Crossed block type four-groove grinding clamp

A cross block and grinding technology, applied in the direction of grinding workpiece supports, grinding drive devices, grinding machine parts, etc., can solve the problems of reducing the service life of the VE type fuel injection pump, the transmission is not stable, and it is difficult to achieve. Achieve significant technical and economic advantages, stable transmission, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

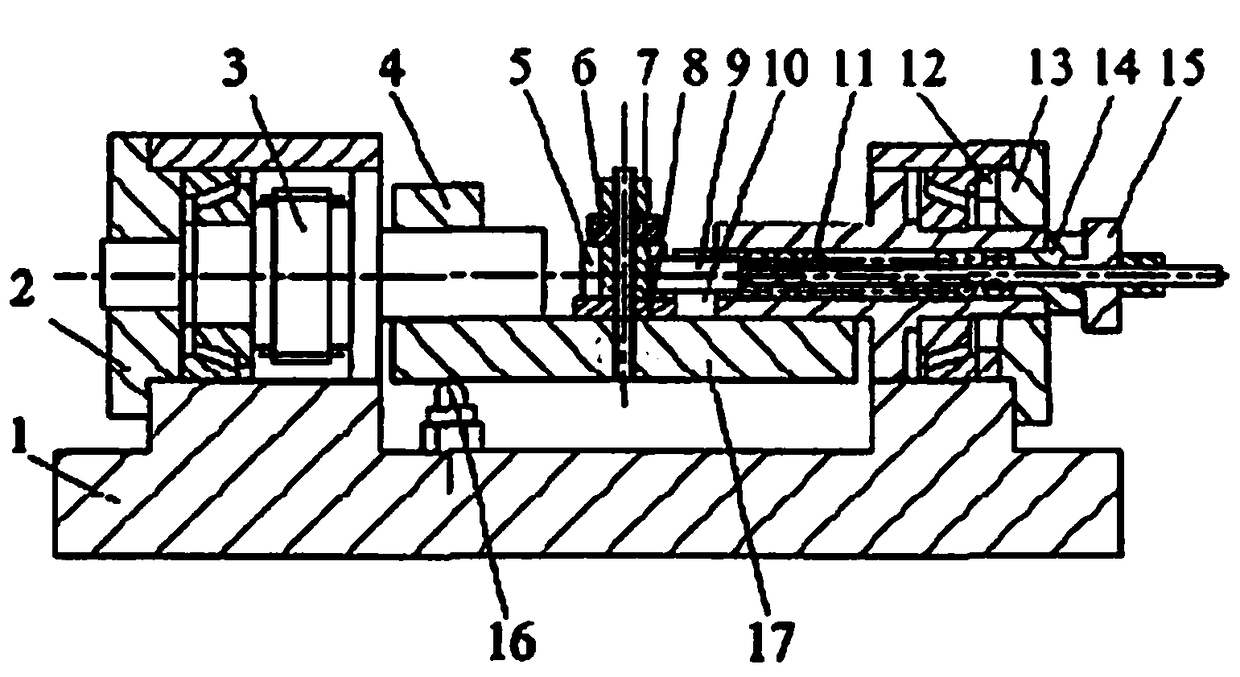

[0013] figure 1 The four-slot grinding jig of the middle cross block is mainly composed of the main body of the jig, the left bearing cover, the rotary shaft, the baffle plate, the pressure plate, the clamping nut, the positioning piece, the positioning pin assembly, the guide groove, the compression spring, the adjusting washer, the right bearing cover, Nuts, handwheels, support screws, overturning plates, etc.; the rotary shaft is fastened in the clamp body with a pair of tapered roller bearings; the positioning parts and guide grooves are fixed on the overturning plate; the positioning pins The assembly is located in the middle hole of the rotary shaft; the flip plate is fixed on the rotary shaft with screws; there are two support screws, the height of which can be adjusted, and the height of one support screw is adjusted so that the upper plane of the flip plate is at the level position, then turn it over 180°, and adjust the other support screw, so that after the turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com