Grinding tool for supporting plate for centerless grinding machine, and planar grinding machine

A centerless grinding machine and supporting plate technology, which is applied to machine tools designed for grinding the rotating surface of workpieces, grinding bed, grinding machines, etc., can solve the problem that the supporting plates used in centerless grinding machines cannot be reused, so as to save processing costs and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

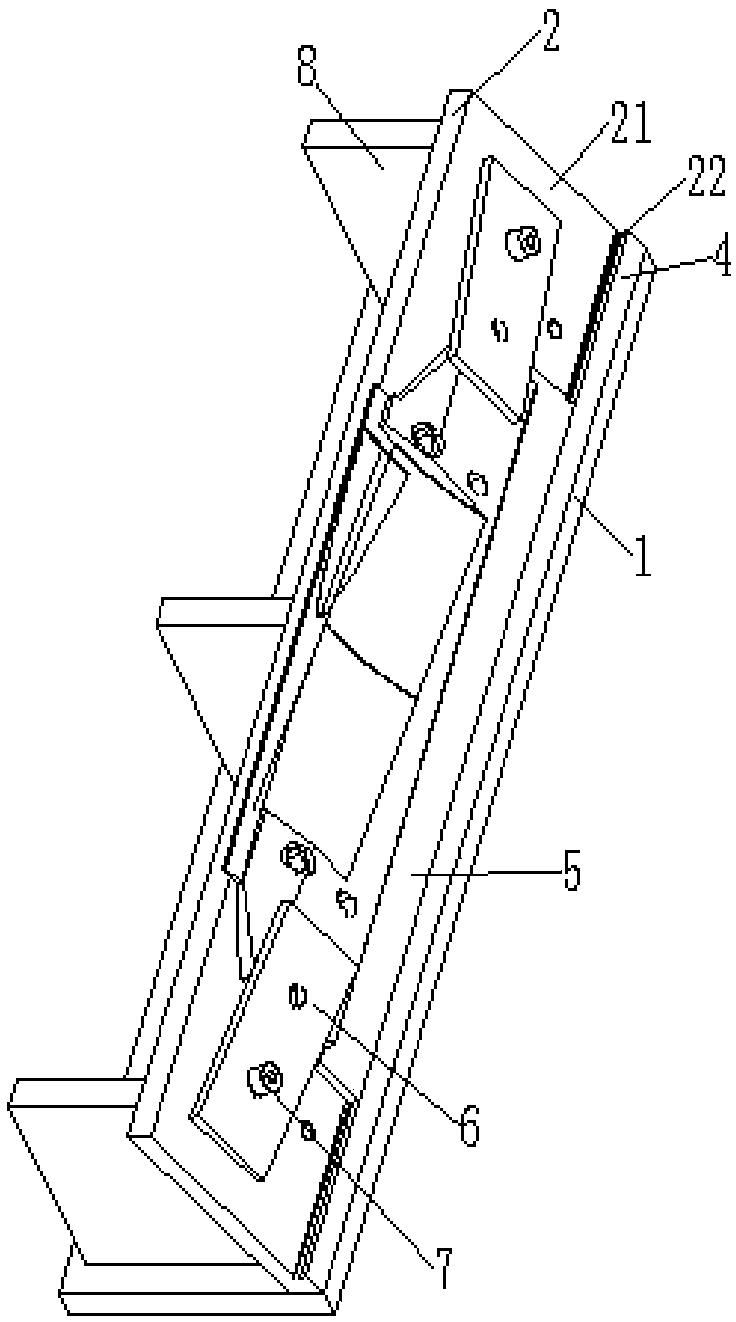

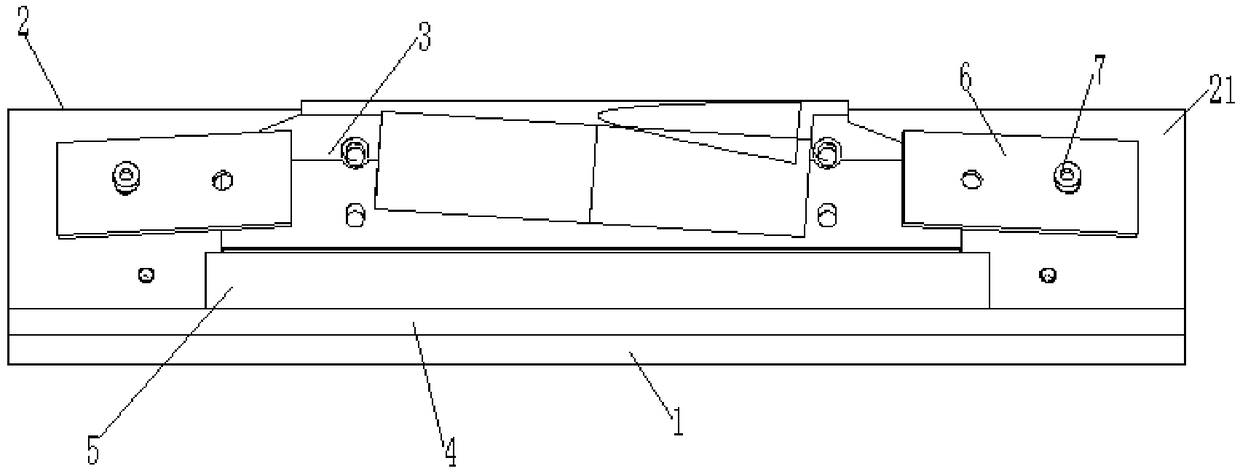

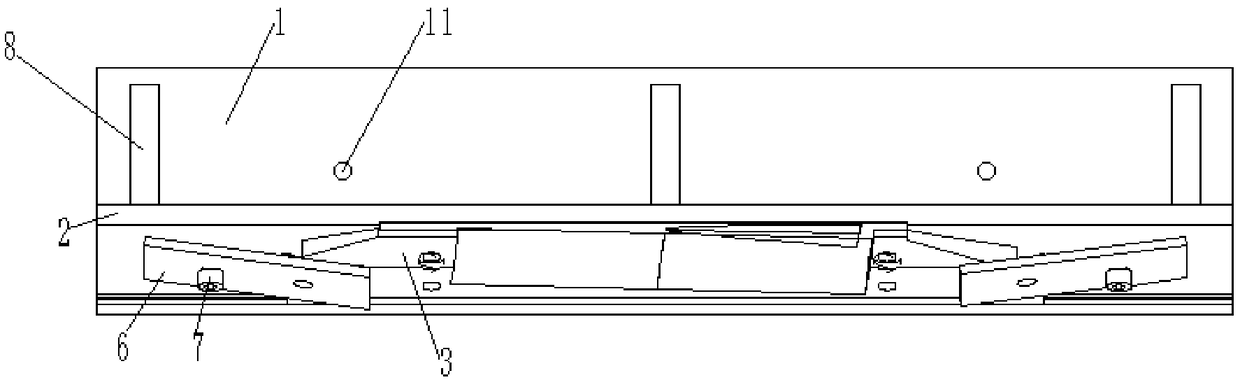

[0031] like figure 1 - Figure 4 As shown, the embodiment of the present invention provides a pallet grinding tool for a centerless grinder, including a base 1, a slant plate 2 and a fixing member; The upper side is the pallet installation surface 21, the pallet installation surface 21 can be in contact with the pallet 3, and the angle formed between the pallet installation surface 21 and the horizontal plane is equal to the one side of the pallet 3 facing the pallet installation surface 21 and the The angle formed between the support slopes 31 on the pallet 3;

[0032] The pallet grinding tool for a centerless grinder provided by the embodiment of the present invention includes a base 1, a slant plate 2 and a fixing member, wherein the base 1 is used to be horizontally fixed on the workbench of a surface grinder, and the lower end of the slant plate 2 is fixed on the base 1 At this time, the supporting plate installation surface 21 on the inclined plate 2 is a smooth plane,...

Embodiment 2

[0056] An embodiment of the present invention provides a surface grinder, including the pallet grinding tool for a centerless grinder as described above.

[0057] The surface grinder provided by the present invention includes a horizontal workbench, and the base 1 on the pallet grinding tooling of the centerless grinder is horizontally fixed on the workbench to ensure that the flatness and bevel angle of the supporting inclined surface 31 of the pallet 3 are kept consistent after being ground. , and then guarantee the quality of the supporting plate 3 after grinding. In addition, other technical advantages of the surface grinder provided by the present invention are the same as those of the above-mentioned pallet grinding tool for the centerless grinder, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com