Patents

Literature

245 results about "Knife sharpener" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

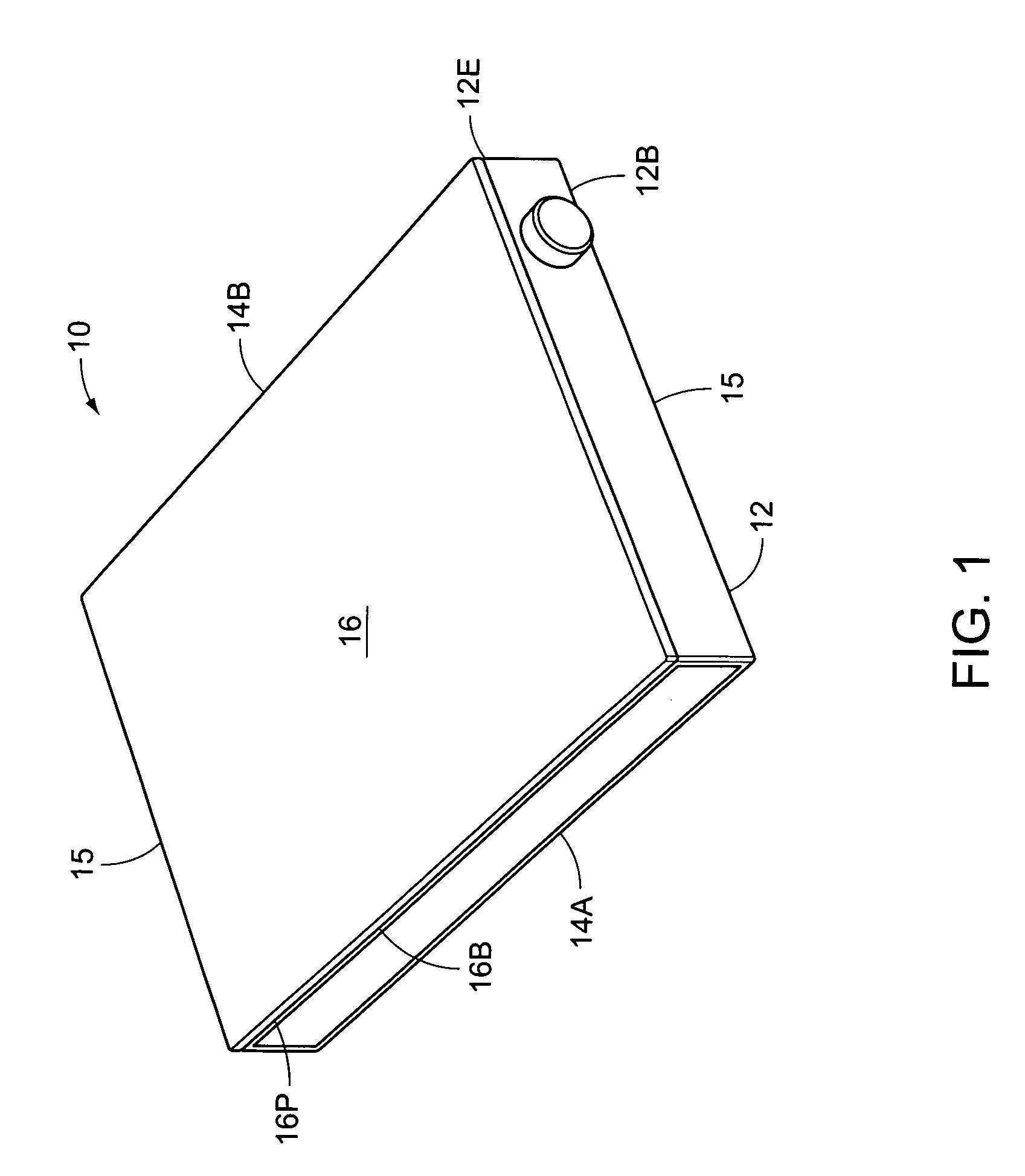

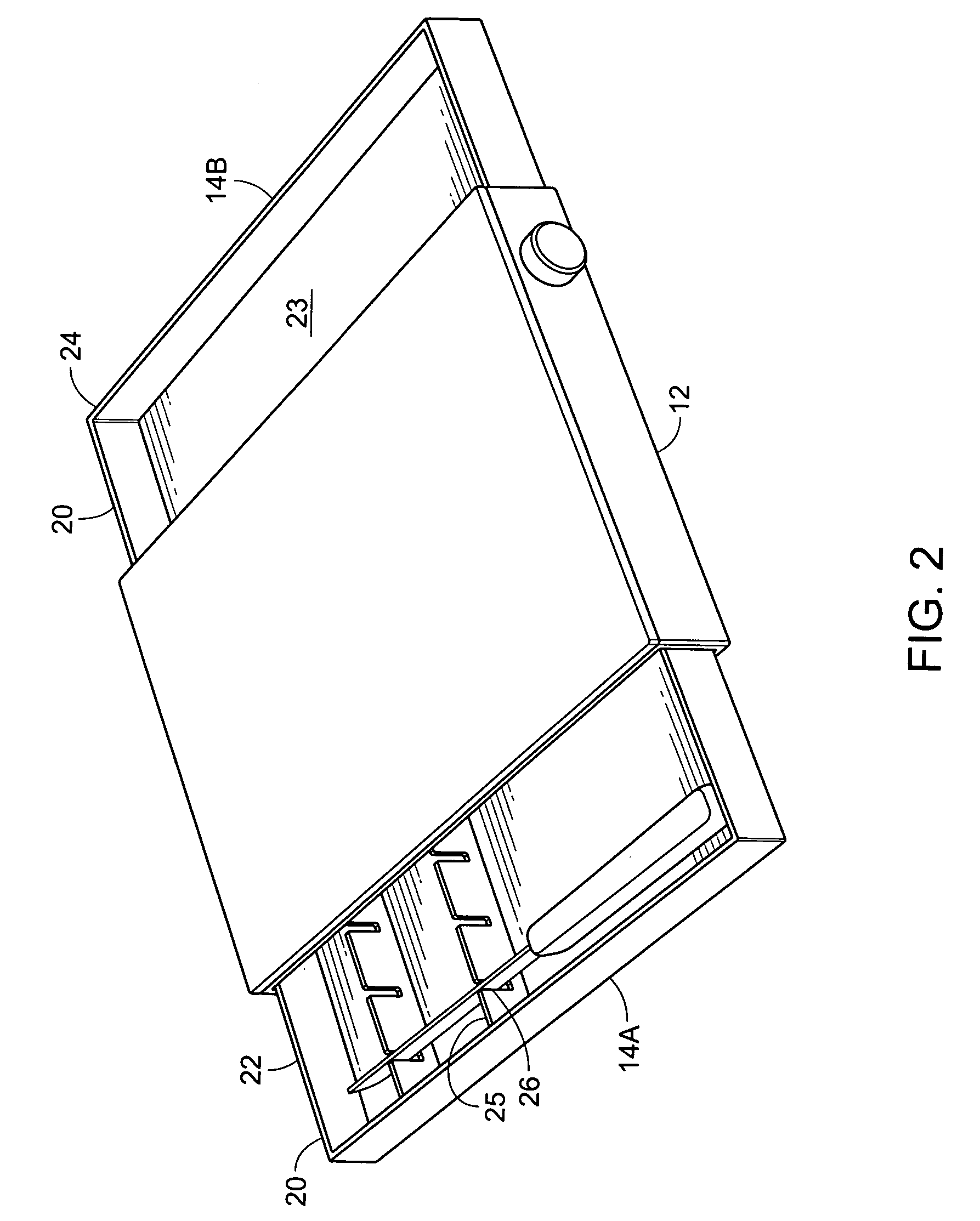

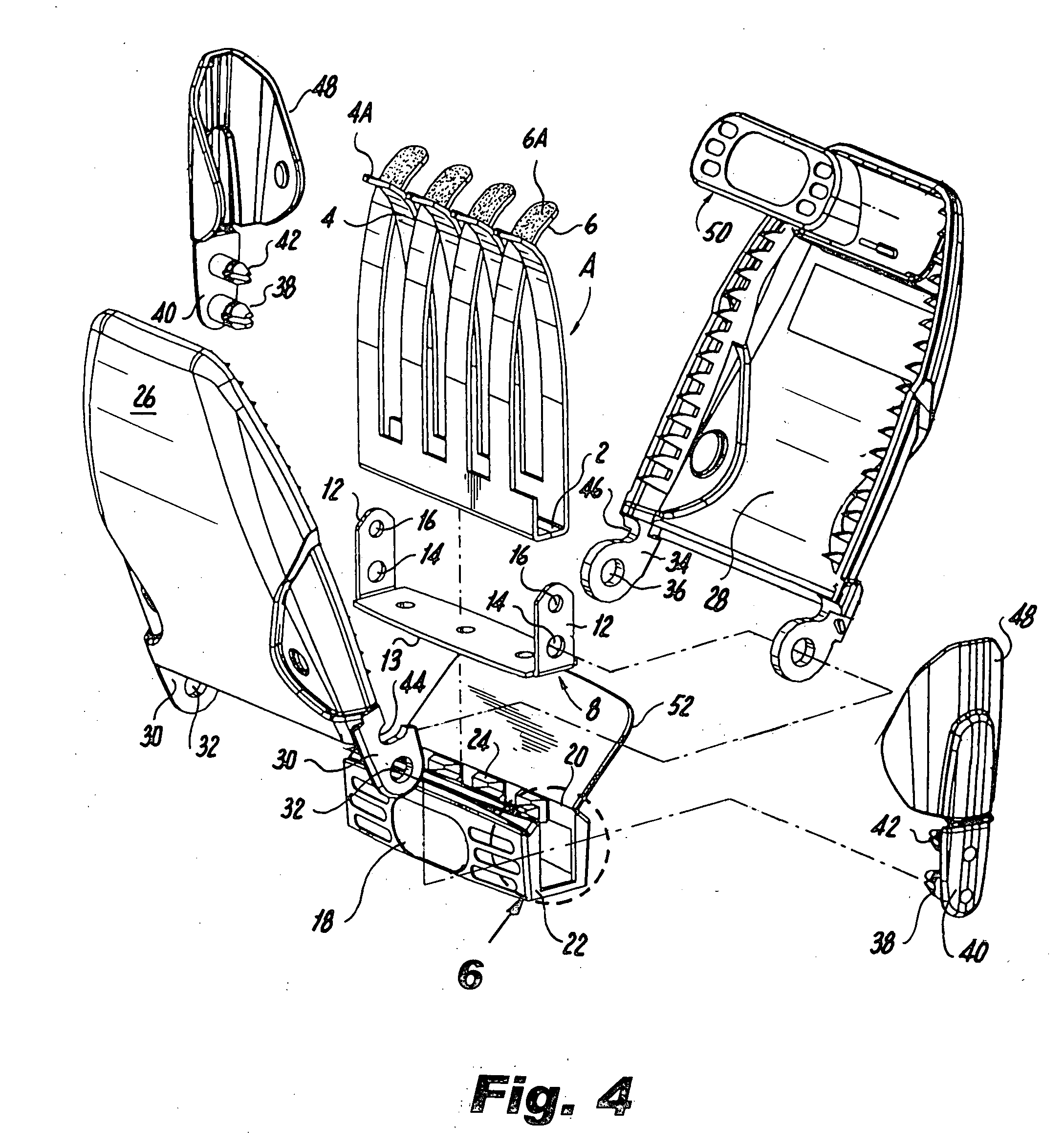

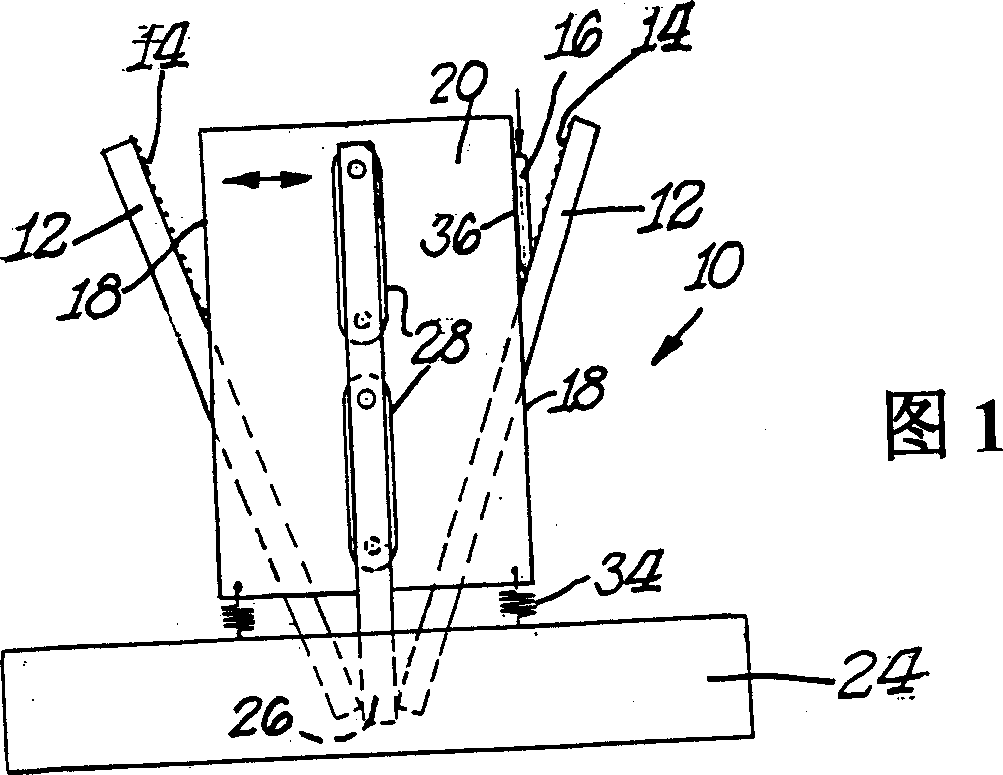

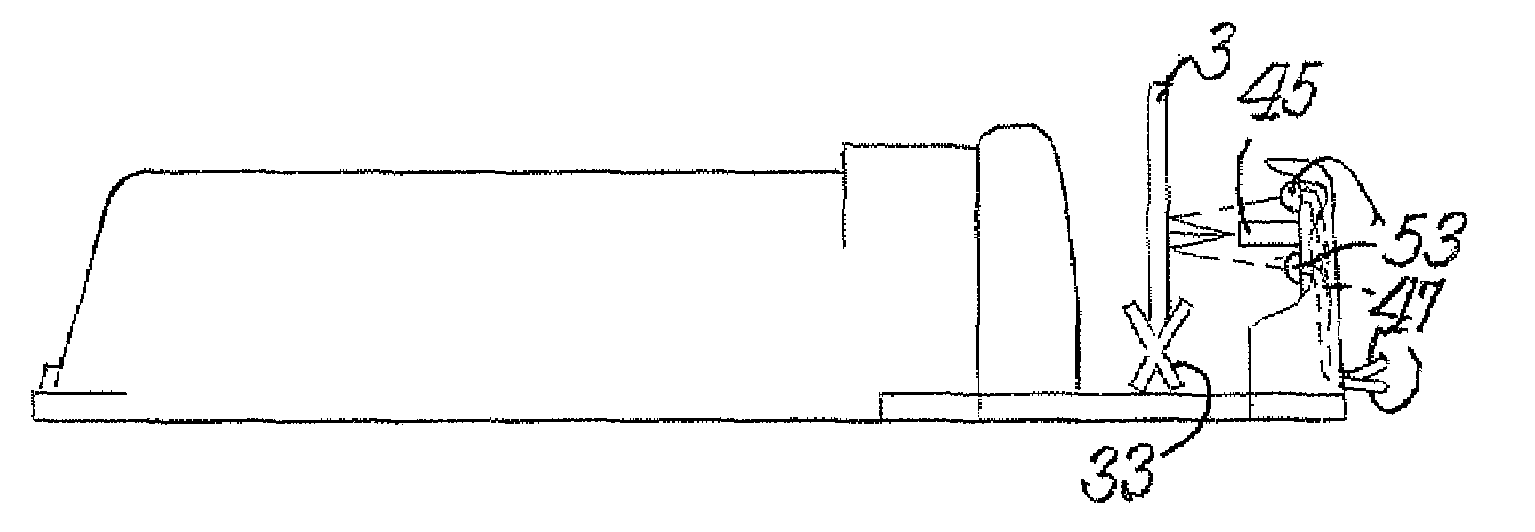

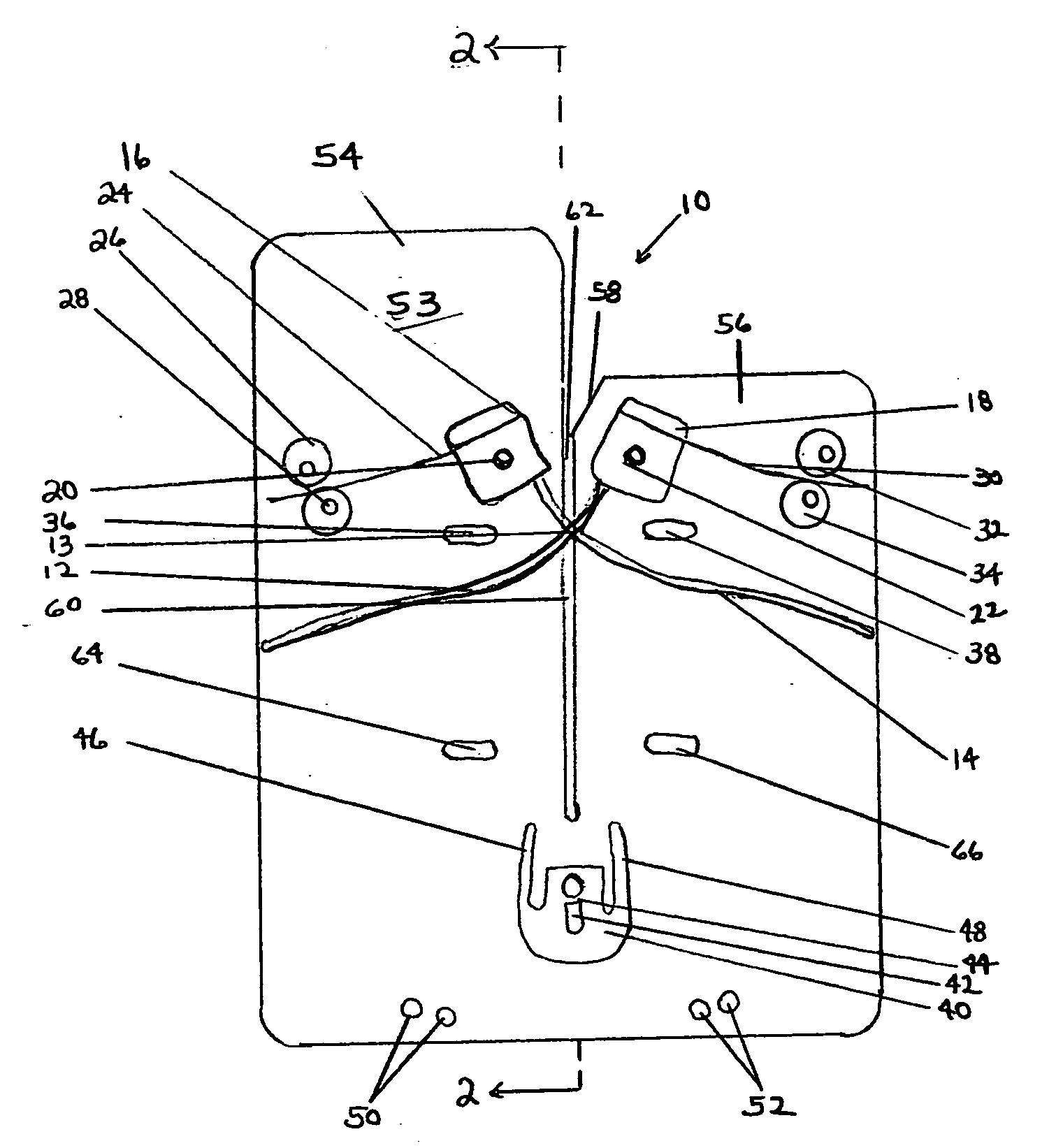

Manual knife sharpener with angle control

InactiveUS6881137B2Ease of useImprove portabilityEdge grinding machinesRevolution surface grinding machinesKnife sharpenerEngineering

A sharpener for blades comprises a physical structure supporting at least one abrasive surface. A displaceable guiding plate having an integral linear structural feature of the support is disposed toward one side of the abrasive surface. The linear structural feature provides sliding contact with a face of the blade to establish the relative angle of the plane of the edge facet of the blade with the plane of the abrasive surface at the point of mutual contact as the facet is guided into contact with the abrasive surface.

Owner:EDGECRAFT

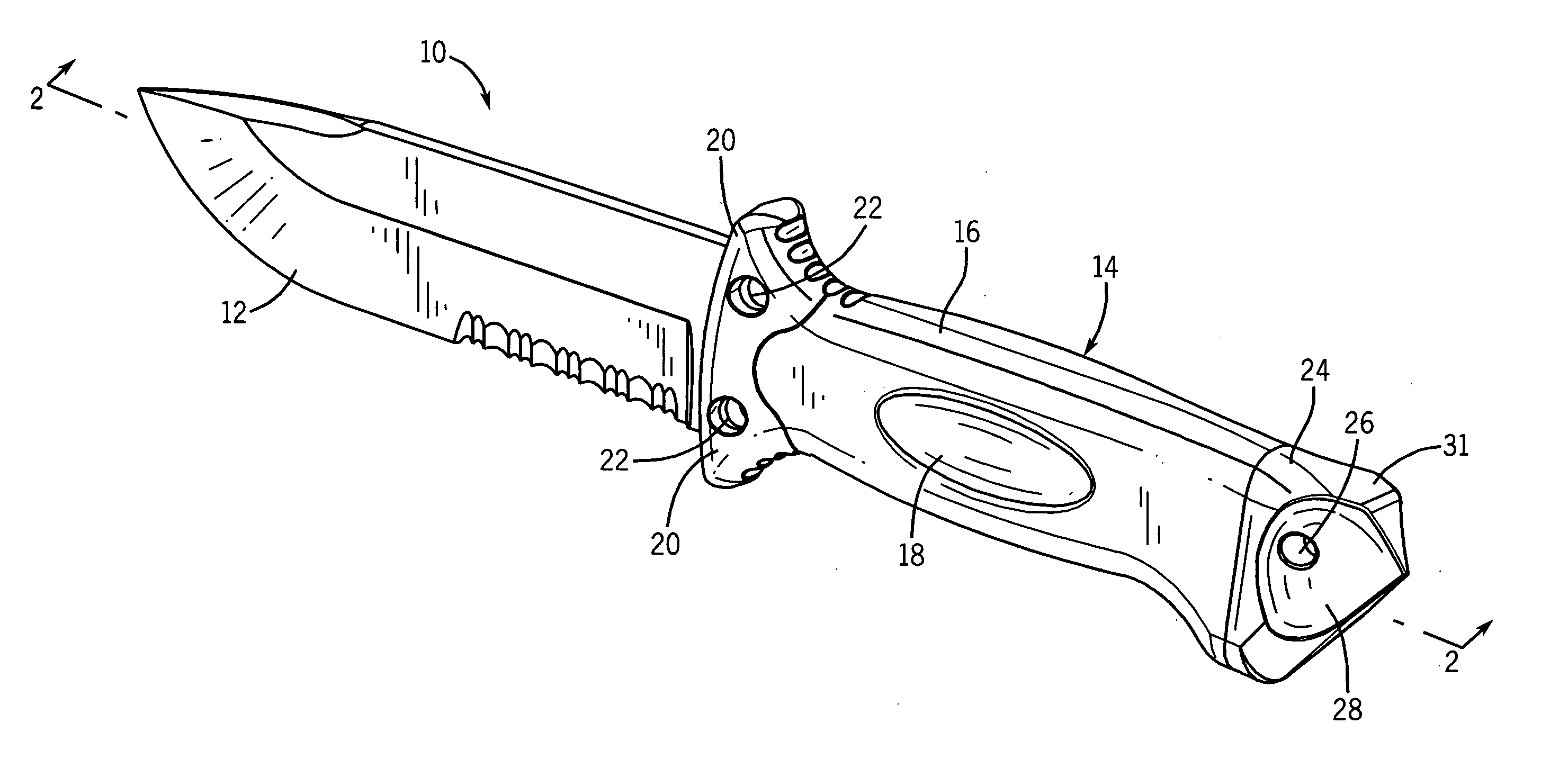

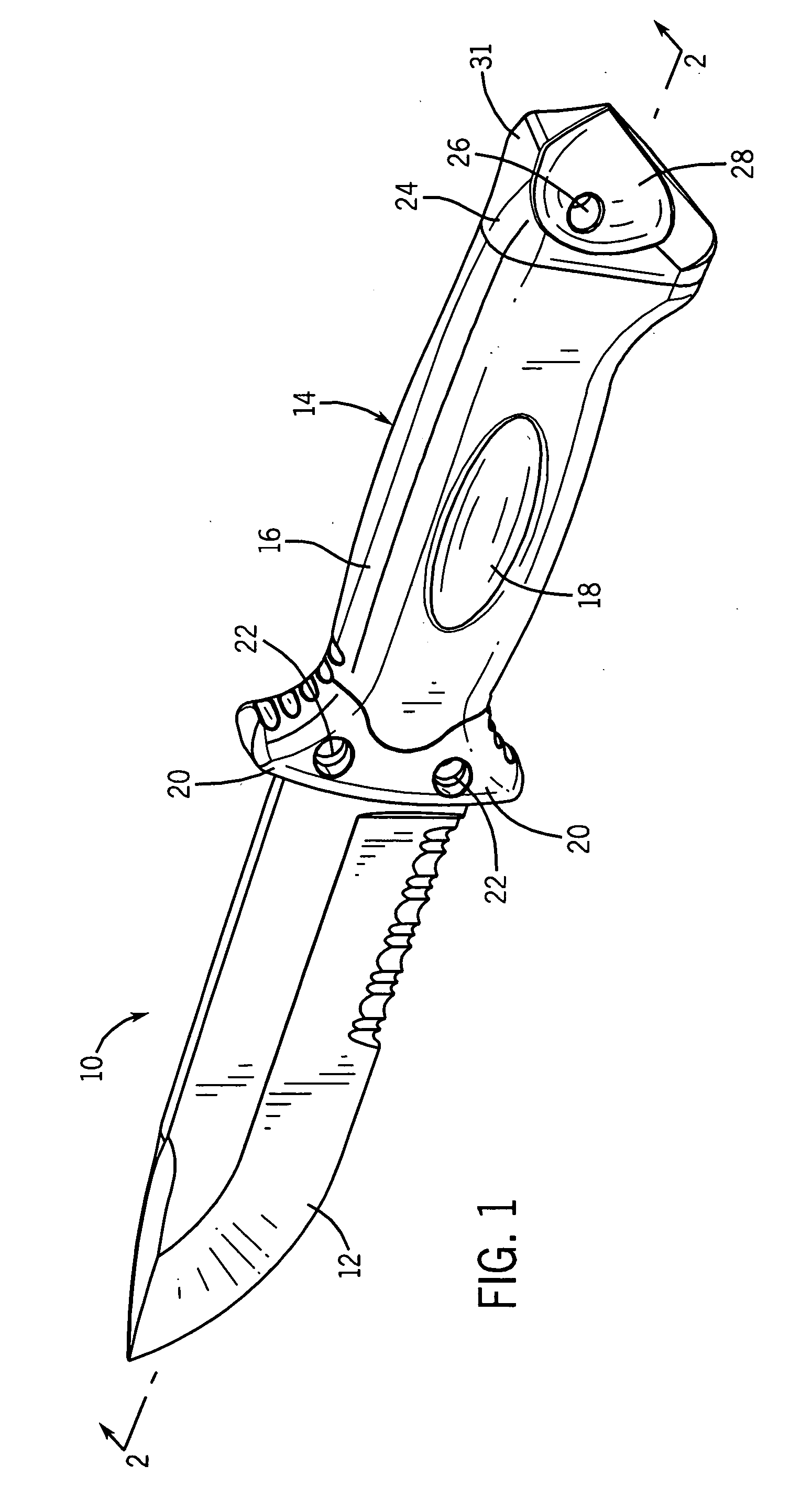

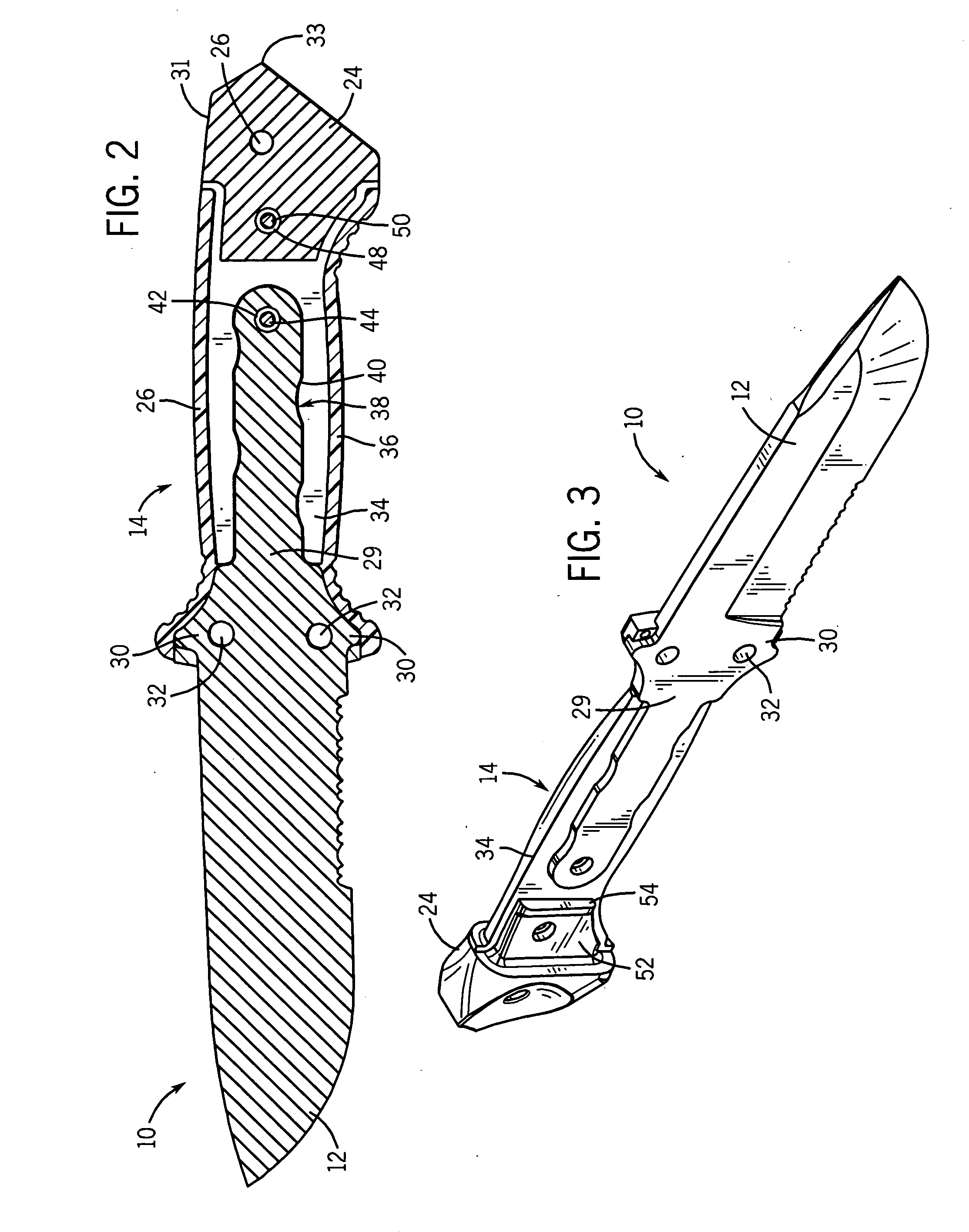

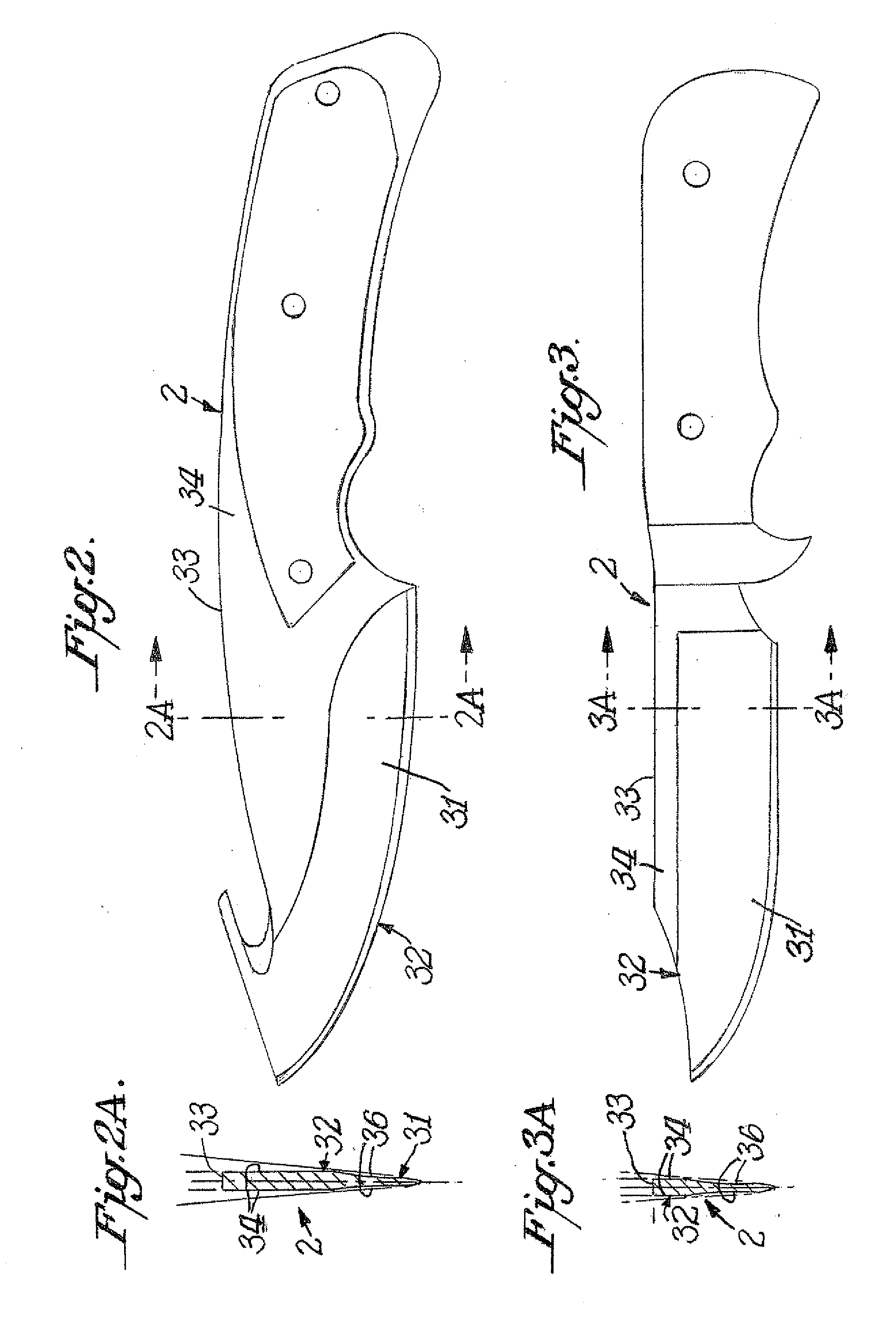

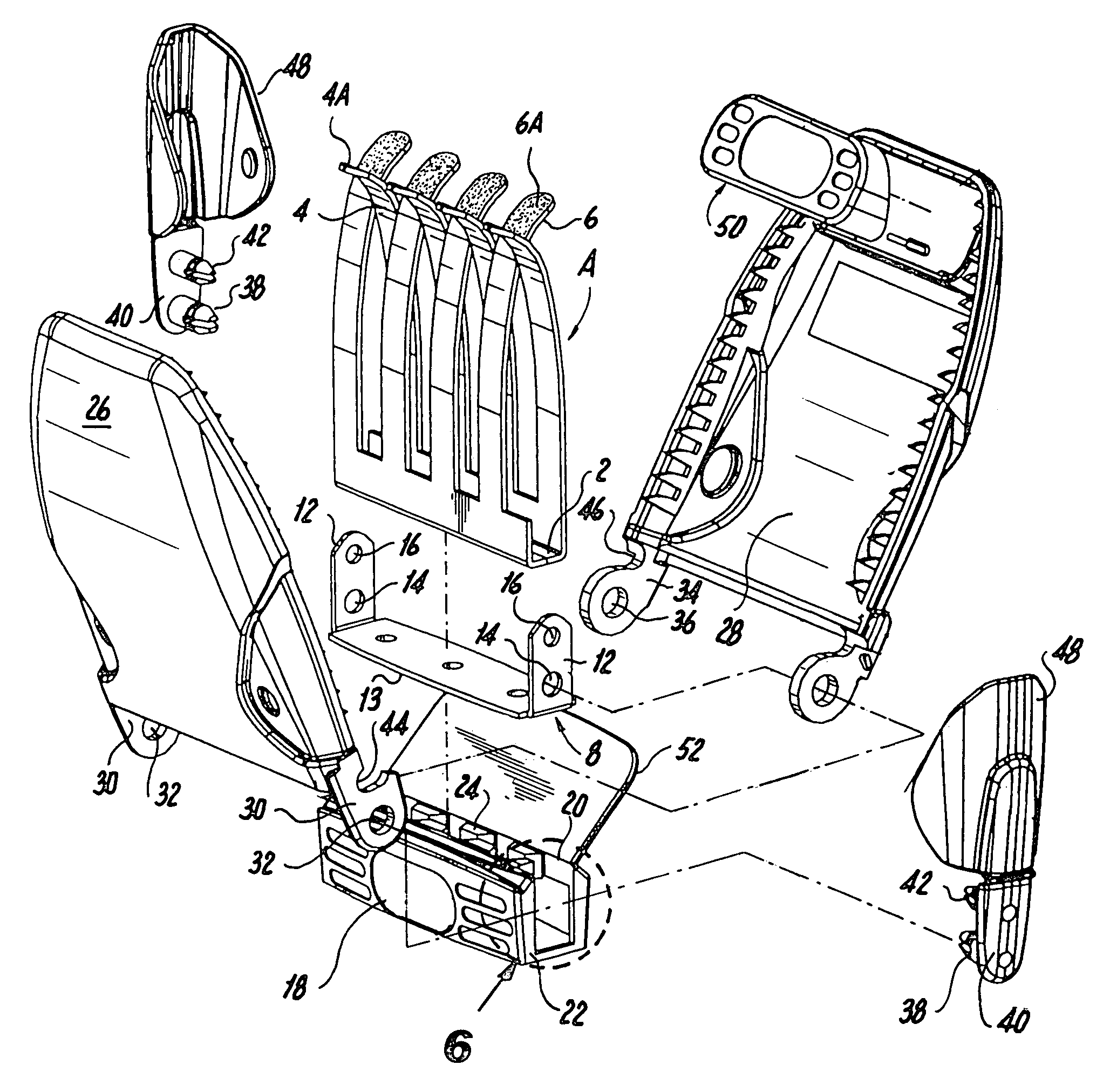

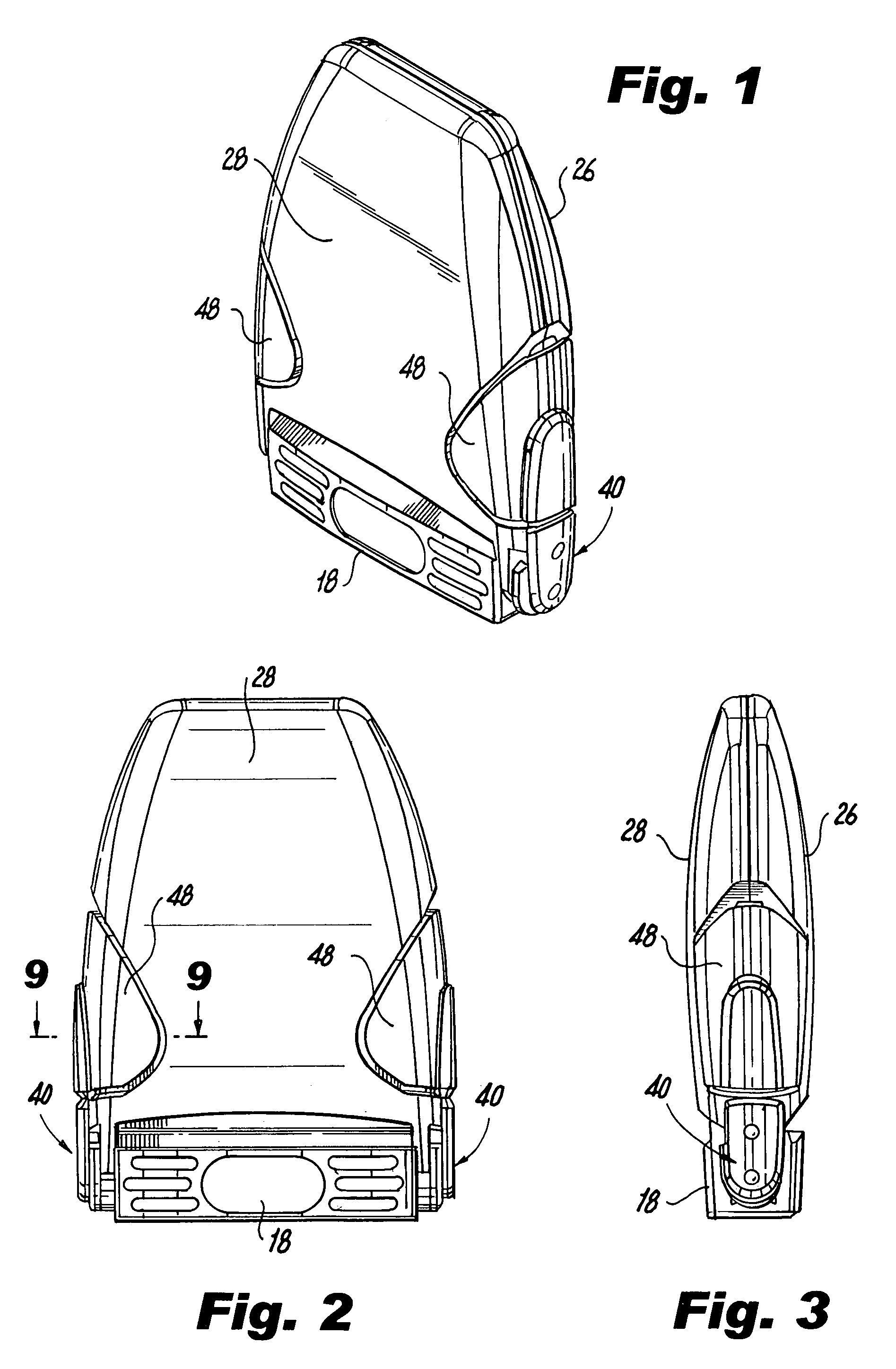

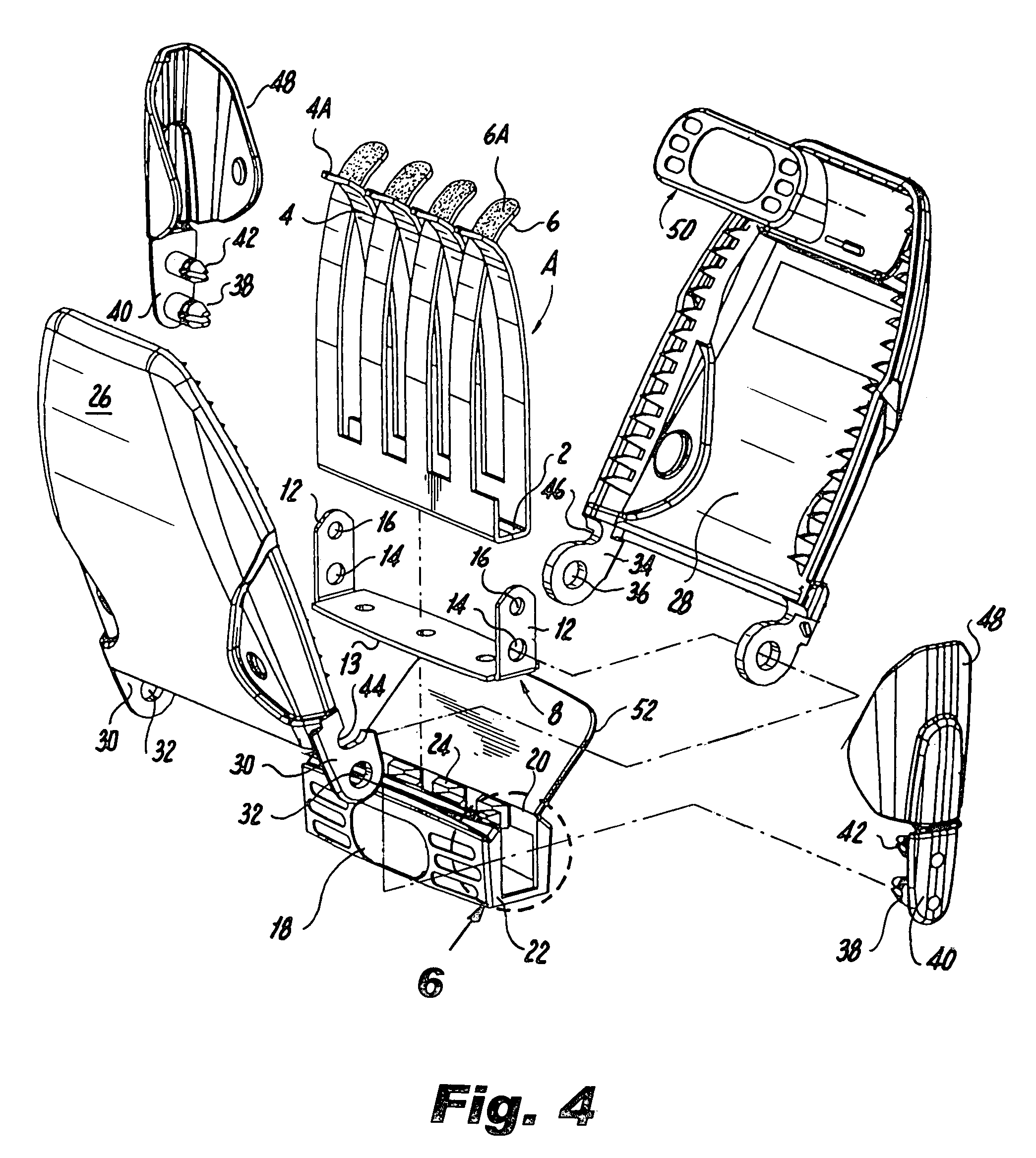

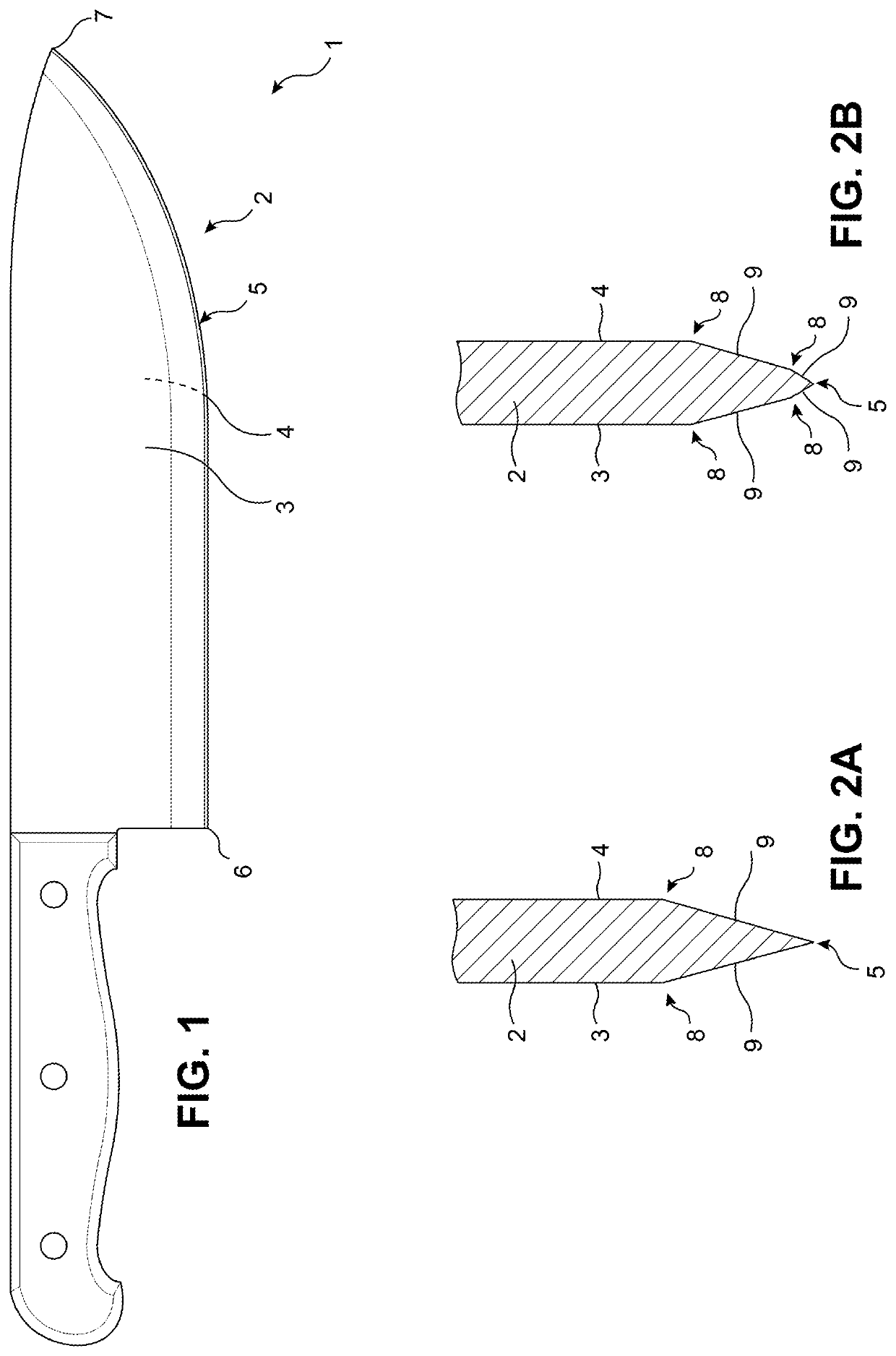

Fixed blade knife

InactiveUS20060080840A1Easy to disassembleThrusting weaponsWeapon componentsKnife sharpenerEngineering

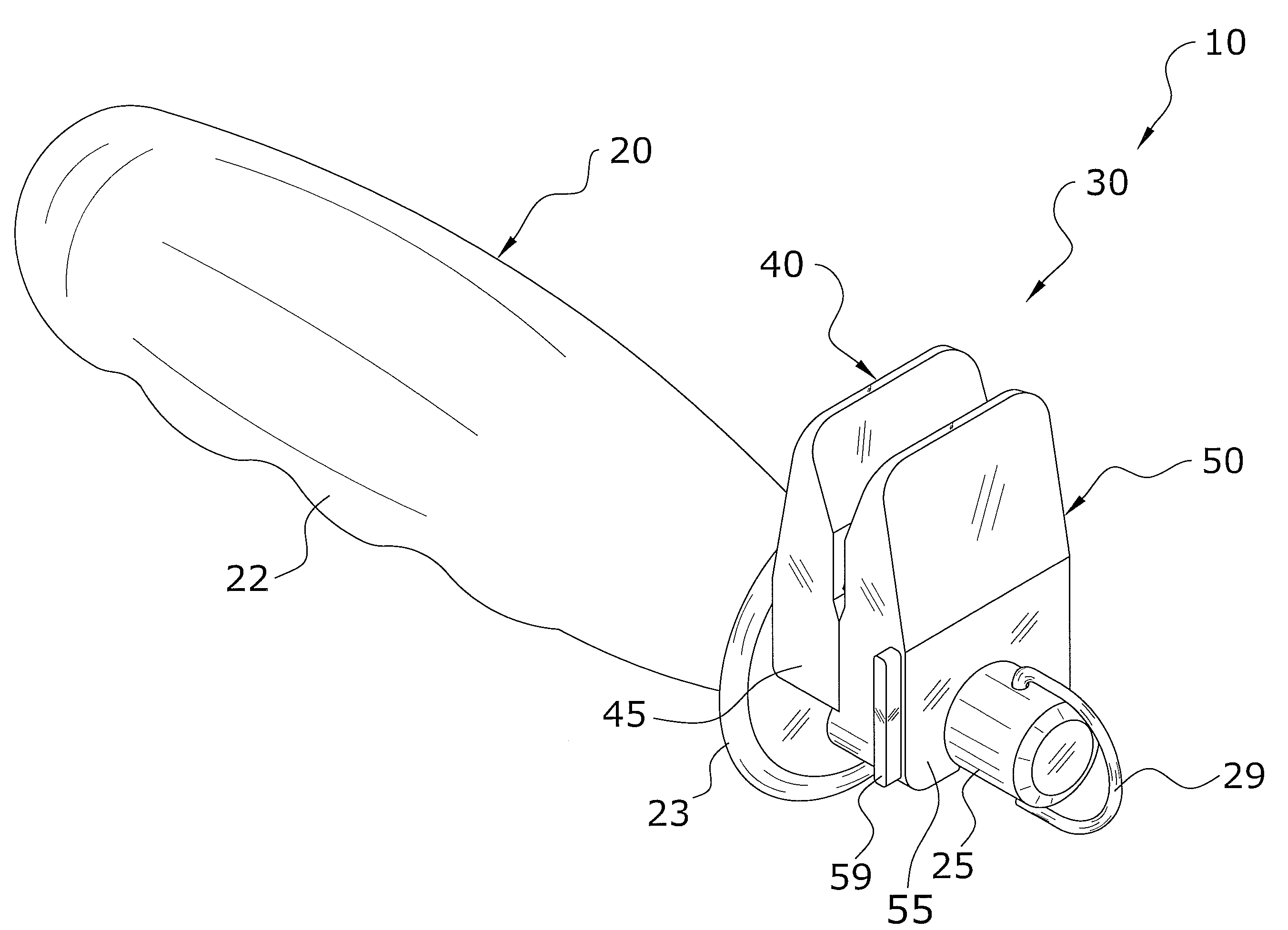

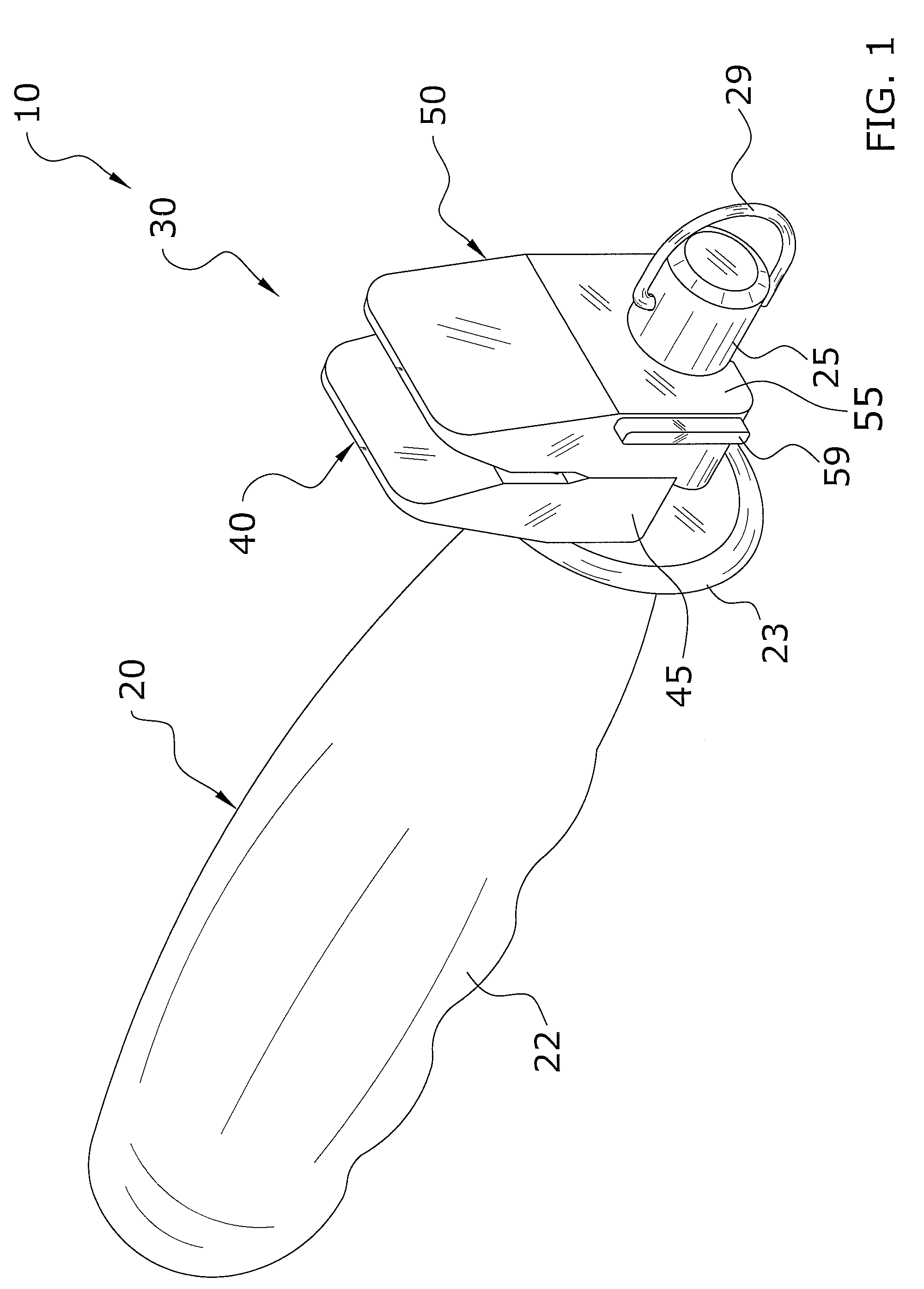

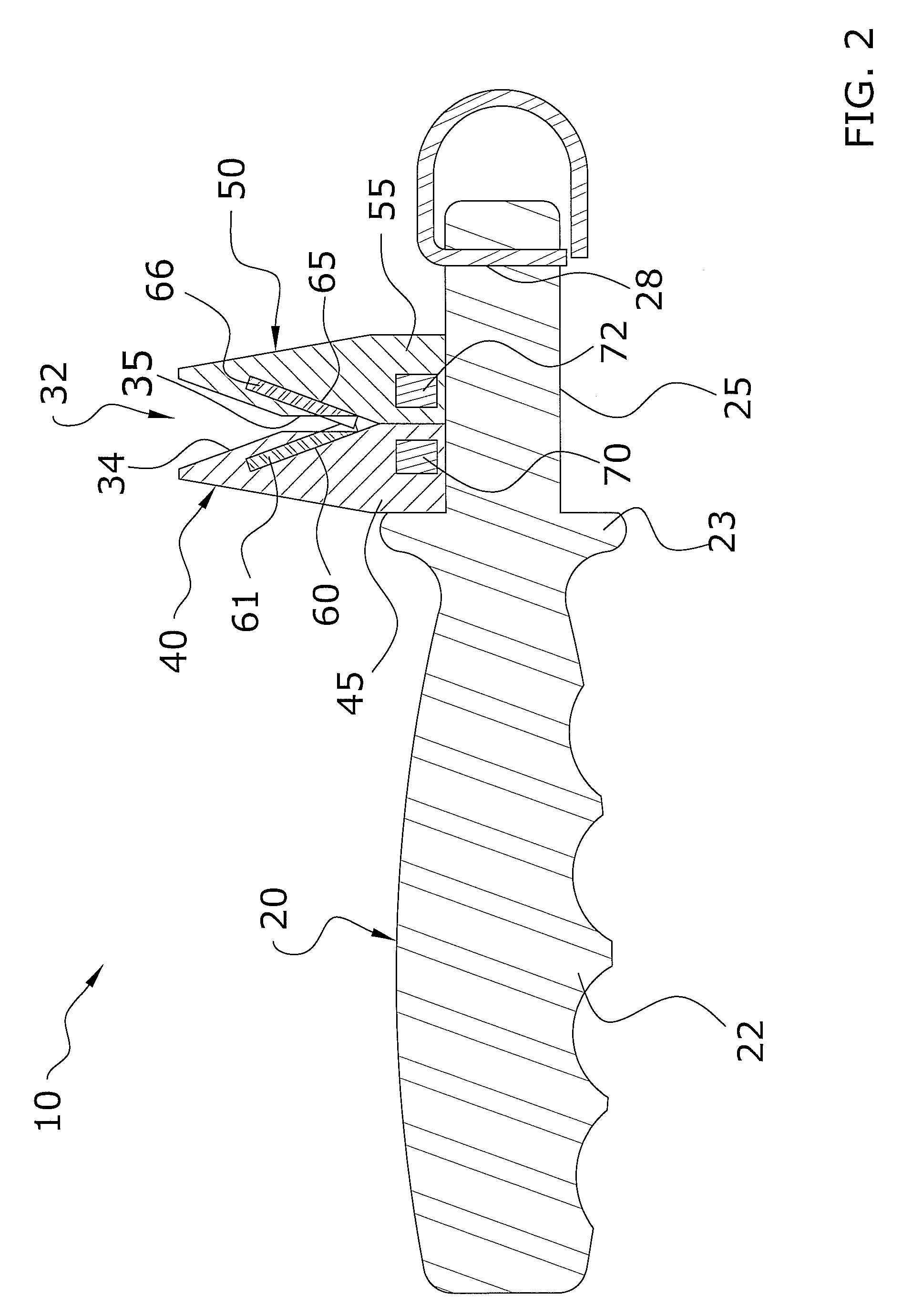

A fixed blade knife, includes a handle, and a blade, coupled to the handle. The blade has a tang received within the handle. A plurality of lashing points defined by passages extending through both the handle and the tang are provided. The knife may be carried in a sheath with a knife sharpener removably coupled to the sheath.

Owner:OY FISKARS AB

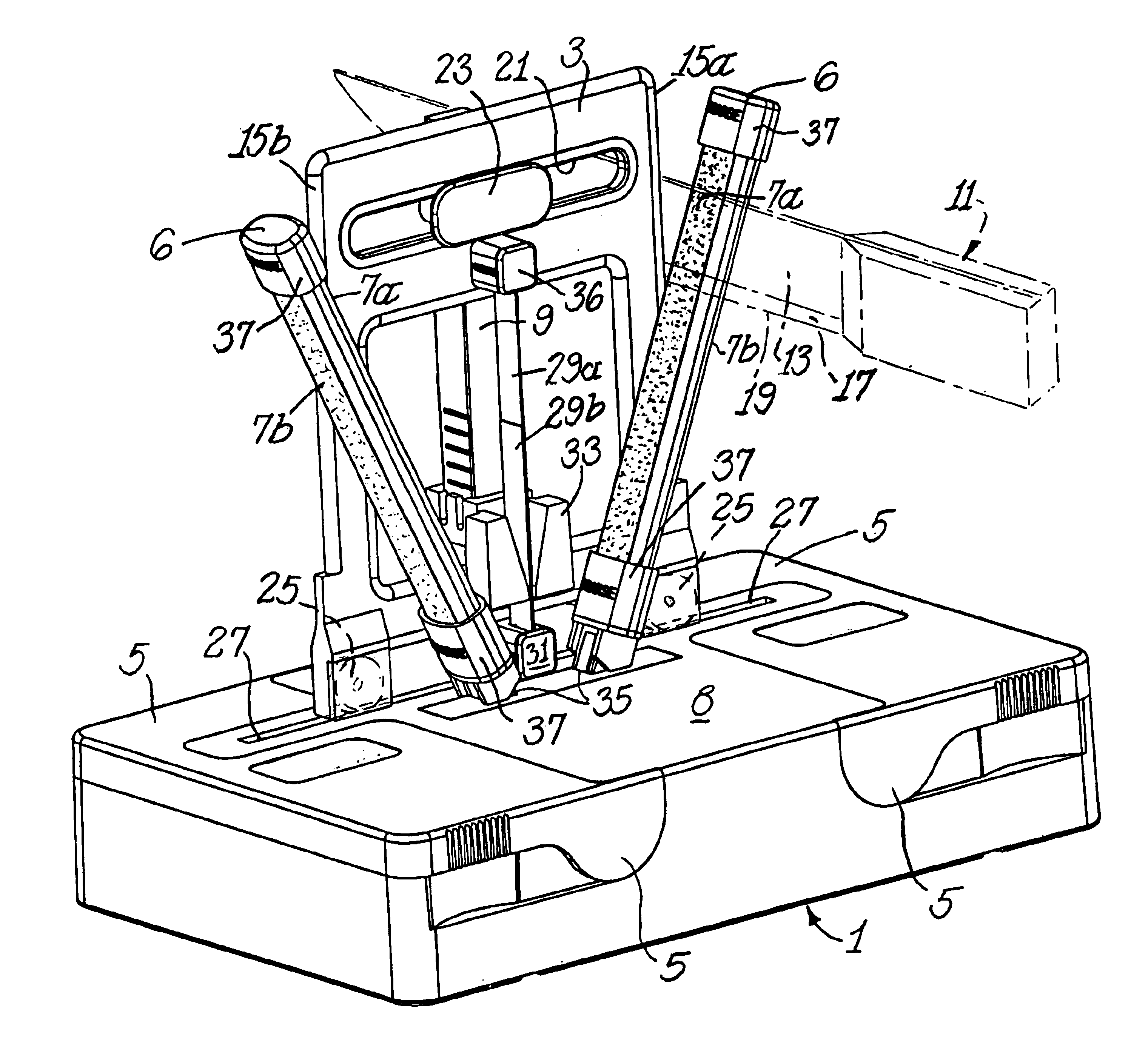

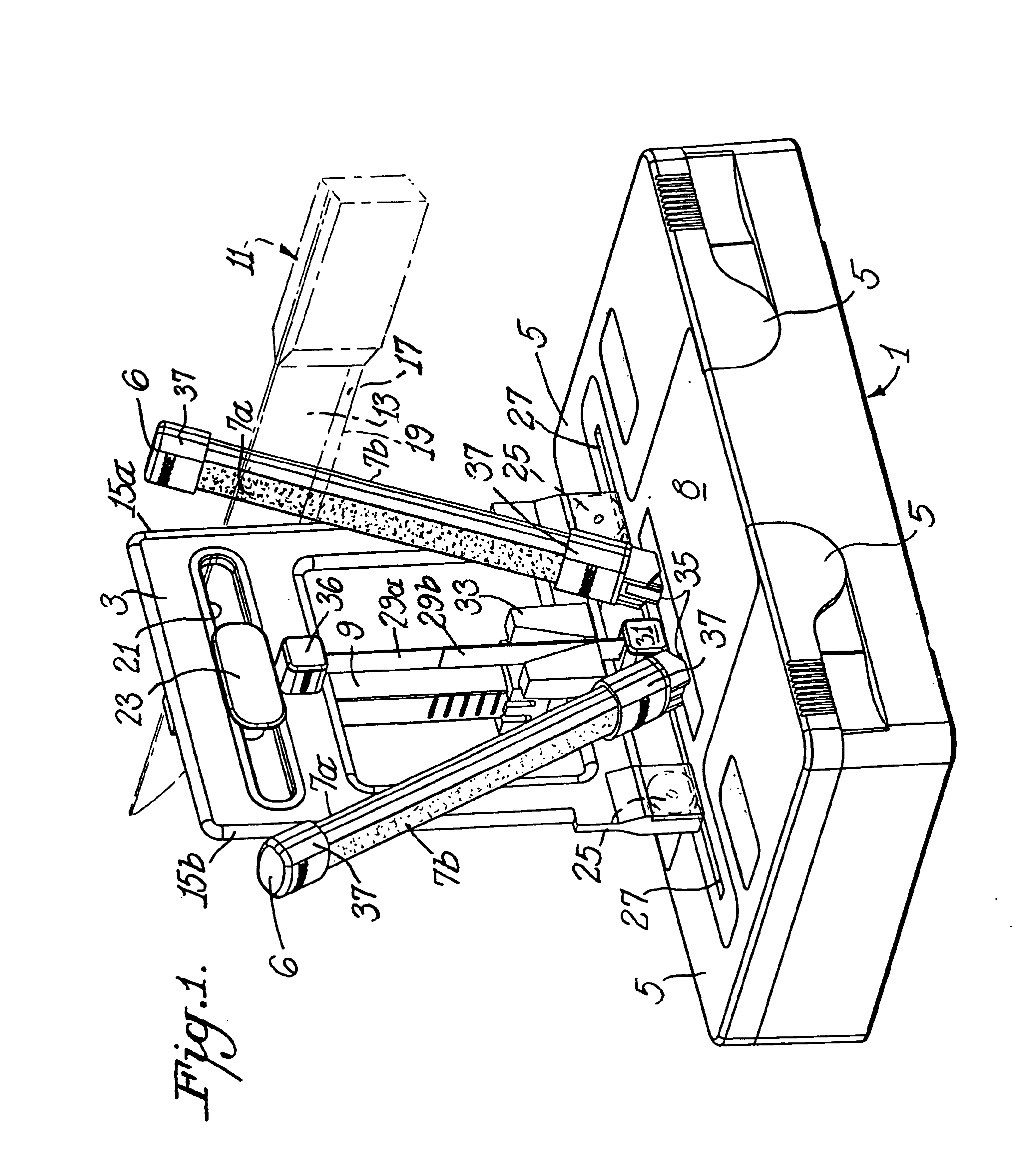

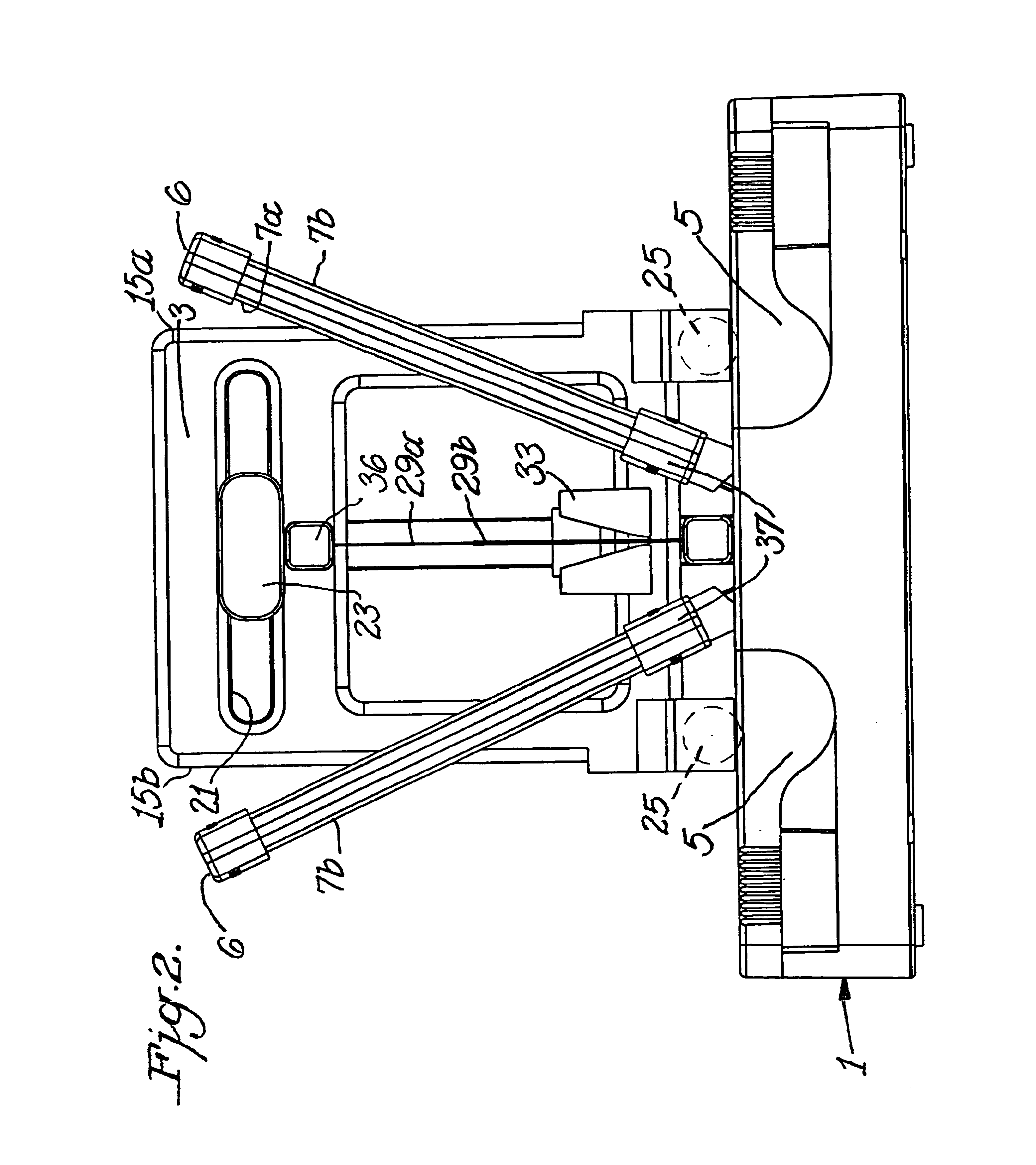

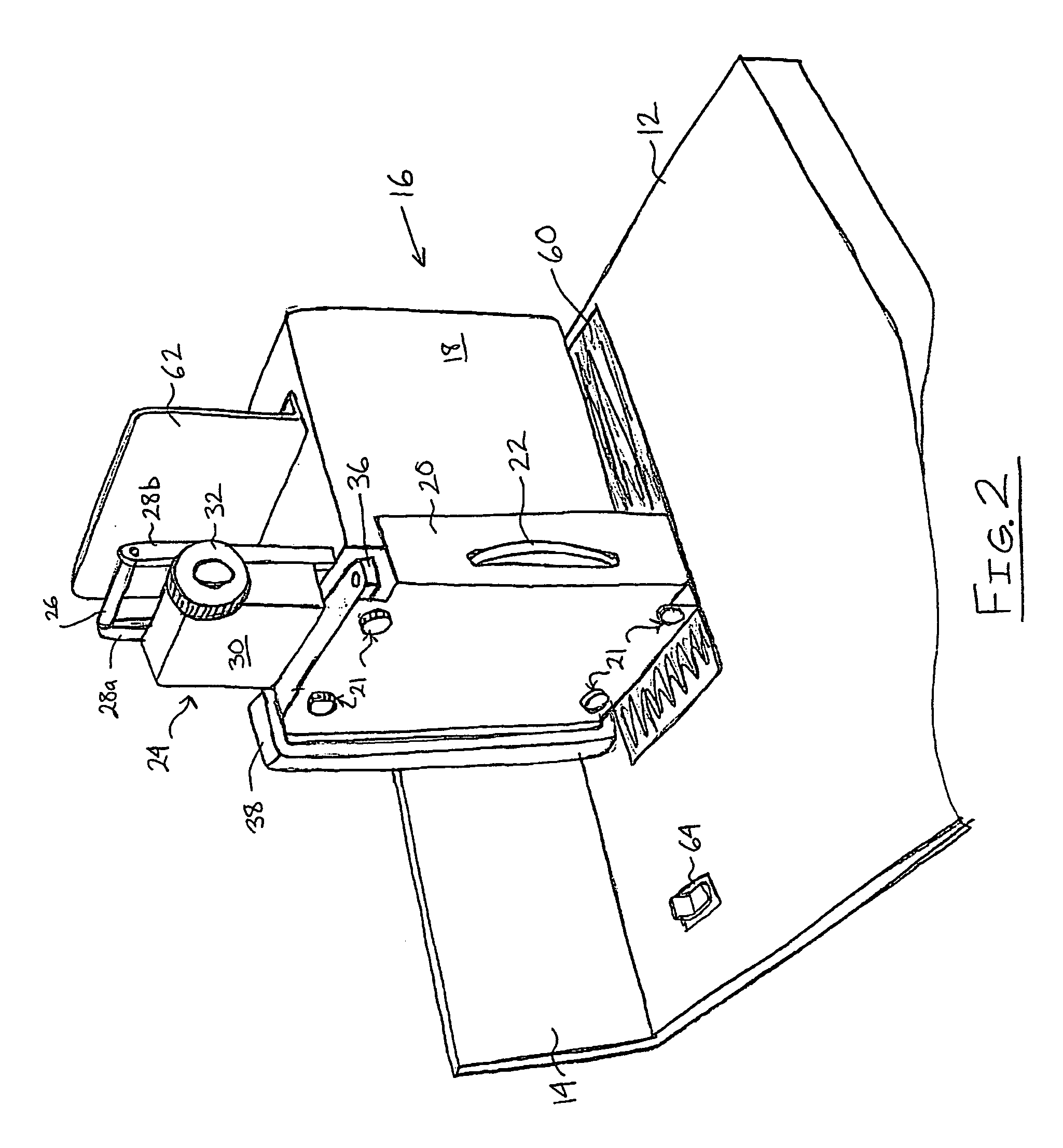

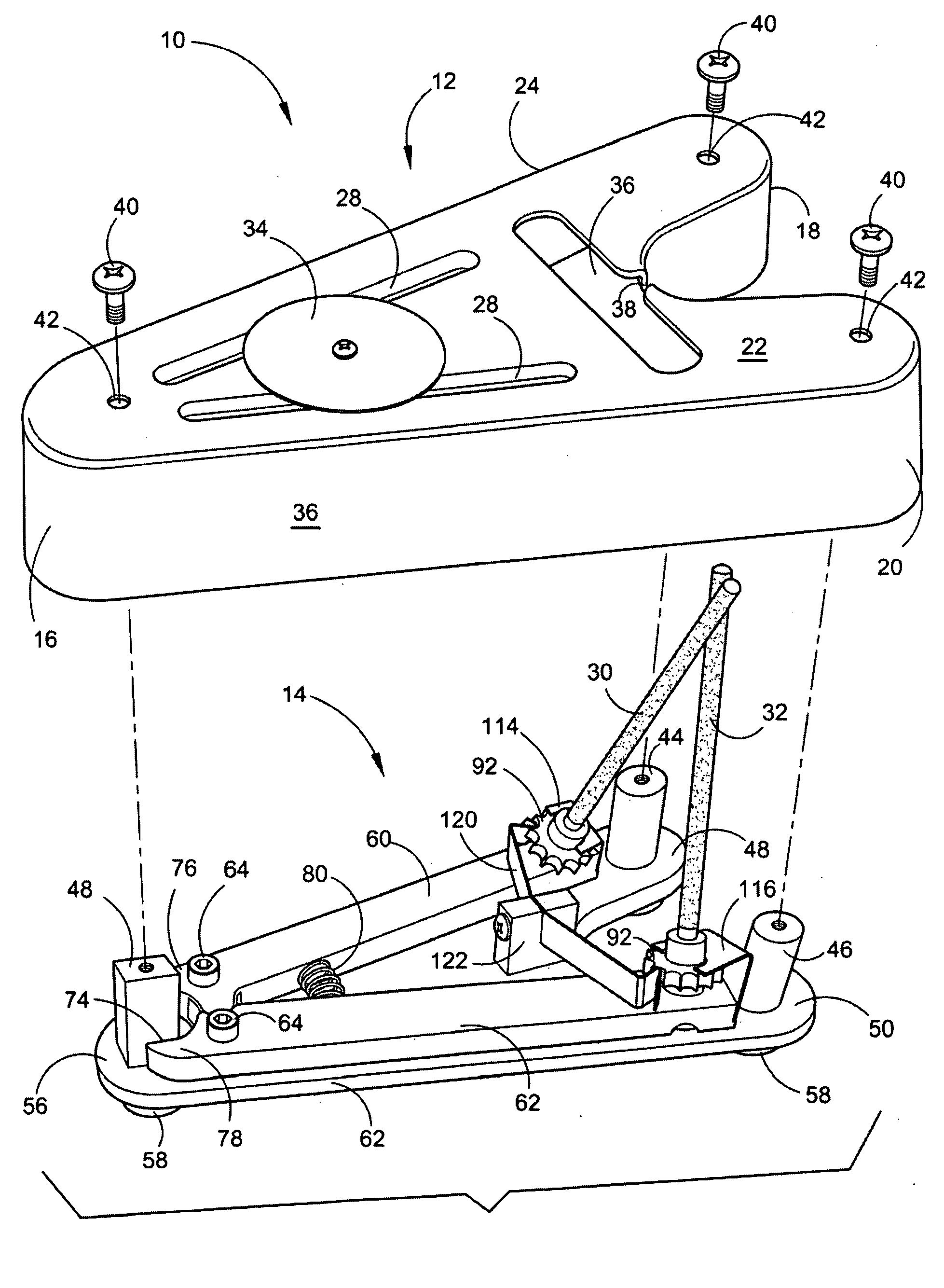

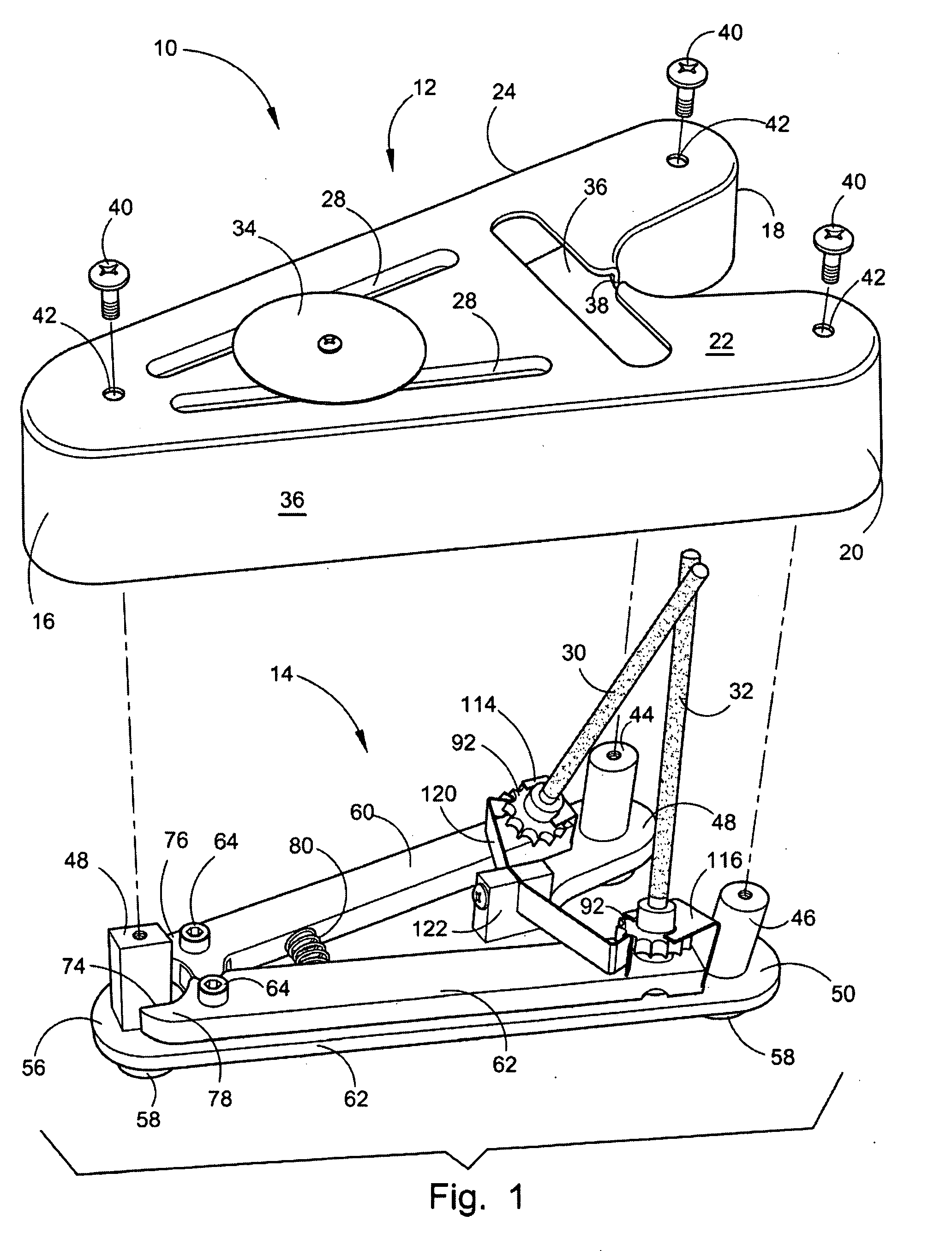

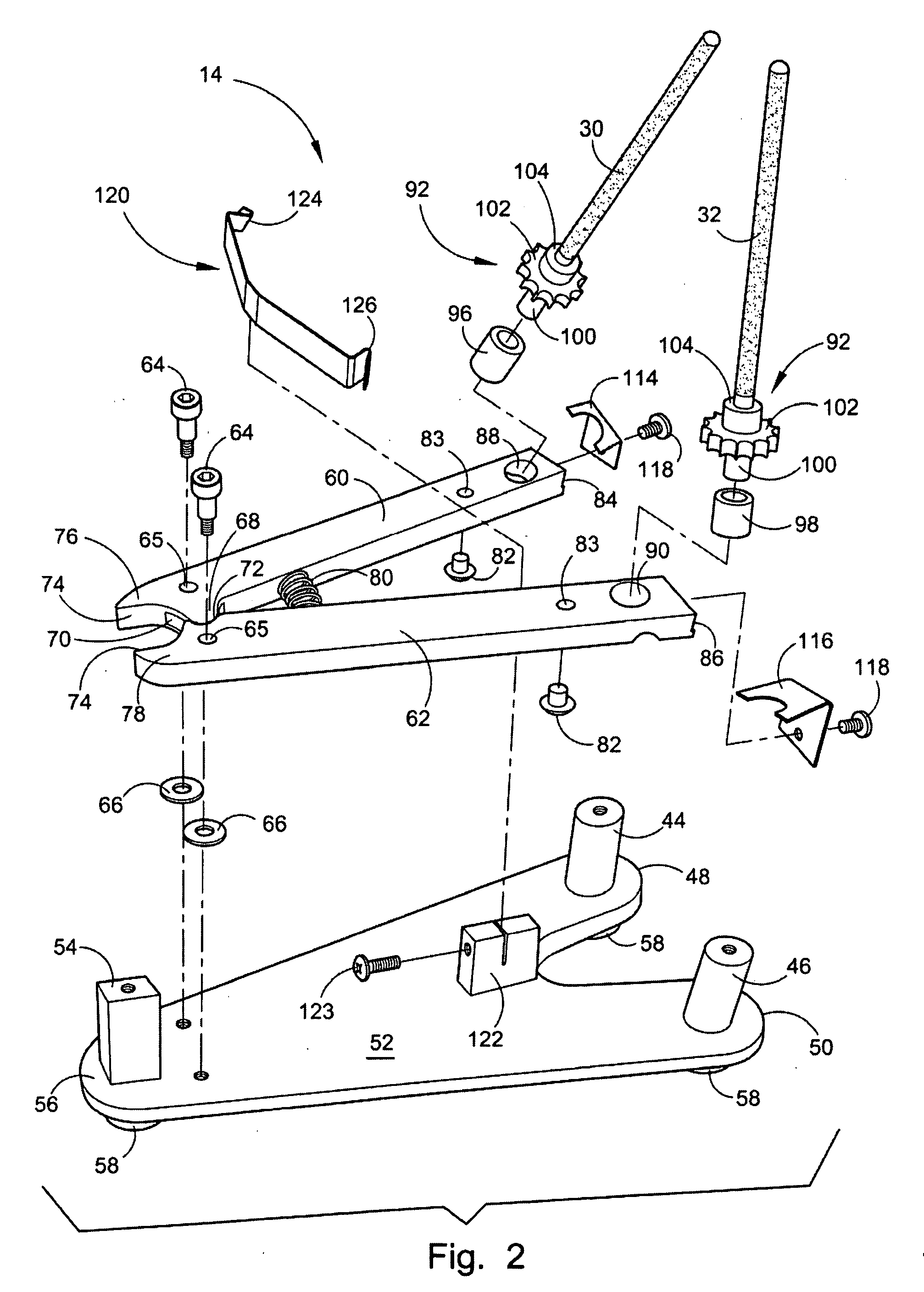

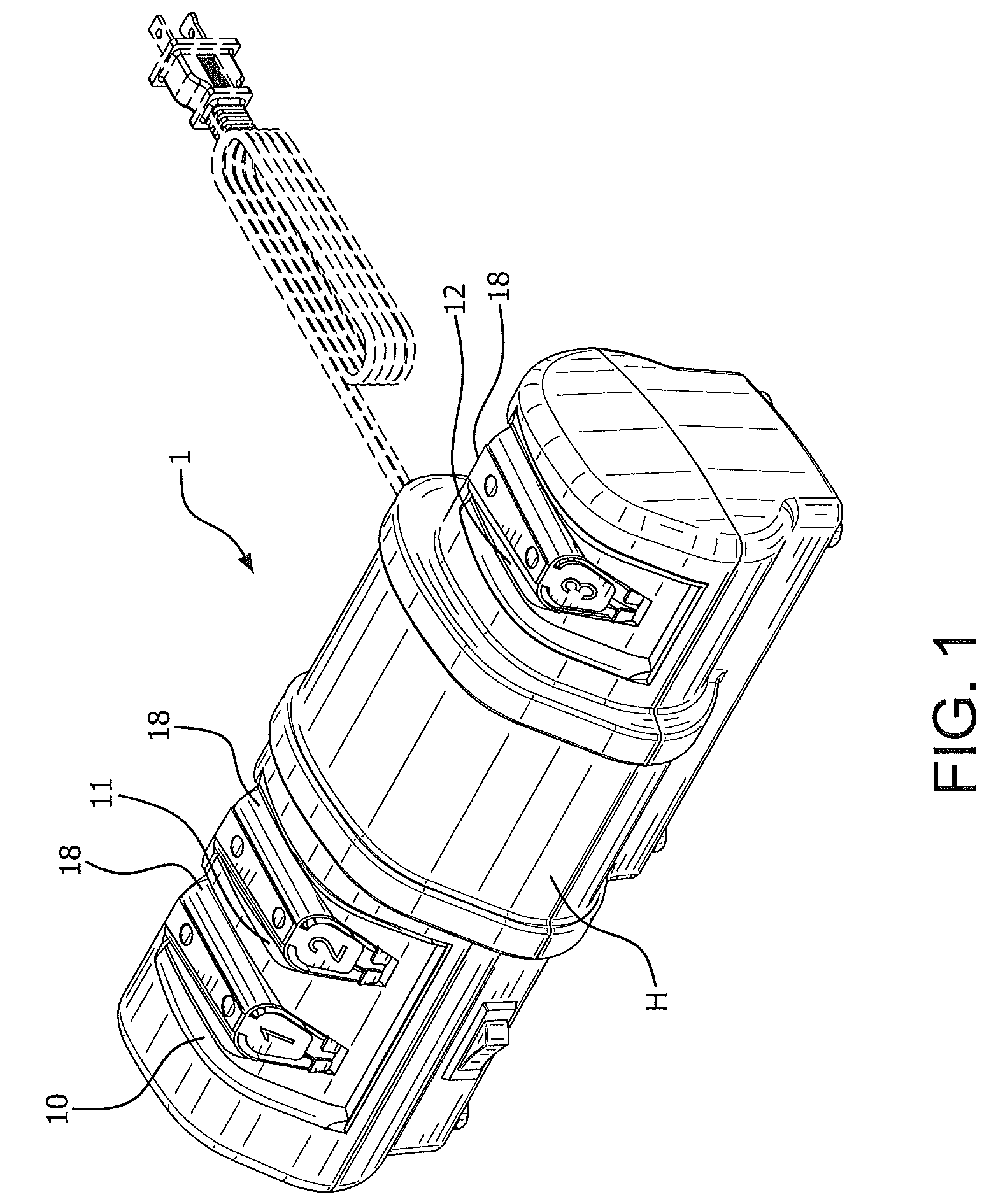

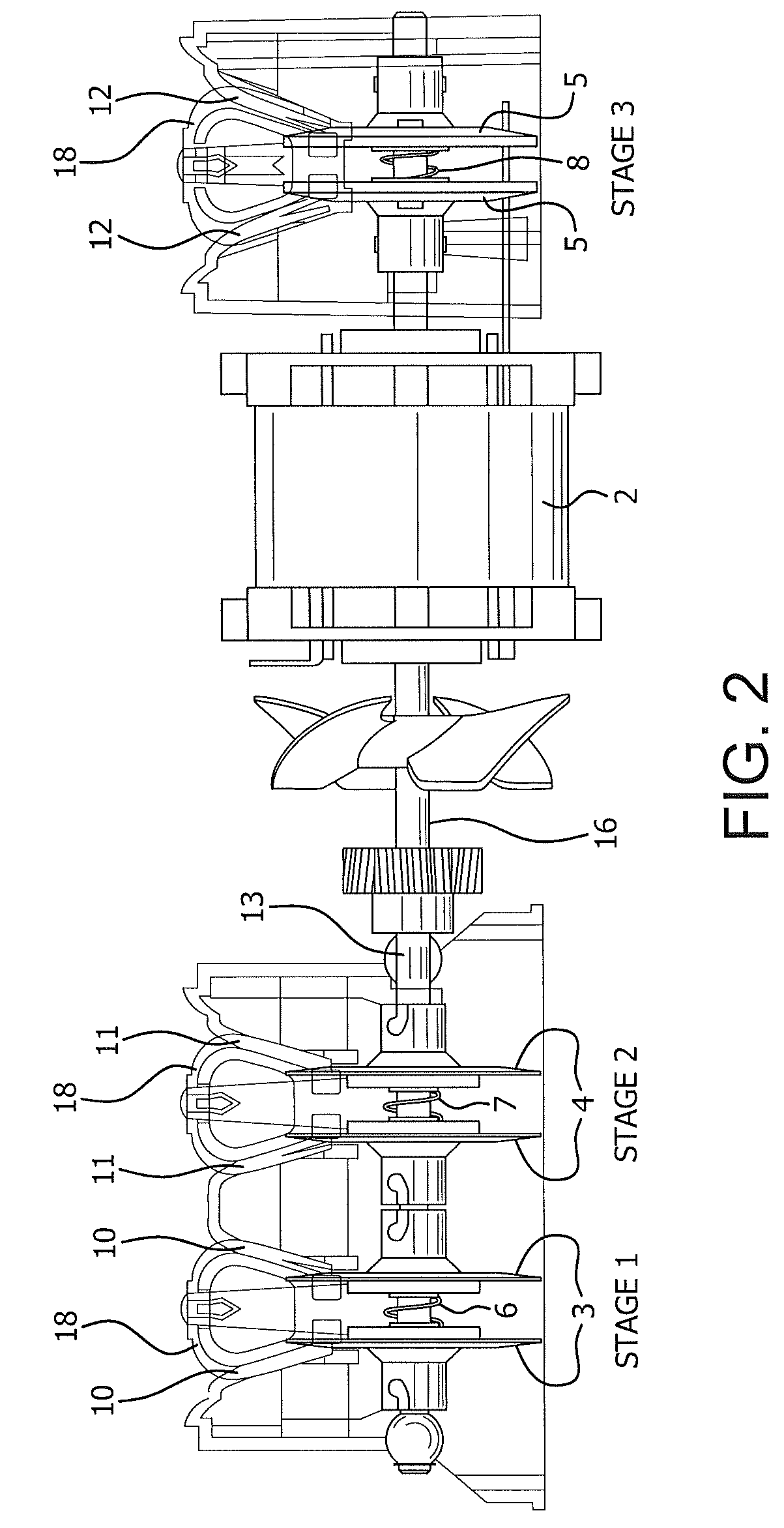

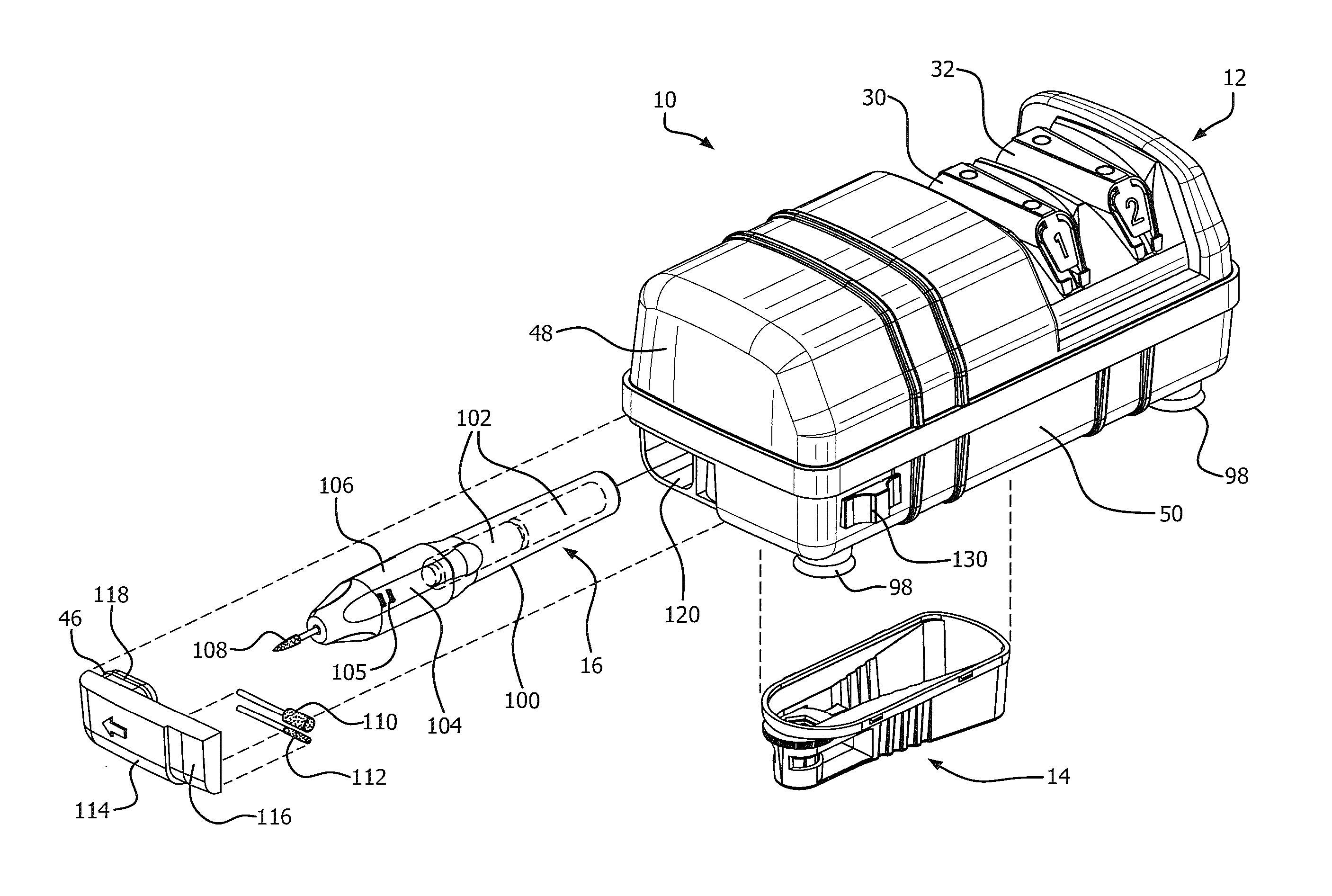

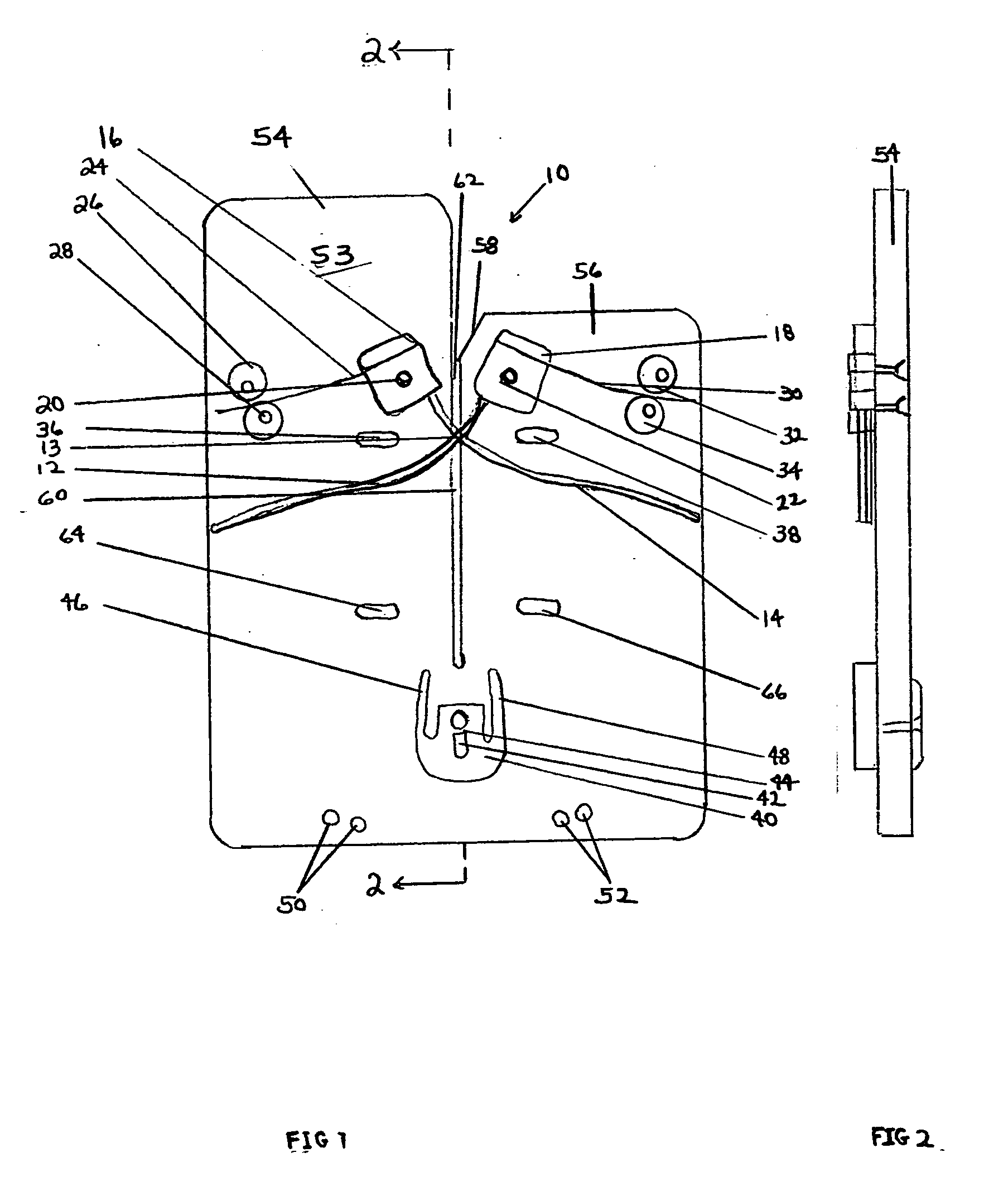

Portable skate sharpener

A skate sharpening device is provided which allows a grinding device to rotate with respect to a working surface of the device in both a cross grind configuration and a finish grind configuration. The grinding device pivots about a pin and is guided by a threaded stud protruding through an arcuate slot and securable using a flared, hand operated nut. A slidable rack attached to the grinding device is moveable in fore and aft directions relative thereto. A dressing tool may be attached to the rack and its forward position is governed by an actuating system. The actuating system allows a user to selectively inhibit forward movement of the rack to position the dressing tool at a suitable position to allow a dressing bit to contact a grinding wheel attached to and powered by the grinding device to dress the grinding wheel.

Owner:GUSPRO

Knife sharpener

InactiveUS7172500B1Easy to useExtend your lifeAgriculture tools and machinesCutting toolsKnife sharpenerEngineering

A knife sharpener has a housing, a base, a sharpening device and an adjustable device. The housing has a case, a cavity and a slot. The cavity is defined in the case and the slot is defined in the case and communicates with the cavity. The base is mounted on the housing and has a base board and two side walls formed on the base board. The sharpening device is movable mounted on the base and is received inside the housing. The sharpening device has two sharpening arms with sharpening rods. The adjustable device is mounted on the sharpening device mounted between the two sharpening arms. When the knife sharpener is used, the adjustable device is rotated to change the cross-position of the sharpening device. Therefore, a knife may be sharpened at a different site on the sharpening rods for prolonging the life span of the knife sharpener.

Owner:WU WEN CHIU

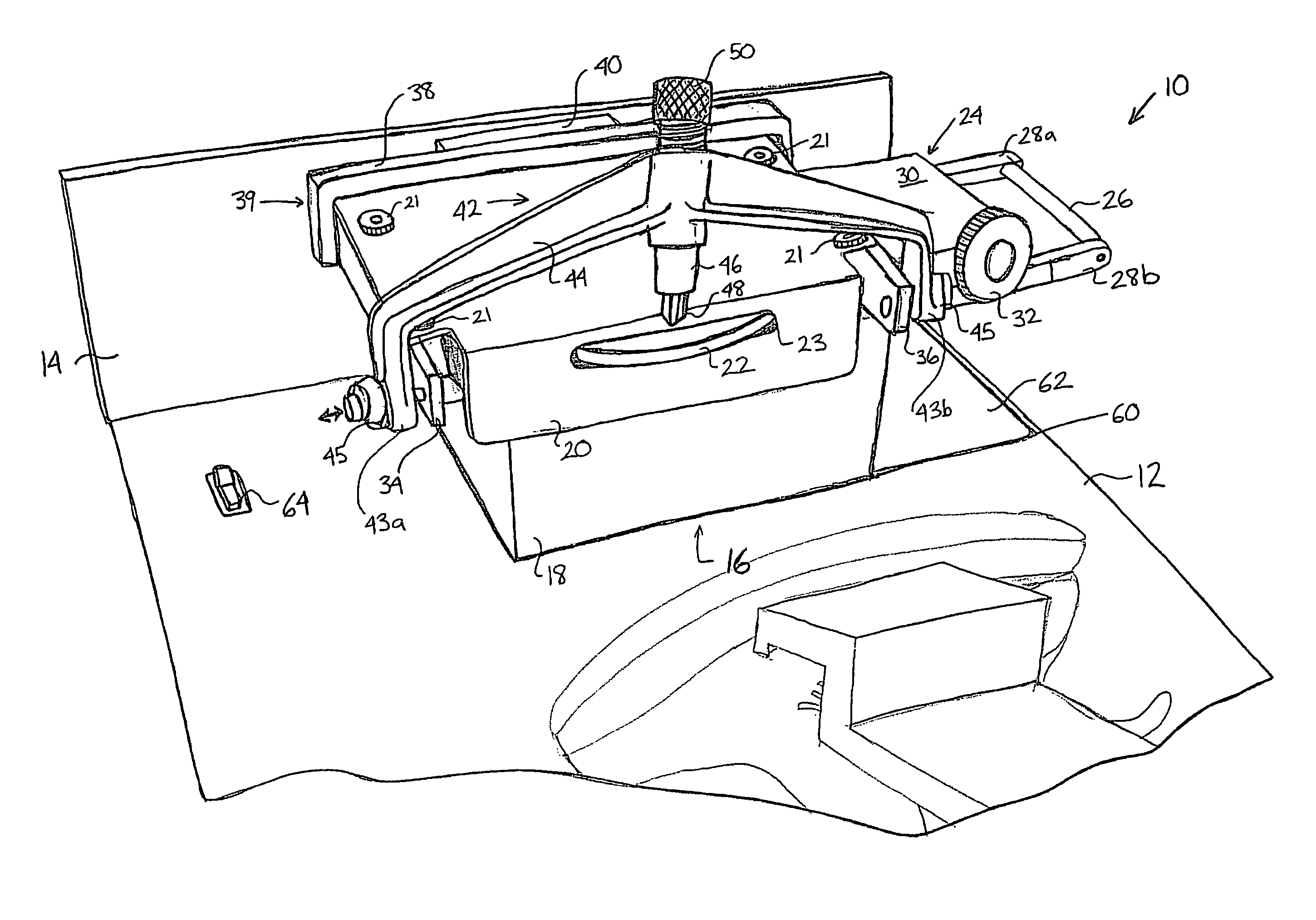

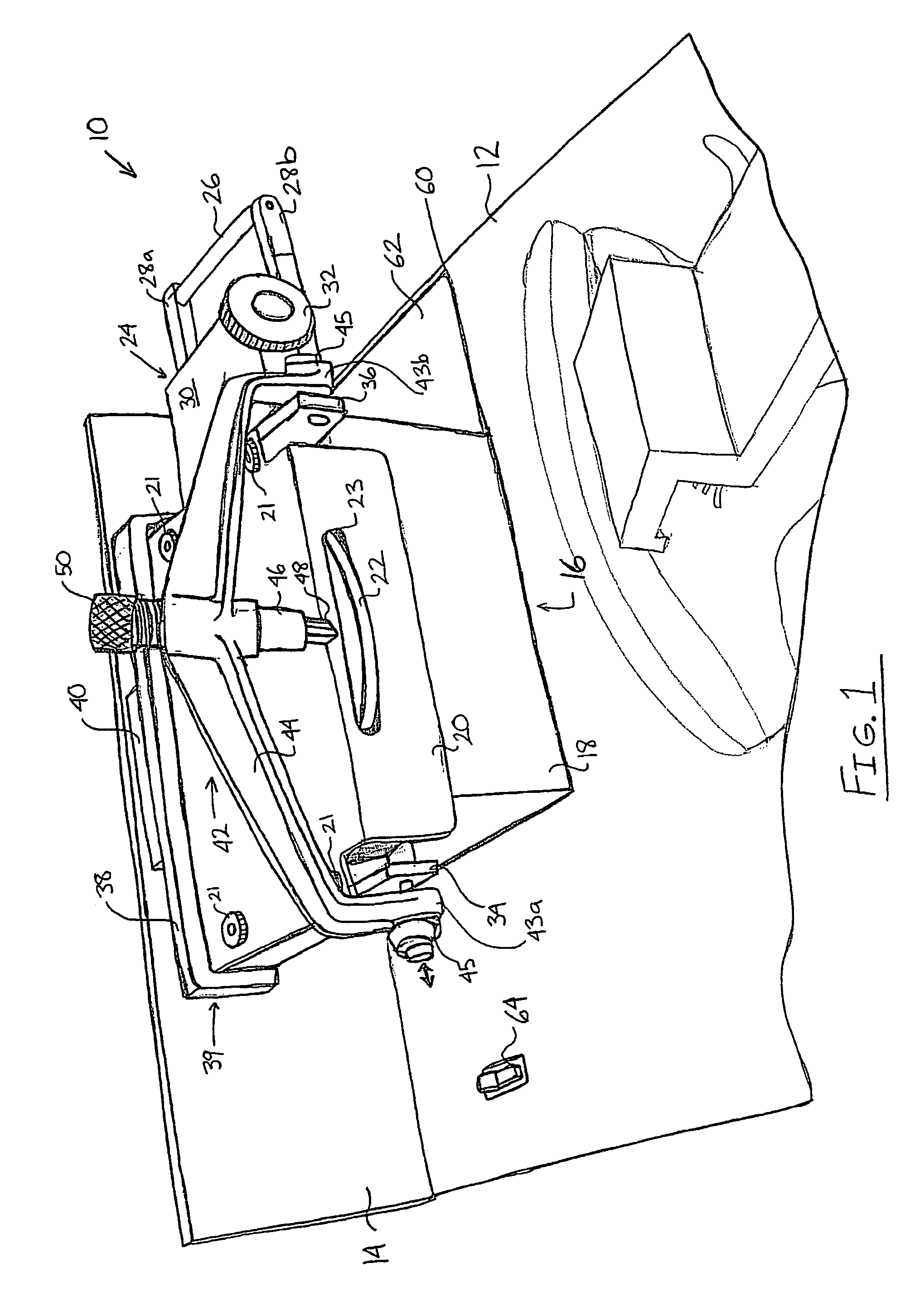

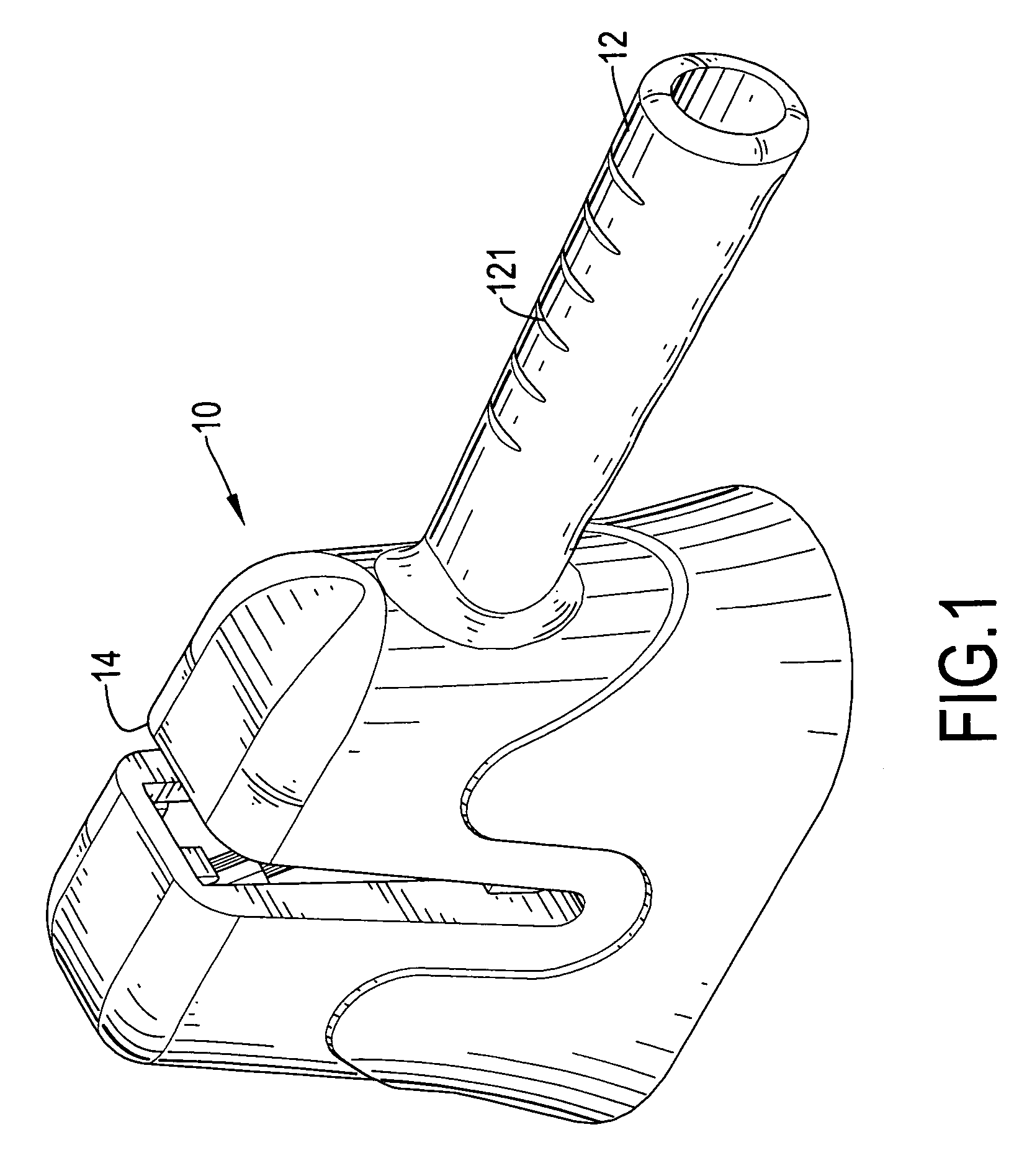

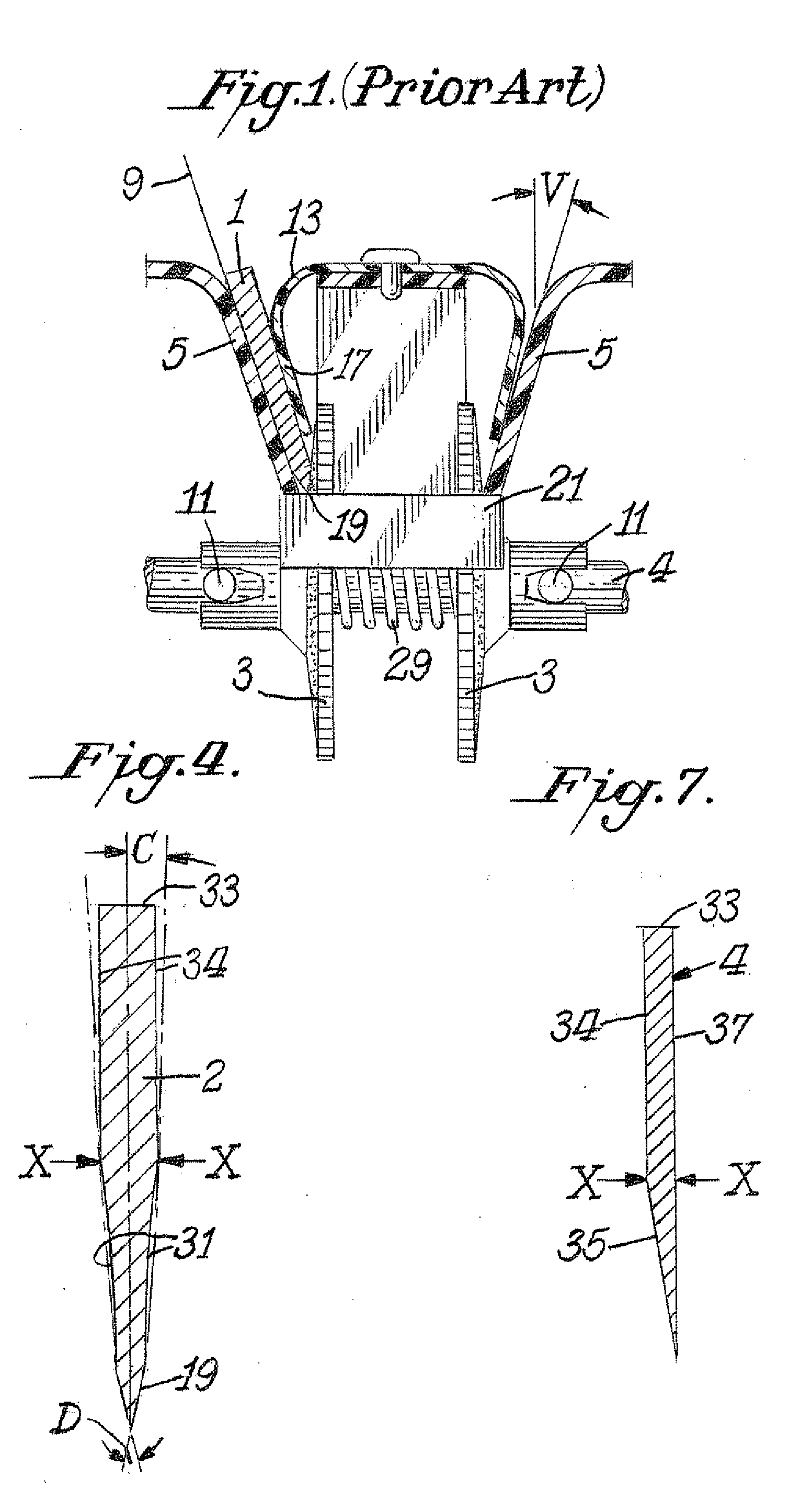

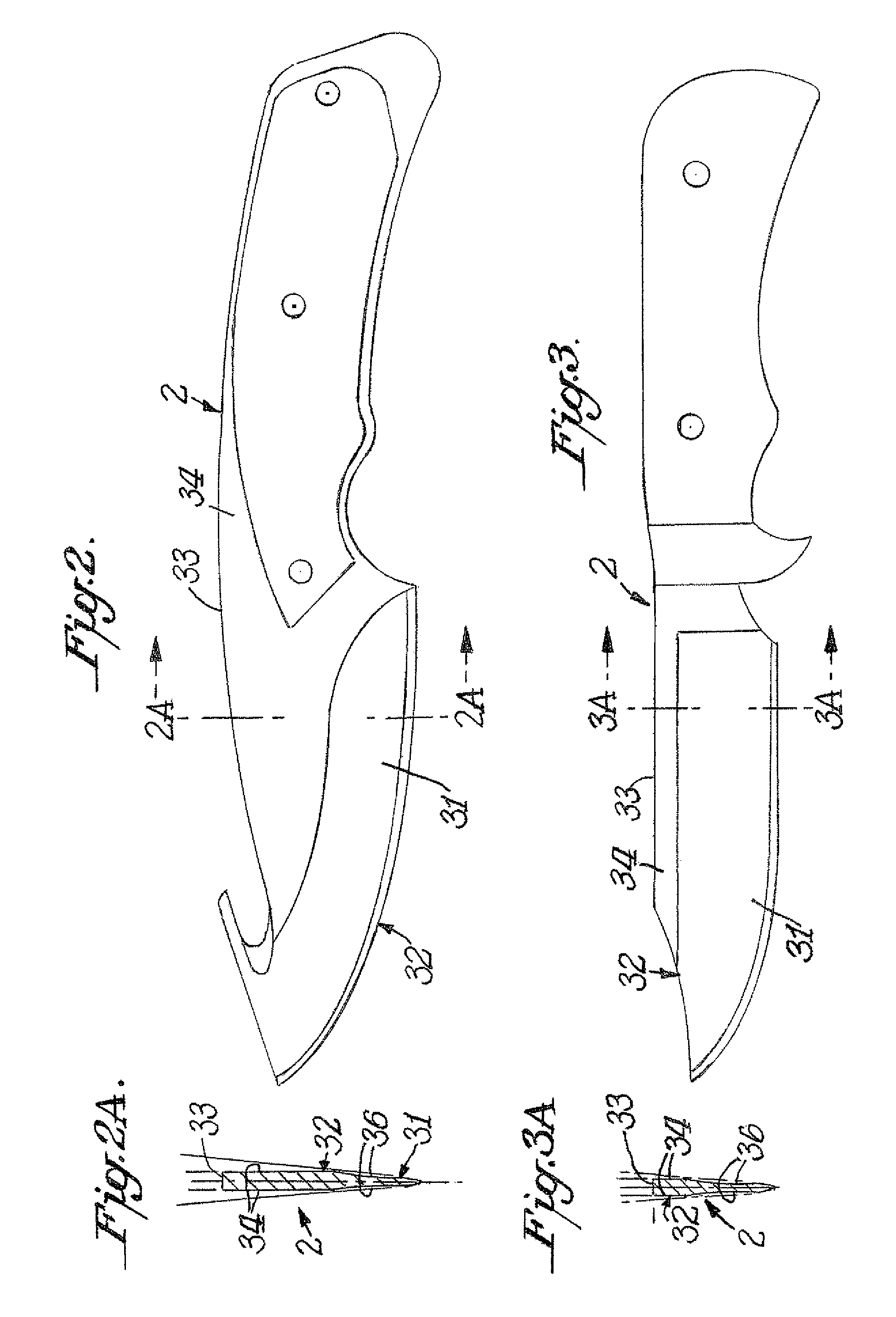

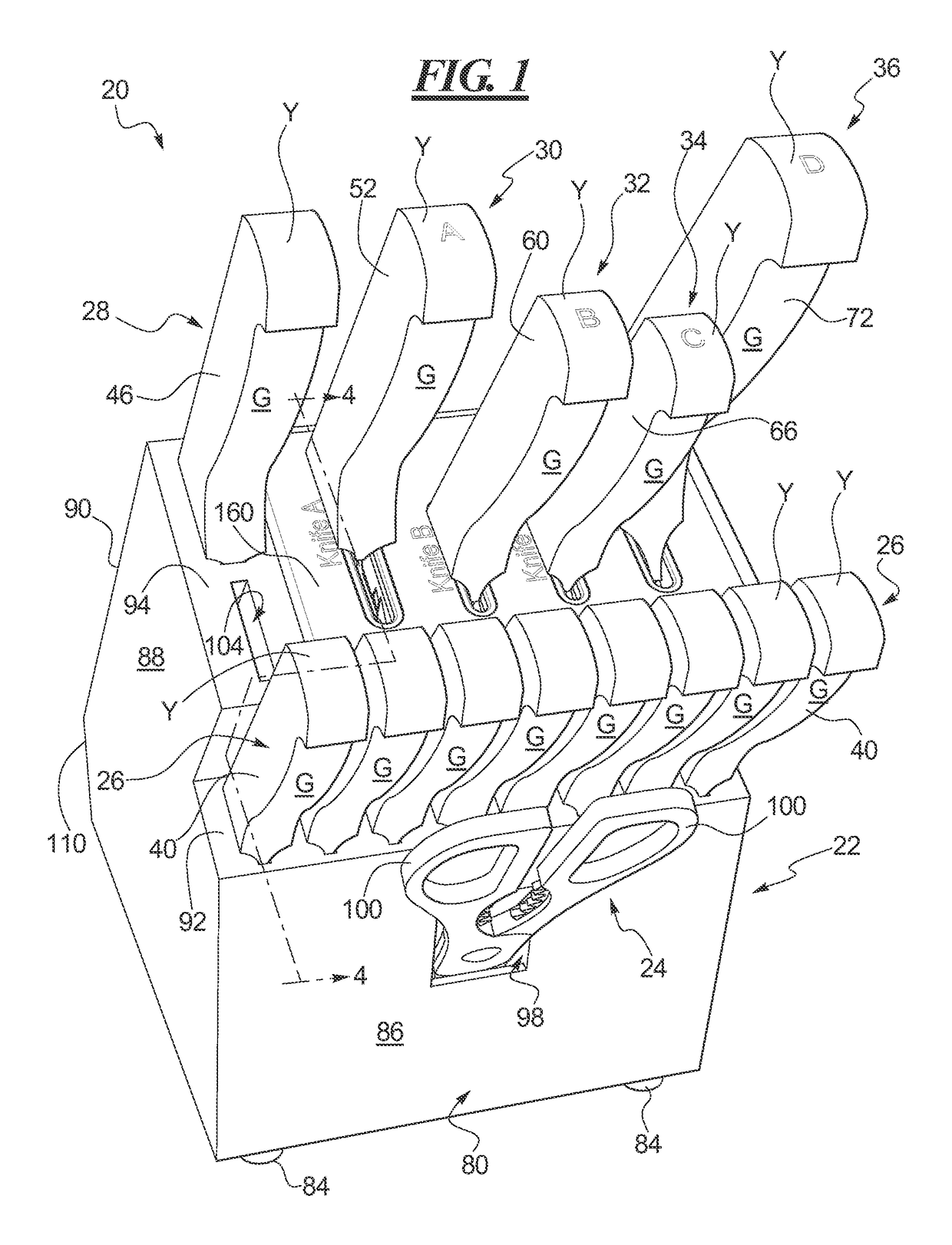

Precision sharpener for hunting and asian knives

ActiveUS20080261494A1Eliminate the problemPrecise alignmentEdge grinding machinesCutting toolsCoated surfaceKnife sharpener

A knife sharpener is provided which is capable of precision sharpening of hunting and similar knives that have a first and second blade face, each of which terminates at a facet that meets the corresponding facet to create the knife edge. At least the first of the blade faces has a lower distinct planar or concave section adjacent the edge facet with the lower planar or concave section of the face being set at an angle to the center line of the blade thickness that is different from the angle of the adjoining upper section of the same blade face located adjacent to the back of the blade. The sharpener includes a sharpening member such as one having an abrasive coated surface. The sharpener also includes a planar angle knife guide surface of a knife guide which is designed for intimate sliding and sustaining contact with the second face of the blade in order to position an edge facet on the first of the faces into precise angular relation with the sharpening surface. The sharpener also includes a knife holding spring that applies force against the first face of the blade predominantly at one or more locations on the lower planar or concave section of the first face that is adjacent to the edge facet being sharpened in order that the lower section adjacent the edge on the second face of the blade is pressured to align with and remain in intimate sliding alignment with the guide surface as the blade edge facet on the first face is being sharpened.

Owner:EDGECRAFT

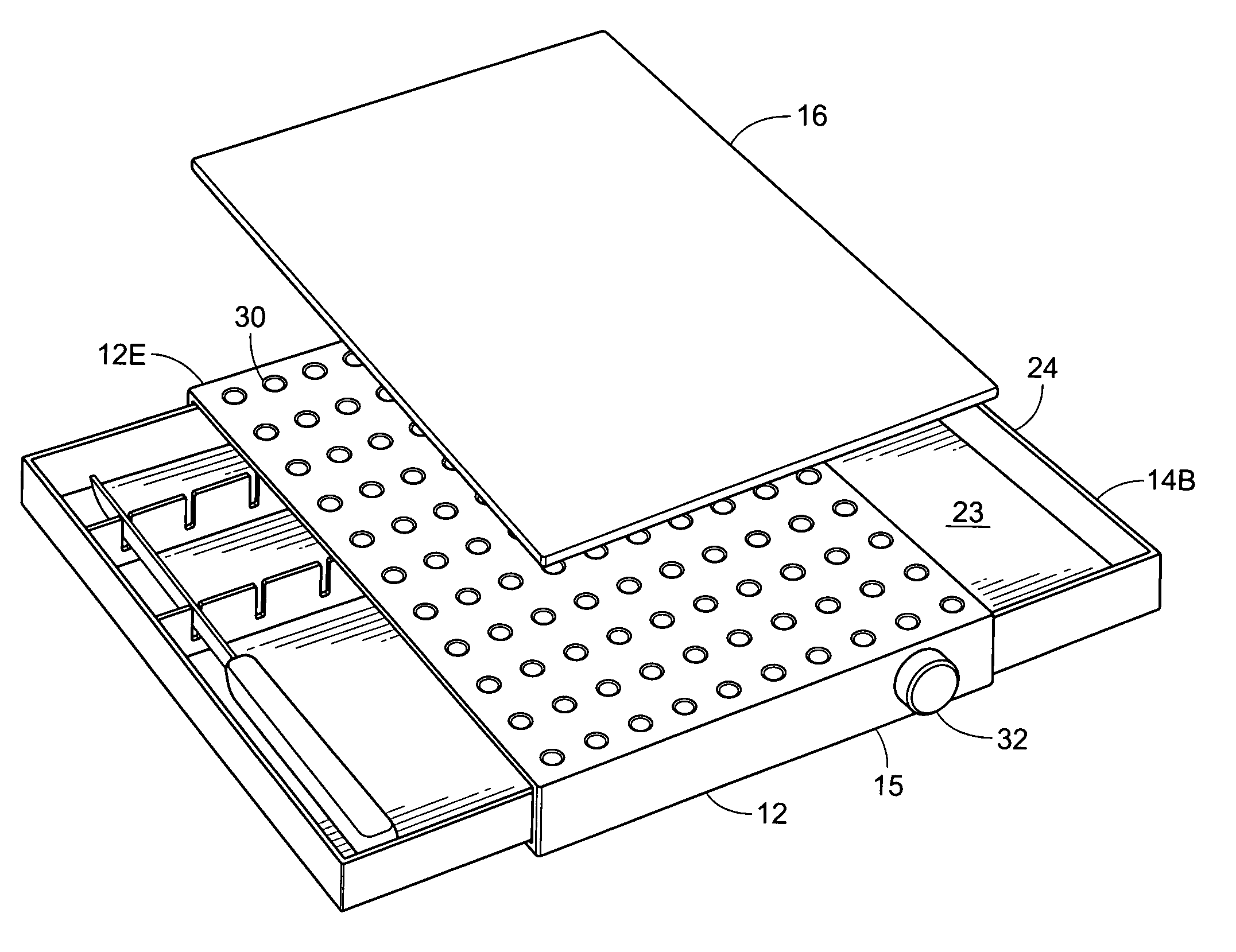

Combination food cutting, storage, and shredder apparatus

InactiveUS7258289B1Safe storageConveniently heldMetal sawing devicesShearing machinesKnife sharpenerEngineering

A combination food cutting, storage and shredder apparatus, having a cutting board and storage box containing a knife drawer and a garbage disposal drawer. A shredder is positioned just above the garbage disposal drawer and just below the cutting board for holding scraps and peelings left over from the cutting board for disposal. The storage box also contains an outwardly extending knife sharpener.

Owner:BUTT MUZAMMAL

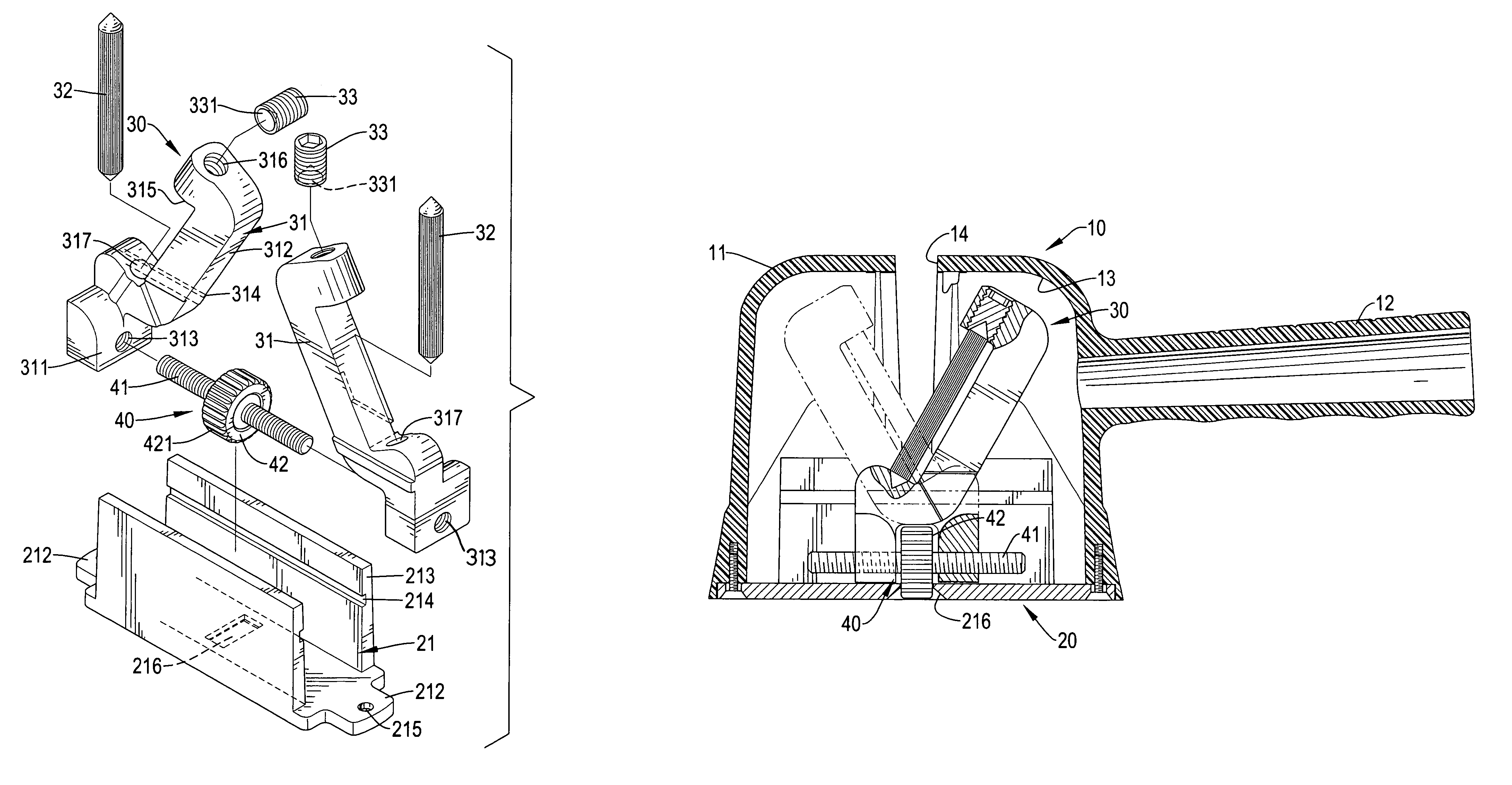

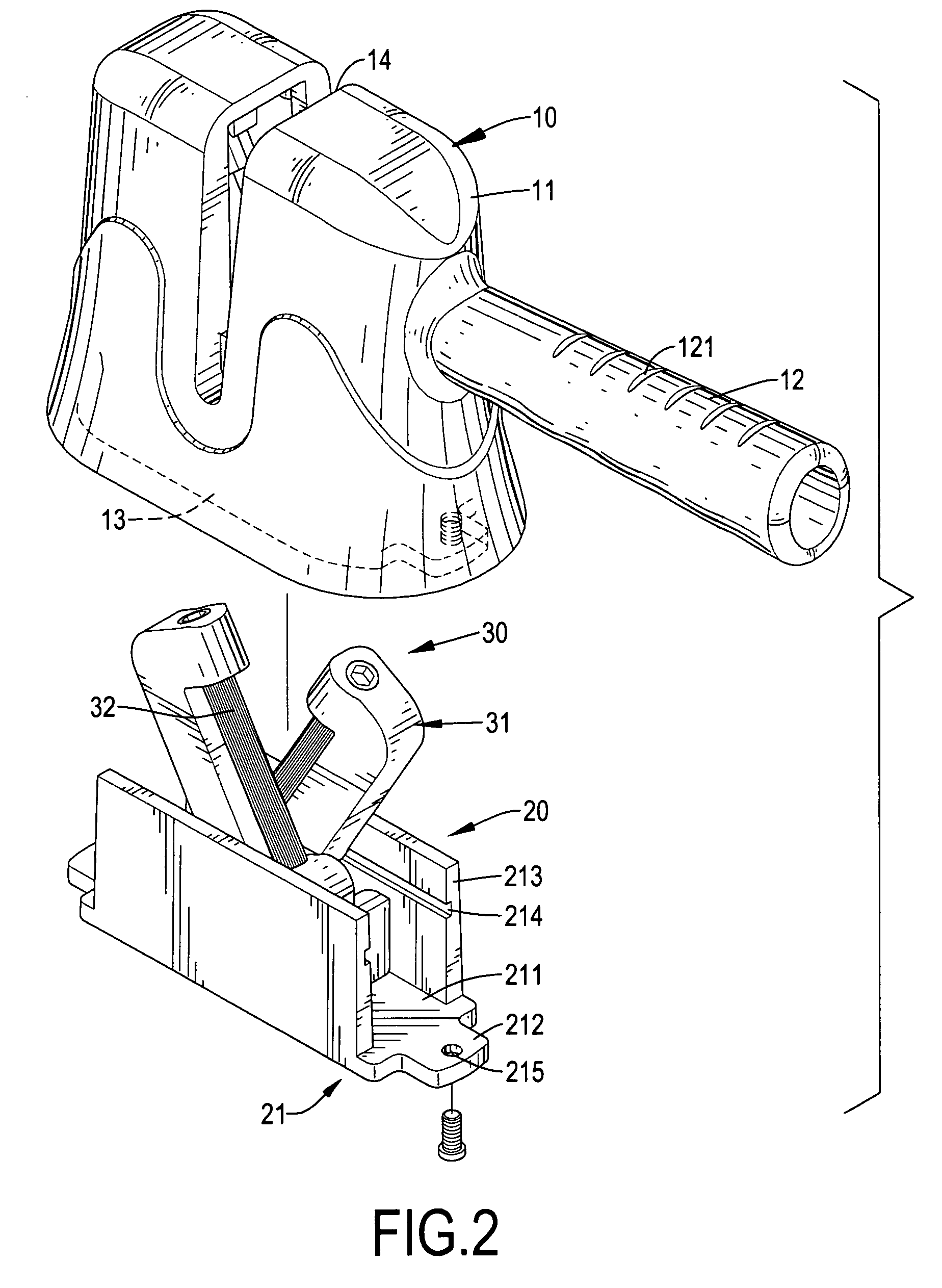

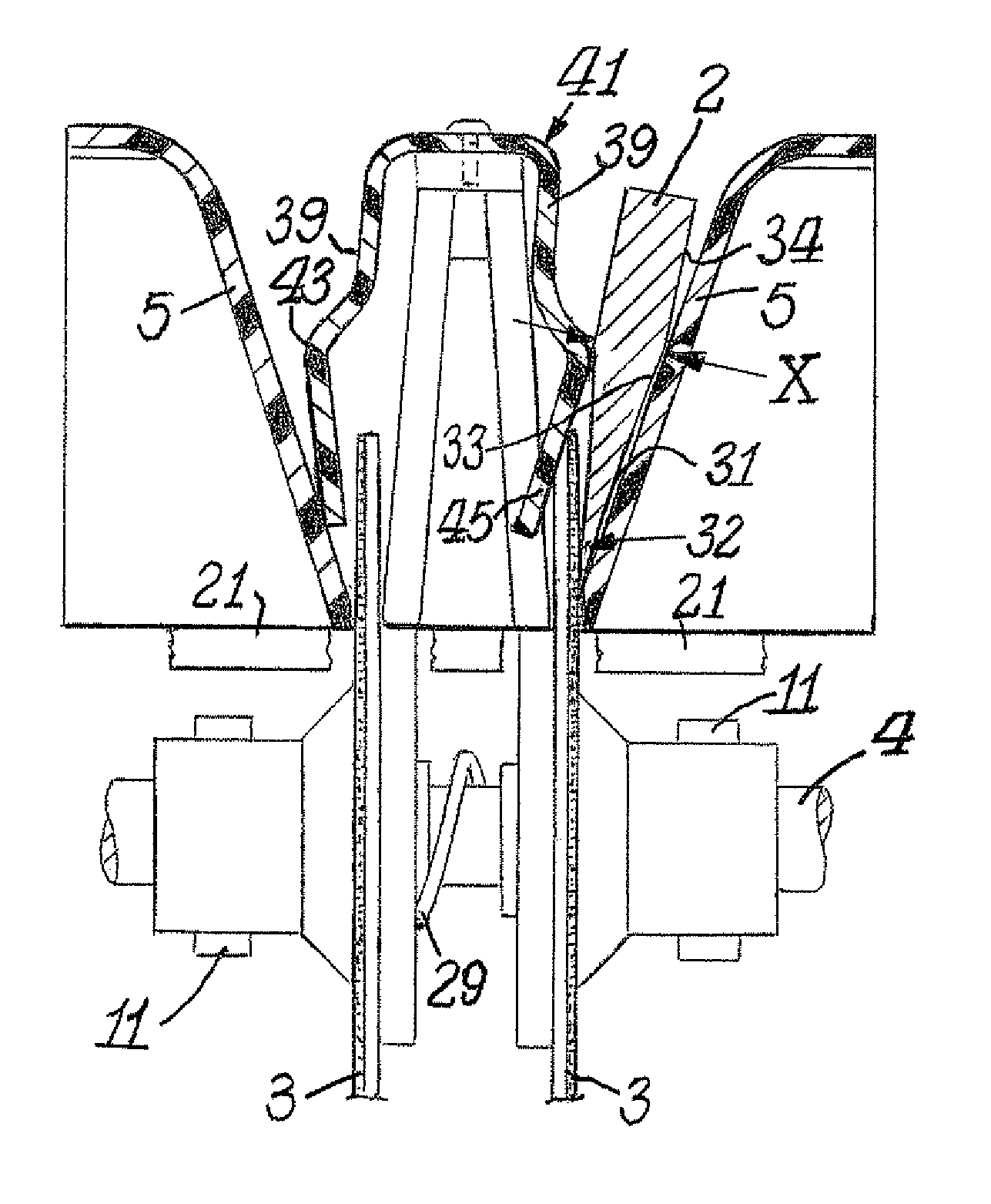

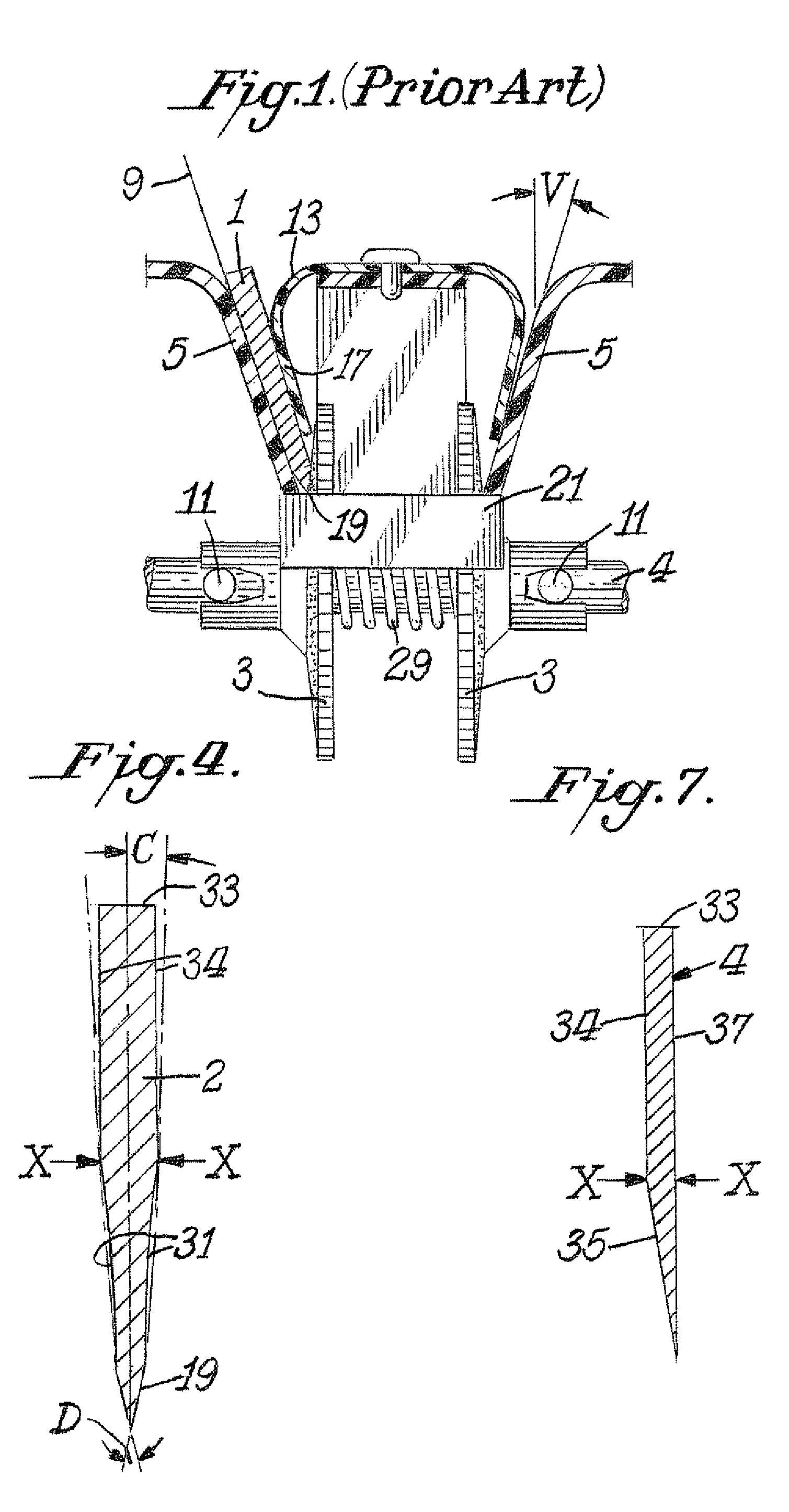

Precision sharpener for hunting and Asian knives

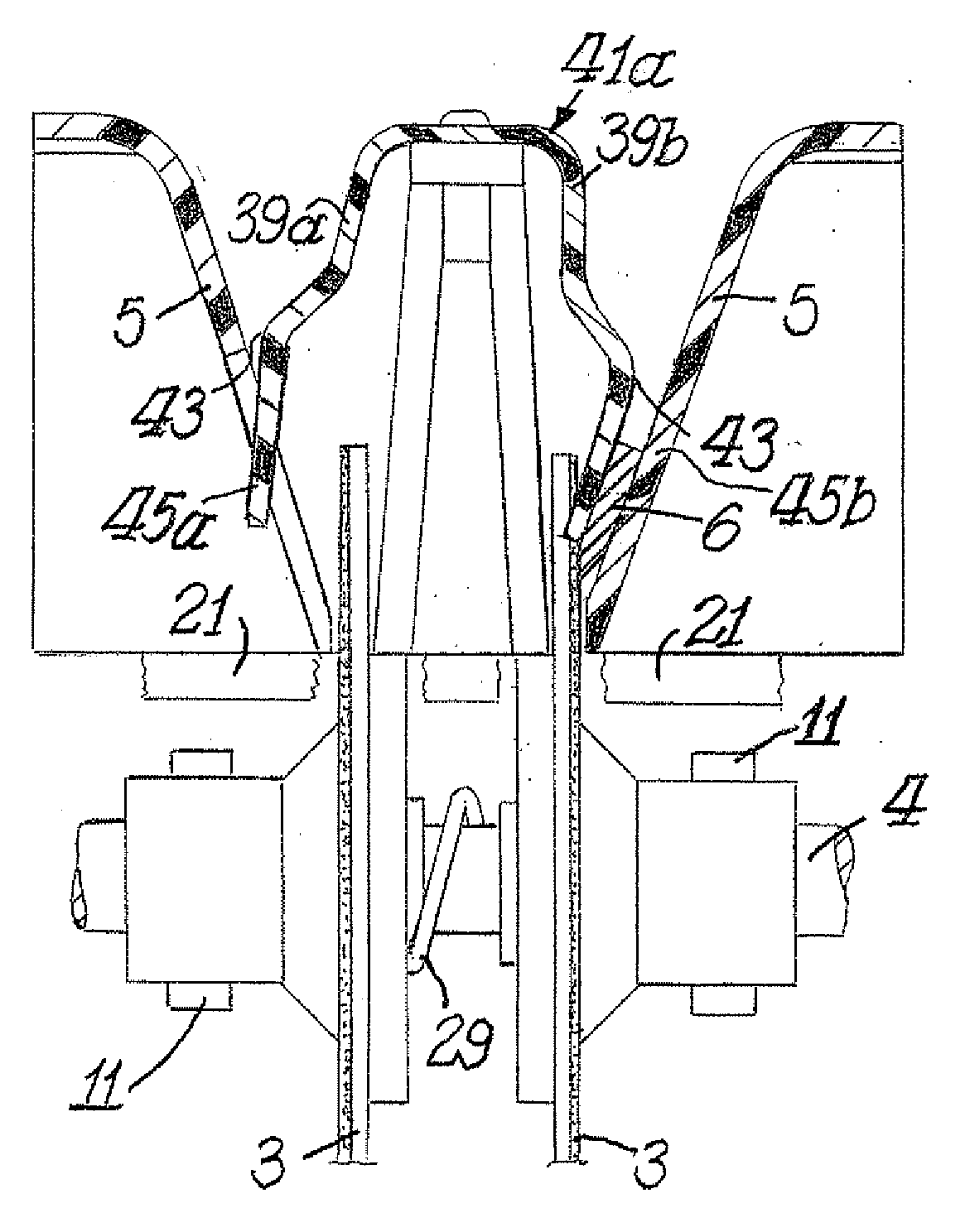

ActiveUS7686676B2Eliminate the problemPrecise alignmentEdge grinding machinesCutting toolsCoated surfaceKnife sharpener

A knife sharpener is provided which is capable of precision sharpening of hunting and similar knives that have a first and second blade face, each of which terminates at a facet that meets the corresponding facet to create the knife edge. At least the first of the blade faces has a lower distinct planar or concave section adjacent the edge facet with the lower planar or concave section of the face being set at an angle to the center line of the blade thickness that is different from the angle of the adjoining upper section of the same blade face located adjacent to the back of the blade. The sharpener includes a sharpening member such as one having an abrasive coated surface. The sharpener also includes a planar angle knife guide surface of a knife guide which is designed for intimate sliding and sustaining contact with the second face of the blade in order to position an edge facet on the first of the faces into precise angular relation with the sharpening surface. The sharpener also includes a knife holding spring that applies force against the first face of the blade predominantly at one or more locations on the lower planar or concave section of the first face that is adjacent to the edge facet being sharpened in order that the lower section adjacent the edge on the second face of the blade is pressured to align with and remain in intimate sliding alignment with the guide surface as the blade edge facet on the first face is being sharpened.

Owner:EDGECRAFT

Automatic rotation knife sharpener

InactiveUS20090275272A1Easy to disassembleRevolution surface grinding machinesOther chemical processesKnife sharpenerEngineering

The present invention is directed to an automatic rotation knife sharpener where the crossed sharpening rods are automatically rotated each time a knife is passed down and through the sharpener. The rotation is derived through the means of a spring steel actuator mechanism making contact with the cogwheels of the sharpening rod holders. Magnets retain the sharpening rods in place within the sharpening rod holders. Sharpening rods may be easily removed and stored in troughs on the upper surface of the protective cover. A variety of sharpening rods with different abrasive surfaces can be easily exchanged in the device.

Owner:BONAPACE MARIO J

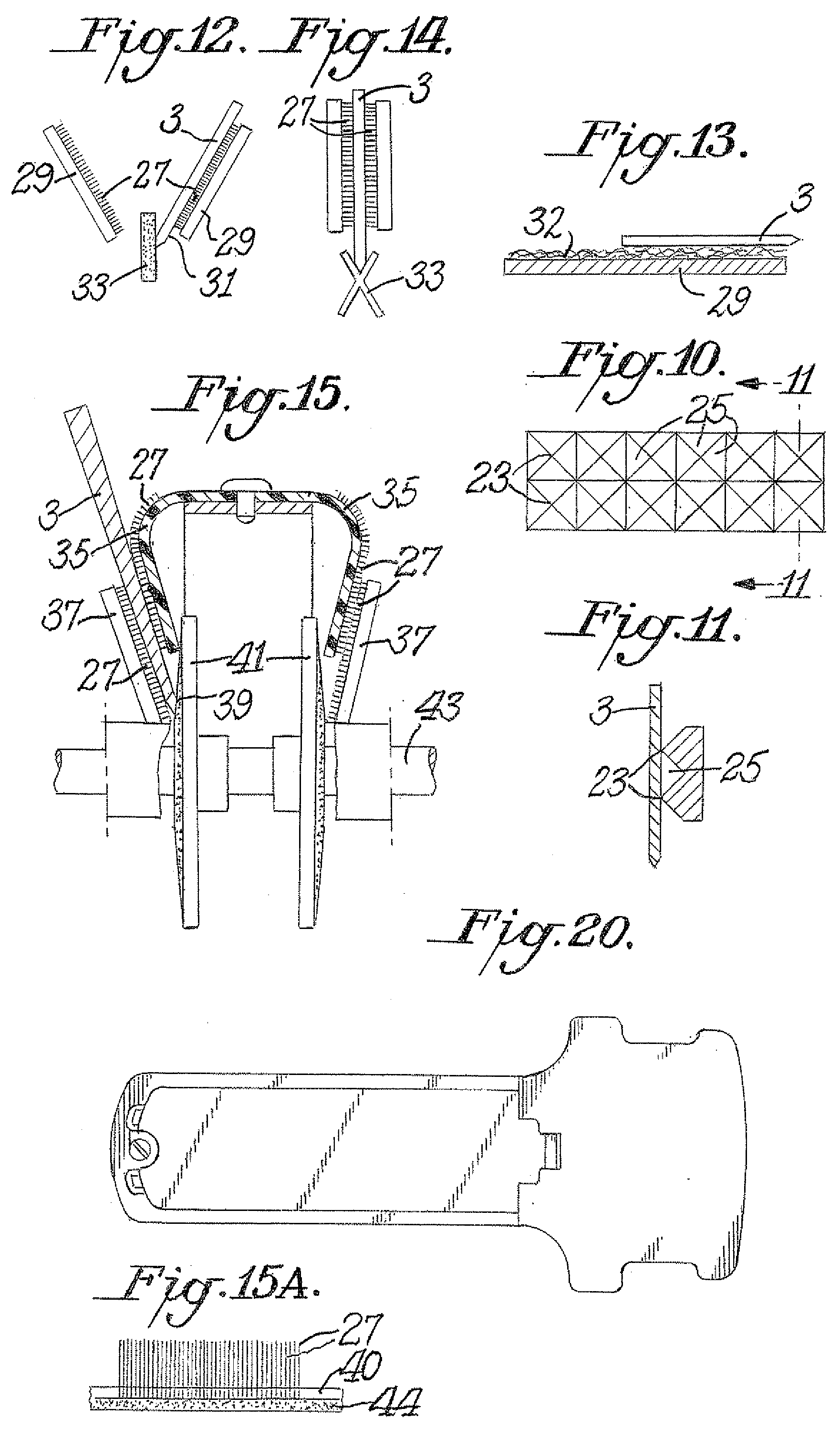

Precision sharpener for ceramic knife blades

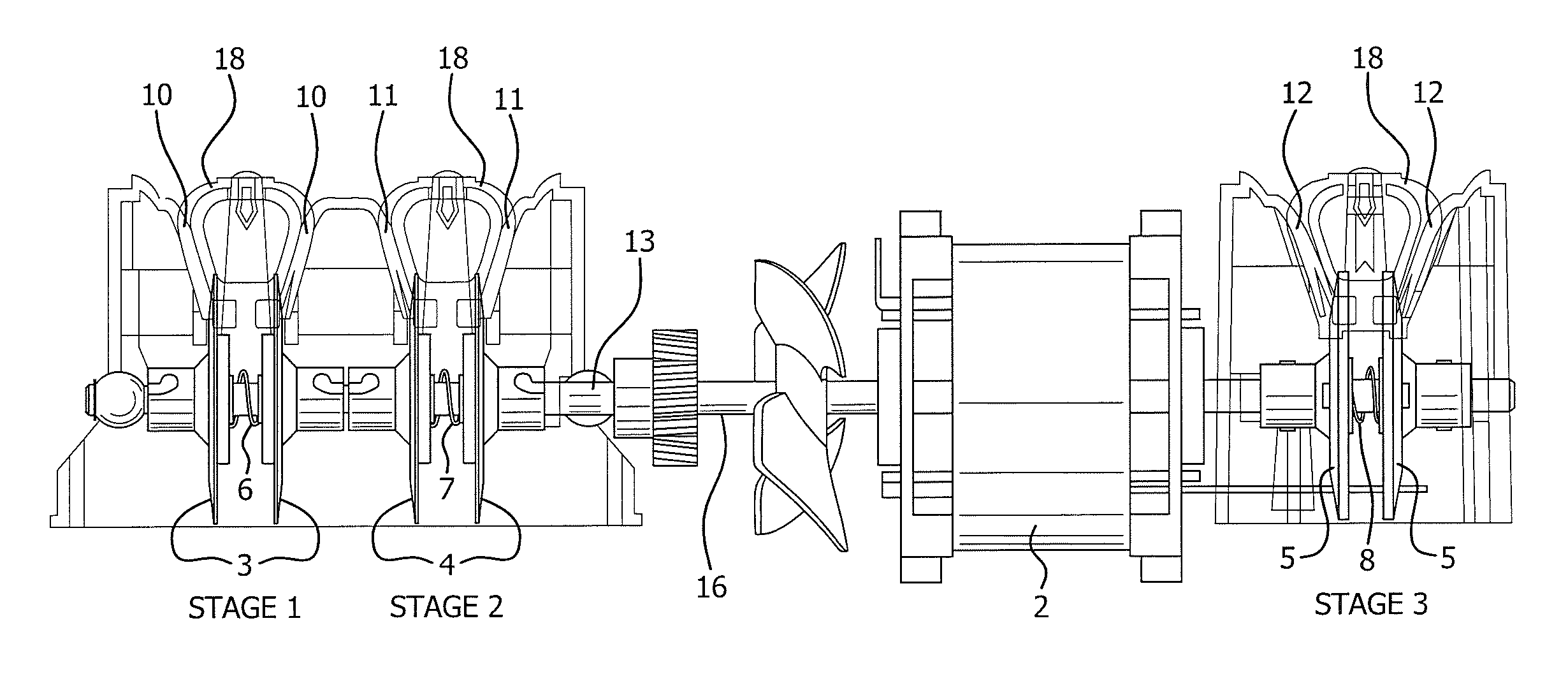

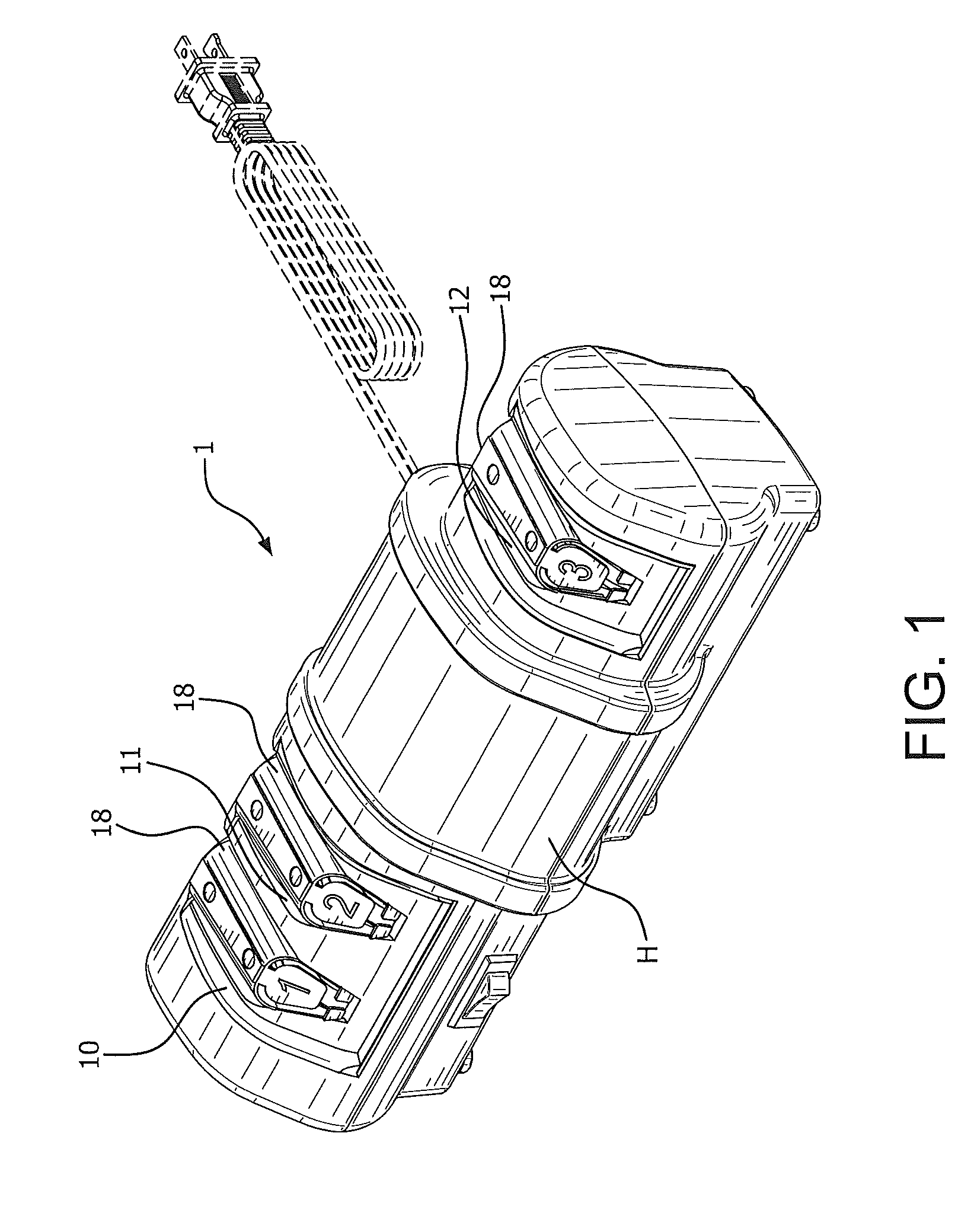

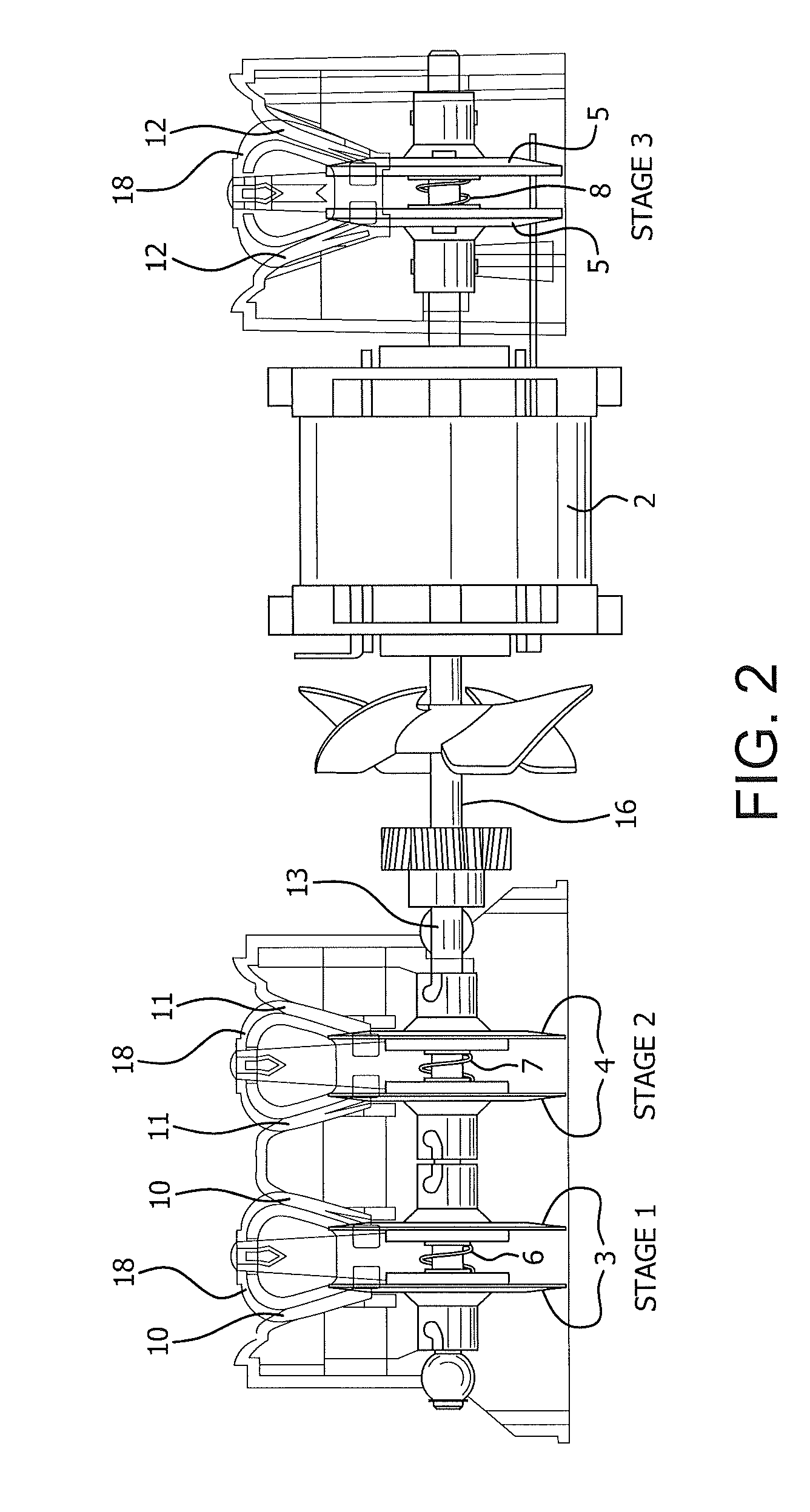

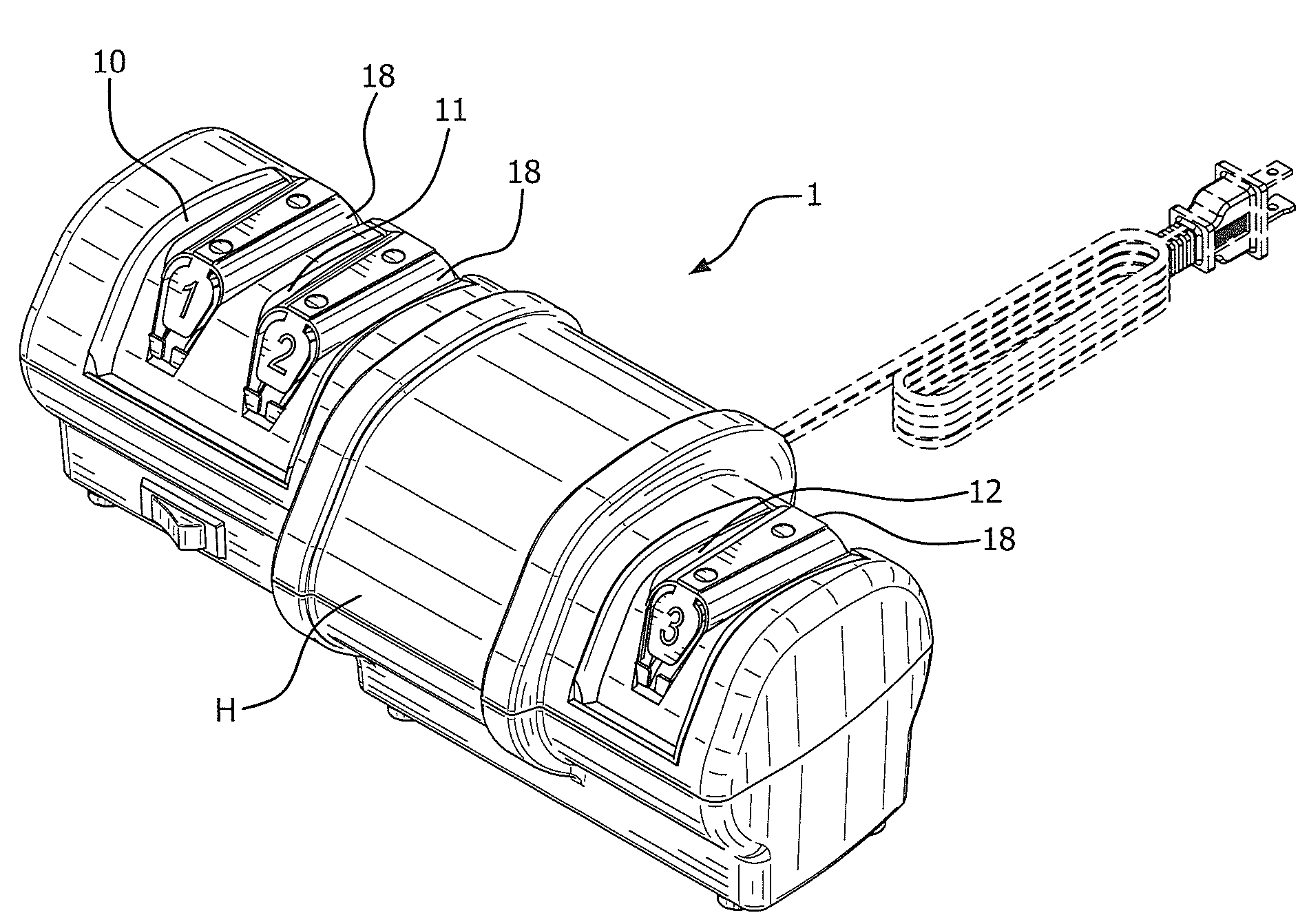

InactiveUS20130165021A1Inexpensive techniqueEdge grinding machinesRevolution surface grinding machinesMotor driveKnife sharpener

An electrically powered knife sharpener for ceramic (or other brittle, crystalline or amorphous media which could be used for blades) knives includes at least one pre-sharpening stage with a sharpening member(s) and includes a final stage with a sharpening member(s). There are one or more motor driven shafts on which the abrasive surfaced sharpening members, such as disks, are mounted. Guide structure is provided to guide the knife for aligning and positioning the knife facet precisely at a defined location on the abrasive surface of each rotating sharpening member. The pre-sharpening stage sharpening member(s) moves in a first direction. The final stage sharpening member(s) moves in a second direction which differs from the first direction.

Owner:EDGECRAFT

Precision sharpener for ceramic knife blades

InactiveUS8585462B2Inexpensive techniqueEdge grinding machinesRevolution surface grinding machinesMotor driveKnife sharpener

An electrically powered knife sharpener for ceramic (or other brittle, crystalline or amorphous media which could be used for blades) knives includes at least one pre-sharpening stage with a sharpening member(s) and includes a final stage with a sharpening member(s). There are one or more motor driven shafts on which the abrasive surfaced sharpening members, such as disks, are mounted. Guide structure is provided to guide the knife for aligning and positioning the knife facet precisely at a defined location on the abrasive surface of each rotating sharpening member. The pre-sharpening stage sharpening member(s) moves in a first direction. The final stage sharpening member(s) moves in a second direction which differs from the first direction.

Owner:EDGECRAFT

Knife sharpener

ActiveUS20070167122A1Improve protectionExacerbated damageGrinding machinesGrinding/polishing hand toolsKnife sharpenerEngineering

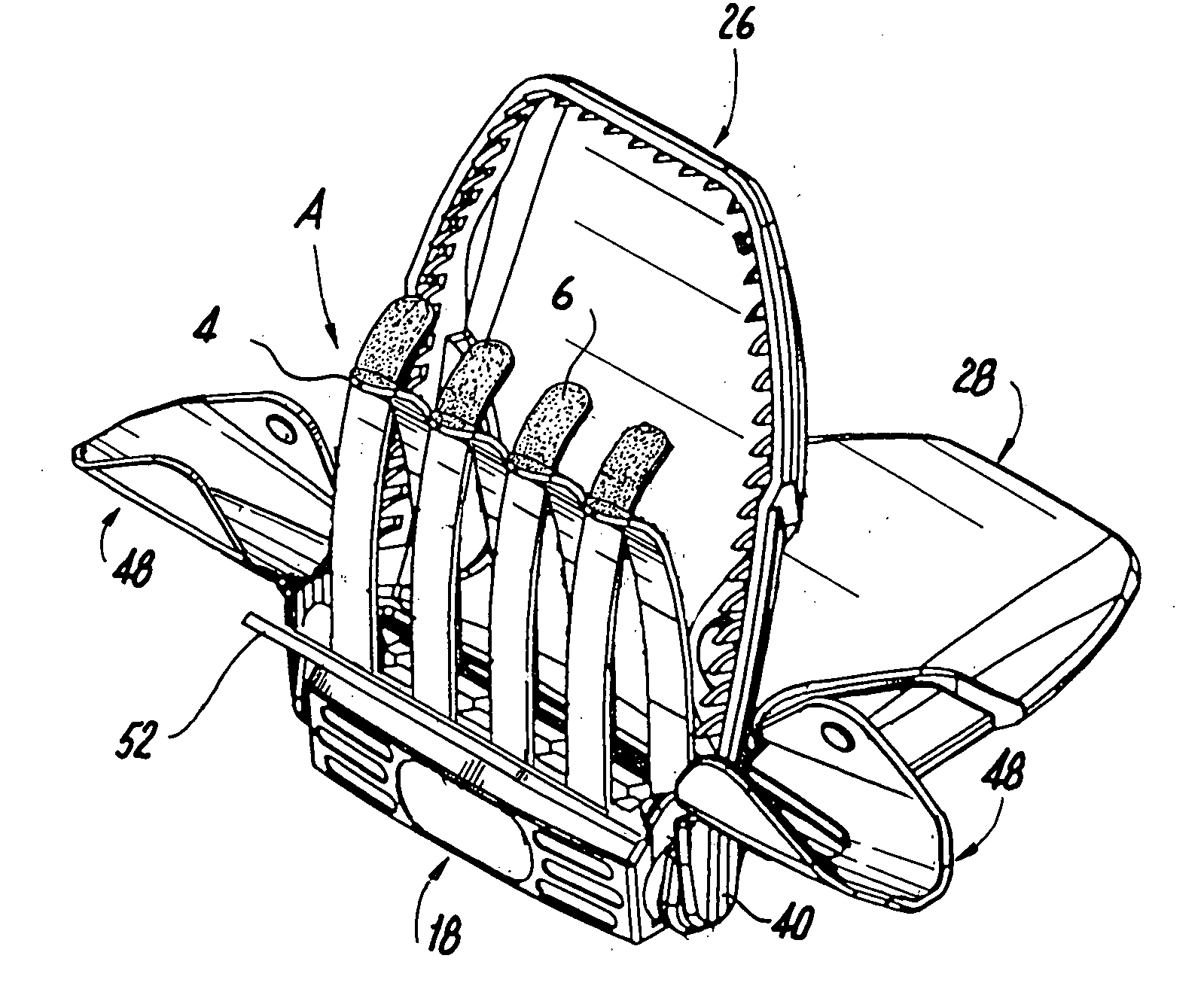

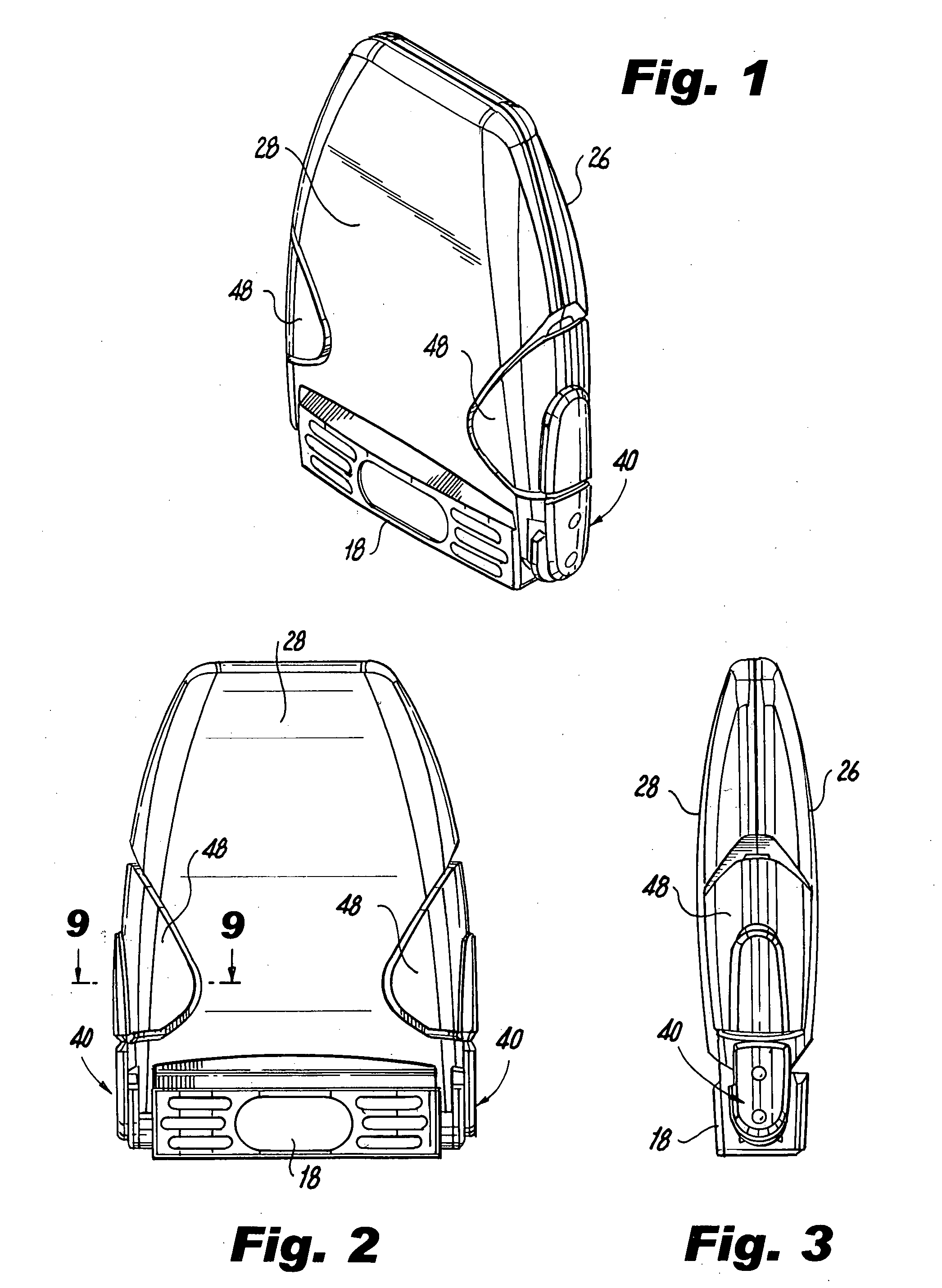

A knife sharpener comprising a sharpening device preferably of the type involving upwardly extending pairs of overlapping, resiliently flexible fingers or strips forming opposed abrasive sharpening faces, provided with a pair of shields respectively operative between closed positions in which they cover and protecting the sharpening device and open positions in which they respectively provide a handhold for the device and protect the hand of the user when it is on the handhold, and preferably provided with locking means moveable between a first position engaging said shields and retaining them in said closed position and a second position releasing said shields from their closed positions and extending out from said assembly to provide protection for the hand of the user.

Owner:FUERITECHNICS GROUP

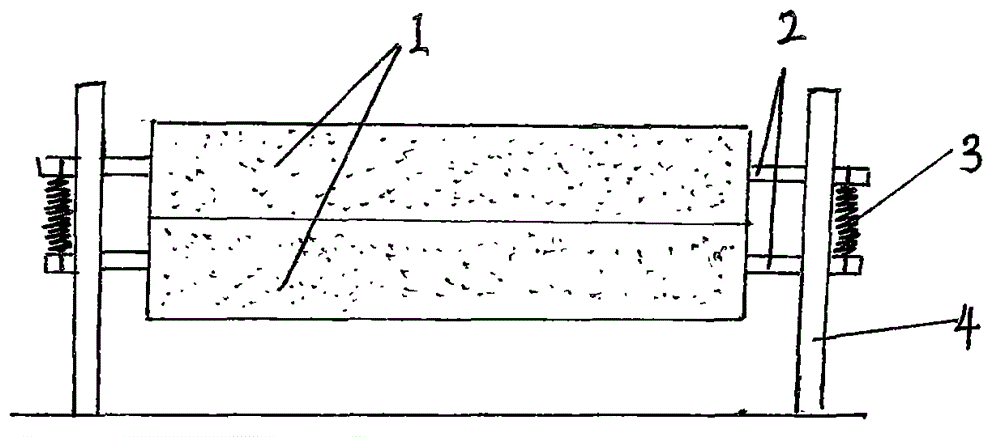

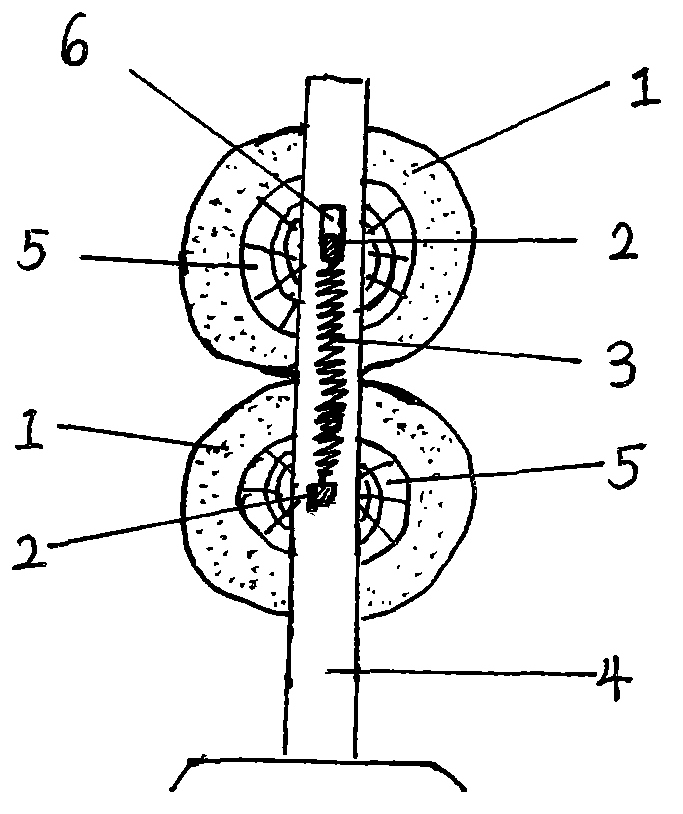

Electric double-sided knife sharpener

InactiveCN102873597AHigh speedSimple structureOther manufacturing equipments/toolsKnife sharpenerGrinding wheel

The invention provides an electric double-sided knife sharpener for people in order to save time and labor and rapidly and efficiently achieve the aim of double-sided knife sharpening. Two cylindrical knife grinders are vertically arranged on a support; cylindrical motors are arranged inside the knife grinders; the knife grinders are connected with the support through square column-shaped motor shafts; the lower knife grinder is fixed on the support; and the upper motor shaft can vertically move within a certain range so that knives with different thicknesses can be inserted. Two sides of the two square column-shaped motor shafts are respectively provided with two springs so that the upper knife grinder is pulled to abut against the lower knife grinder. The grinders rotate towards opposite directions under the drive of the motors to well grind a knife inserted between the two grinders.

Owner:唿长波

Knife sharpener capable of controlling angle

InactiveCN1367065AEasy to carryEasy to useOther manufacturing equipments/toolsGrinding/polishing hand toolsKnife sharpenerKnife blades

A manual knife sharpener has an angle control structure. The structure includes a guide member with a guide surface forming an angle with the grinding surface of the grinding component. When the blade is inserted between the grinding surface and the guide surface, the blade pushes against the guide surface, causing the guide surface to move in a direction perpendicular to the guide surface, so that the movement is lateral movement in a plane, and the guide does not rotate. Or twisted. In this way, no matter how far the guide is moved, the angle between the guide surface and the grinding surface remains unchanged.

Owner:EDGECRAFT

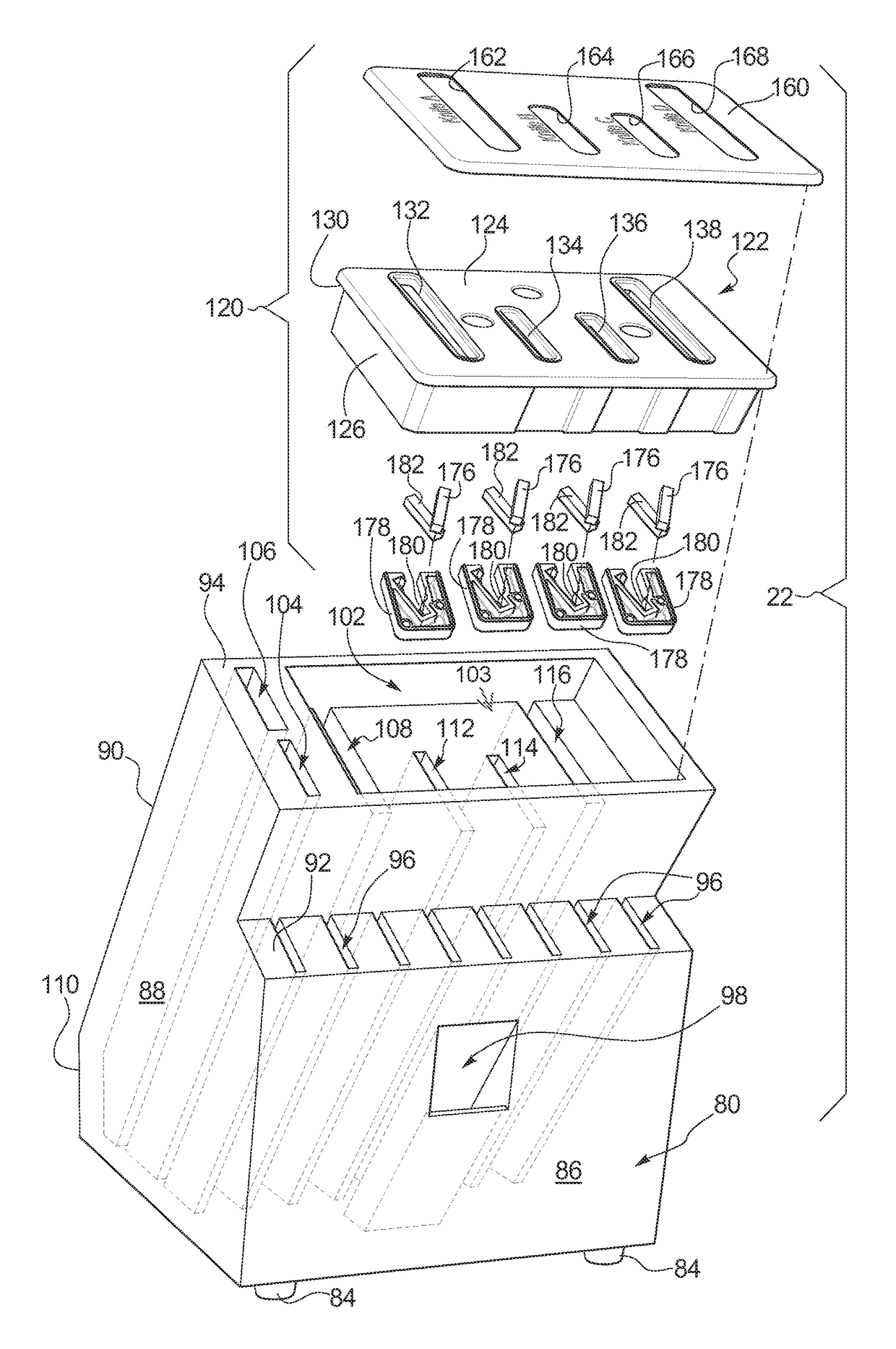

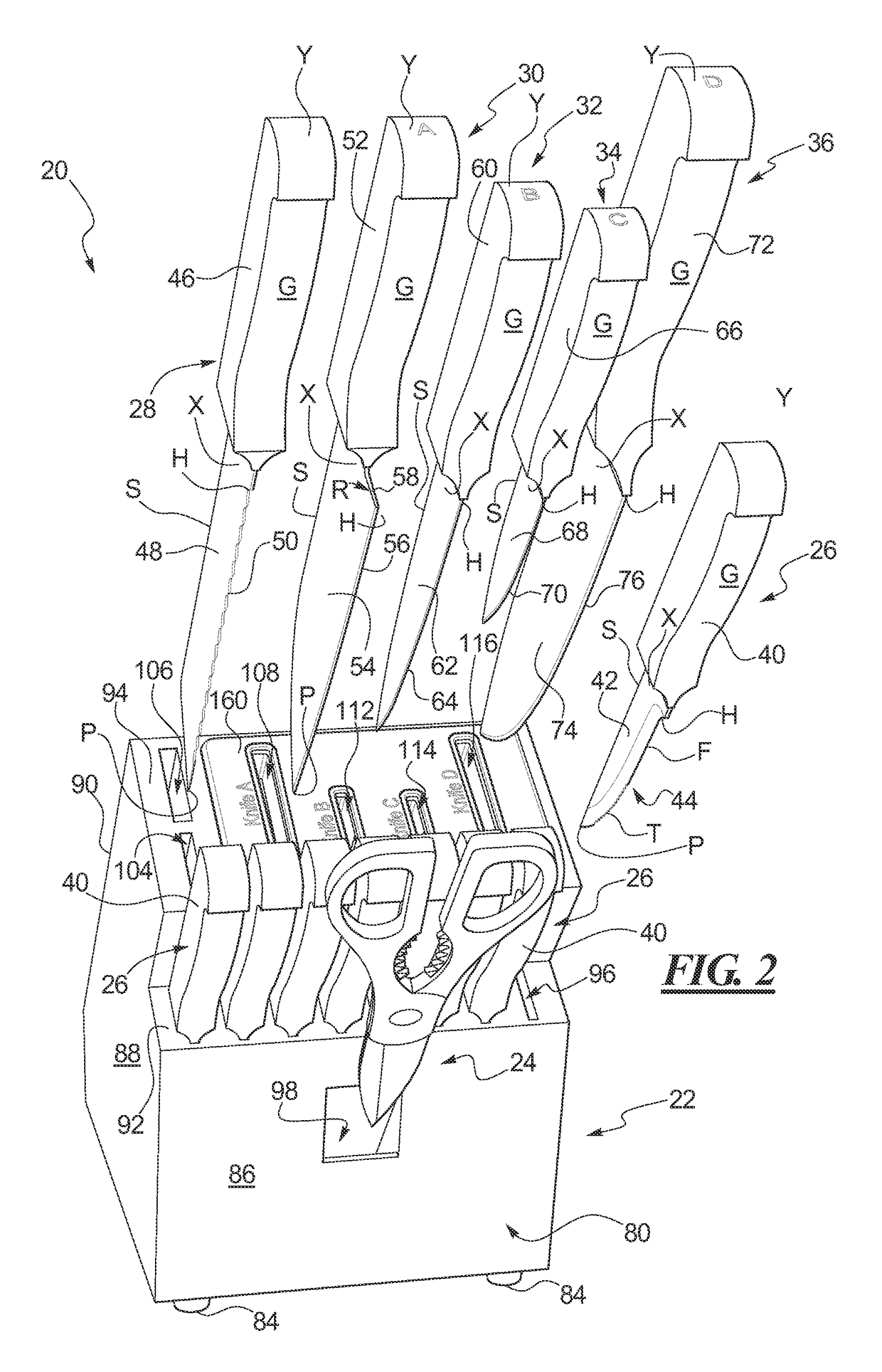

Knife block with storage slot blade sharpeners and cutlery set using same

A knife block has a block body and a plurality of knife storage slots extending into the block body. A first knife sharpener is aligned with a first slot of the plurality of knife storage slots and a second knife sharpener is aligned with a second slot of the plurality of knife storage slots. The first and second knife sharpeners are each configured to contact a blade of a knife stored in the corresponding first and second slots. The knife block can be provided as part of a cutlery set that includes a plurality of knives.

Owner:SUNBEAN PROD INC

Knife sharpener with improved knife guides

ActiveUS20070197148A1Eliminate burnishingEliminate scratchesEdge grinding machinesRevolution surface grinding machinesKnife sharpenerKnife blades

Owner:EDGECRAFT

Knife sharpener

ActiveUS7381120B2Improve protectionExacerbated damageGrinding machinesGrinding/polishing hand toolsKnife sharpenerEngineering

A knife sharpener comprising a sharpening device preferably of the type involving upwardly extending pairs of overlapping, resiliently flexible fingers or strips forming opposed abrasive sharpening faces, provided with a pair of shields respectively operative between closed positions in which they cover and protecting the sharpening device and open positions in which they respectively provide a handhold for the device and protect the hand of the user when it is on the handhold, and preferably provided with locking means moveable between a first position engaging said shields and retaining them in said closed position and a second position releasing said shields from their closed positions and extending out from said assembly to provide protection for the hand of the user.

Owner:FURITECHNICS GROUP PTY LTD

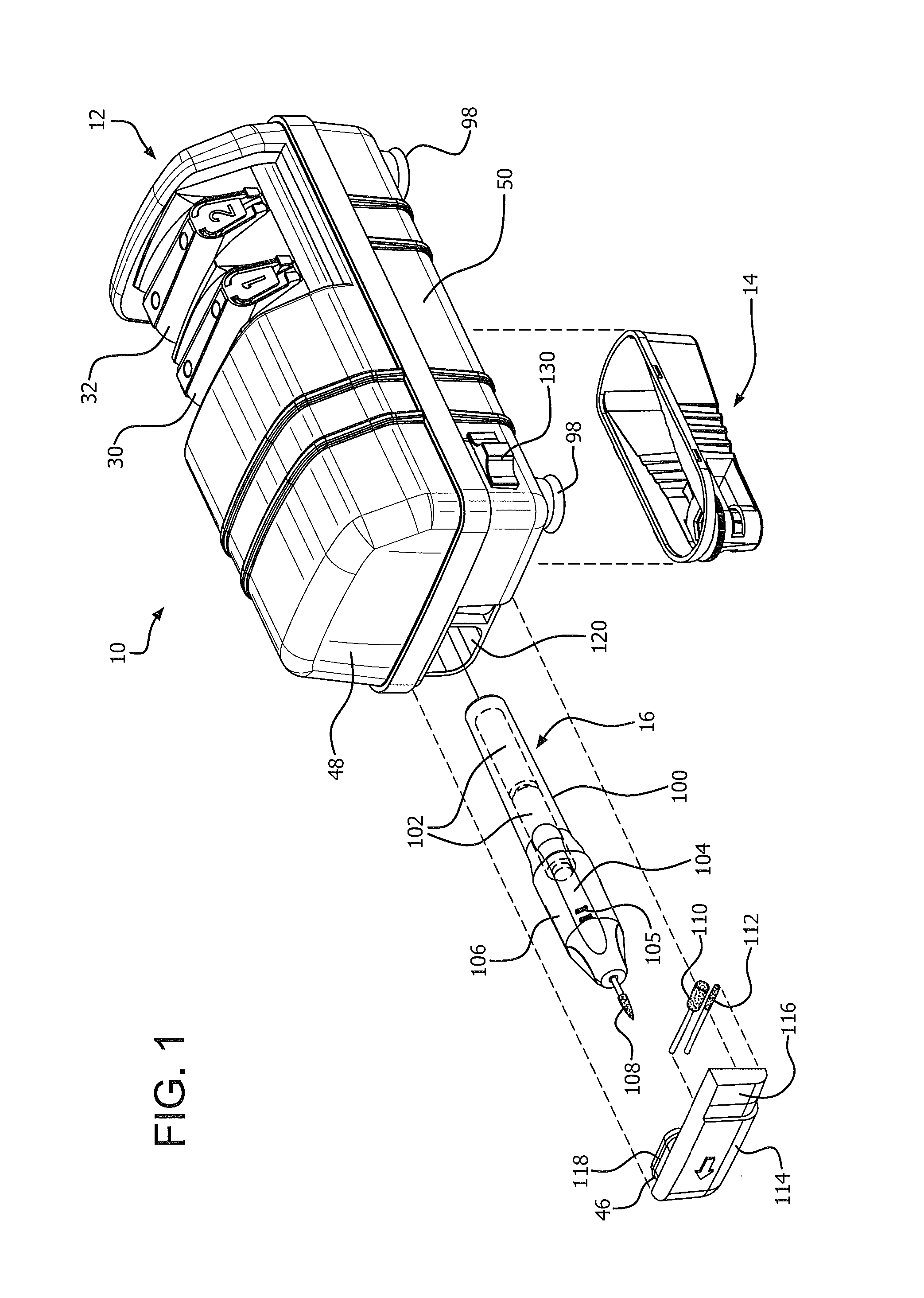

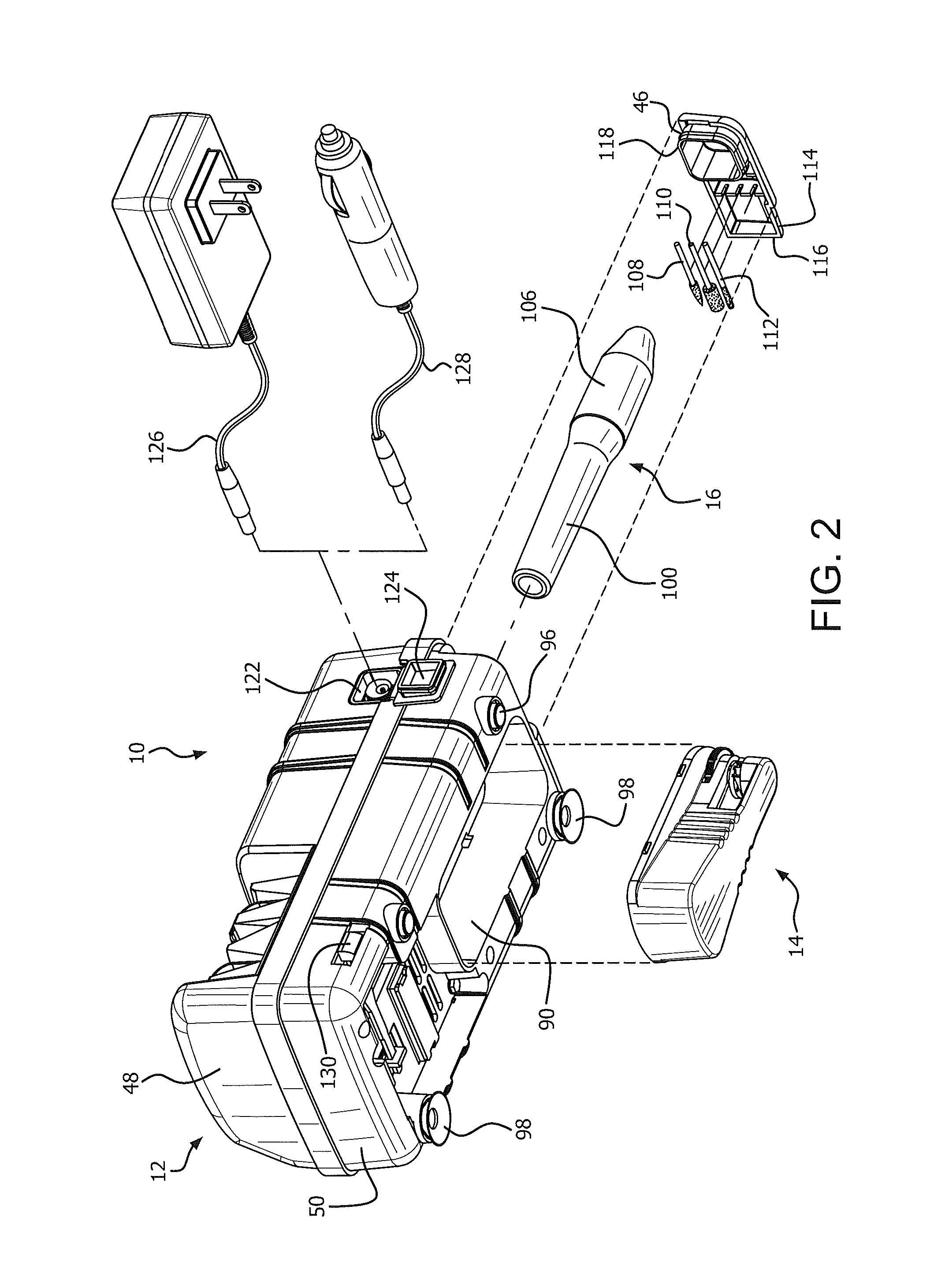

Combination sharpener assembly

InactiveUS8678882B1Easy to polishEdge grinding machinesRevolution surface grinding machinesKnife sharpenerEngineering

A combination sharpener assembly which is particularly useful for fishermen, includes an electrically powered knife sharpener. A manually operated scissors sharpener is mounted in the recess of the housing for the knife sharpener. A hook sharpener is detachably mounted in a compartment in the housing of the knife sharpener. The motor for the knife sharpener is mounted in a sealed inner housing and can be selectively operated under either direct current or alternating current.

Owner:EDGECRAFT

Electric knife sharpener

InactiveCN104070424ASimple structureReduce manufacturing costOther manufacturing equipments/toolsGrinding/polishing hand toolsKnife sharpenerControl system

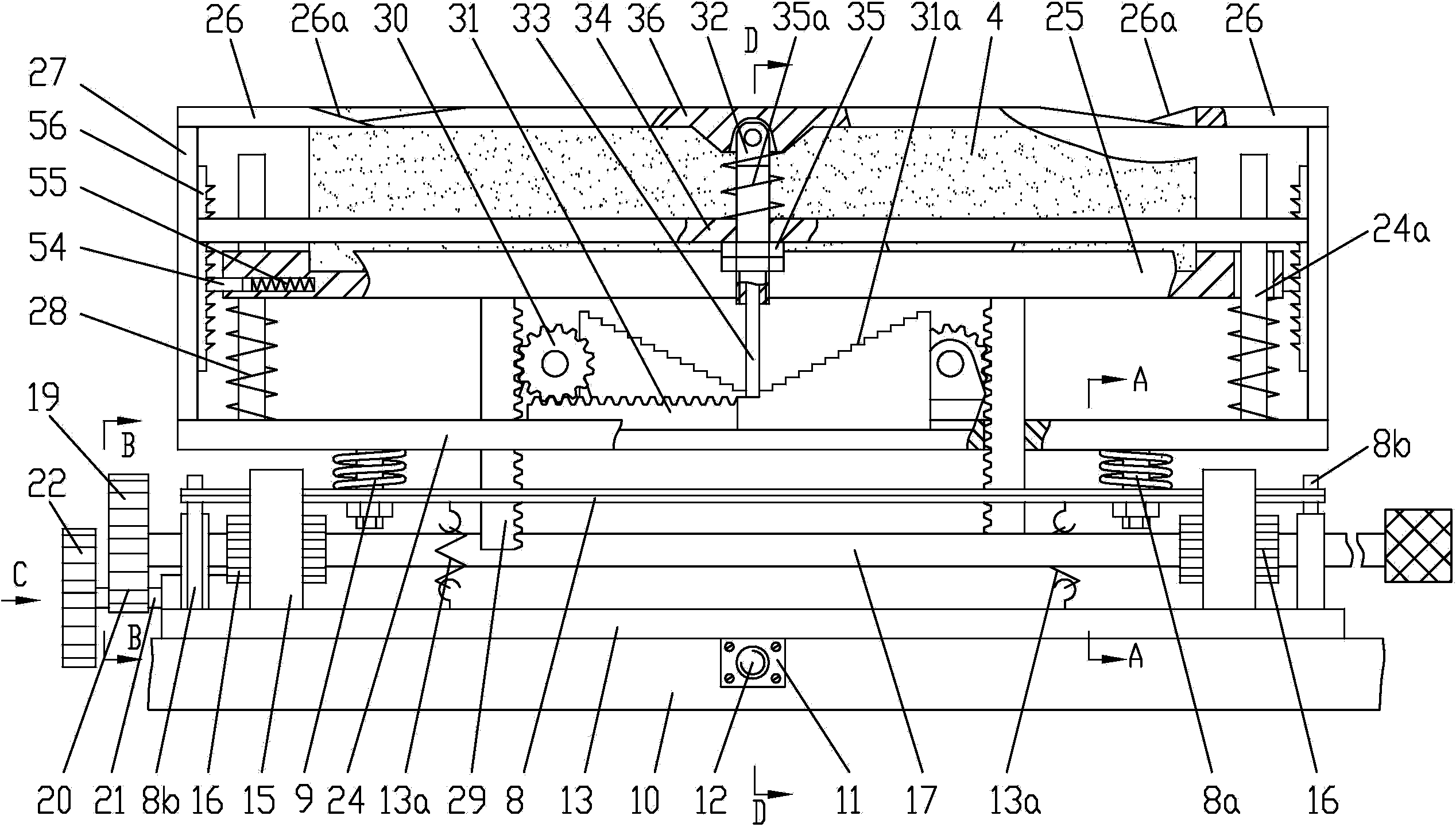

The invention discloses an electric knife sharpener. The electric knife sharpener comprises a rack, a drive motor, a knife rest and a knife sharpening stone device, wherein the knife rest is connected to a base; a first screw rod and a second screw rod which are provided with reciprocating spiral grooves are rotationally supported on the rack respectively, a first slide sleeve and a second slide sleeve are installed on the first screw rod and the second screw rod respectively in a sleeving manner, a first pin shaft which is in slide fit in the reciprocating spiral groove of the first screw rod is fixedly connected to the first slide sleeve, and the first slide sleeve is fixedly connected to the base of the knife rest; a second slide sleeve is installed on the second rod in a sleeving manner, a second pin shaft which is in slide fit in the reciprocating spiral groove of the second screw rod is fixedly connected to the second slide sleeve, and the second slide sleeve is fixedly connected to the knife sharpening stone device; the drive motor is controlled by a control system and used for driving the first screw rod and the second screw rod to rotate according to set directions respectively by virtue of a transmission box with rotary power output. The electric knife sharpener disclosed by the invention has the beneficial effects of simple structure, low manufacturing cost, convenient installation and debugging, and few fault hidden dangers.

Owner:重庆臻憬科技有限公司

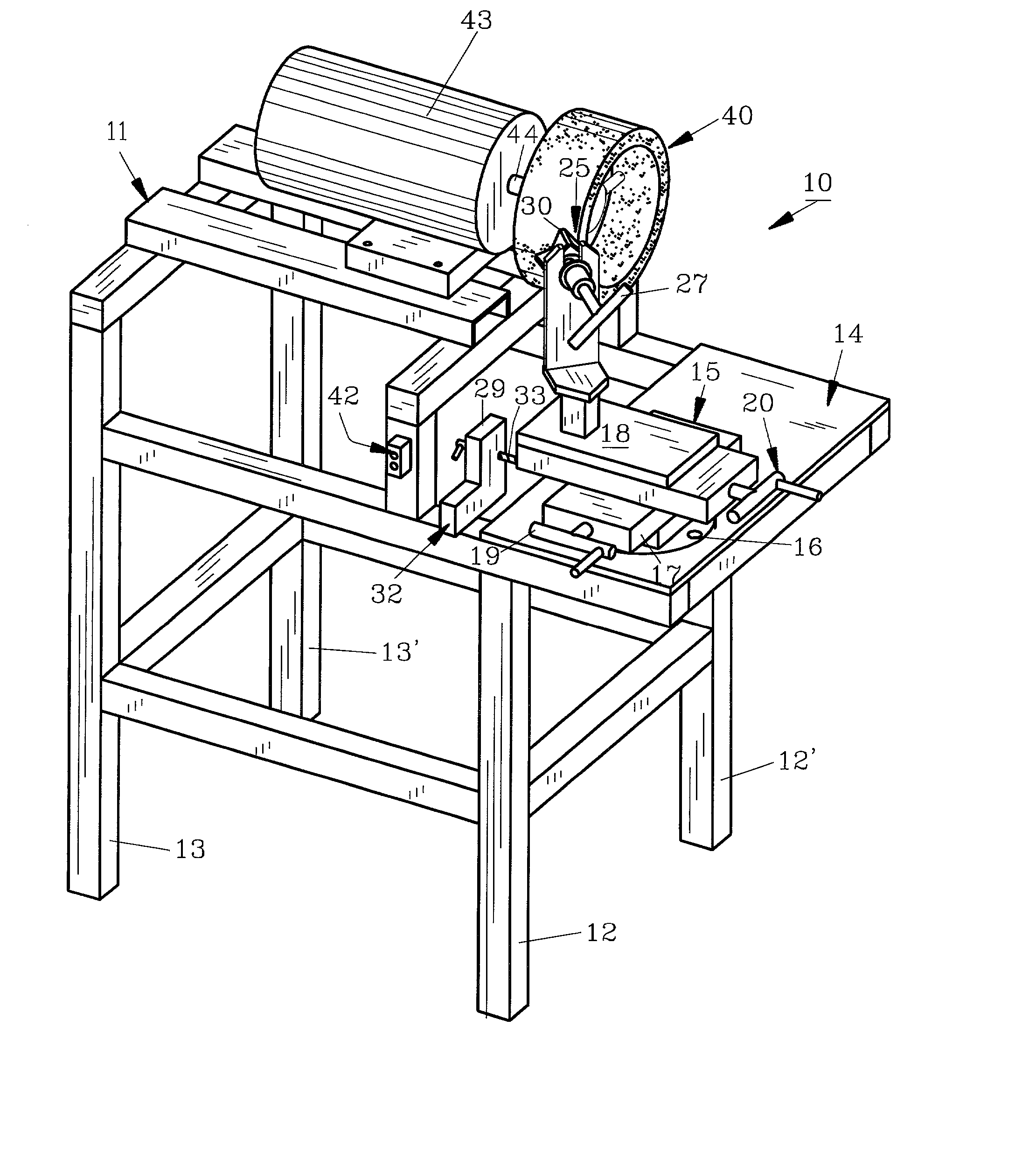

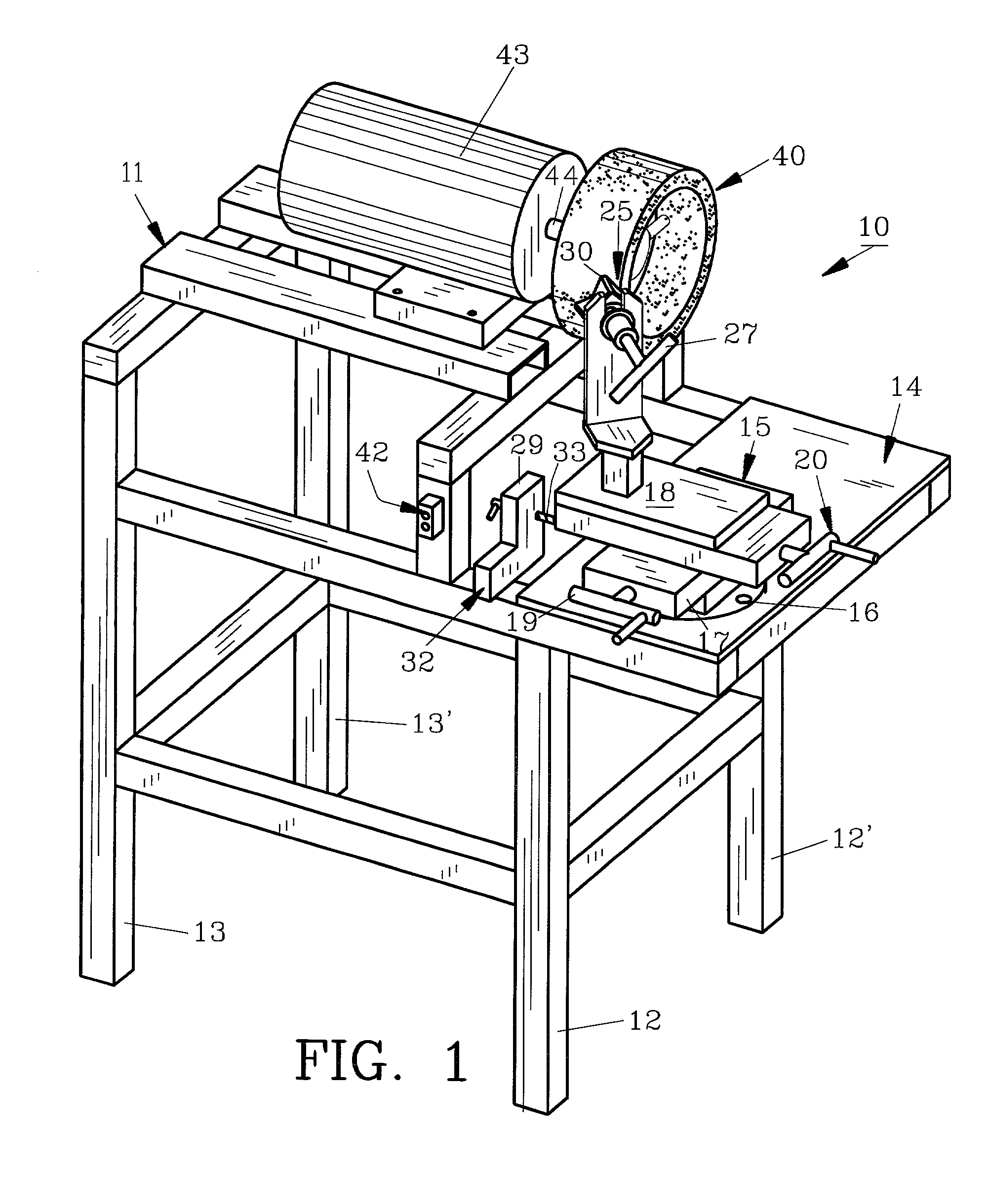

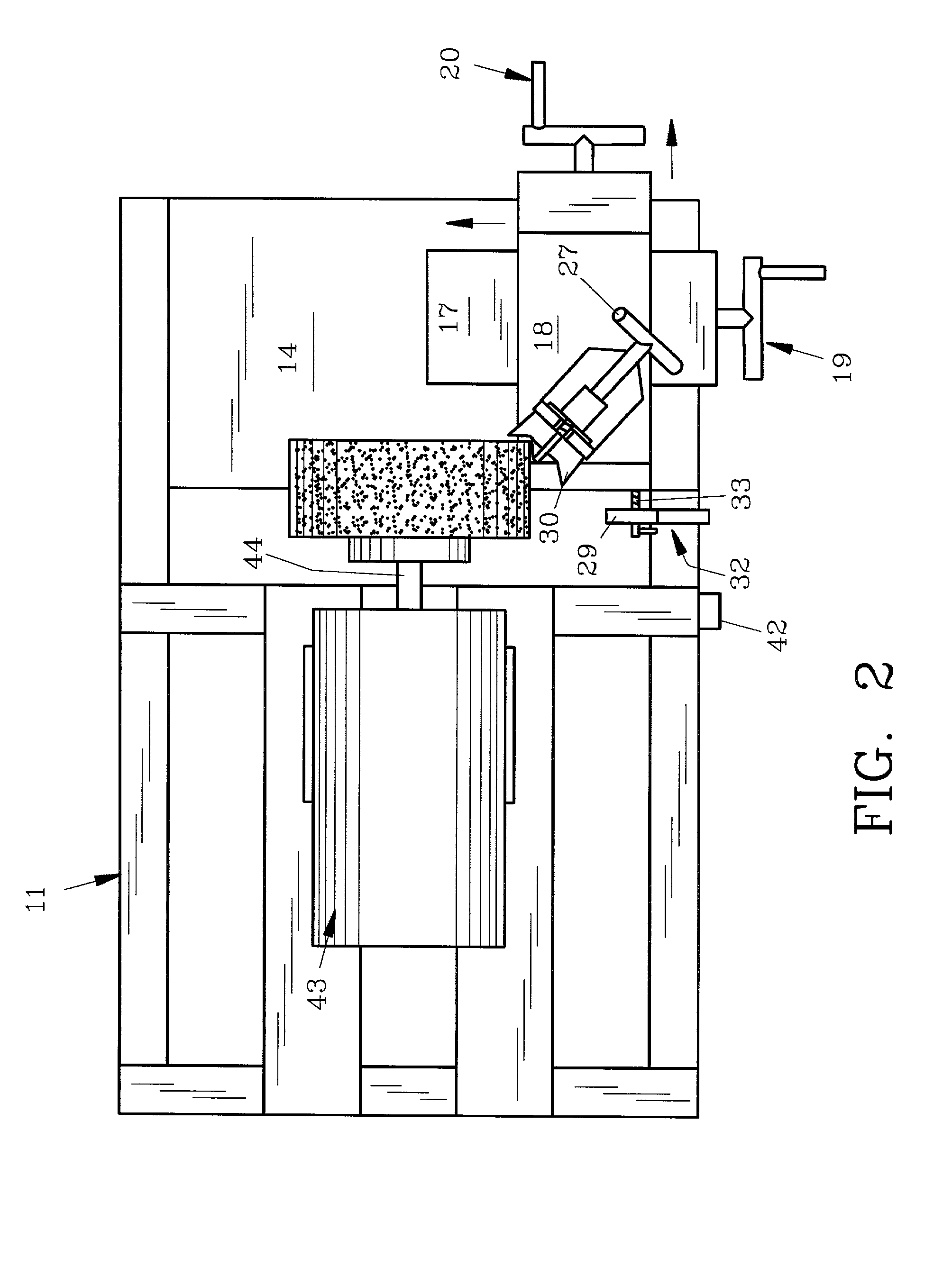

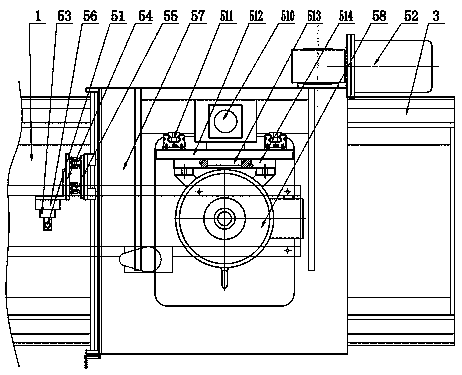

Universal knife sharpener

InactiveCN102303269AEasy to adjust sizeOther manufacturing equipments/toolsKnife sharpenerMicrometer

The invention relates to a universal knife sharpener, which comprises a grinding wheel driven to rotate by a motor, a knife rest clamping seat arranged at one side opposite to the grinding wheel and used for fixing a knife, and a support frame for supporting the knife rest clamping seat, wherein the support frame is fixed on a knife rest base. The universal knife sharpener is characterized in that: the support frame can be driven to move far from or close to the grinding wheel by an external force; and in addition, the universal knife sharpener also comprises a conflicting mechanism arranged on the same side as the grinding wheel, wherein the conflicting mechanism is movably provided with a micrometer head capable of moving far from or close to the support frame. The universal knife sharpener has the advantages of low adjusting error, high precision and simple and practical structure.

Owner:邱坚峰

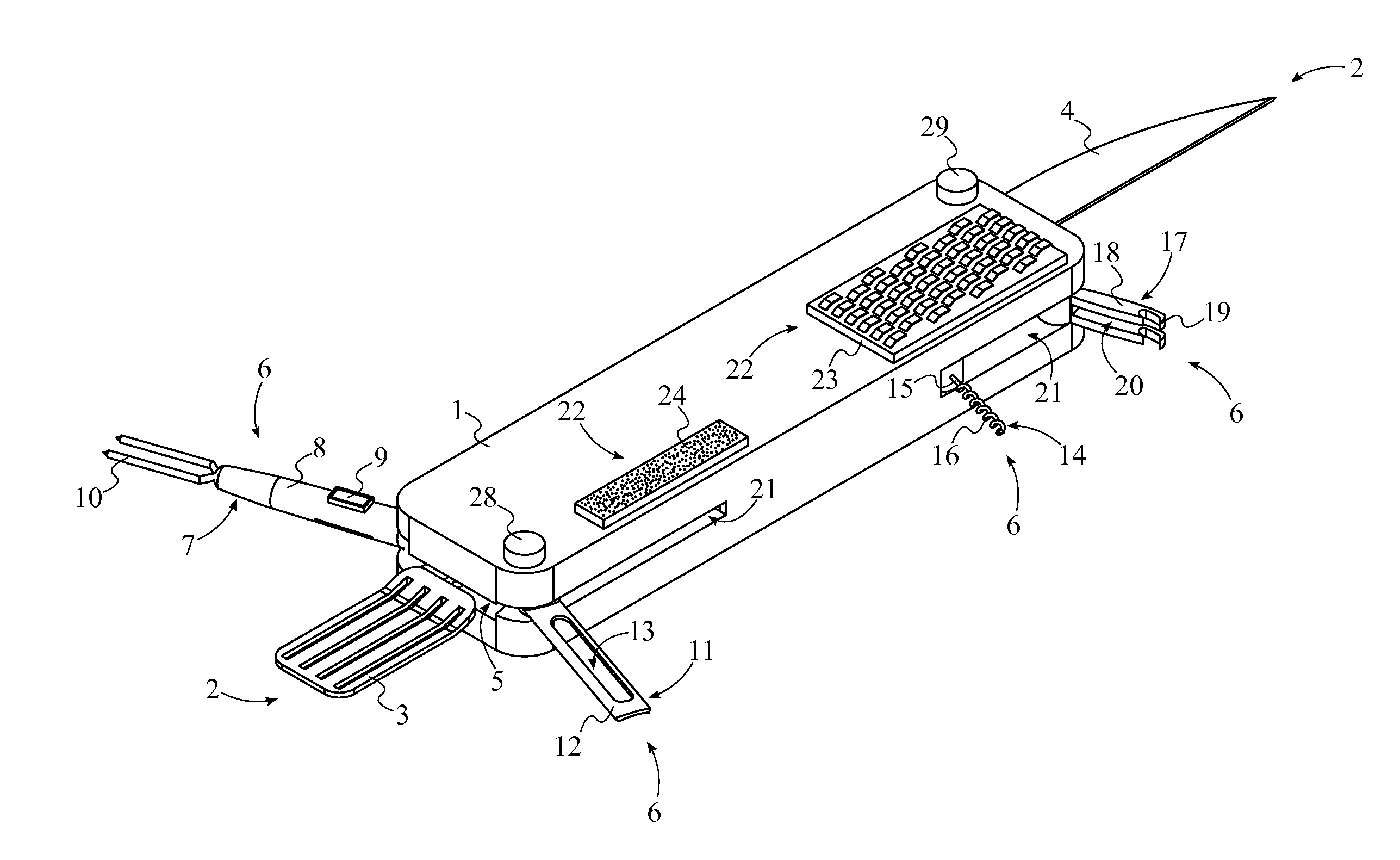

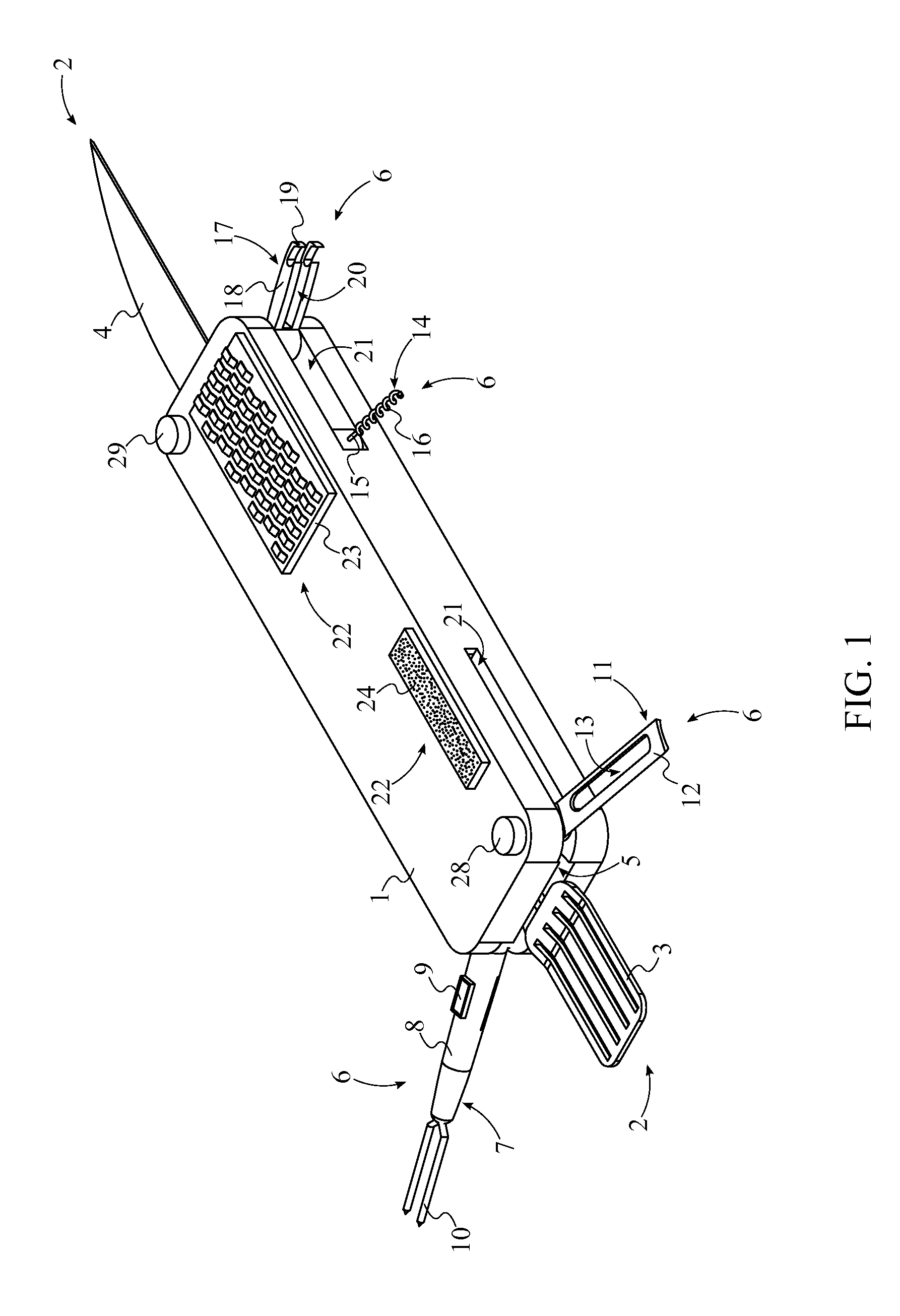

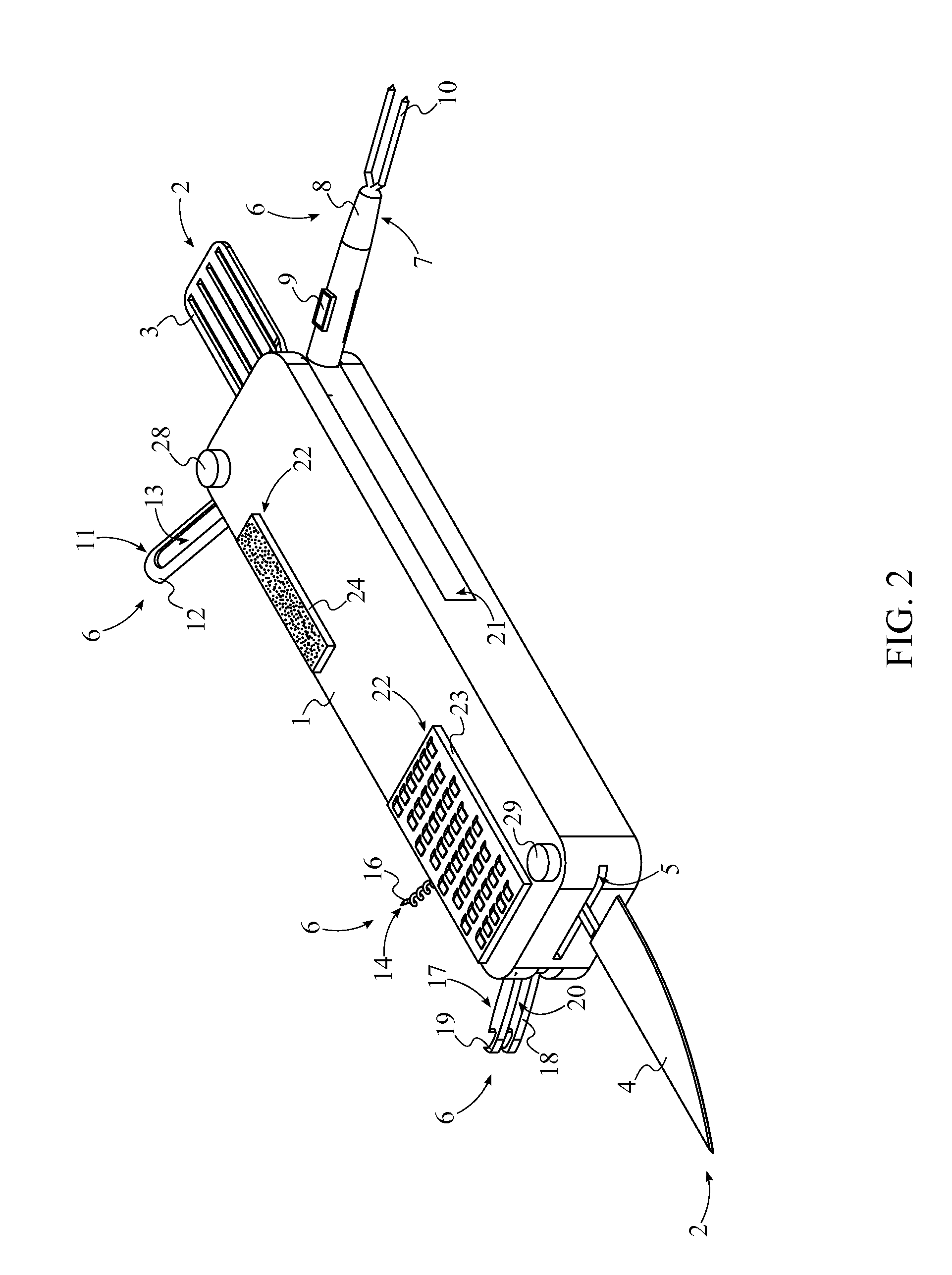

Multifunctional Kitchen Tool

A multifunctional kitchen tool is a device that provides a plurality of retractable tools, a plurality of foldaway tools, and a plurality of detachable tools for performing various kitchen-related activities. A plurality of tool-receiving slots, a plurality of tool trenches, a first recessed space, and a second recessed space are provided on a handle body for housing the tools. The device features a food thermometer, a peeler, a corkscrew, a bottle opener, a spring-loaded grater, a spring-loaded knife sharpener, a spring-loaded spatula, and a spring-loaded knife. The tools may be deployed from the handle body when needed and folded or retracted into the handle body when not in use. The plurality of detachable tools is externally mounted to the handle body and is removable from the device for cleaning or other maintenance purposes.

Owner:NOORZAI MIRWAIS

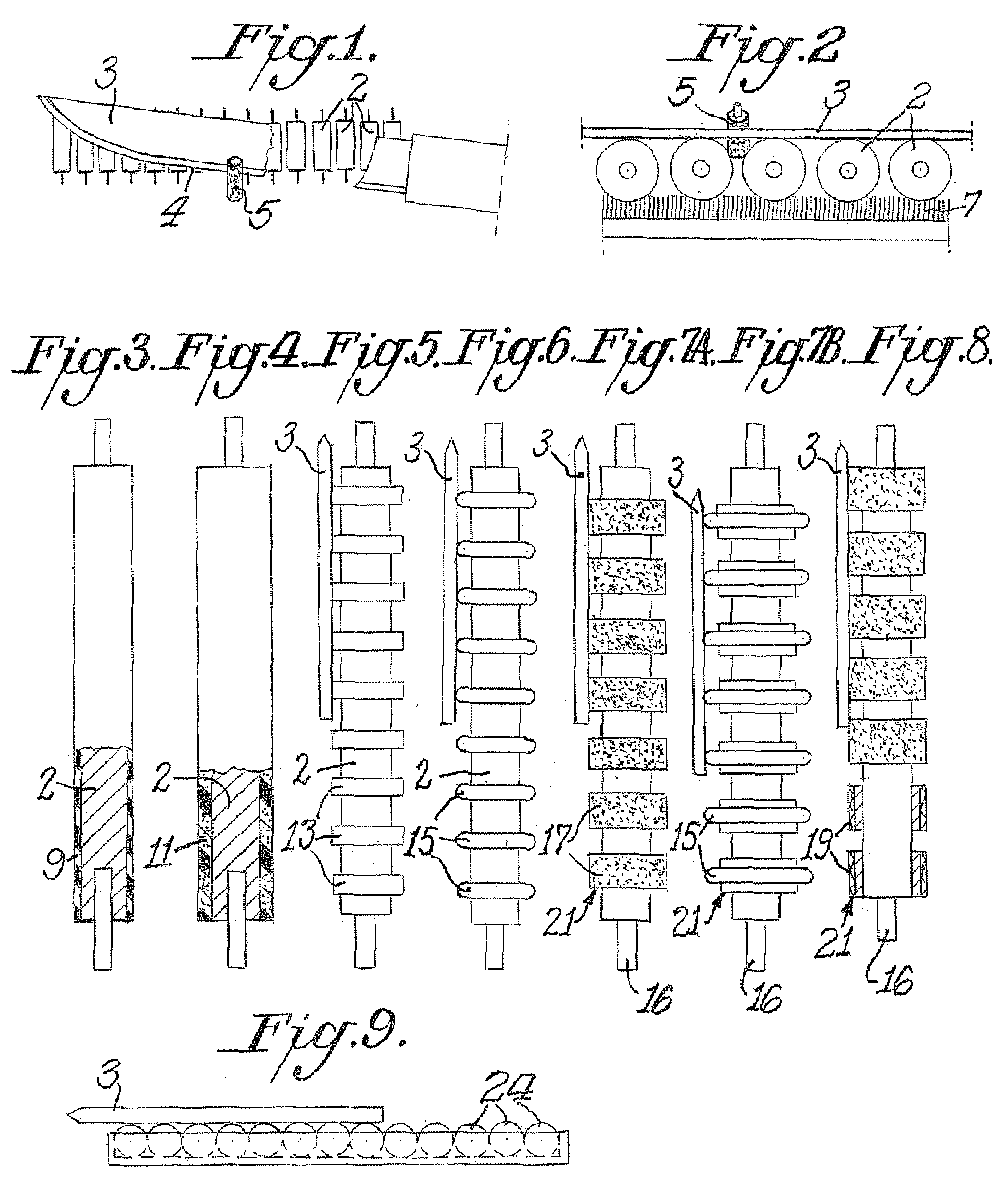

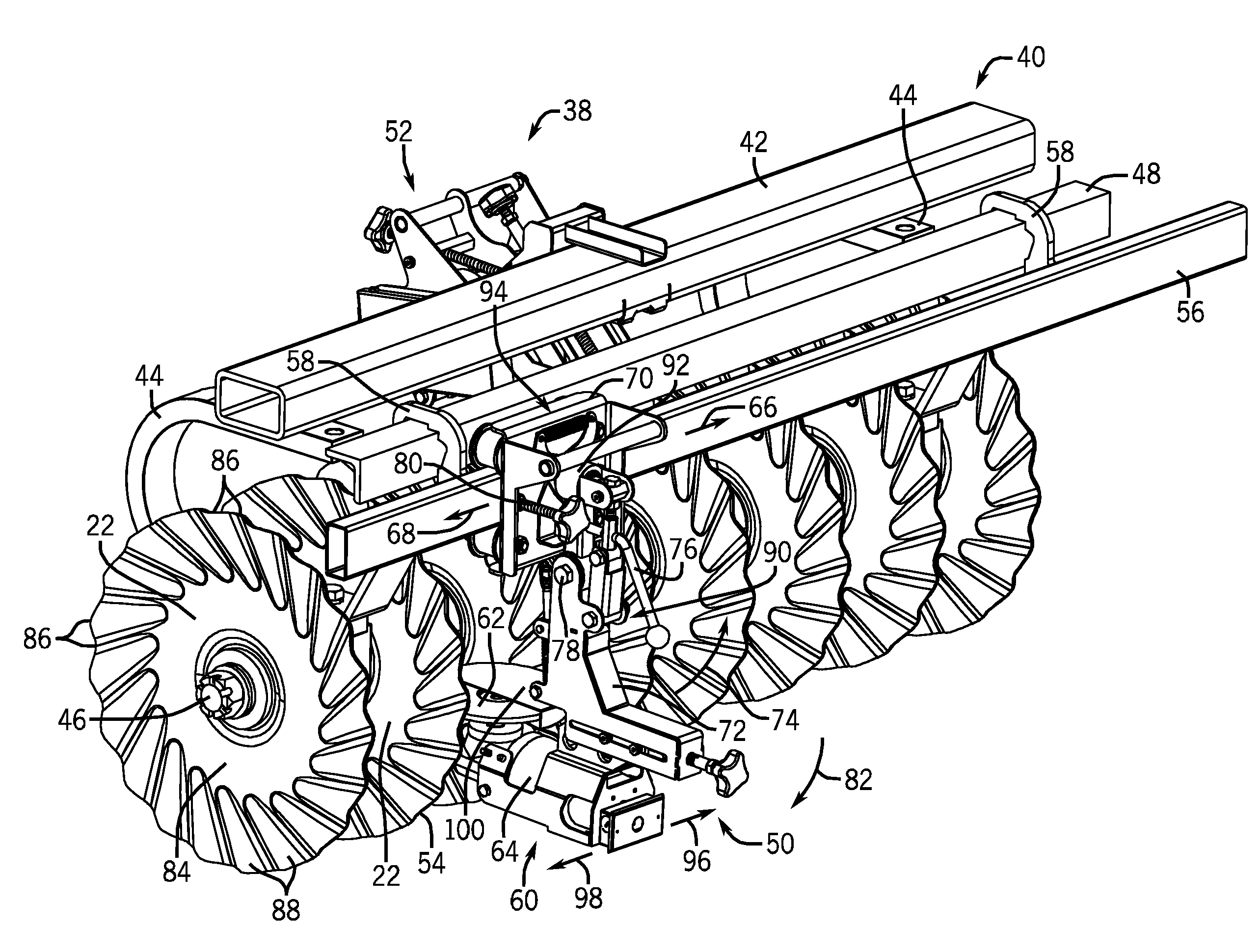

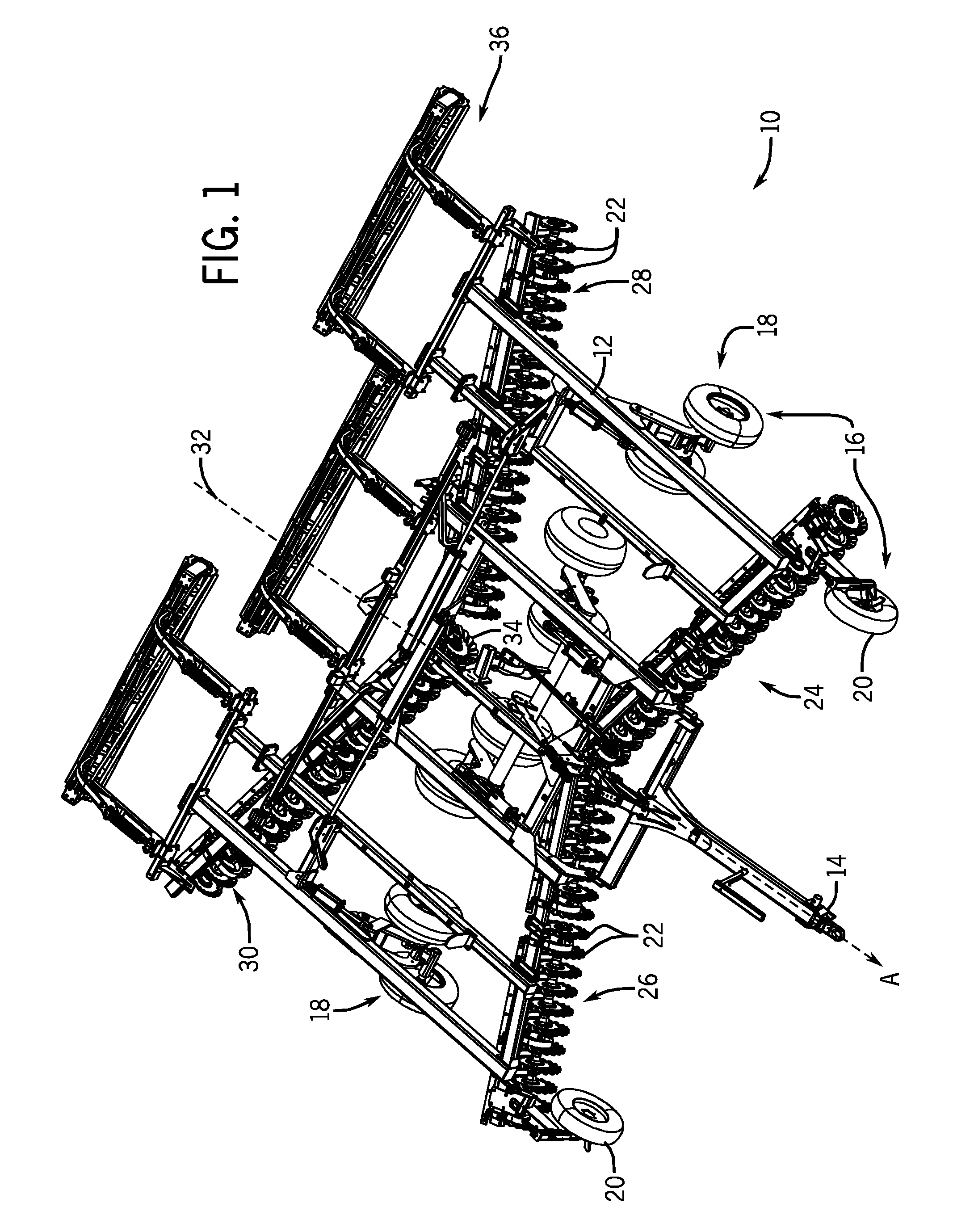

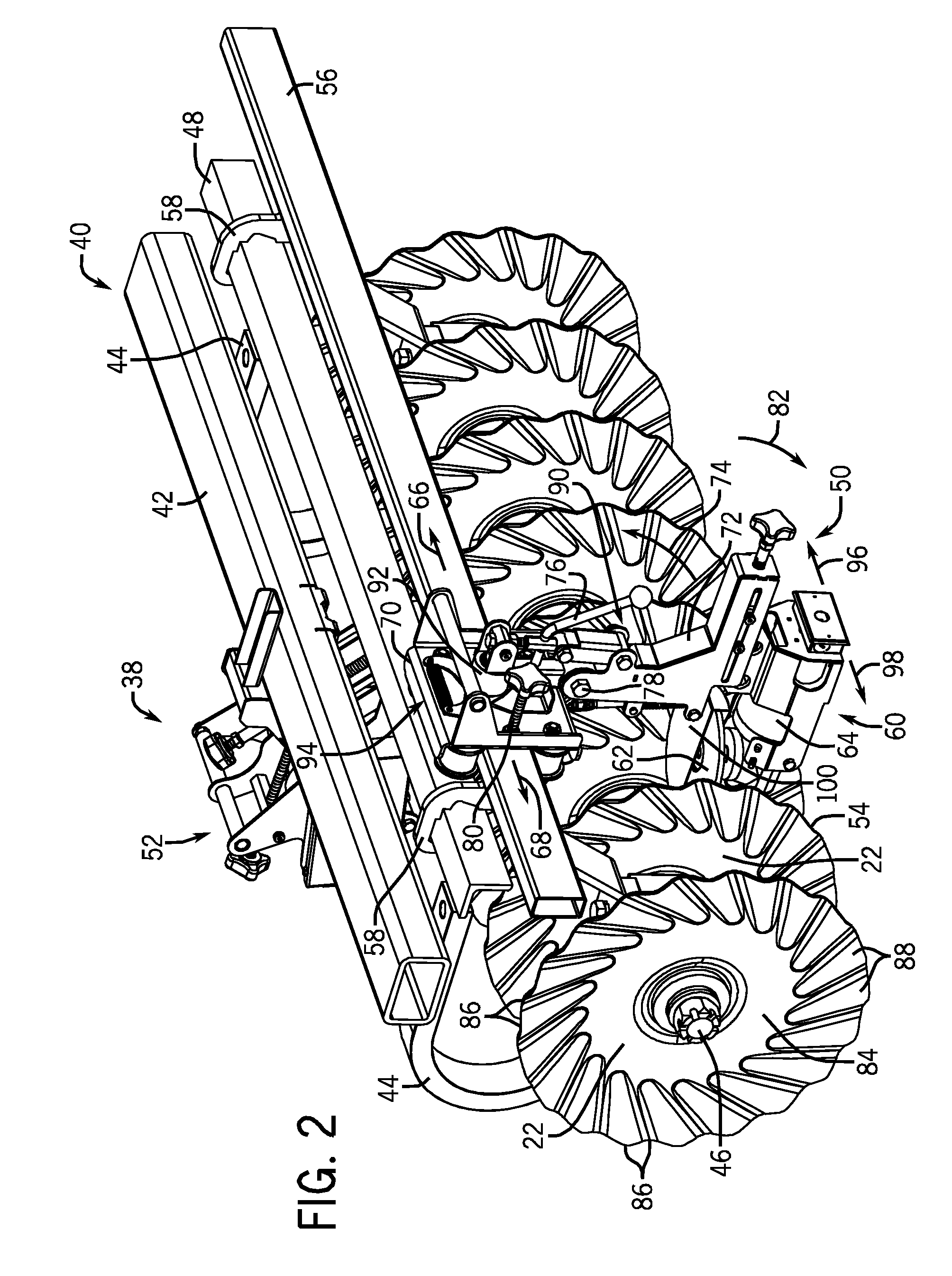

Blade sharpening system for agricultural implements

A blade sharpening system is provide that includes a base and a pendulous arm having a first end rotatably coupled to the base by a pivot joint. The blade sharpening system also includes a sharpener suspended by the pendulous arm and configured to engage a generally circular agricultural implement blade while mounted on the agricultural implement. The pendulous arm is configured to enable movement of the sharpener to accommodate lateral variations in blade profile.

Owner:BLUE LEAF I P

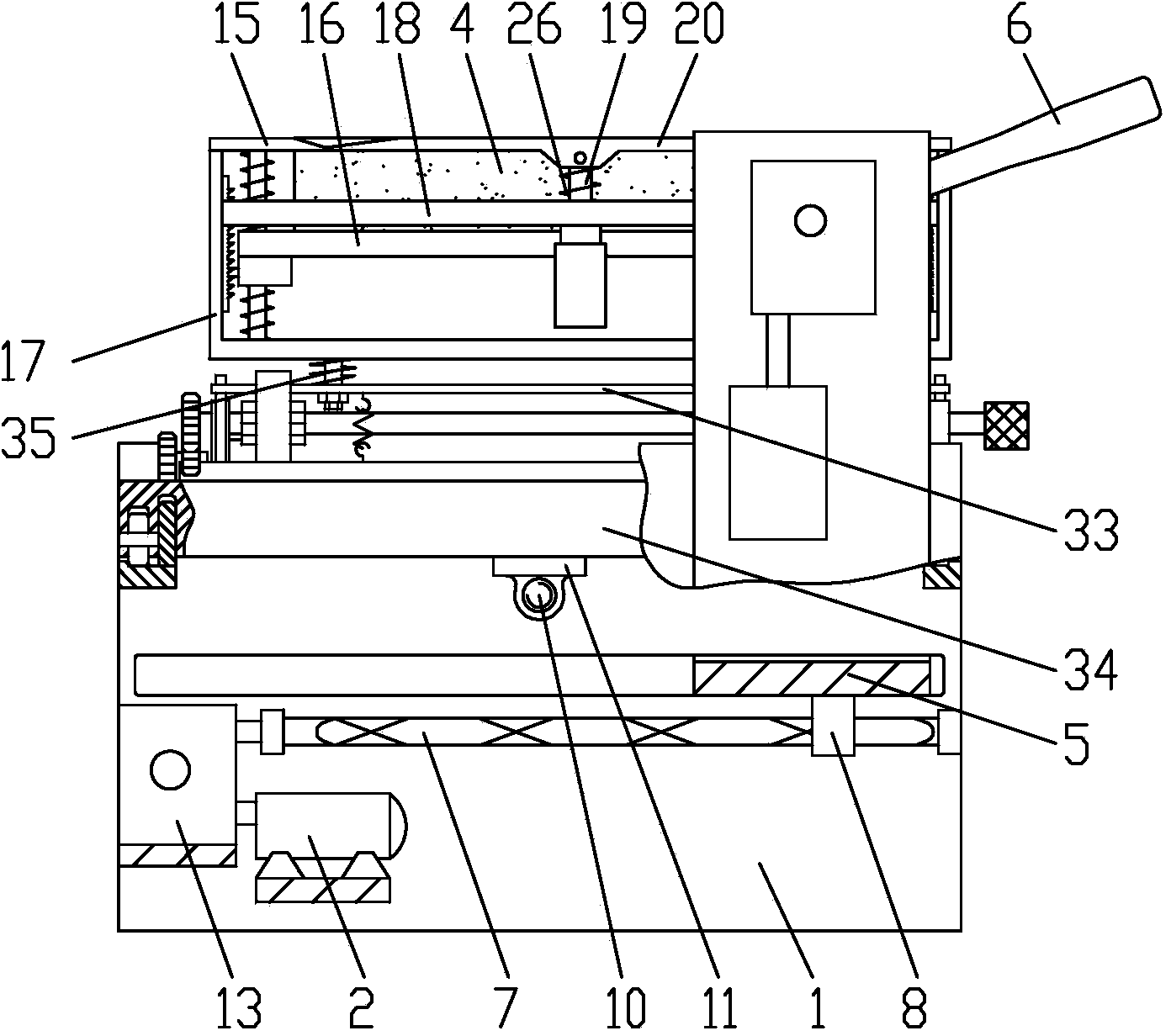

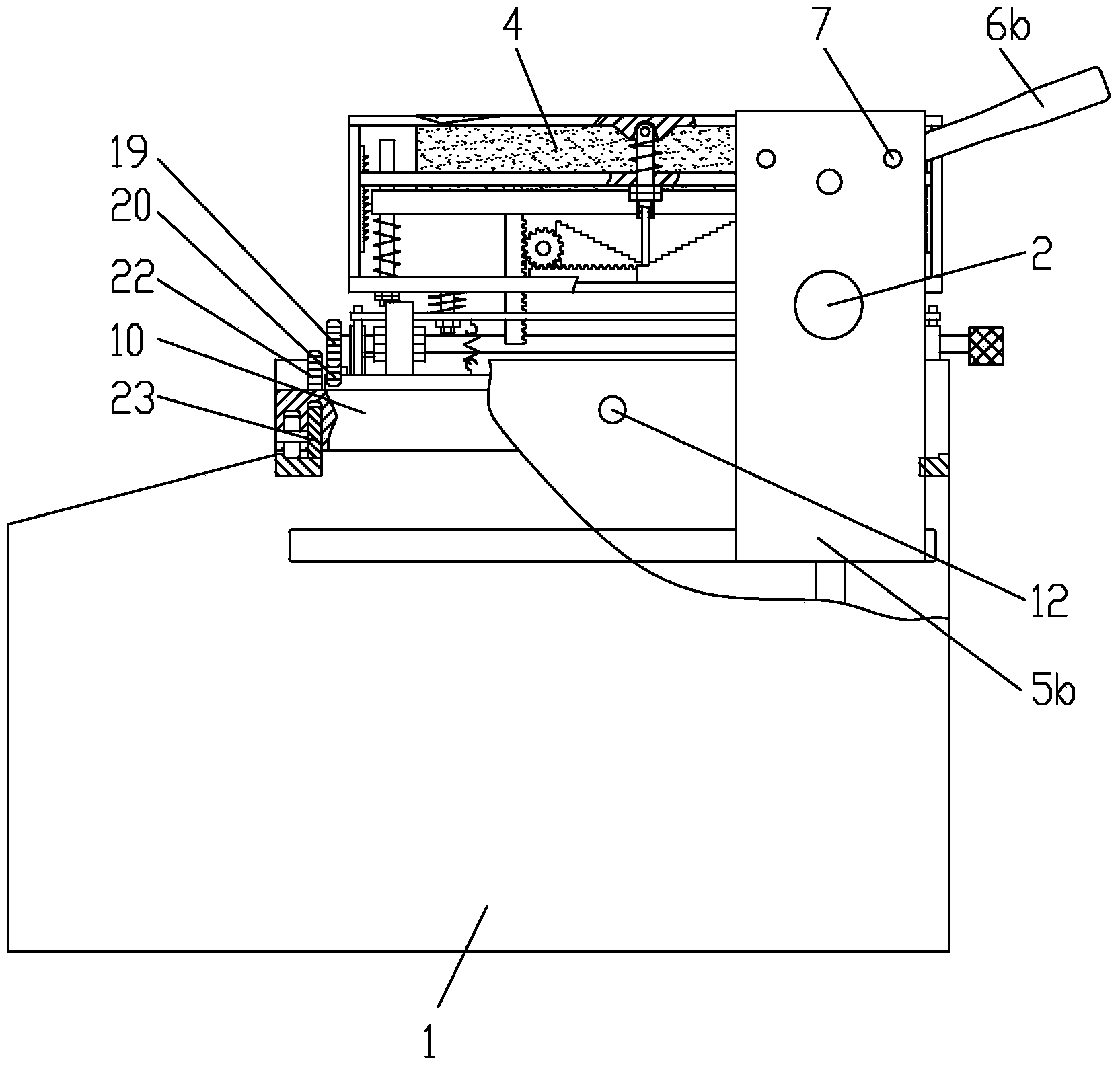

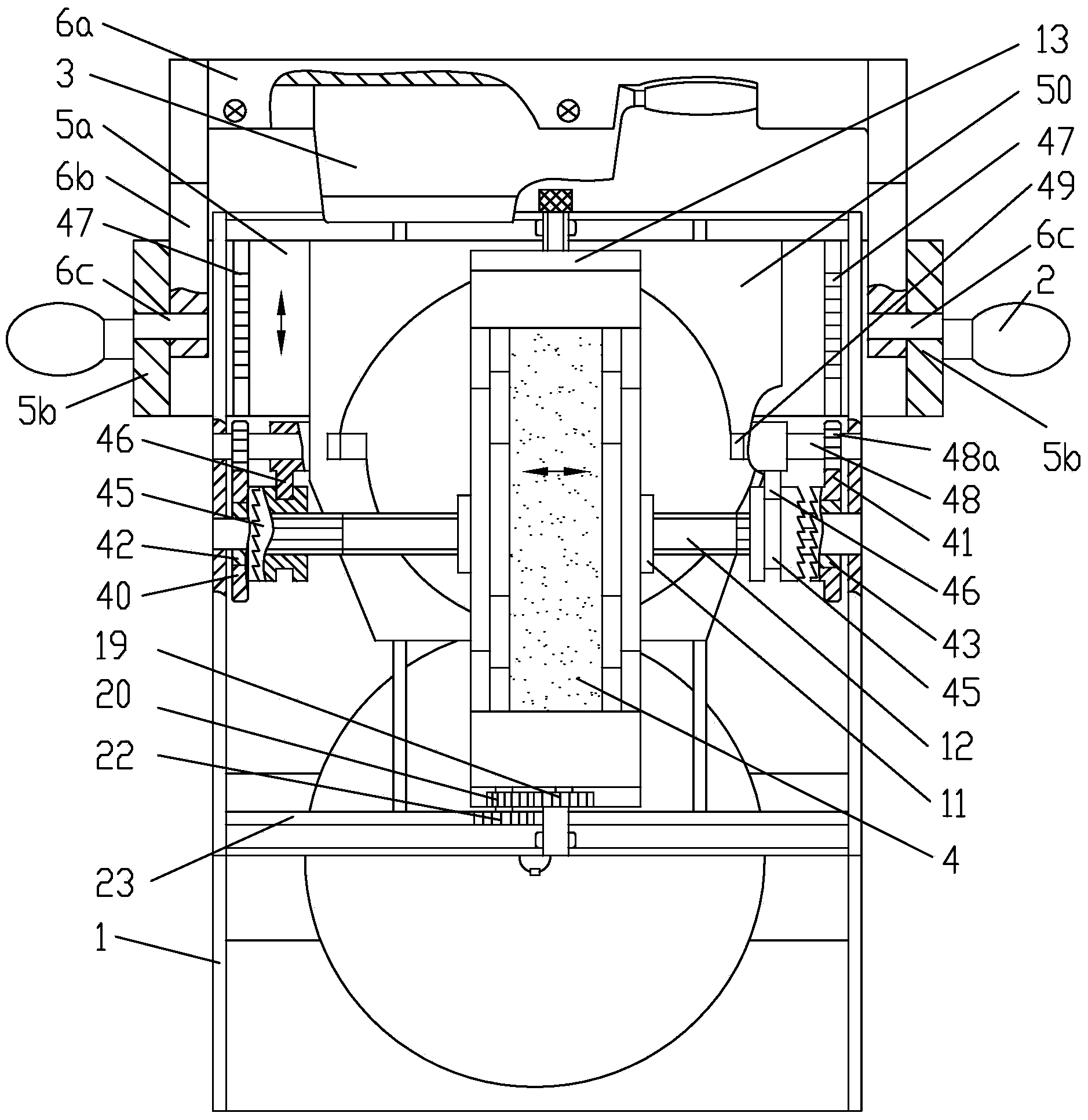

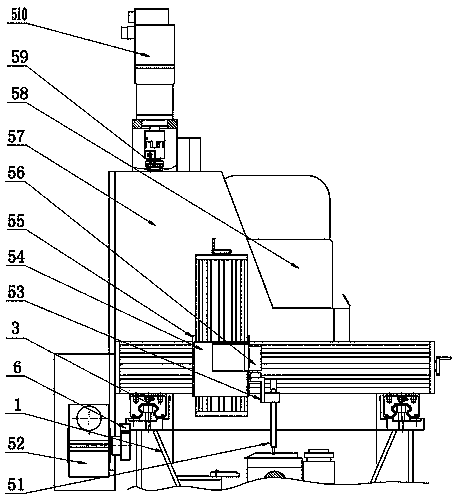

Kitchen knife sharpener

InactiveCN103817609AReal-time control of grinding timeReal-time control of grinding timesGrinding/polishing hand toolsPush and pullKnife sharpener

The invention discloses a kitchen knife sharpener comprising a frame, a drive motor and a control system. A knife rest and a grinder device are disposed on the frame. The knife rest comprises a knife rest base and a knife clamping part. The knife rest base comprises a horizontal base plate which is manually pushed and pulled to move longitudinally back and forth on the frame. The knife clamping part comprises a horizontal knife-mounting transverse arm and a vertical connecting arm. The vertical connecting arm is connected to a vertical connecting plate of the knife rest base and driven to rotate by a rotating motor. The grinder device is arranged between the horizontal base plate and the horizontal tool-mounting transverse arm. The knife clamping part forms two grinding positions, having an angle larger than 120 degrees and smaller than 180 degrees, on the knife rest base; when a knife is at one optional grinding position, the central plane of the knife and the upper plane of a grinder have an included angle larger than 0 degree. The kitchen knife sharpener has the advantages that knife grinding loss is low, environmental pollution is zero, knife sharpening effect is high, and utilization rate of the grinder is high.

Owner:重庆臻憬科技有限公司

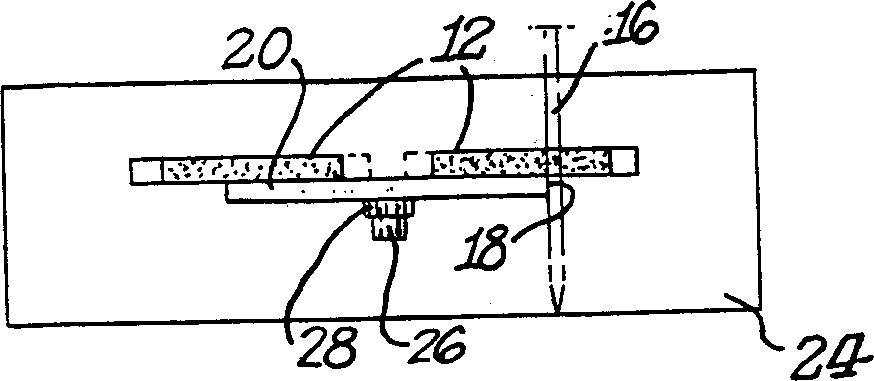

Cutter blade sharpener and method

InactiveUS20020173251A1Easy to operateUniform sharpeningRevolution surface grinding machinesOther manufacturing equipments/toolsKnife sharpenerClassical mechanics

A cutter blade sharpener and method allows for quick, easy and uniform sharpening of tree felling head circular cutters. Each cutter blade is individually removed from the circular cutter and is positioned on the sharpener, one at a time whereby the cutter blades are then ground in uniform fashion. The sharpener includes a tubular frame having a slide table mounted thereon for both lateral and longitudinal movement of the cutter blade proximate the grinding wheel.

Owner:COBBLER LARRY R

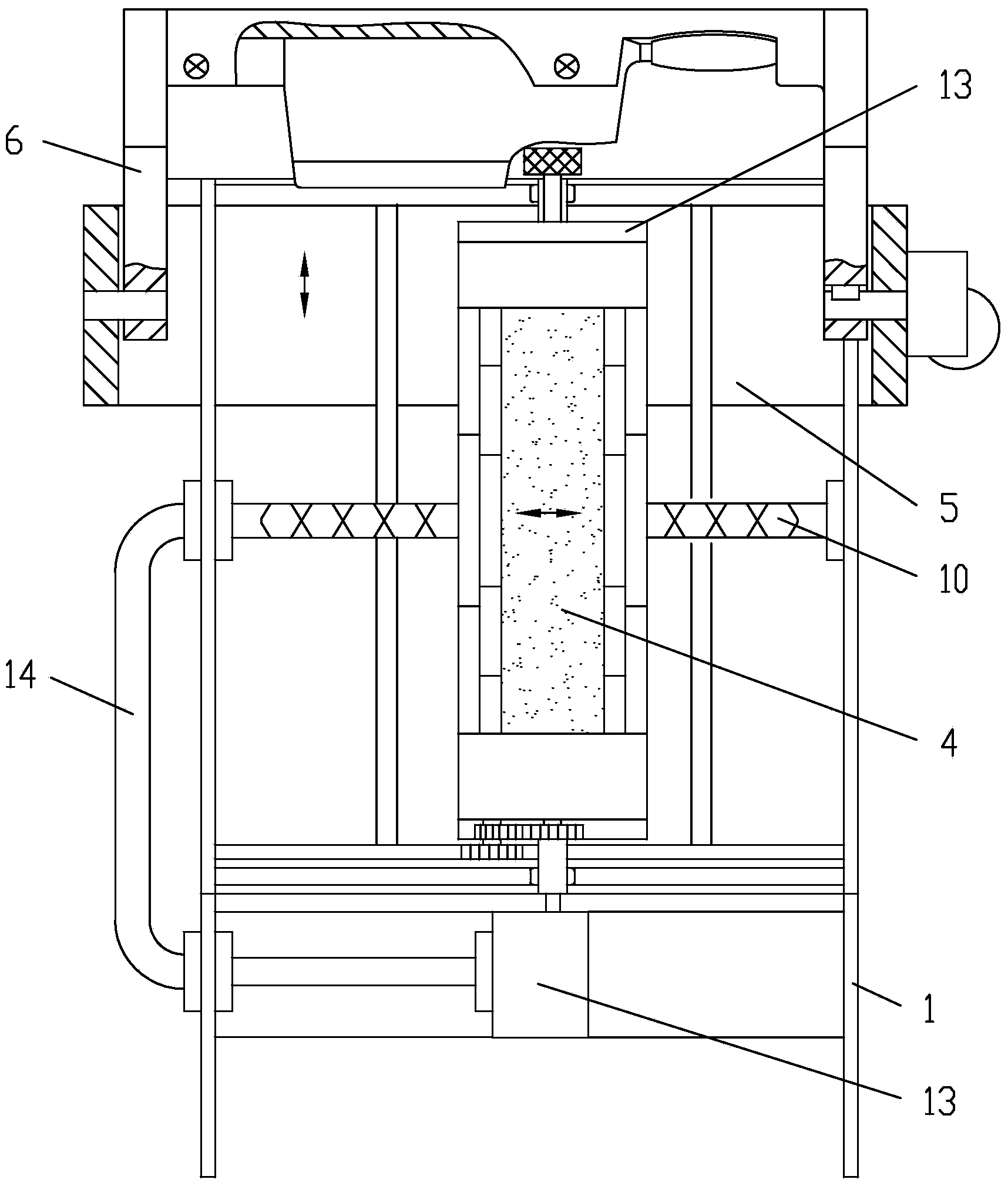

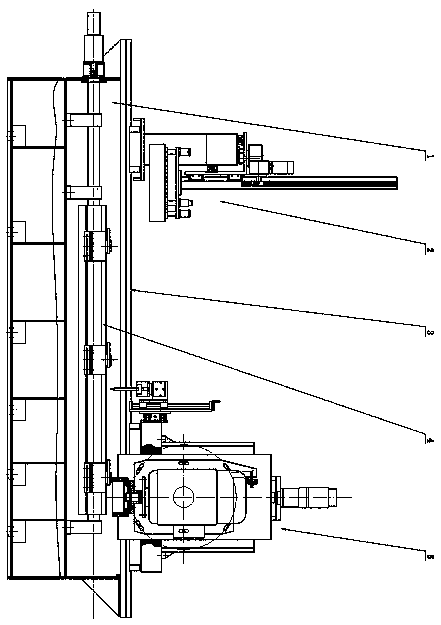

Straight knife sharpener

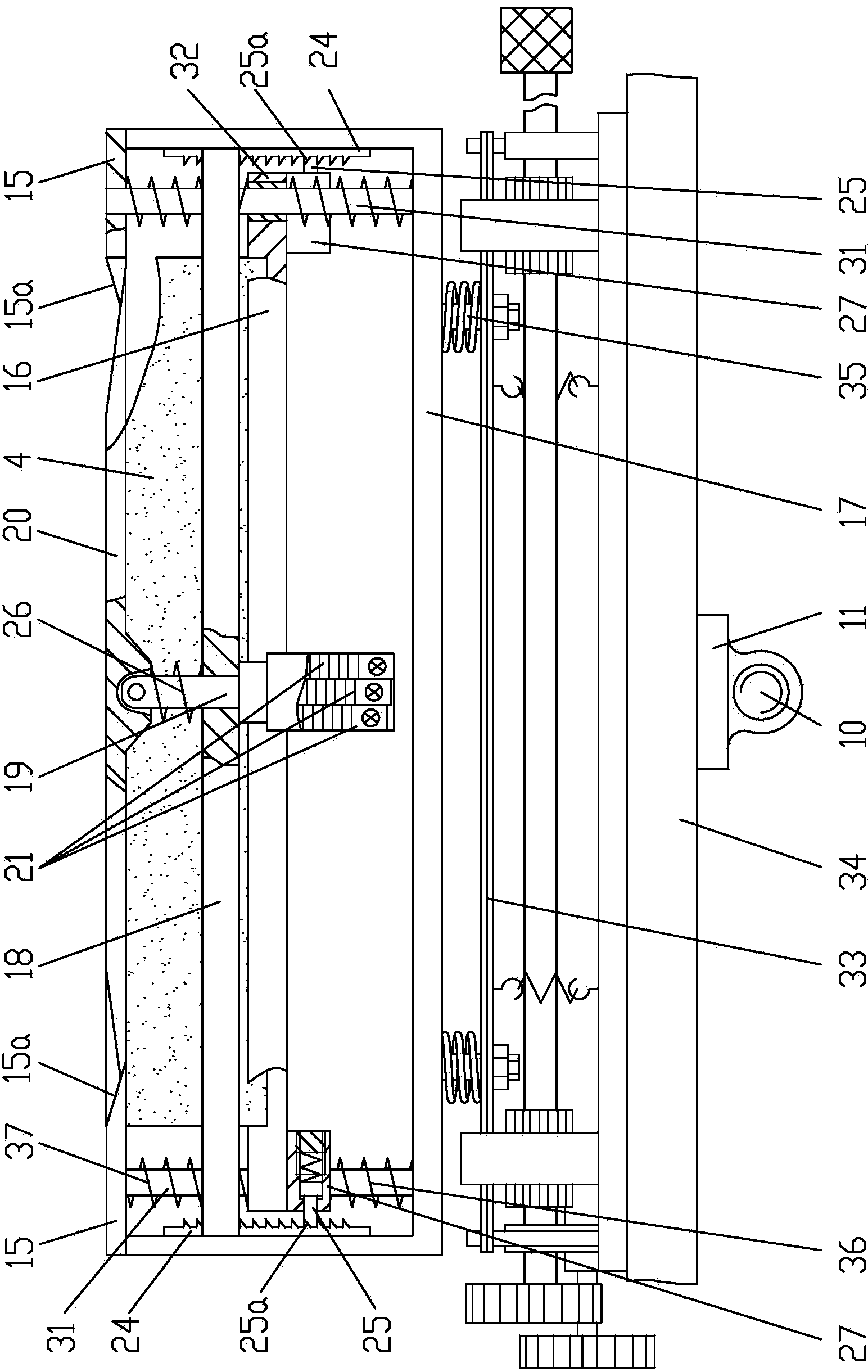

PendingCN109531293AMeet grinding requirementsSimple structureGrinding carriagesGrinding drivesAutomatic controlKnife sharpener

The invention discloses a straight knife sharpener comprising a lathe body, a grinding head assembly and a workbench assembly. Two lathe body linear guide rail pairs are arranged on the top face of the lathe body. The grinding head assembly is supported on the lathe body slidably by a grinding head movable base through the two lathe body linear guide rail pairs. A grinding head motor is installedon a grinding head sliding seat through a grinding head installing plate, and the grinding head sliding seat is driven by a grinding head feed motor and is slidably supported on the grinding head movable base. Position sensors are arranged on the grinding head movable base through vertical and transverse moving sliding seats and a detection driving device. The workbench assembly is located betweenthe left and right lathe body linear guide rail pairs. A workbench is supported on a lathe body in an oscillatory mode. A workpiece locating plate and a workpiece locating push arm are arranged on the two sides of a workbench body correspondingly. A grabbing manipulator is further slidably supported on the lathe body through the lathe body linear guide rail pairs and a side face linear guide railpair. Automatic feeding and discharging and automatic control of grinding precision can be achieved through the straight knife sharpener, a straight knife plane and a cutting edge bevel can be groundthrough one time of clamping, and production efficiency is high.

Owner:江苏贝斯特数控机械有限公司

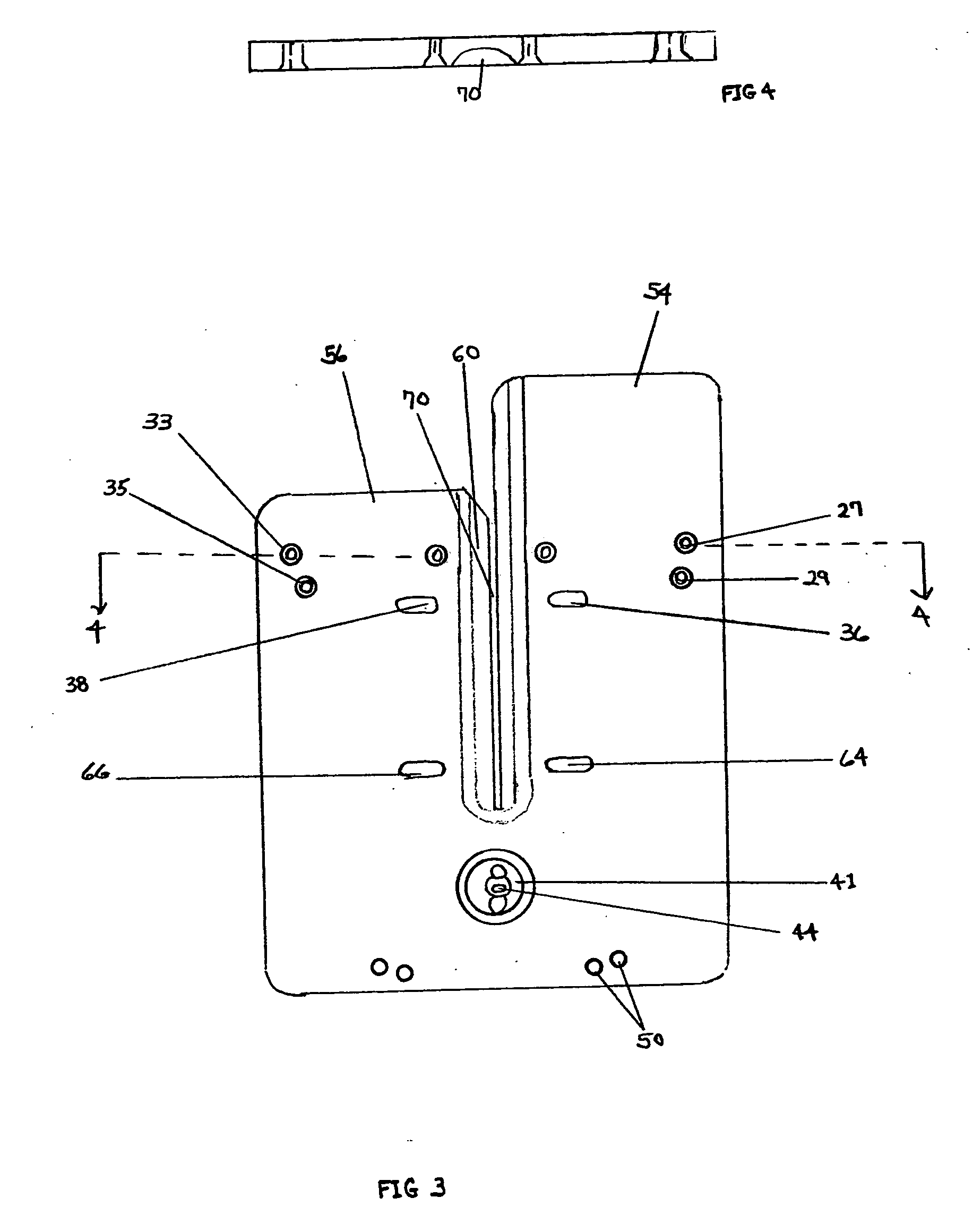

Knife sharpener

InactiveUS20070101826A1Easy to useMore durableCutting toolsGrinding/polishing hand toolsKnife sharpenerCam

A knife sharpener comprising a housing plate supporting a pair of special treated sharpening rods that are curved to a specified dimension for maximizing the knife sharpener's ability to utilize and engage adjustable flexible bumper arms mounted on a positive stop that provides the sharpener's rods best angles and pressure for obtaining an even, consistent edge realignment, no matter what sharpening technique is used. Adjustable spring and cam mechanisms enable easy positioning of the initial, crossing-point of the sharpening rods over the center of a sharpening slot. A stop member and resilient device are used as a single integral stop unit vertically moveable and mounted on the rear face of the housing plate.

Owner:SOUTHERN MECHANICAL & STRUCTRUAL

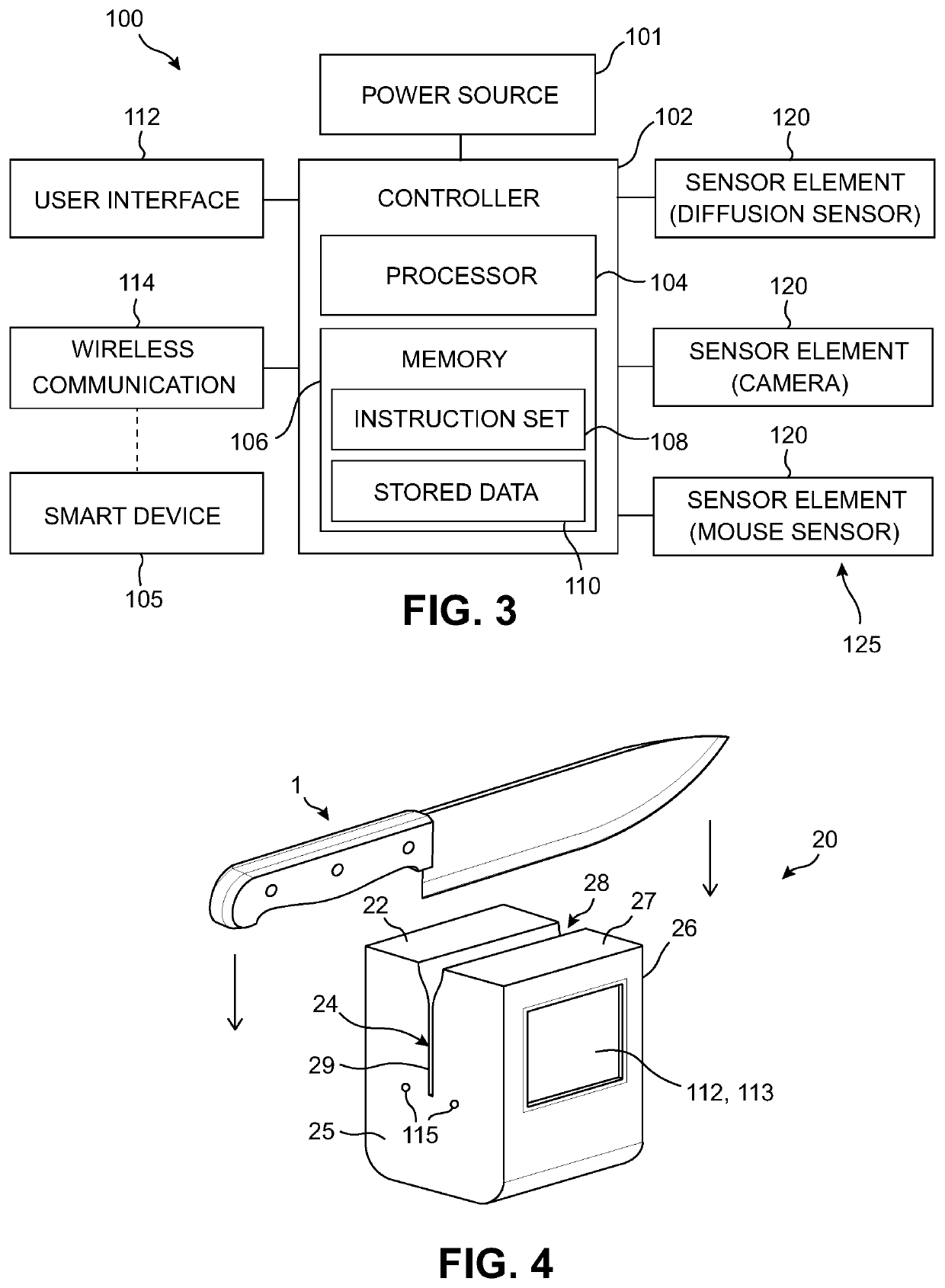

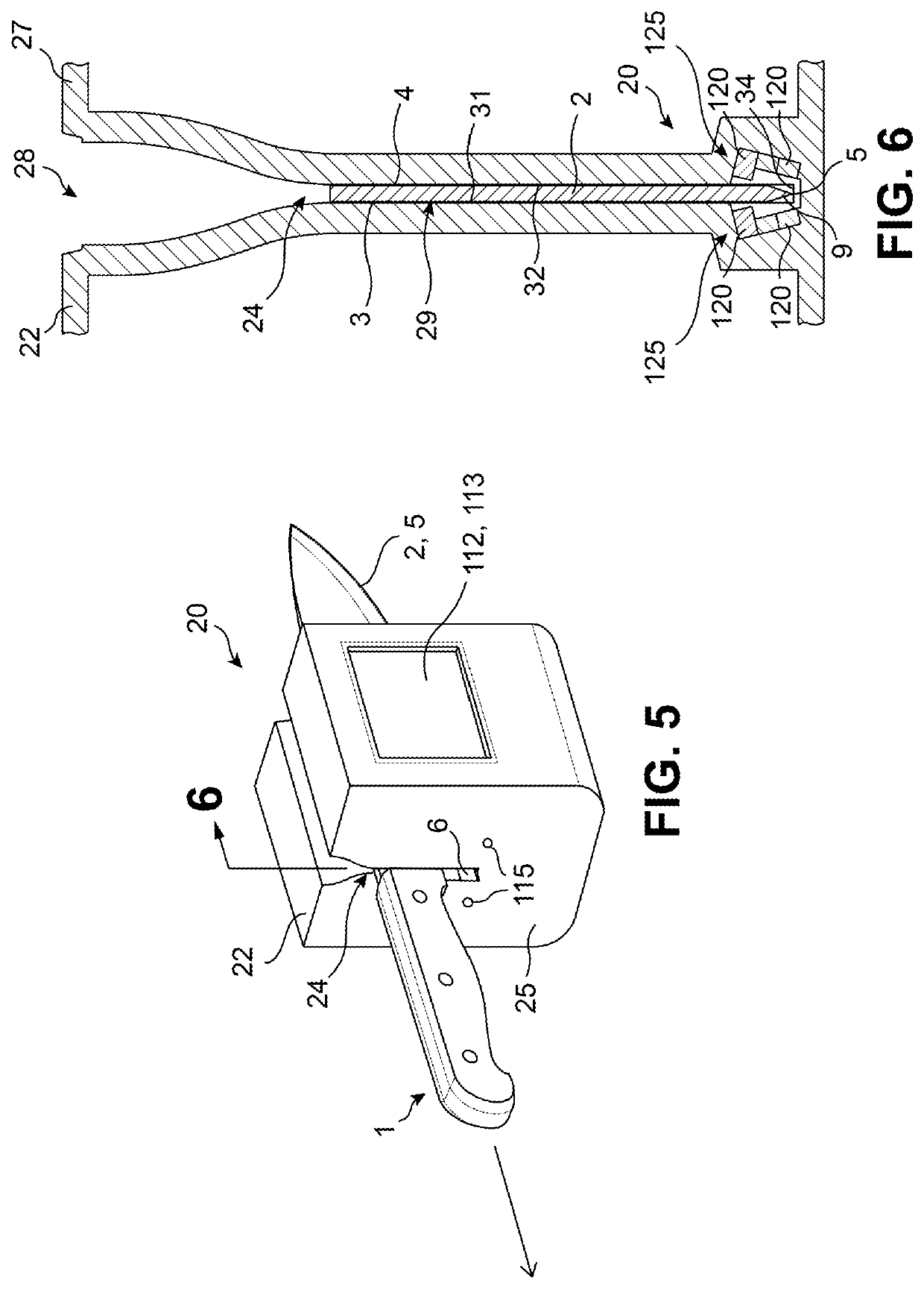

Assembly for sharpening and observing wear on a blade

ActiveUS20190358763A1Grinding feed controlOther manufacturing equipments/toolsKnife sharpenerEngineering

A knife sharpener comprises a grinding surface for grinding a blade of the knife when the blade is moved relative to the grinding surface and an observation device including a sensor element and a display element. The sensor element is configured to observe the blade and to collect data regarding the blade when the blade is moved relative to the sensor element. The display element is configured to communicate a condition of the blade to an operator of the observation device. The condition of the blade is based on the data collected by the sensor element when the blade is moved relative to the sensor element.

Owner:EDGECRAFT

Knife Sharpener System

InactiveUS20090056503A1Dishwasher safeNot rust over timeCutting toolsGrinding/polishing hand toolsKnife sharpenerEngineering

A knife sharpener system for efficiently and quickly sharpening a blade of a knife. The knife sharpener system generally includes a support structure, a sharpening unit including a retaining portion, wherein the sharpening unit extends from the support structure, at least one sharpening member extending from the sharpening unit and at least one magnet positioned within the sharpening unit, wherein the retaining portion is positioned between the sharpening member and the magnet and wherein a metal residue of a blade is magnetically attracted to the retaining portion via the magnet.

Owner:FRIESEN BRETT A +2

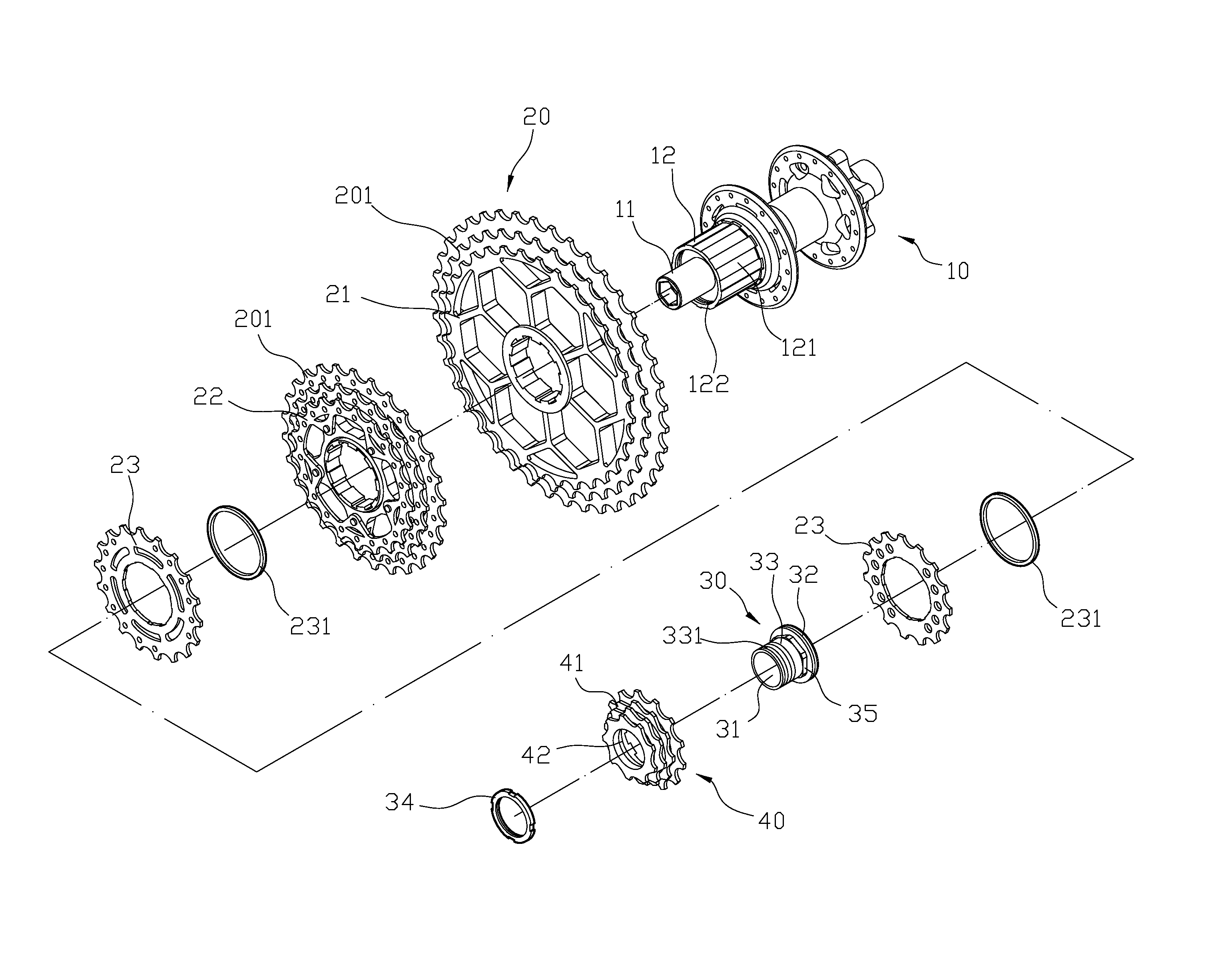

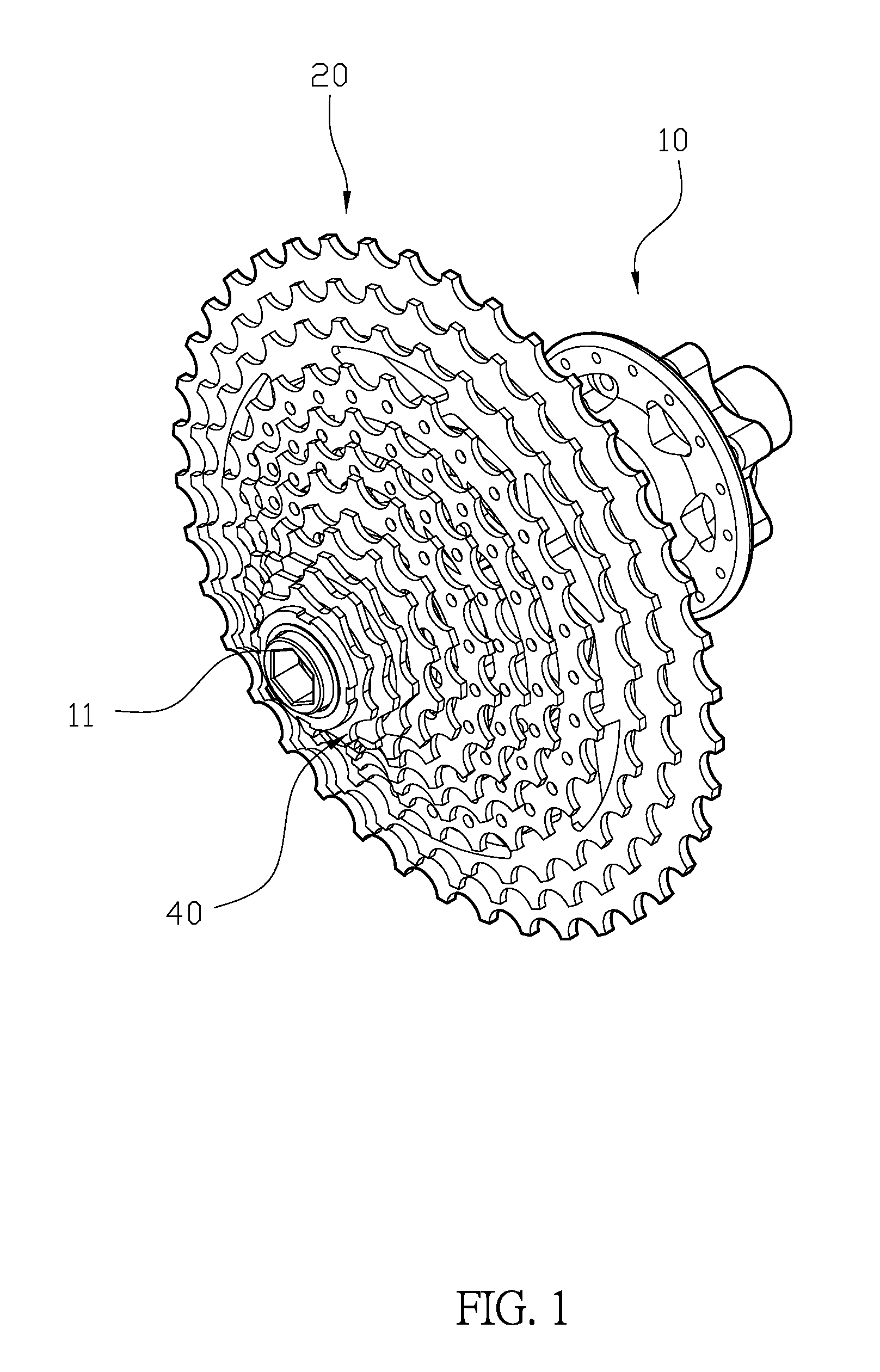

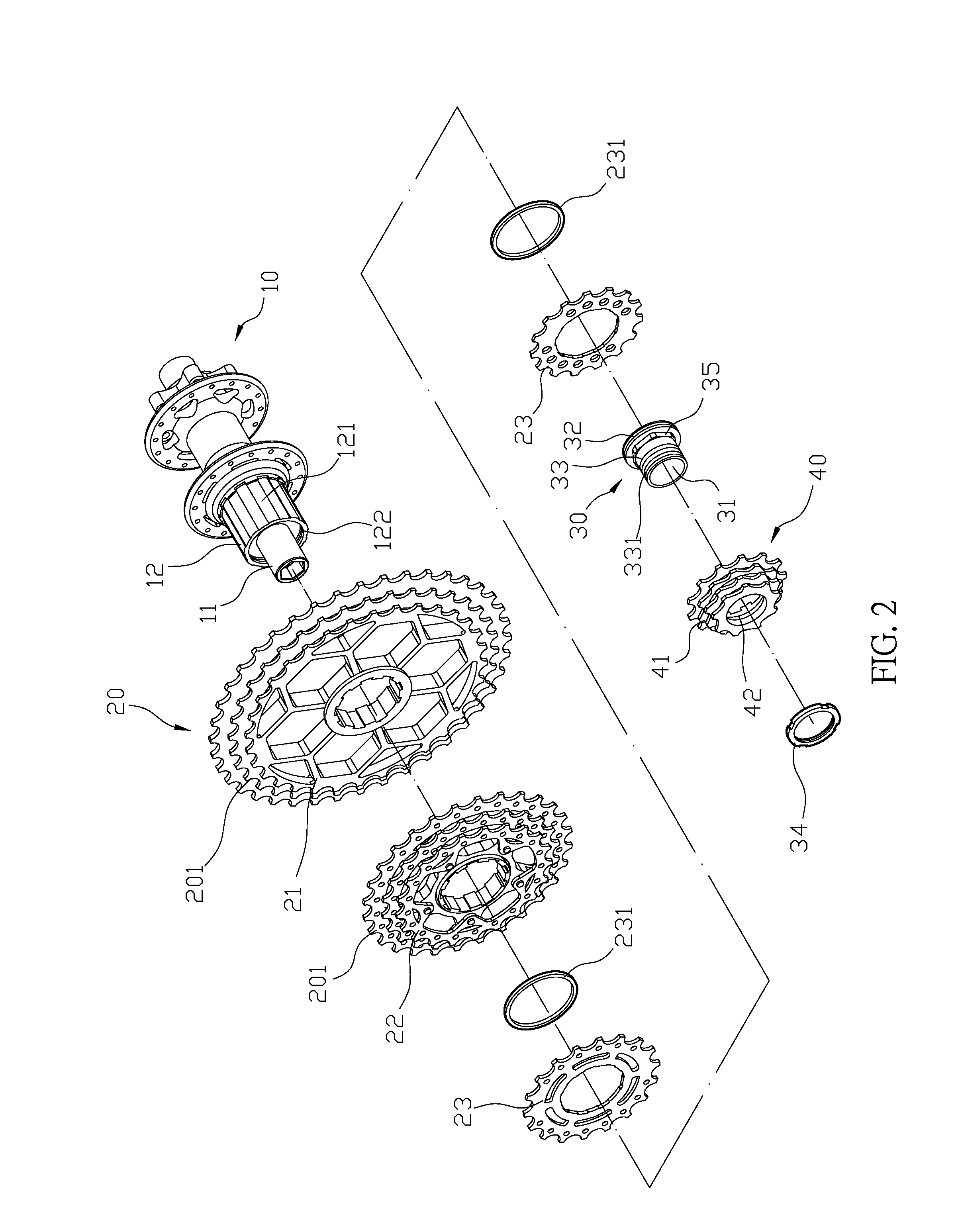

Bicycle hub and flywheel structure

An improved knife sharpener may include a hub body, a freewheel unit, a connecting sleeve and an external freewheel. The connecting sleeve connects to the ratchet sleeve of the hub body in order to provide more space for the external freewheel. With the design of the connecting sleeve and the external freewheel unit, the hub body loaded with more smaller freewheels provides more pedaling speeds for a bicycle travelling downhill. When cycling downhill by using the smaller diameters of the sprockets, the smaller sprockets of the external freewheel can help a cyclist to maintain an optimum pedaling speed in a slopy terrain, and the speed of the bicycle can be easily controlled.

Owner:CHOSEN

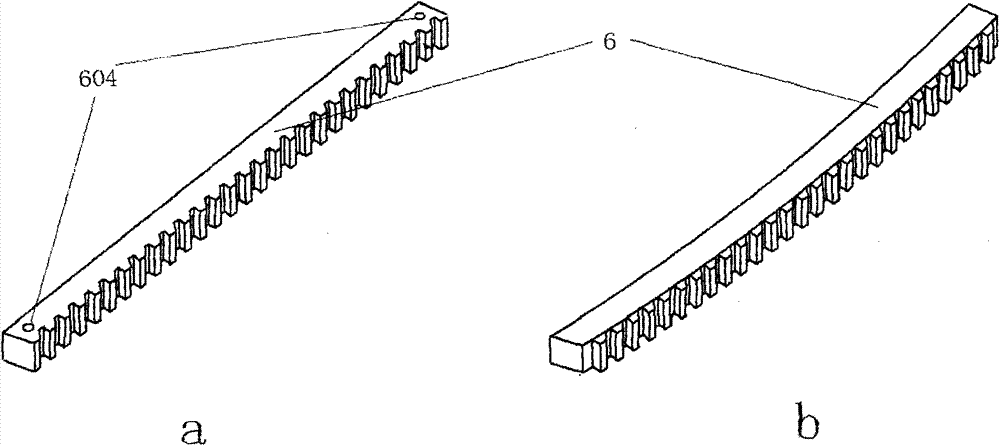

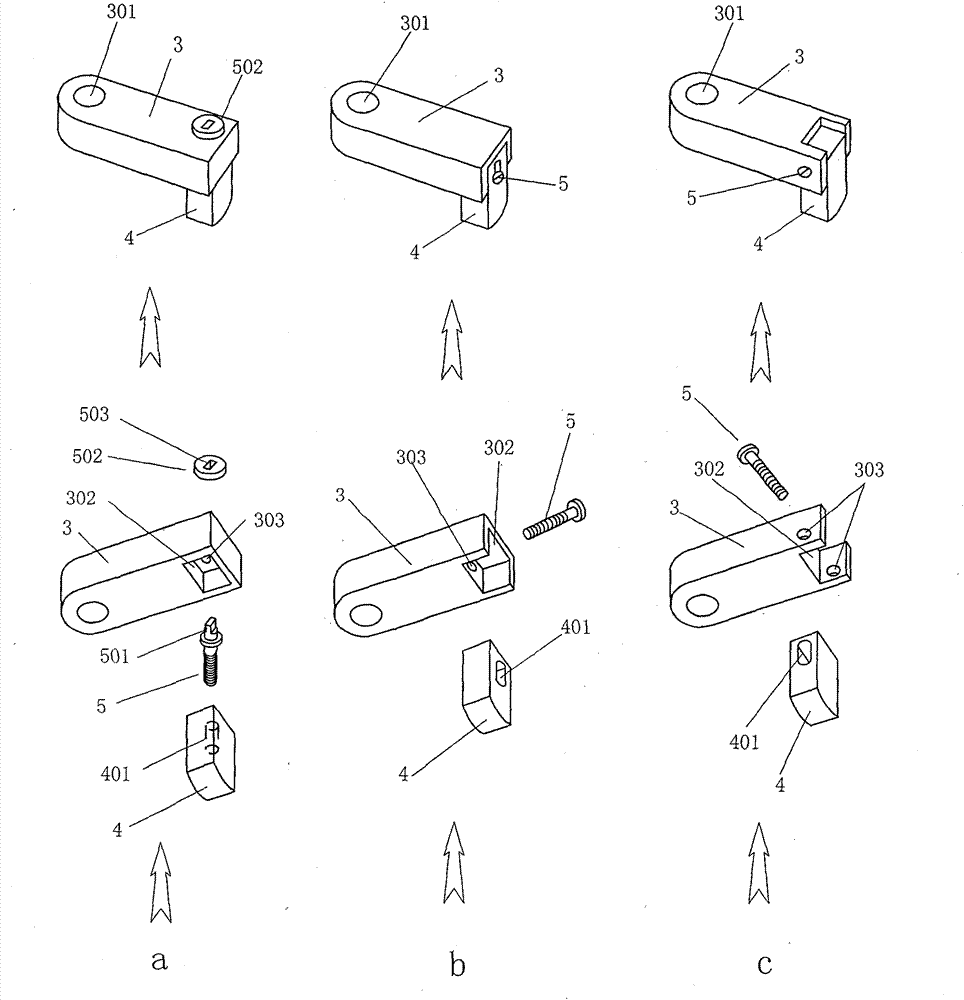

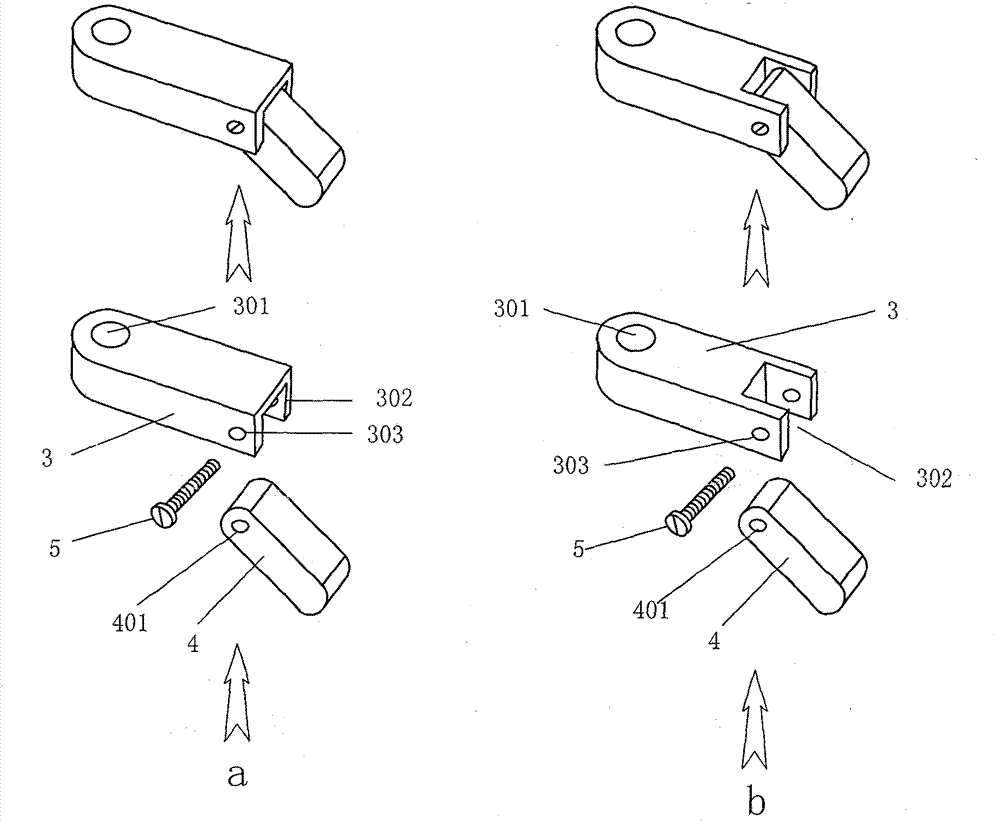

Gear grinding head and guide rail type manual knife sharpener

InactiveCN103659474ASolve the problem of partial wearUniform wearGrinding machine componentsOther manufacturing equipments/toolsLinear motionGear grinding

The invention discloses a gear grinding head and a guide rail type manual knife sharpener. The guide rail type manual knife sharpener mainly comprises the gear grinding head which is composed of a grinding body and a stem gear, a grinding head fixing part, a connecting rod, an adjustable tailstock, a tailstock positioning screw rod and a rack type guide rail, wherein the grinding body is a cylinder, one end face of the grinding body is a grinding surface, the other end face of the grinding body is an installation surface, a gear is arranged in the middle of the stem gear, a center positioning pillar is arranged at one end of the stem gear, the end, provided with the center positioning pillar, of the stem gear is bonded with and fixed to the grinding body, the other end of the stem gear is a grinding head shaft which is mounted at one end of the connecting rod, a tailstock installation groove is formed in the other end of the connecting rod, the adjustable tailstock is mounted in the groove, the adjustable tailstock is stretchable or foldable entirely, the rack type guide rail is linear or arc-shaped, a tooth row is arranged on one lateral side of the guide rail and can drive the gear on the gear grinding head in a rubbing mode to enable the gear to rotate proactively and limit the linear motion of the gear grinding head so that the grinding surface of the gear grinding head can be abraded evenly and be prevented from deforming, and meanwhile, the sharpening efficiency is improved remarkably.

Owner:郭广仁

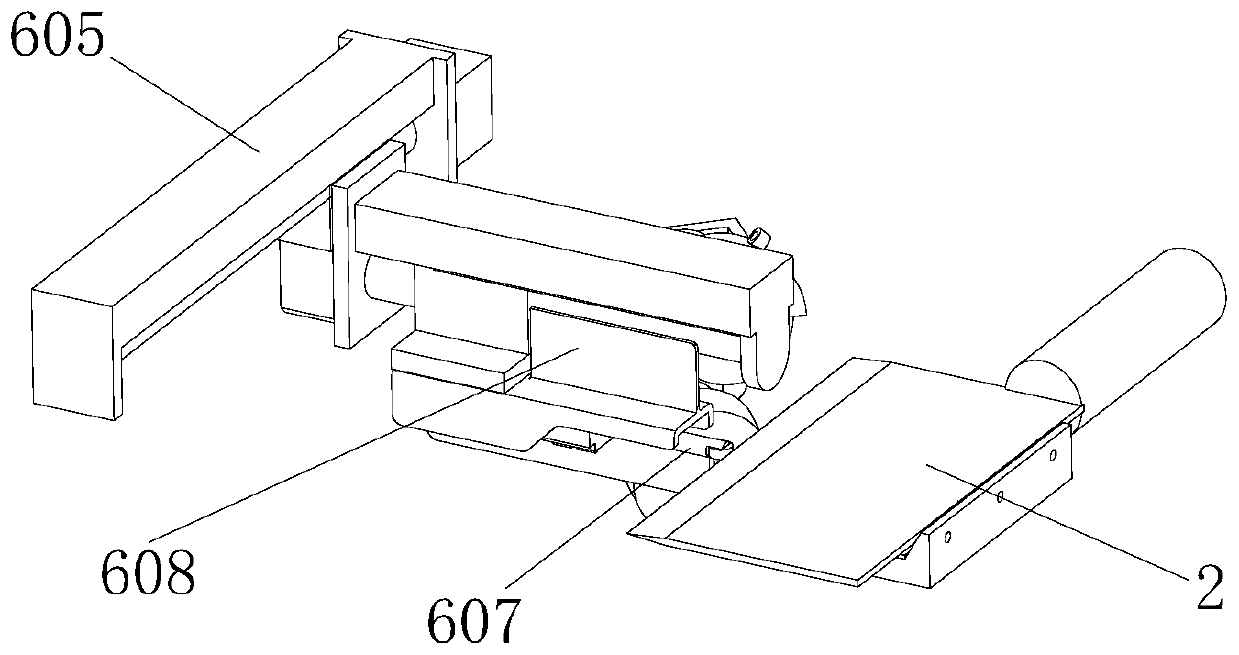

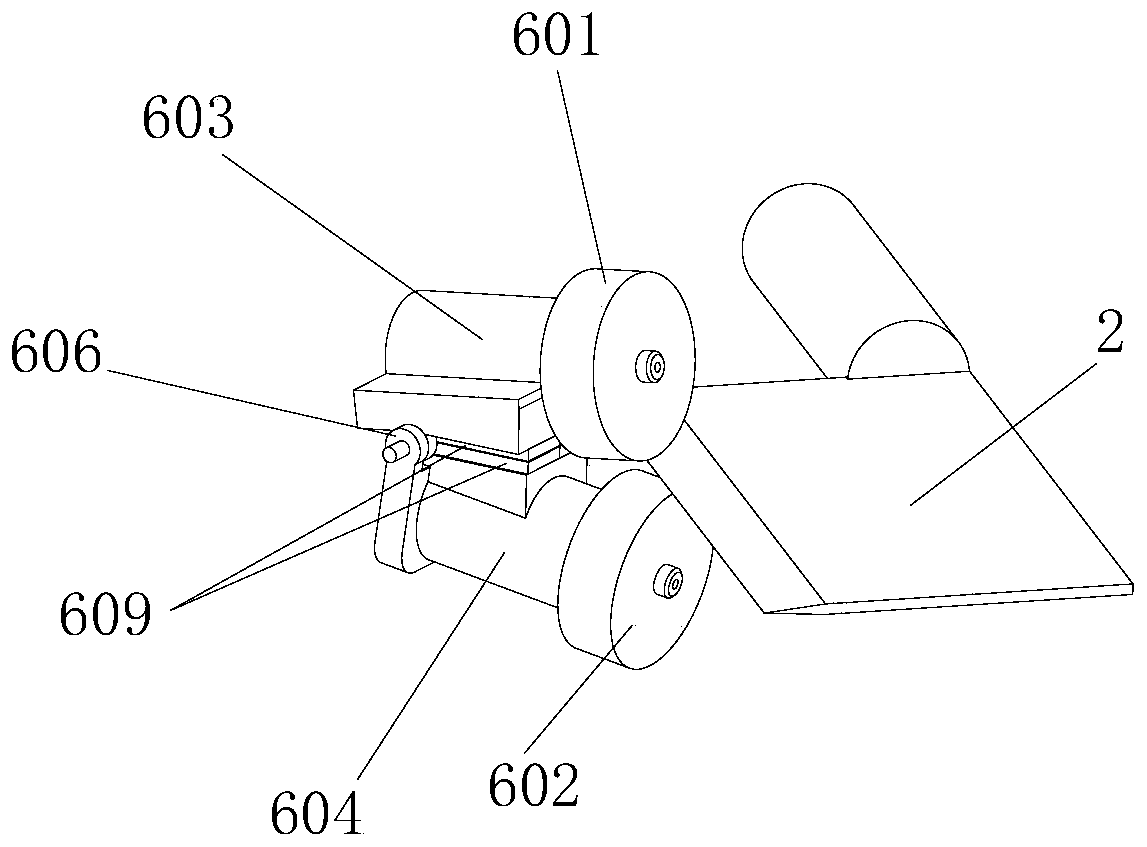

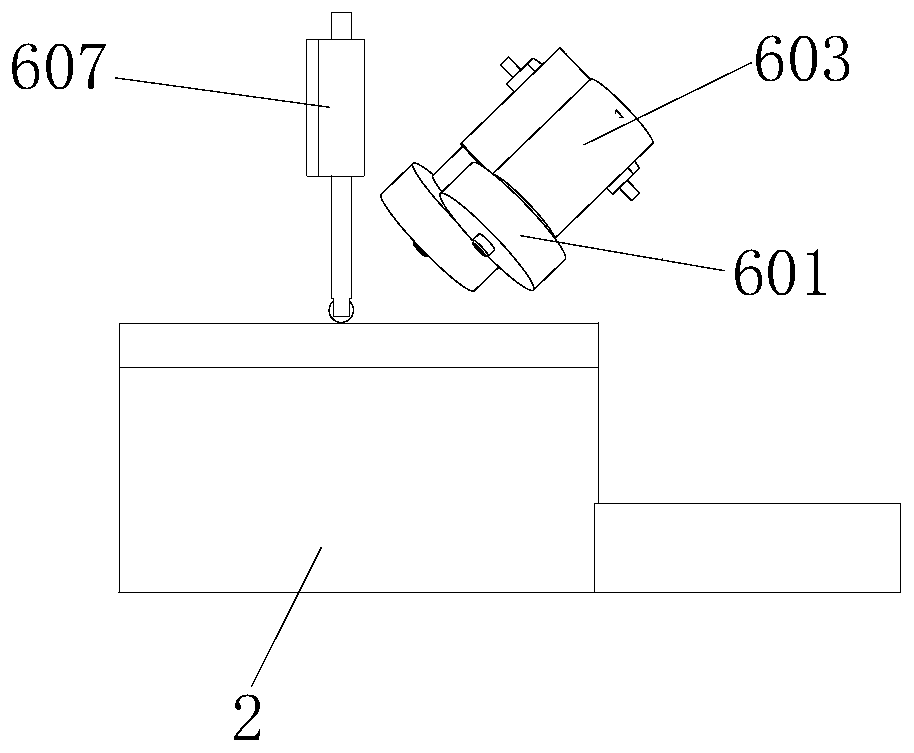

Knife sharpening assembly of knife sharpener

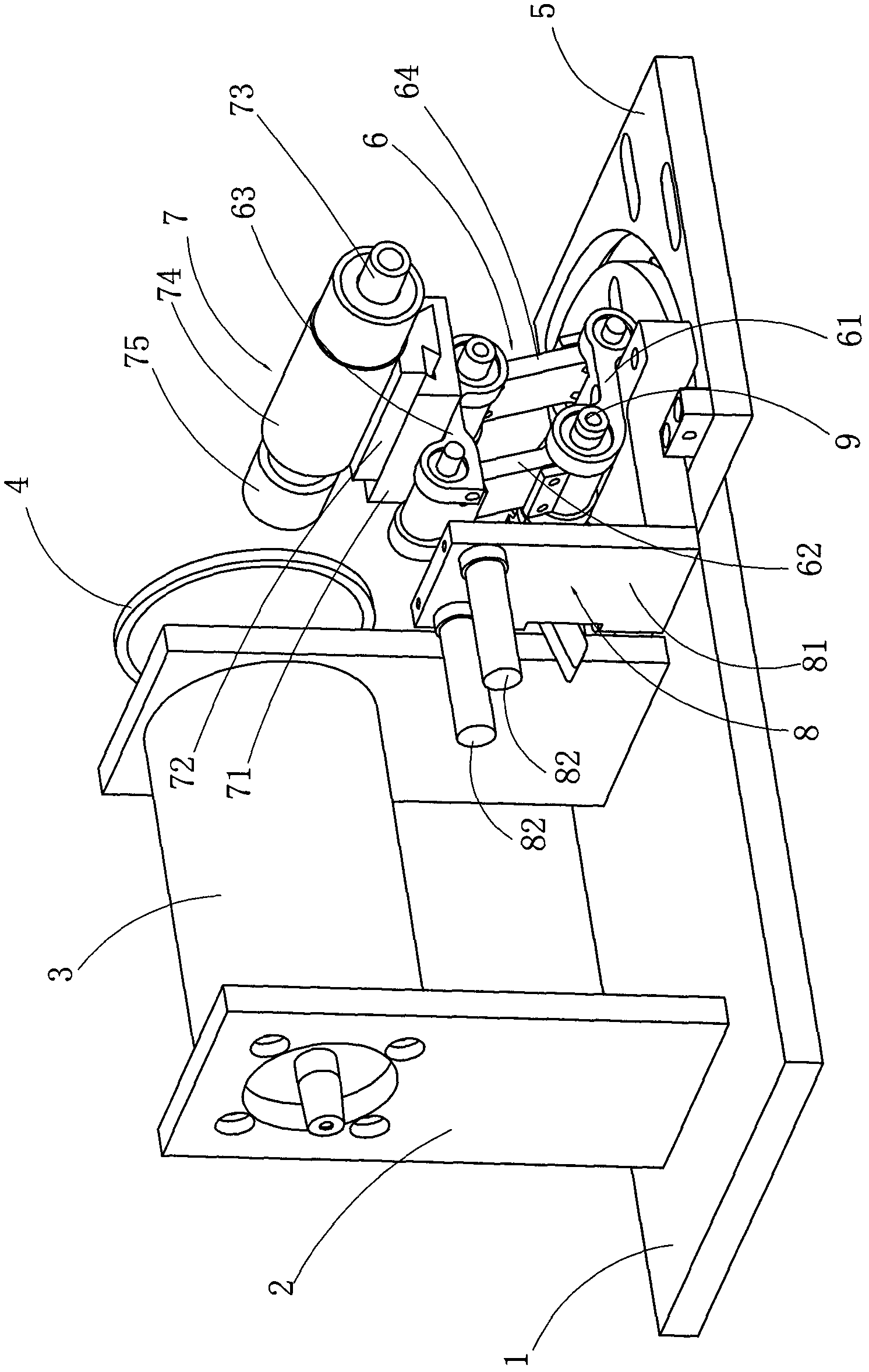

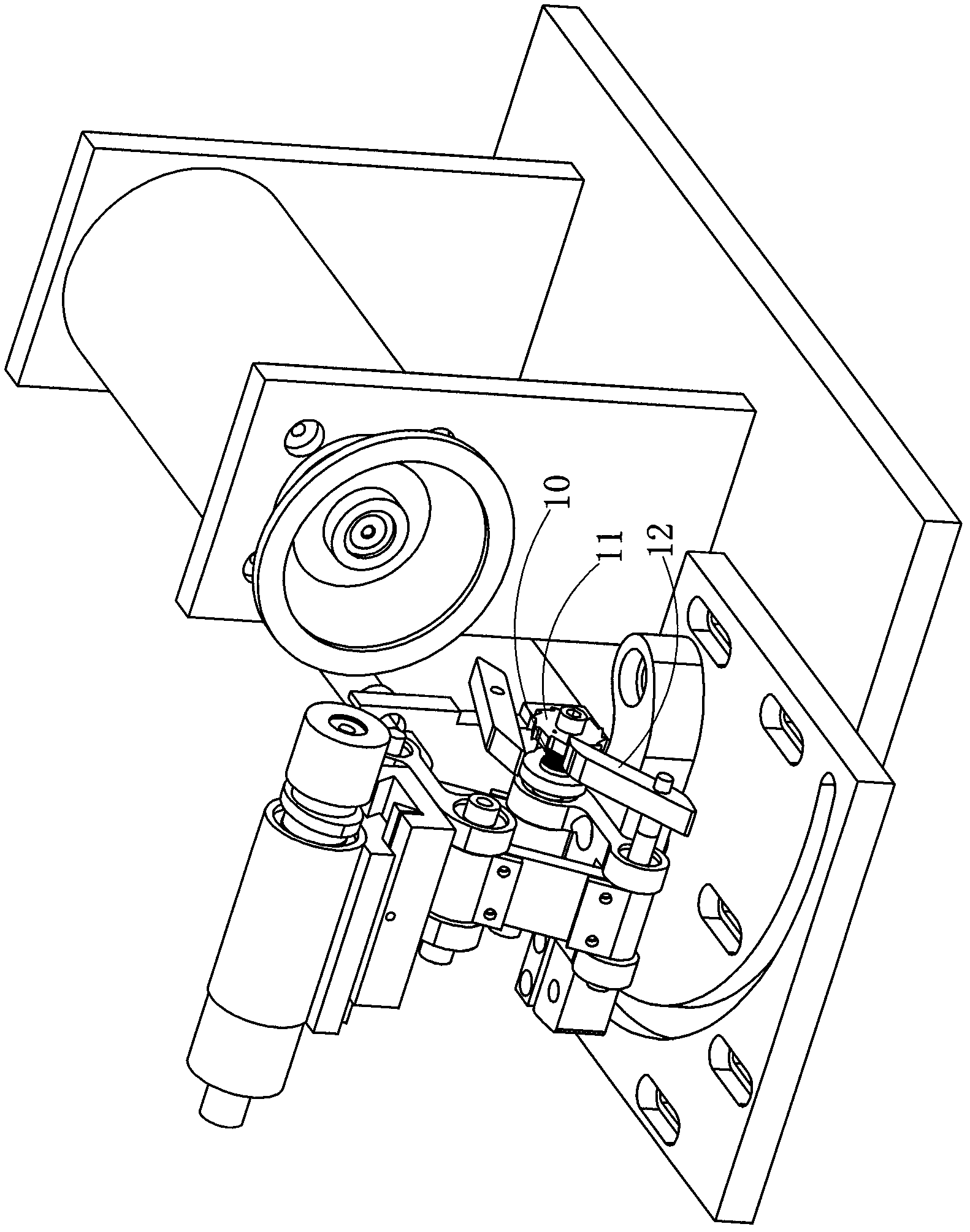

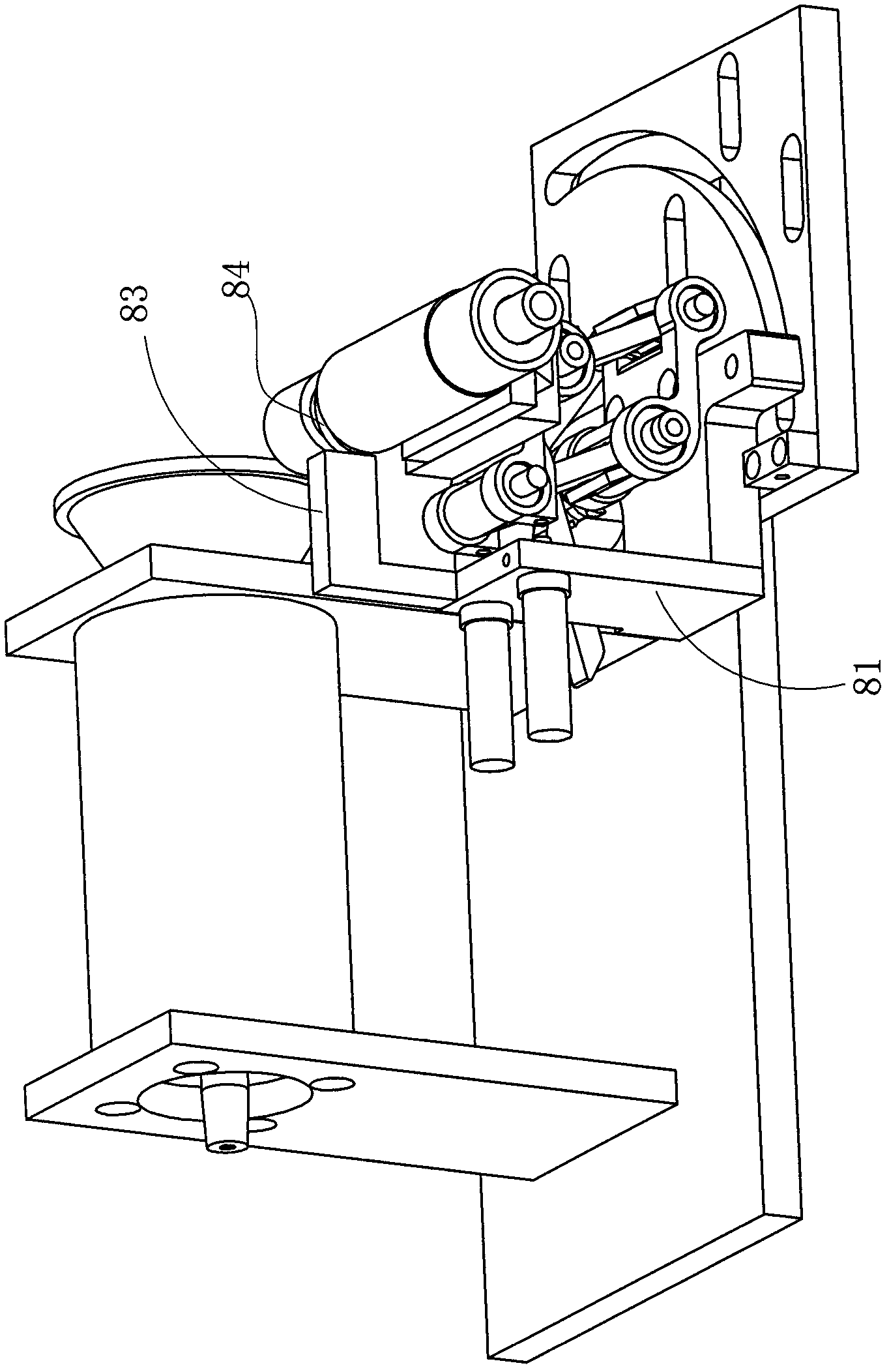

InactiveCN110524322ASolve the current situation that the same knife grinder cannot be used for grindingOther manufacturing equipments/toolsGrinding machinesKnife sharpenerEngineering

The invention discloses a knife sharpener, in particular to a knife sharpening assembly of the knife sharpener. The knife sharpening assembly is installed in a knife sharpener body and comprises an upper grinding wheel (601), a lower grinding wheel (602), an upper grinding wheel motor (603), a lower grinding wheel motor (604) and a grinding wheel walking device (605), and a contracting device (609) enabling the upper grinding wheel (601) and the lower grinding wheel (602) to get close to each other is arranged between an upper twisting base and a lower twisting base. According to the invention, the distance between the upper grinding wheel and the lower grinding wheel can be automatically adjusted according to the thickness of the knife edge of the knife so as to adapt to different knives,so that the knife sharpener can be suitable for most household knives, and the current situation that a household knife grinder is poor in universality is solved.

Owner:成都零柒叁科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com