Knife sharpening assembly of knife sharpener

A knife sharpening machine and component technology, applied in the direction of grinding machines, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve problems such as mechanical grinding that cannot be automated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

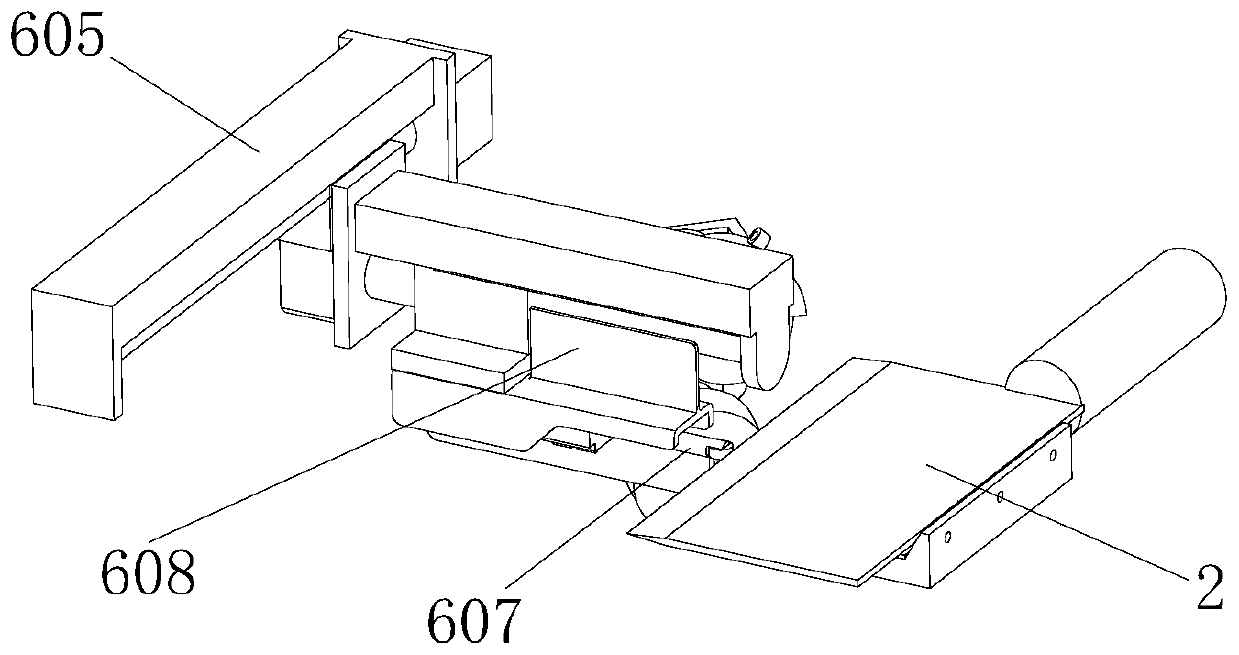

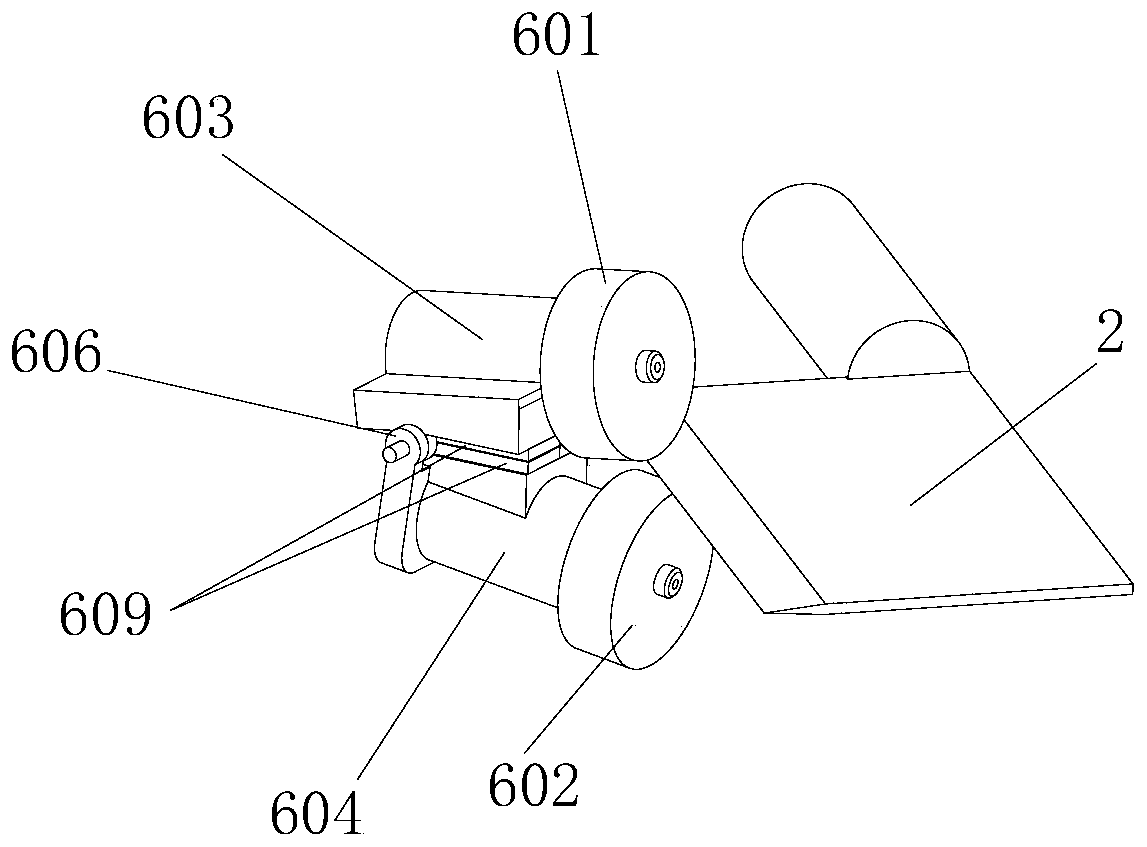

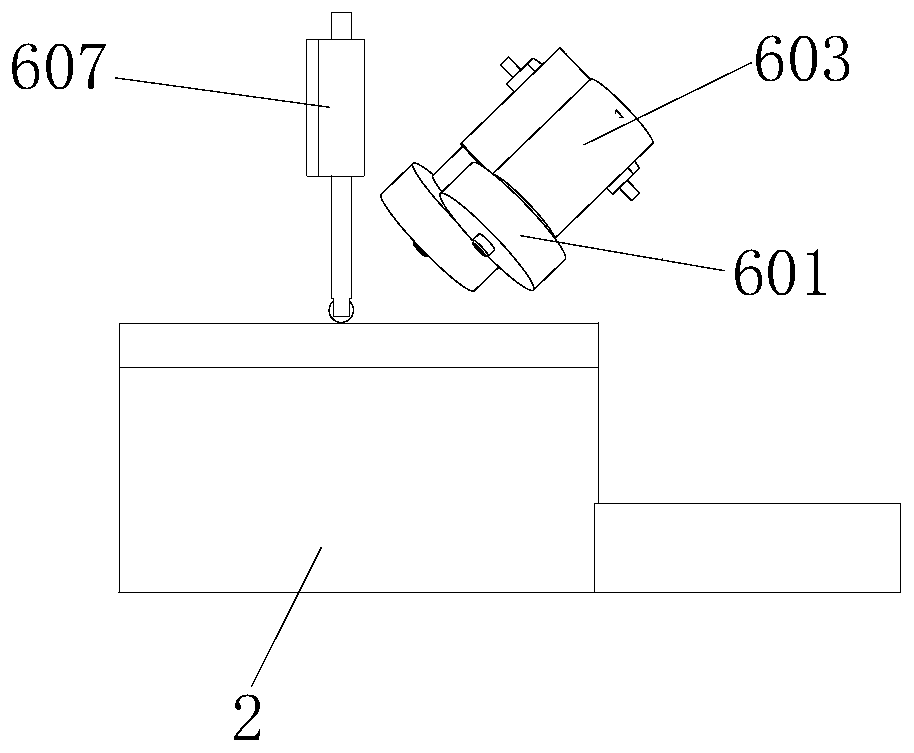

[0029] Such as figure 1 and figure 2 As shown, a sharpening assembly of a knife grinder is installed in the body of the knife sharpener, and is characterized in that it includes an upper grinding wheel 601, a lower grinding wheel 602, an upper grinding wheel motor 603, a lower grinding wheel motor 604, and a grinding wheel walking device 605. The grinding wheel travels The fixed end of the device 605 is installed in the body of the sharpener, and the movable end of the grinding wheel walking device 605 is equipped with a grinding wheel torsion fixing seat 606, which is divided into an upper torsion seat and a lower torsion seat, an upper torsion seat and a lower torsion seat The upper grinding wheel motor 603 is installed on the upper torsion seat, the lower grinding wheel motor 604 is installed on the lower torsion seat, the upper grinding wheel 601 is installed on the rotating shaft of the upper grinding wheel motor 603, and the lower grinding wheel 602 is installed on the ...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is mainly that the shrinking device 609 is a magnet. In this embodiment, magnets are used as the shrinking device 609, which can achieve very special effects. The traditional shrinking device is generally realized by using springs and other devices, but the spring has a fatal shortcoming. The larger the spacing, the greater the force, and the smaller the spacing, the smaller the force. After testing, it is not suitable for use on the grinding wheel. Therefore adopt magnet, when the blade of cutter 2 is thicker, then the tight pressure between upper emery wheel 601 and lower emery wheel 602 during grinding becomes smaller because the distance between magnets is far away, and light force grinding is carried out; when the blade of cutter 2 is thinner , then the pressing force between the upper emery wheel 601 and the lower emery wheel 602 becomes larger due to the close distance between the magnets during grinding, so...

Embodiment 3

[0034] The difference between this embodiment and the previous embodiment is that there are two magnets, which are respectively installed on the sides of the upper torsion seat and the lower torsion seat that are close to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com