Straight knife sharpener

A knife grinder and grinding head technology, which is applied in the direction of grinding frame, grinding machine parts, grinding bed, etc., can solve the problems of low production efficiency, low efficiency, slow handling speed, etc., and achieve a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

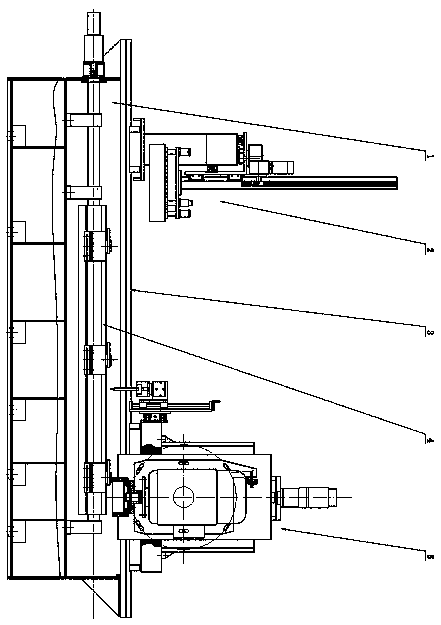

[0031] exist figure 1 In the straight knife sharpener shown, the straight knife sharpener includes a bed 1, a grinding head assembly 5 and a workbench assembly 4. The bed 1 is the basic supporting component of the entire straight knife sharpener, and the top of the bed 1 Two bed linear guide rail pairs 3 are respectively installed on the left and right sides of the surface, the workbench assembly 4 is located between the left and right bed linear guide rail pairs 3, and the grinding head assembly 5 is slidably supported on the bed body 1 by the two bed linear guide rail pairs 3 , On the lathe bed 1, there is also a gripping manipulator 2 slidably supported.

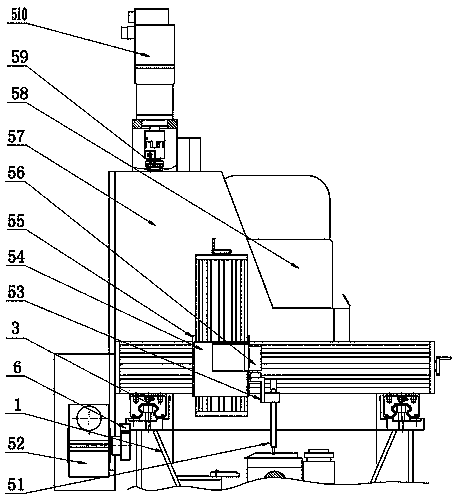

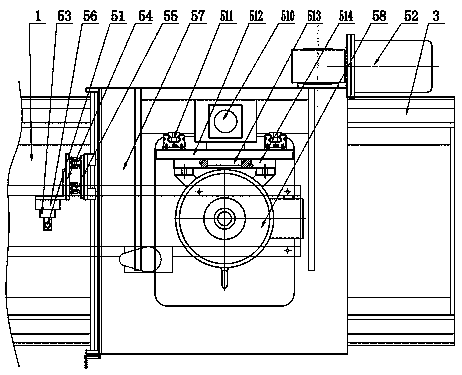

[0032] see Figure 4 , Figure 5 with Image 6 , the workbench assembly 4 includes a workbench body 42, on which an electromagnetic chuck 46 is fixedly installed, on the workbench body 42 is provided with a workbench rotating shaft 45, and the workbench rotating shaft 45 is arranged along the length direction of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com