Portable skate sharpener

a technology of sharpener and blade, which is applied in the direction of grinding machine, skating parts, sports apparatus, etc., can solve the problems of affecting the portability of the device, the difficulty of properly aligning or “centering” the blade with the convex periphery of the grinding wheel, and the bulkiness of the machin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

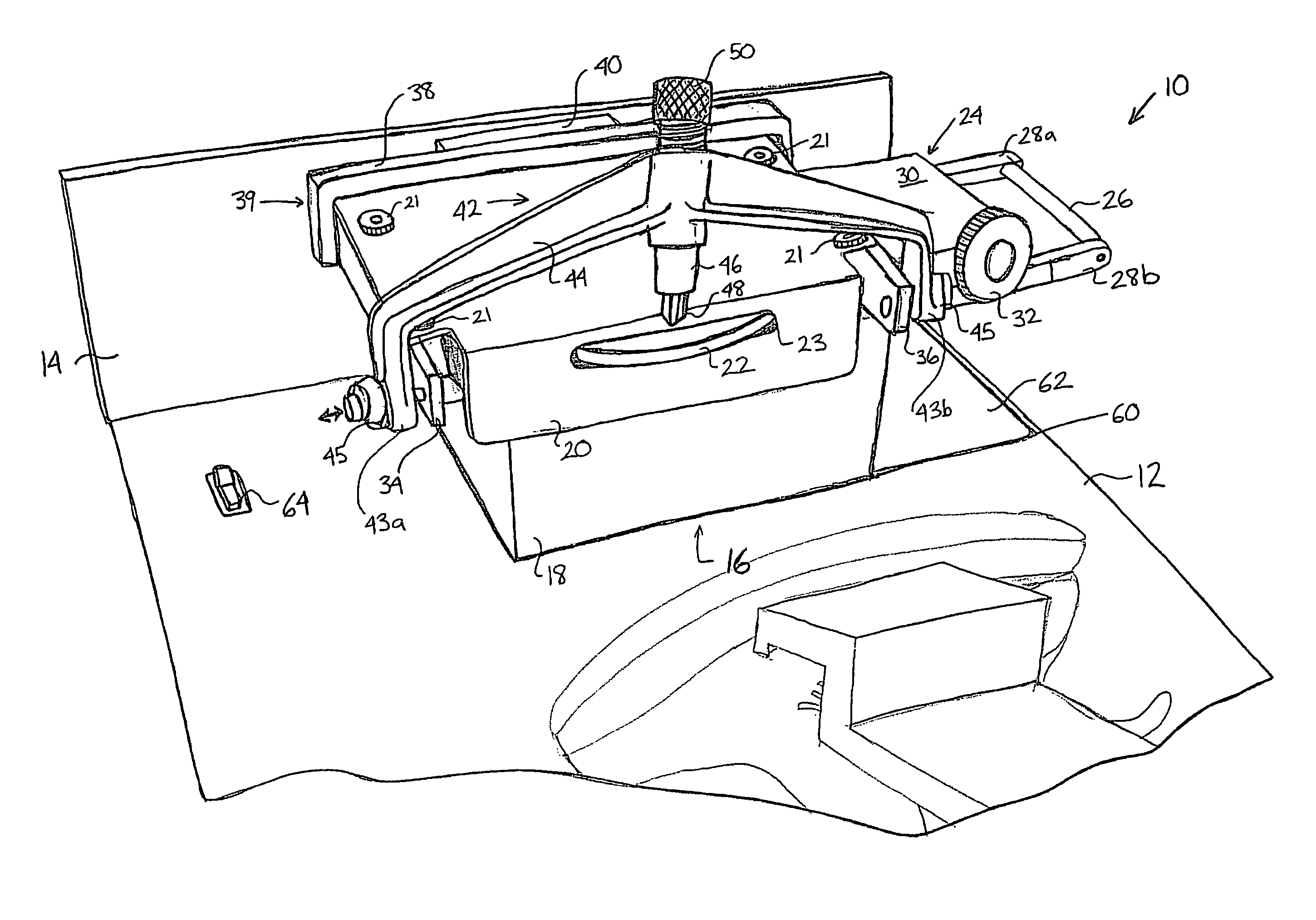

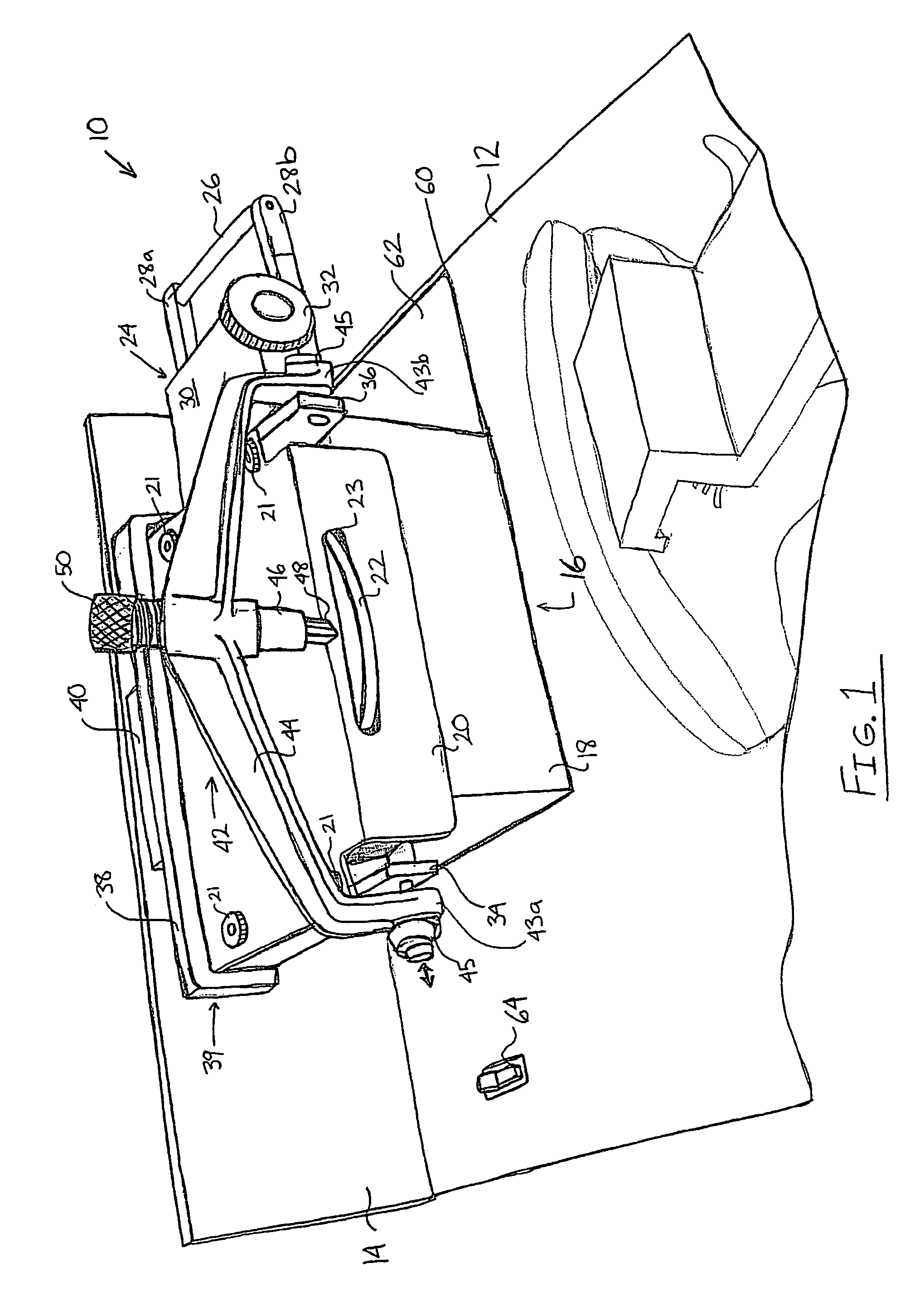

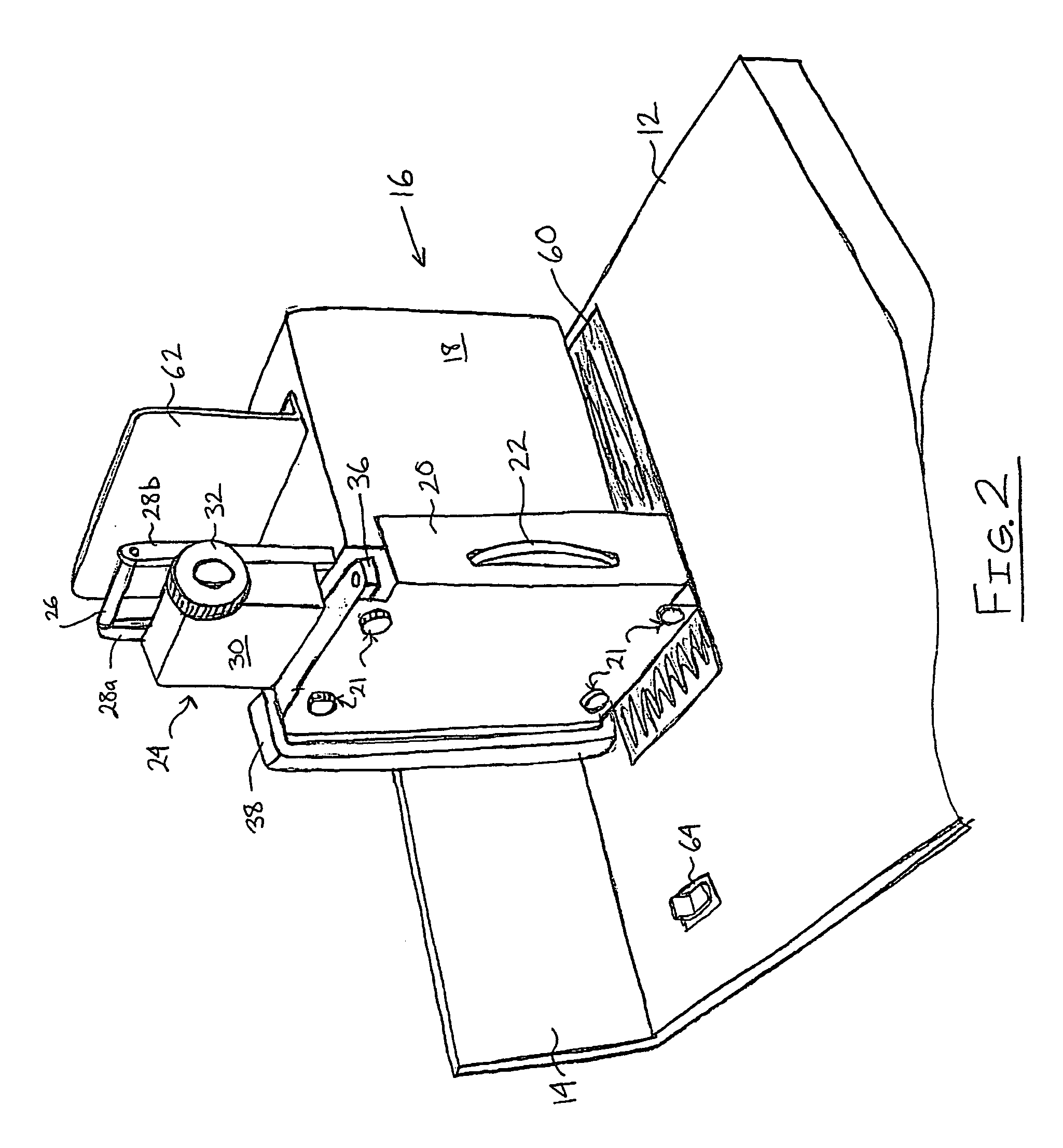

[0020] Referring therefore to FIGS. 1 and 2, a portable skate sharpening device is generally denoted by numeral 10. The device 10 generally comprises a relatively smooth table top surface 12 with an upstanding wall or trunnion 14 attached at a rear edge of the surface 12, and a rotatable grinding device 16. The device 16 is supported such that its lower portion protrudes downwardly through an aperture 60 in the surface 12 when positioned in the configuration shown in FIG. 1. The grinding device 16 has a body 18, a guard 20 attached to the top of the body 18, and an actuating system 24 attached to the right wall of the body 18. The body 18 is attached to a plate 40 which is slidable relative to the trunnion 14

[0021] As best shown in FIG. 4, the grinding device 16 is pivotally attached to the trunnion 14 with a pin 100 and a threaded stud (not shown). The pin 100 is preferably supported by the trunnion 14 with a bearing 105. The threaded stud protrudes through an arcuate slot 102 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com