Knife sharpener capable of controlling angle

A knife sharpener and surface grinding technology, applied in the field of angle control, can solve problems such as inconvenient and clumsy devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

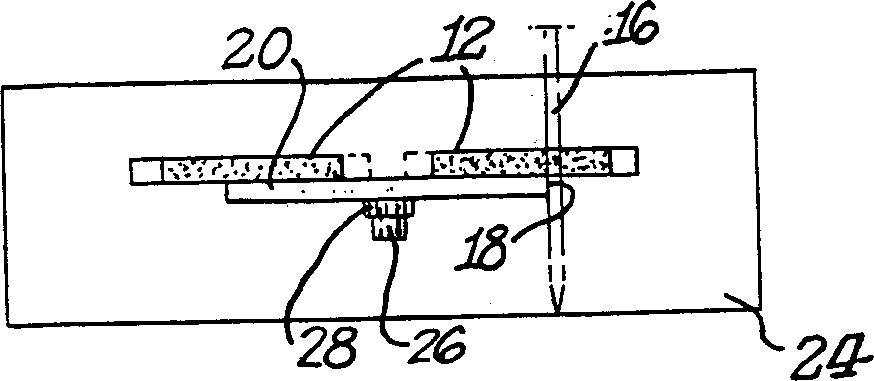

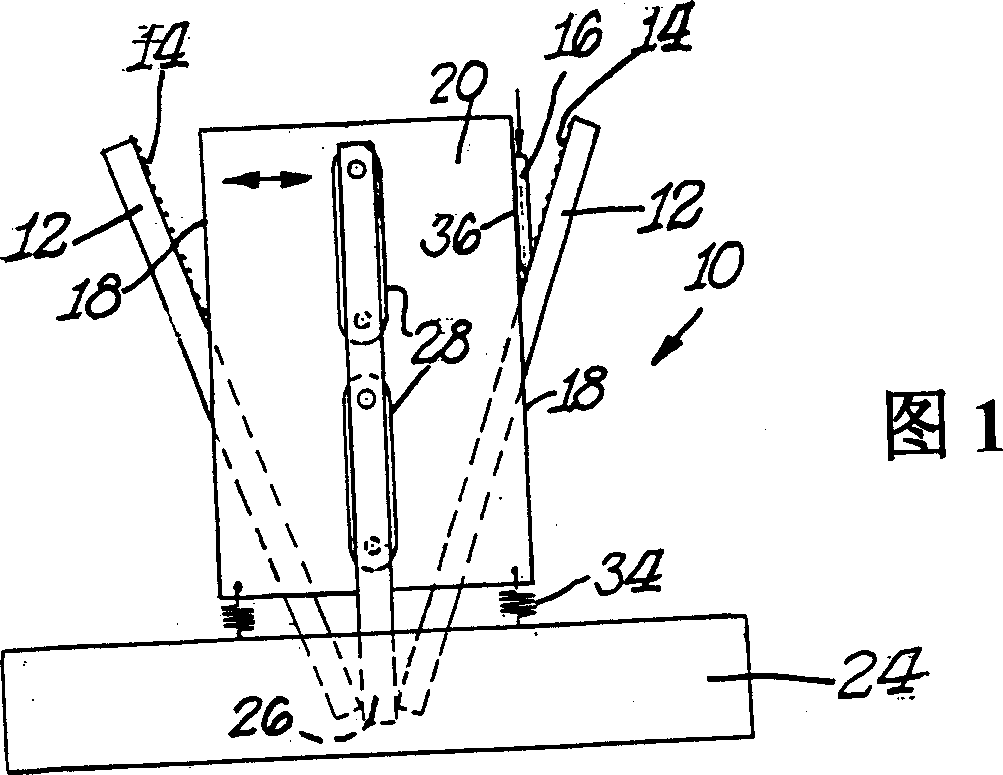

[0022] Detailed description of the preferred embodiment

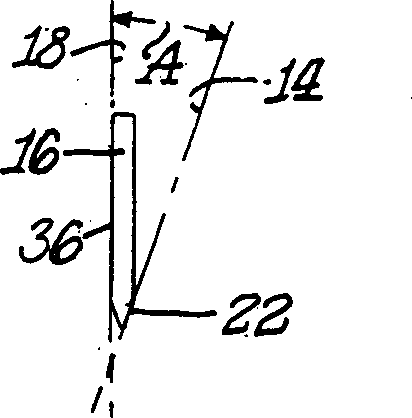

[0023] The above figures show a sharpener with a guide surface near the grinding surface so that the knife can rest on the guide surface and move on the grinding surface to sharpen the blade. In the different embodiments shown here, the linear guide surface can move along a direction perpendicular to the plane where it is located, and at the same time, the linear guide surface can remain parallel to its original plane at each position of the movement. In this way, the linear guide surface moves sideways without changing the angle. This movement is completely different from the following movement, that is, the linear guide surface of the knife surface is part of a heavy fixture or tool holder, and the movement of the linear guide surface is completely parallel to the plane of the contact point of the knife on the grinding surface.

[0024] Figures 1-3 show a manual sharpener 10 according to an embodiment of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com