Toner and production method thereof, image forming apparatus and image forming method, and process cartridge

A toner and image technology, applied in the field of toner, can solve the problems of delay in initial charge accumulation, unstable charge of toner particles, and difficulty in cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A-1

[0271] -Preparation of Spherical and Hydrophobic Silica-

[0272] According to the sol-gel method, tetramethoxysilane and ammonia water react with each other at 50°C to produce spherical silica. After washing the silica with water, the silica was rinsed with methanol, then dispersed in toluene without a drying operation, and then treated with hexamethyldisilazane (HMDS) to obtain inorganic oxide particles 1 . The inorganic oxide particles were stirred in methanol using an ultrasonic dispersing device, and the number average diameter thereof was measured by a laser-diffraction-scattering-particle size-distribution sieve. The number average diameter of the generated primary particles was 120 nm.

[0273] -Synthesis of Organic Microparticle Emulsion-

[0274] In the reaction vessel that stirrer and thermometer are equipped with, pour the sodium salt of the sulfuric acid ester (ELEMINOL RS-30 of the water of 683 mass parts, 11 mass parts of ethylene oxide adducts of methacrylic ...

Embodiment A-2

[0303] A toner was obtained in the same manner as in Example A-1, except that the method of rinsing to mixing of the external additive was changed to the method of the following conditions.

[0304] -rinsing-

[0305] After filtering 100 parts by mass of dispersion slurry 1 under reduced pressure,

[0306] (1): 100 parts by mass of ion-exchanged water was added to the filter cake, mixed in a TK homomixer for 10 minutes at a rotation speed of 12,000 rpm, and filtered.

[0307] (2): To the filter cake of (1), 100 parts by mass of a 10 mass % sodium hydroxide solution was added, mixed in a TK homomixer at 12,000 rpm for 30 minutes and filtered under reduced pressure.

[0308] (3): 100 parts by mass of 10% by mass hydrochloric acid was added to the filter cake of (2), mixed in a TK homomixer for 10 minutes at a rotation speed of 12,000 rpm, and filtered.

[0309] (4): 300 parts by mass of ion-exchanged water was added to the filter cake of (3), mixed in a TK homomixer at a rotat...

Embodiment A-3

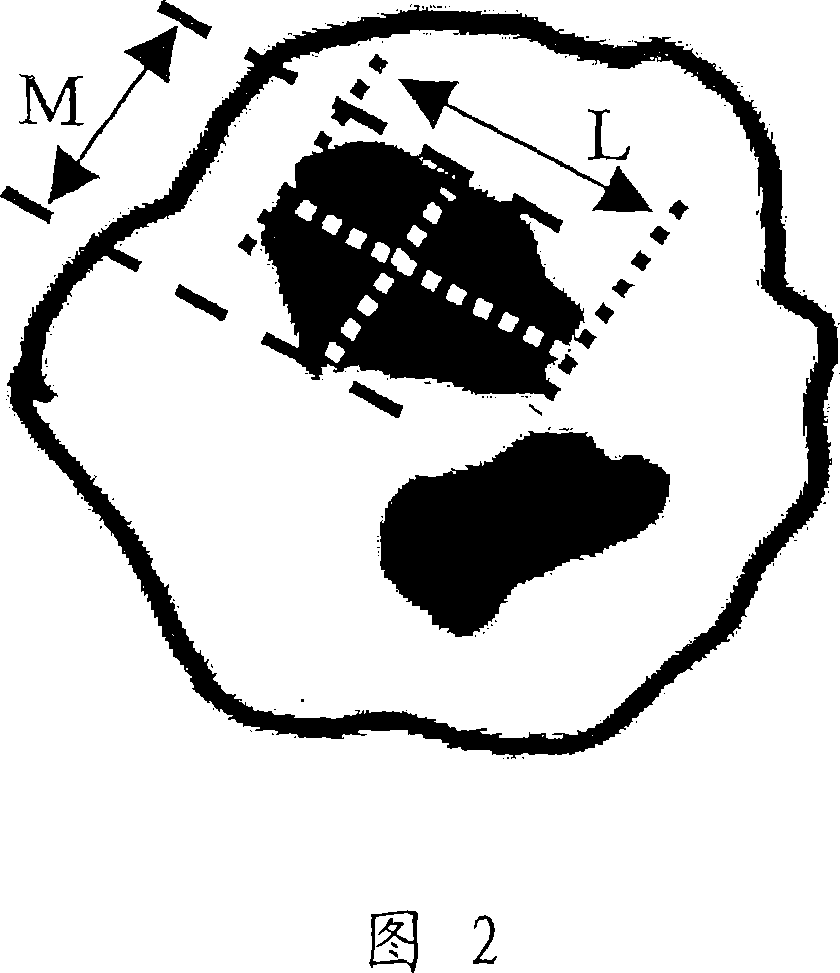

[0317] Toner 3 was obtained in the same manner as in Example A-1 except that the conditions were changed to the following. The thickness of the filler layer in the toner is 0.01 μm to 0.2 μm.

[0318] -Emulsification, solvent removal-

[0319] Put 749 mass parts of pigment wax dispersion liquid 1, 115 mass parts of prepolymer 1, 2.9 mass parts of ketimine compound 1 and 100 mass parts (10 mass %) filler (Organo Silicasol MEK-ST- UP, the number-average particle diameter of the primary particles=12nm), was mixed at 5,000 rpm for 2 minutes by a TK homomixer (manufactured by TOKUSHU KIKA KOGYO CO., LTD.), and then 1,200 parts by mass of Water phase 1 and mixed in a TK homomixer at 13,000 rpm for 10 minutes to obtain emulsion slurry 2.

[0320] The emulsion slurry 2 was put into a container equipped with a stirrer and a thermometer, then the solvent was removed at 30° C. for 6 hours, and the product was aged at 45° C. for 5 hours to obtain a dispersion slurry 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com