Knife Sharpener System

a knife and blade technology, applied in the field of knife sharpeners, can solve the problems of increasing the time it takes to clean the knife sharpener, affecting the life of the knife sharpener, and affecting the sharpening effect of the knife blade, so as to achieve the effect of not rusting over time and quick sharpening the knife blad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A. Overview

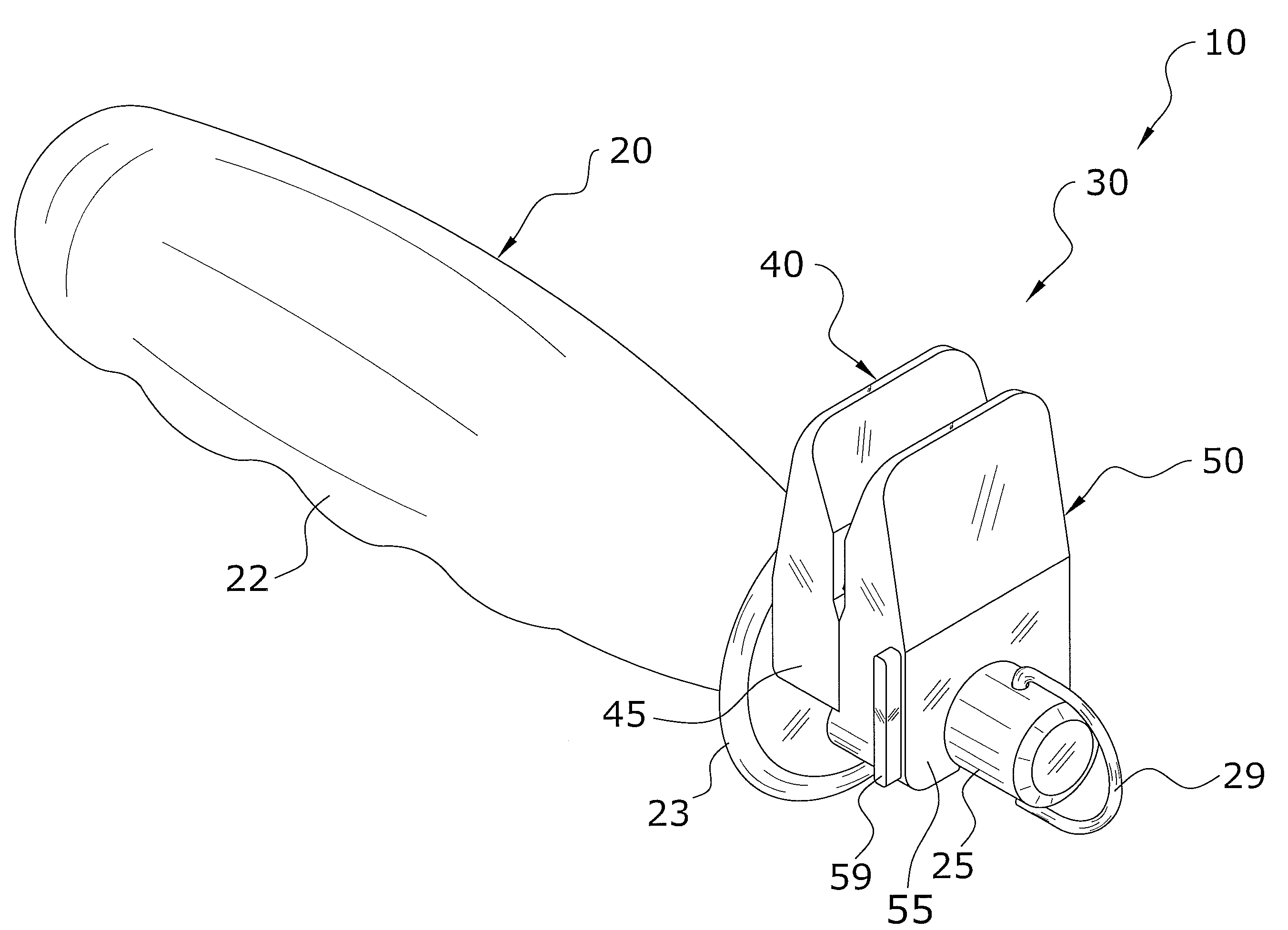

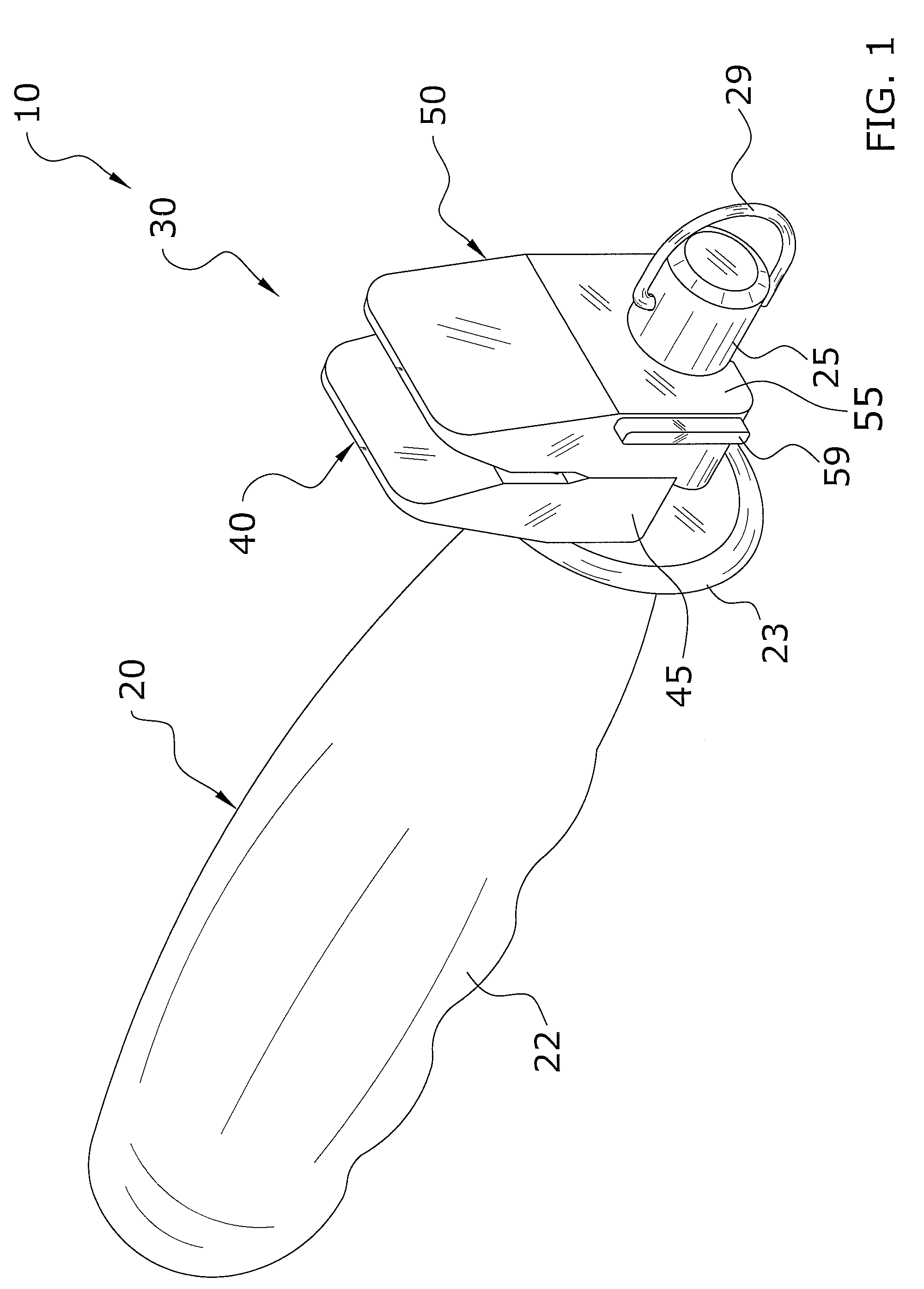

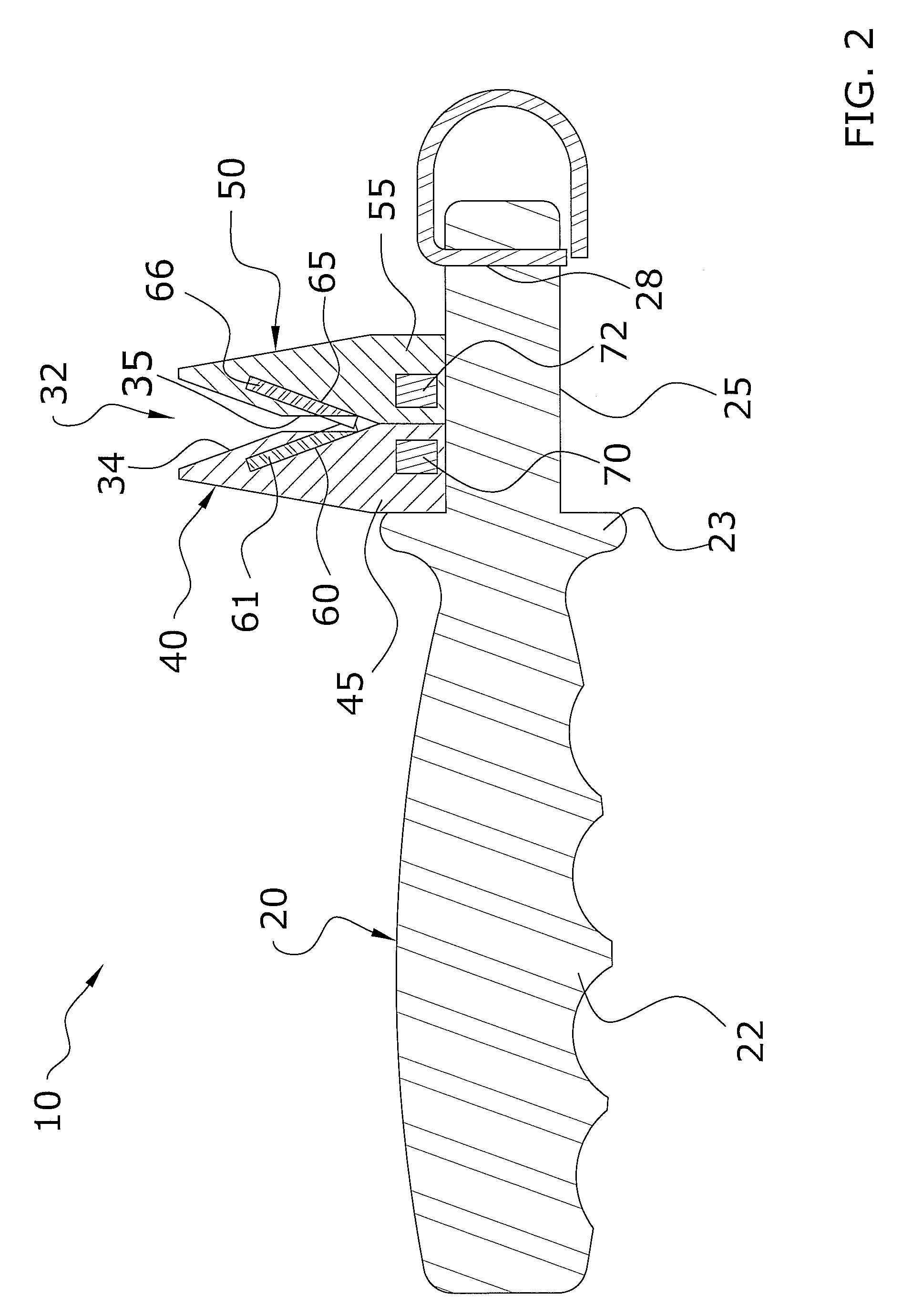

[0032]Turning now descriptively to the drawings, in which similar reference characters denote similar elements throughout the several views, FIGS. 1 through 10 illustrate a knife sharpener system 10, which comprises a support structure 20, a sharpening unit 30 including a retaining portion 36, wherein the sharpening unit 30 extends from the support structure 20, at least one sharpening member 60, 65 extending from the sharpening unit 30 and at least one magnet 70, 72 positioned within the sharpening unit 30, wherein the retaining portion 36 is positioned between the sharpening member 60, 65 and the magnet 70, 72 and wherein a metal residue 17 of a blade 12 is magnetically attracted to the retaining portion 36 via the magnet 70, 72.

B. Support Structure

[0033]The support structure 20 includes a handle 22 for a user to grasp while utilizing the present invention and also a support member 25 extending from the handle 22 to receive and secure the sharpening unit 30 as illustrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com