Electric knife sharpener

A knife sharpener, electric technology, applied in grinding/polishing equipment, grinding/polishing hand tools, other manufacturing equipment/tools, etc., can solve the problems of complex transmission structure, many hidden troubles, difficult manufacturing, etc. The effect of fewer hidden dangers, convenient installation and debugging, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

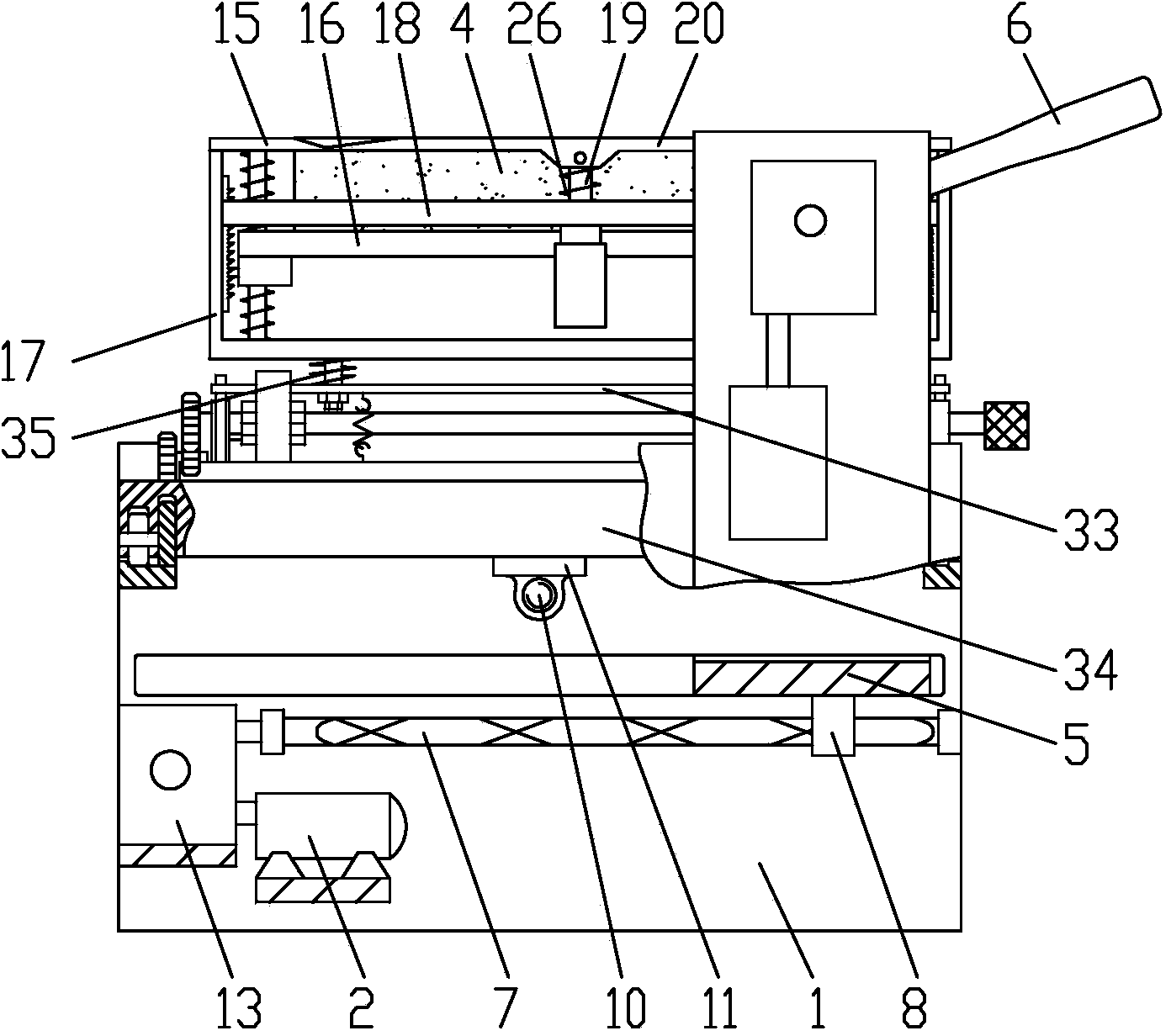

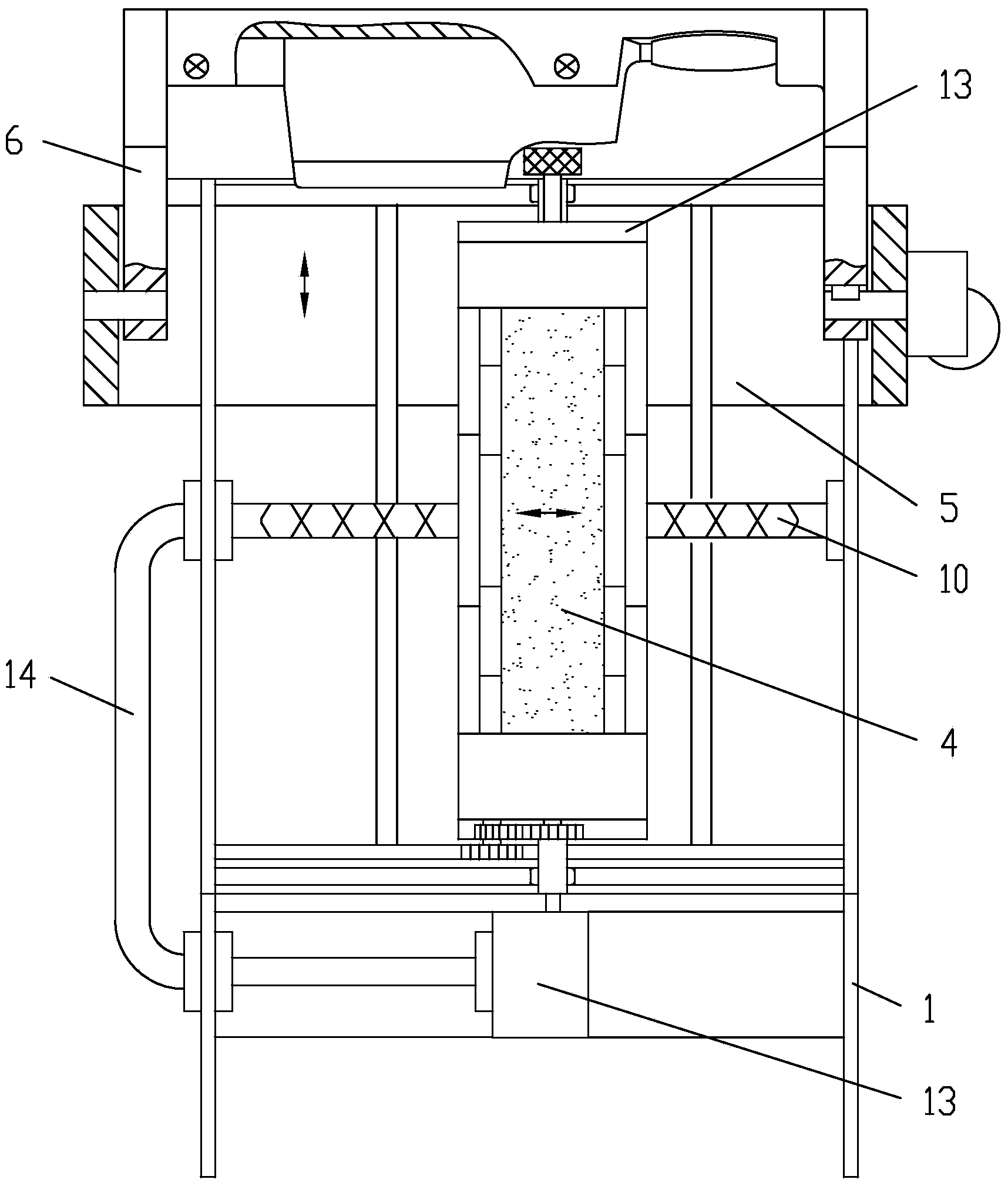

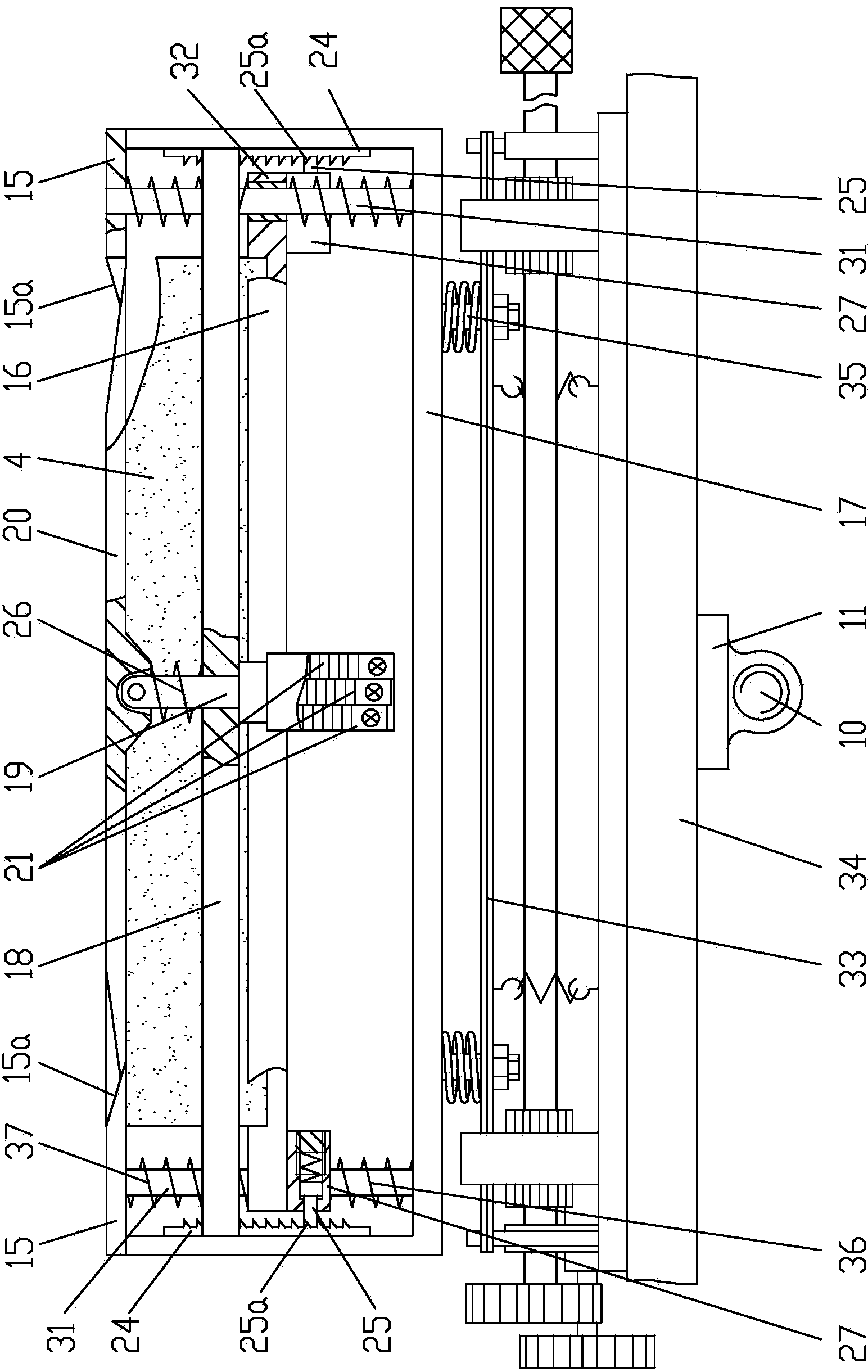

[0028] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , an electric sharpening machine, comprising a frame 1 and a drive motor 2 connected to a control system, the frame 1 is provided with a knife rest and a whetstone device, and the whetstone device includes a base 33, a lower base 34 and a For installing the bar-shaped whetstone 4 mounting part, the length direction of the bar-shaped whetstone 4 after installation is consistent with the longitudinal direction of the frame 1; the base 33 is connected below the bar-shaped whetstone mounting part, and A knife sharpening pressure loading spring 35 is arranged between the two, and the base 34 is located below the base 33, and the bar-shaped sharpening stone mounting part,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com