Cutter blade sharpener and method

a cutter blade and sharpener technology, applied in the field of cutter blade sharpeners, can solve the problems of uneven fashion, constant wear of cutter blades, cost of labor and equipment, etc., and achieve the effect of uniform sharpening and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

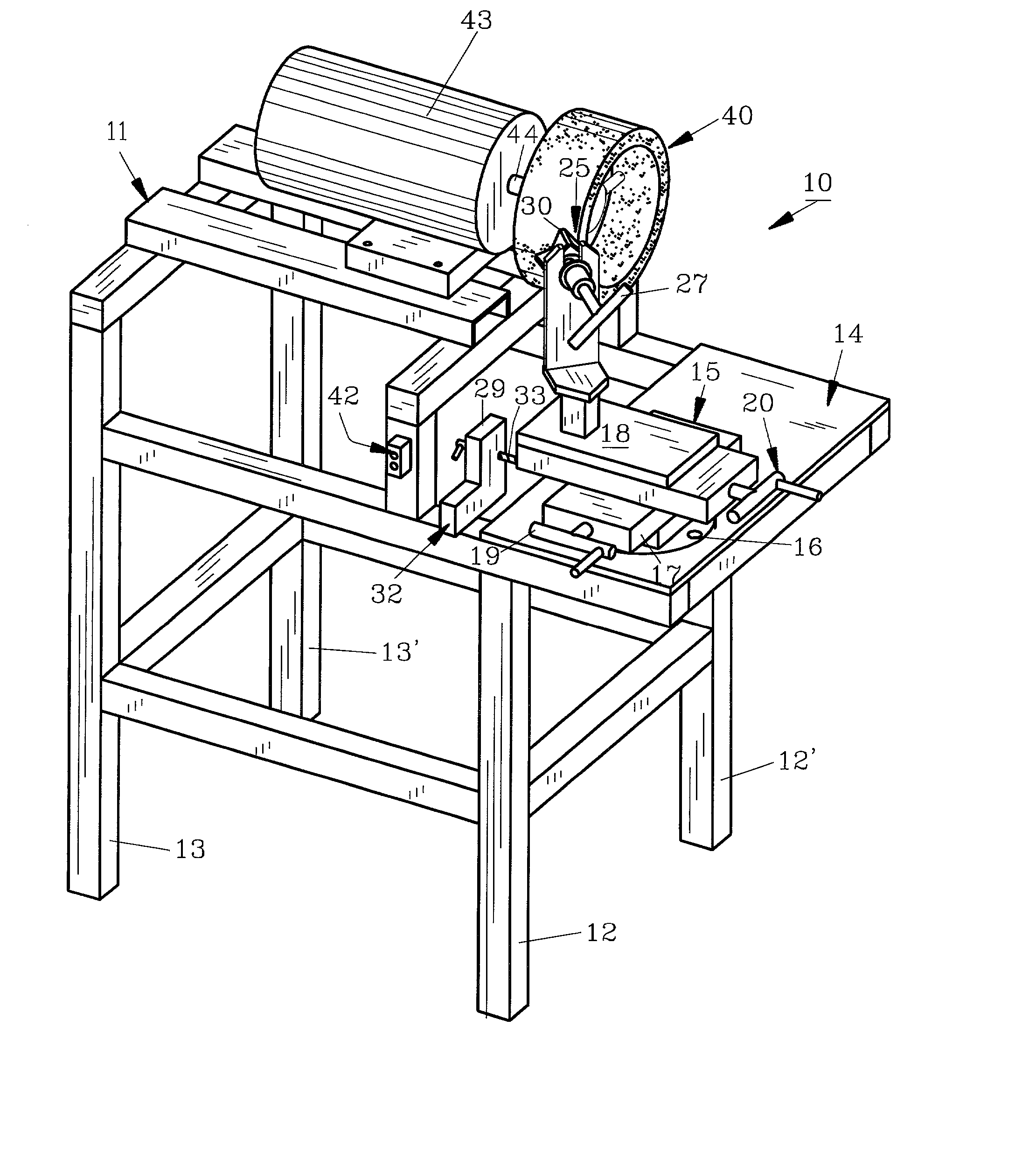

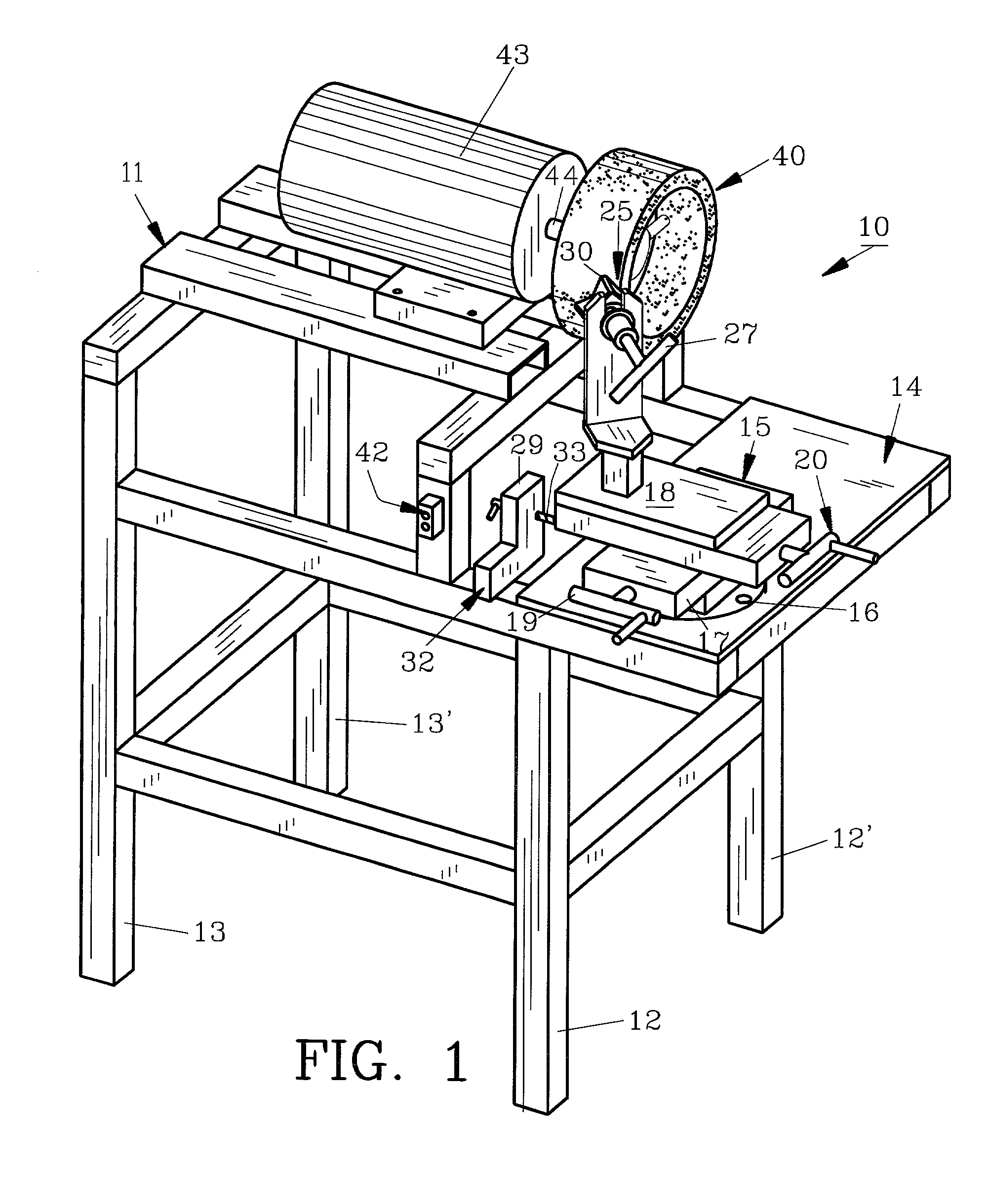

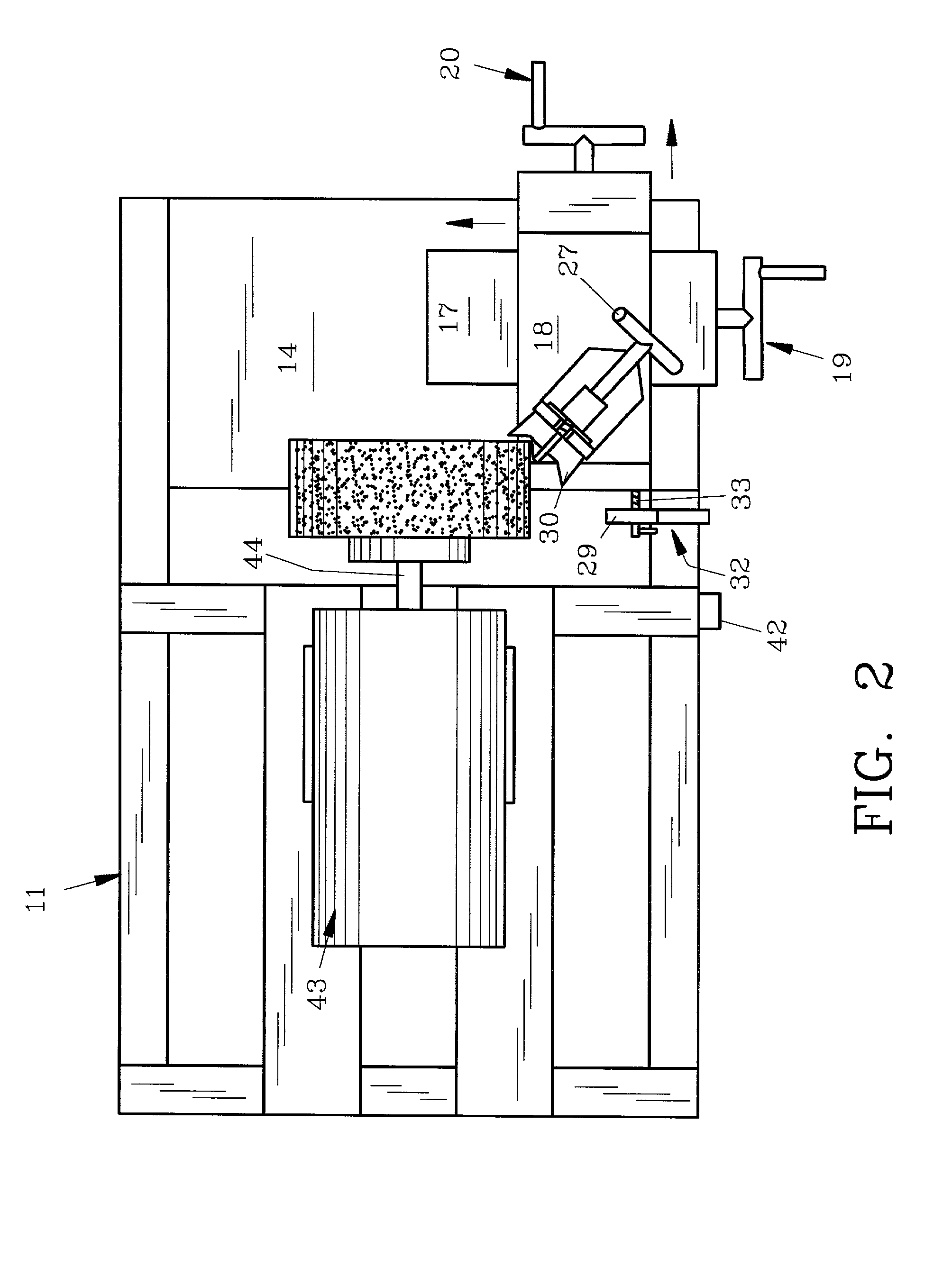

[0018] For a better understanding of the invention and its method of operation, turning now to the drawings, FIG. 1 illustrates preferred cutter blade sharpener 10 having frame 11 preferably formed from tubular steel. Frame 11 includes front legs 12, 12' and rear legs 13, 13'. Rigidly positioned on tubular frame 11 is shelf 14 to which slide table 15 is mounted. Slide table 15 is preferably a conventional compound or bi-directional milling table as sold by Enco Manufacturing of 135 South LaSalle, Chicago, Ill. 60674. Other manufacturers of such slide tables include Penn Tool Company, 1776 Springfield Avenue, Maplewood, N.J. 07040. Slide table 15 is mounted to shelf 14 as by bolts 16 (only one shown in FIG. 1) and includes table base 17 and table top 18. Table base 17 is movable laterally on frame 11 by turning crank handle 19 whereas table top 18 is movable longitudinally on frame 11 by turning crank handle 20 as seen by the arrows in FIG. 2. As would be understood, table base 17 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com