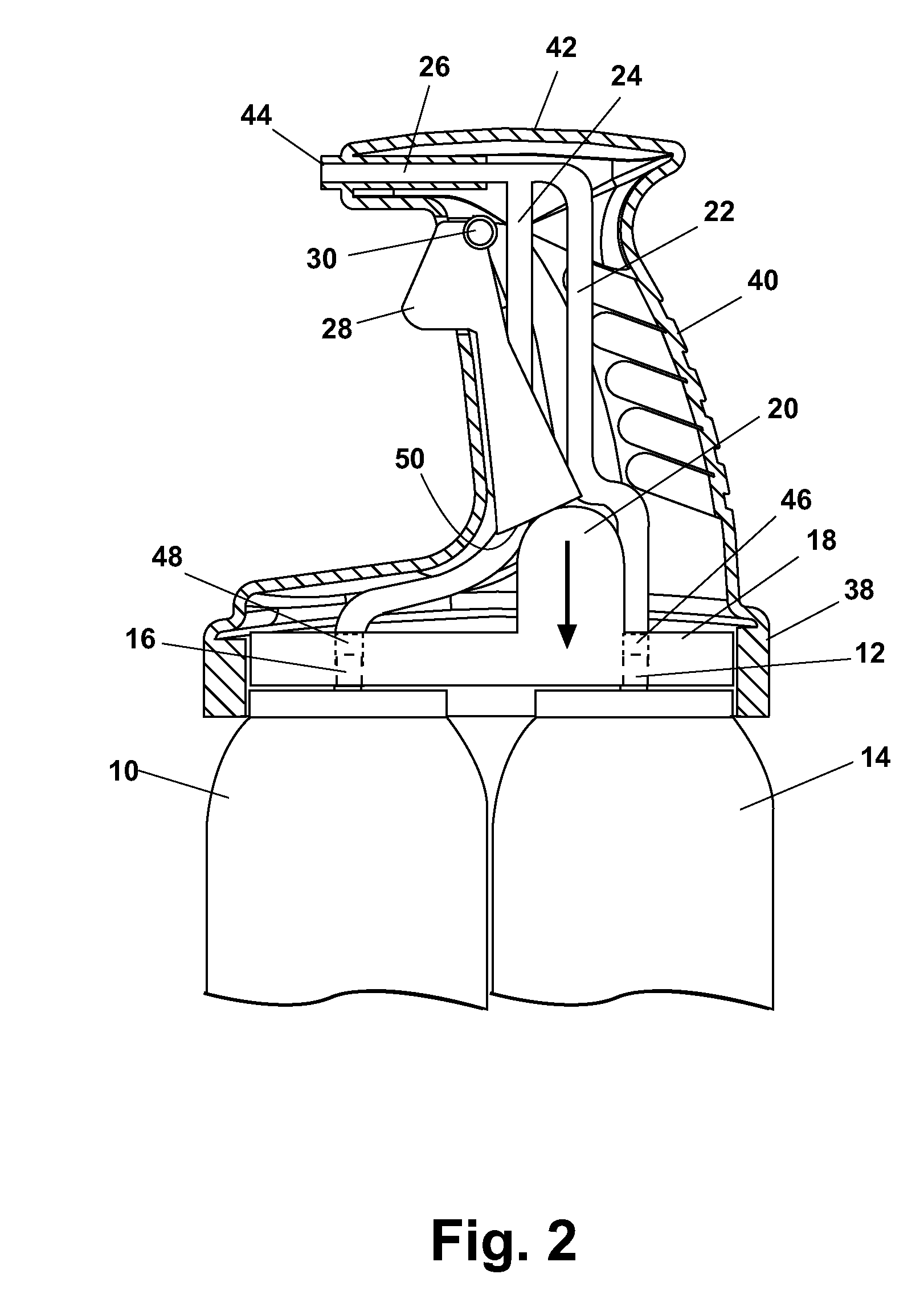

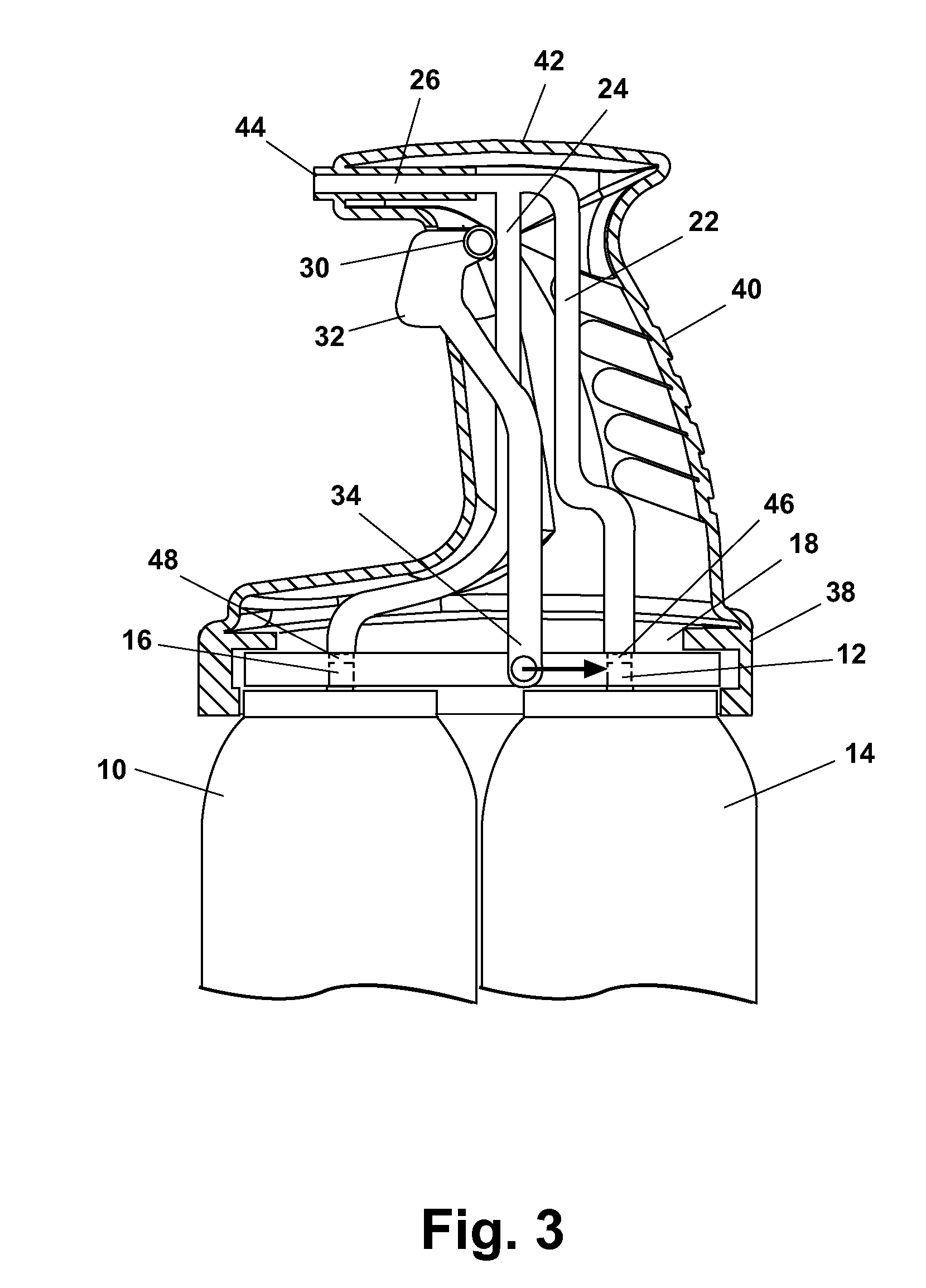

Manual spray cleaner

ActiveUS20040063600A1Reduce deliveryPacked tightlyCleaning machinesDry-cleaning apparatus for textilesEngineeringSpray bottle

Abstract of the Disclosure A manual spray cleaner for removing dirt and stains from fabrics and carpets comprising a spray bottle having two separate chambers and a single dispensing spray outlet for dispensing controlled amounts of liquids from each of the chambers. One of the chambers has a fabric / carpet cleaning composition therein and the other chamber has an oxidizing composition that enhances the cleanability of the fabric / carpet cleaning composition. The fabric / carpet cleaning composition and the oxidizing composition are simultaneously drawn from their respective chambers and mixed together at the time that they are dispensed from the spray bottle. At least one of the oxidizing composition and the fabric / carpet cleaning composition includes a fabric / carpet protectant. The two compositions are mixed before or after they are sprayed from the bottle. The two compositions can be pressurized with an aerosol propellant or drawn from their respective chambers by a mechanical pump.

Owner:BISSELL INC

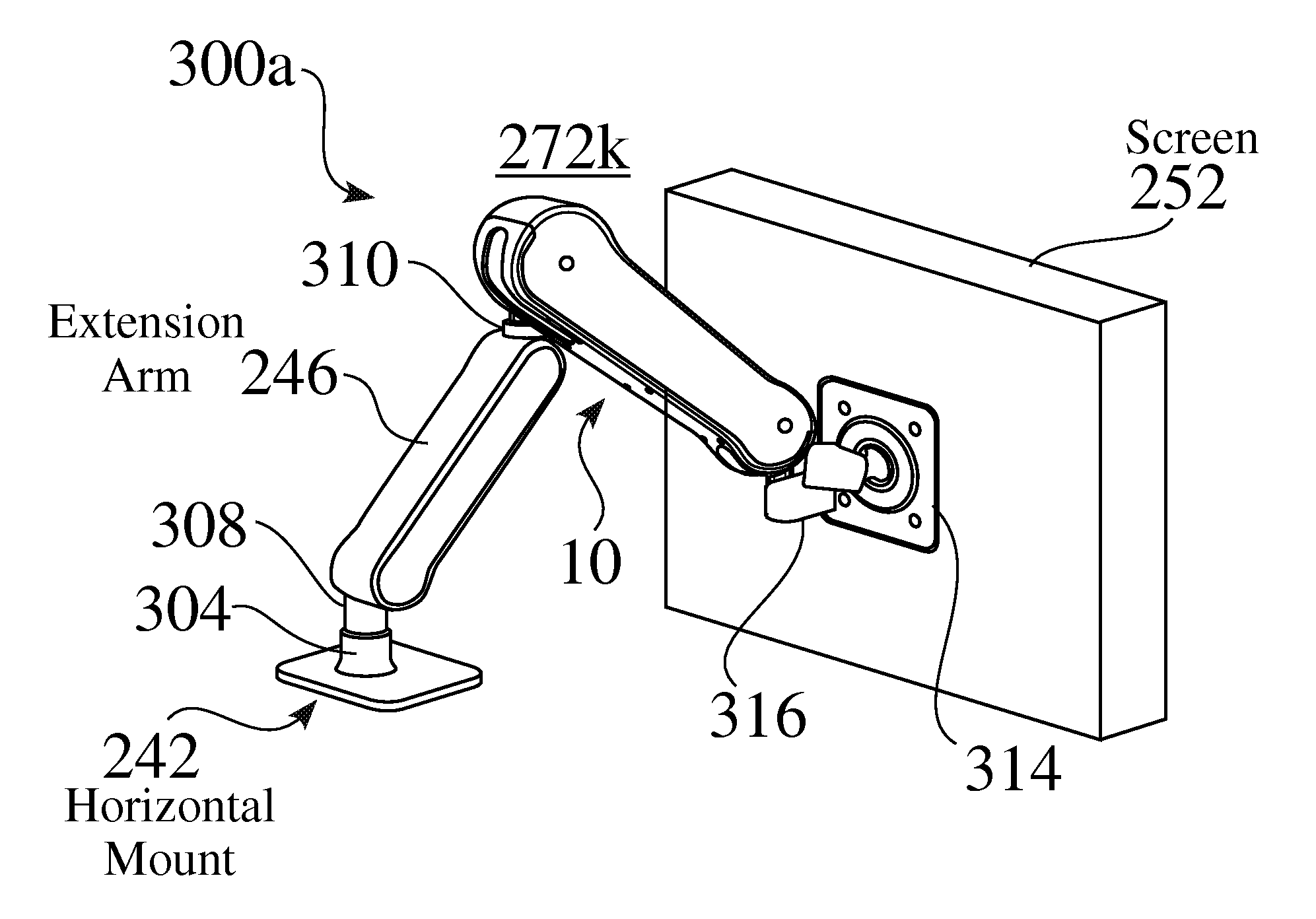

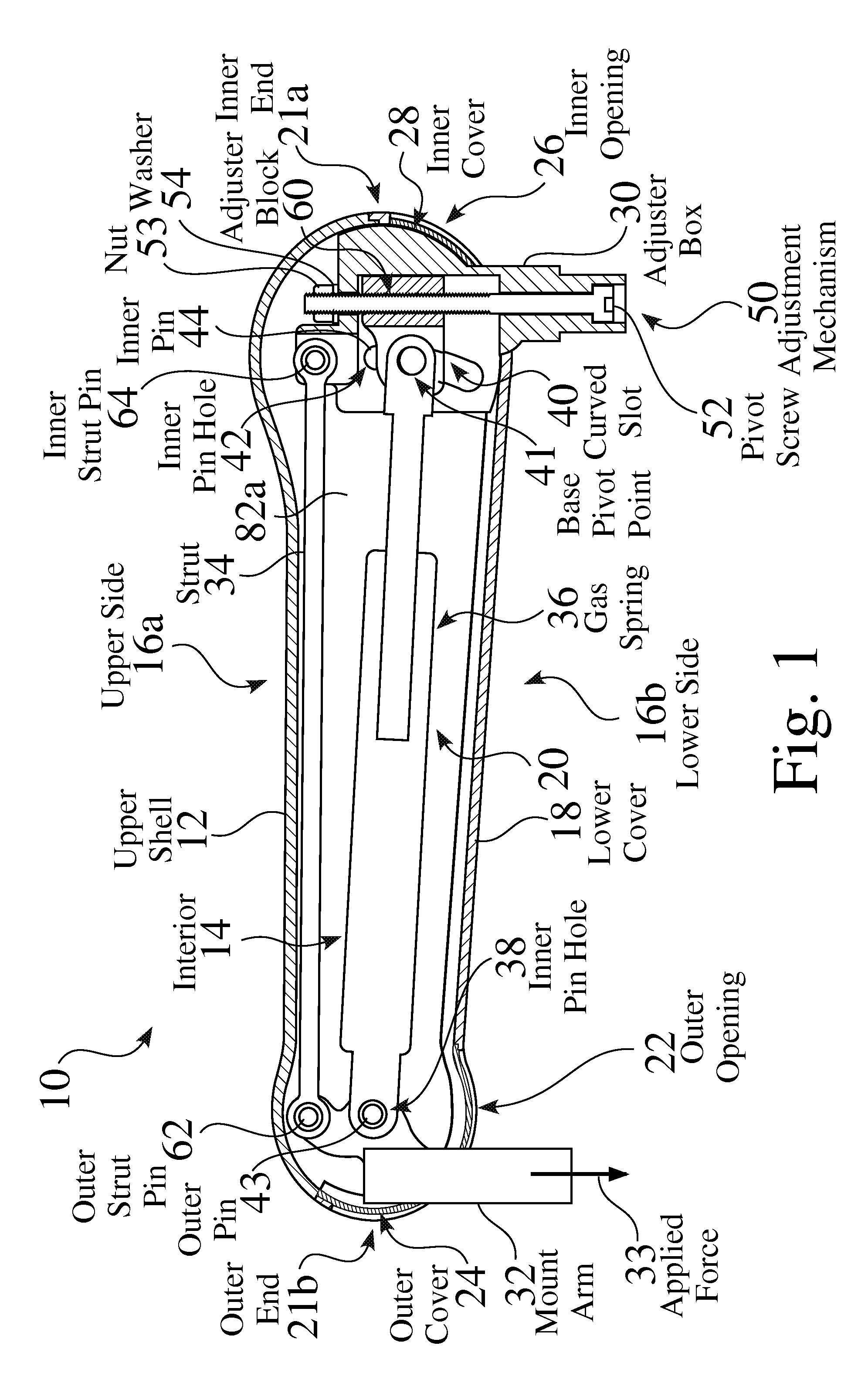

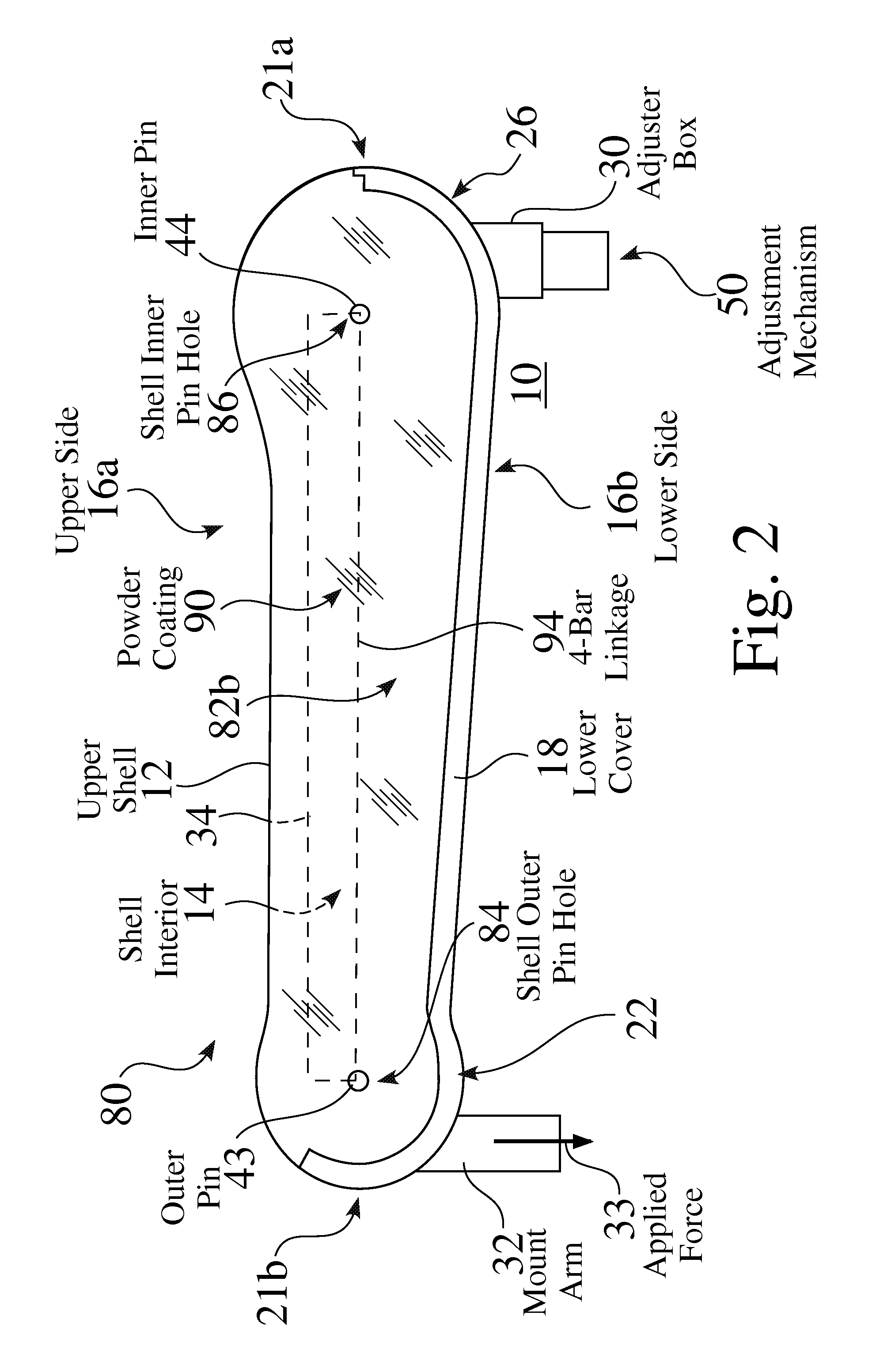

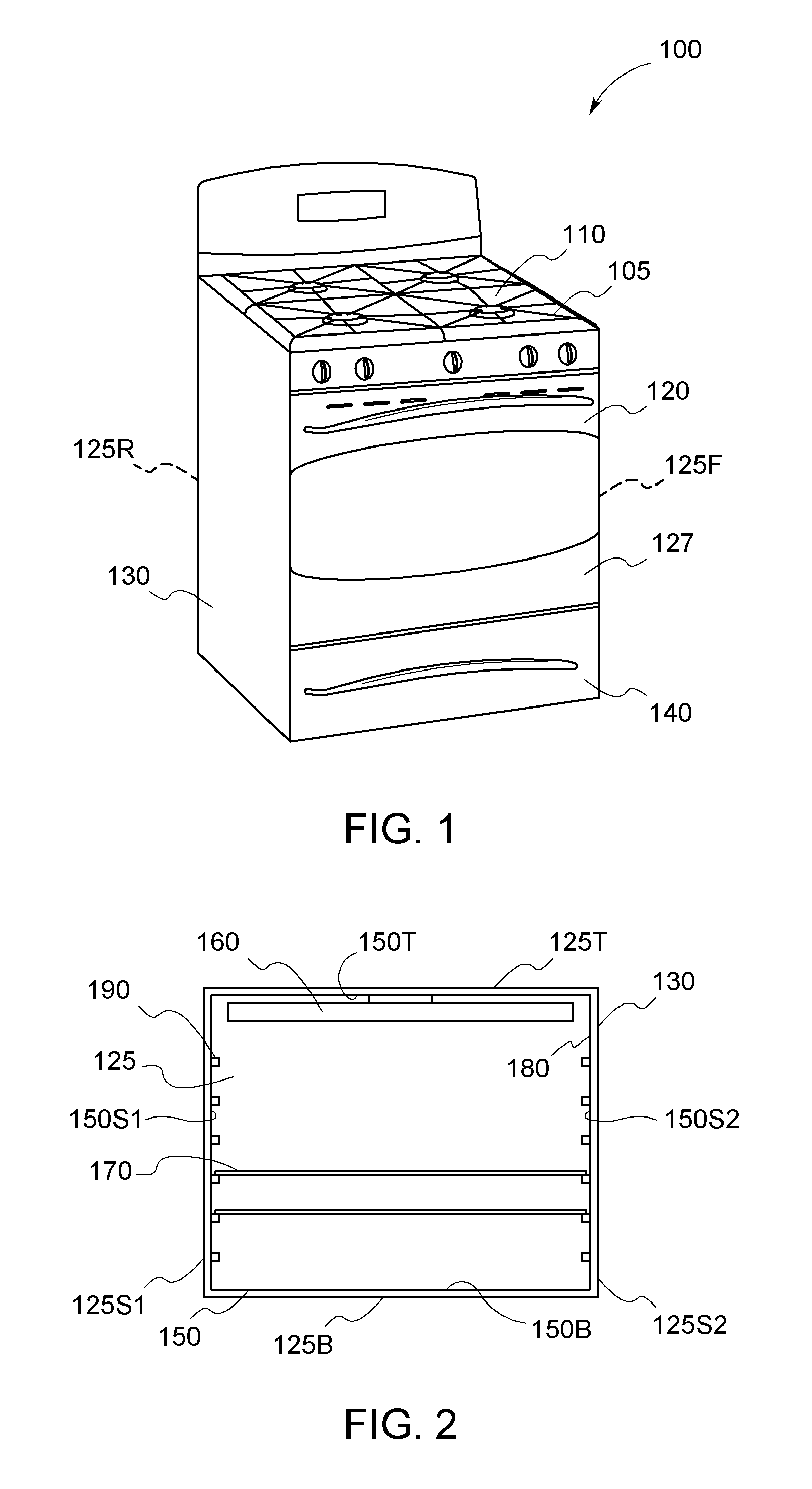

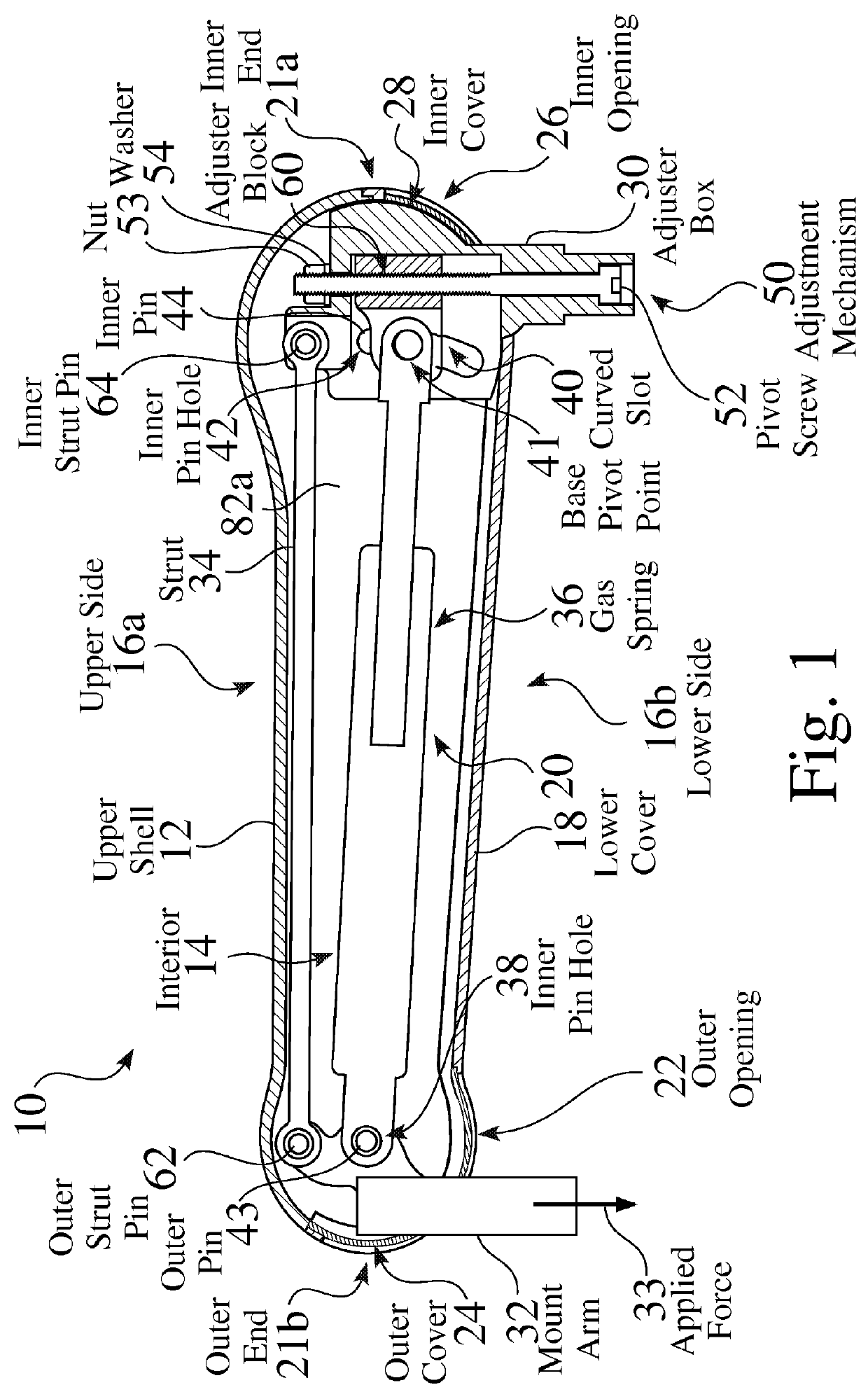

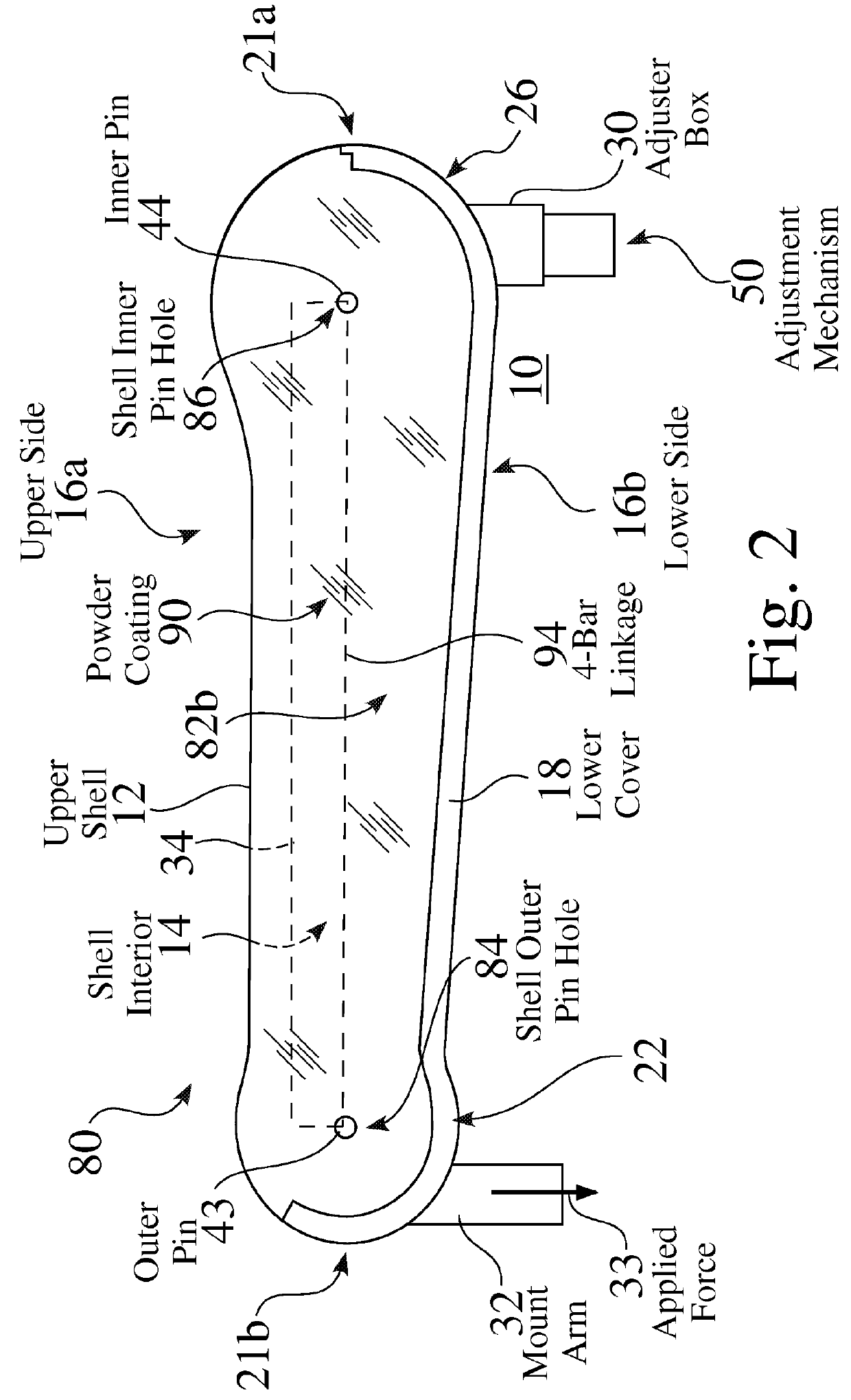

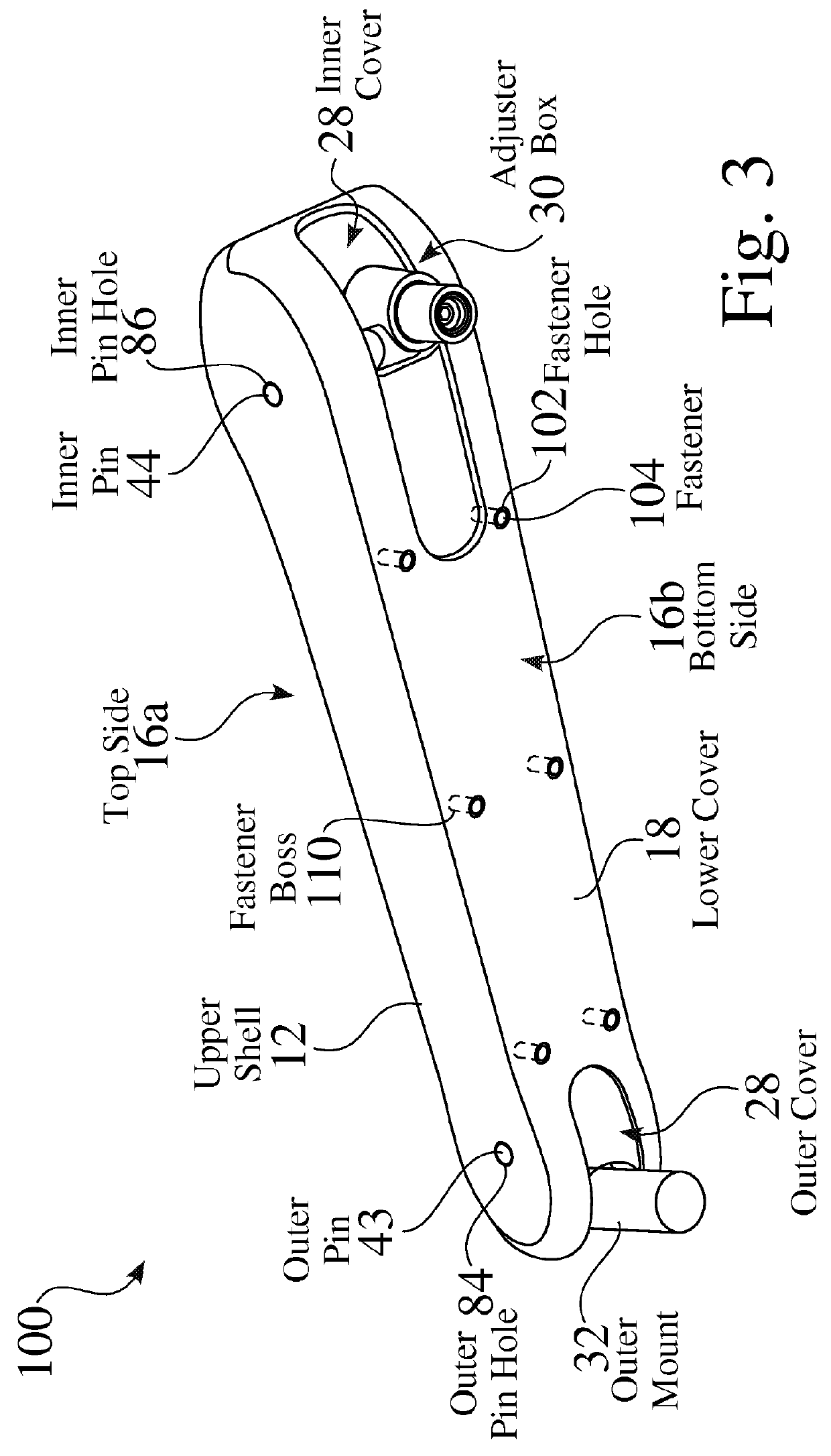

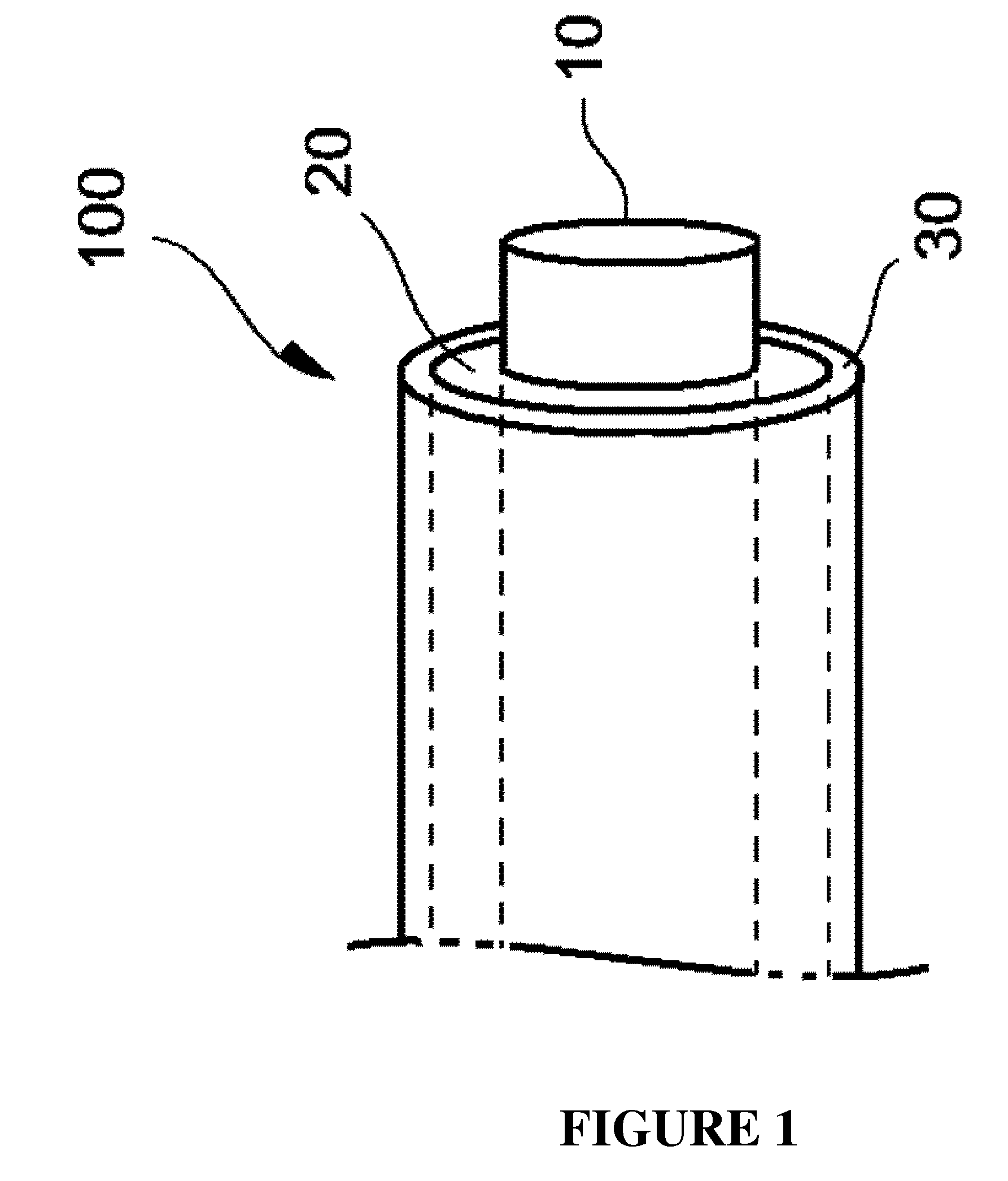

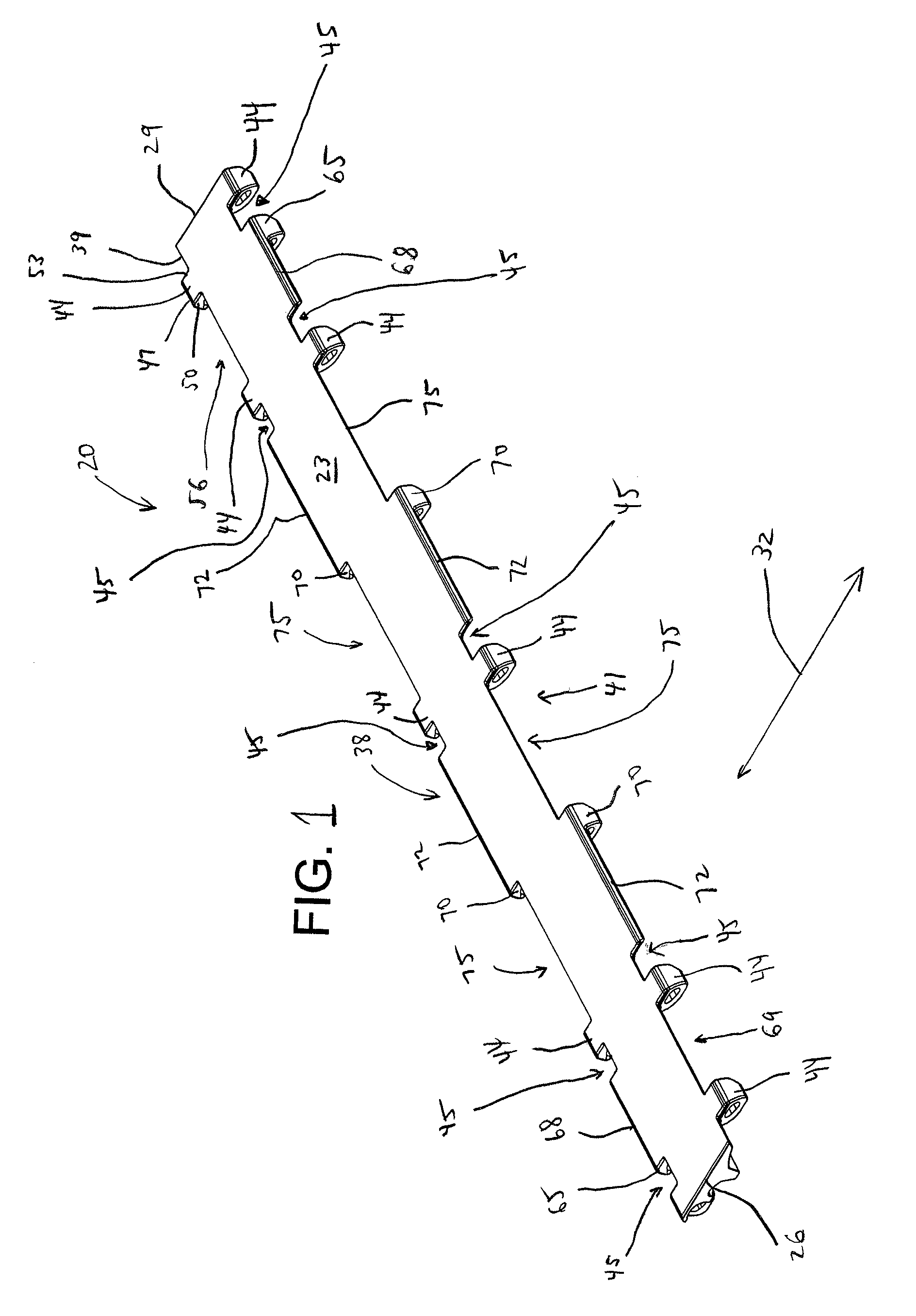

Variable height arm structures, systems, and methods

ActiveUS20120235000A1Good cleanabilityIncrease heightStands/trestlesKitchen equipmentEngineeringCleanability

Enhanced variable-height mounting arms comprise structures that allow any of improved cleanability and / or improved adjustment of height or counterbalancing. An exemplary enhanced variable-height arm comprises an upper shell structure that substantially extends over the upper and side regions of the mounting arm, forming a four-bar linkage. A lower cover is mounted to the upper cover across the bottom side of the arm, and defines holes therethrough for extension of the opposing ends of the arm. The variable-height arm further comprises a bias element, wherein one end of the bias element is adjustably fixable in relation to a defined curve, non-linear path or slot, such as within a curved slot. The variable-height arm may preferably further comprise a mechanism for adjusting any of the height or counterbalance for the structure.

Owner:GCX CORP

Toner and image forming method

InactiveUS20140329176A1Not impair transferabilityNot cause member contaminationDevelopersWaxHigh humidity

Provided is a toner that allows a transferred image to be stably output regardless of smoothness of a transfer material even under high-temperature and high-humidity environment or under low-temperature and low-humidity environment, that is excellent in cleanability for a transfer member even at the time of high-speed printing, and that causes less member contamination. The toner is a toner including toner particles each containing a binder resin and a wax, and silica fine particles on surfaces of the toner particles, wherein the silica fine particles have a number-average particle diameter of primary particles of 60 nm or more and 300 nm or less, a coverage rate of the surfaces of the toner particles with the silica fine particles is 15% or more and 95% or less, and the toner has a uniaxial collapse stress at a maximum consolidation stress of 10.0 kPa, of 2.5 kPa or more and 3.5 kPa or less.

Owner:CANON KK

Fluid shield fabric

InactiveUS6136730AInsufficient stiffnessEasy to solveFibre treatmentSynthetic resin layered productsResistEngineering

An improved fabric for use in applications such as furniture upholstery is provided which possesses desirable flexibility, cleanability, and fluid resistant properties. The fabric includes a textile substrate treated with a fluorochemical stain resist agent. The treated textile substrate is covered substantially on the back with a layer of extrusion coated thermoplastic polymer which is pressed at least partially into the fabric substrate. A process for forming the fluid shield fabric according to the present invention is also provided. Preferably, the fabric is comprised of solution dyed nylon and the polymeric material is ethylene methyl acrylate polymer.

Owner:SAGE AUTOMOTIVE INTERIORS INC

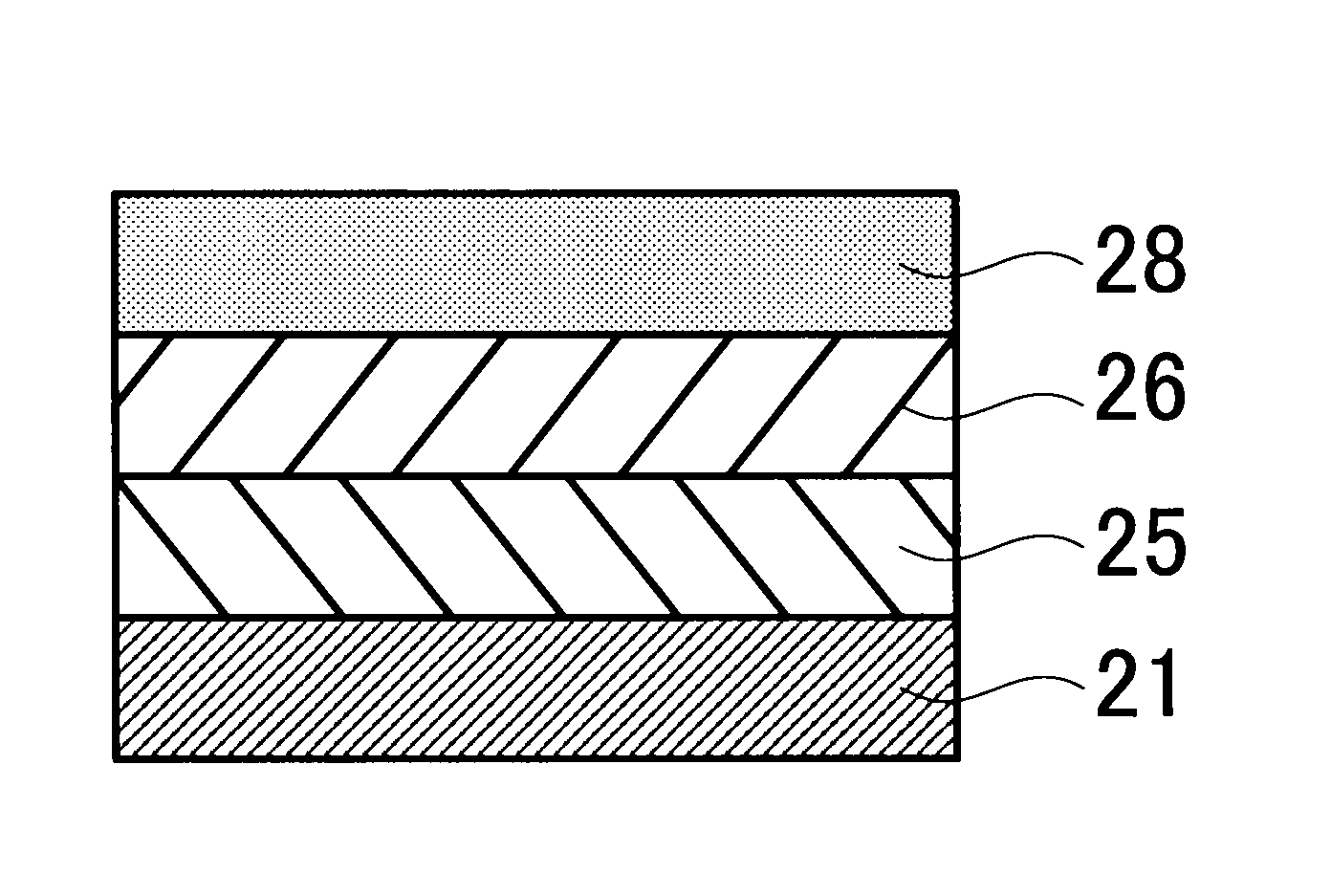

Electrophotographic photoconductor, electrophotographic process cartridge containing the same and electrophotographic apparatus containing the same

InactiveUS20080227008A1Low increase in friction coefficient and wearEasy to cleanElectrographic process apparatusCorona dischargeElectrical conductorSurface layer

An object of the present invention is to provide an electrophotographic photoconductor having an extremely low increase in friction coefficient and wear, while also having superior cleanability even after long-term or large-volume printing, and to provide an electrophotographic apparatus for forming an image using a polymerization toner without providing a unit for externally supplying a lubricant to a photoconductor. Namely, the present invention provides an electrophotographic photoconductor having a photosensitive layer and a crosslinked resin surface layer over a conductive substrate, wherein the crosslinked resin surface layer at least contains trimethylolpropane triacrylate, a dimethylpolysiloxane having a radically polymerizable functional group, and lubricating fine particles.

Owner:RICOH KK

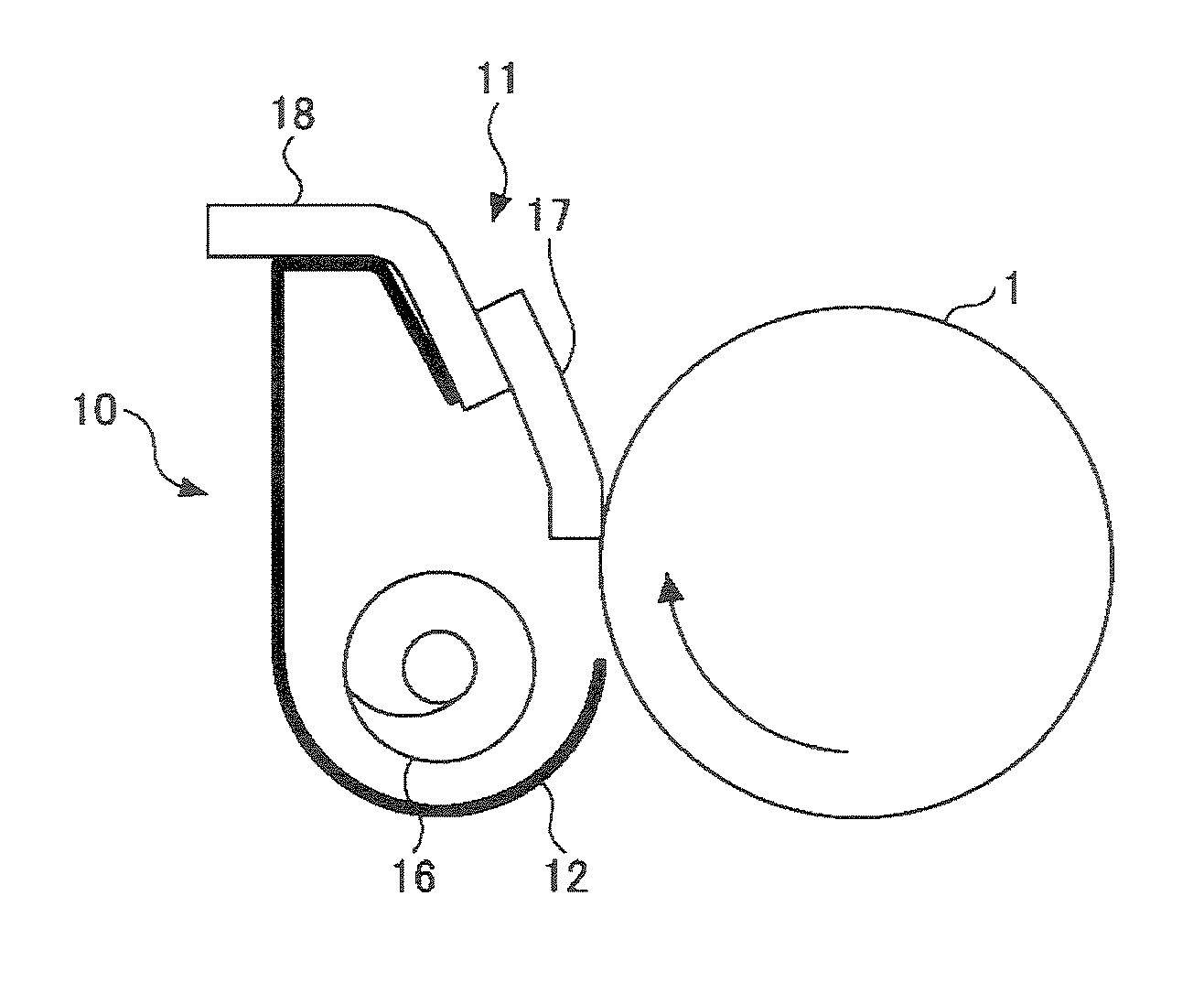

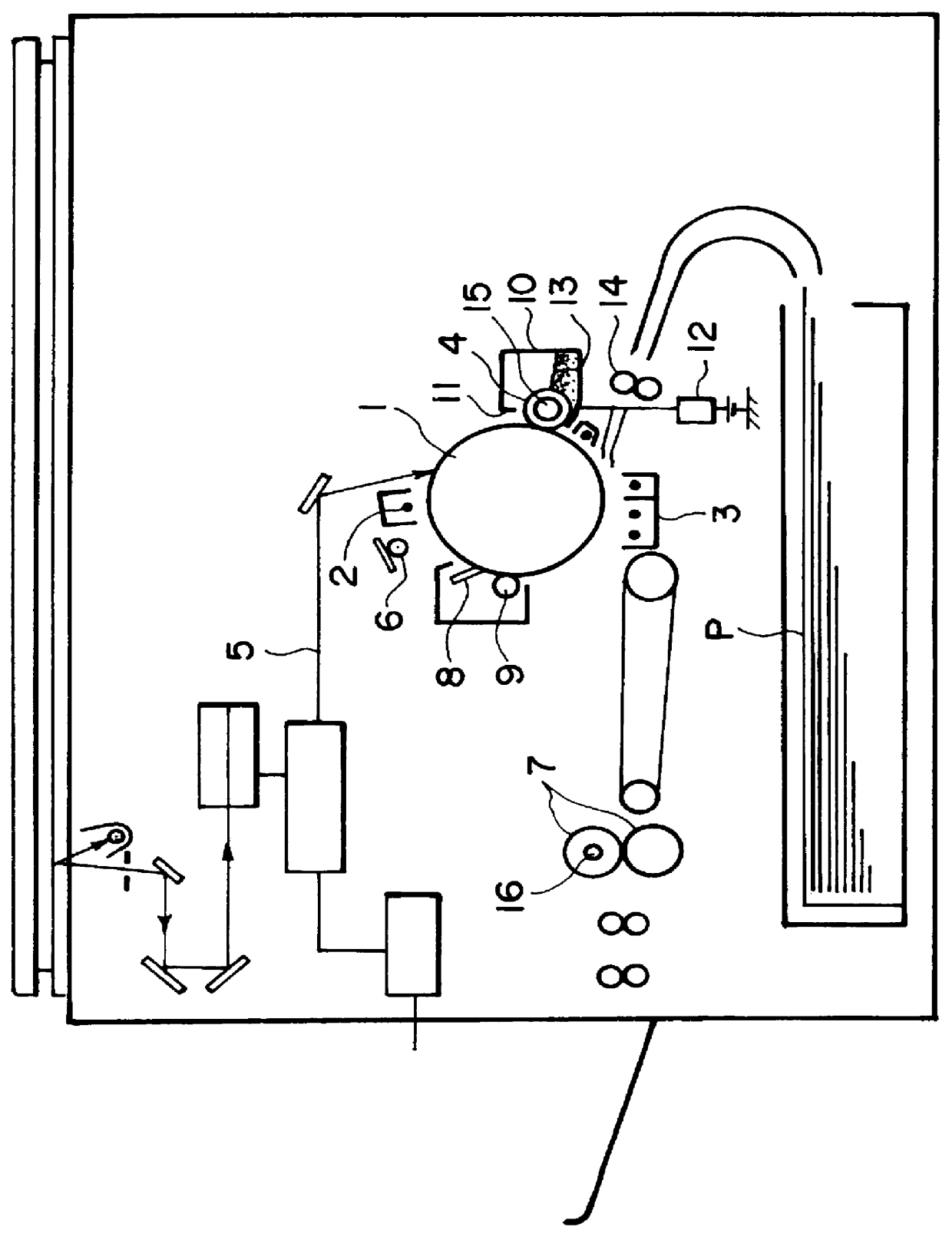

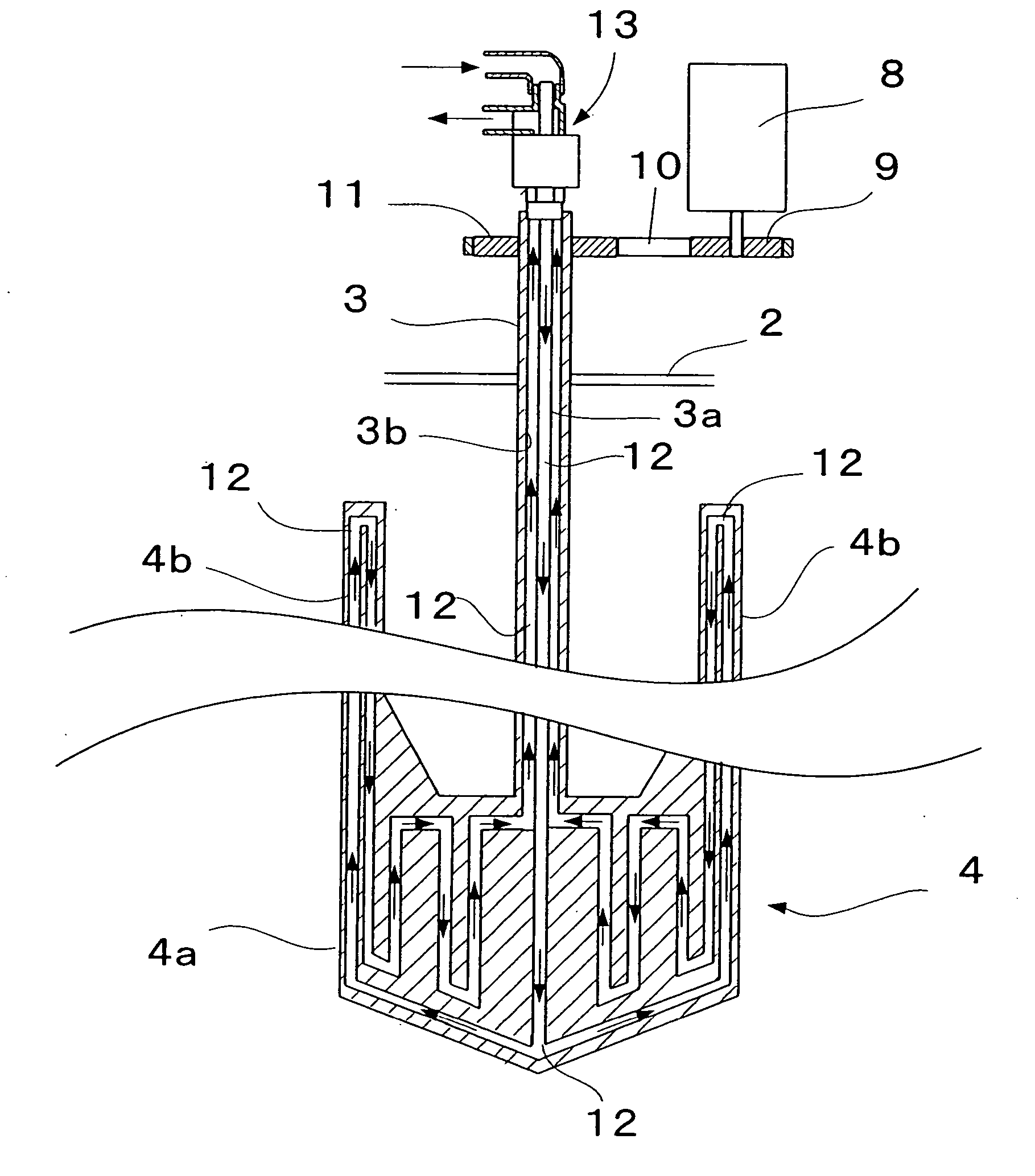

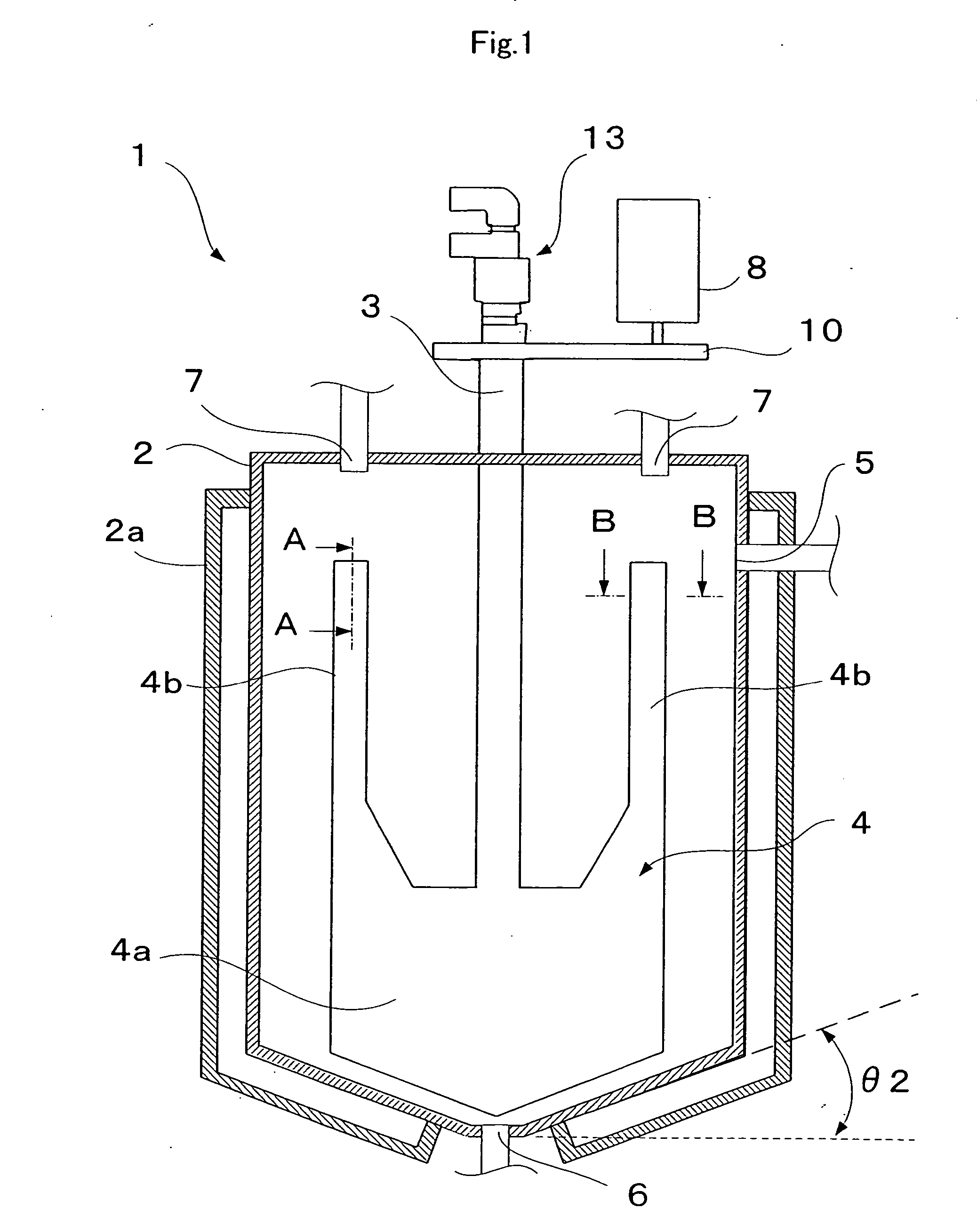

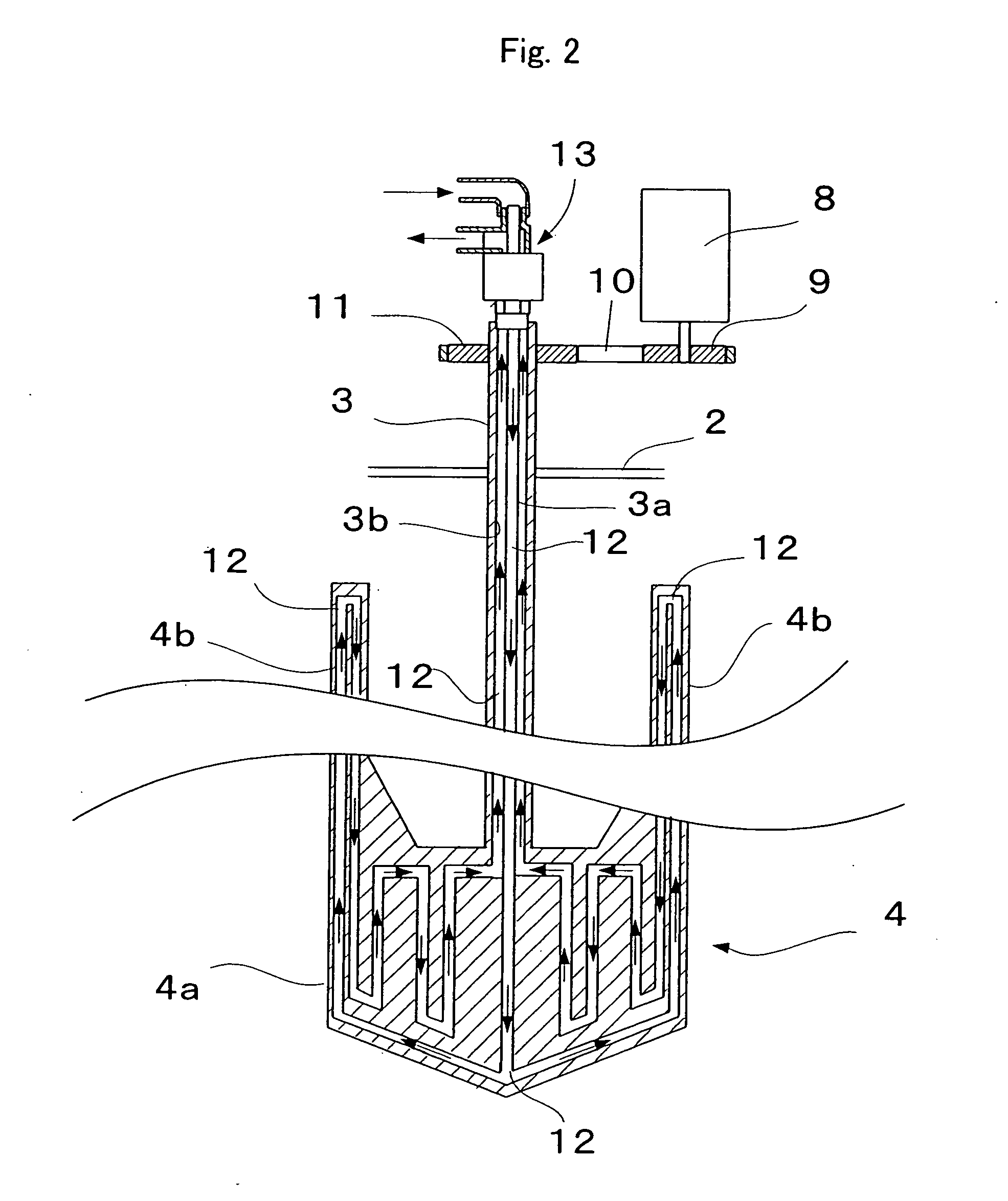

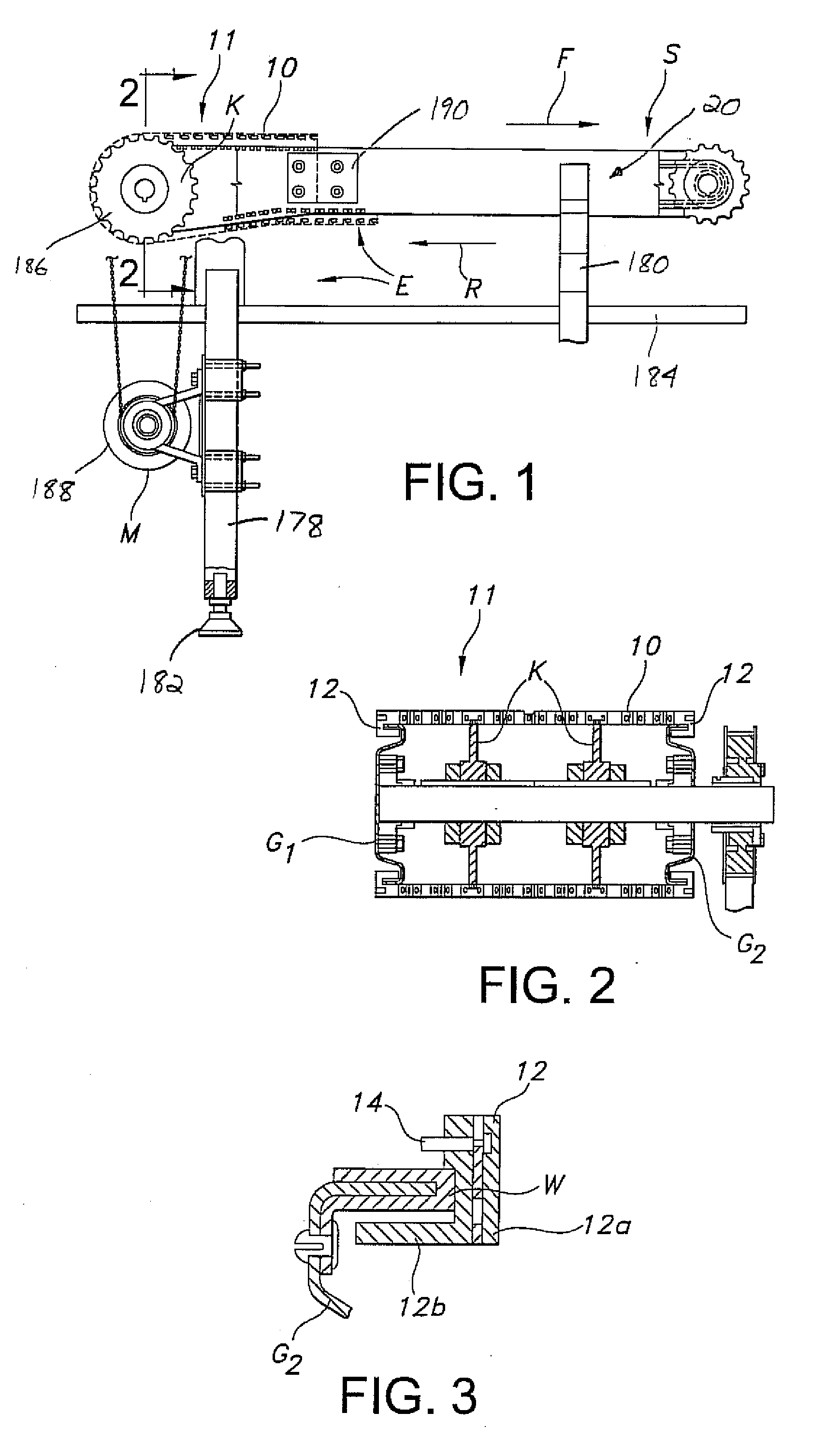

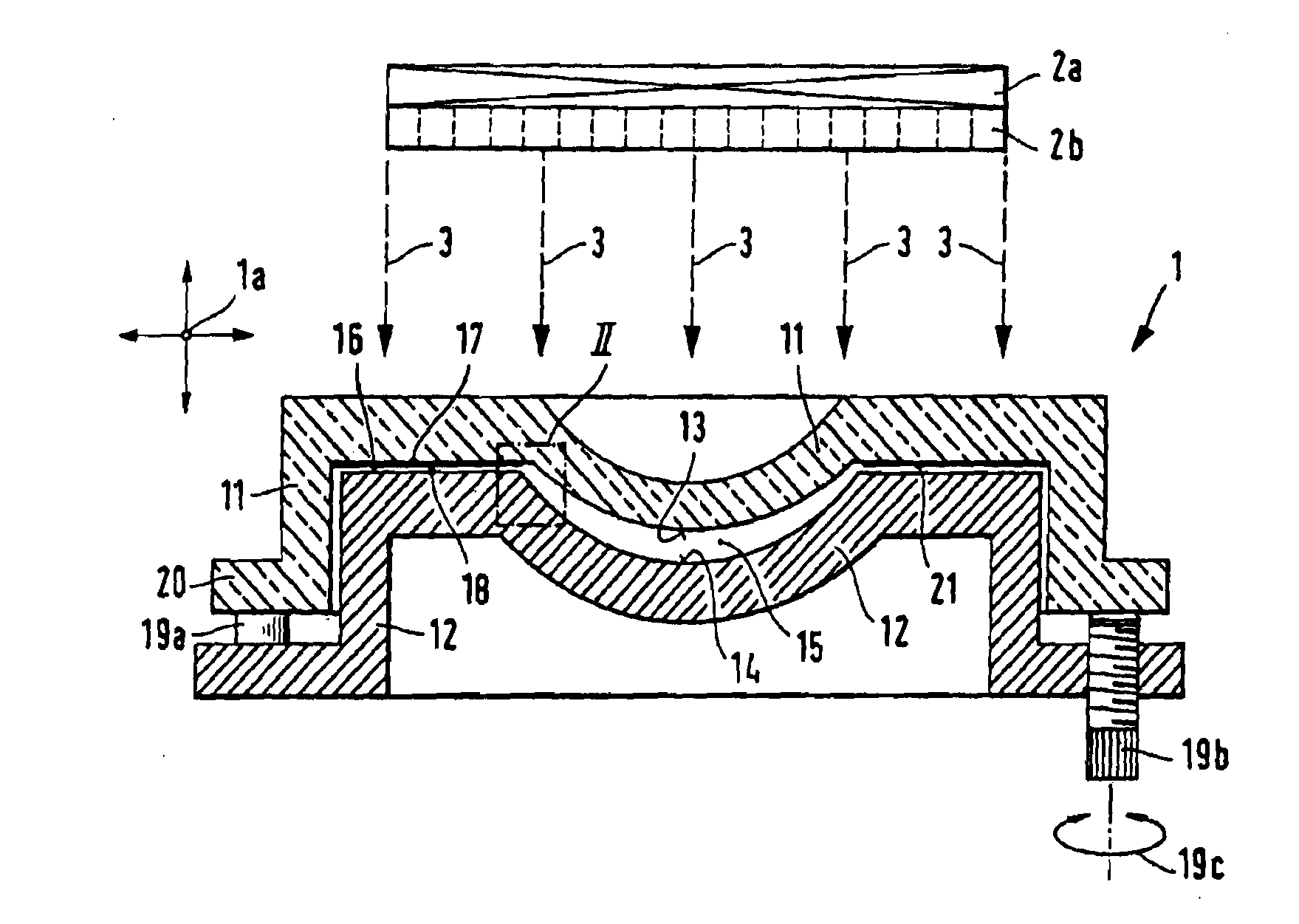

Agitator, a circulatory cleaning device attached to the agitator, and a circulatory line system comprising the circulatory cleaning device

InactiveUS20050232071A1Increase frictionIncrease temperatureFlow mixersRotary stirring mixersCleanabilityCooling medium

An agitator able to mix and disperse a variety of fluids of various fluid volumes with different viscosities ranging from low to high, and having excellent, cleanability and improved cooling efficiency is provided. The agitator comprises a rotating shaft 3 extending vertically inside an agitating vessel 2, and a flat paddle blade 4 mounted on the rotating shaft 3. The flat paddle blade has a bottom flat paddle blade portion 4a extending outwards from the bottom of the rotating shaft 3 and a rectangular upper flat paddle blade portion 4b extending upward from an upper part of each side end of the bottom flat paddle blade portion 4a. The dimensional ratio (b / a) of the blade diameter (b) of the bottom flat paddle blade portion 4a to the inner diameter (a) of the agitating vessel 2 is from 0.6 to 0.9, and the dimensional ratio (d / c) of the height (d) of an upper flat paddle blade portion 4b to the height (c) of the bottom flat paddle blade portion 4a is from 1 to 4. A passage 12 is formed inside the rotating shaft 3 and flat paddle blade 4 for passing a coolant medium therethrough.

Owner:KANSAI PAINT CO LTD

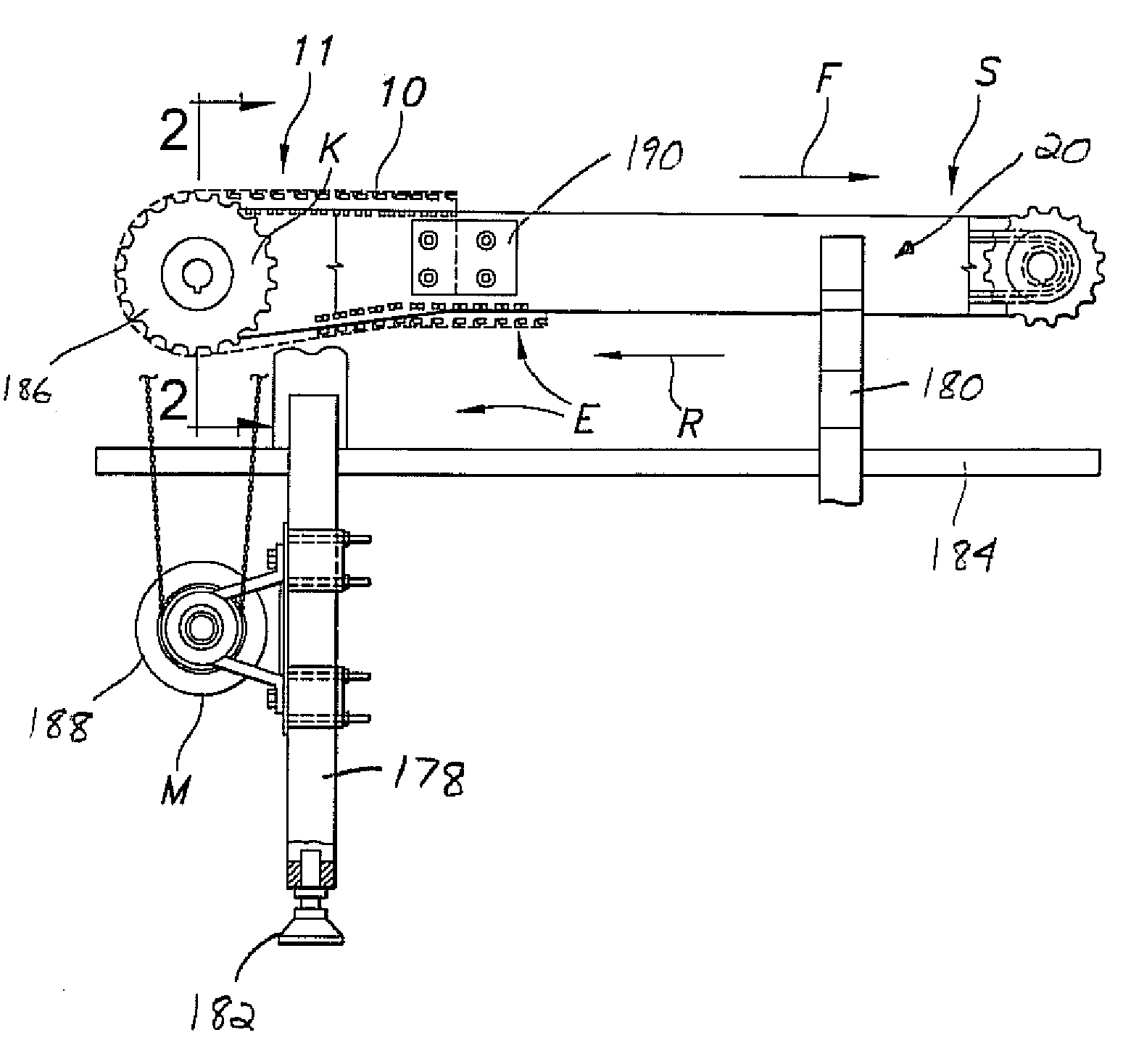

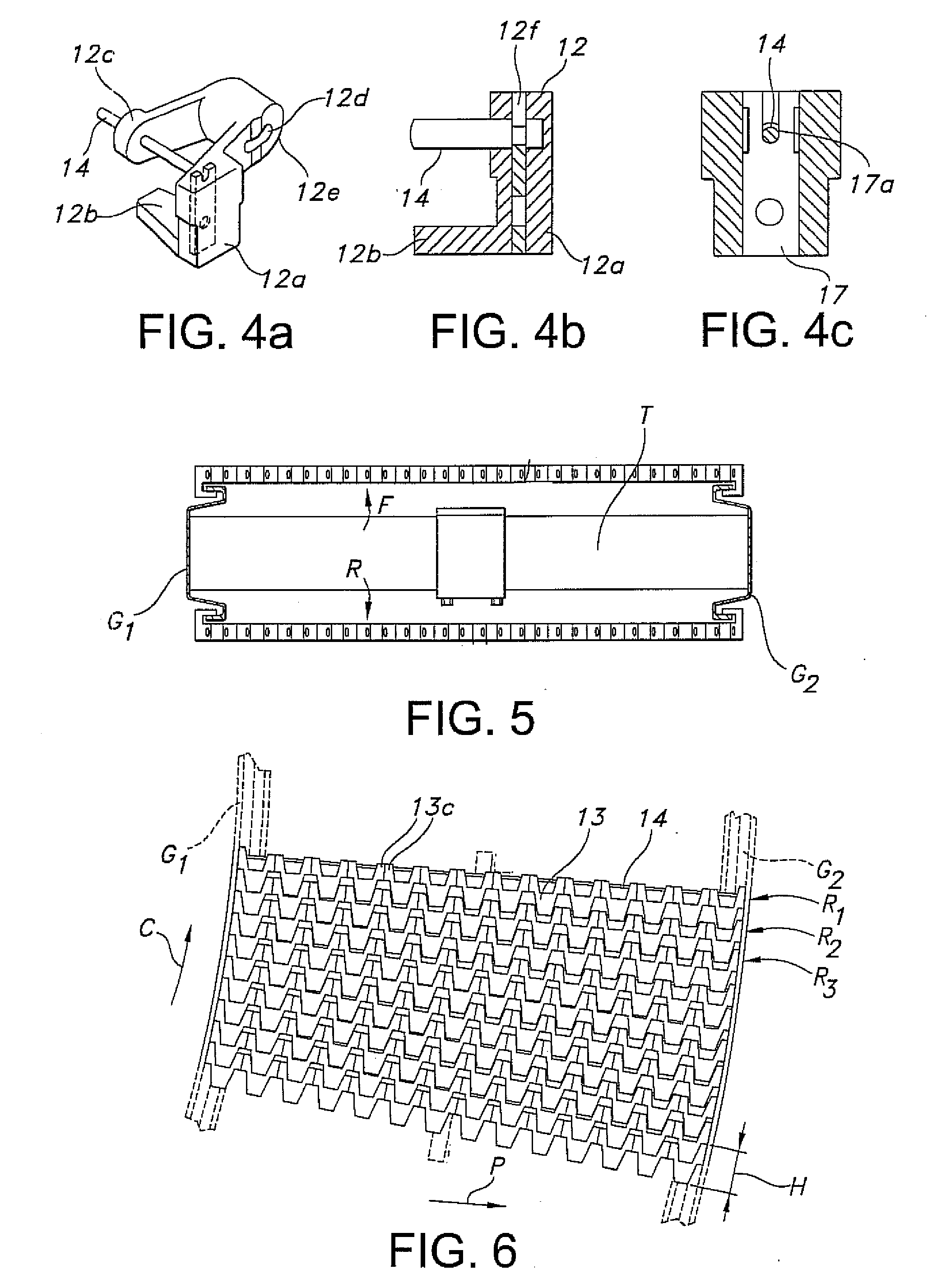

Powder coating components to reduce friction, increase wear resistance, and improve cleanability

ActiveUS20090218199A1Improve wear resistanceGood cleanabilityLiquid surface applicatorsConveyorsFriction reductionPolyester

A component subjected to wear during use includes a powder coating formed of a polymer selected from the group consisting of a polyamide, polyolefin, polyester, urethane, epoxy, acrylic, and mixtures thereof to provide improved wear resistance, enhanced cleanability, and reduced surface friction. Preferably, the component is for use in conveying product, such as in a conveyor system, and includes: (1) a metal core and a nylon powder coating; or (2) a stainless steel core and a powder coating. Most preferably, the coating is generally clear or translucent so as to give the appearance that the underlying component, which is typically made of metal, is neither coated nor made entirely of a polymer.

Owner:SPAN TECH

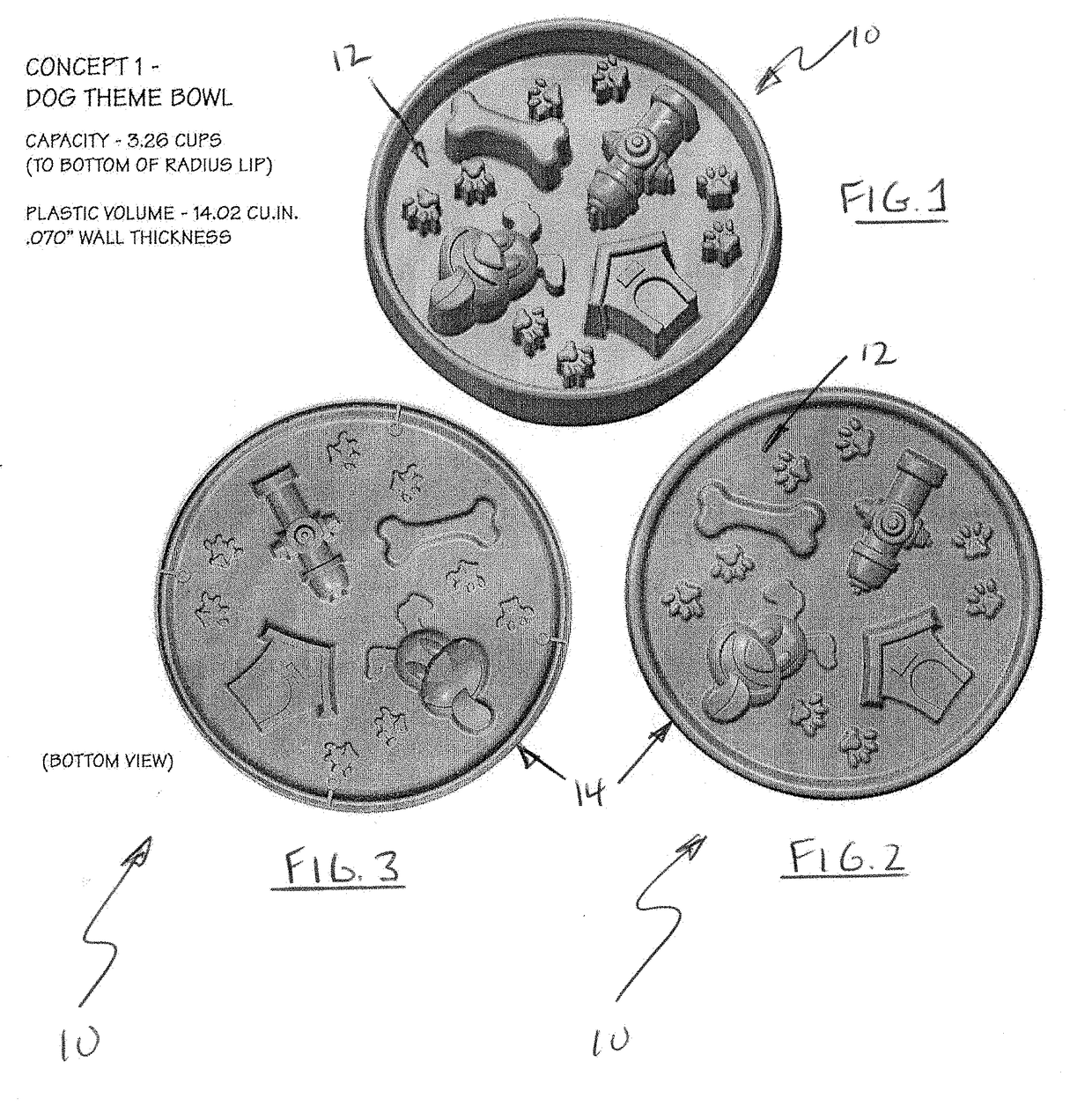

Metallized Plastic Pet Product

InactiveUS20180133991A1Not be readily and shapedMetallic coatingAnimal watering devicesAnimal feeding devicesBlow moldingSurface finish

A variety of pet related products are provided formed initially of plastic and finalized with a metallized surface finish. The pet product is molded using injection molding, rotational molding, vacuum forming, blow molding, compression molding, thermoforming or other plastic forming techniques that can provide a structure having a shape that cannot be readily or economically shaped by metal stamping or other conventional metalworking method. The semi finished plastic part is then subjected to a metallizing process in an individualized non-contiguous manner, where a thin metallic layer is deposited on at least one of the product surfaces. The resultant pet product item simulates the appearance metal, and may provide the durability, cleanability and the general antimicrobial nature resulting metal surfaces.

Owner:OUR PETS

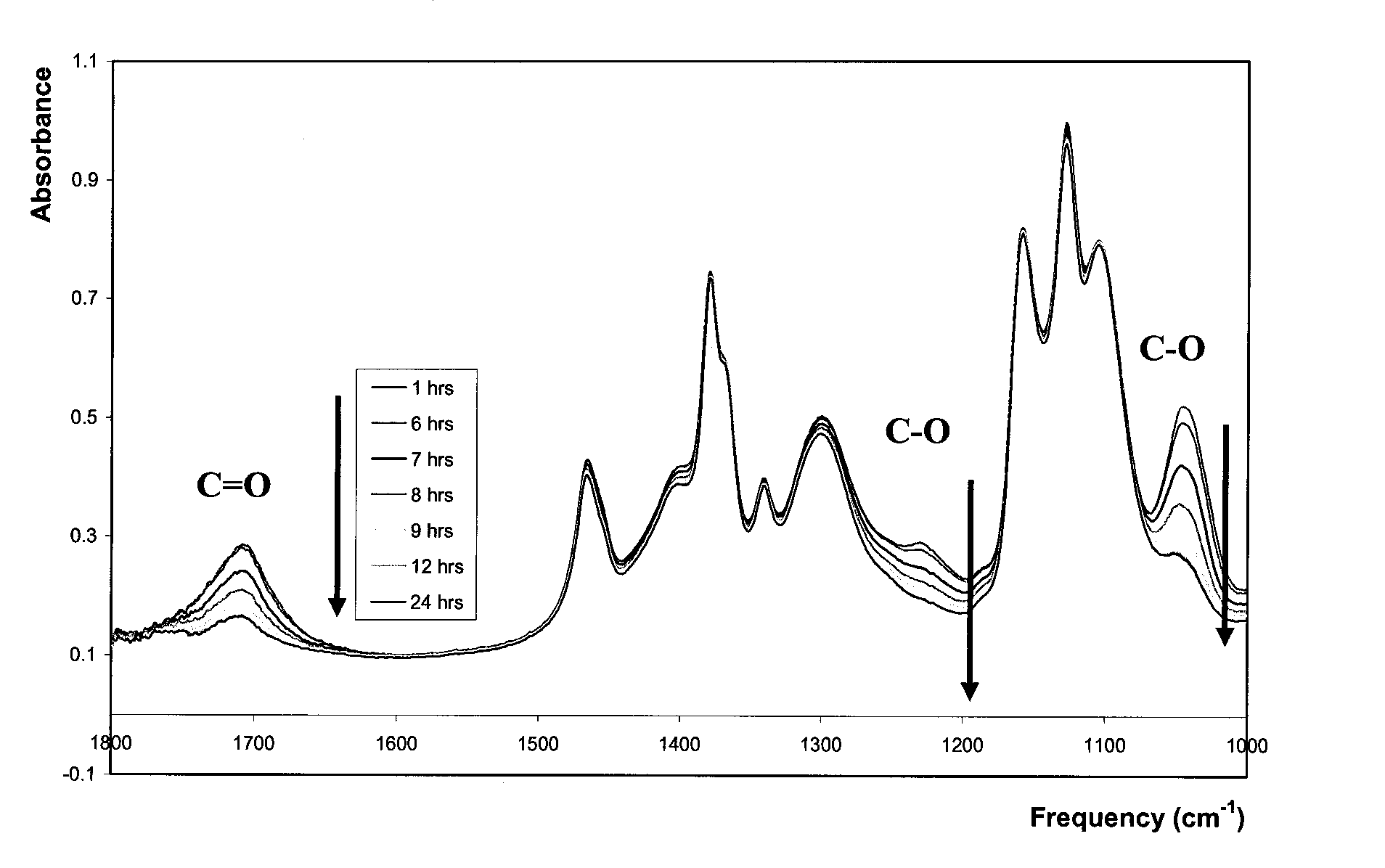

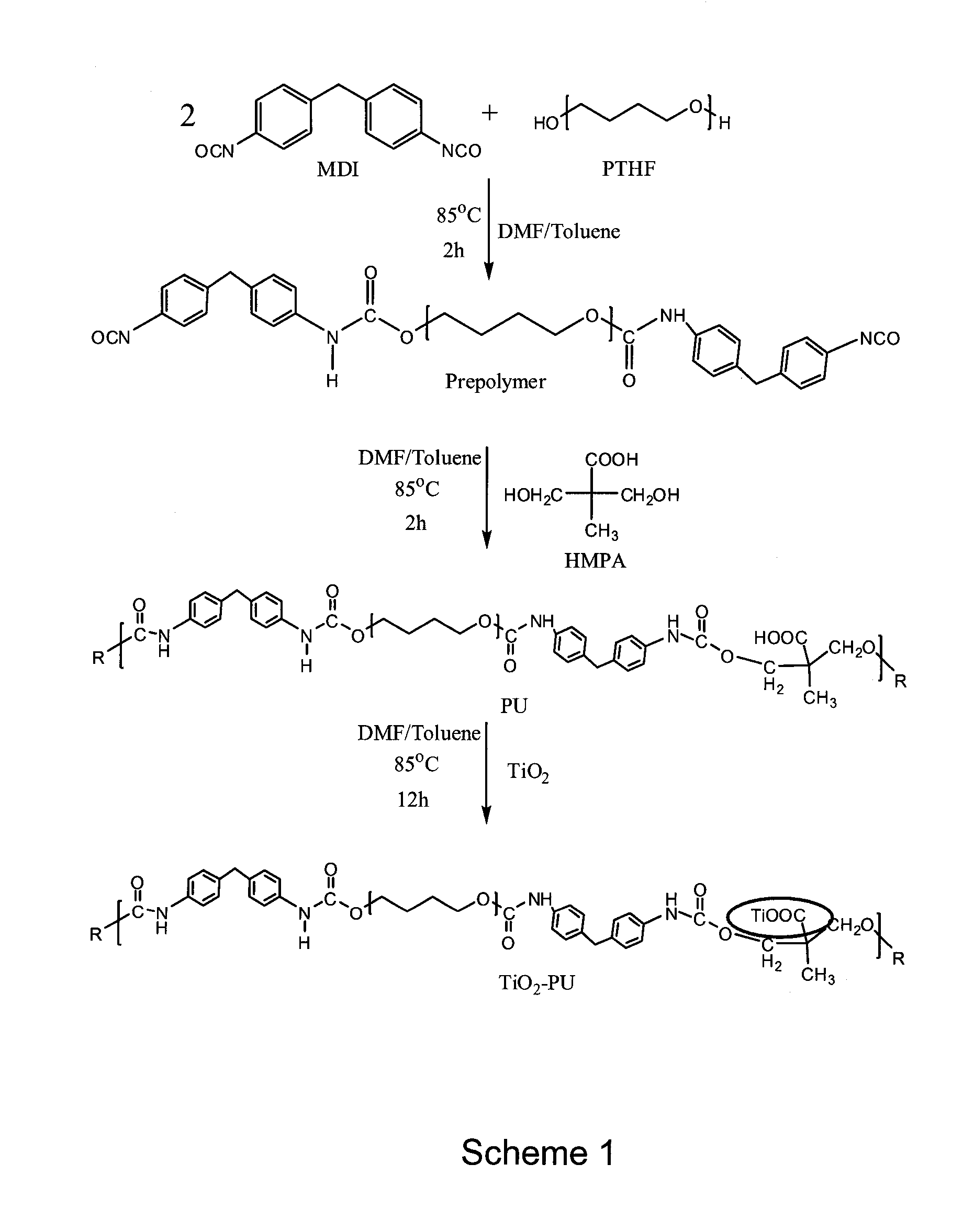

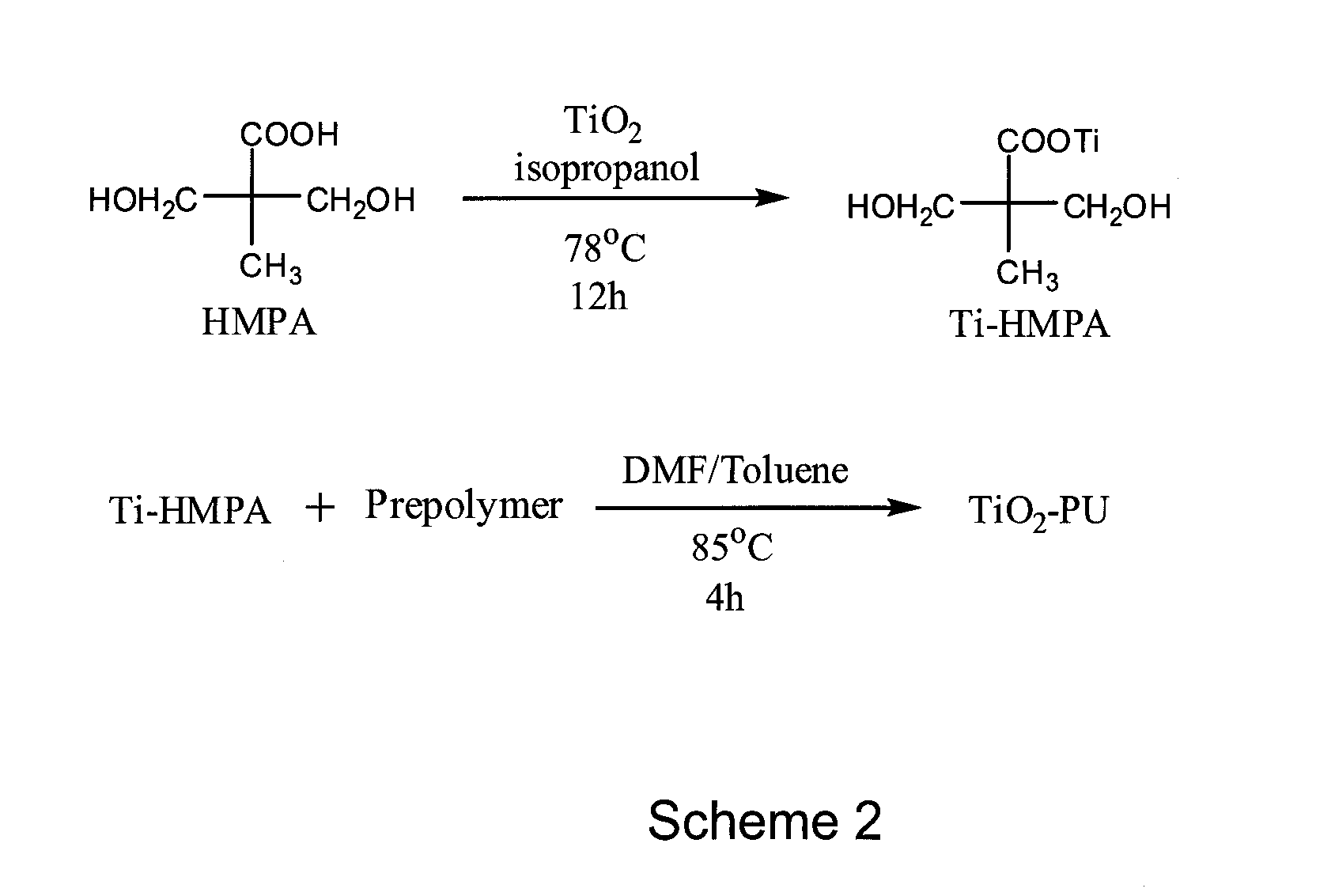

Self-cleaning coatings

InactiveUS20120010314A1Material nanotechnologyPolyurea/polyurethane coatingsPropanoic acidStearic acid

The present invention provides two methods for synthesizing novel titania-polyurethane (nTiO2-PU) nanocomposites for self-cleaning coatings, one a polymer functionalization method (“grafting to”) and the other, a monomer functionalization method (“grafting from”). Here, 2,2 bis(hydroxymethyl) propionic acid (HMPA) was used as the coordination agent, which was reacted with n-TiO2 (50:50 anatase / rutile) to form nTiO2-HMPA, then polymerized in the monomer functionalization method. In the polymer functionalization method, HMPA was reacted with a pre-polymer to form the PU, and then subsequently reacted with n-TiO2 to form the polymer nanocomposite. The photocatalytic cleanability of the nanocomposites was investigated when exposed to ultraviolet radiation using additional unreacted HMPA or stearic acid as the model “dirt” compounds. Nanocomposites prepared using both strategies showed similar self-cleaning behavior, although the monomer technique gave less substrate degradation.

Owner:UNIV OF WESTERN ONTARIO

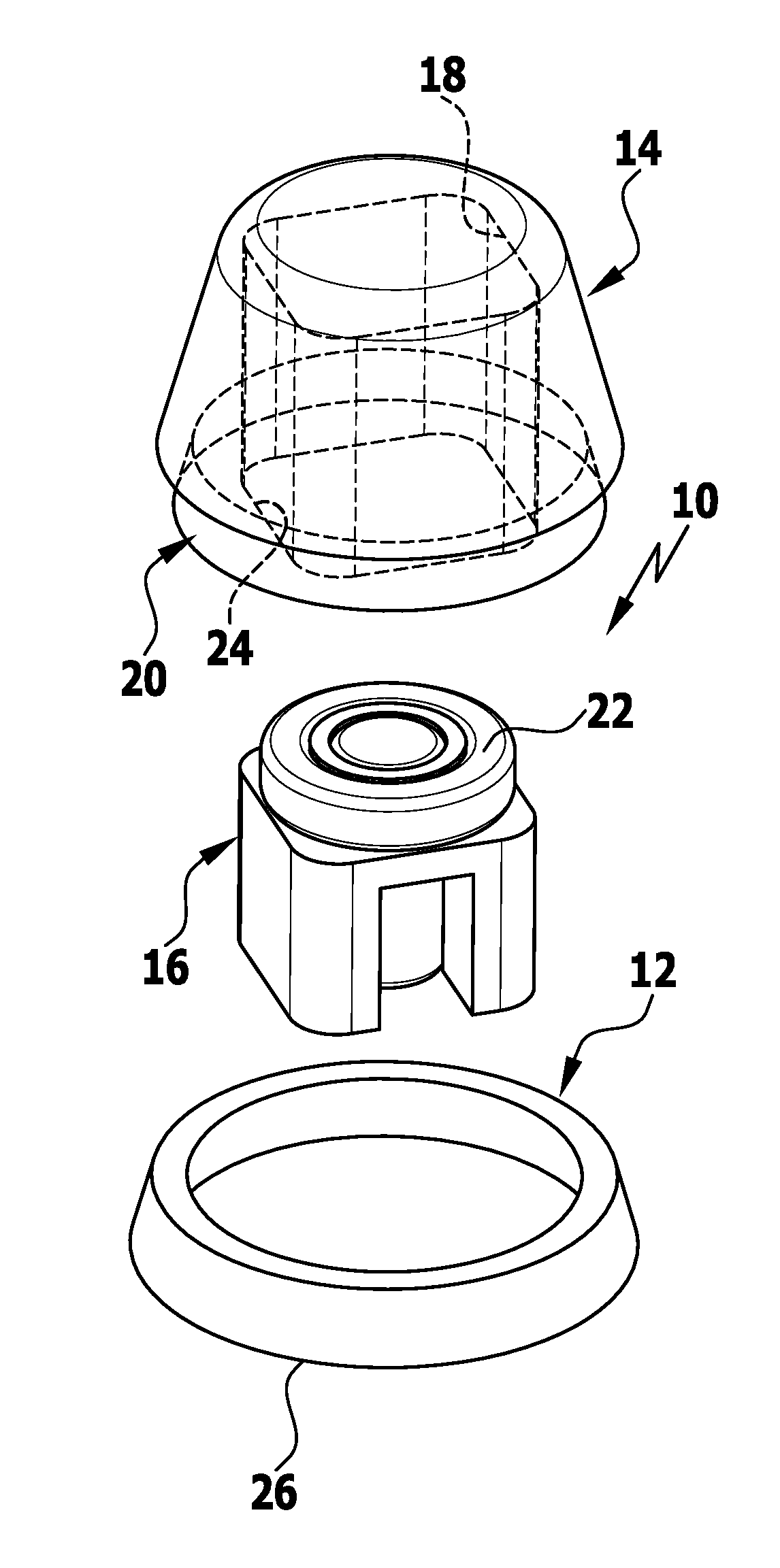

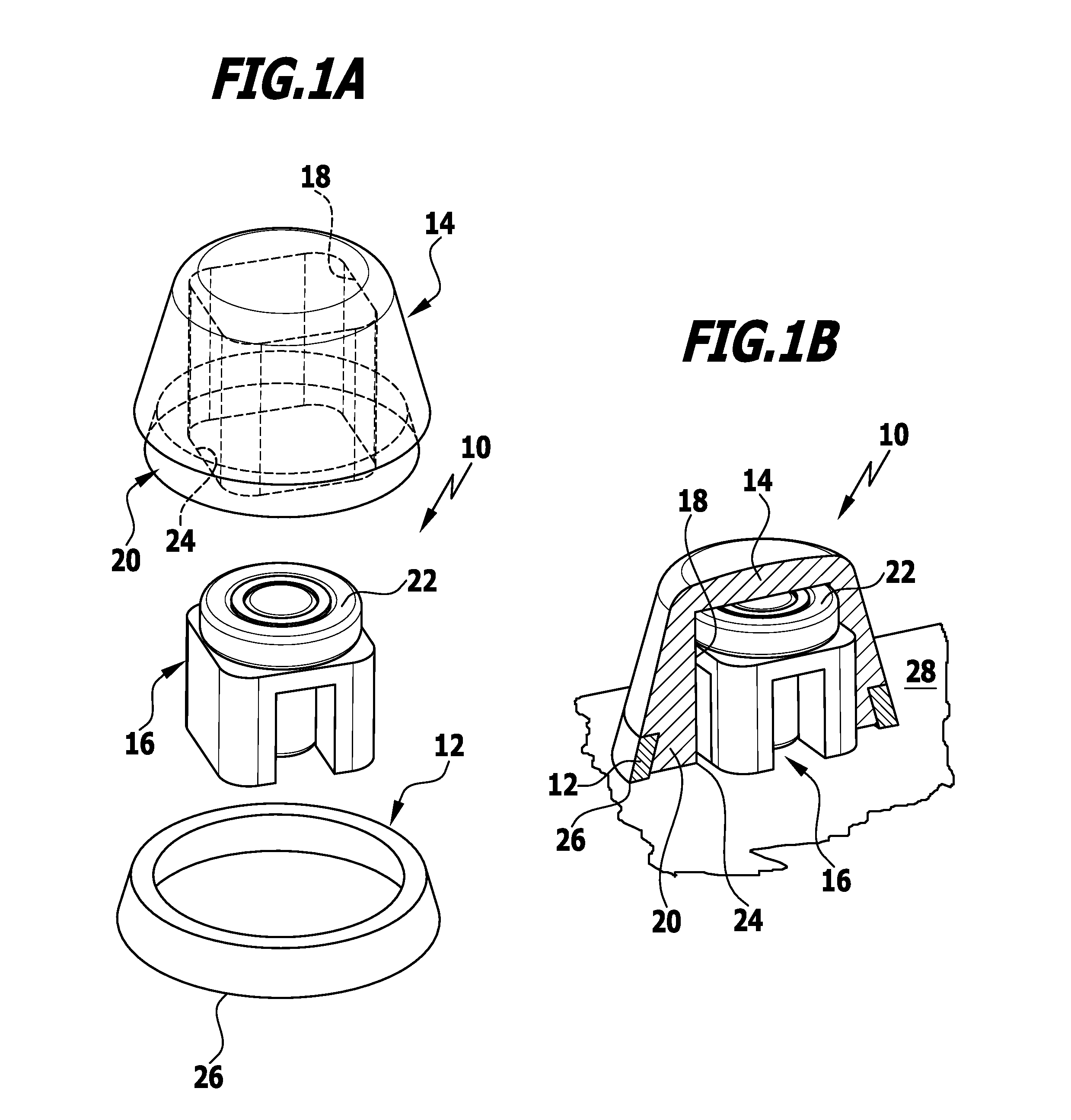

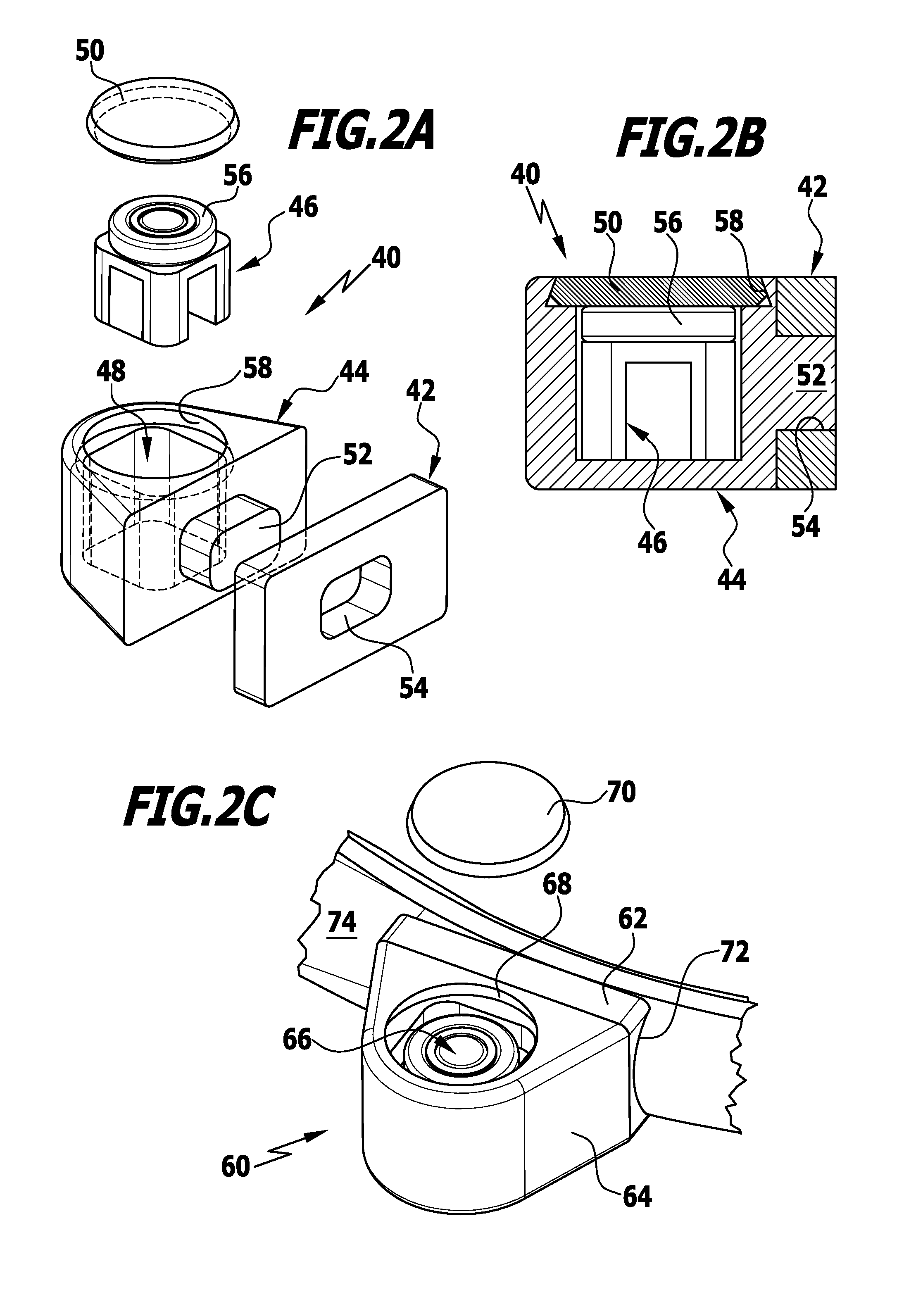

RFID tag

ActiveUS20140131454A1Reliable anchoringEasy to cleanIncision instrumentsDiagnosticsConductive materialsEngineering

An RFID tag is provided that is suitable for mounting on surgical instruments, and by means of which stable anchoring on the instrument, encapsulation of the RFID elements from the surroundings, good cleanability and improved detectability can be achieved. The RFID tag has a metal holder, a housing that is made of an electrically non-conductive or slightly conductive material, an accommodating chamber and an RFID element with an antenna. The RFID element is arranged in the accommodating chamber of the housing. The housing has a first end which is held on the metal holder. The accommodating chamber in the housing is formed to be spatially spaced apart from the first end of the housing. The RFID element is positioned in the accommodating chamber in such a way that the antenna of the RFID element is spatially arranged substantially outside of the metal holder.

Owner:AESCULAP AG

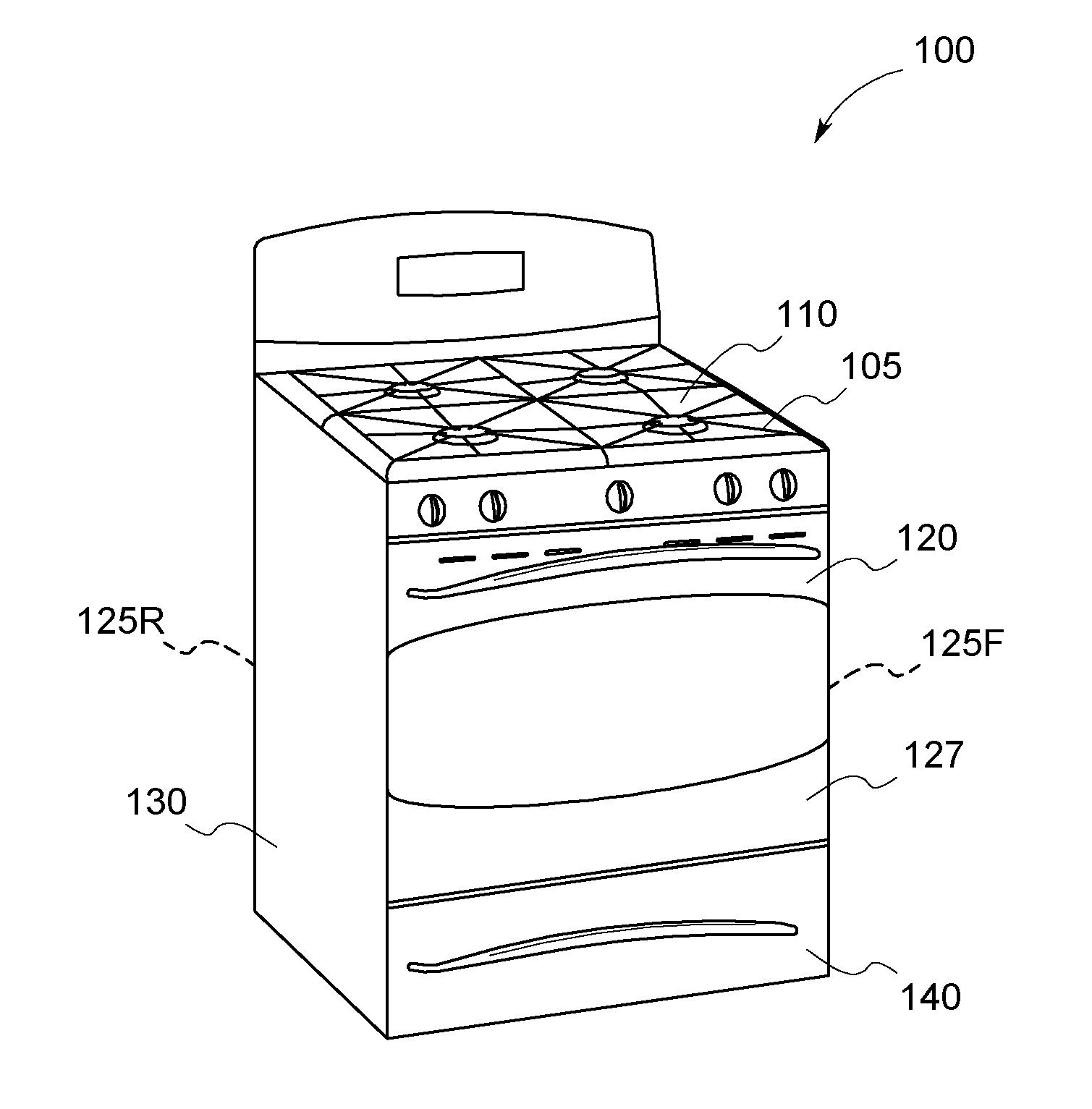

Cleanability of ovens and cooktops

An oven cavity for an oven or range appliance includes a heat-stable base substrate, and a hard ceramic coating disposed on the base substrate. The hard ceramic coating is a poly-condensated silicone, polymeric silazane or poly-ceramic coating composition. A method of forming a surface for an oven or range appliance is also disclosed.

Owner:GENERAL ELECTRIC CO

Variable height arm structures, systems, and methods

Owner:GCX CORP

Preparation method of high-purity lecithin

InactiveCN102924506AHigh yieldHigh recovery ratePhosphatide foodstuff compositionsChromatographic separationNatural product

The invention belongs to the technical field of separation and extraction of natural products, and particularly relates to a preparation method of high-purity lecithin. The method is applied to the preparation of pharmaceutical high-purity lecithin. The invention provides a large-scale preparation and production method of high-purity lecithin for pharmaceutic adjuvant injection, adopts a simulated moving bed continuous chromatographic separation technology to ensure that lecithin is effectively separated from other constituents in material lipid, so as to obtain high-purity lecithin products, can also realize the recovery of residual products and the recycle of solvent, avoids the unreasonable consumption and waste of raw material and auxiliary material, completely eradicates the producing of wastewater and waste residue, ensures that the product yield and the product purity are more than 98 percent, ensures that the quality of the lecithin products meets the technical requirements of pharmaceutic adjuvant, greatly reduces the production cost, realizes the cleanability and no pollution of the lecithin production, and has a wide application prospect.

Owner:JIANGNAN UNIV +1

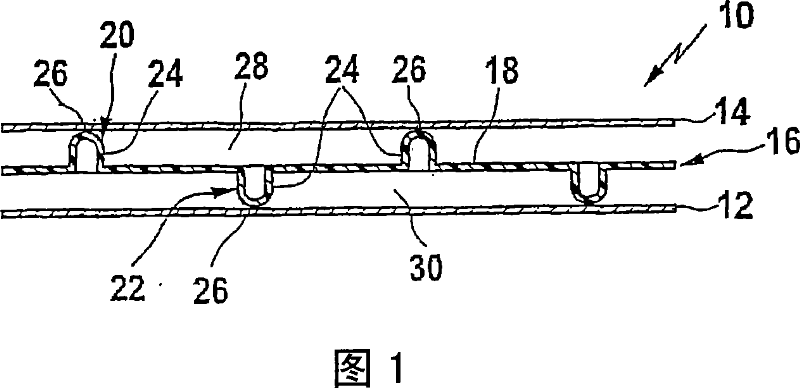

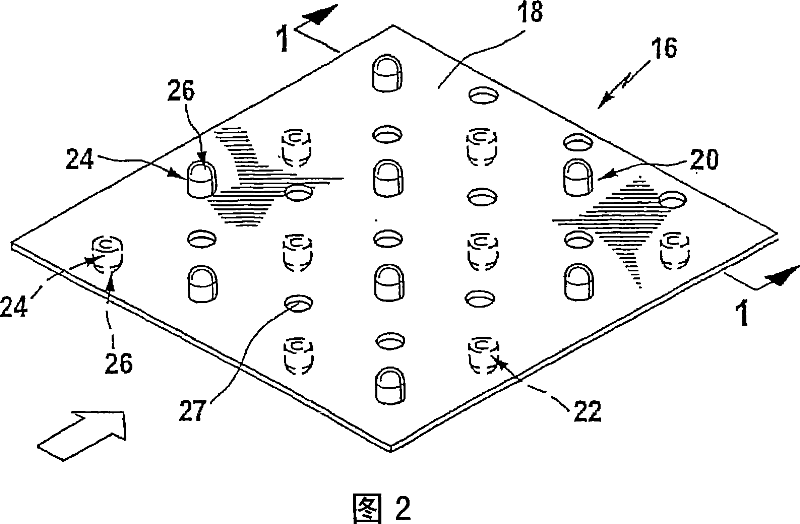

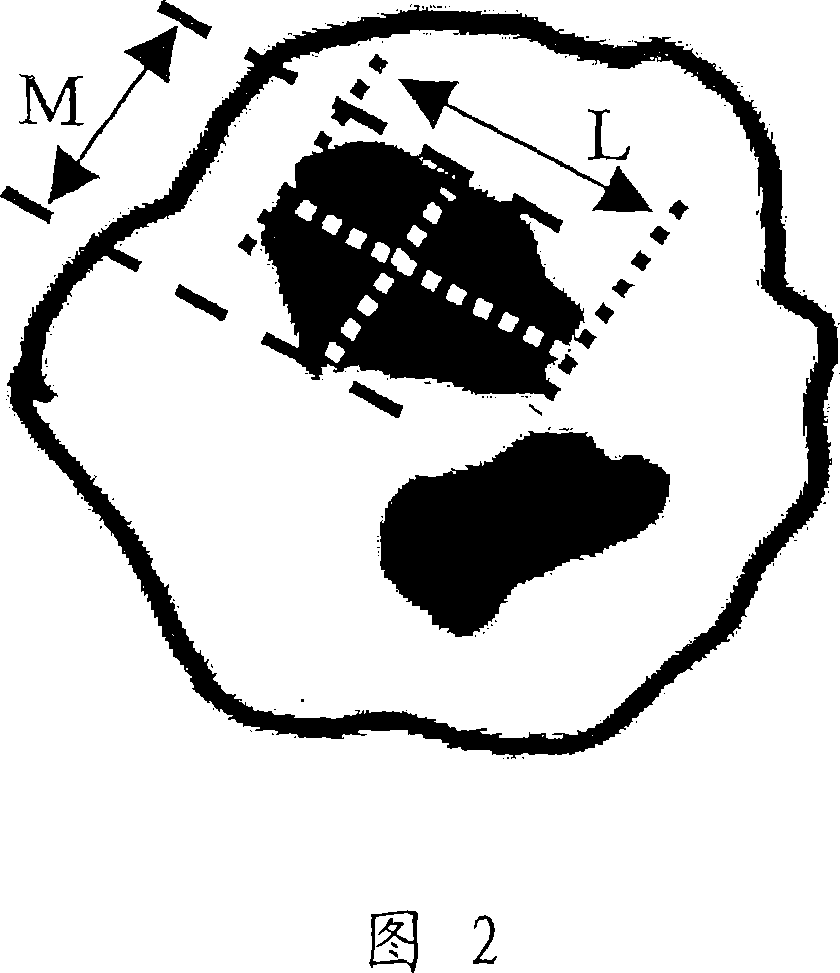

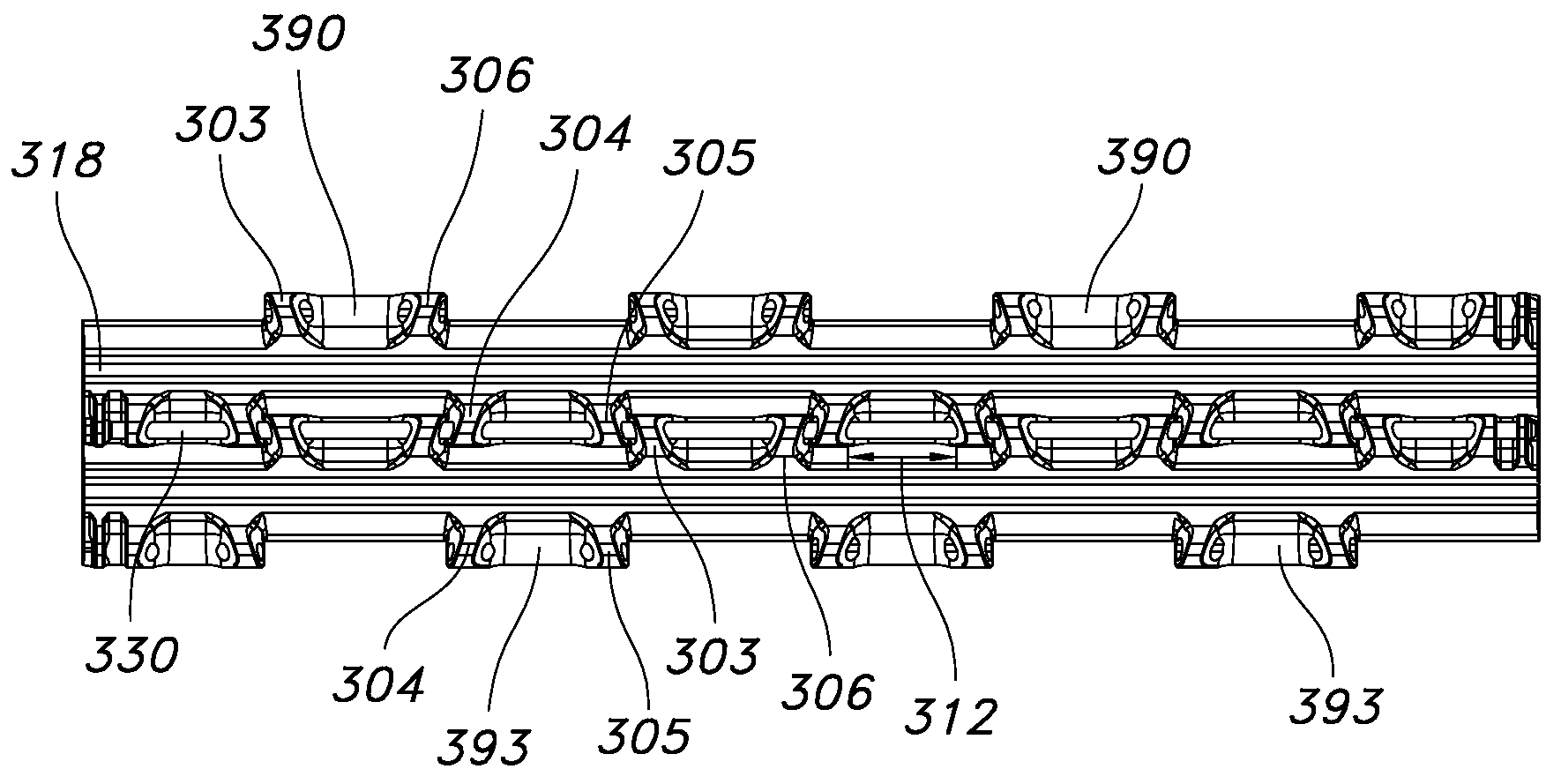

Spacer for filter modules

InactiveCN101039738AReduce areaTendency to reduce depositionMembranesSemi-permeable membranesFilter mediaSpiral wound

In order to provide a spacer for filter modules which may be used not only for plate and frame filter modules, but also for spiral wound-type filter modules and which allows high packing densities while providing optimized cleanability, a spacer for filter modules is proposed to be disposed between two layers of a filter medium, said spacer comprising an essentially flat structured sheet material having upper and lower projections on the upper and lower surfaces thereof, respectively, said upper and lower projections defining an upper and lower bearing face for the layers of filter medium, wherein said projections rise from said upper and lower surfaces with wall portions and terminate in top portions, said upper and lower projections being spaced from each other in a direction parallel to the surface of the sheet material.

Owner:PALL CORP

Roll cover

InactiveUS20090117303A1Necessary conductivityReduce charge rateMaterial nanotechnologyLayered productsThermoplasticSurface cleaning

A roll cover of the invention is a tubular roll cover made of a thermoplastic fluoropolymer for covering a round rod-like or cylindrical roll body, wherein the thermoplastic fluoropolymer contains from 0.5 to 5% by weight of a carbon nanotube. Since the thermoplastic fluoropolymer thus contains from 0.5 to 5% by weight of the carbon nanotube, the roll cover of the invention can secure necessary conductivity, in other words, have low chargeability of static electrification, secure good antistatic property and prevent an offset phenomenon by static electrification. Further, flexibility, mold releasability, surface cleanability and the like inherent in an ordinary fluoropolymer can be maintained well.

Owner:JUNKOSHA

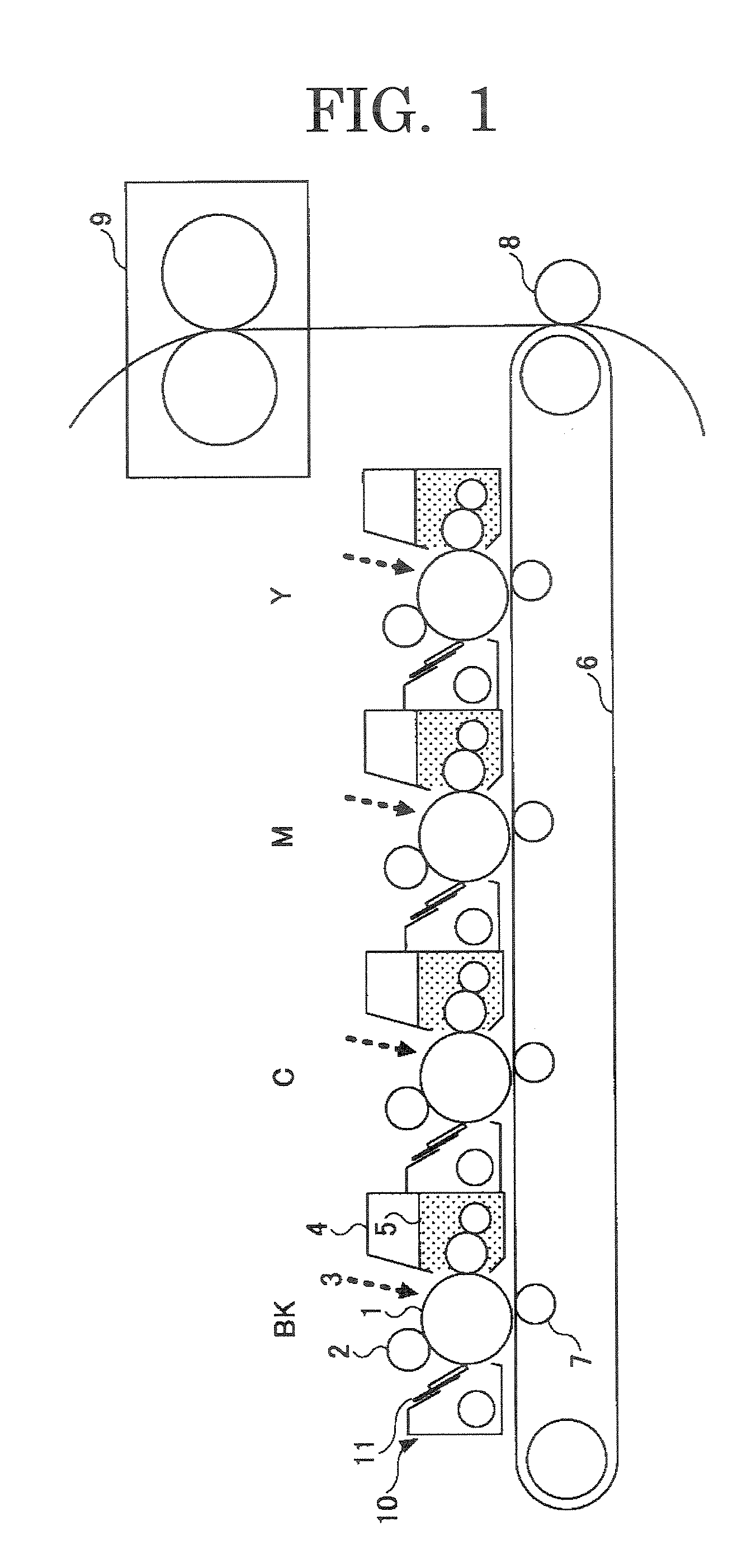

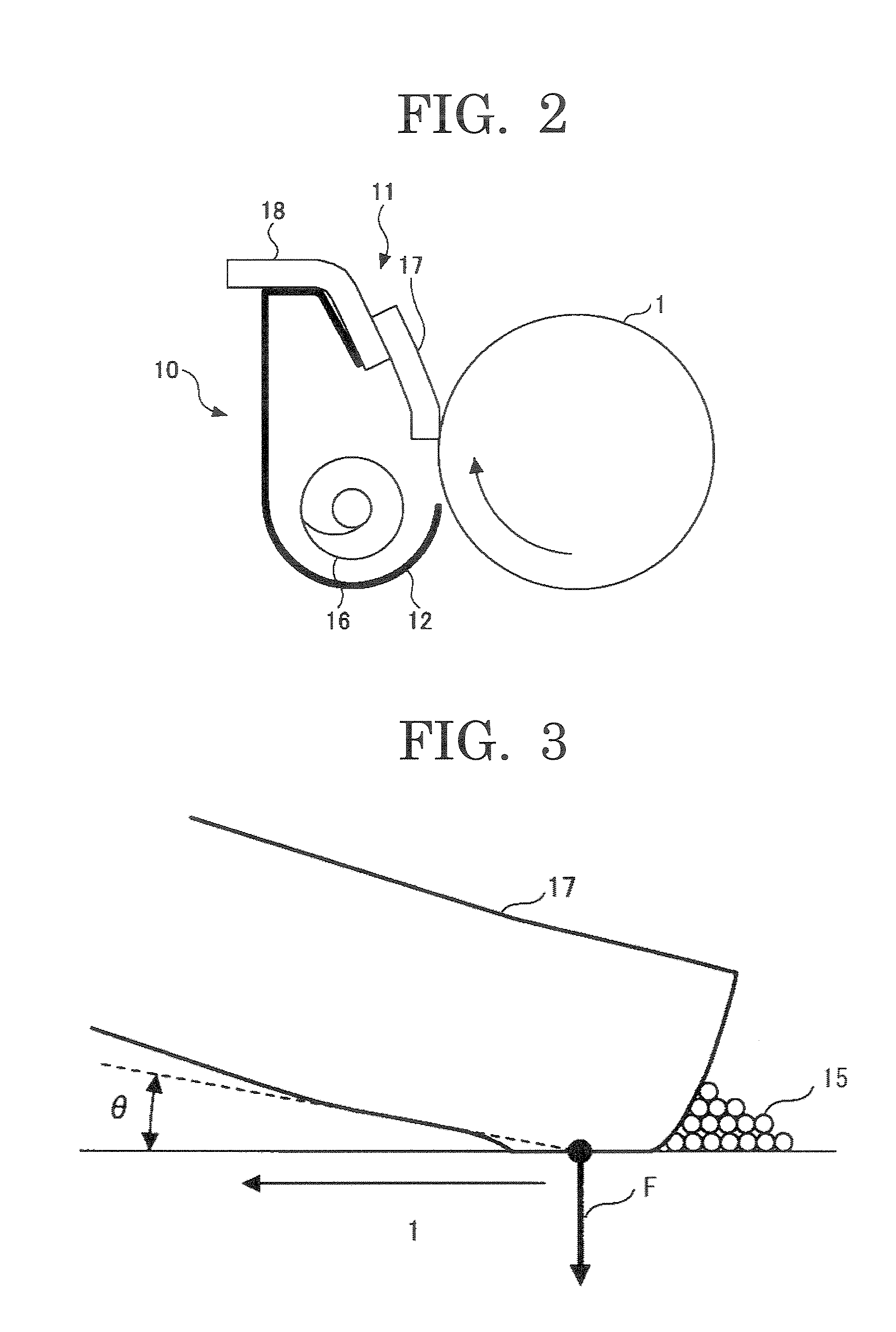

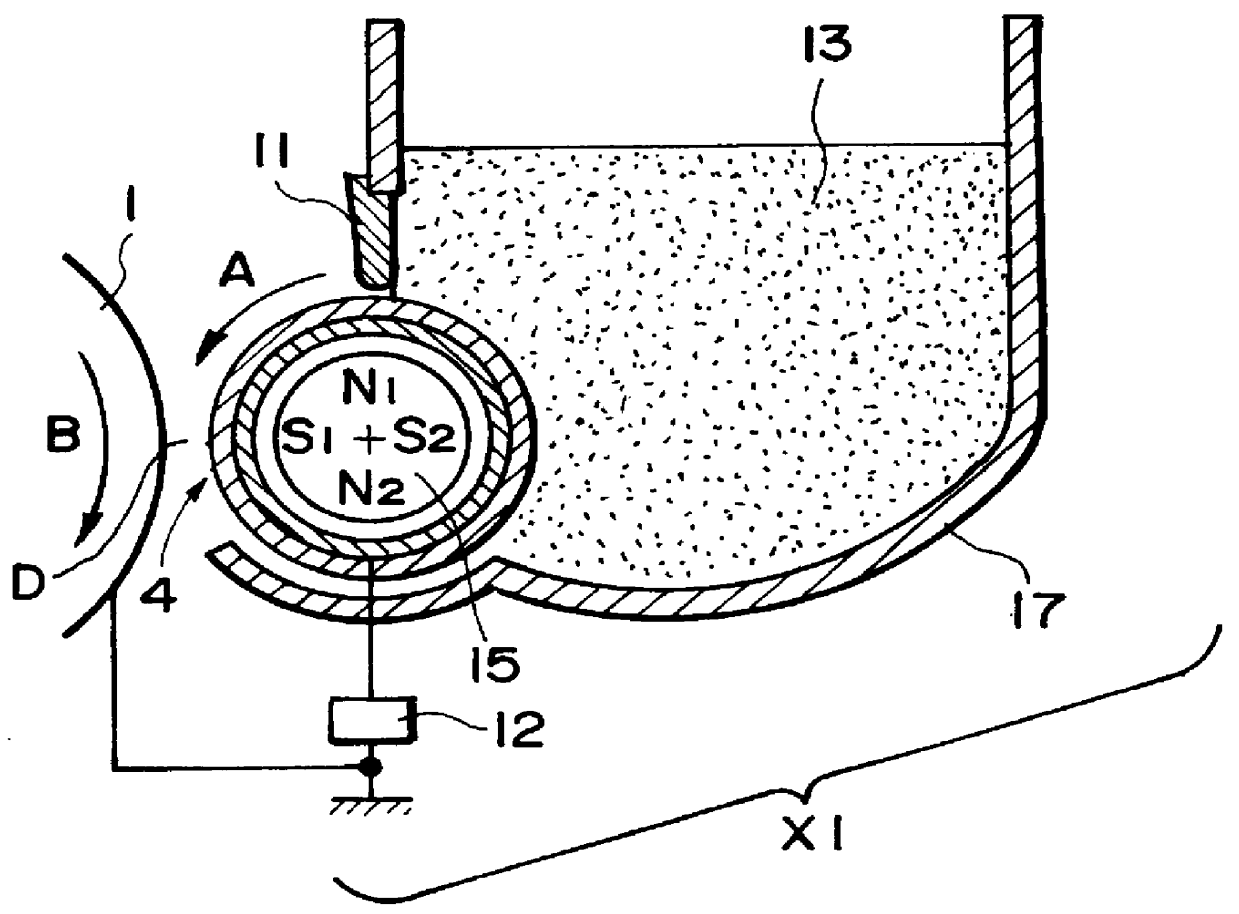

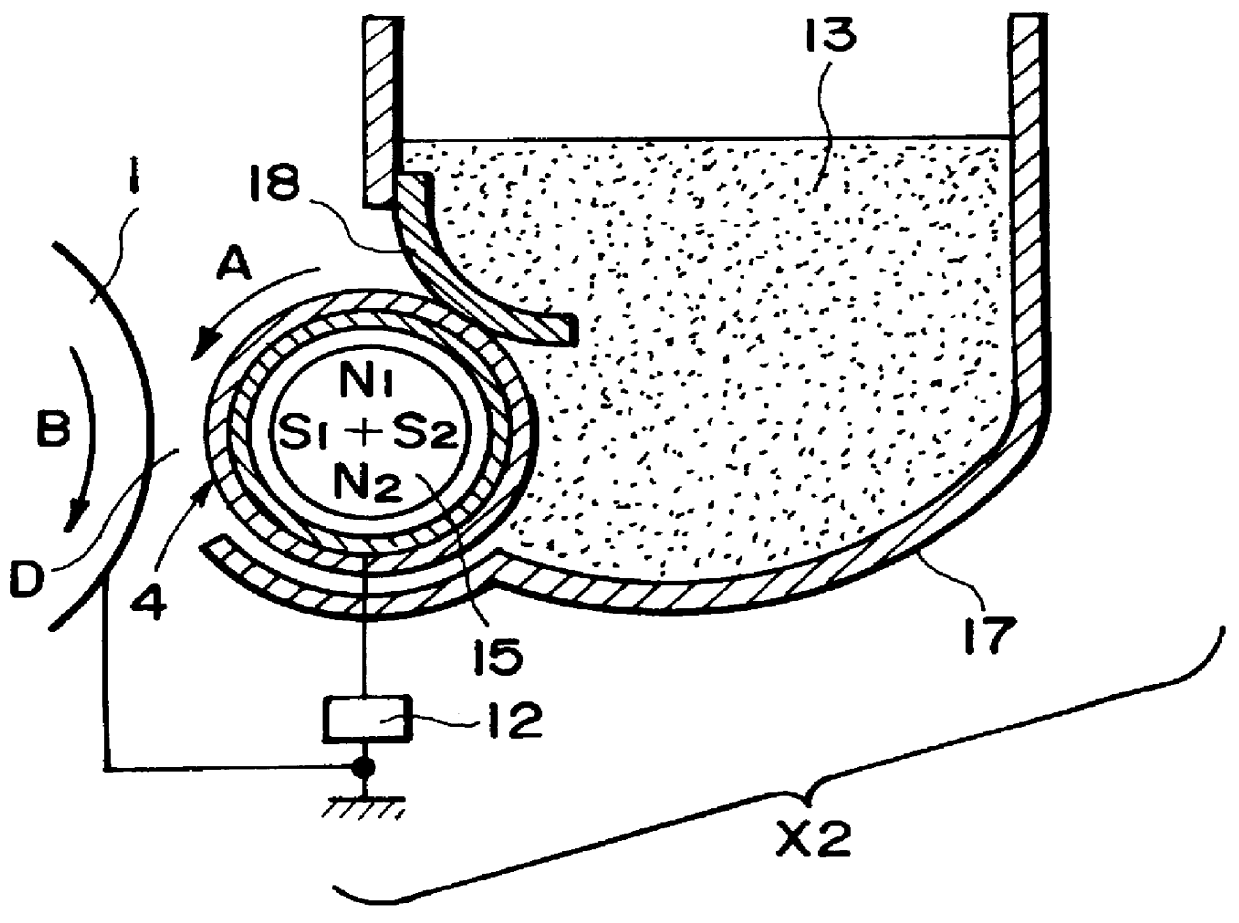

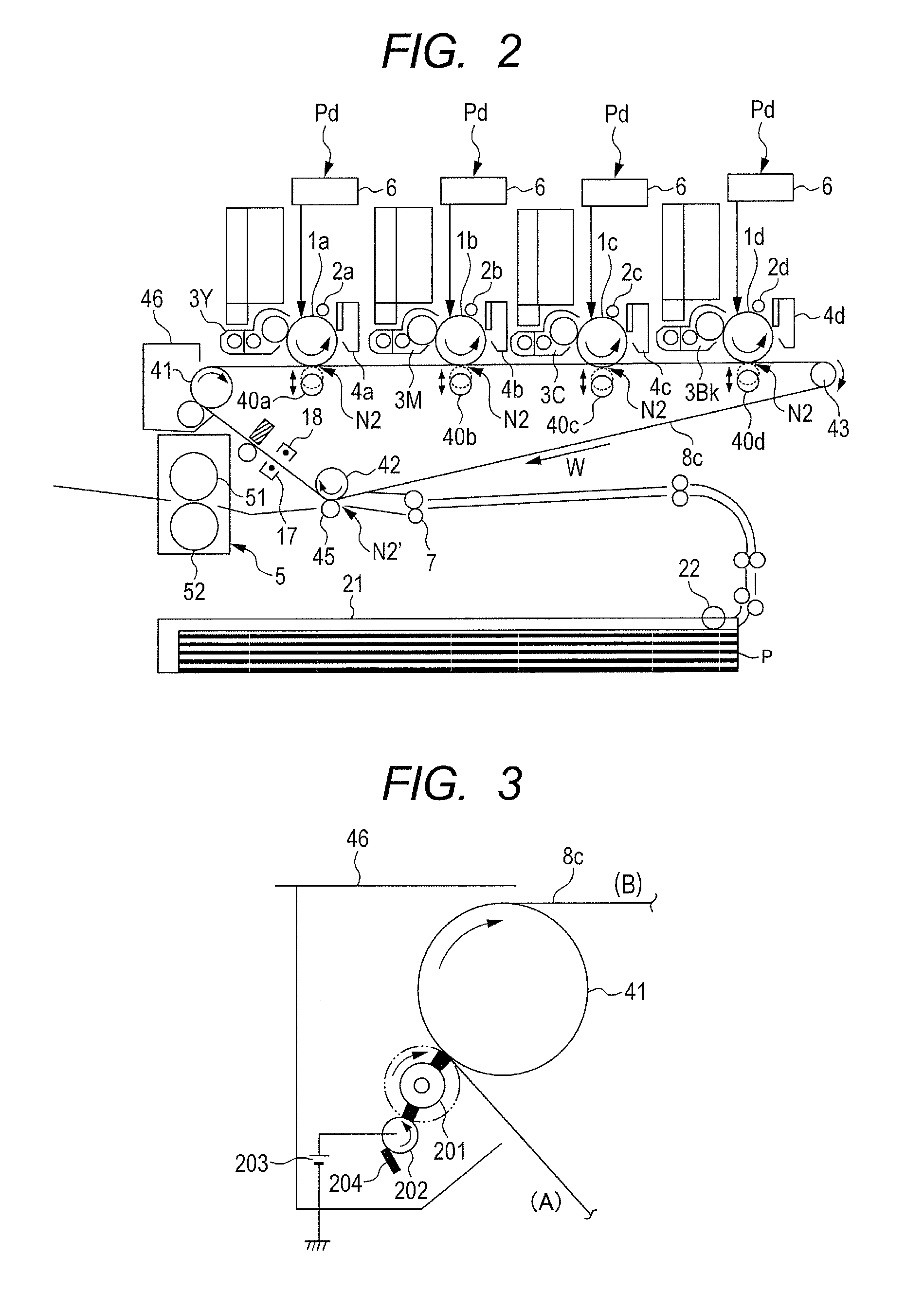

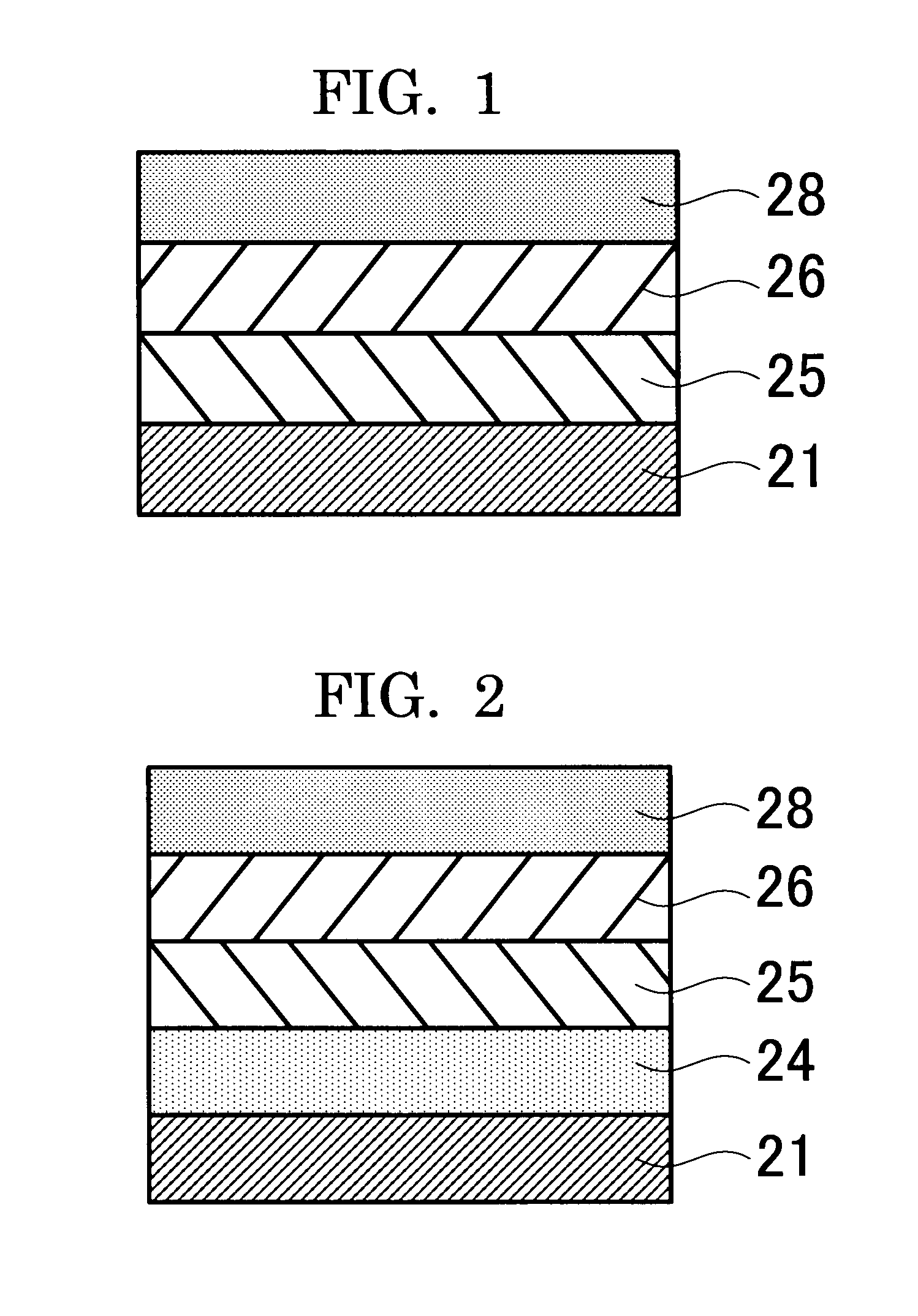

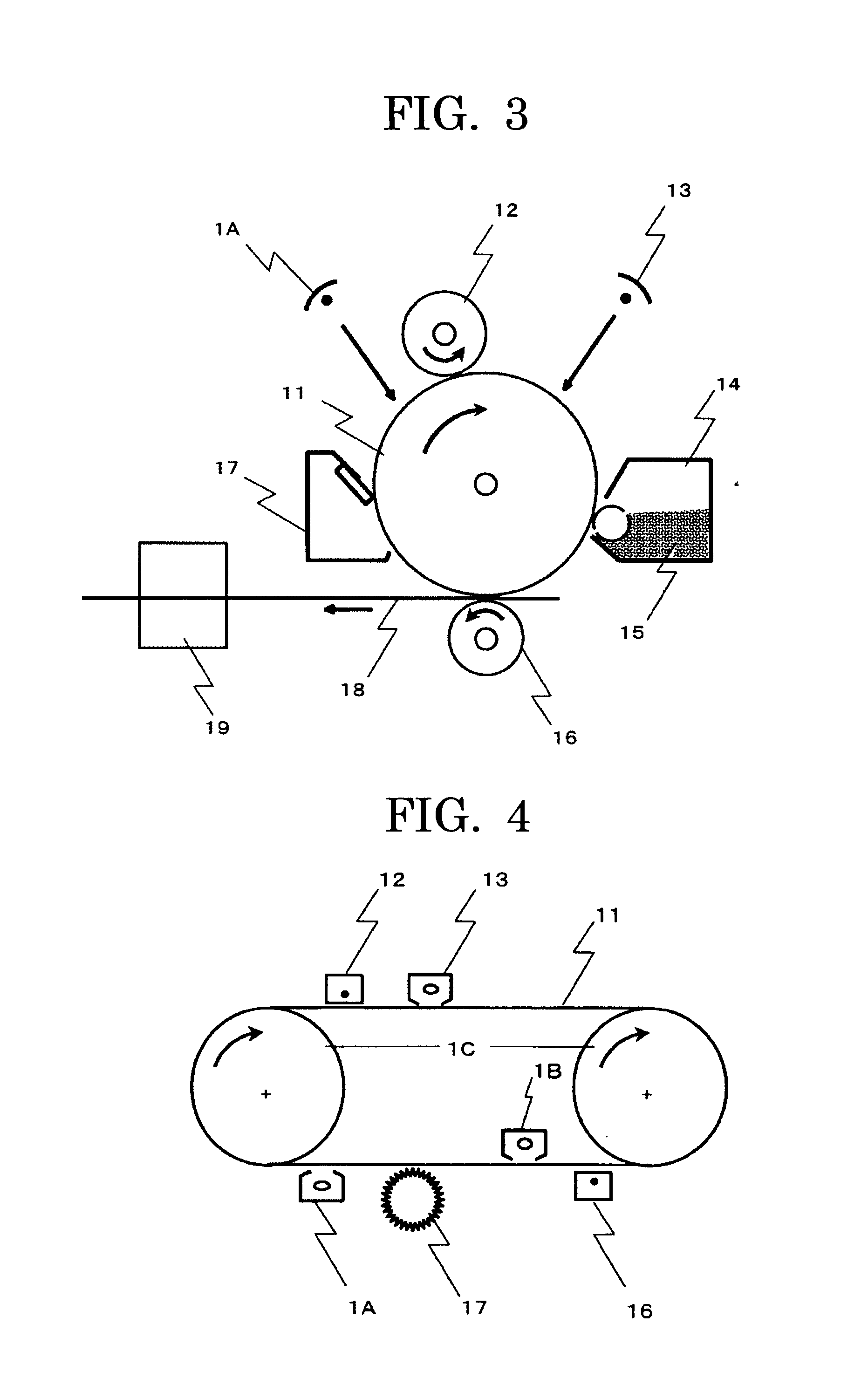

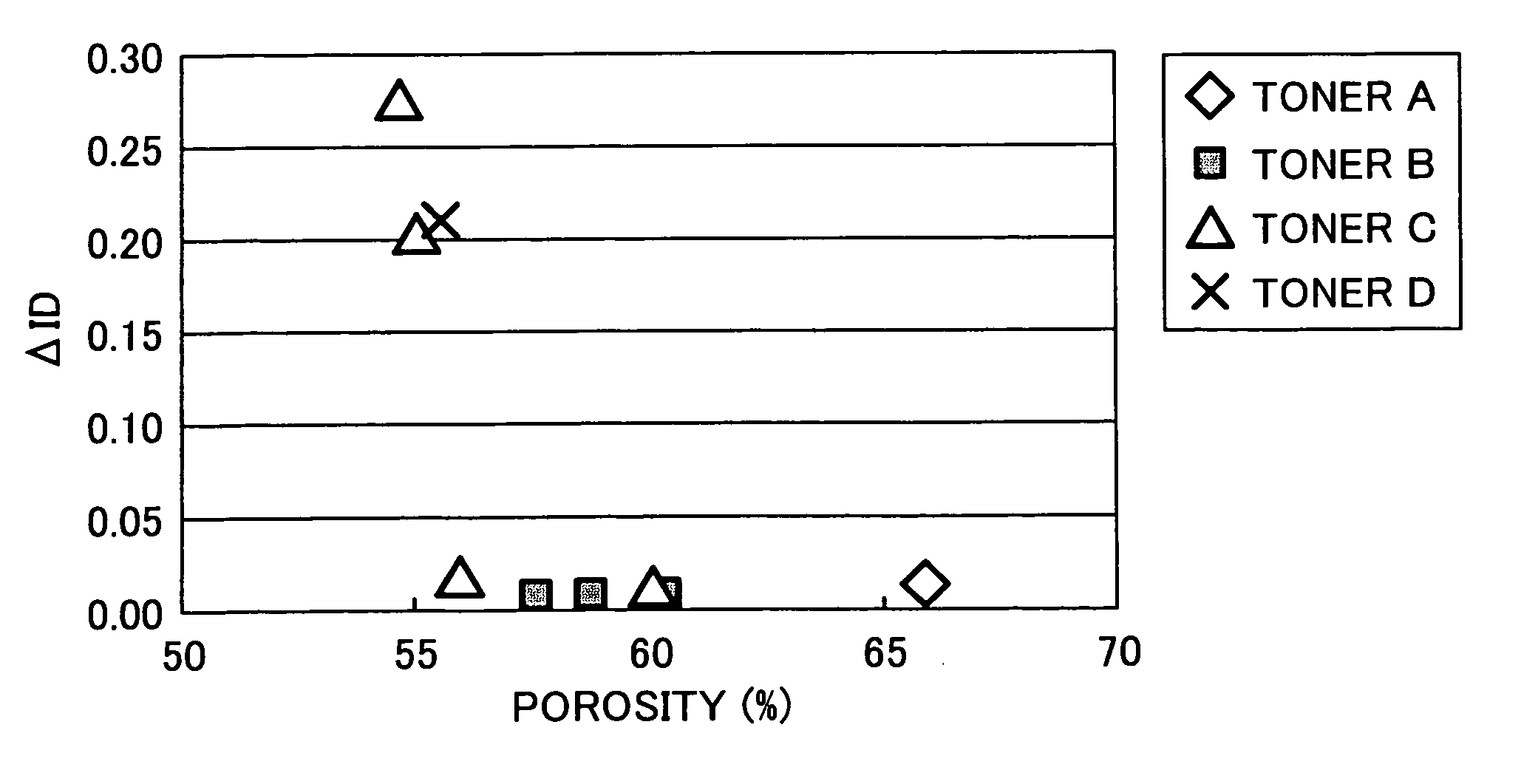

Method and apparatus for electrophotographic image forming capable of using a toner enhancing image quality and cleanability, and the toner used in the image forming

An image forming apparatus performs electrophotographic image forming using a toner and includes an image bearing member configured to bear an electrostatic latent image on a surface thereof, a developing mechanism configured to develop the electrostatic latent image in to a toner image by using a toner, a transfer mechanism configured to transfer the toner image from the image bearing member to an image receiver, a cleaning mechanism including a cleaning blade and configured to remove a residual toner on the image bearing member after toner image is transferred to the image receiver. The toner includes a binder resin and a colorant, forms a toner powder layer, and satisfies an inequality Y≧−0.05X+0.029, in which “X” expresses a porosity of the toner powder layer after uniformly compressed at a constant force and “Y” expresses a torque value obtained by rotatably sticking a conical rotor into the toner powder layer.

Owner:RICOH KK

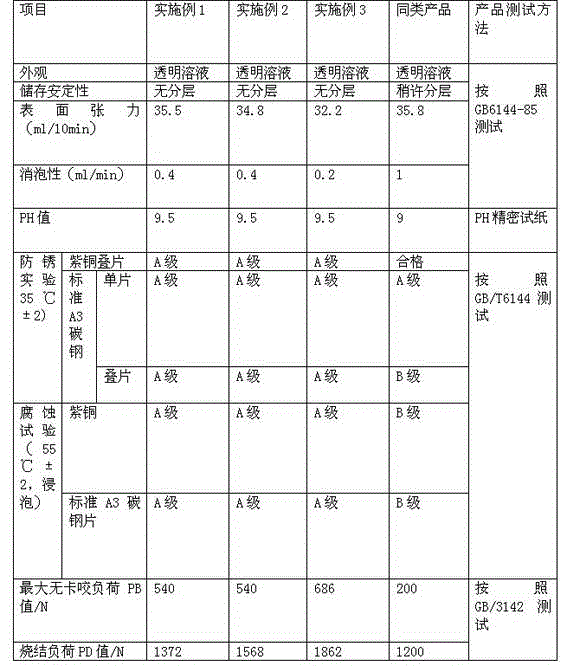

Total synthesis metal cutting solution and preparation method thereof

The invention discloses a total synthesis metal cutting solution comprising the following components by weight percent: 0.5-1% of pH regulator, 10-20% of antirust agent, 10-15% of mixed hydramine, 5-8% of lubricating agent, 0.1-0.3% of copper alloy corrosion inhibitor, 1-2% of sterilizing agent, 0.1-0.2% of defoaming agent, 0-0.5% of EDTA-4 sodium and the balance of water. The invention provides a preparation method of the total synthesis metal cutting solution. The total synthesis metal cutting solution is good in lubricating performance, and the use effect is superior to that of emulsification solution. By utilizing the total synthesis metal cutting solution, surface smoothness of a workpiece can be improved, a grinding wheel can not be sticked, and abrasion of the grinding wheel is reduced. The total synthesis metal cutting solution has a good sedimentation effect and is less in bubbles, long in service life and excellent in anti-rust property, cooling property, permeability and cleanability. By utilizing the total synthesis metal cutting solution, the service life of the grinding wheel can be effectively prolonged. The total synthesis metal cutting solution is suitable for materials, such as bearing steel, carbon steel and the like, the solution is colorless and transparent, and surface processing conditions are easy to observe. Meanwhile, the total synthesis metal cutting solution does not contain toxic and harmful substances, such as sodium nitrite, phenols and the like and is harmless to environment and operator health.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

Molds for making contact lenses

The present invention general related to a reusable mold for making a contact lens comprises a first mold half having a first mold surface in contact with a polymerizable and / or crosslinkable silicone containing lens forming composition and a second mold half having a second mold surface in contact with the lens-forming composition, and the first mold half and the second mold half are configured to receive each other such that a cavity is formed between the first mold surface and the second mold surface. The cavity defines the shape of a contact lens to be molded. The reusable mold has at least one of the mold halves being made from an oxide glass comprising fluorine and / or fluoride. The mold made by oxide glass comprising fluorine and / or fluoride demonstrates improving mold cleanability with water based cleaning process.

Owner:ALCON INC

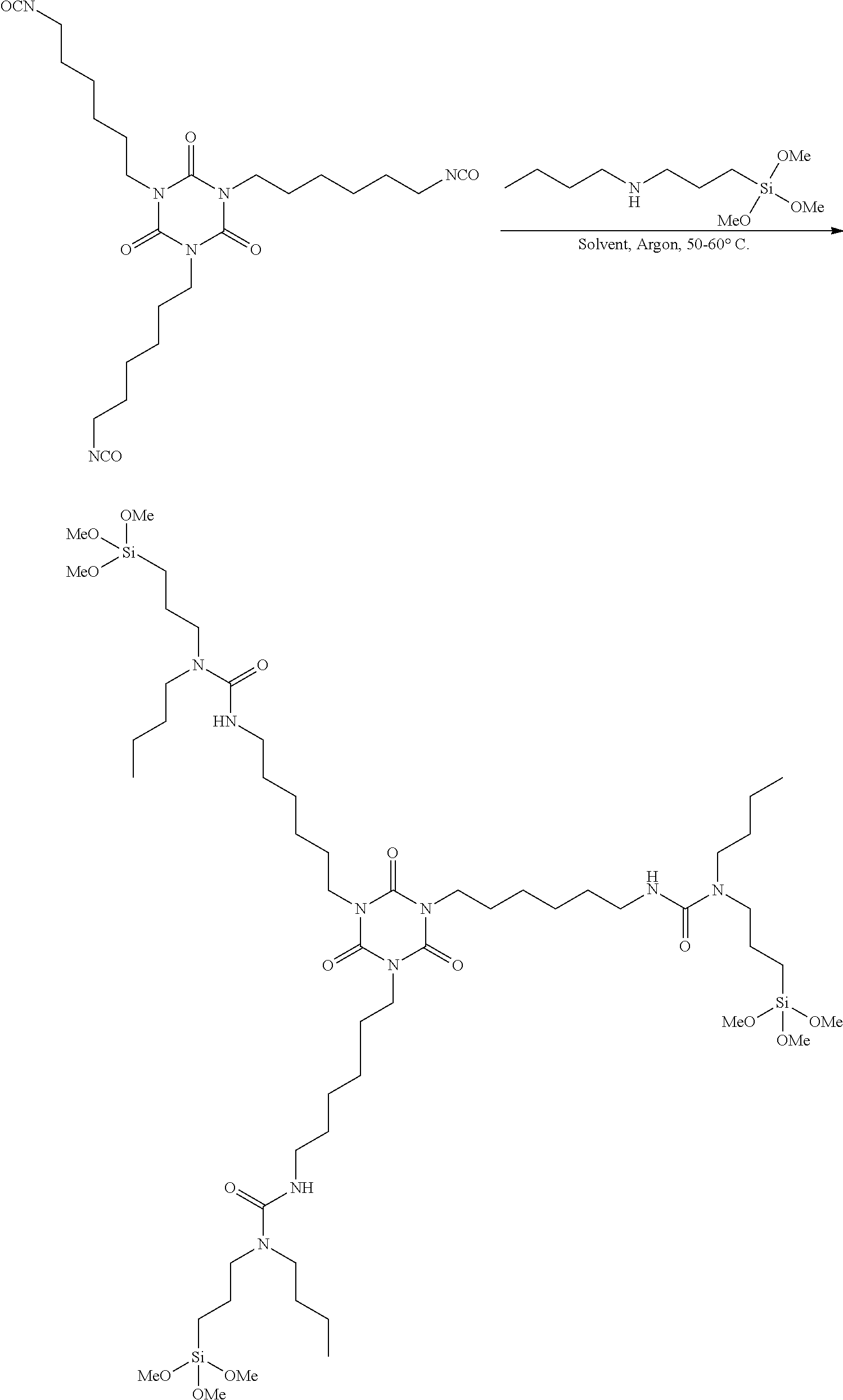

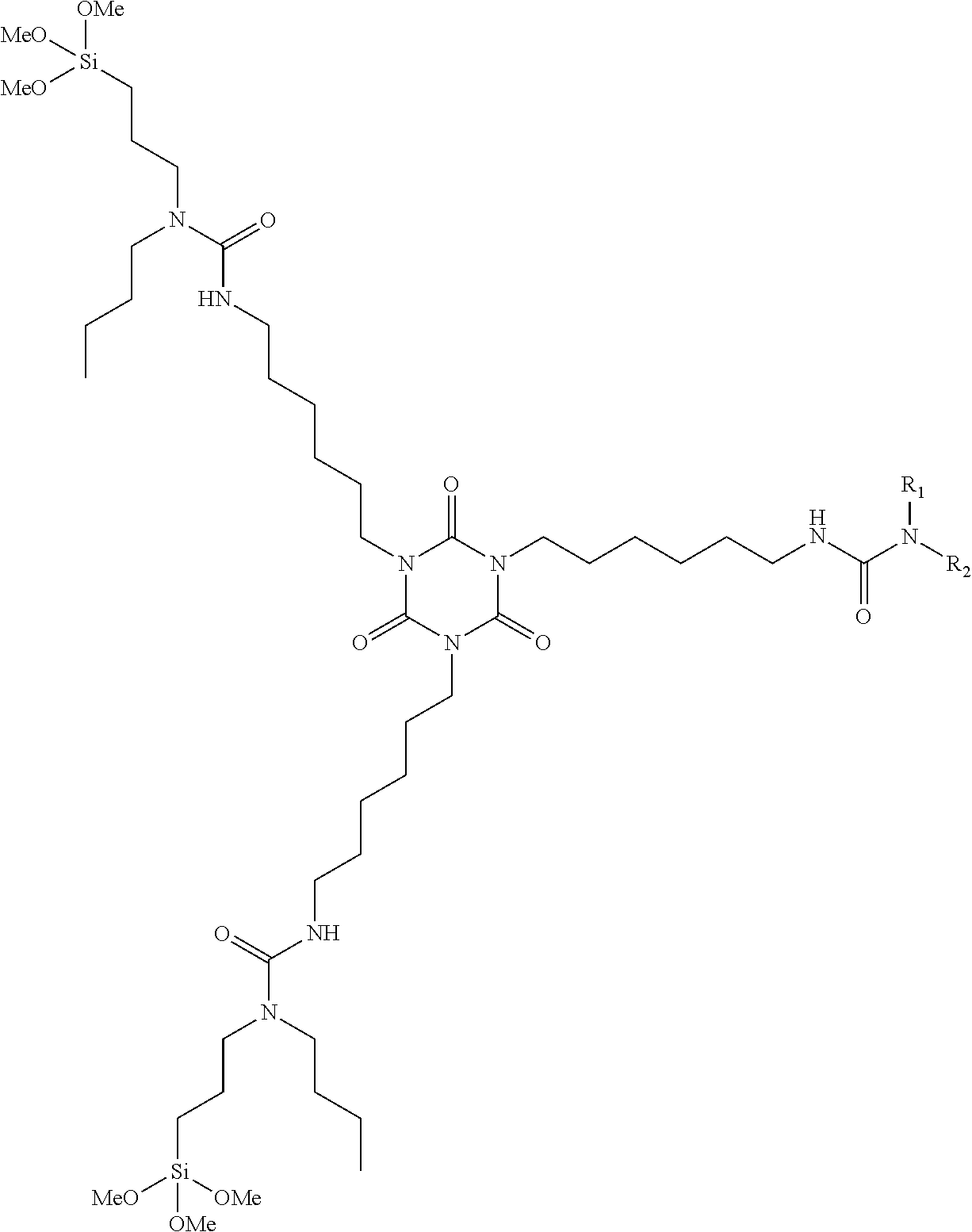

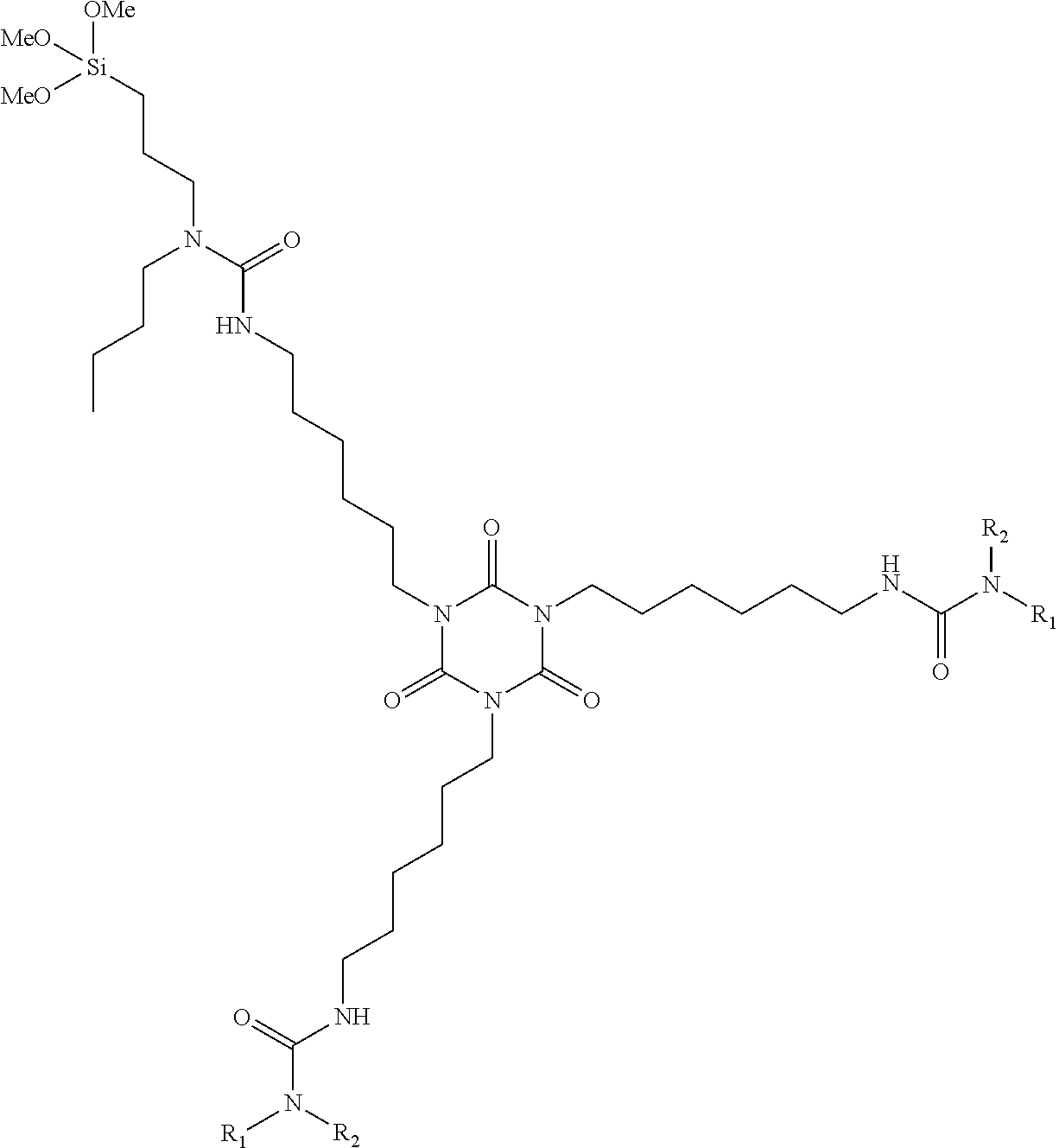

Single-component coating having alkoxysilane-terminated n-substittued urea resins

InactiveUS20110319555A1Improve external stabilityLow VOC contentPolyurea/polyurethane coatingsSilanesUltraviolet

The coating described herein attempts to provide this solution by synthesizing alkoxysilane-terminated N-substituted urea resins, then formulating them into moisture-curable single-component (1K) topside coatings. These coatings will provide greater external stability (to UV and visible radiation), cleanability, flexibility, cure times and lower VOC content than the currently qualified silicone alkyd topside coatings that are found on Navy ships. The single-component coating can include at least an alkoxysilane-terminated N-substituted urea resin, a reactive diluent, a pigment, a filler, and a catalyst. The resin can include an amino-functional silane substituted at the N-position and a non-aromatic isocyanate.

Owner:LEIDOS

Toner and production method thereof, image forming apparatus and image forming method, and process cartridge

ActiveUS7759036B2Excellent transferring property and cleanability and fixabilityQuality improvementElectrographic process apparatusDevelopersImaging qualityImage formation

The object of the invention is to provide a toner enabling excellent transferring properties, cleanability, and fixability and forming a high-precision image without substantially degraded image quality even after printed on a number of sheets of paper. The invention also provides the toner-production method, an image forming apparatus, an image forming method, and a process cartridge. To this end, the present invention provides a toner which comprises toner-base particles containing a binder resin and a filler, and inorganic fine particles, in which the filler is included in a filler-layer in the vicinity of surfaces of the toner-base particles, the number average particle diameter of the primary particles of the inorganic fine particles is 90 nm to 300 nm, and the average circularity of the toner is 0.95.

Owner:RICOH KK

Aqueous cutting fluid, aqueous cutting agent, and process for cutting hard brittle materials with the same

InactiveUS6228816B1Good dispersionEasily re-dispersedWork treatment devicesLiquid carbonaceous fuelsDispersion stabilitySodium Bentonite

An aqueous cutting liquid comprises a cationic water-soluble resin having an amine value of 20 to 200 mgKOH / g, and at least one rheology control agent selected from the group consisting of an inorganic bentonite, an organic bentonite and an aqueous silica sol, wherein the content of a nonvolatile matter of the rheology control agent is 0.1 to 30 percent by weight of the amount of the nonvolatile matter of the cationic water-soluble resin. An aqueous cutting agent comprises the aqueous cutting liquid, and an abrasive grain, wherein the content of the abrasive grain is 100 to 1000 percent by weight of the amount of the nonvolatile matter of the aqueous cutting liquid. A hard and brittle material is cut by a cutting device using the aqueous cutting agent. The present invention provides an aqueous cutting agent which is excellent in dispersion stability of the abrasive grain and viscosity stability during cutting / slicing operations, aqueous cutting liquid usable for the aqueous cutting agent, and a cutting / slicing method excellent in cutting performance, cleanability and the like of the work material on cutting / slicing hard and brittle material by using the cutting agent.

Owner:NOF CORP +1

Manufacture method of solar silicon single crystal

ActiveCN101565851AReduce wasteImprove processing qualityPolycrystalline material growthBy pulling from meltCrucibleEconomic benefits

The invention relates to a preparation method of a solar silicon single crystal and aims to provide an improvement of the preparation method of the solar silicon single crystal. The improved preparation method saves resources, reduces production cost and improves economic benefit, and simultaneously, the solar silicon single crystal prepared by using the preparation method also has good cleanability and safety, long service life and favorable product performance. The technical proposal is as follows: the manufacture method of the solar silicon single crystal is characterized by using discarded leftovers of polysilicon as the raw material to prepare the solar silicon single crystal, and includes: step 1. firstly classifying the leftovers of polysilicon; and step 2. putting the leftovers into a crucible to be drawn.

Owner:徐国六

Toner and production method thereof, image forming apparatus and image forming method, and process cartridge

The object of the invention is to provide a toner enabling excellent transferring properties, cleanability, and fixability, and forming a high-precision image without substantially degraded image quality even after printed on a number of sheets of paper. The invention also provides the toner-production method, an image forming apparatus, an image forming method, and a process cartridge. To this end, the present invention provides a toner which comprises toner-base particles containing a binder resin and a filler, and inorganic fine particles, in which the filler is included in a filler-layer in the vicinity of surfaces of the toner-base particles, the number average particle diameter of the primary particles of the inorganic fine particles is 90nm to 300nm, and the average circularity of the toner is 0.95.

Owner:RICOH KK

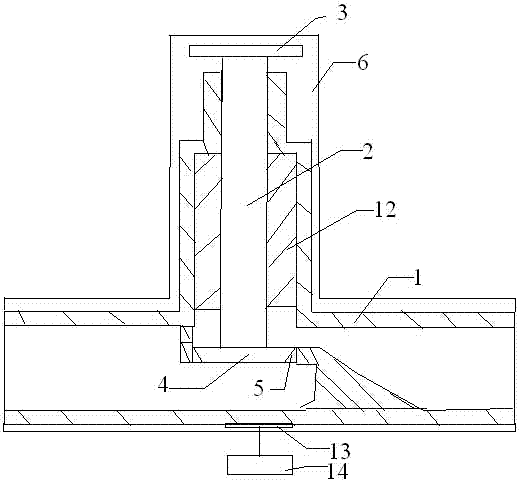

Antifreezing cleanable valve

InactiveCN104500925APlay the role of fixing nailsPlay a role in heat preservationThermal insulationPipe protection by thermal insulationThermal insulationPolystyrene

The invention discloses an antifreezing cleanable valve which comprises a valve body (1), a valve rod (2), a valve handle (3) and a valve core (4). The antifreezing cleanable valve is characterized by further comprising a heat-insulating cover (6) arranged on the periphery of the valve body (1), and an ultrasonic cleaning device, the heat-insulating cover (6) wraps the periphery of the valve body (1) through a locking device, the ultrasonic cleaning device comprises an ultrasonic vibrator (13) positioned on the lower surface of the valve body (1), and an ultrasonic generator (14) electrically connected with the ultrasonic vibrator (13), the outer layer of the heat-insulating cover (6) is made by plastic while the inner layer of the same is made by a phenolic foam or polystyrene foam plate heat-insulating material, a filler (12) is arranged in the valve body (1) and is soft rubber, and the heat-insulating cover (6) on the periphery of the locking device is made by plastic wholly. Through the heat-insulating cover and the ultrasonic cleaning device, the antifreezing cleanable valve has functions of heat insulation, cleanability and deicing.

Owner:SUZHOU FURUN MACHINERY

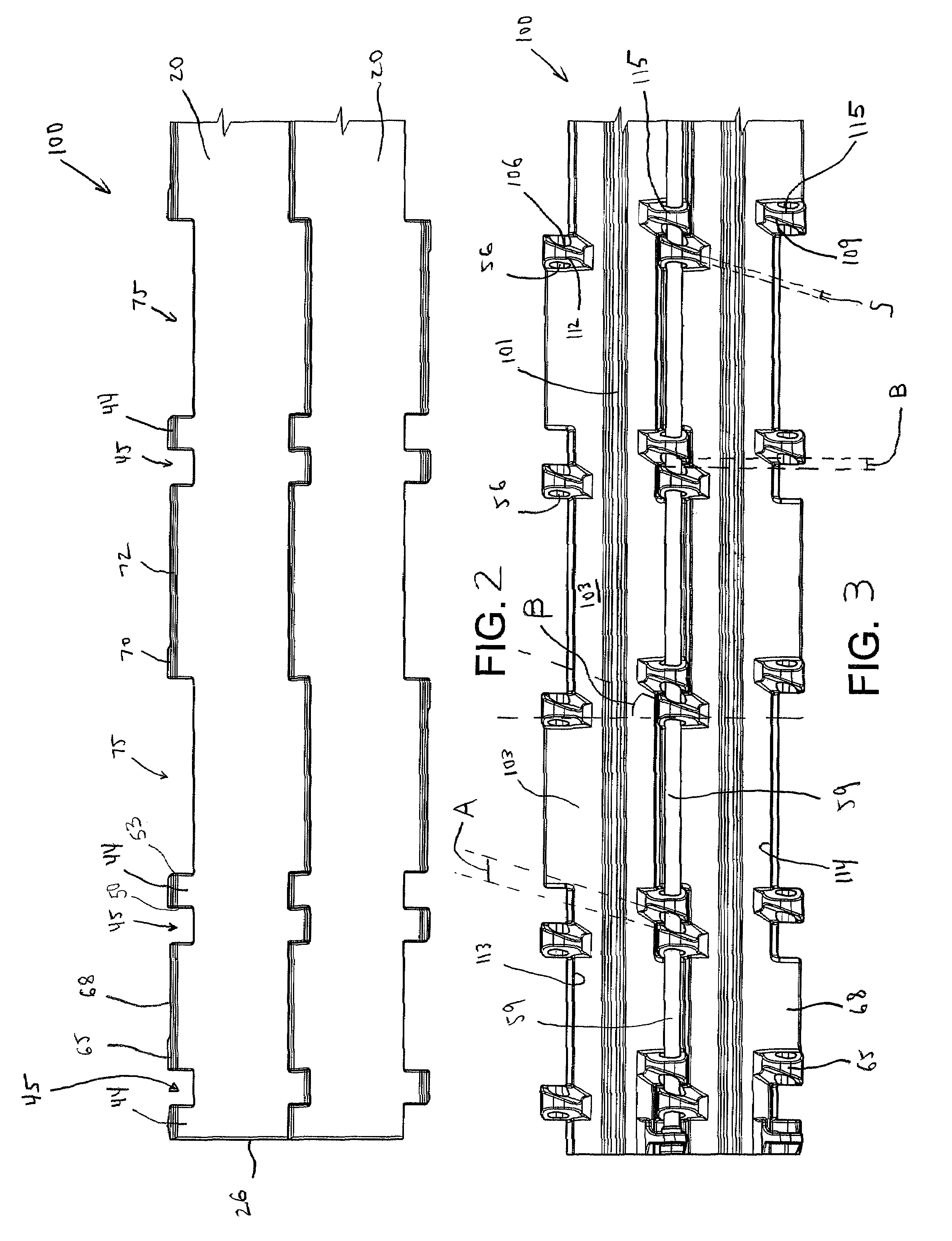

Module with large open hinge for easy cleaning

InactiveUS7530455B2Reduces undesirable elasticityConveyorsPackagingEngineeringMechanical engineering

Owner:HABASIT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com