Nano composite abrasion-resistant alloy for abrasion-resistant steel and preparation technology for nano composite abrasion-resistant alloy

A wear-resistant alloy and nano-composite technology, applied in the field of nano-composite wear-resistant alloys, can solve the problems of short service life of wear-resistant steel parts, achieve the effects of improving wear resistance, convenient use, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

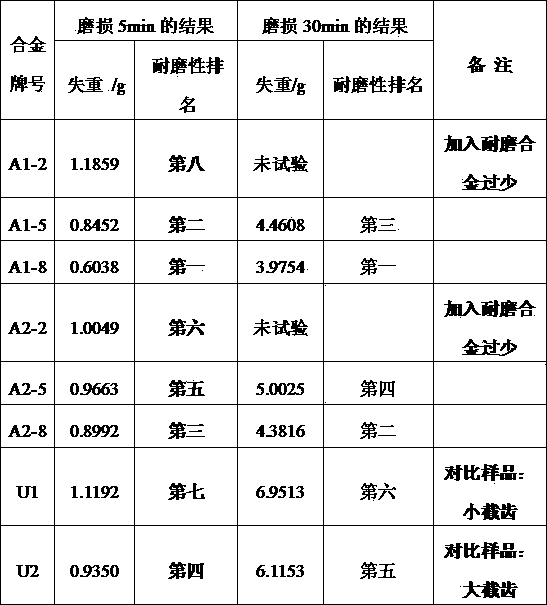

Embodiment 1

[0034] Example 2:

[0035] The invention belongs to a nano-composite wear-resistant alloy for wear-resistant steel. The wear-resistant alloy is prepared by compounding nano-ceramic powder and metal powder. The total weight of the prepared wear-resistant alloy is 5000g, and the ratio of various raw materials is: the total weight of nano-ceramic powder is 1000g, of which WC:TiC:SiC:Ce 2 O: Y 2 o 3 The ratio is 1: 0.15 : 0.25 : 0.25 : 0.15, the sum of the weight of the following four items is 444.44g; the rest is nano WC powder. The ratio in the metal powder is: reduced iron powder: nickel-chromium composite powder: aluminum powder, manganese powder, magnesium powder = 1:0.7:0.025 (0.01+0.01+0.005); among them, the weight of aluminum, manganese, and magnesium powder The sum is 57.97g; the reduced iron powder is 2318.84g, and the nickel-chromium composite powder is 1623.19g.

Embodiment 2

[0037] Example 3:

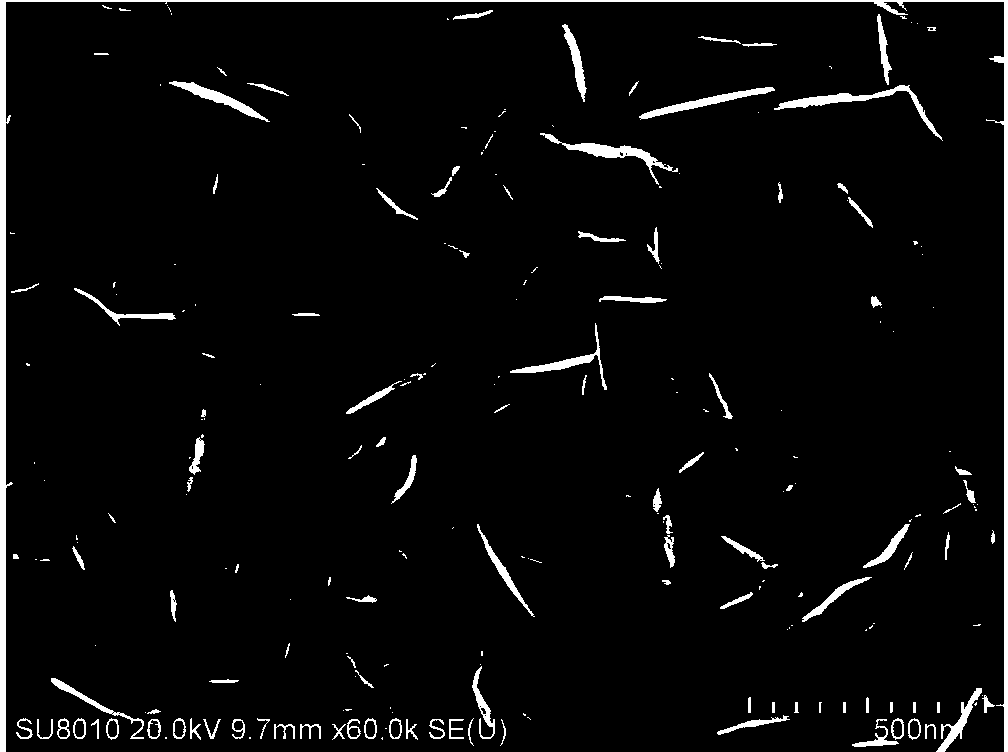

[0038] A nano-composite wear-resistant alloy for wear-resistant steel is prepared by compounding nano-scale ceramic powder and various metal powders. The nano-ceramic powder is composed of nano-scale WC, TiC, SiC, Ce 2 O, Y 2 o 3 Composition, the particle size of nano-ceramic powder is 80-500nm; the sum of their weight accounts for 6% of the total weight of wear-resistant alloy, and their weight ratio relationship is: WC:TiC:SiC:Ce 2 O: Y 2 o 3 = 1:0.05:0.32:0.01:0.01; 5% free carbon in WC; TiC particle size less than 0.5μm; WC, SiC, Ce 2 O, Y 2 o 3 The particle size of the powder is nanoscale. The metal powder is a mixture of reduced iron powder, nickel-chromium powder, manganese, aluminum, and magnesium powder, and the amount added accounts for 94% of the total weight of the wear-resistant alloy; iron, nickel-chromium, aluminum, manganese, and magnesium The ratio of powder mixing is iron powder: nickel-chromium powder: aluminum powder, manganese ...

Embodiment 3

[0040] (2) Do plastic discharge treatment on the body, that is, use an ordinary electric furnace to heat the body to 200°C under air conditions and keep it warm for 300 minutes to form an oxide film on the surface of the metal particles and discharge colloidal polyethylene at the same time Alcohol butyral;

[0041] (3) Then sinter the green body. The sintering is completed under the condition of atmosphere protection. The protection gas is argon, the sintering temperature is 900°C, and the heat preservation is 240 minutes. After sintering, the sintered body is made into powder, which is the wear-resistant alloy product.

[0042] In the glue prepared by nano-scale ceramic powder, the speed of slow stirring at the beginning is 80 rpm; after adding all the metal powder, the speed of the mixer is adjusted to 300 rpm.

[0043] The amount of absolute ethanol is determined by the density of the powder, generally add 150ml of absolute ethanol per 100g of powder.

[0044] Example 4: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com