Pumping rod centralizer

A technology of centralizer and sucker rod, which is used in drill pipe, drilling equipment, earthwork drilling, etc., can solve problems such as many reworked wells, the problem of preventing eccentric wear by the centralizer, and reducing the space of oil flow channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

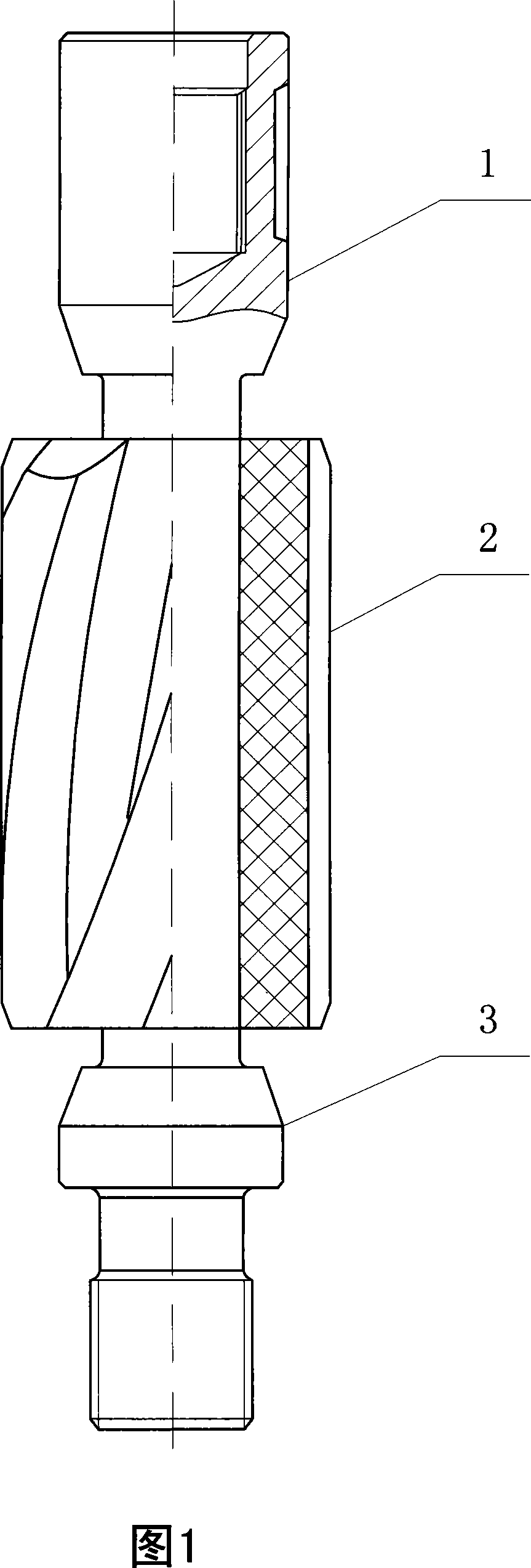

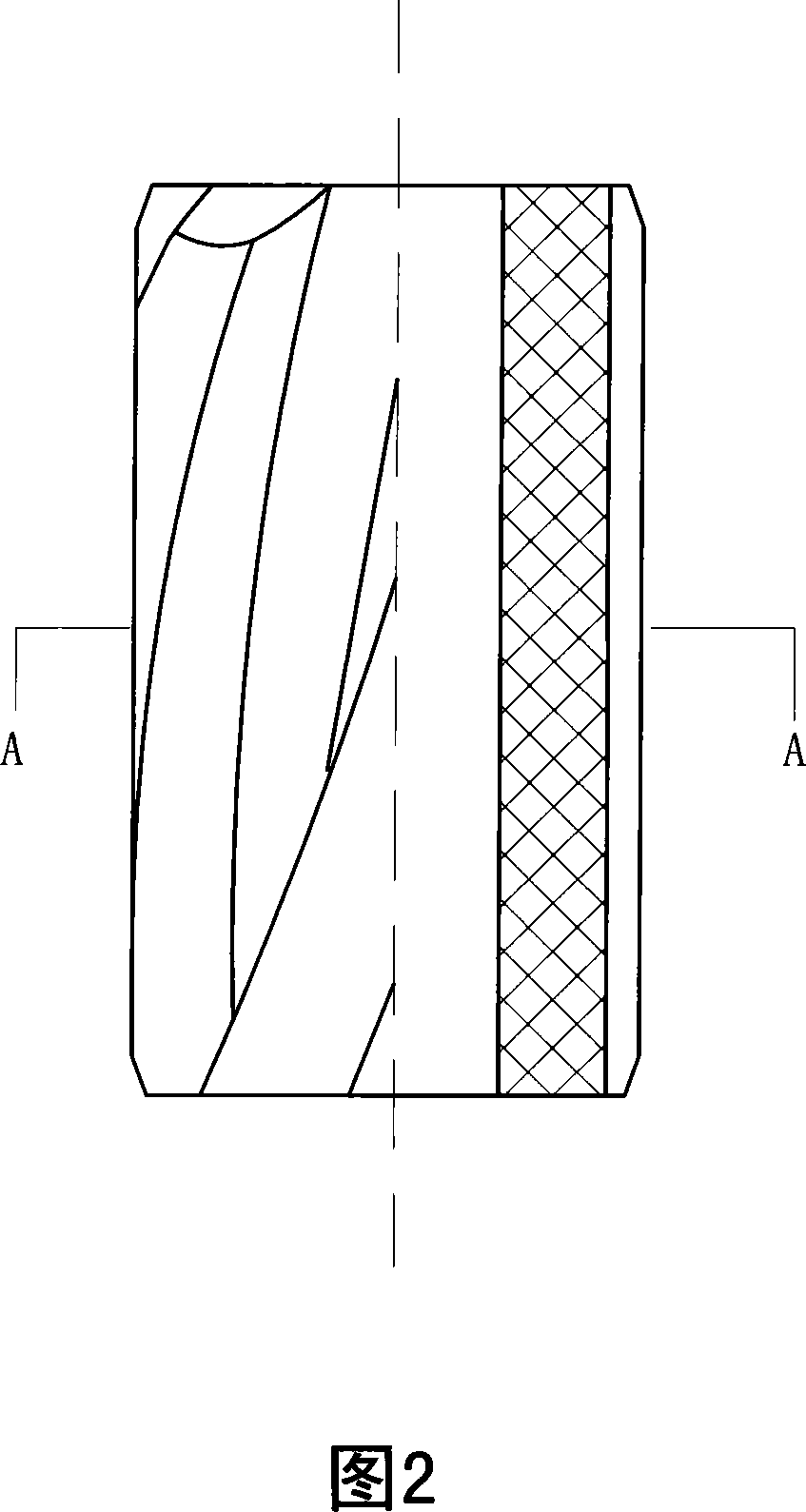

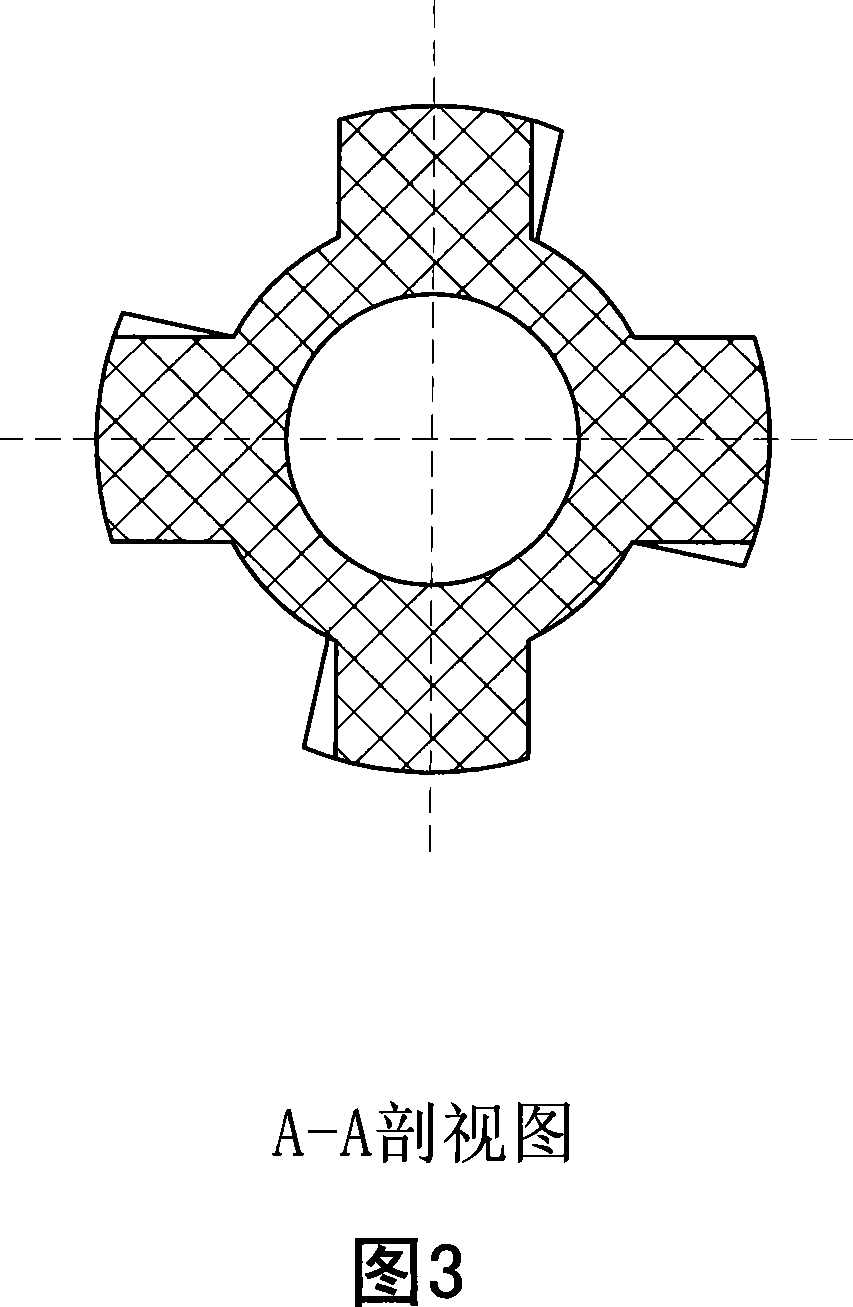

[0025] Fig. 1 is a schematic structural view of an embodiment of the present invention, in which the centralizer rod body (1) meeting the material requirements of Table 1 is composed of an integral rod with one end being an internal thread and the other end being an external thread, and the outer circle has a longitudinal inclination ≥ The centralizer (2) with at least three convex ribs on its outer circle is assembled on the center of the centralizer rod body (1) with a helix angle of 25° or a straight edge, which can meet the area of the flow passage and meet the requirements of the technical indicators in Table 2. shaft, and then connect the lock nut (3) to the centralizer rod body (1), so that the centralizer (2) can float up and down around the centralizer rod body (1) and rotate left and right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com