Kitchen knife sharpener

A knife sharpener, kitchen technology, applied in grinding/polishing equipment, grinding/polishing hand tools, metal processing equipment, etc., can solve problems such as large tool wear, low tool service life, and kitchen environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

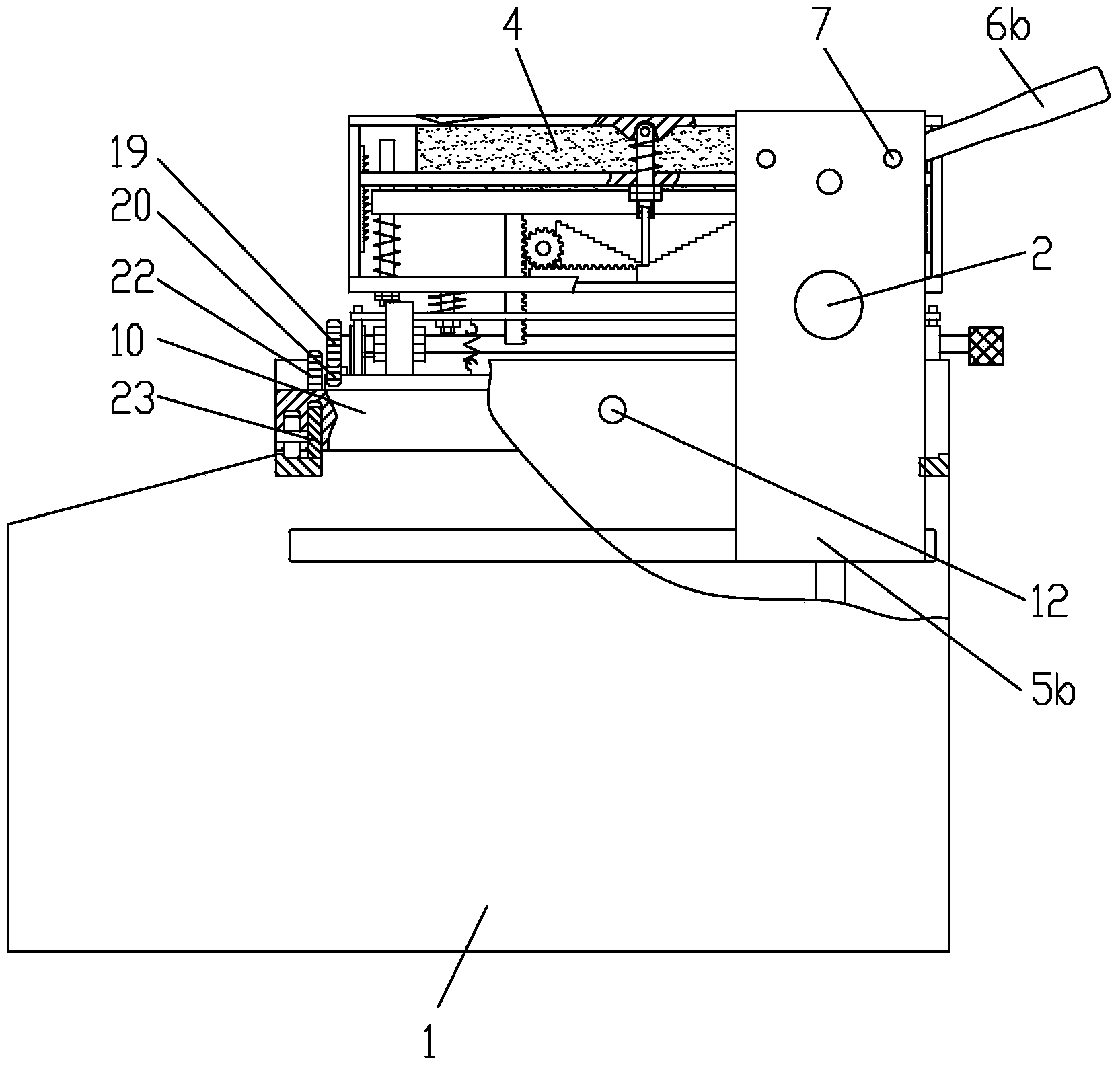

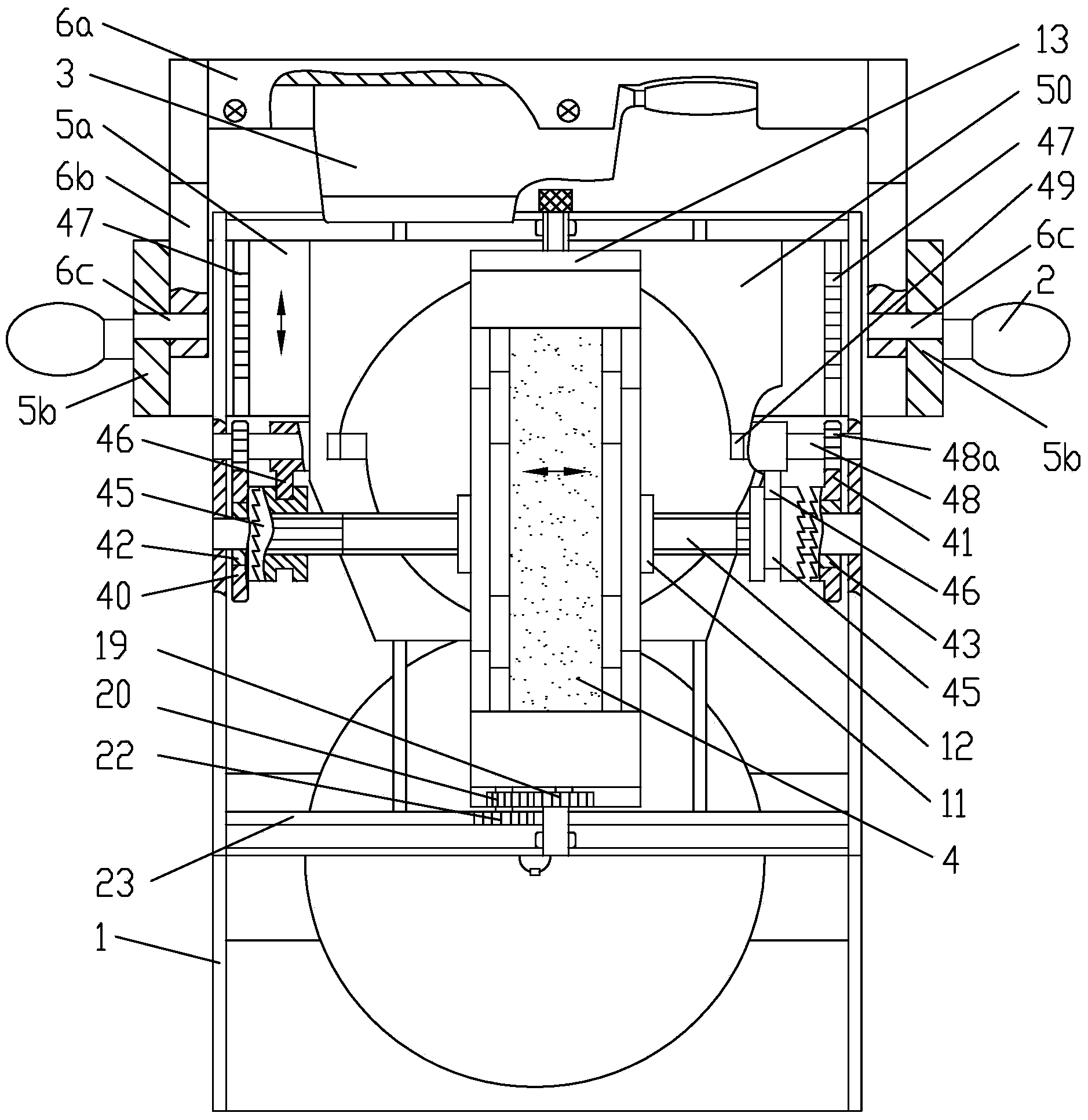

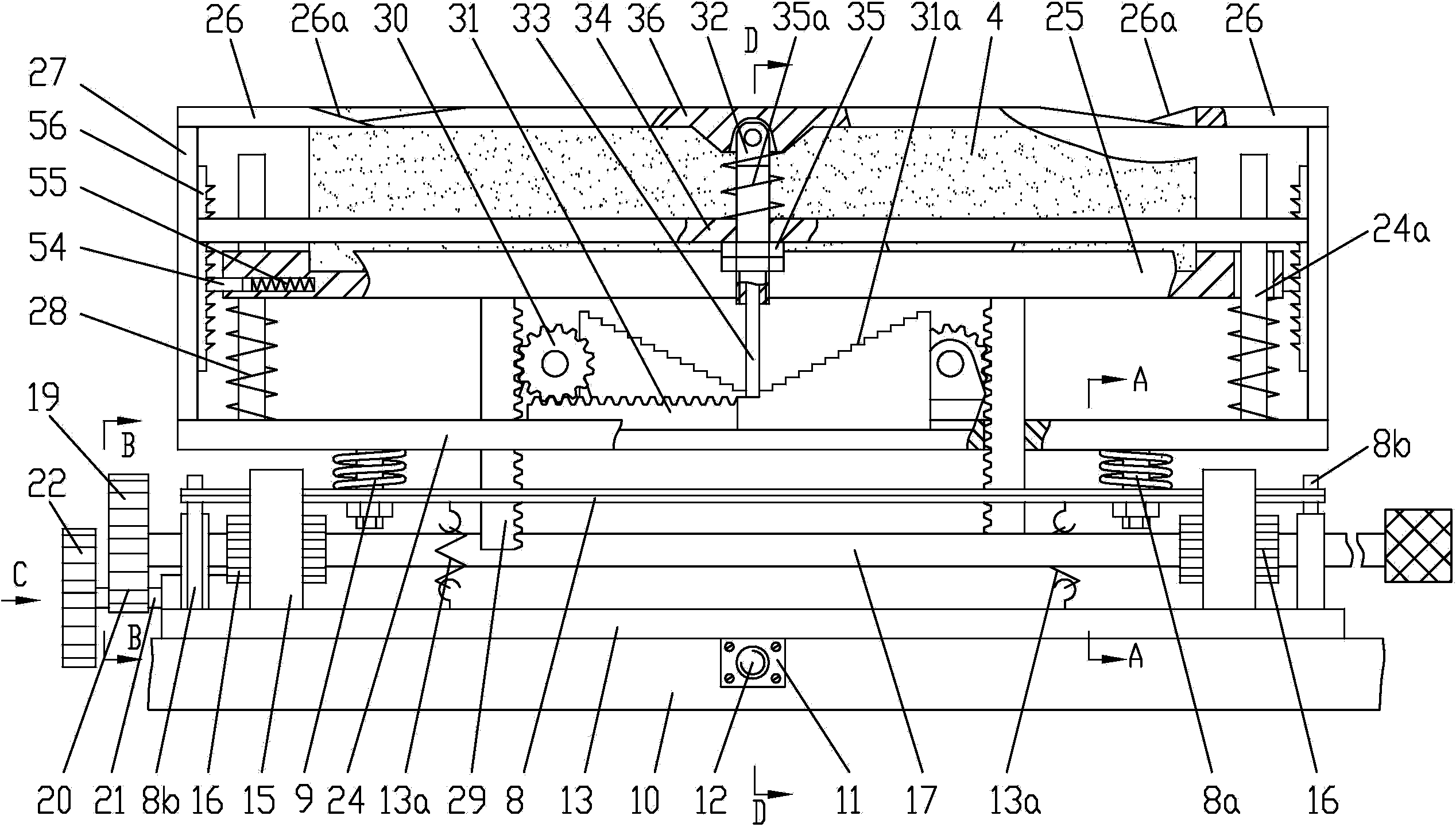

[0033] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 13, a kitchen knife sharpening machine, including a frame 1, the frame 1 is provided with a knife holder and a whetstone device equipped with a strip whetstone 4, the knife holder is composed of a knife holder base and a It consists of a knife clamping part for installing a kitchen knife 3, the knife holder base includes a horizontal base plate 5a, the horizontal base plate 5a runs through the middle of the two side walls of the frame 1 transversely, and the two sides of the horizontal base plate 5a The ends are respectively fixedly connected with a vertically upward vertical connecting plate 5b, and the horizontal base plate 5a is slidably connected to the two side walls of the frame 1 through the guide rail sub-structure, and the outer sides of the two vertical connecting plates 5b are respectively fixedly...

Embodiment 2

[0039] Example 2, see Figure 15 , a first elastic element 9 is respectively provided between the installation slot on the horizontal arm 6a of the knife holding part and the two planes of the kitchen knife 3; the kitchen knife 3 passes through two first elastic The component 9 is clamped in the installation slot.

[0040] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0041] see Figure 16 , In this embodiment, the third bottom plate 24 and the base plate 8 can also be fixedly connected without the technical solution of setting the first elastic element 9 between the third bottom plate 24 and the base plate 8 to replace it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com