Gear grinding head and guide rail type manual knife sharpener

A knife sharpener and gear technology, applied in the direction of grinding machine parts, grinding/polishing equipment, other manufacturing equipment/tools, etc., can solve the problems of grinding surface wear, etc. The effect of local wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] One, after smearing glue on the side that has the center positioning post (1022) on the coupling gear (102), fit and stick firmly with the mounting surface that has the center positioning hole (1011) on the grinding body (101).

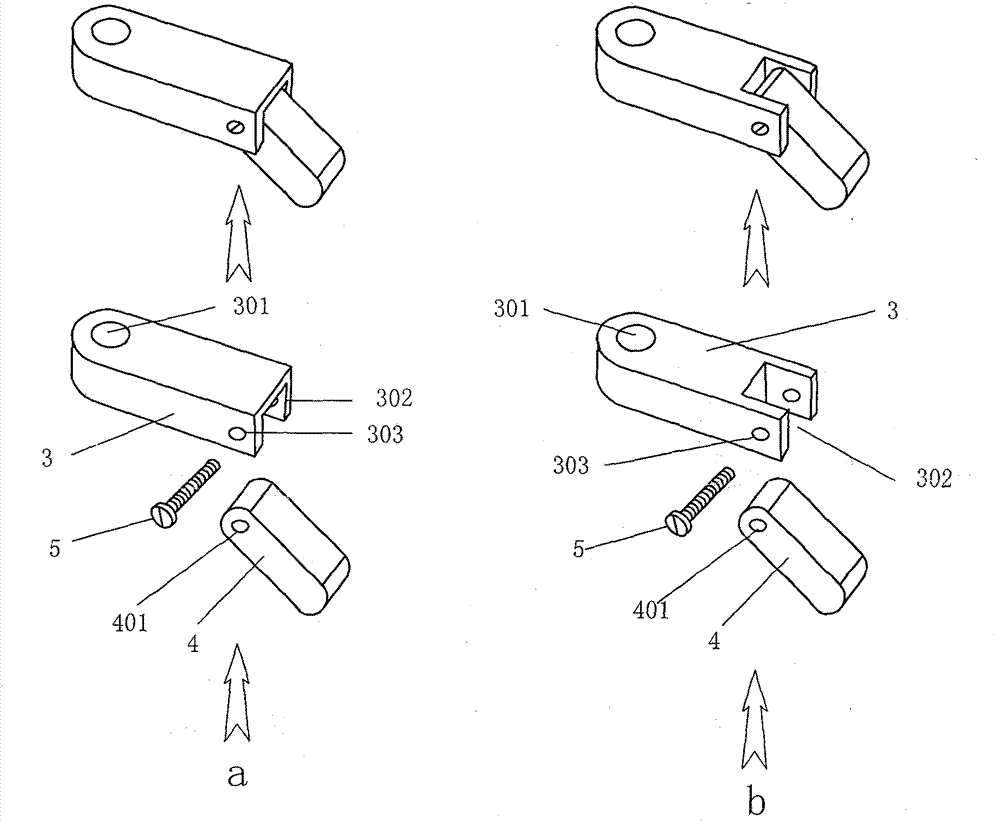

[0053] Insert the grinding head shaft (1021) of the gear grinding head (1) into the grinding head installation hole (301) on the connecting rod (3), and then fix it with a jumper spring (2).

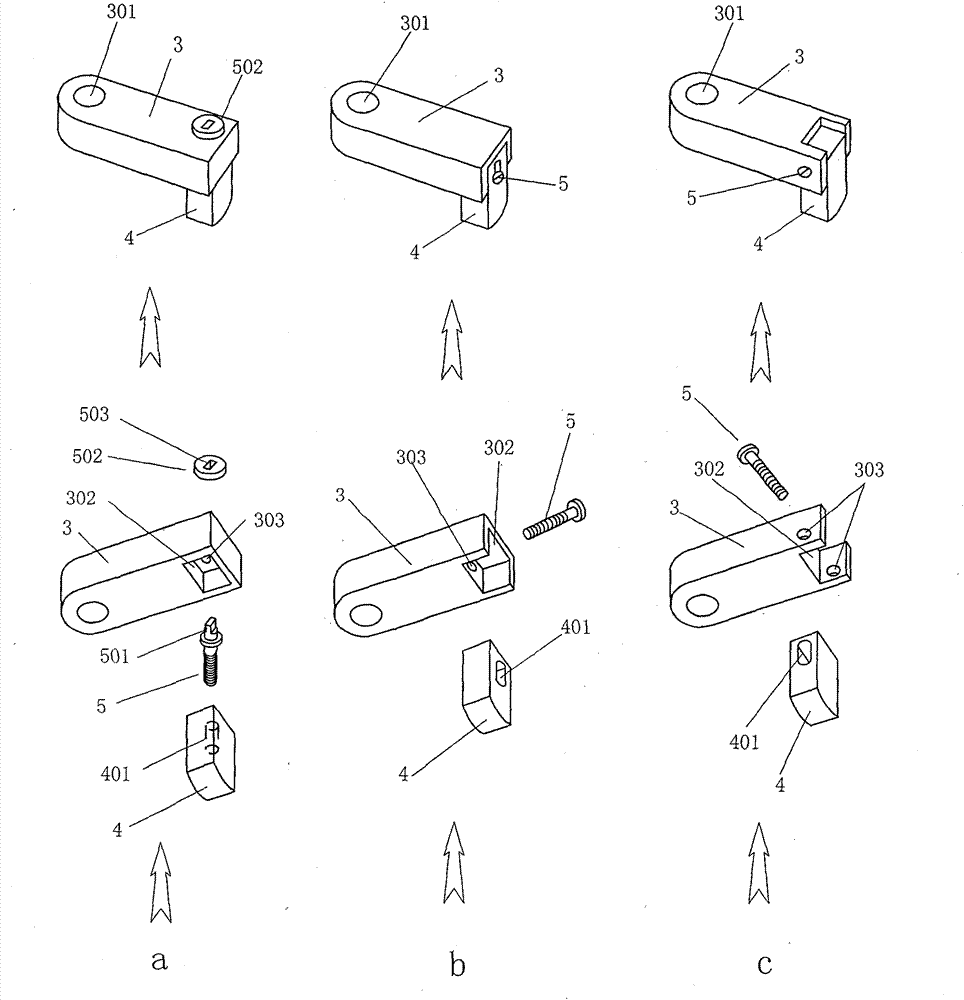

[0054] Install the threaded end of the tailstock positioning screw (5) (special-shaped screw) in the tailstock adjustment hole (401) (threaded blind hole) on the adjustable tailstock (4) with the hole above, and then place the tailstock positioning screw (5) After the synchronization plug (501) at the other end passes through the tailstock positioning hole (303) from the tailstock installation groove (302), it is installed in the synchronization socket (503) on the adjustment knob (502) (see Figure 4 a).

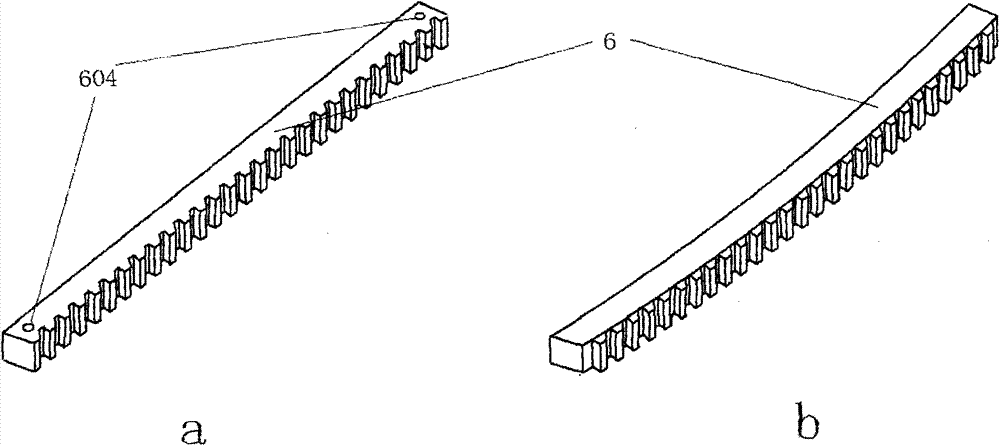

[0055] Use two screw rods (605) to pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com