Method for preventing eccentric wear of pumping rod and oil tube and separate-zone whole production tubular column

A technology of pipe string and rod pipe, which is applied in the field of layered simultaneous production pipe string, can solve the problems of eccentric wear of sucker rod and oil pipe, rod and pipe eccentric wear, etc. grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

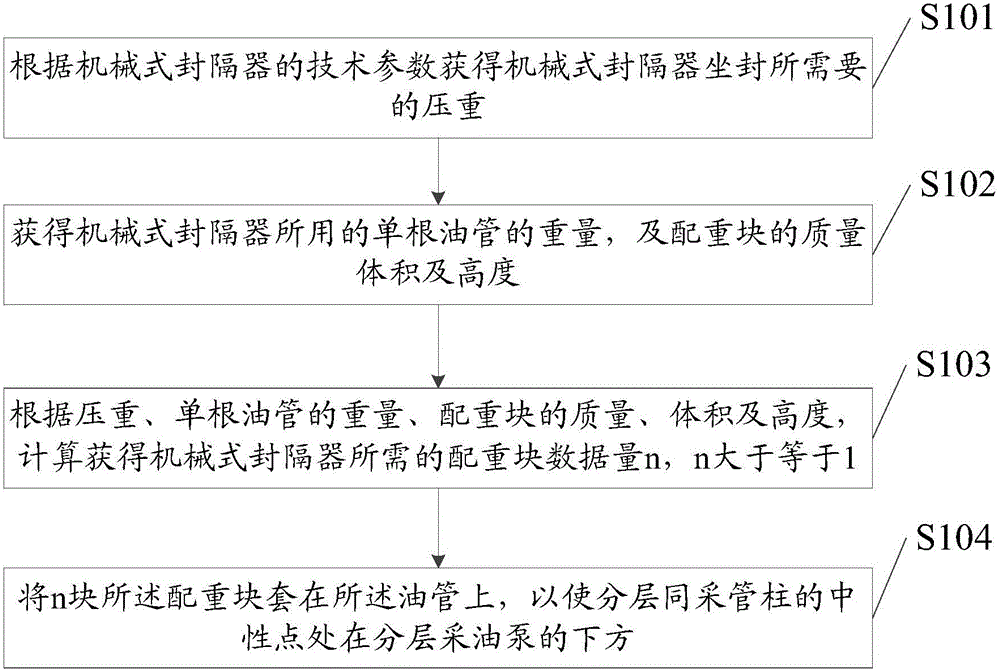

[0034] Please refer to figure 1 , the embodiment of the present application provides a method for preventing eccentric wear of the rod and tube of the stratified co-production string, the method comprising:

[0035] S101: Obtain the pressure required for setting the mechanical packer according to the technical parameters of the mechanical packer;

[0036] S102: Obtain the weight of a single tubing used in the mechanical packer, and the mass, volume and height of the counterweight;

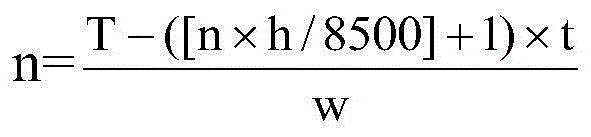

[0037] S103: According to the pressure weight, the weight of the single tubing, the mass, volume and height of the counterweight, calculate the number n of counterweights required by the mechanical packer, where n is greater than or equal to 1 ;

[0038] S104: Put n pieces of counterweights on the oil pipe, so that the neutral point of the layered production string is below the layered oil recovery pump.

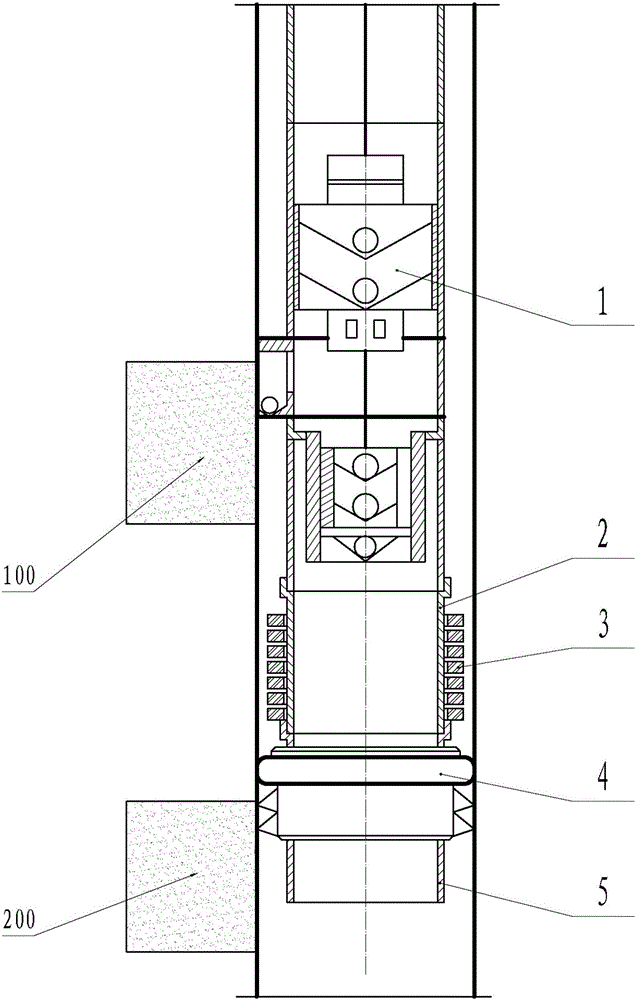

[0039] Please refer to figure 2 , the above method provided in the embodiment of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com