Spacer for filter modules

A technology of filter components and partitions, which is applied in thin material processing, membranes, general water supply saving, etc., can solve the problem of ensuring the limited distance between the partition and the surface of the filter material, the inability to clearly predict the filtration characteristics, blocking the substantial part of the surface of the filter medium, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

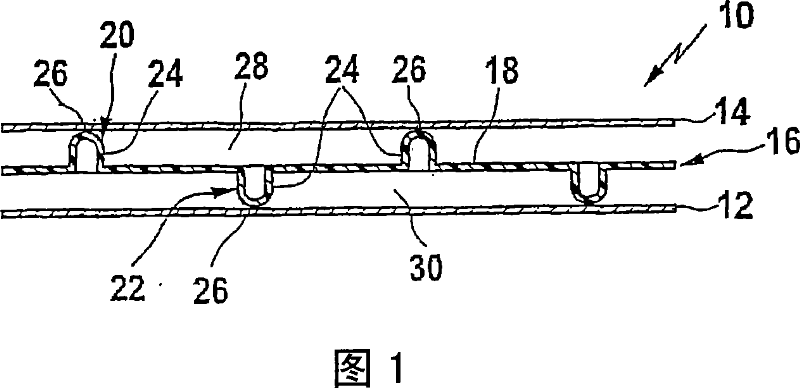

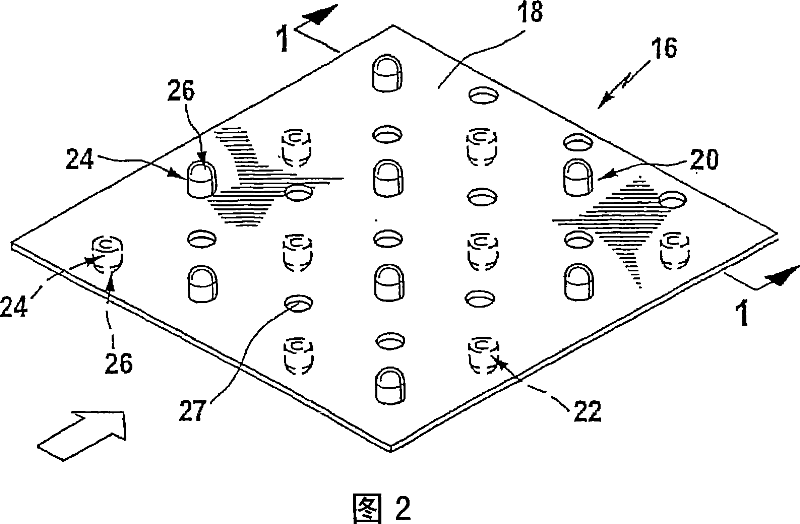

[0079] 1 schematically shows a filter assembly 10 consisting of a first filter medium layer 12 and a second filter medium layer 14, the two filter medium layers 12 and 14 being formed by a plate 18 with upper and lower projections 20, 22. The partitions 16 are spaced apart in parallel directions, wherein the upper and lower projections rise respectively from the upper and lower surfaces of the sheet 18 to define upper and lower support surfaces for the layers of filter media 12 and 14 .

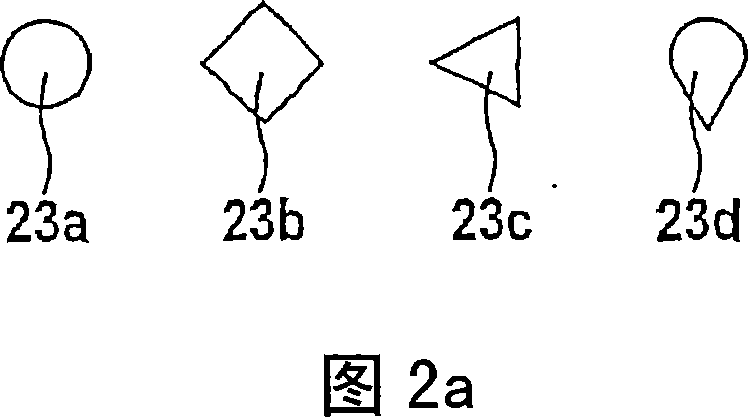

[0080] The protrusions 20 and 22 are in the form of point-like needle-like or column-like protrusions comprising a cylindrical wall portion 24 and a rounded top 26 in contact with the layers of filter media 14 and 12 respectively.

[0081] Due to the vertical orientation of the cylindrical wall 24 with respect to the plate 18, no areas are created that block the feed fluid to be observed. Thus, the tendency to fouling is greatly reduced.

[0082] Furthermore, the upper and lower protrusions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com