Drill

A technology of drill bit and main body, which is applied in the direction of drill repairing, twist drill, drilling tool accessories, etc. It can solve the problems of messy cleaning, chip scattering, etc., and achieve the effects of reducing processing costs, ensuring tool rigidity, and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]

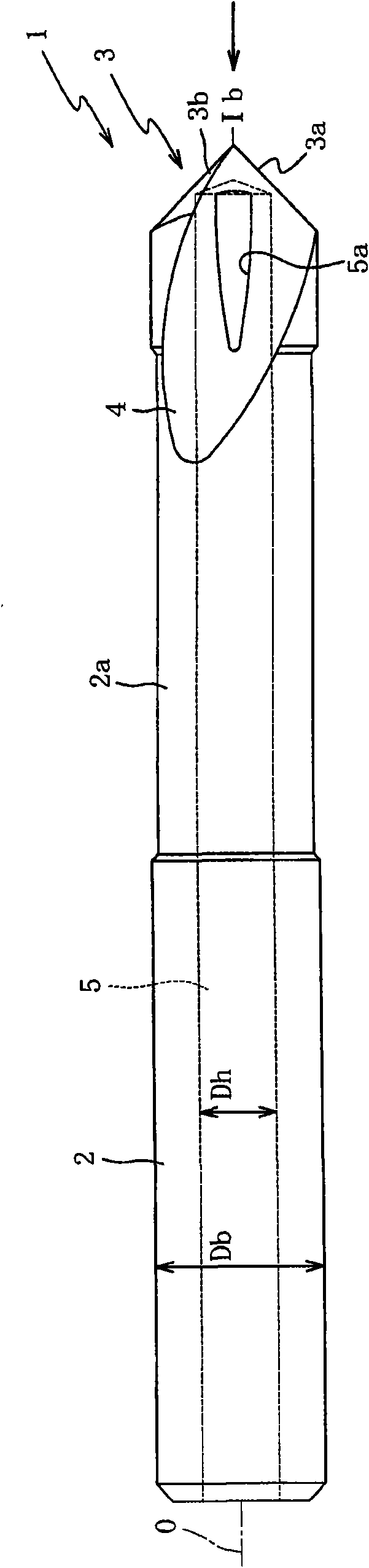

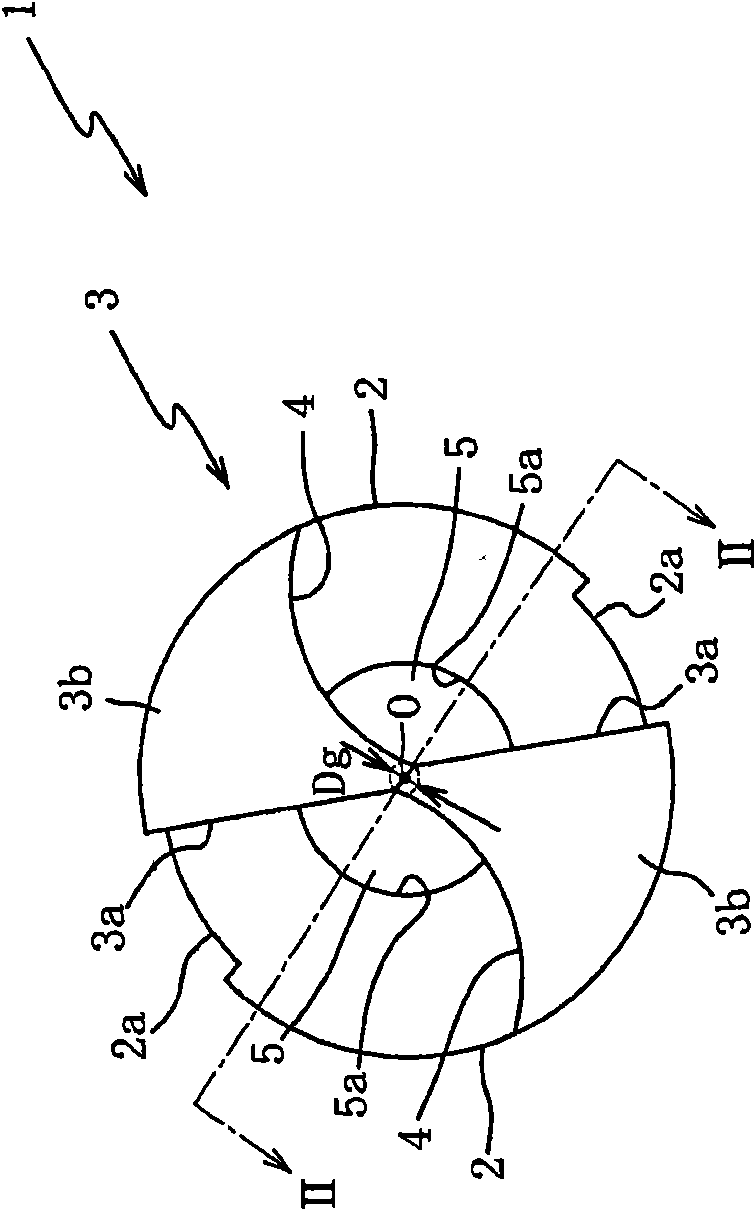

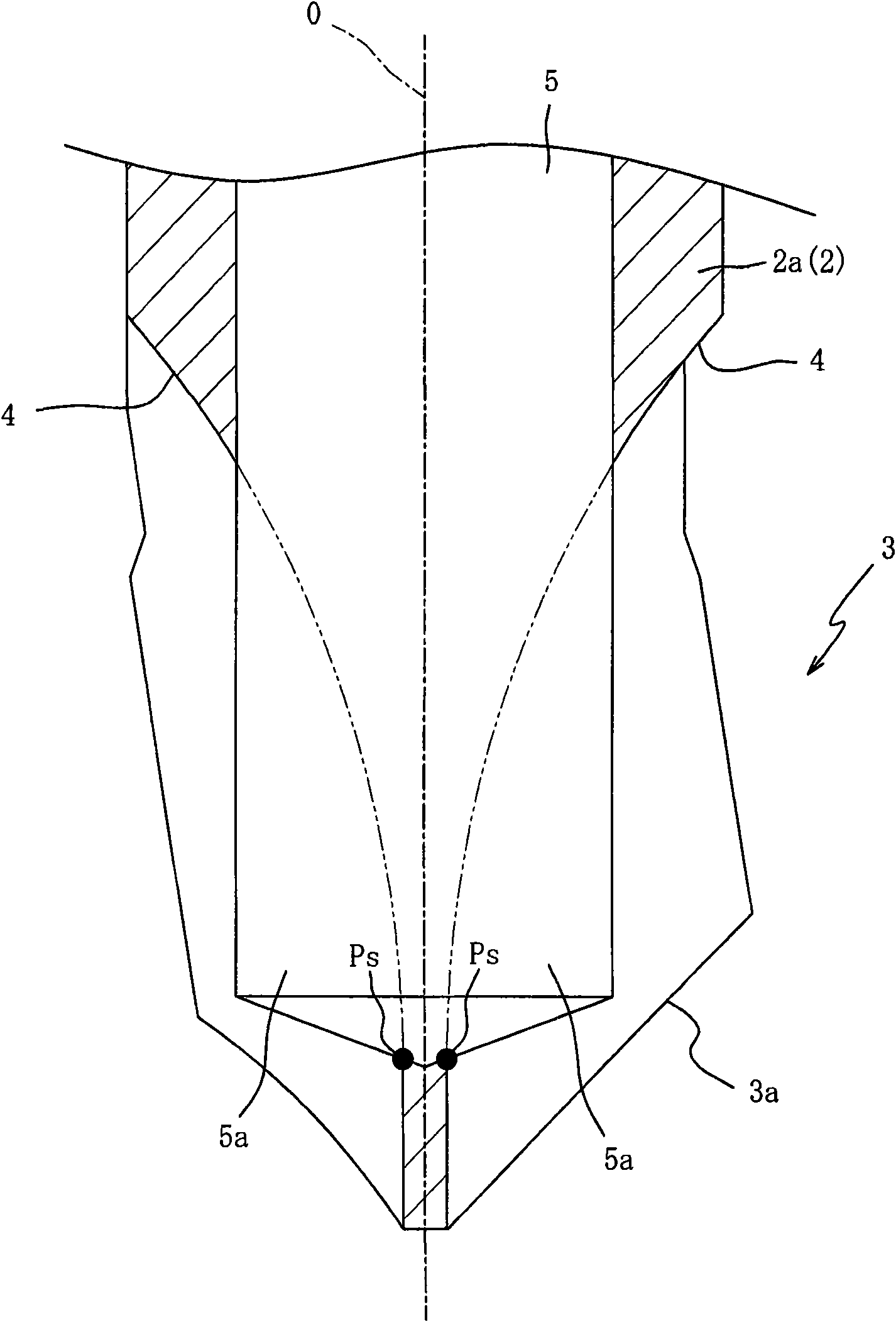

Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. First, a drill 1 according to an embodiment of the present invention will be described with reference to FIG. 1 . Fig. 1 (a) is the front view of drill bit 1; Fig. 1 (b) is the side view of the drill bit seen from the arrow Ib direction of Fig. 1 (a).

[0035]

As shown in Figure 1, the drill bit 1 is a tool for drilling a workpiece (not shown) under the torque transmitted by the processing equipment (not shown), and it is integrally composed of superhard alloy, wherein the superhard alloy It is obtained by pressing sintered cemented carbide (WC) or the like, and the drill bit 1 is mainly provided with a main body 2 and a blade 3 integrally connected with the main body 2 . However, the drill 1 is not limited to cemented carbide, and may be made of high-speed tool steel.

[0036]

The main body part 2 is through the drill sleeve 10 (refer to image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com