High-voltage transformer substation cable insulating sheath material and preparation method thereof

A technology for insulating sheaths and substations. It is applied in the direction of insulators, insulated conductors, and insulated cables. It can solve the problems of low mechanical strength of sheath materials, affecting the normal operation of cables, and easy damage of sheaths, and achieves excellent mechanical strength and wear resistance. Sex, solving flame retardancy, good effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

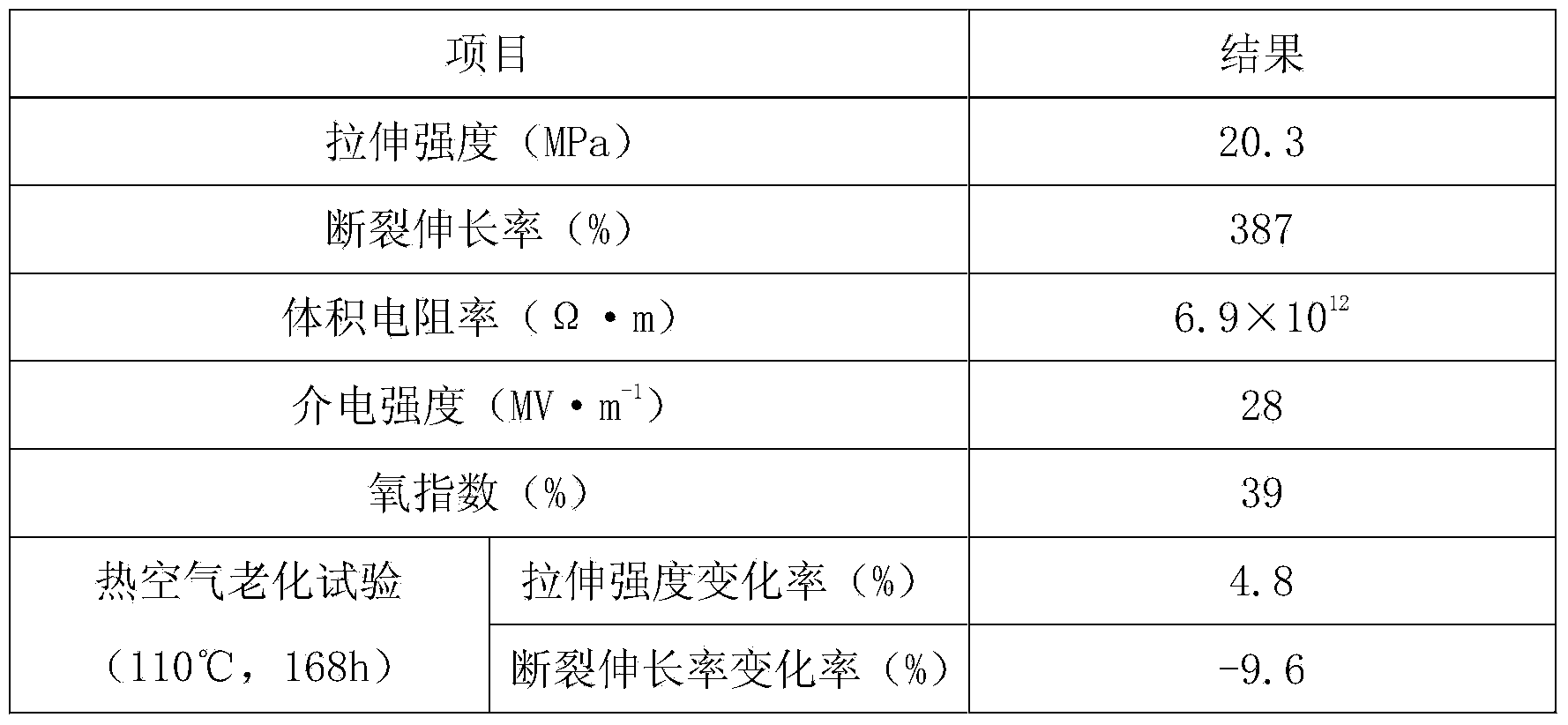

[0010] An insulating sheath material for high-voltage substation cables, made of the following raw materials in weight (kg): metallocene linear low-density polyethylene 70, isotactic polypropylene 30, EVA10, aluminum hydroxide 10, magnesium hydroxide 8, tin Zinc acid 6, siliceous rock powder 16, polyethylene wax 5, zinc terephthalate 2.5, magnesium oxide 1.5, dimethyl silicone oil 4, basic lead silicate 2, triallyl trimellitate 8, γ -Methacryloxypropyl trimethoxysilane 1, fumed silica 20, activated calcium carbonate 12, antioxidant 1681, composite filler 4;

[0011] The preparation method of the composite filler is as follows: a. Take bentonite, barite, and monazite in a weight ratio of 6:4:3, then add 2% coal powder and 1.5% activated carbon by weight of bentonite, and mix them uniformly at 560 ° C. Calcined for 3 hours, cooled to room temperature, crushed to a particle size below 15 μm, then added water and beat to make a slurry with a concentration of 45%, added hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com